Patents

Literature

98results about How to "Guaranteed synchronous rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

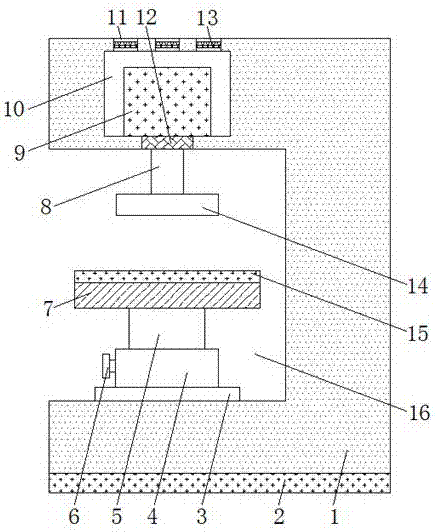

Chemical material mixing device

InactiveCN105536613AReduce manufacturing costIncrease productivityRotary stirring mixersTransportation and packagingElectromagnetic inductionEngineering

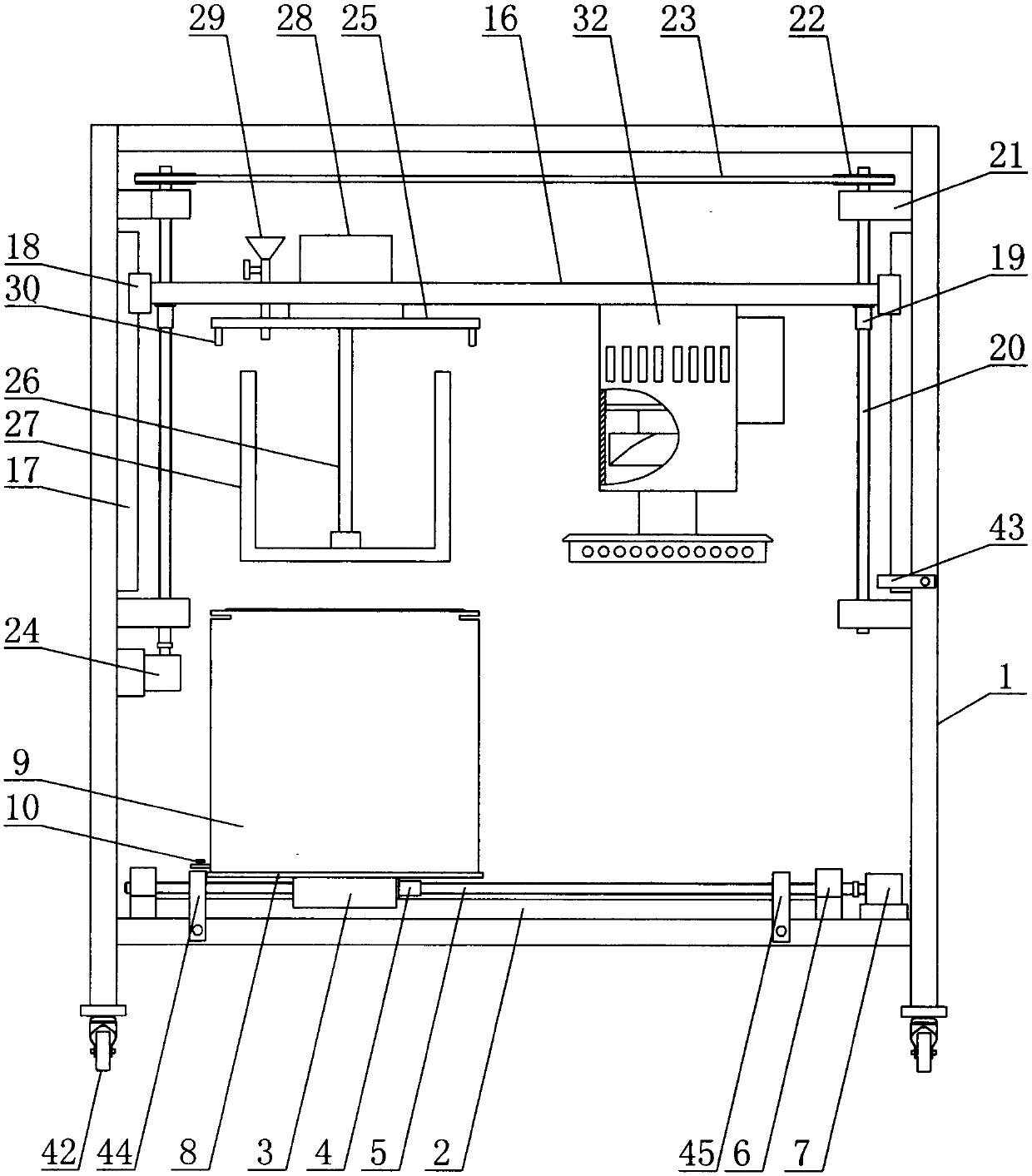

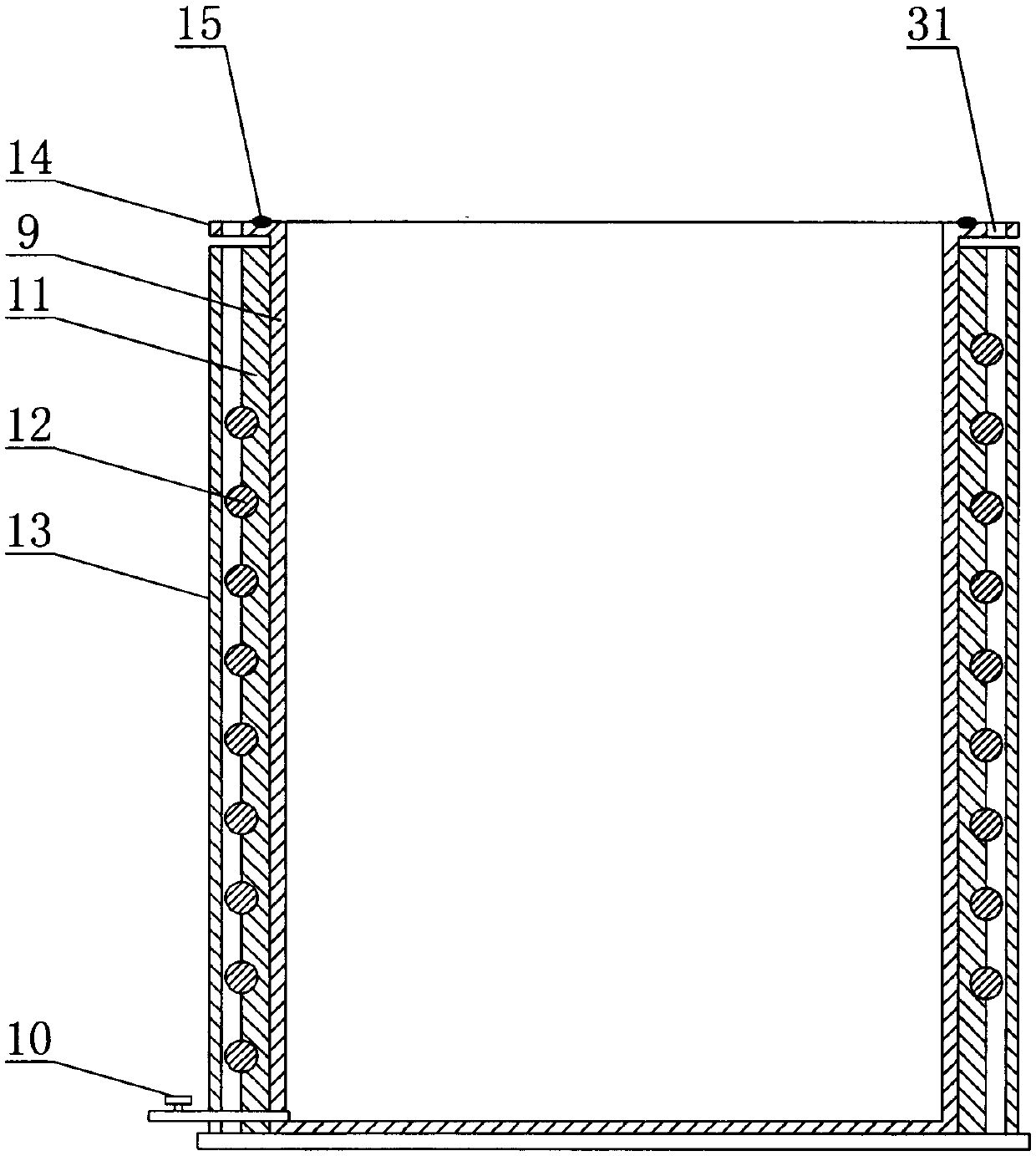

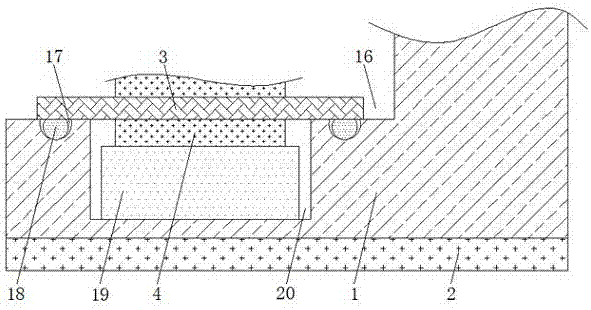

The invention discloses a chemical material mixing device and mainly relates to the technical field of chemical material mixing. The device comprises a machine frame, wherein a first guide rail is horizontally arranged on the lower portion of the machine frame, a first sliding block is arranged on the first guide rail, a first nut is arranged on the first sliding block, and a first lead screw is arranged in the first nut; a connecting plate is arranged on the first sliding block, a mixing cylinder is arranged on the connecting plate, a heat insulation cotton layer is arranged on the side wall of the mixing cylinder, and an electromagnetic induction heating coil is arranged on the heat insulation cotton layer; a movable supporting frame is horizontally arranged above the mixing cylinder, a cover is arranged on the movable supporting frame, a rotary shaft is arranged in the middle of the cover, a stirring paddle is arranged on the rotary shaft, and a cleaning device is arranged on the movable supporting frame. The device has the advantages that materials can be dried while being mixed, so that production cost is reduced and production efficiency is improved; materials left in the mixing cylinder can be cleared automatically, so that the labor intensity of workers is relieved.

Owner:HENAN INST OF SCI & TECH

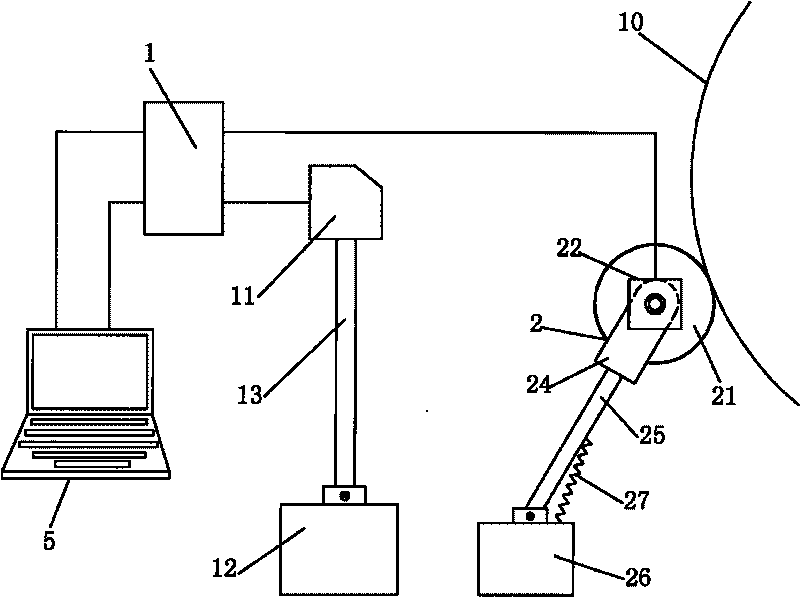

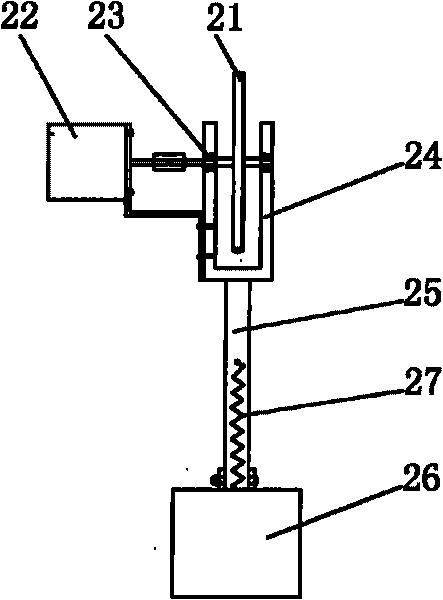

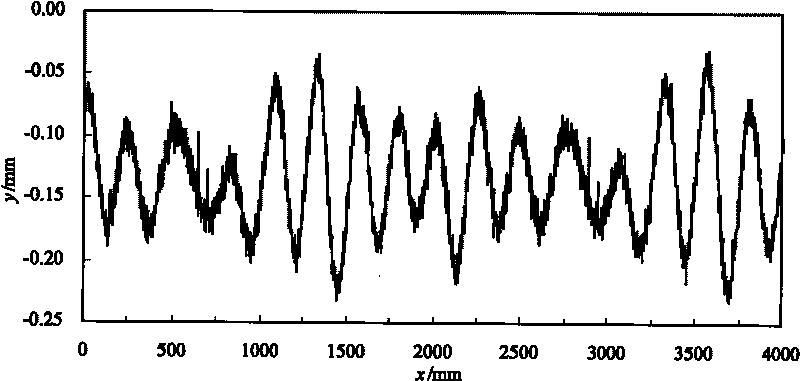

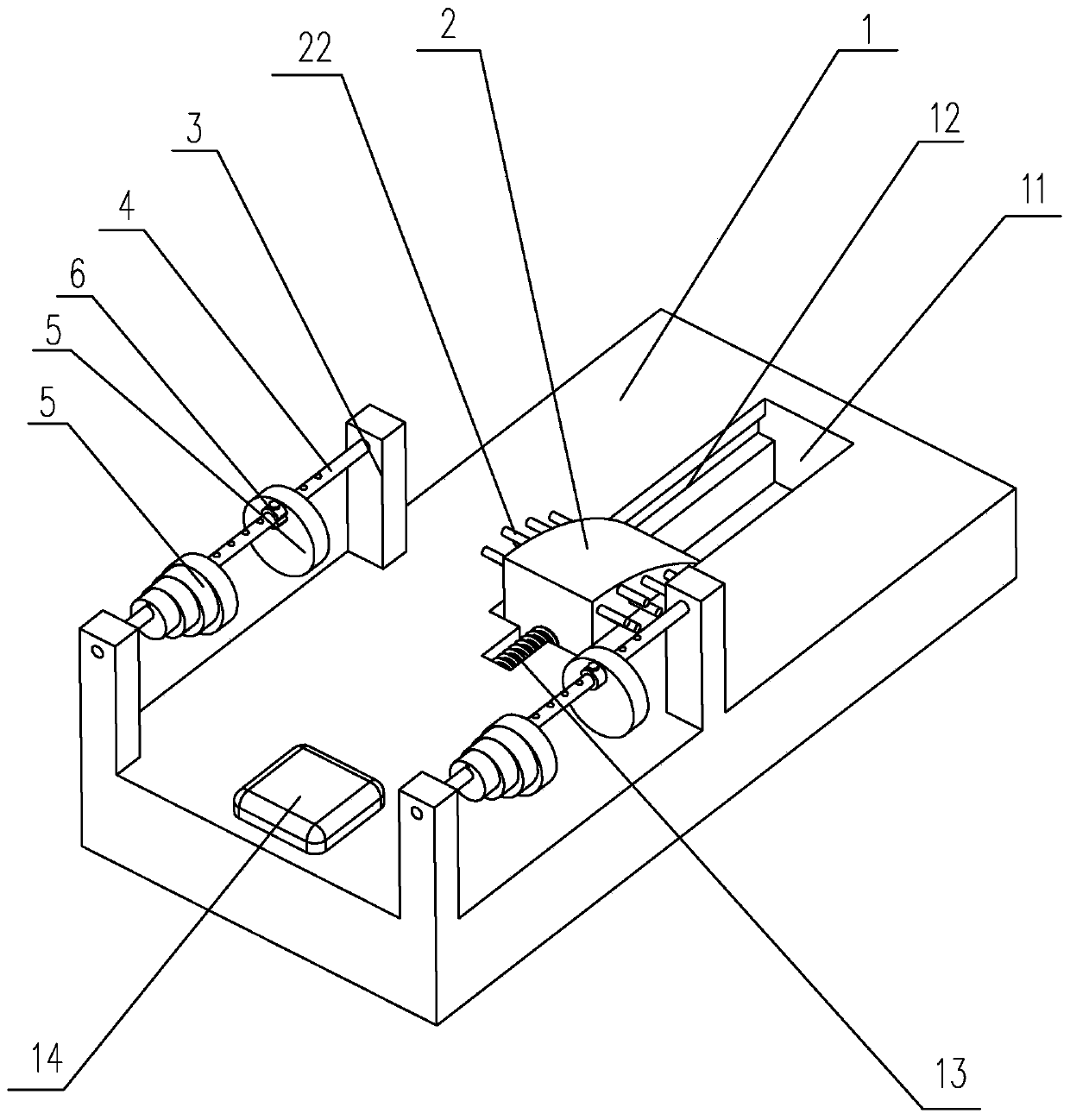

Portable laser measuring device for wheel circumference surface roughness and non-rounding abrasion

The invention relates to a portable laser measuring device for wheel circumference surface roughness and non-rounding abrasion, a laser head (11) of a laser displacement sensor (1) is fixed on a laser head supporting seat (12); a serial port and a USB interface of the laser displacement sensor (1) are respectively connected with the serial port and the USB interface of a computer (5); and a truckle (21) of a truckle mechanism (2) is axially connected with an increment photoelectric encoder (22), and a signal output end of the increment photoelectric encoder (22) is connected with a control signal input end of the laser displacement sensor (1). The testing device can conveniently measure the surface roughness and non-rounding abrasion conditions of various wheel circumferences on the spot; the device is convenient to carry and has high degree of automation, simple and convenient operation, high control and testing precision and good reproducibility of test data.

