Preparation of self-dispersing reactive nano carbon powder and method for dyeing cotton fabric by using self-dispersing reactive nano carbon powder

A technology of nano-carbon powder and dyeing method, applied in the field of textiles, can solve the problems of high energy consumption efficiency and great environmental harm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

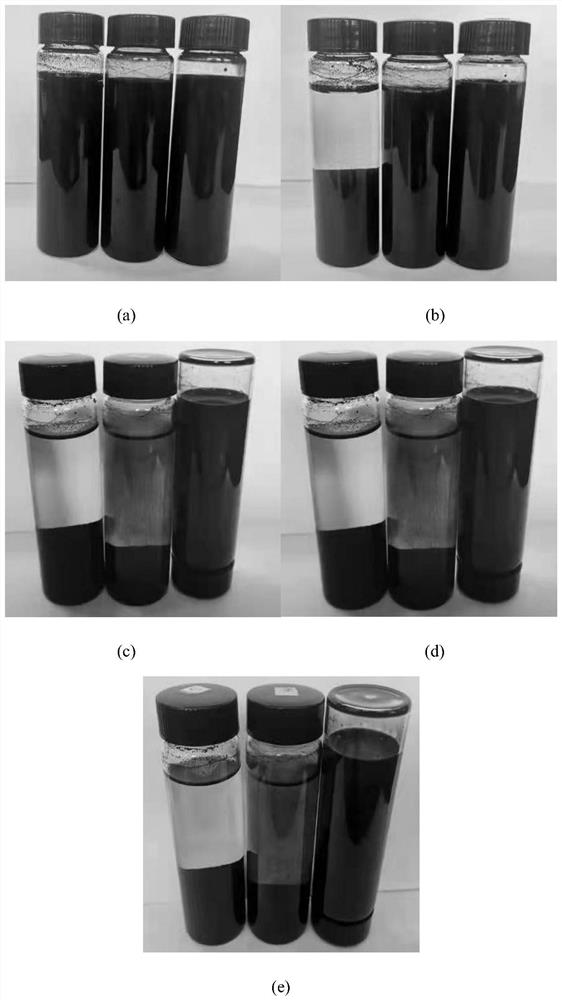

Image

Examples

Embodiment 1

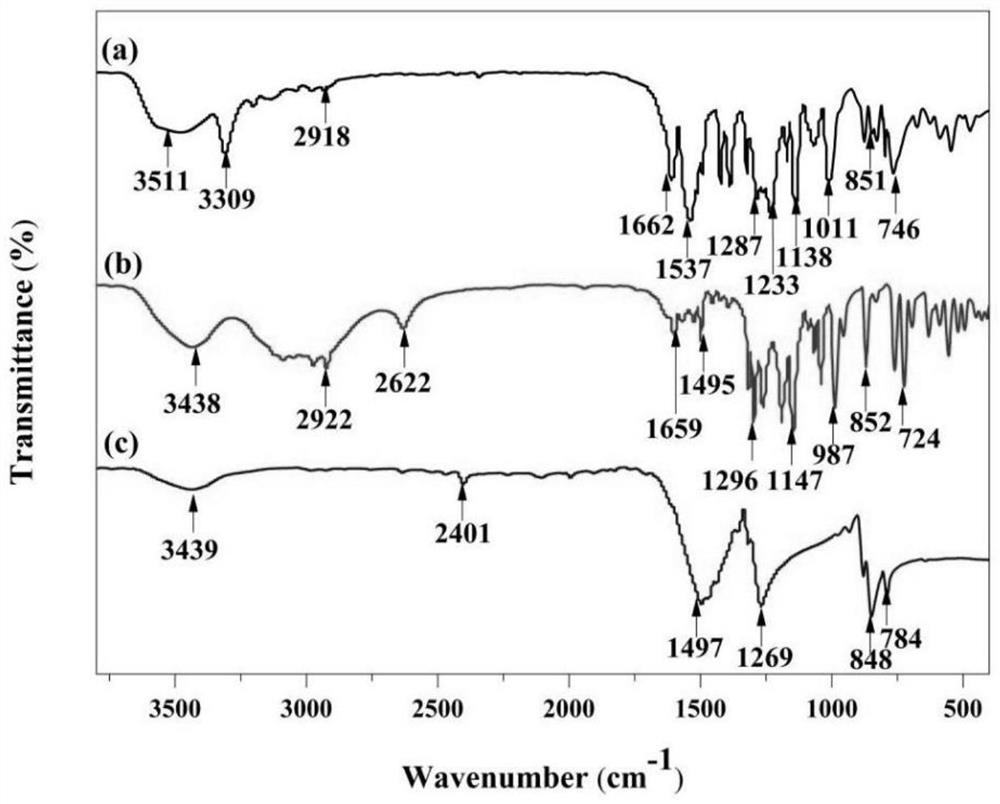

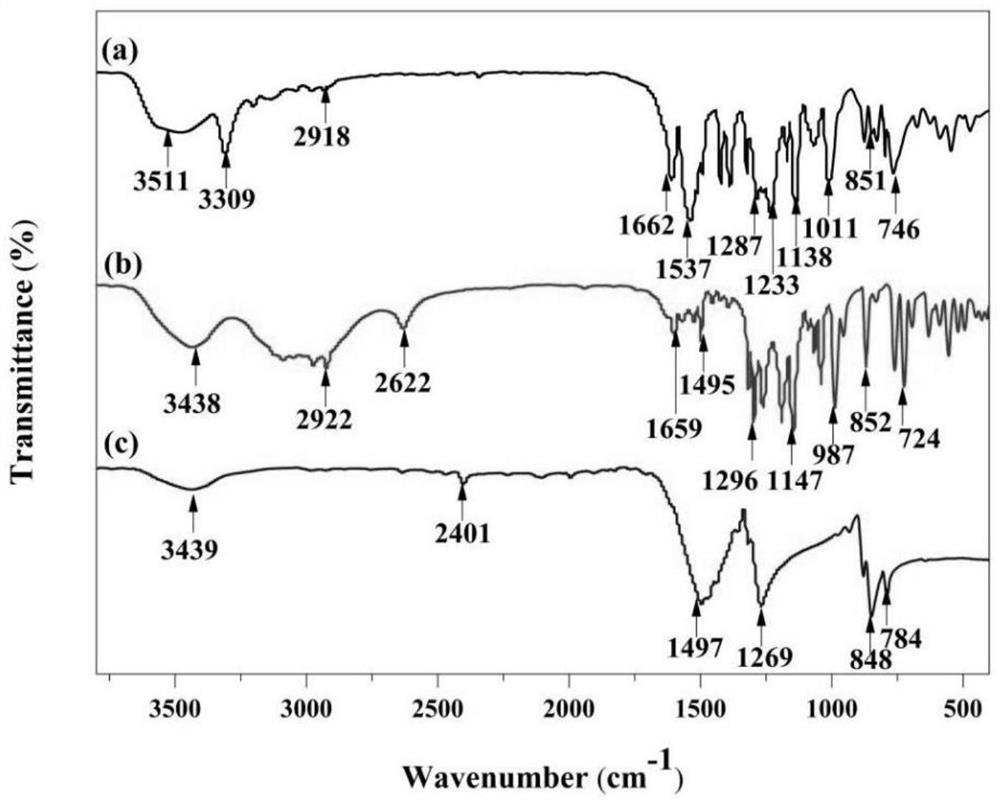

[0056] Add 4-nitrobenzyl chloride (0.0857mol) and absolute ethanol (50mL) into a single-necked flask, stir at room temperature to obtain a 4-nitrobenzyl chloride solution, and then slowly drop trimethylbenzyl into the 4-nitrobenzyl chloride solution Amine solution (0.12855mol), stirred at 45°C, the stirring parameter was 90rpm, and the stirring time was 15min, then condensed and refluxed, reacted for 2h, and removed ethanol, water and unreacted trimethylamine by rotary evaporation (90-95°C), washed with acetone, After filtration, the resulting crude product was recrystallized in ethanol, filtered and dried in vacuo to remove ethanol to obtain Compound A.

