A kind of finishing method of nylon hydrophobic fabric based on butyl titanate

A technology of butyl titanate and fabric, applied in fiber treatment, textiles and papermaking, fiber types, etc., can solve environmental problems, application restrictions and other problems, achieve low cost, great social and economic significance, and increase hydrophobic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Fabric: Nylon woven fabric (50D*50D / 109*81)

[0027] 1) BTCA pre-treated fabric

[0028] Prescription: BTCA: 2%

[0029] Method: The fabric is dipped twice in the reaction solution and rolled twice, the excess rate is about 65%, pre-baked at 70°C for 3 minutes, and baked at 170°C for 1.5 minutes.

[0030] 2) Butyl titanate treated fabric

[0031] Prescription: butyl titanate: ethanol = 1:10 (v / v)

[0032] Butyl titanate: acetic acid = 1:0.1 (v / v)

[0033] Water: butyl titanate = 0.4:1 (v / v)

[0034] Method: The bath ratio is 1:20, soak at room temperature for 2 hours, and then dry at 105°C.

[0035] 3) Octadecylamine treated fabric

[0036] Prescription: Methanol as solvent

[0037] Ammonia 1%

[0038] Octadecylamine 4%,

[0039] Method: Liquor ratio: 1:30, double dipping and two rolling, the excess rolling rate is 65%, pre-baking at 70°C for 3 minutes, and baking at 110°C for 5 minutes.

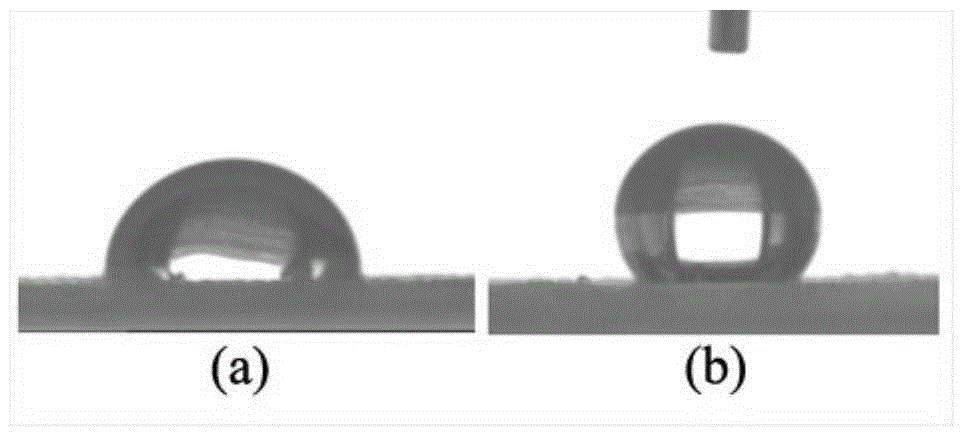

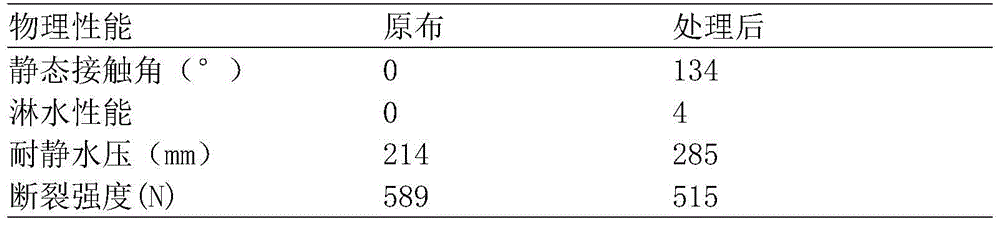

[0040] Table 1 The physical properties of nylon before and after the me...

Embodiment 2

[0045] Fabric: Nylon woven fabric (50D*50D / 109*81)

[0046] 1) BTCA pre-treated fabric

[0047] Prescription: BTCA: 2%

[0048] Method: The fabric is dipped twice in the reaction solution and rolled twice, the excess rate is about 65%, pre-baked at 70°C for 3 minutes, and baked at 170°C for 1.5 minutes.

[0049] 2) Butyl titanate treated fabric

[0050] Prescription: butyl titanate: ethanol = 1:15 (v / v)

[0051] Butyl titanate: acetic acid = 1:0.2 (v / v)

[0052] Water: butyl titanate = 0.6:1 (v / v)

[0053] Method: The bath ratio is 1:20, soak at room temperature for 2 hours, and then dry at 105°C.

[0054] 3) Octadecylamine treated fabric

[0055] Prescription: Methanol as solvent

[0056] Ammonia 1%

[0057] Octadecylamine 4%,

[0058] Method: Liquor ratio: 1:30, double dipping and two rolling, the excess rolling rate is 65%, pre-baking at 70°C for 3 minutes, and baking at 110°C for 5 minutes.

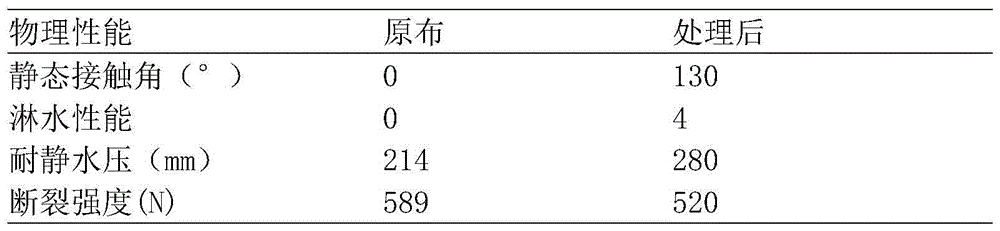

[0059] Table 2 Nylon physical properties before and after the method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com