Owner:SOUTHWEST JIAOTONG UNIV

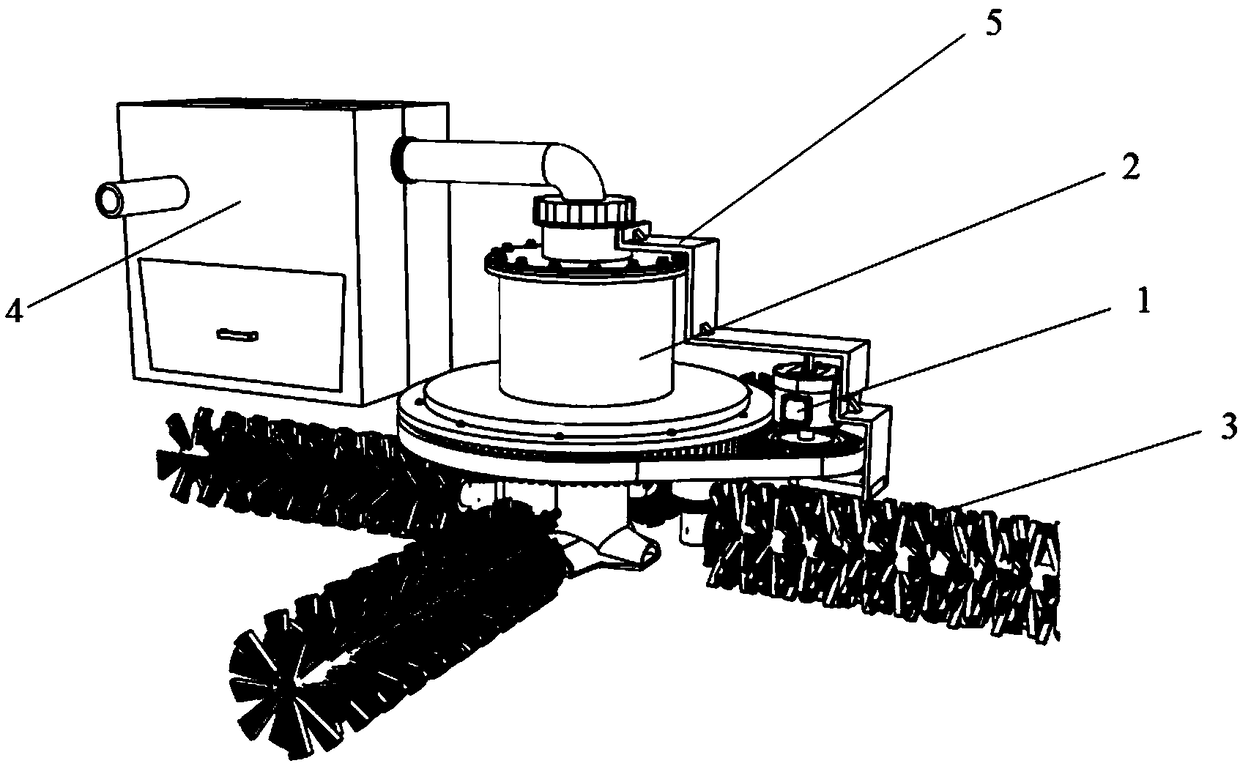

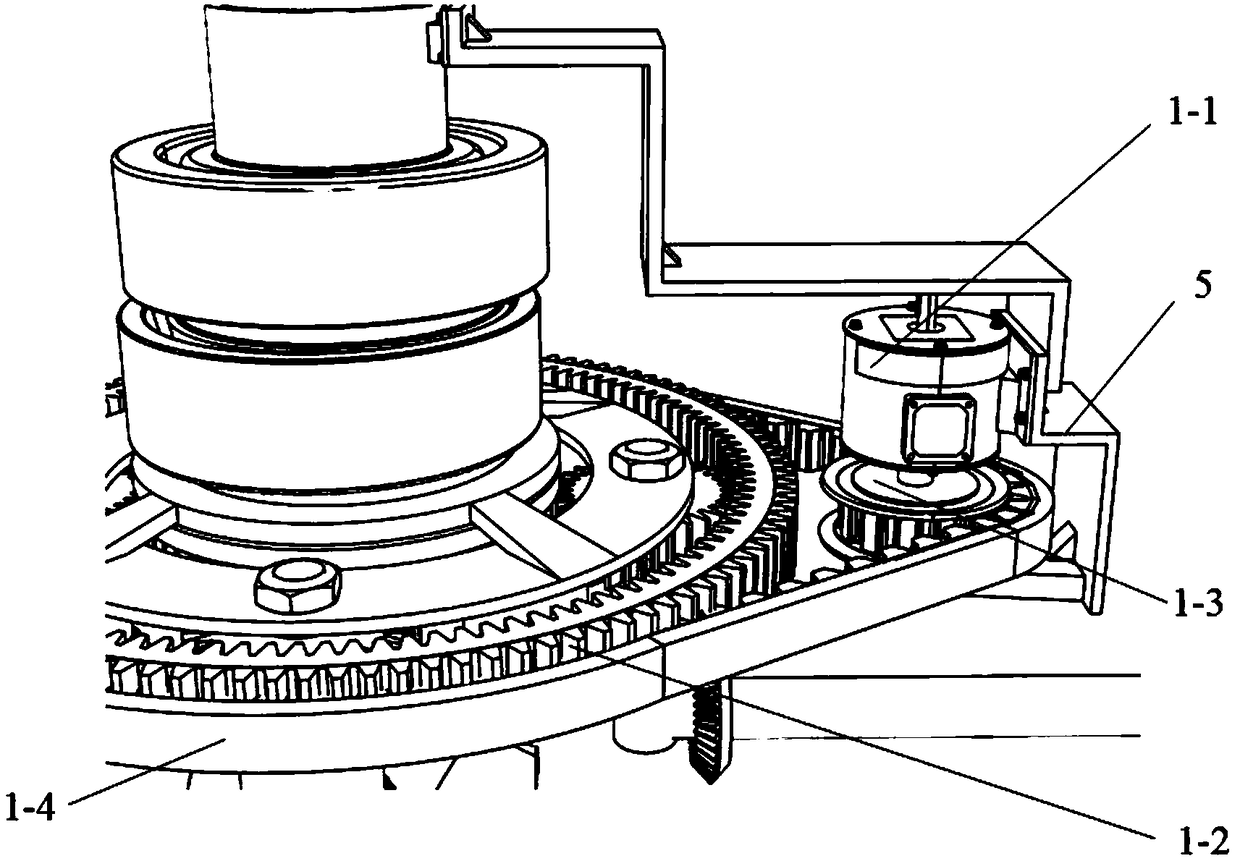

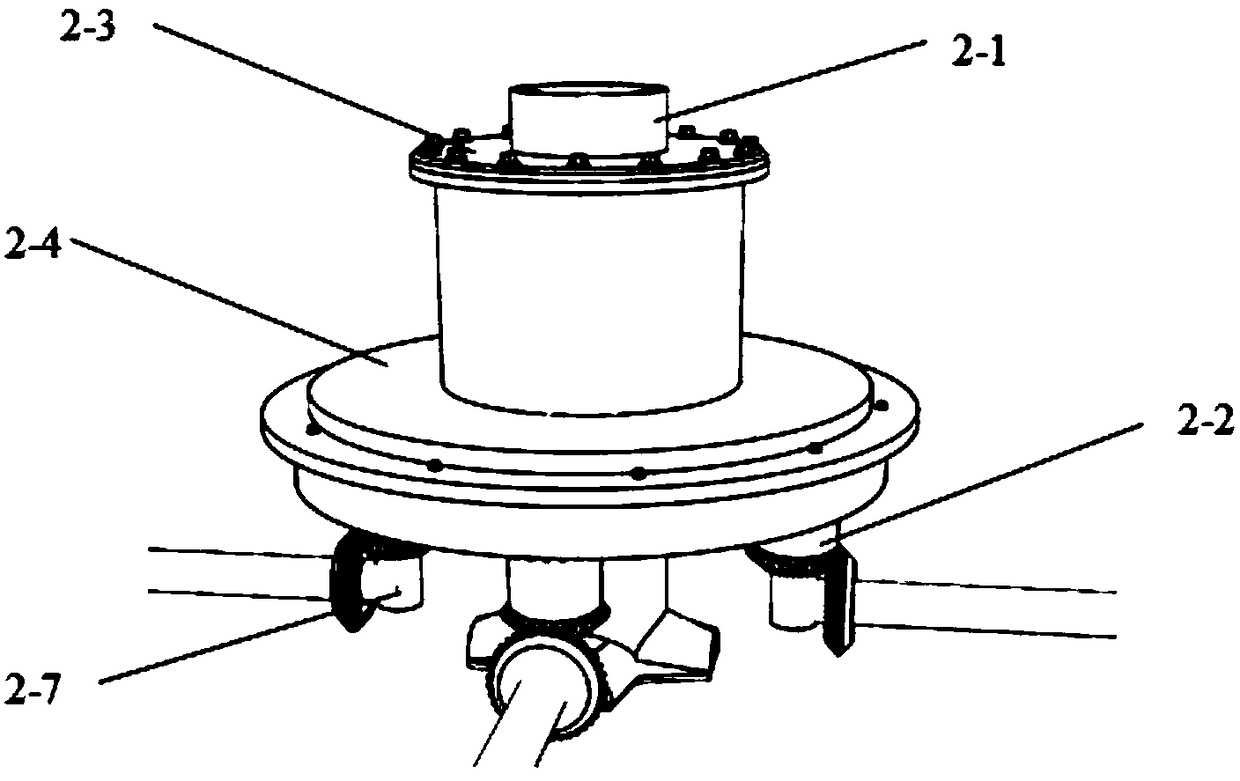

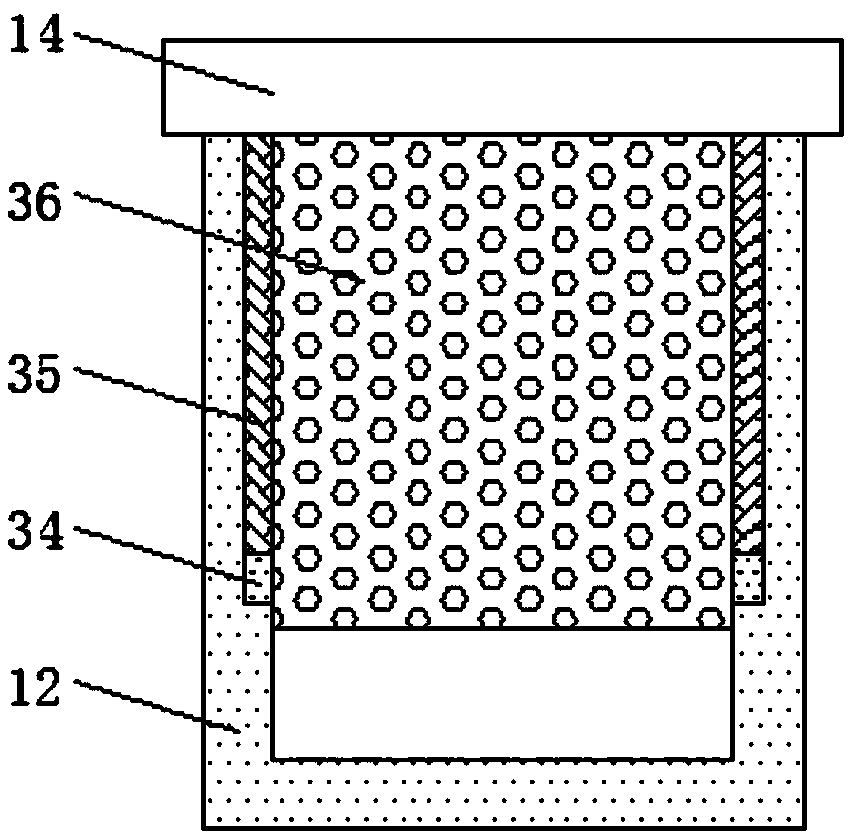

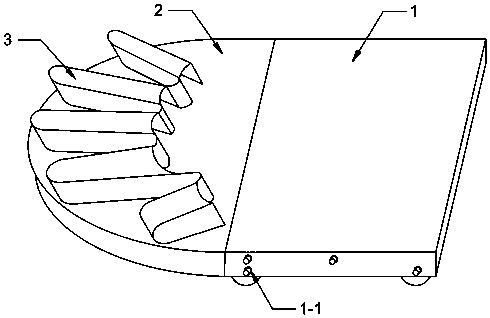

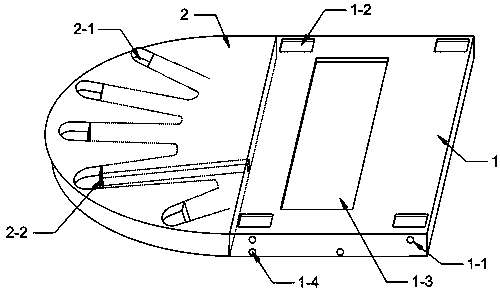

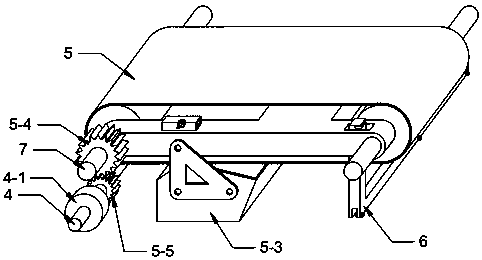

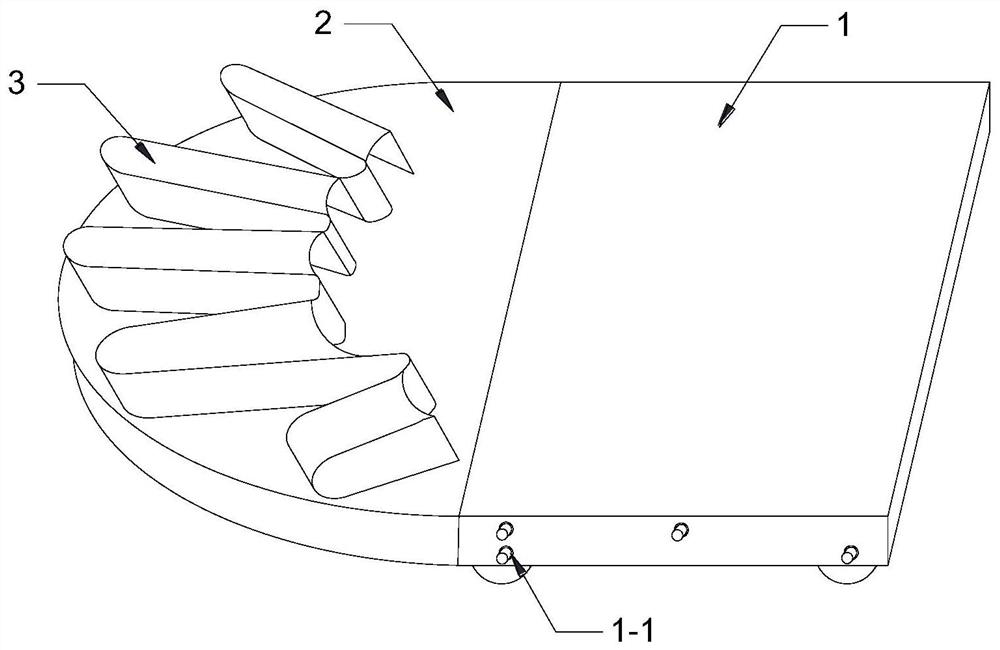

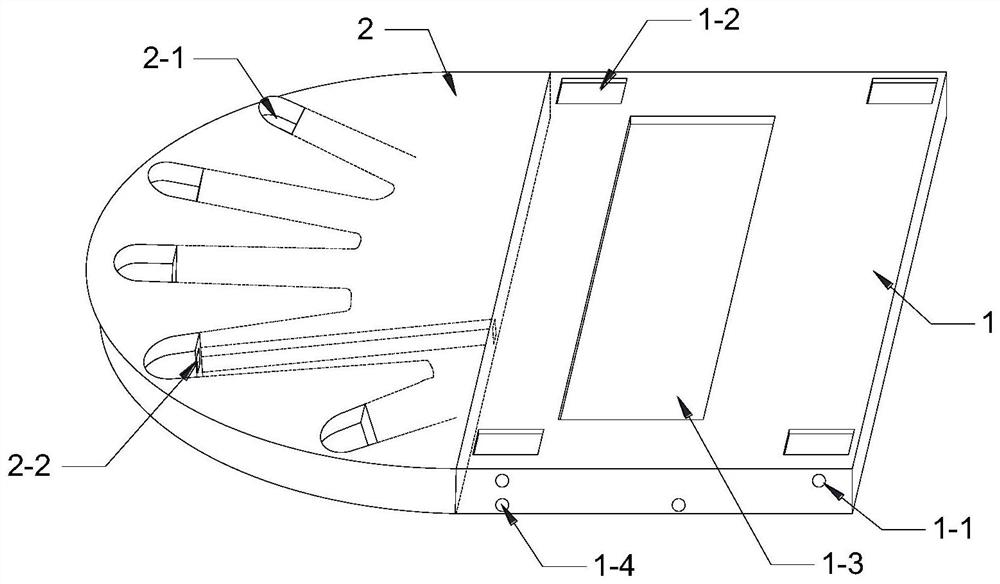

Planetary pavement garbage rolling brush device

PendingCN108239951AImprove cleaning efficiencyIncrease contact frequencyRoad cleaningRefuse collectionWaste collection

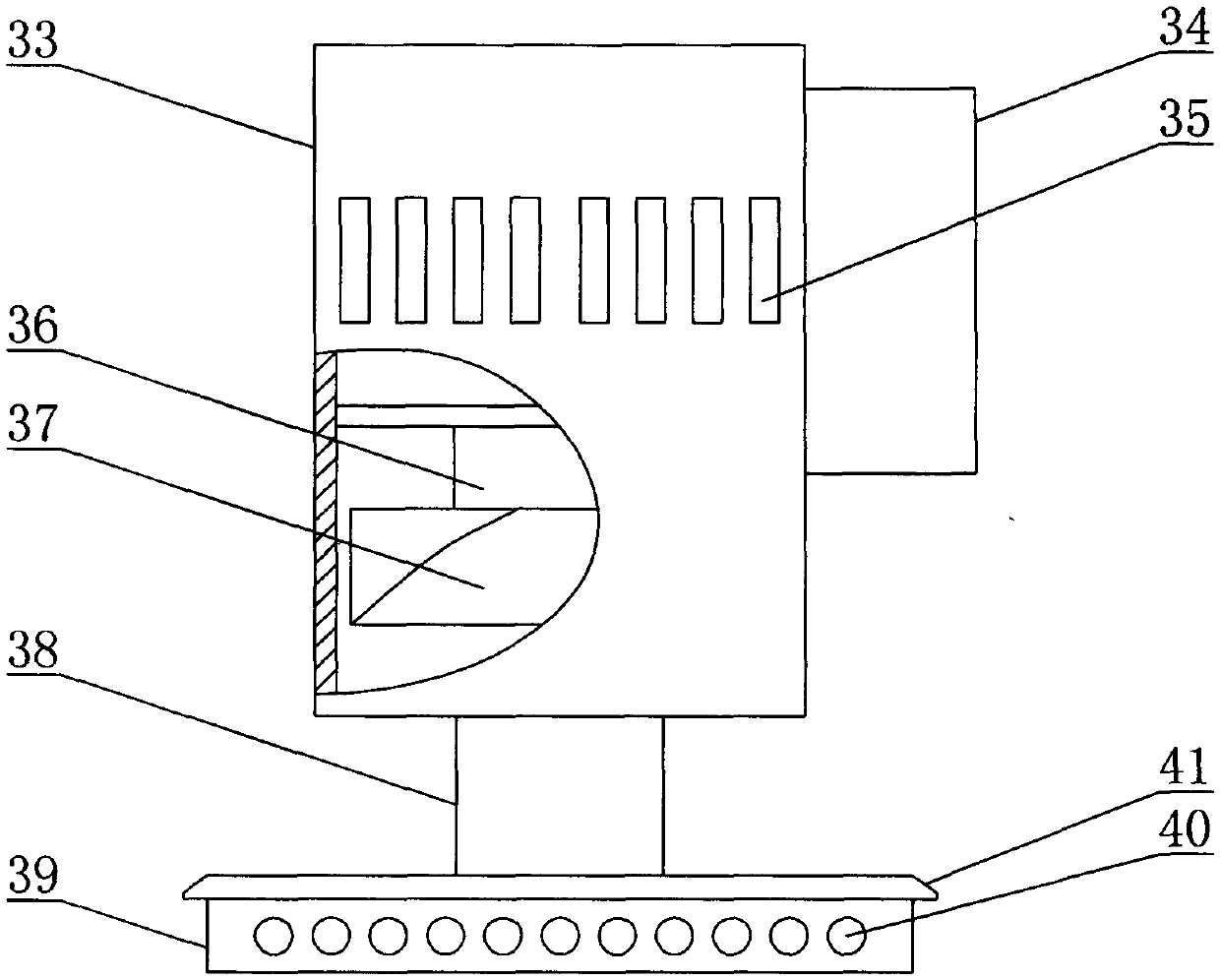

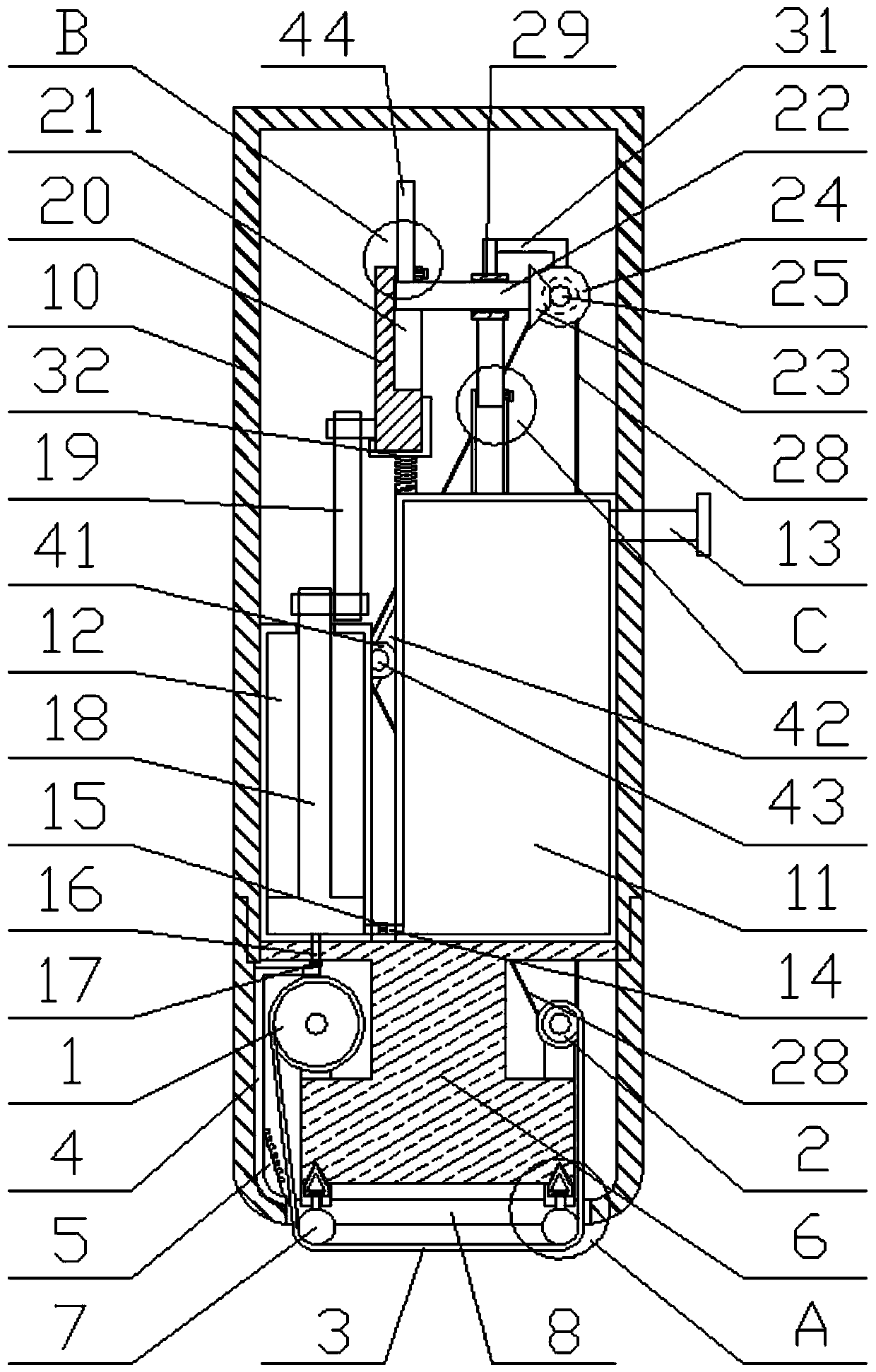

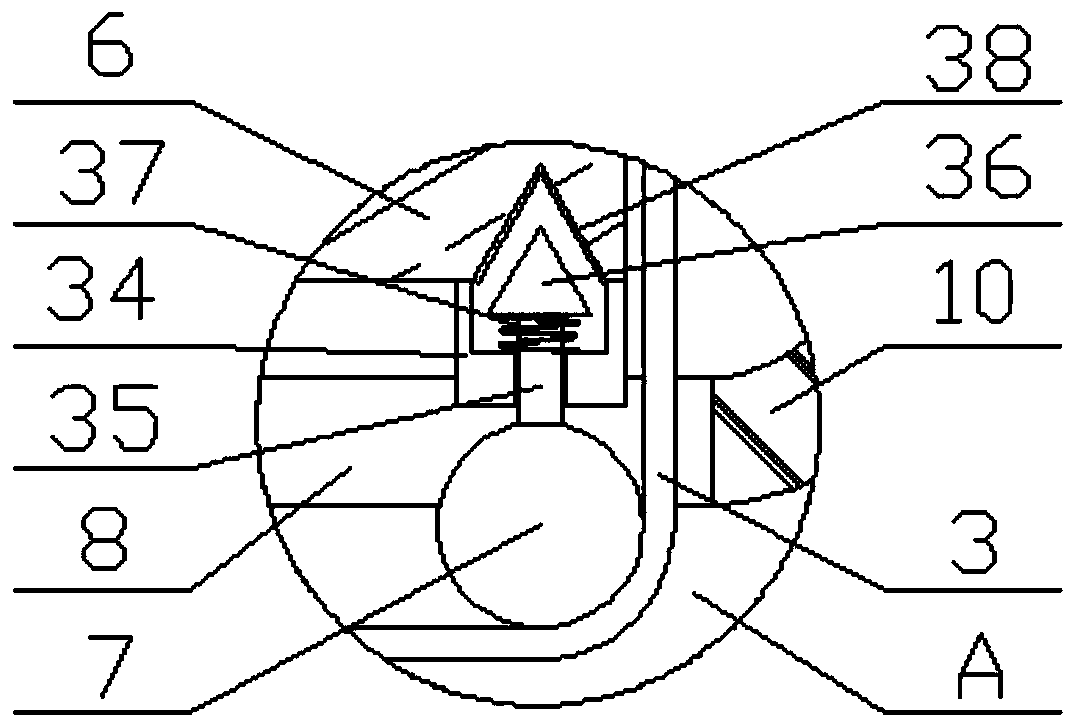

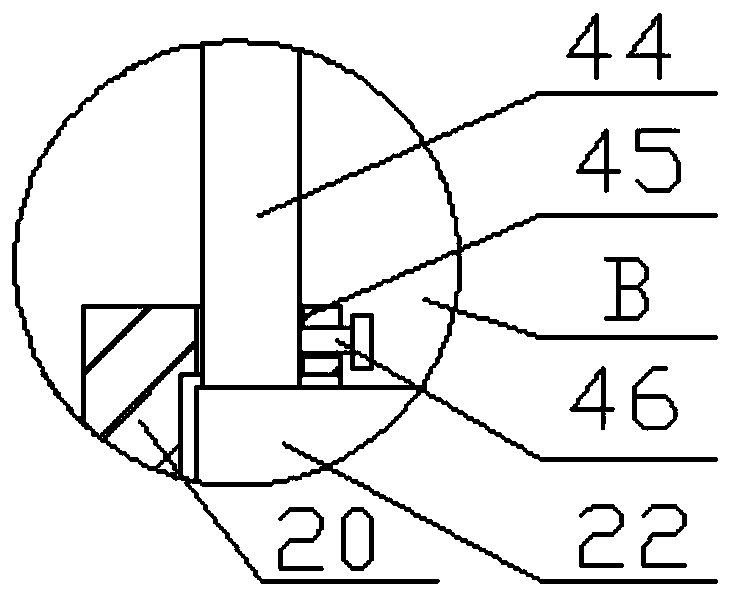

The invention discloses a planetary pavement garbage cleaning device. The planetary pavement garbage cleaning device comprises a machine frame, a power device, a transmission device, rolling brush devices and a garbage collection device. The power device and the transmission device are mounted on the machine frame, and the power device drives the transmission device to work, thereby driving spiralbrushes of a plurality of rolling brush devices to revolve and rotate; and pavement garbage is efficiently swept to the center. The garbage collection device collects the garbage concentrated on thecenter into a trash can through a suction pipe, a coarse filter screen and a centrifugal separator by negative pressure. The planetary pavement garbage cleaning device is suitable for the cleaning ofrelatively large pavement garbage in common cities or districts and townships, and has the characteristics of high cleaning efficiency and good effect on the relatively large pavement garbage.

