Application of Artemisia argyi Pigment Dyestuff in Cotton Fiber Post-mordant Dyeing Process

A technology of cotton fiber and mugwort leaves, which is applied in the application field of mugwort leaf pigment dyes in the post-mordant dyeing process of cotton fibers, so as to avoid damage, simplify the ethanol solvent extraction process, and reduce large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

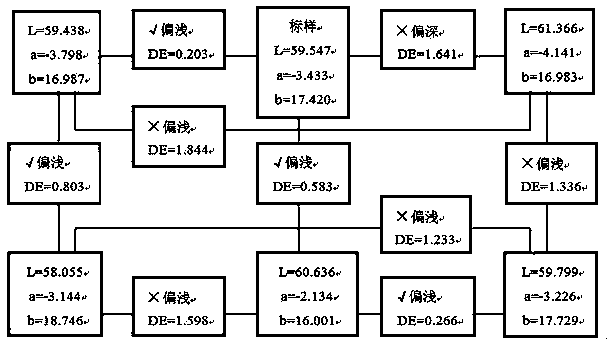

Image

Examples

preparation example 1

[0030] After the prepared mugwort leaves are washed and dried, the walls are broken with a wall breaking machine to obtain a dark green paste liquid, which releases the unique aroma of mugwort. Take 100g of pasty liquid each time, use ethanol as solvent to dissolve according to the ratio in the table, and then filter with suction to get the filtrate. The dyes were prepared according to the mass ratio of pasty liquid and ethanol solvent as 1:1, 1:2, 1:3, and 1:4 respectively.

[0031] Take an equal amount (100g) of dye, and under the same conditions, directly dye an equal amount of cotton fabric (2.5g) for 50 minutes at a temperature of 65°C and a bath ratio of 1::30. The results are shown in the table below:

[0032]

[0033] Combining the state and color of the dyeing liquor after filtration and the effect of direct dyeing of the fabric, further through the determination of parameters such as dyeing depth, dry and wet rubbing fastness, staining, and discoloration, the mass...

Embodiment

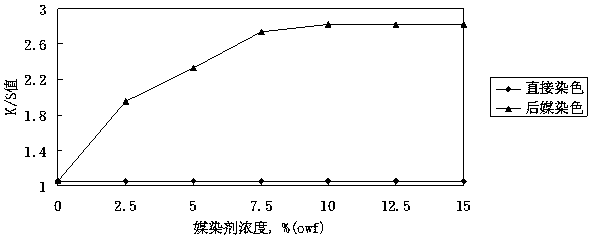

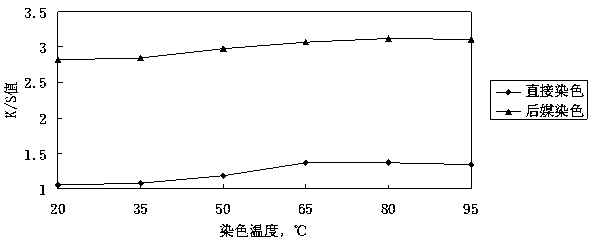

[0035] Post-mordant staining:

[0036] At room temperature, take mugwort leaf pigment to prepare 300ml of dye solution, the mass concentration of mugwort leaf pigment is 33%, heat up to 80°C (3°C / min), add dyeing accelerator salt, and after it dissolves evenly, add 10g of pure cotton bleached twill fabric, The bath ratio is 1:30. After the dyeing is completed, add mordant, and then mordant for 15 minutes. After the mordant is completed, fix the color salt, keep it warm for 15 minutes, wash it with water, and dry it.

[0037] Direct staining method:

[0038] At room temperature, take mugwort leaf pigment and make dye solution 300ml, the mass concentration of mugwort leaf pigment is 33%, add dyeing accelerator salt, heat up to 65°C (2°C / min), add mordant and 10g of pure cotton bleached twill fabric, liquor ratio The ratio is 1:30. After the dyeing is completed, add color-fixing salt and keep warm for 15 minutes to fix the color. After dyeing, wash with water and dry.

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com