[0057] Compound A (0.0446 mol) was dissolved in absolute ethanol (200 mL) to obtain solution A. SnCl 2 2H 2 O (0.1561mol) and hydrochloric acid (36%, 1.44mol) were added into the three-necked flask, stirred at room temperature to obtain SnCl 2 solution. Solution A slowly drop by drop into SnCl 2 in solution. Stir at 45...

Embodiment 2

[0060] In this paper, the silane coupling agent KH550 is used to graft on the surface of carbon nano powder, and the silane coupling agent KH550 (2 mmol) and ammonia water (28%, 1 mL) are dissolved in 90% ethanol water (100 g). Add nano-carbon powder (5g) and ultrasonicate for 60min. Then, the suspension was continuously stirred and reacted at 40° C. for 20 h, and the precipitate was centrifuged and washed three times with absolute ethanol. Finally, dry at 60° C. for 12 hours and grind into powder to obtain amino-modified nano-carbon powder.

Embodiment 3

[0062] Compound C (2 mmol) and CB / KH550 (0.5 g) were continuously dispersed in acetone (20 mL). Slowly add sodium carbonate solution (15%) to adjust the pH to 5-6, then continuously stir at 40°C for 2h at a stirring speed of 100rpm, remove acetone by centrifugation of the precipitate, wash with absolute ethanol and centrifuge three times, and dry at 45°C to obtain Self-dispersing reactive nano carbon powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com