Owner:CHANGAN UNIV

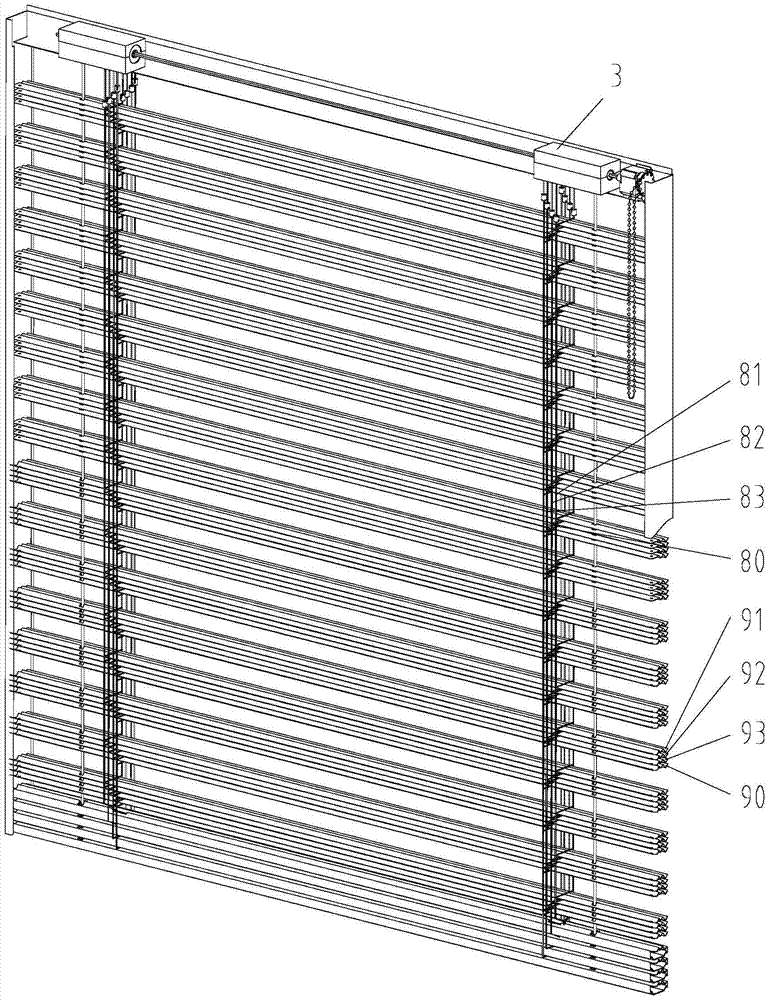

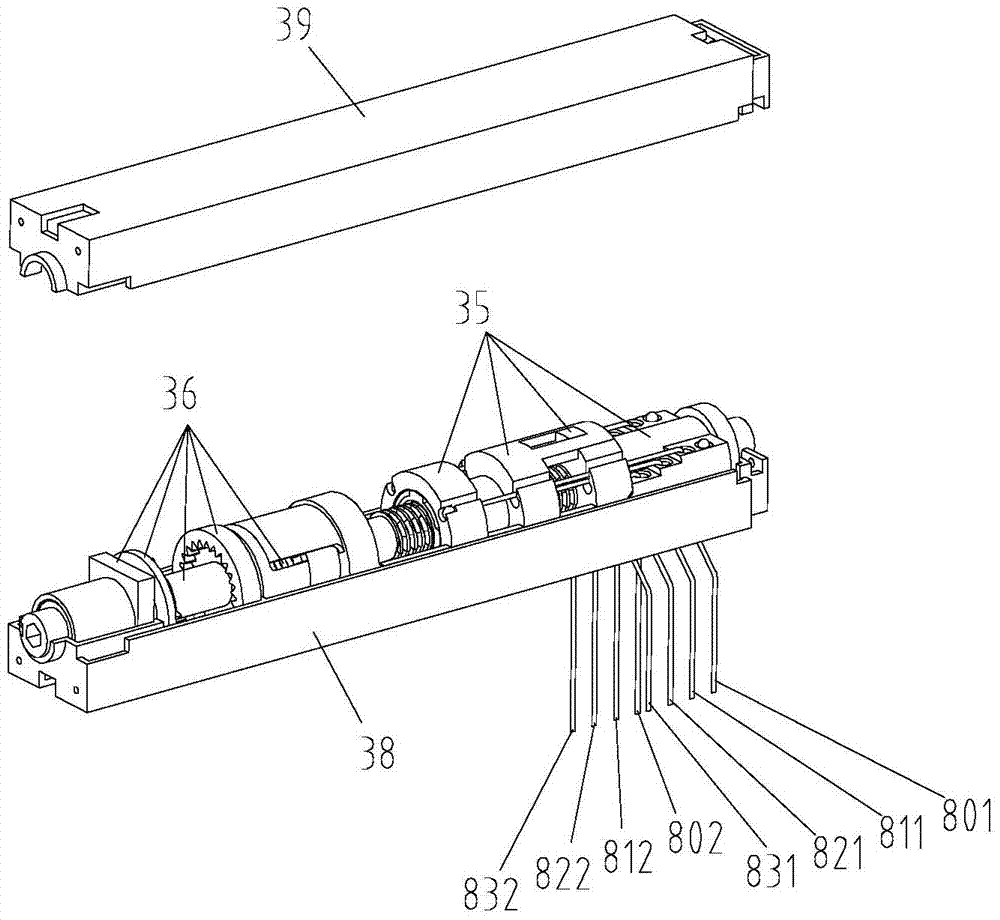

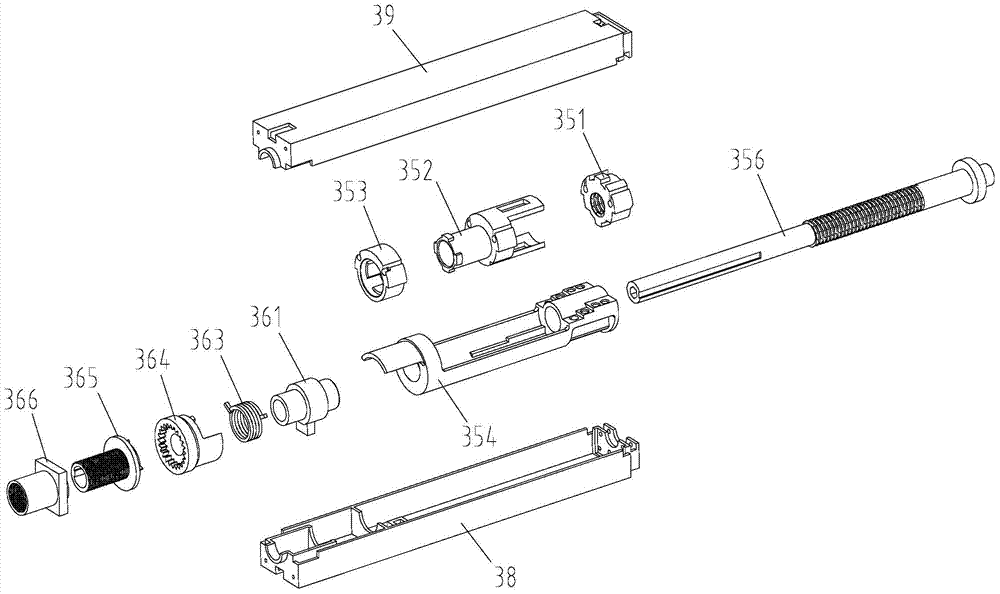

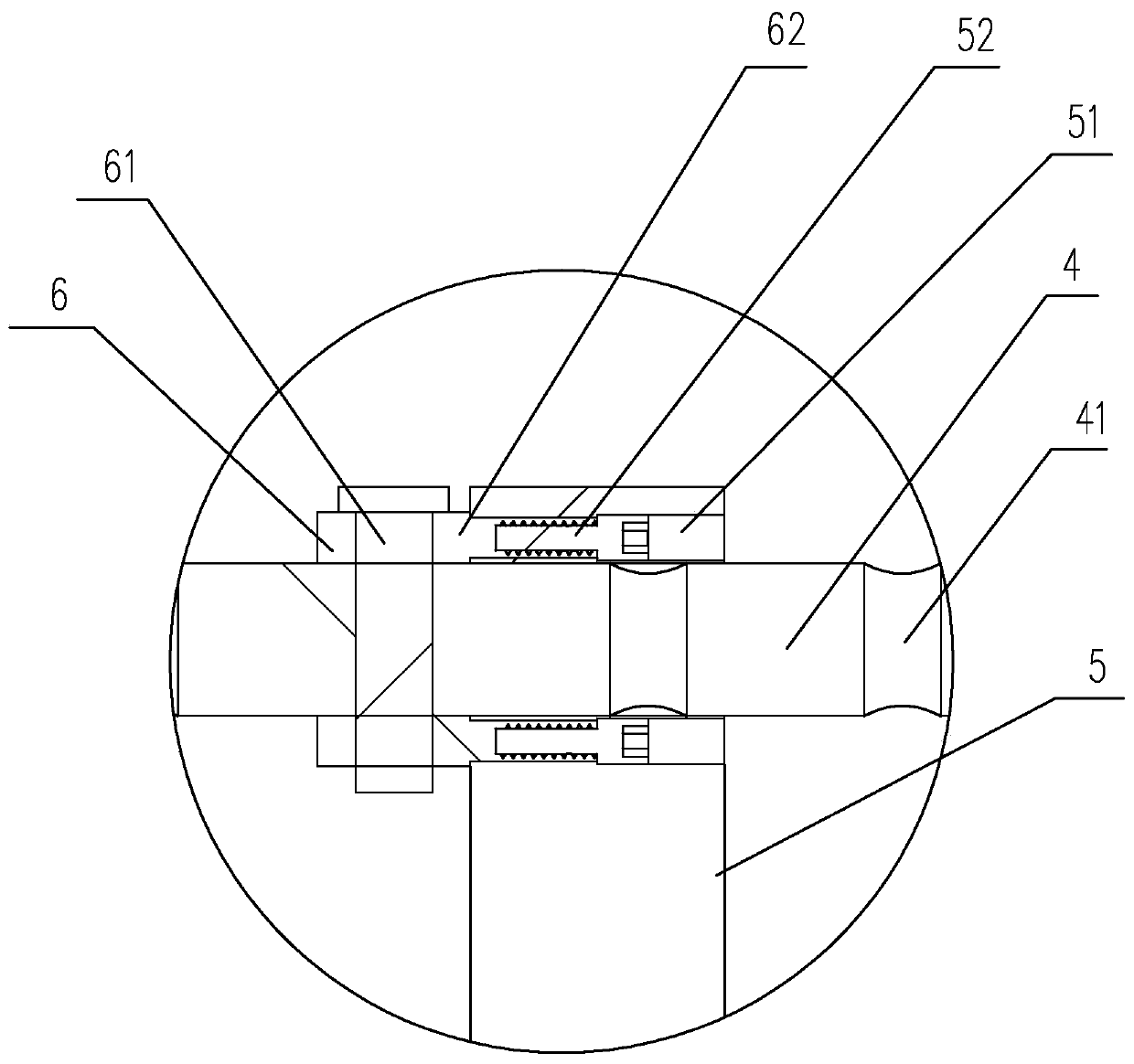

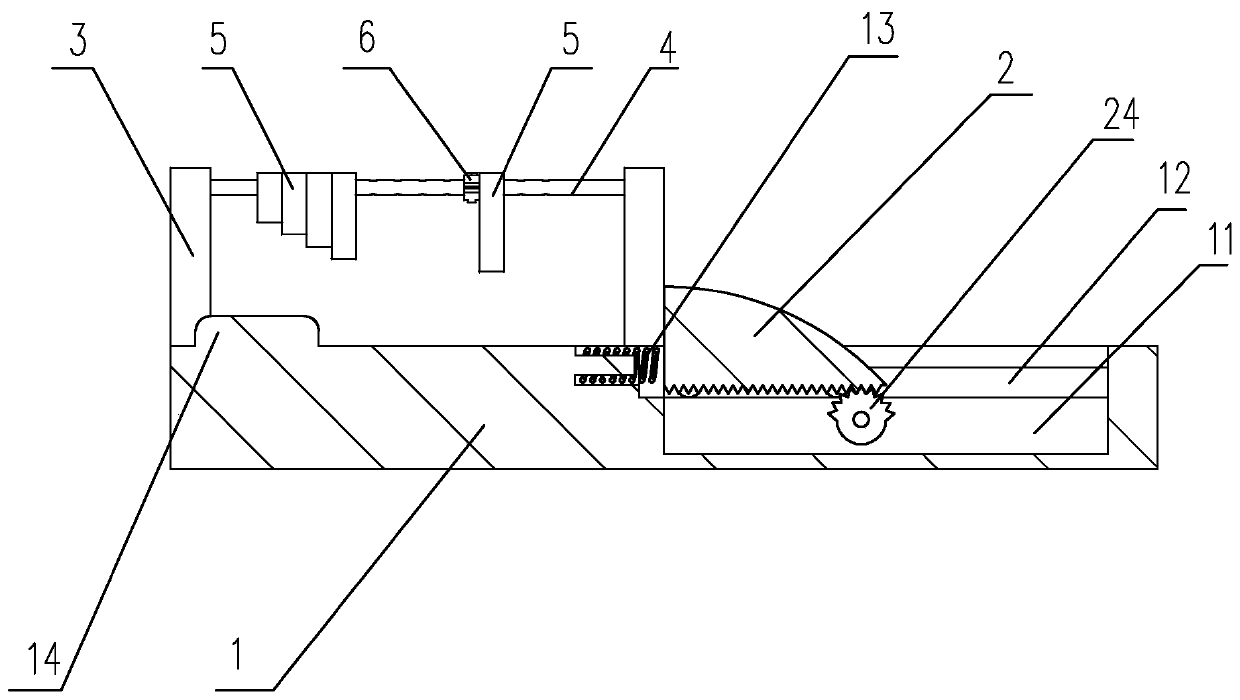

Sliding block mechanisms and variable-pitch louver sliding block system with same

ActiveCN103696675AImplementing Synchronous FlipLess prone to distortionDoor/window protective devicesGear wheelTorque transmission

The invention discloses sliding block mechanisms which are respectively used on a thrice quartered variable-pitch louver and a double dichotomy variable-pitch louver and a variable-pitch louver sliding block system with one of the two sliding block mechanisms. The variable-pitch louver sliding block system comprises gear torsion spring clutch turnover mechanisms, a base and a top cover, wherein the sliding block mechanisms are tightly adjacent to the gear torsion spring clutch turnover mechanisms, the sliding block mechanisms and the gear torsion spring clutch turnover mechanisms are all arranged on a rotating shaft of the sliding block mechanisms, each gear torsion spring clutch turnover mechanism comprises a fixing sleeve, a torsion spring, a torsion spring unlocking gear, a clutch gear and a fixing nut which are sequentially sleeved on the rotating shaft, and the torsion spring unlocking gears are connected with the sliding block mechanisms through a clamping part in a transmission way. According to the sliding block mechanisms and the variable-pitch louver sliding block system, which are disclosed by the invention, an existing sliding block mechanism and an existing variable-pitch louver sliding block system are improved, the problems that a torque transmission piece is not synchronous with a turnover drum, and ladder belts are easily abraded are effectively solved, and the sliding mechanisms are also suitable for the double dichotomy variable-pitch louver.

Owner:HANGZHOU WOKASOLAR TECH

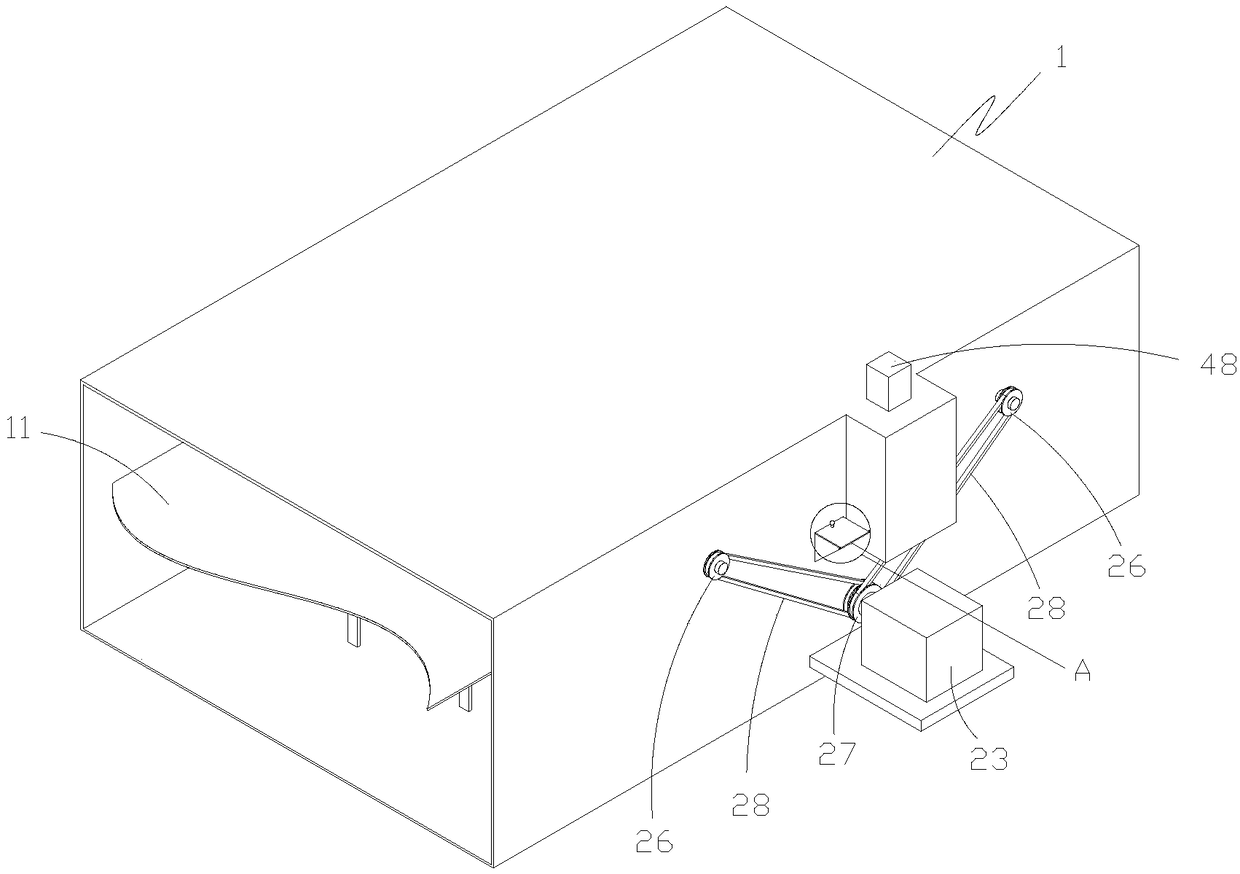

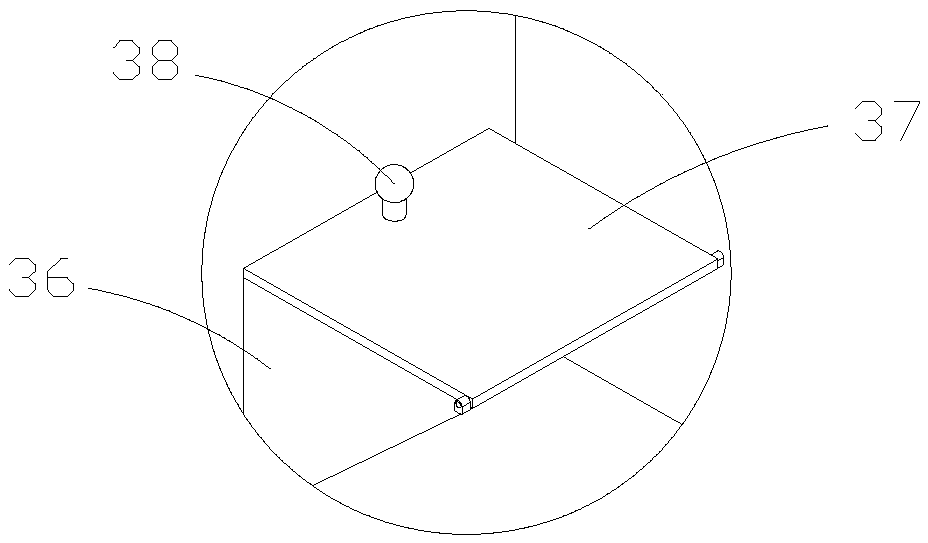

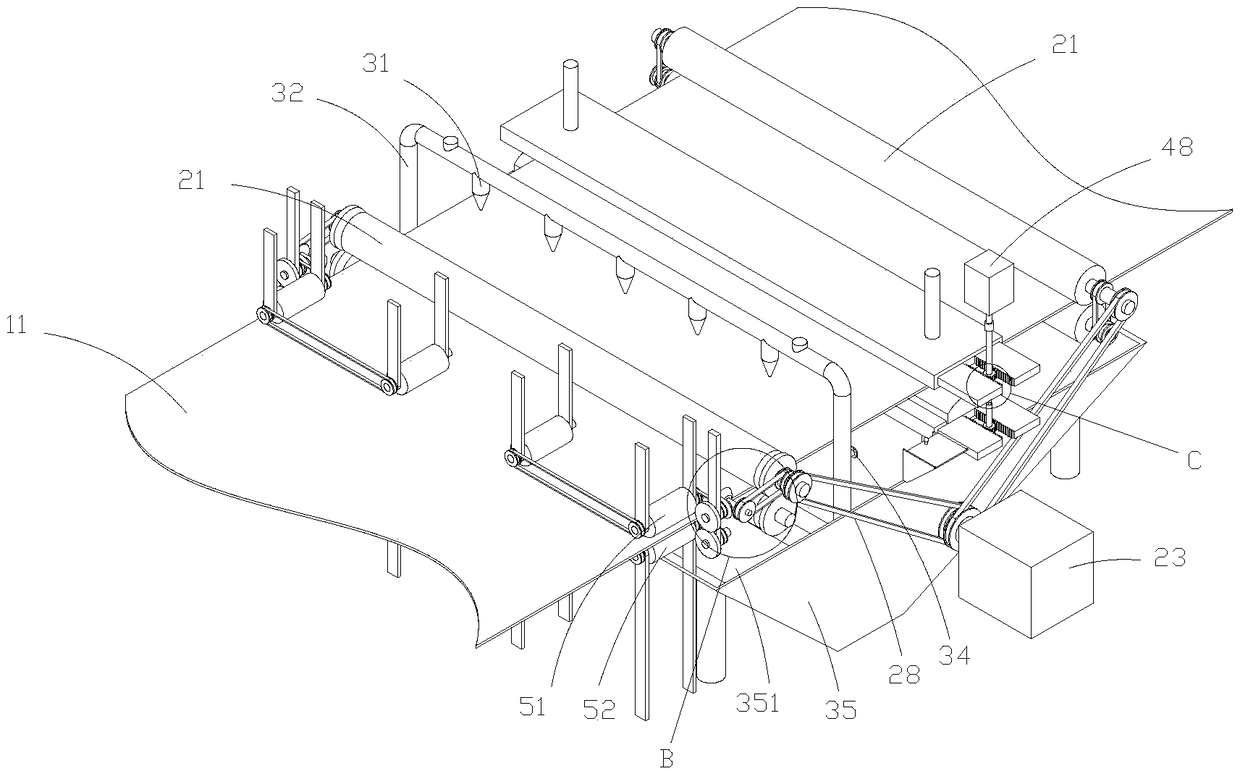

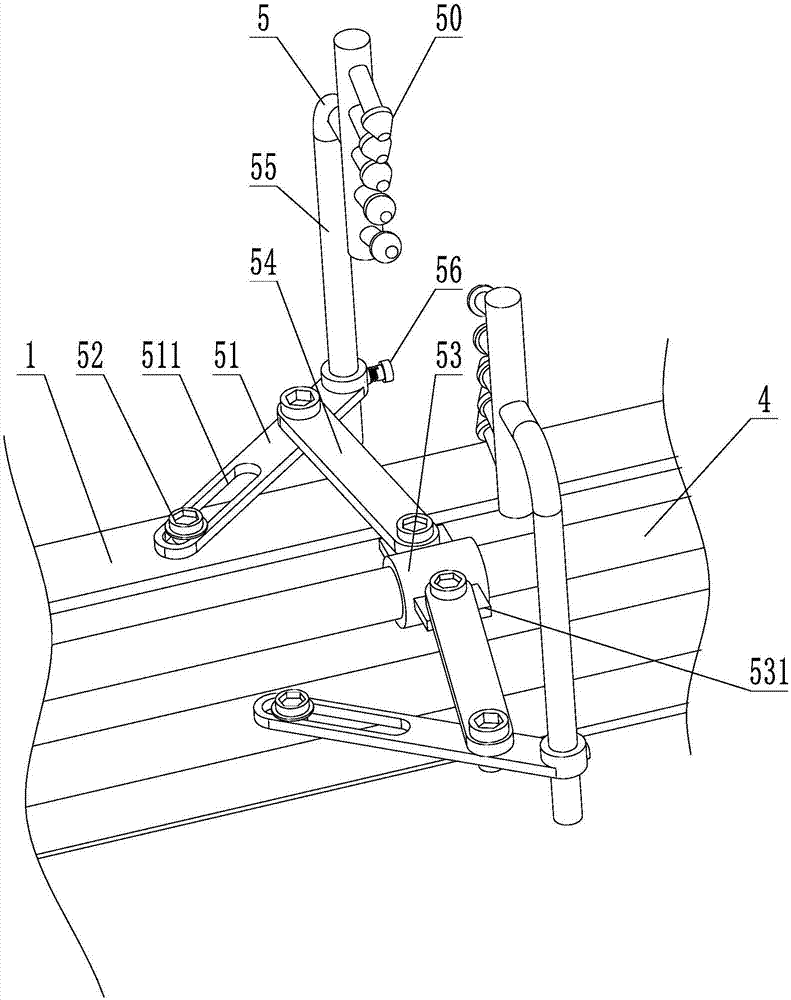

Spray-dyeing device with good dyeing effect

ActiveCN109295629AAvoid damageGuaranteed synchronous rotationTextile treatment by spraying/projectingTextile treatment carriersEngineeringRaw material

The invention discloses a spray-dyeing device with a good dyeing effect. The device comprises a frame, a raw material roller movably connected with the frame, a receiving roller movably connected withthe frame, a driving device for driving the movement of a fabric, an applicator for smearing evenly the dyeing liquid on the fabric and a flattening device for flattening the fabric; the flattening device comprises a left roller shaft set, a right roller shaft set matched with the left roller shaft set, a left transmission structure for being in drive connection with the left roller shaft set andthe driving device and a right transmission structure for being in driving connection with the right roller shaft set and the driving device; the device pulls the two edges of the fabric to the sidesby the arrangement of the left and right roller shaft sets, so that the surface of the fabric is kept flat, and the appearance of wrinkles is avoided so that the dyeing liquid can be evenly sprayed on the fabric to ensure uniform dyeing of the fabric.

Owner:SHAOXING UNIVERSITY

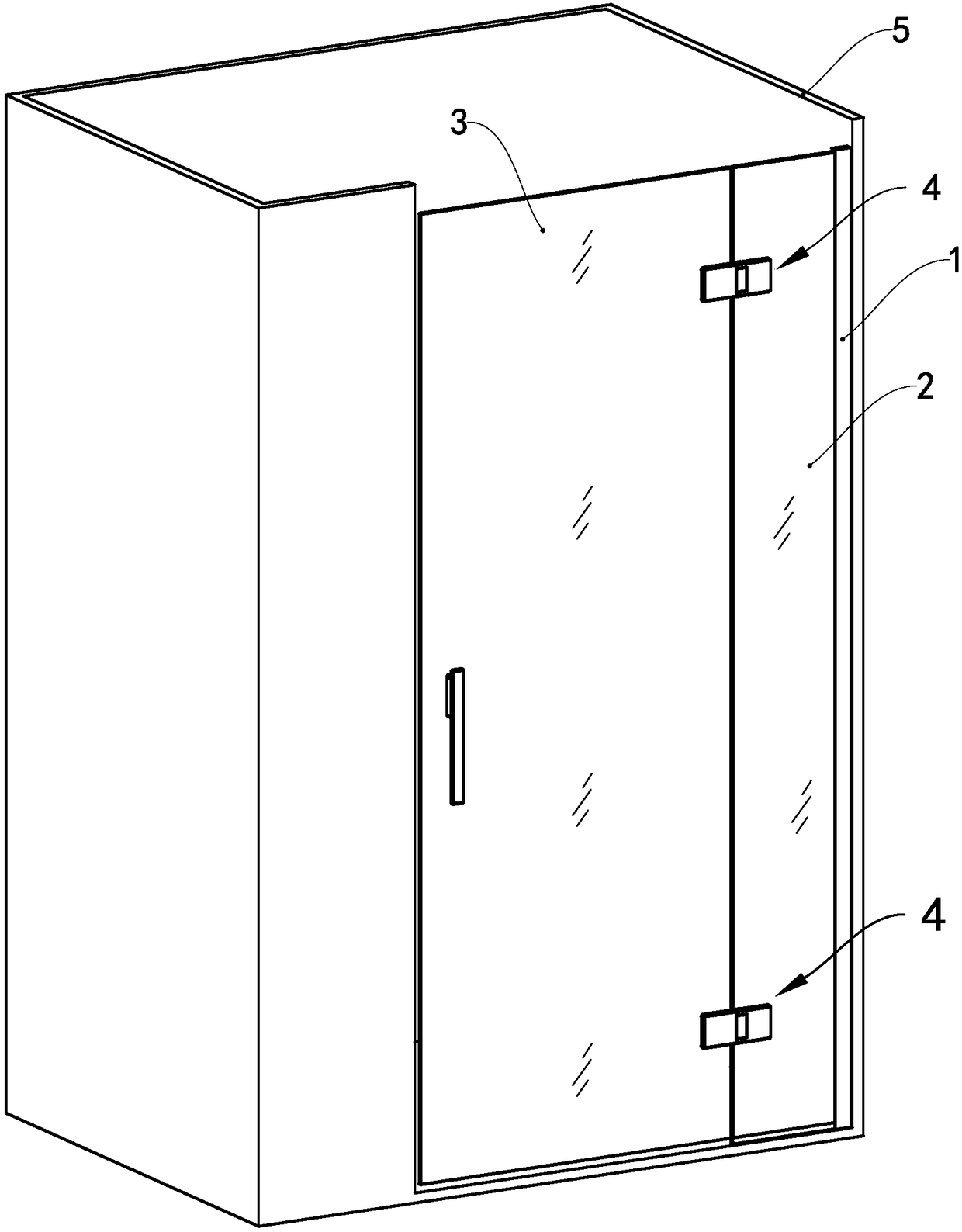

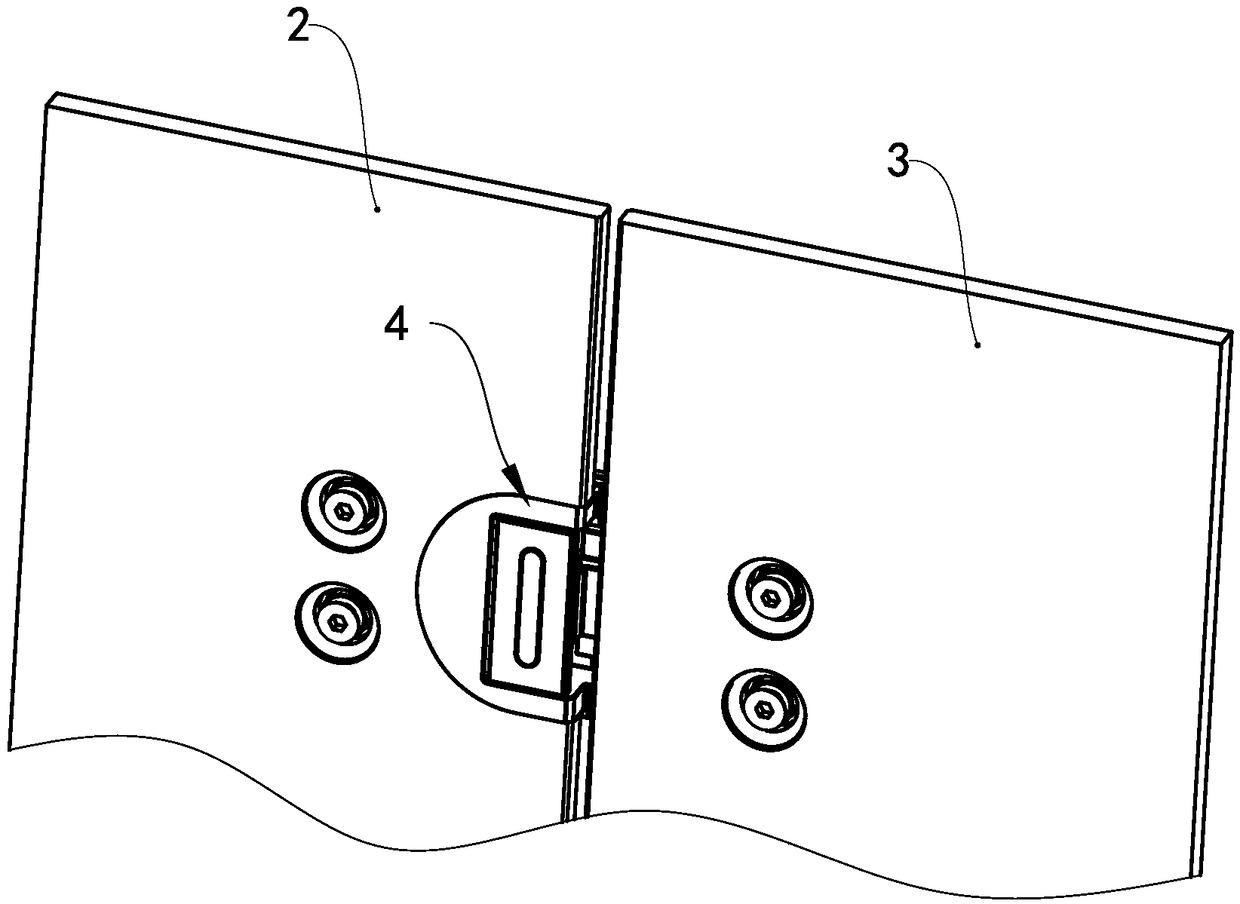

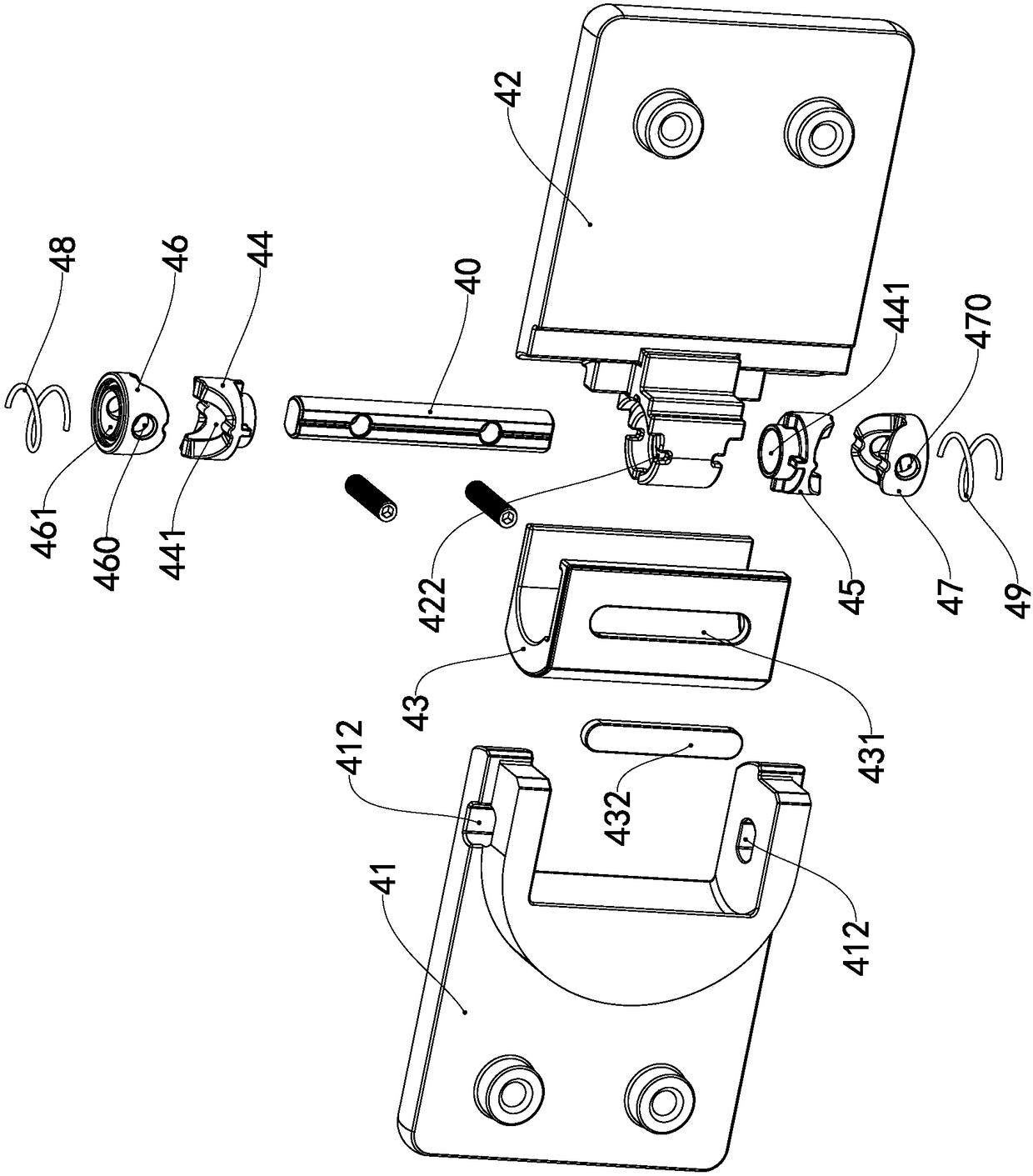

Lifting hinge and shower door

InactiveCN108064319ARealize internal and external opening and closingPrevent rotationGlass wingsHingesEngineeringMechanical engineering

The invention relates to the field of sanitary appliances, and provides a lifting hinge. The lifting hinge comprises a concave hinge, a convex hinge and two first lifting and positioning members, a second lifting and positioning member and an elastic member; wherein the concave hinge is provided with two first connecting portions, a recess is formed between the two connecting portions, and a second connecting portion is arranged on the convex hinge. The concave hinge and the convex hinge are pivotally connected by a connecting member, and the two first lifting and positioning members are sleeved on the connecting member and are located in the concave portion; one second lifting and positioning member and one first lifting and positioning member are clamped, and each of the second lifting and positioning members is opened with a first fixing hole extending through a radial direction thereof, and the position of the connecting member corresponding to the two first fixing holes are openedwith a second fixing hole, and one first fixing member and corresponding second fixing hole are internally provided with fixed parts; the elastic member abuts between the first connecting portions and the second lifting and positioning members. The present invention also provides a shower door using the lifting hinge.

Owner:FOSHAN IDEAL

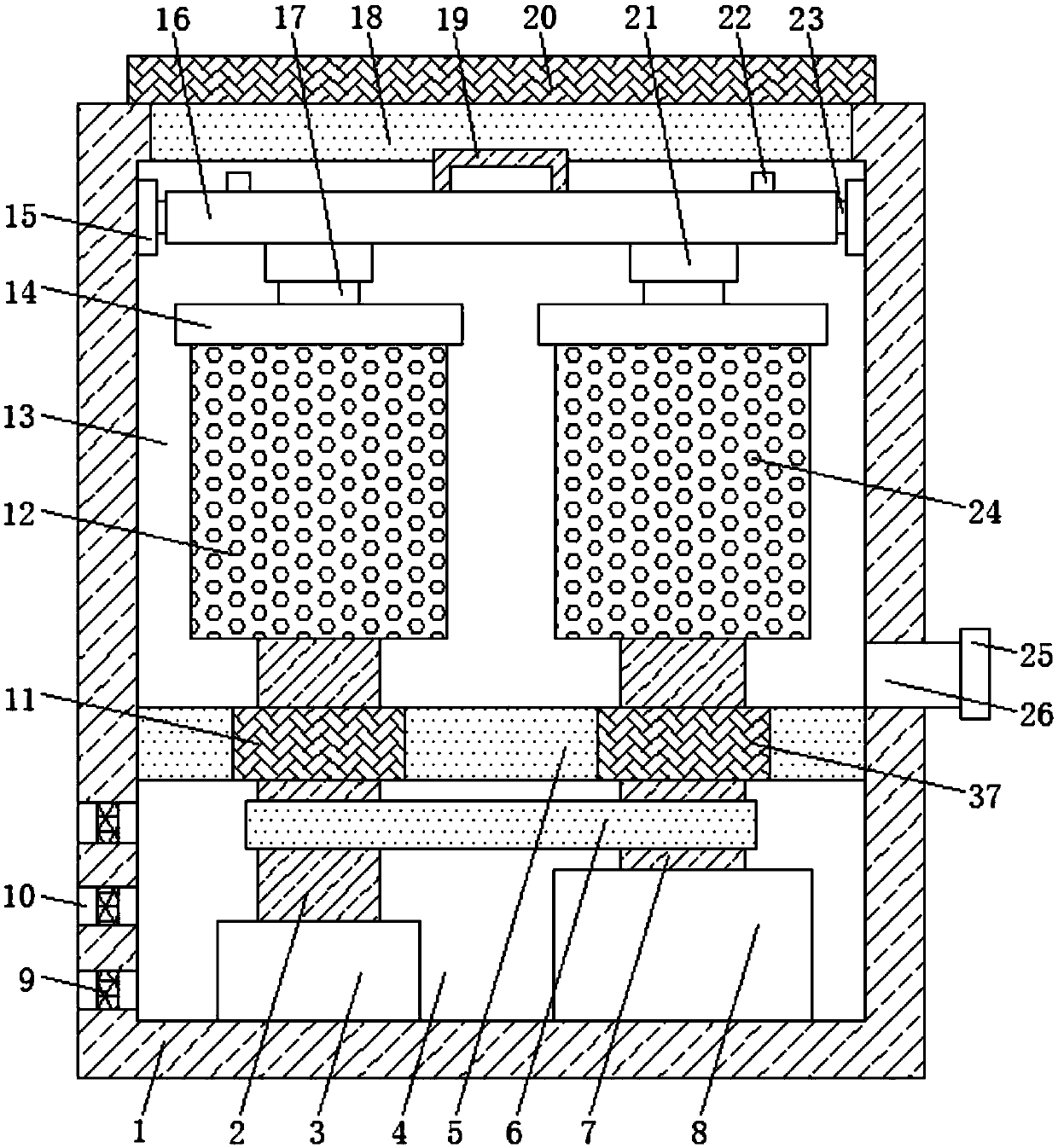

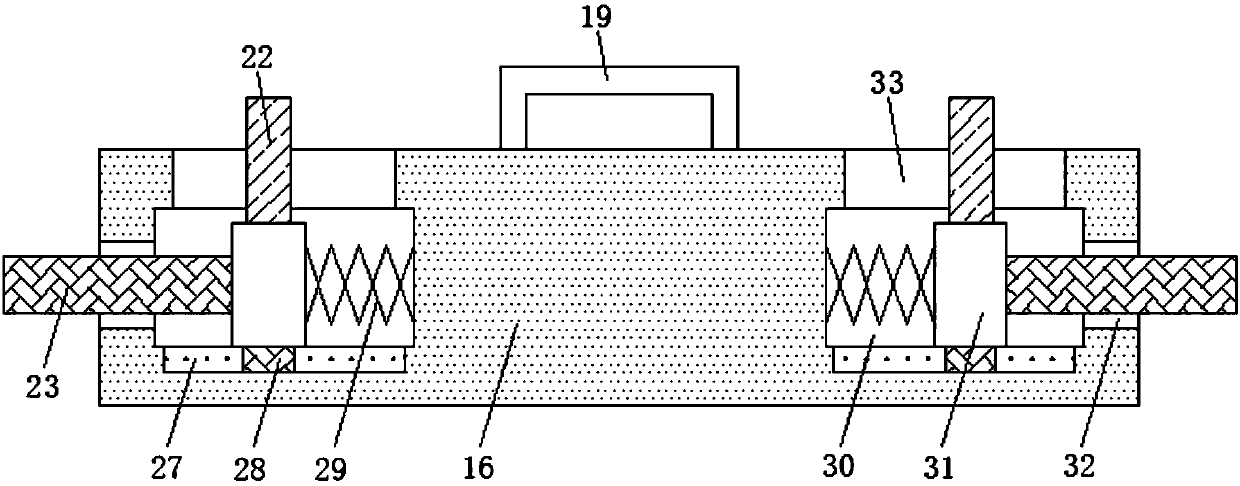

Traditional Chinese medicine cleaning robot for medicine processing

InactiveCN107824528AEasy to cleanSave human effortCleaning using liquidsBiochemical engineeringRelative stability

The invention discloses a traditional Chinese medicine cleaning robot for medical processing, which comprises a device body. A support plate is fixedly connected to the inside of the device body. A first sealed bearing and a second sealed bearing are fixedly embedded in the inside of the support plate. The support plate will The equipment body is divided into a power room and a cleaning room. The traditional Chinese medicine cleaning equipment for pharmaceutical processing can effectively clean the traditional Chinese medicine inside the cleaning basket, effectively liberates manpower, saves time and effort, and has high cleaning efficiency, ensuring the cleanliness of the first cleaning cylinder, the second cleaning cylinder and the cleaning basket. Synchronous rotation, can carry out rotary cleaning of traditional Chinese medicine, the cleaning effect is better, ensure the relative stability of the fixed plate, ensure the smooth rotation of the cleaning basket, more convenient to use, effectively ensure the production and processing of traditional Chinese medicine, and can clean the power room The internal heat is effectively discharged, has a certain dustproof performance, can effectively take and place traditional Chinese medicine, and is more convenient to use.

Owner:赵涛

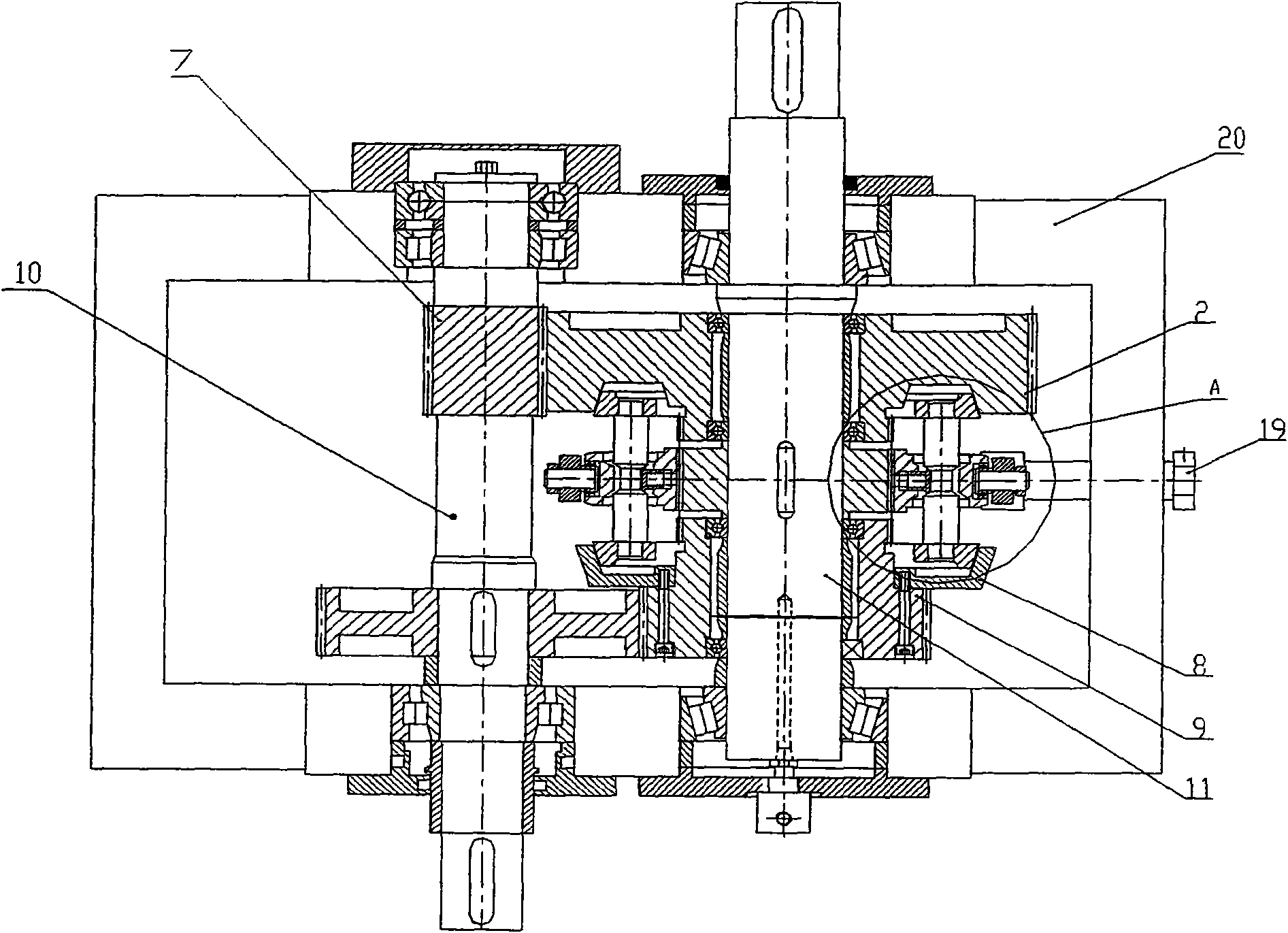

Non-stop variable speed gear box for coiler with big reel or large tension

ActiveCN101608683AReduce frictionGuaranteed normal rotationControlled membersToothed gearingsAxial distanceConcentric ring

The invention relates to a non-stop variable speed gear box for a coiler with a big reel and large tension, wherein the opposite surfaces of the two gears of a speed adjusting shaft are provided with concentric ring-shaped outer friction ring grooves or friction rings; the distance from the edge openings of the ring-shaped outer friction ring grooves to the center of the shaft is larger than the distance from the bottoms of the grooves to the center of the shaft; the groove walls in the edge openings of the ring-shaped outer friction ring grooves are friction surfaces; an internal spline sleeve is a disc structure, wherein the center is provided with an internal spline, the outer margin is a fork slot, and the concentric periphery is provided with synchronization pin holes which are uniformly distributed and comprise synchronization pins; two ends of the synchronization pins are provided with friction inner rings, the ring bodies of which are located in the edge openings of the ring-shaped outer friction ring grooves, and the outer margins of the friction inner rings are inclined planes which are rough friction surfaces with the taper consistent with the groove walls; the inclined planes are rough friction surfaces; and when the internal spline is meshed with a fixed external spline on the shaft, the axial distance between the friction surfaces of the friction inner rings and the friction surfaces of the ring-shaped outer friction ring grooves is less than the distance between the external splines on the two gears and the external splines fixed on the shaft.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

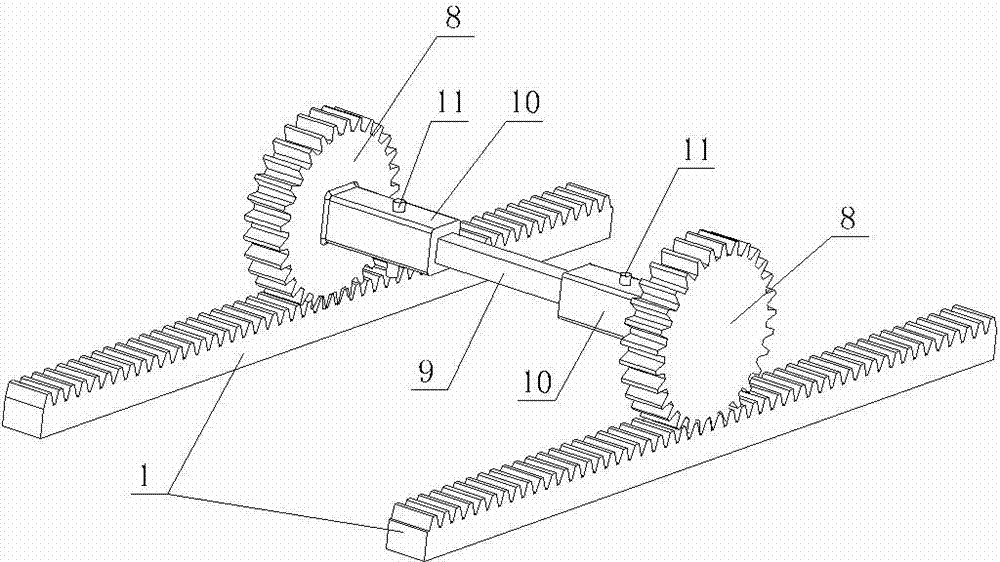

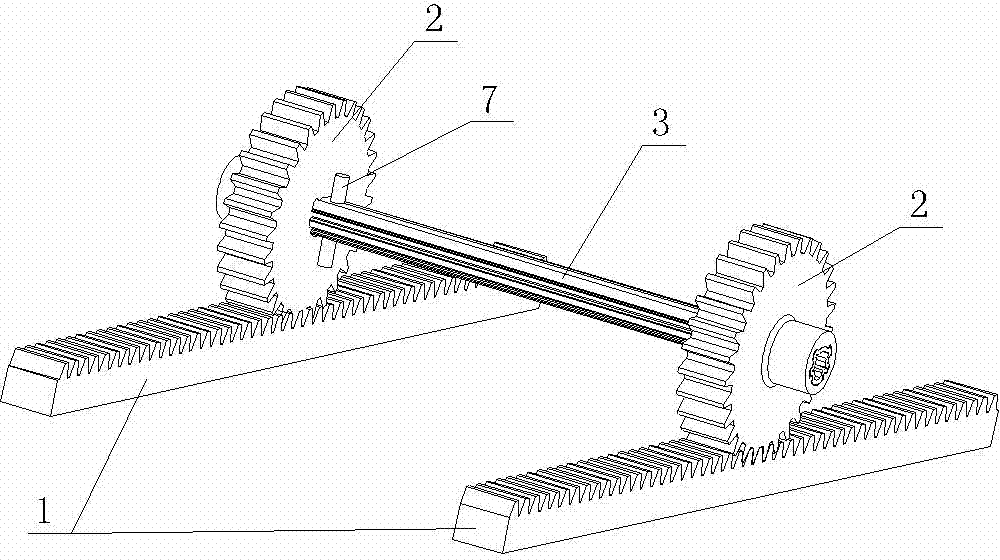

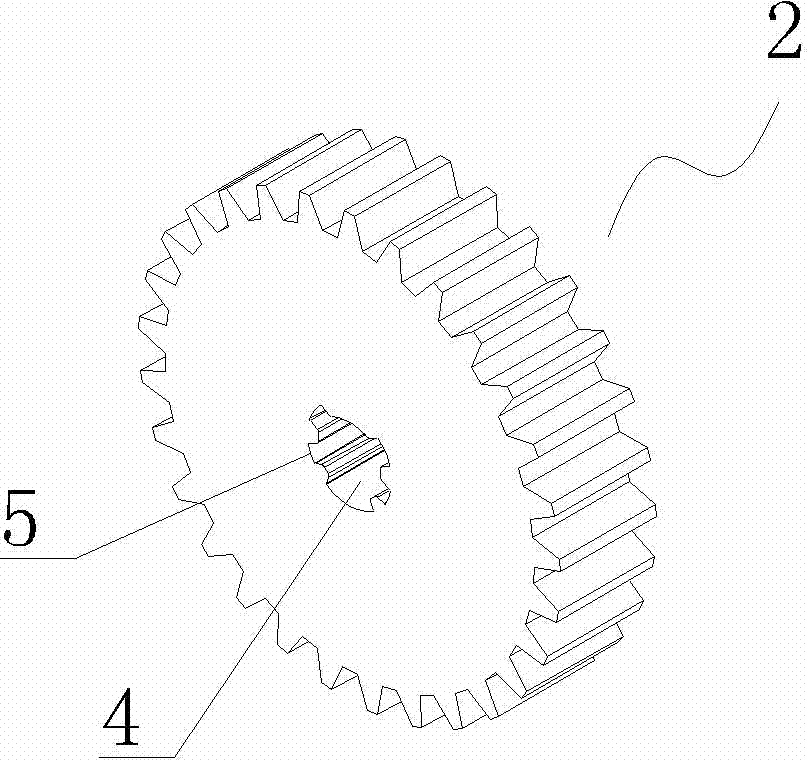

Connecting structure of sliding-rail synchronous gears

ActiveCN103206832AGuaranteed synchronous rotationSmooth and reliable slidingLighting and heating apparatusSupportGear wheelEngineering

Owner:WUXI HAIDAER PRECISION SLIDES CO LTD

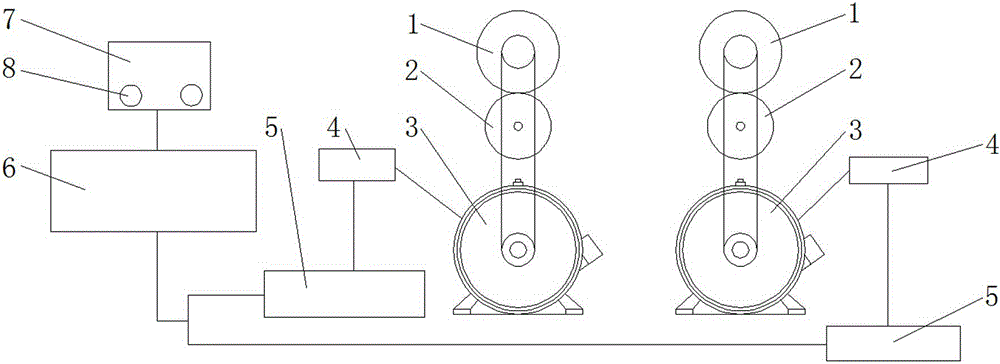

Laminating machine multi-roll synchronization control device

InactiveCN106292502ASimple structureIncrease productivityProgramme control in sequence/logic controllersElectric machineControl system

A laminating machine multi-roll synchronization control device comprises a plurality of heat rollers and pressure rollers arranged corresponding to the heat rollers. The heat rollers are connected with motors, the motors are provided with encoders, the encoders are connected with controllers, the controllers are connected with a PLC control system, and the PLC control system is provided with a control panel. The laminating machine multi-roll synchronization control device is simple in structure, reasonable, stable in work and high in efficiency and can effectively ensure the synchronization of the heat rollers.

Owner:瑞安市立信印刷机械有限公司

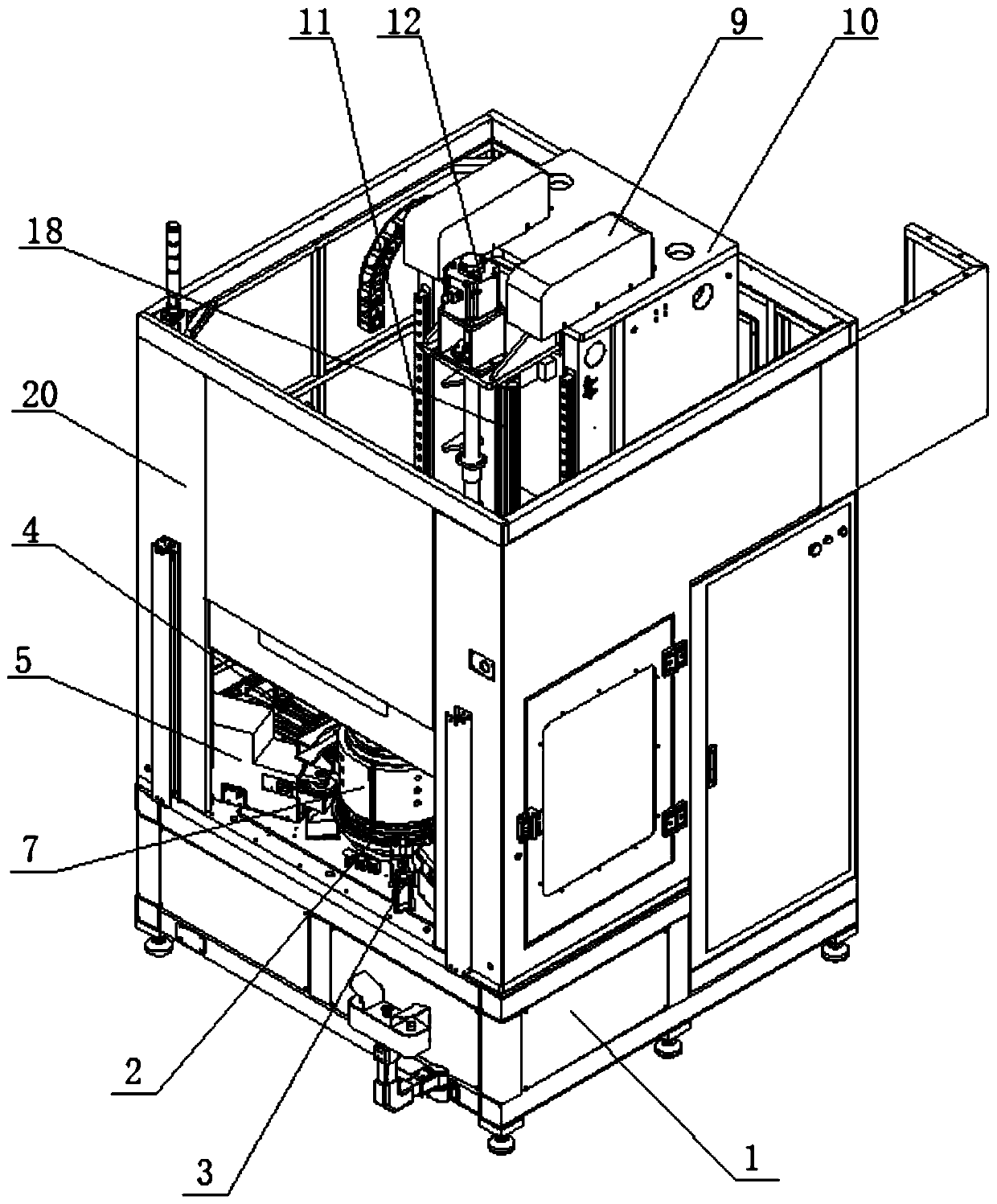

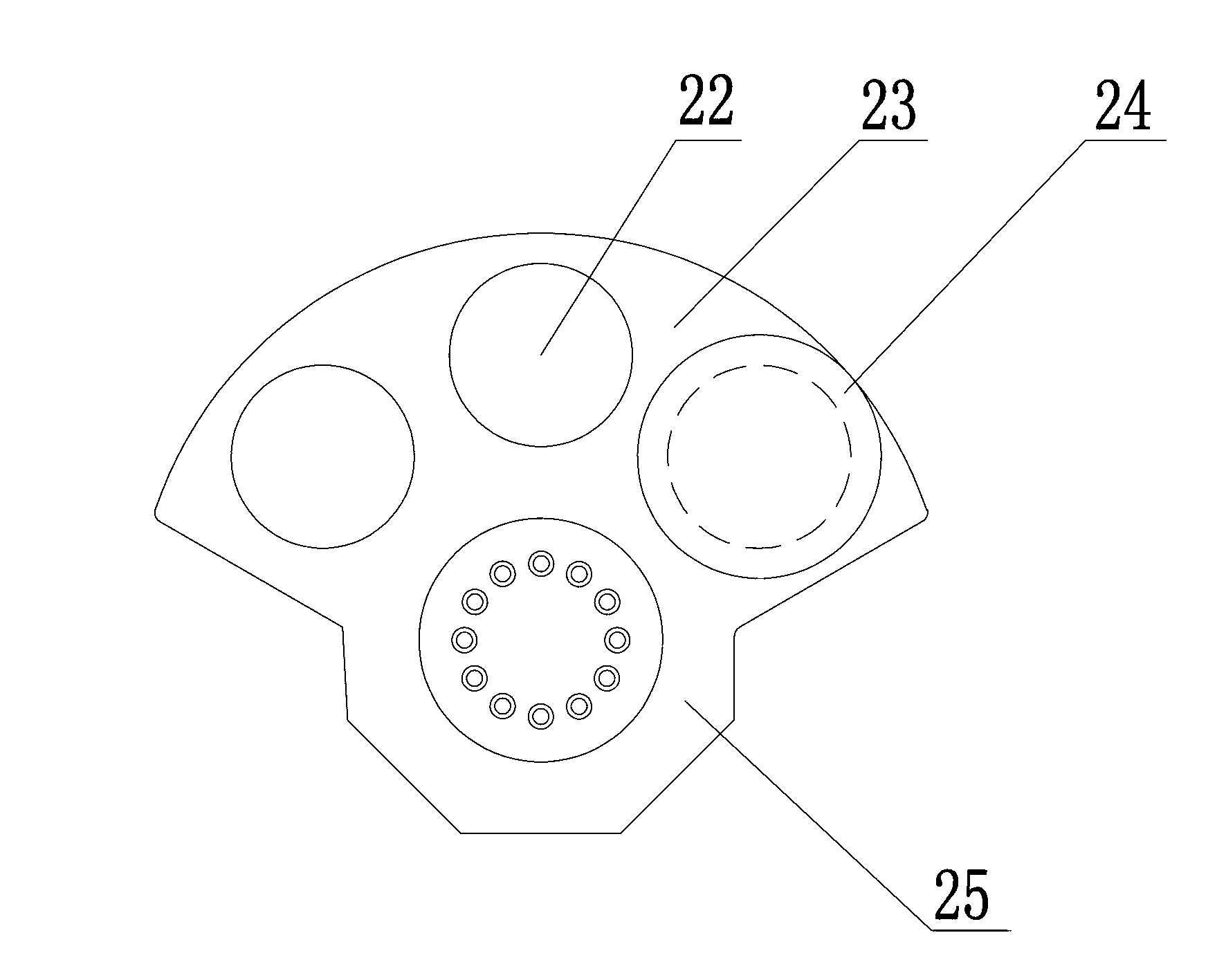

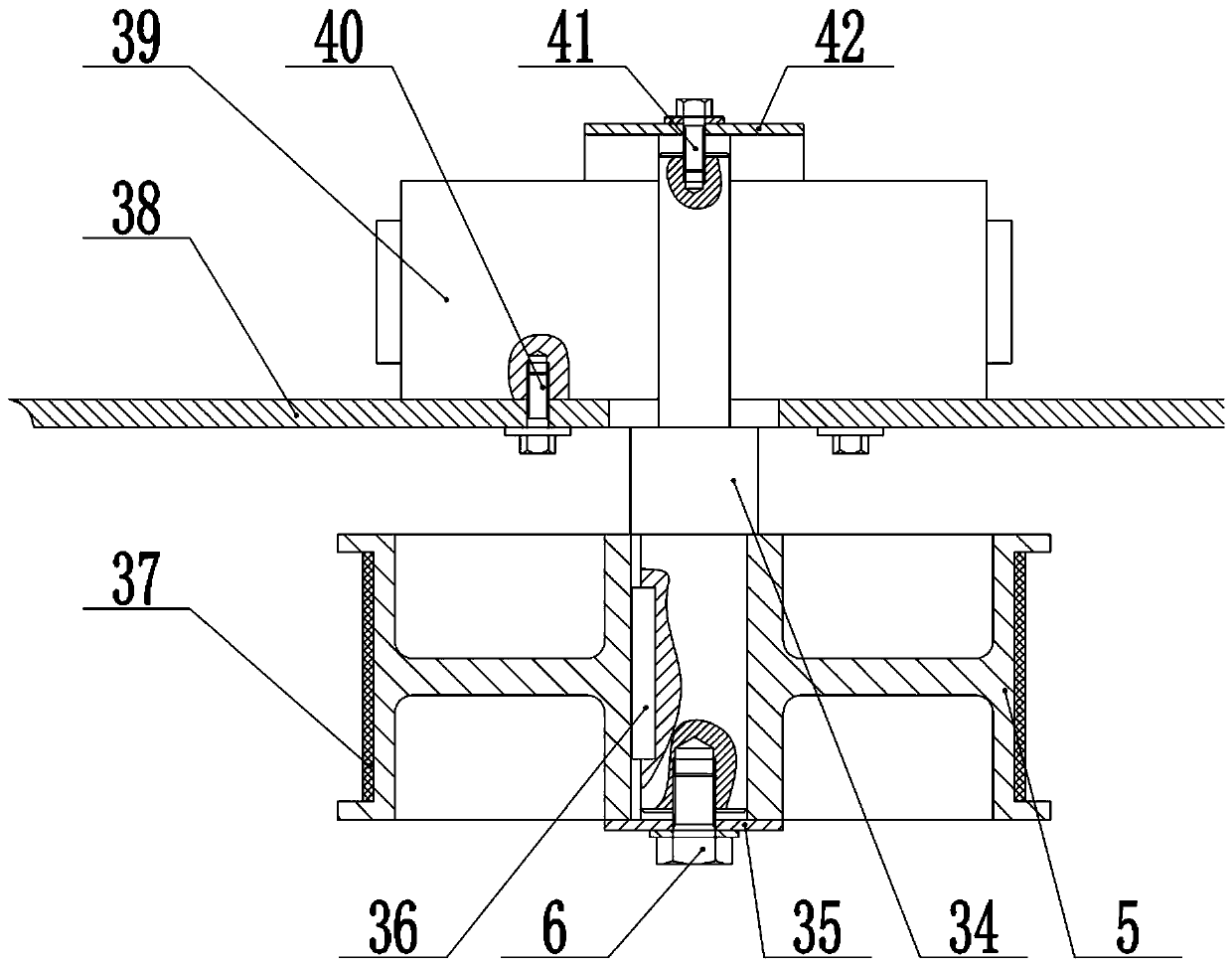

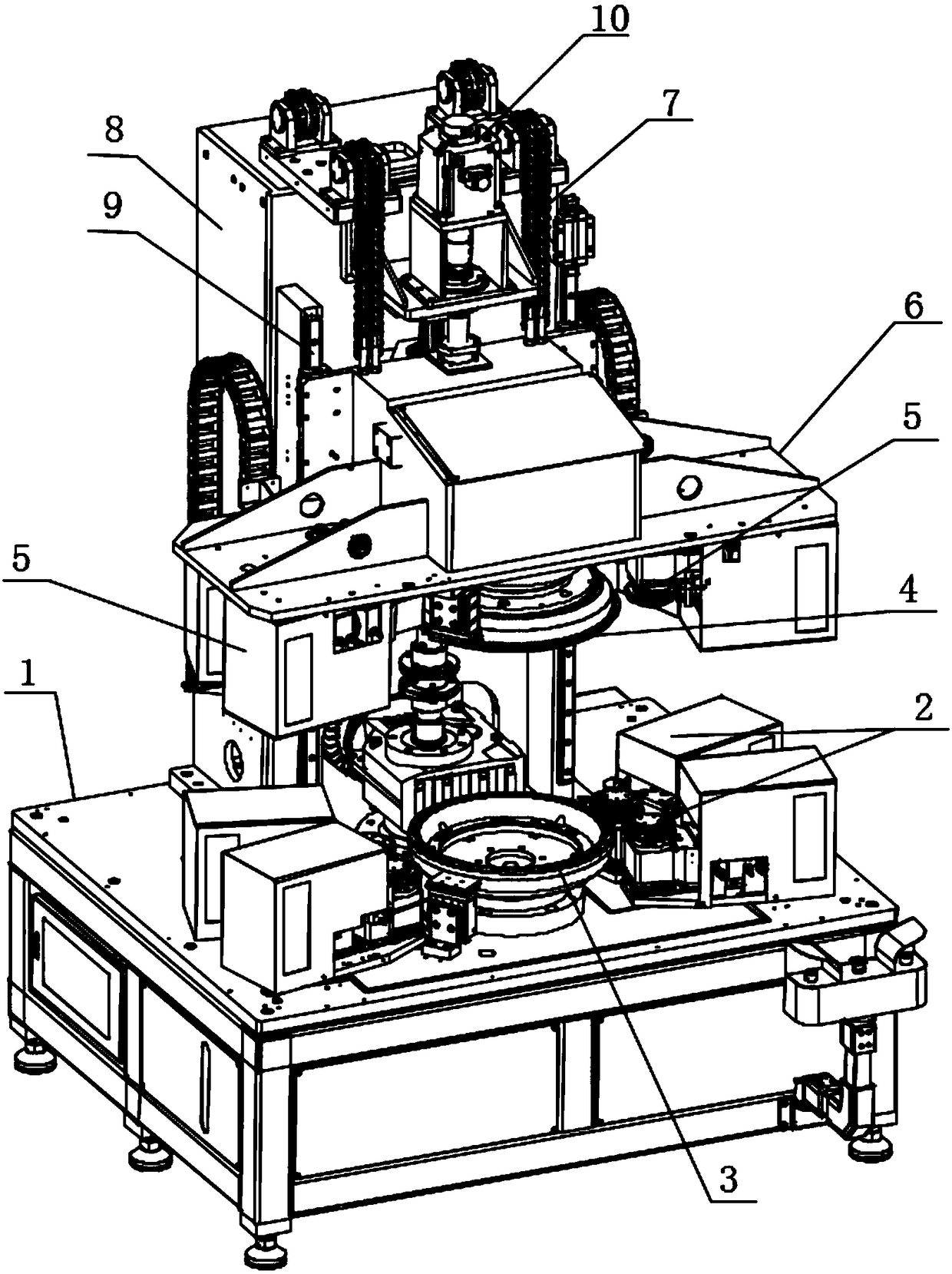

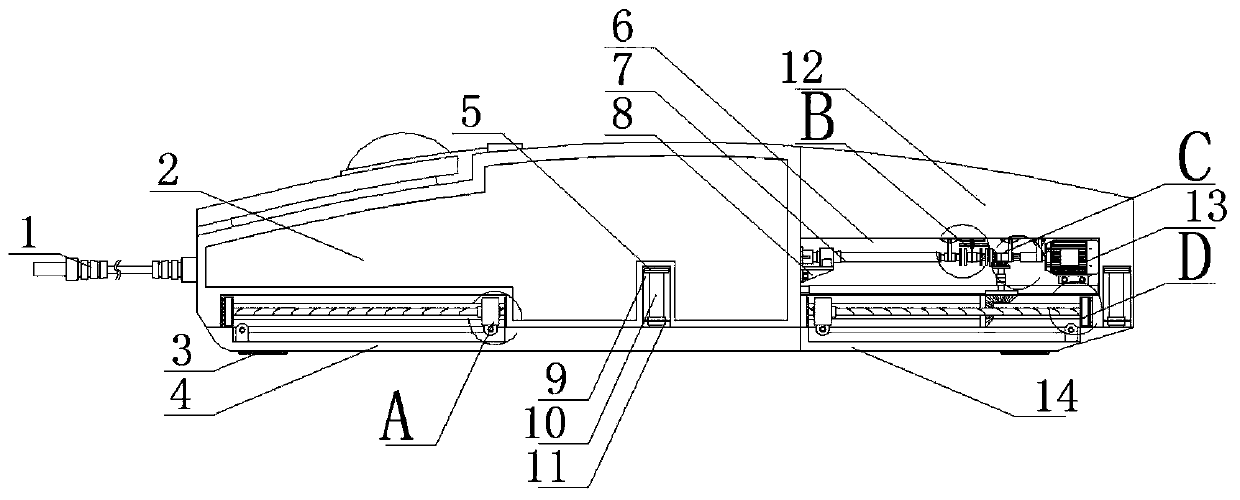

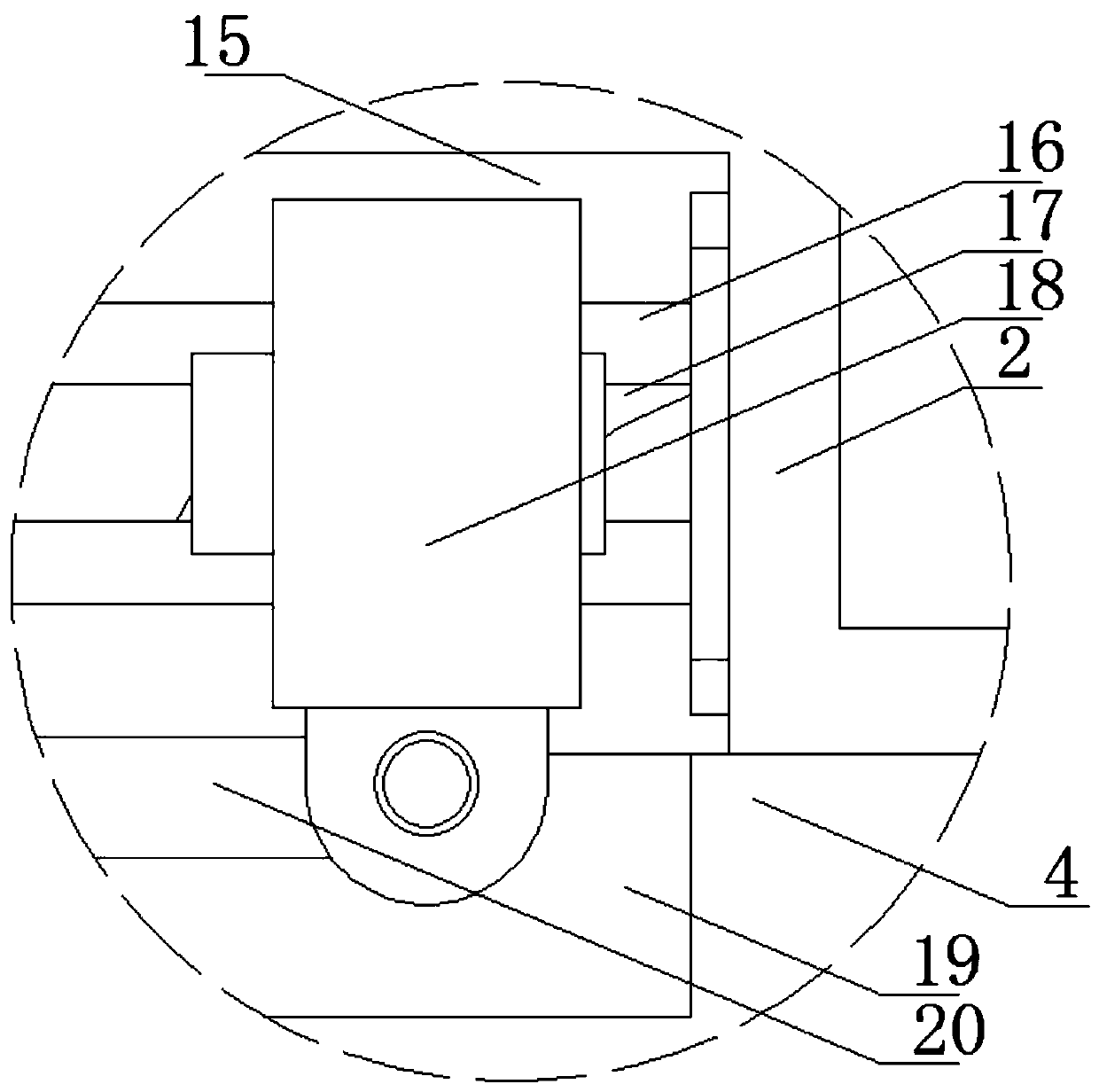

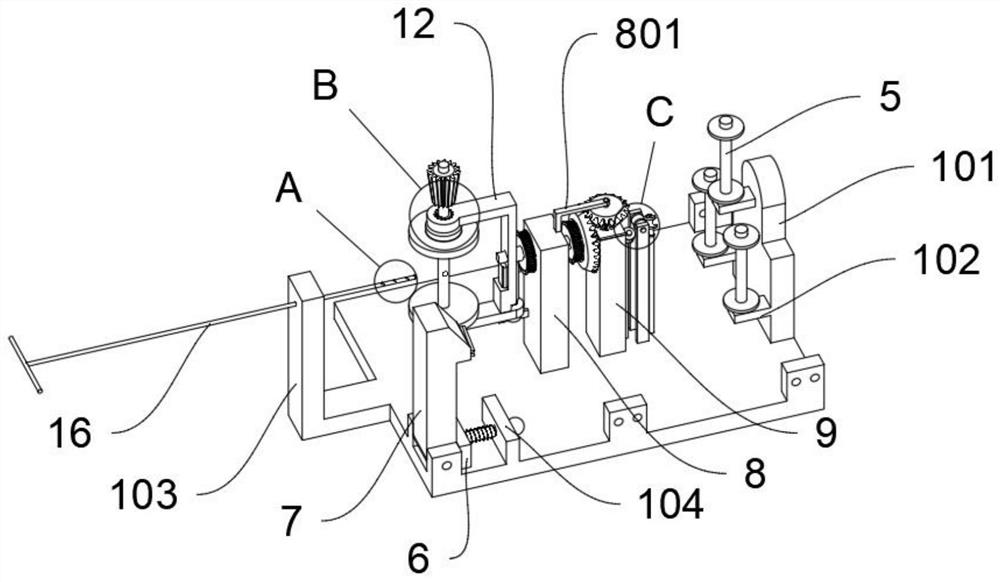

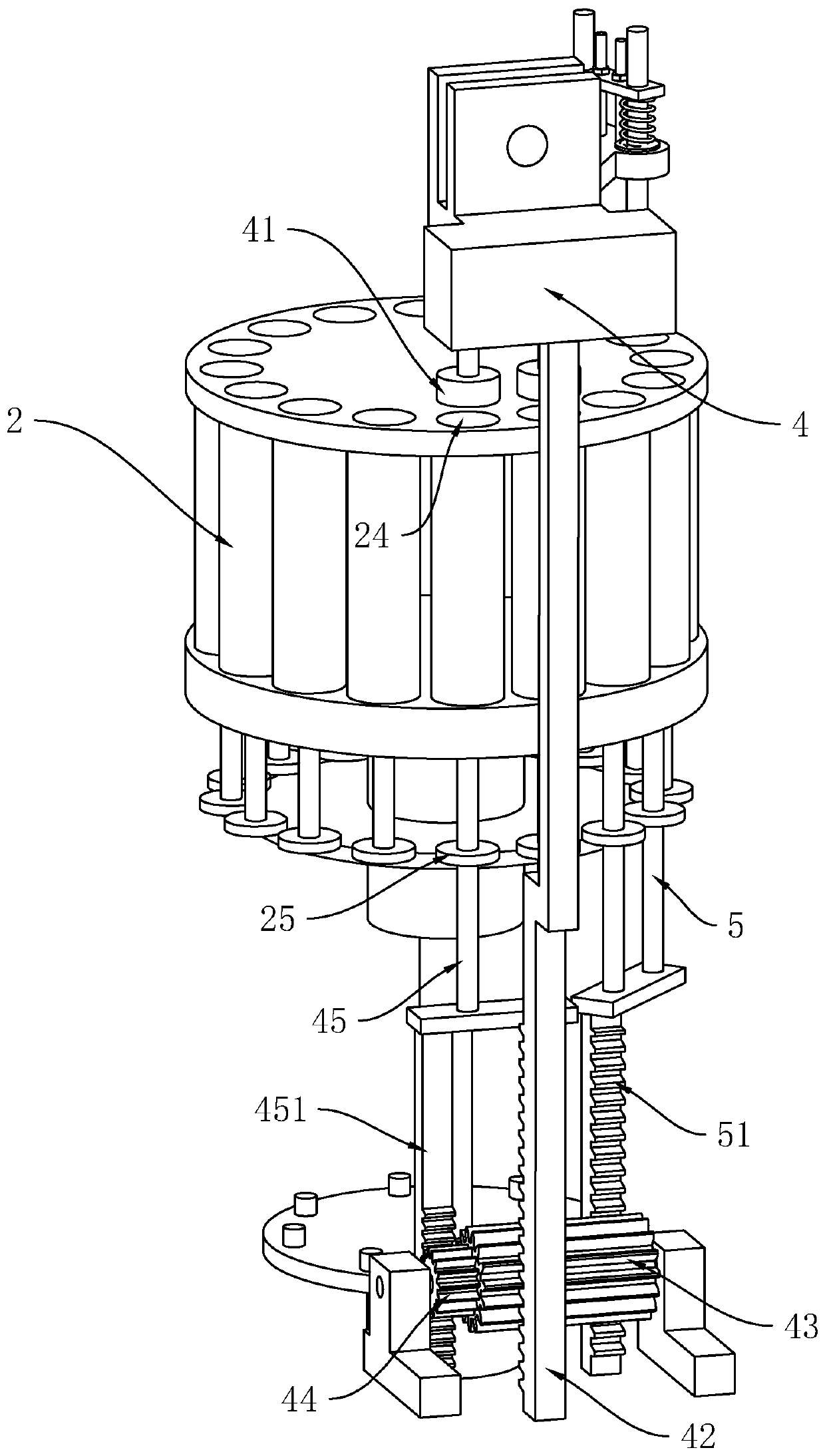

Spin riveting equipment for bottom of pulsator drum of washing machine and spin riveting method of spin riveting equipment

PendingCN110052543AAvoid deformationGuaranteed concentricityMetal-working feeding devicesShaping safety devicesMotor driveEngineering

The invention relates to spin riveting equipment for the bottom of a pulsator drum of a washing machine and a spin riveting method of the spin riveting equipment. The spin riveting equipment comprisesa rack and a work platform arranged at the top, wherein a weight box is mounted on the rear side of the work platform, a mold propping assembly driven by a servo motor to move vertically is arrangedon a guide rail on the front side surface of the work platform, and a mold core is mounted at the lower part of the mold propping assembly; a profiling plate is mounted on the work platform under themold core, and a clamping assembly, a positioning assembly and multiple spin riveting assemblies are distributed in the circumferential direction of the profiling plate; a main motor is mounted underthe weight box, and an output shaft of the main motor drives the mold core and the profiling plate to rotate together under driving of a spline shaft and a belt. The drum body is pre-positioned from the outside by adopting the clamping assembly and the positioning assembly and then is supported from the inside by the mold propping assembly and the mold core, finally, spin riveting connection of the body and the bottom of the pulsator drum of the washing machine is realized under the action of the main motor and the spin riveting assemblies, the spin riveting efficiency is high, and spin riveting press fit quality is good.

Owner:WUXI IDO SCI & TECH CO LTD

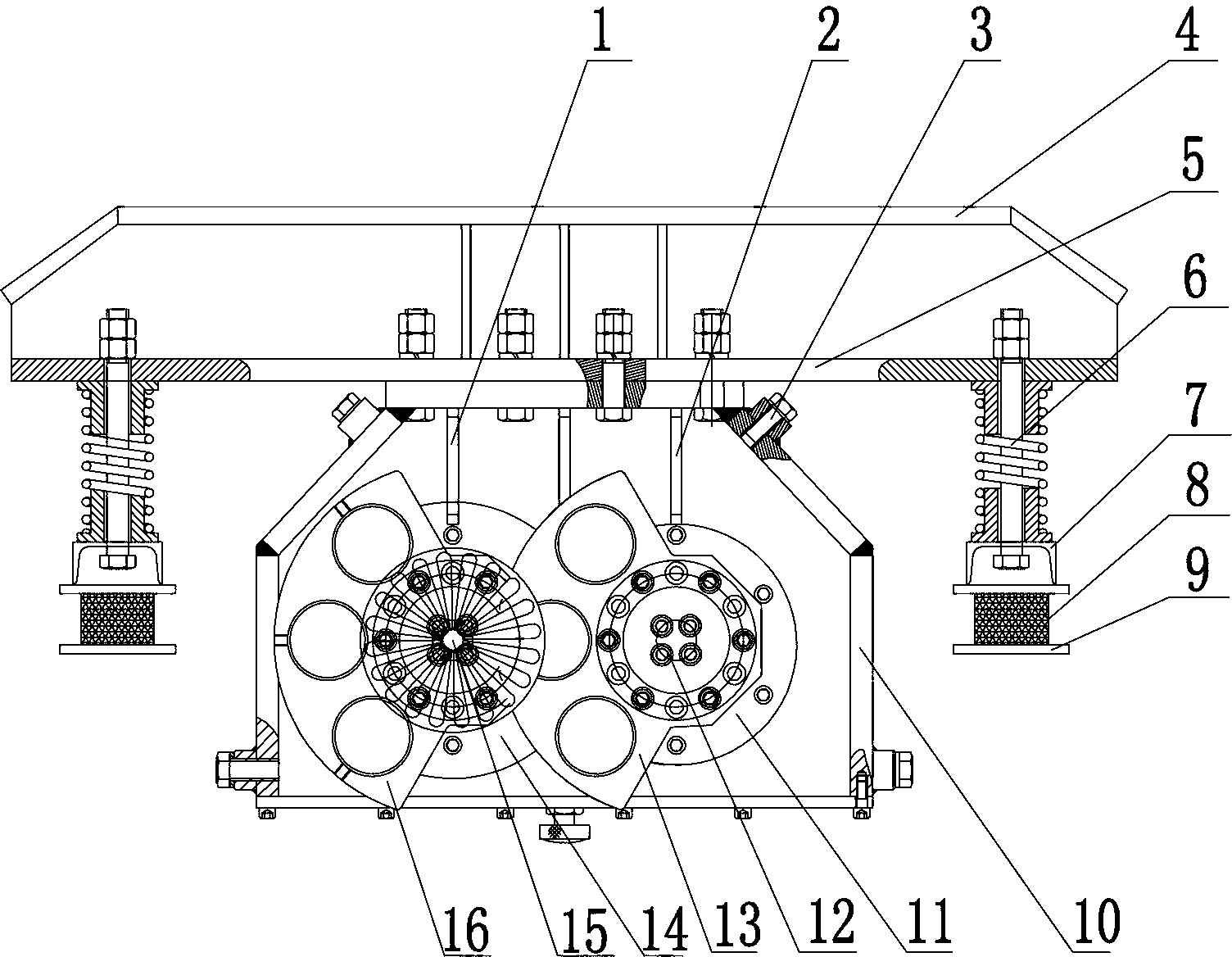

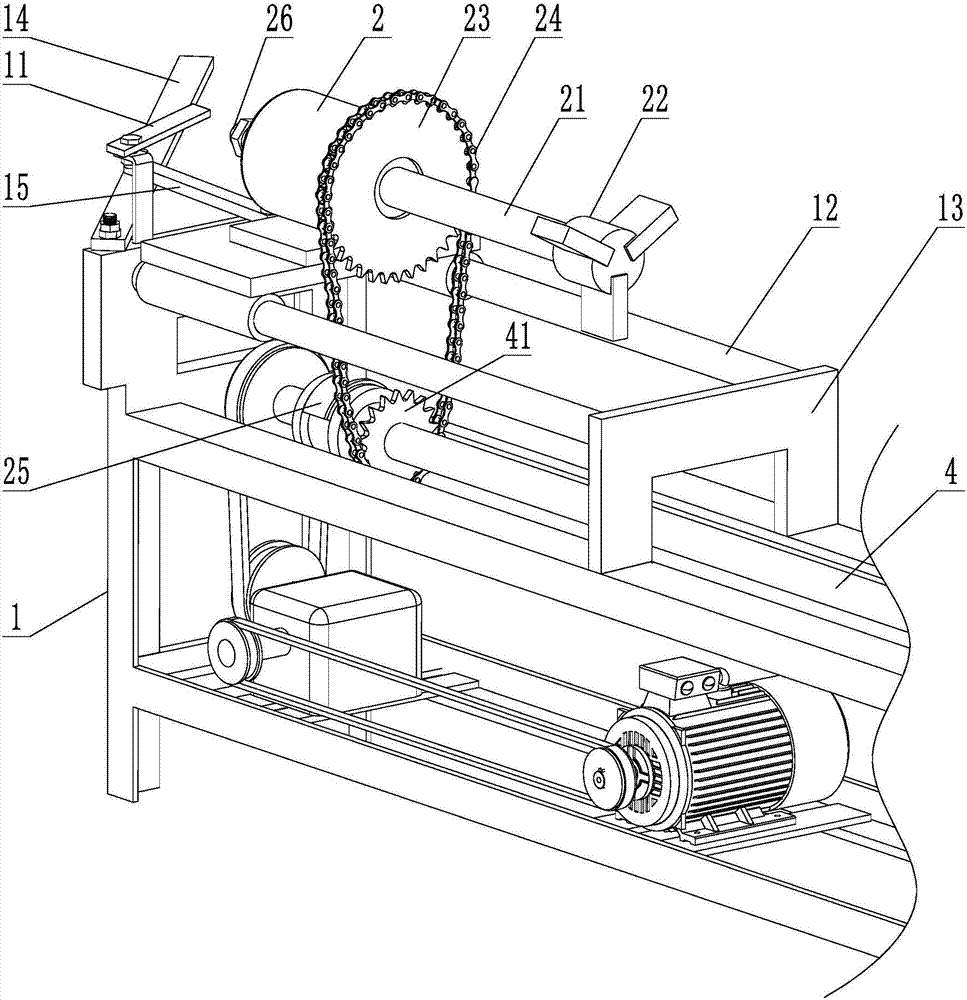

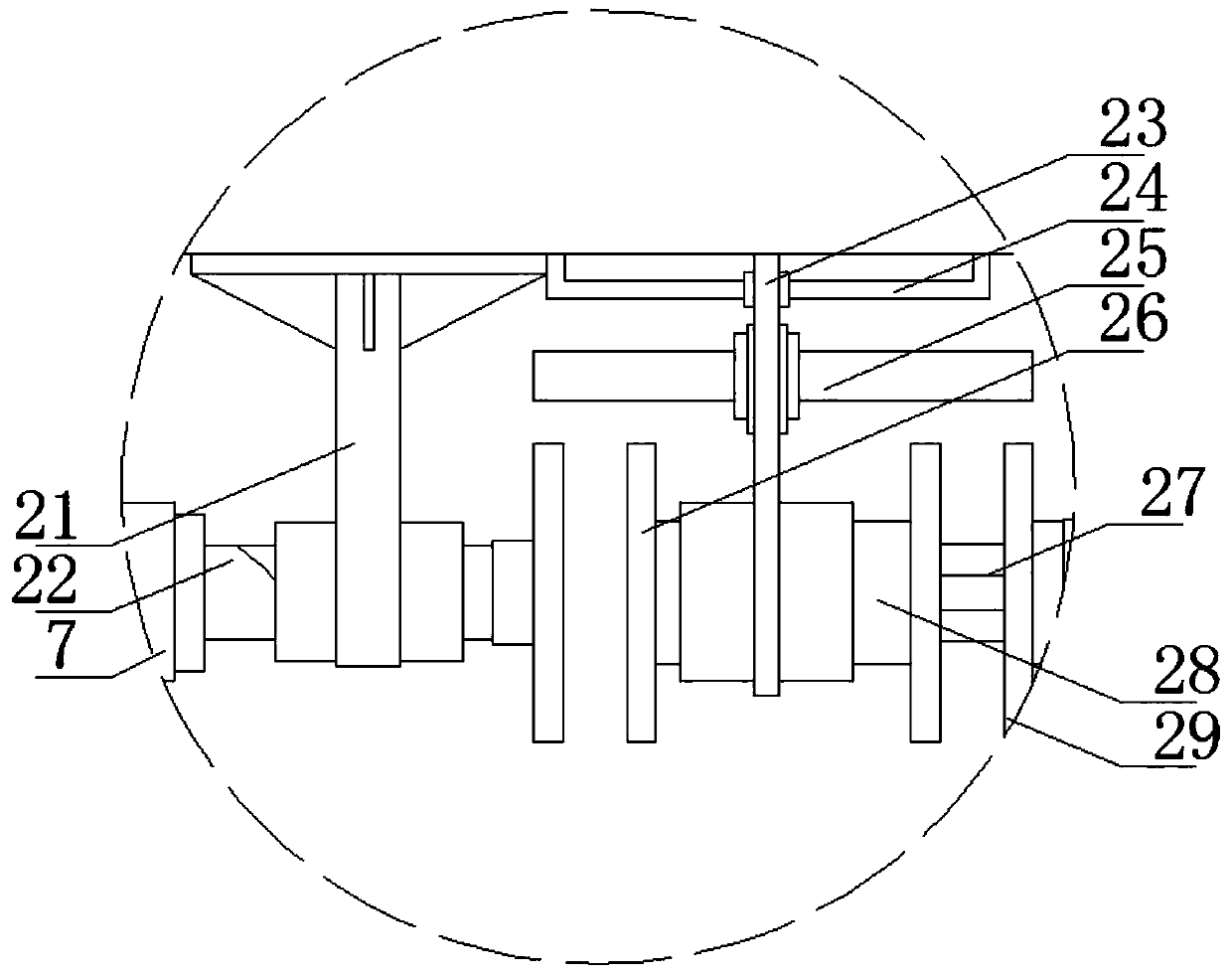

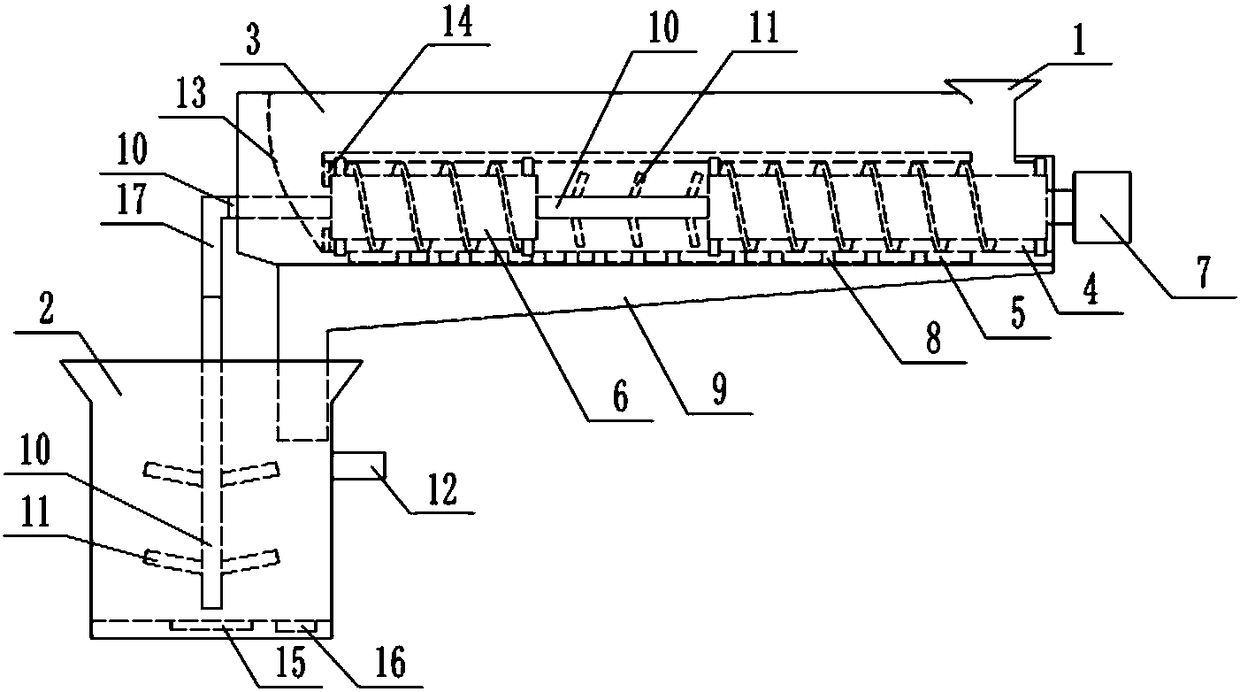

Adjustable vibrating mechanism of iron alloy granule-casting machine

The invention belongs to the technical field of alloy ingot continuous production and in particular relates to an adjustable vibrating mechanism of an iron alloy granule-casting machine. The adjustable vibrating mechanism comprises a driving vibrating device, a spring bed assembly and a vibrating plate connected with the spring bed assembly. The adjustable vibrating mechanism is characterized in that the driving vibrating device comprises a driving motor, a driving gear shaft, a driving gear, weighting blocks I arranged at two ends of the driving gear shaft, a connecting bracket I, a driven gear shaft, a driven gear engaged with the driving gear, weighting blocks II arranged at two ends of the driven gear shaft and a connecting bracket II; both the connecting bracket I and the connecting bracket II are connected with a vibrating box body; and the vibrating box body is connected with the spring bed assembly. With the adoption of the double-gear drive manner, the synchronous rotation of the two groups of weighting blocks is greatly ensured; both the superposition and the separation of the two groups of weighting blocks are finished according to a predetermined point of strength, the relative vertical running of the centrifugal force and the material is ensured, and thus the expected purpose and effect of the vibration are achieved.

Owner:LIAONING DINGSHIDA METALLURGICAL EQUIP MFG

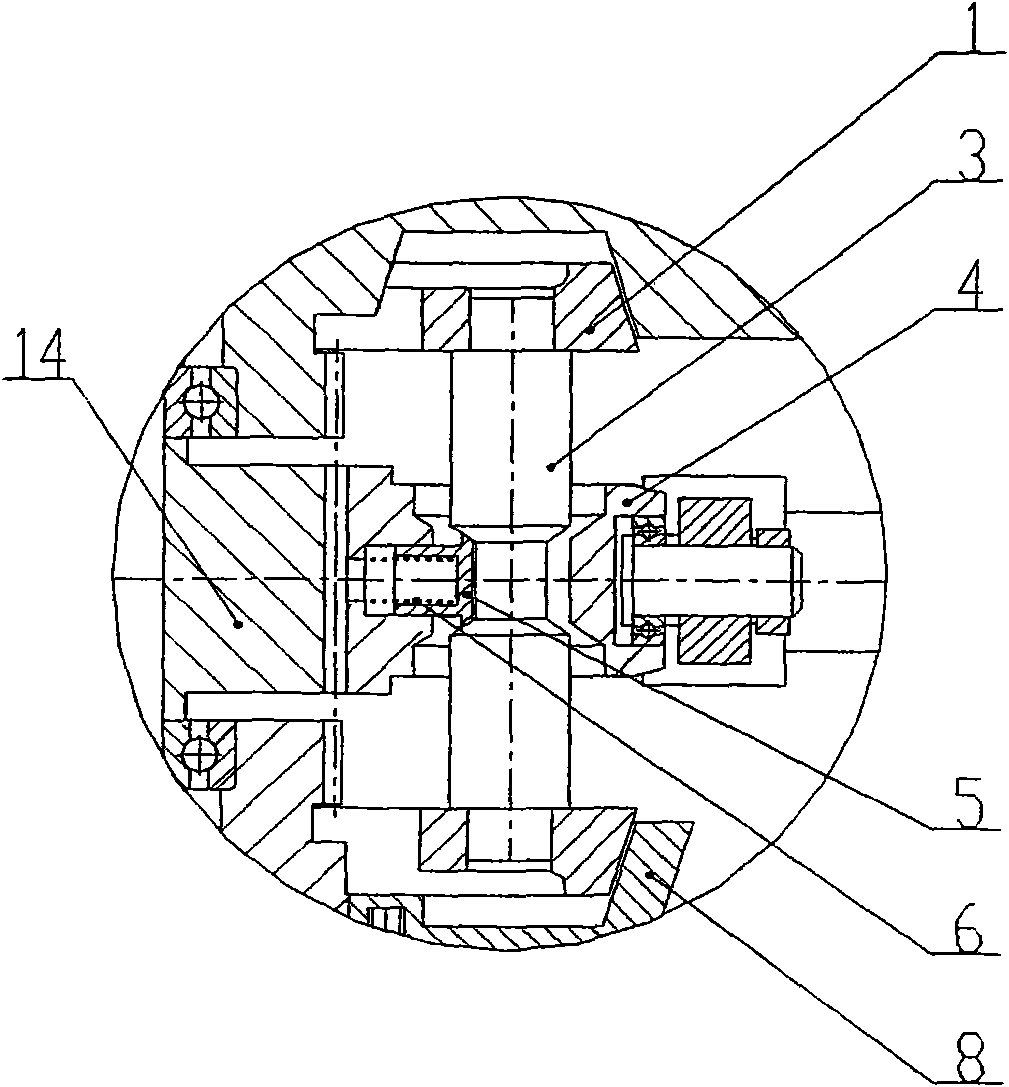

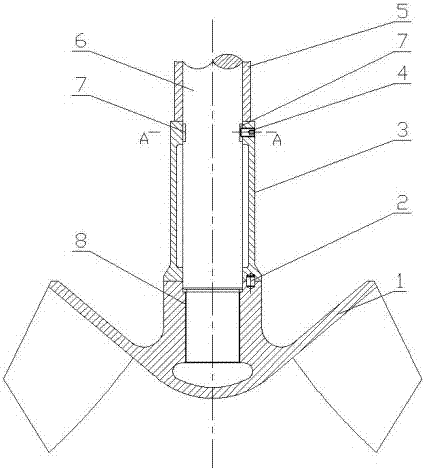

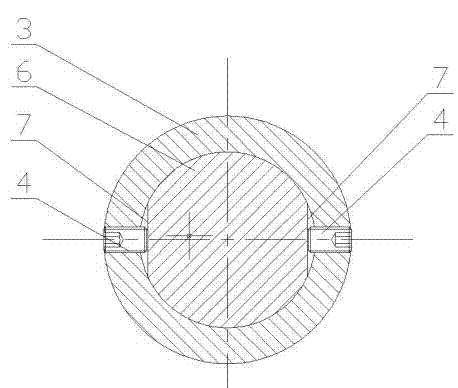

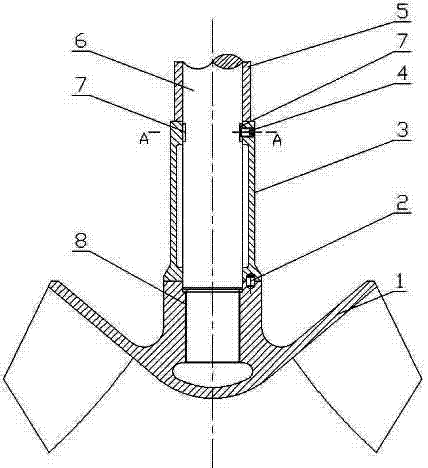

Looseness-preventing mechanism in reversion of pump impeller

InactiveCN102444613AProtect the impellerExtended service lifePump componentsPumpsImpellerScrew thread

The invention relates to a looseness-preventing mechanism in reversion of a pump impeller, which is characterized by comprising the impeller, a cylinder pin, a shaft sleeve, an inner hexagon screw, an upper shaft sleeve, a main shaft, a plane and a coupling thread, wherein the impeller is screwed on the main shaft by the coupling thread; the impeller abuts against the shaft sleeve which abuts against the upper shaft sleeve, so that the axial movement of the impeller is limited; the impeller is connected with the shaft sleeve by the cylinder pin, and the relative movement of the impeller and the shaft sleeve in the circumferential direction is limited, so that the synchronous rotation of the impeller and the shaft sleeve is ensured; and the inner hexagon screw is screwed on the shaft sleeve and abuts against the plane on the main shaft to limit the relative movement the shaft sleeve and the main shaft in the circumferential direction, so that the synchronous rotation of the shaft sleeve and the main shaft is ensured. The looseness-preventing mechanism has the advantages that the taken measure is as follows: the plane is cut on the original main shaft and simple parts such as a column pin, the inner hexagon screw and the like are added, so that the looseness preventing action in reversion of the impeller can be effectively played. The method is very simple, convenient and reliable, and the cost is low.

Owner:ZHENJIANG ZHENGHAN PUMP

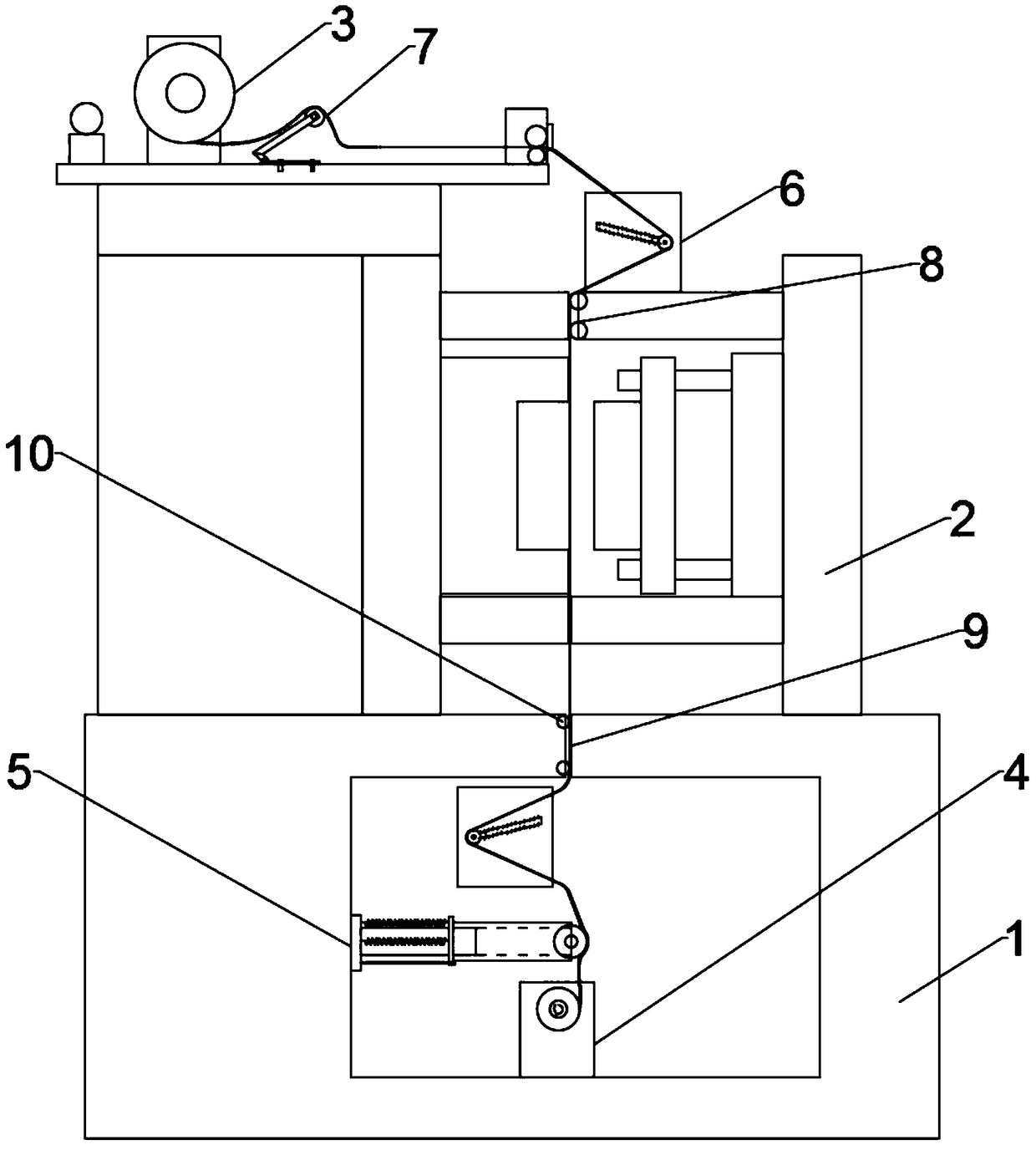

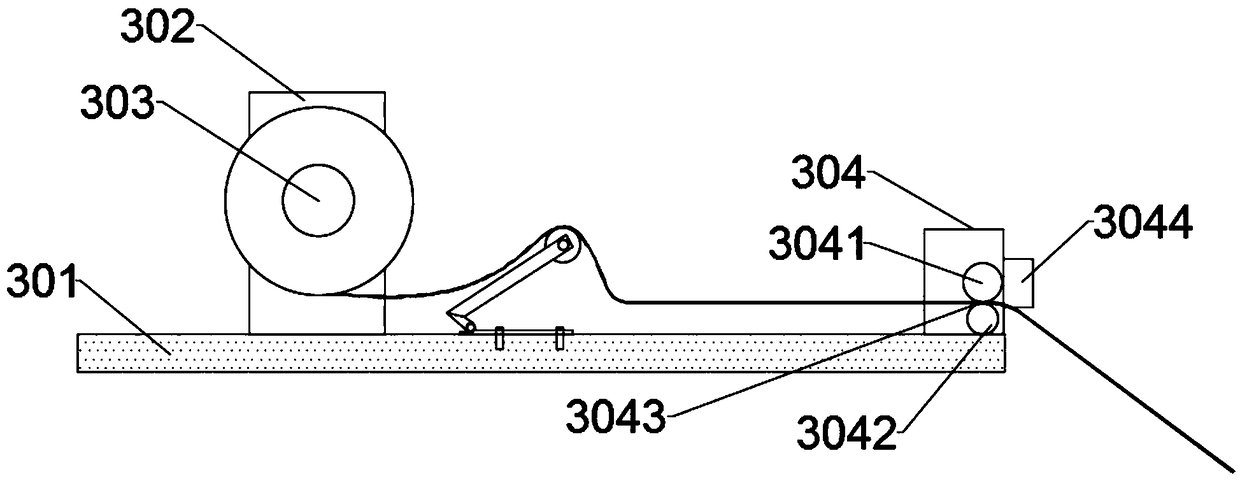

IMT in-mold transfer printing device and method

The invention discloses an IMT in-mold transfer printing device. A bearing base and an injection molding framework base arranged on the upper surface of the bearing base are included; a base materialfeeding mechanism is arranged at the upper end of the injection molding framework base; a waste film winding mechanism for reeling base material waste subjected to injection molding cutting is arranged in the bearing base, and a material receiving tensioning mechanism is further arranged above the waste film winding mechanism; and the upper surface and the lower surface of the injection molding framework base are each provided with an injection molding base material compensating mechanism for compensating for the mold closing extruding length of a base material. The invention further relates to a transfer printing method. A base material passes through the injection molding framework base in the vertical direction; the injection molding framework base performs mold closing, and the injection molding base material compensating mechanisms provide a pressed movement amount of the base material; the injection molding framework base performs mold opening, and the injection molding base material compensating mechanisms automatically return. Due to the scheme, the base material movement amount can be compensated for in the injection molding extruding process, the transfer printing qualityproblem caused by the fact that the surface tension of the base material at the injection molding position is too large is solved, the production quality of in-mold transfer printing is improved, using is convenient and fast, the control principle is simple, and the production quality is improved.

Owner:东莞华誉精密技术有限公司

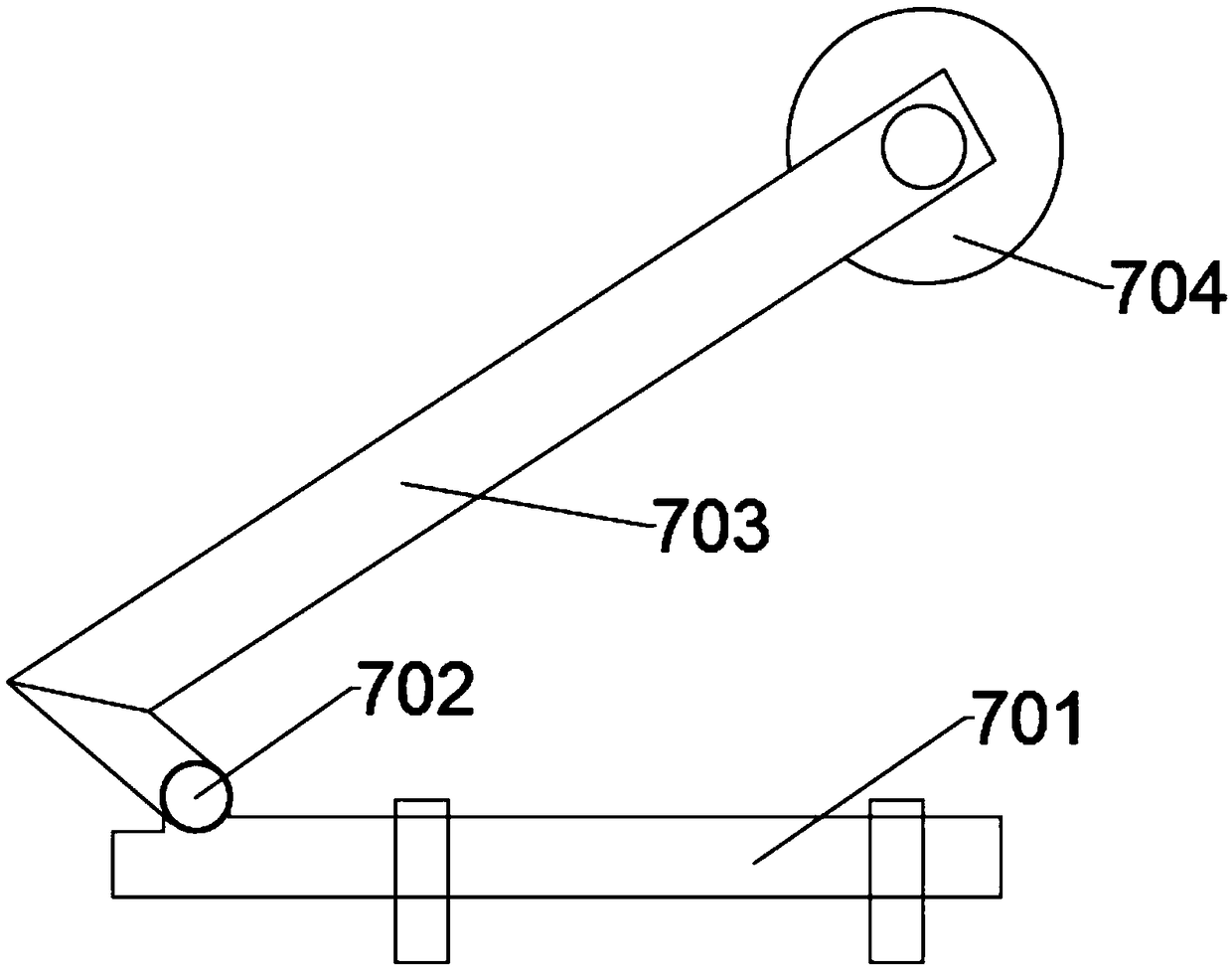

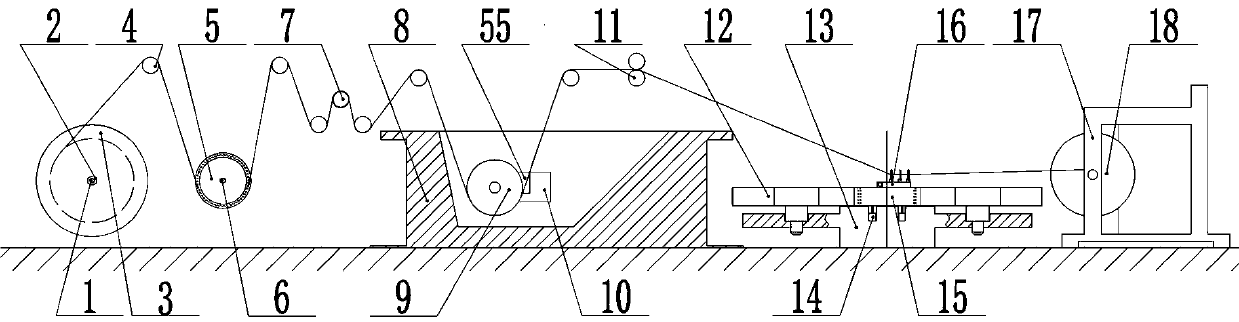

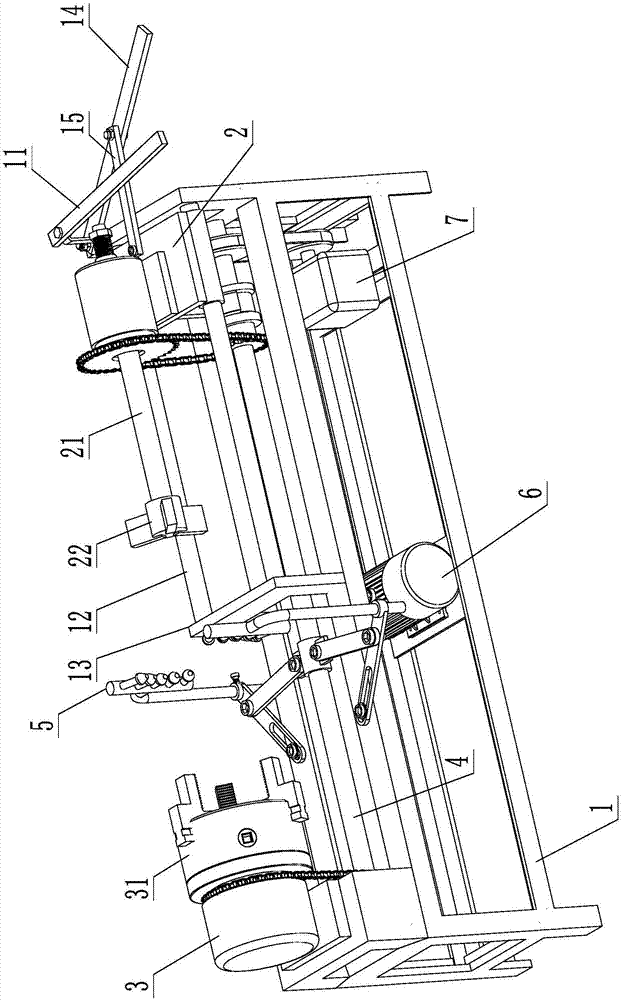

Device for forming basalt fiber-wound composite pipe

The invention provides a device for forming a basalt fiber-wound composite pipe. The device comprises a fiber unwinding part, a tension control part, a glue dipping part and a fiber winding part. Thefiber unwinding part comprises an unwinding roller, an unwinding shaft and a torque motor. The tension control part comprises a main speed roller, a magnetic powder brake and a tension detection mechanism. The glue dipping part comprises a glue dipping pool, a glue dipping roller and a glue extrusion roller. The fiber winding part comprises a rack, incomplete gears, a bevel gear reversing mechanism, a supporting table, a guide rail, a guide wheel, the composite pipe, a mandrel, a three-jaw chuck and a yarn nozzle, wherein the two sides of the rack are each provided with one incomplete gear, the yarn nozzle is fixed to the rack, and the bevel gear reversing mechanism drives the incomplete gears to rotate synchronously. According to the device, a horizontal structure is adopted to prevent manual interference of all the parts, so that the stability is high; the tension can be kept constant all the time in the fiber winding process, it is guaranteed that basalt fibers are uniformly wound on the surface of the composite pipe, and the physical properties of the composite pipe are improved.

Owner:SOUTHWEST PETROLEUM UNIV

Automobile part machining polishing equipment convenient to adjust

InactiveCN107081668AGuarantee processing qualityEasy to adjustGrinding carriagesPolishing machinesAutomotive engineering

The invention discloses automobile part machining polishing equipment convenient to adjust. The automobile part machining polishing equipment convenient to adjust comprises a workbench. A groove is formed in the middle of the left side face of the workbench. A cavity is formed inside the top end of the workbench. A first bearing is fixedly connected to the inner bottom wall of the cavity. A motor is arranged in the cavity. The output end of the motor is fixedly connected with a rotating shaft. According to the automobile part machining polishing equipment convenient to adjust, the height of a storage block can be adjusted correspondingly, the storage block can be rotated reasonably, the storage height and polishing angle of parts can be adjusted reasonably as required, adjustment is more convenient, and the machining quality of automobile parts is effectively ensured; a containing cavity can be effectively sealed, and a second bearing is prevented from being polluted by dust; and heat in the cavity can be dissipated in time, and the burning loss of the motor is effectively avoided, and using is more convenient.

Owner:于法周

Self-replacement nursing and cleaning device

InactiveCN110354379ARealize intelligent automatic controlAvoid frequent replacementMedical devicesMedical applicatorsTransmission beltDrive shaft

The invention discloses a self-replacement nursing and cleaning device, and belongs to the technical field of medical care. The device comprises an absorbent cotton reel, a rolling-up roller, a liquidconveying tube and a shell body, the rolling-up roller is connected with a motor, and a pushing injection cylinder body is arranged in the shell body; an oscillating bar is hinged to the upper end ofa pushing injection piston in the pushing injection cylinder body, a crank disc is hinged to the upper end of the oscillating bar, and one side of the crank disc is connected with a driving shaft; the other end of the driving shaft is connected with a transmission shaft through a bevel gear pair, and the transmission shaft is connected with the rolling-up roller through a belt wheel and a transmission belt; a strip-shaped slide groove vertically formed is formed in the portion, connected with the driving shaft, of the crank disc, the driving shaft and the transmission shaft are lifted and lowered synchronously, a lifting locking assembly is arranged in the strip-shaped slide groove, and a tensioning assembly is arranged on one side of the transmission belt. According to the self-replacement nursing and cleaning device, self-replacement of absorbent cotton can be achieved, medicine liquid spray is synchronously achieved, the spray amount of medicine liquid can be adjusted, and cross infection can be avoided; frequent replacement of cotton buds or frequent starting of corresponding components can be avoided, the self-replacement nursing and cleaning device is convenient to use, thenursing effect is improved, and the nursing efficiency is improved.

Owner:靳芳

Bogie rectifying device capable of overcoming airflow resistance

The invention discloses a bogie rectifying device capable of overcoming the airflow resistance and relates to the technical field of train belly rectification. The bogie rectifying device capable of overcoming the airflow resistance comprises a fairwater cone rail, fairwater cone wheels, a shell frame, access doors, a fairwater cone shell, a carriage underbody, a bogie, a guide wheel bracket, a guide wheel and a steel rail, and is characterized in that the fairwater cone shell covers the bogie; the upper and lower parts of the fairwater cone shell are provided with openings; the front and rear surfaces of the fairwater cone shell are arc surfaces; baffle plates on two sides of the fairwater cone shell are provided with the access doors; the two sides of the exteriors of the upper ends on the front and rear surfaces of the fairwater cone shell are provided with the fairwater cone wheels; the fairwater cone shell is connected with the fairwater cone rail by virtue of the fairwater cone wheels; the fairwater cone rail is connected with the carriage underbody by virtue of welding; a shell frame is welded and connected in the fairwater cone shell; a transverse rack at the lower end of the shell frame is connected with the guide wheel bracket; and the guide wheel is connected with the guide wheel bracket. The bogie rectifying device has the characteristics of reducing the air resistance of train running, reducing the energy consumption and improving the running speed.

Owner:UNIV OF JINAN

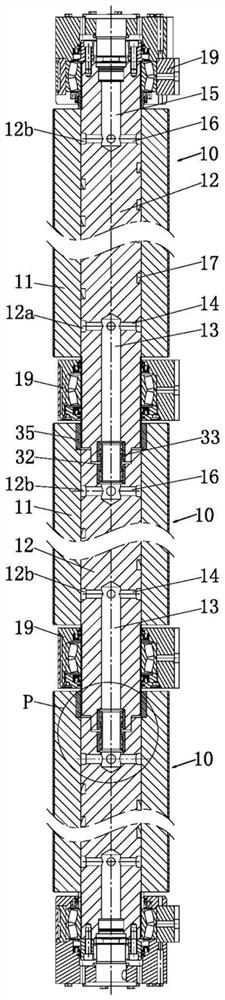

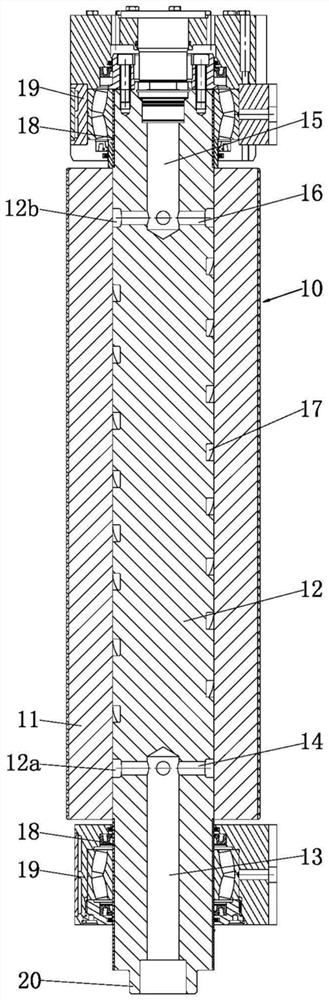

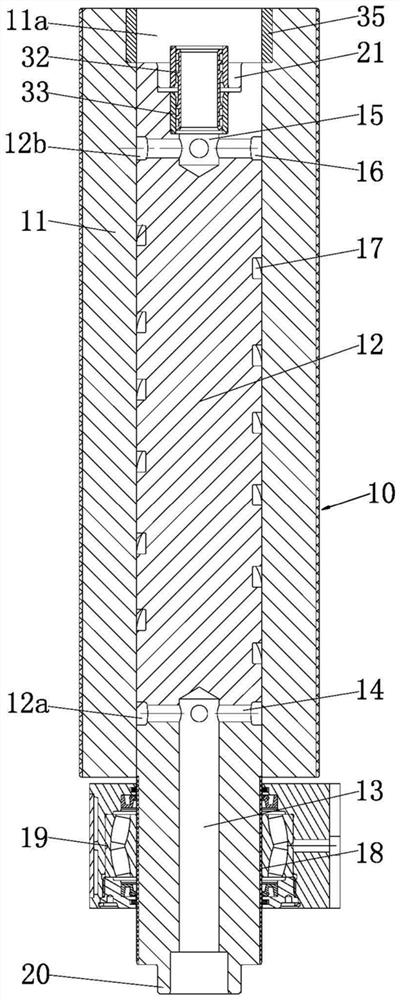

Continuous casting roller and assembling method thereof

The invention relates to a continuous casting roller. The continuous casting roller comprises at least two splicing assemblies, and each splicing assembly comprises a roller sleeve, and a core shaft; after the roller sleeves and the core shafts are in interference fit, a first radial hole, a second radial hole and a cooling medium flowing groove in the same core shaft are covered with the same roller sleeve to form a cooling channel, the part, located between the corresponding roller sleeve and the axial end face of the corresponding core shaft, of the corresponding core shaft forms an installation part, when two adjacent splicing assemblies are spliced, the first axial blind hole in the core shaft of one splicing assembly is matched with a second axial blind hole in the core shaft of the other splicing assembly; and the bearing assemblies are arranged on the installation parts in a sleeving mode and is fixed with the installation parts. The C]continuous casting roller has the advantage of being easy to mount and dismount.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Dermatological hair shaving device for body surfaces with lesions

ActiveCN109172004AGuaranteed to scrape and cleanLighten the thumbDiagnosticsSurgeryIndex fingerEngineering

The invention relates to the technical field of medical appliances, in particular to a dermatological hair shaving device for body surfaces with lesions, comprising a rear support plate, a front support plate, a skin collecting device and a skin scraping device, wherein the front support plate is semicircular and the upper end is fixedly connected with a five-finger sleeve; and the front support plate of the lower end of the first joint of the five-finger sleeve is provided with a first through groove similar to the front support plate, and the right end of the first through groove of the lower end of the index finger and ring finger is provided with a second through groove. Therefore, the structure design of the invention is reasonable, through front support plate, a rear support plate and a skin scraping device can reduce the force of the thumb and index finger of the healthcare worker during skin scraping, and the pulley height is equal to the height when the blade is perpendicularto the pulley, so that the meshing of the second gear and the first gear ensures the synchronous rotation of the pulley and the conveyor belt, thus ensuring a scraping and cleaning of the skin, avoiding cross-infection, and having complete functions, and having a good popularization prospect.

Owner:周红梅

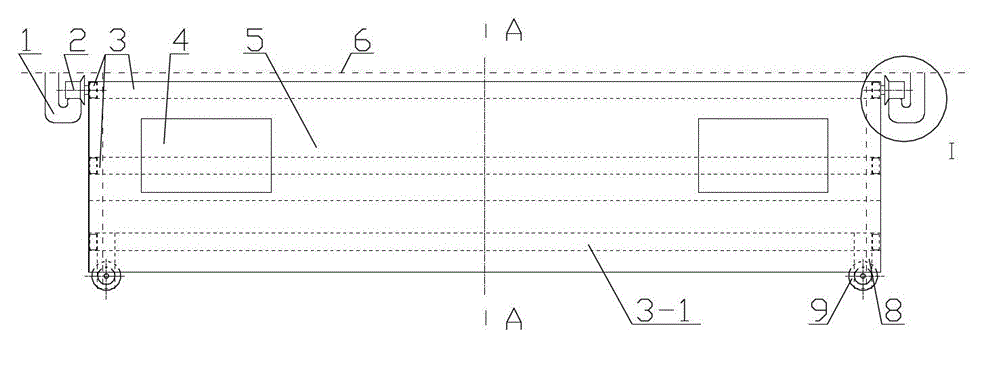

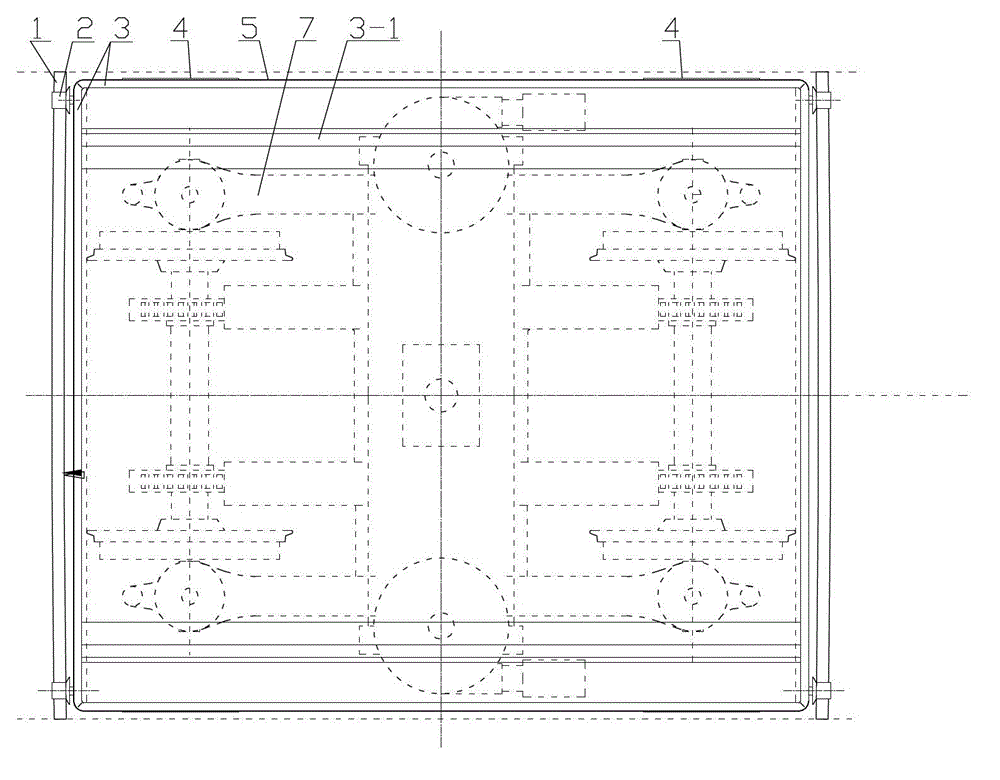

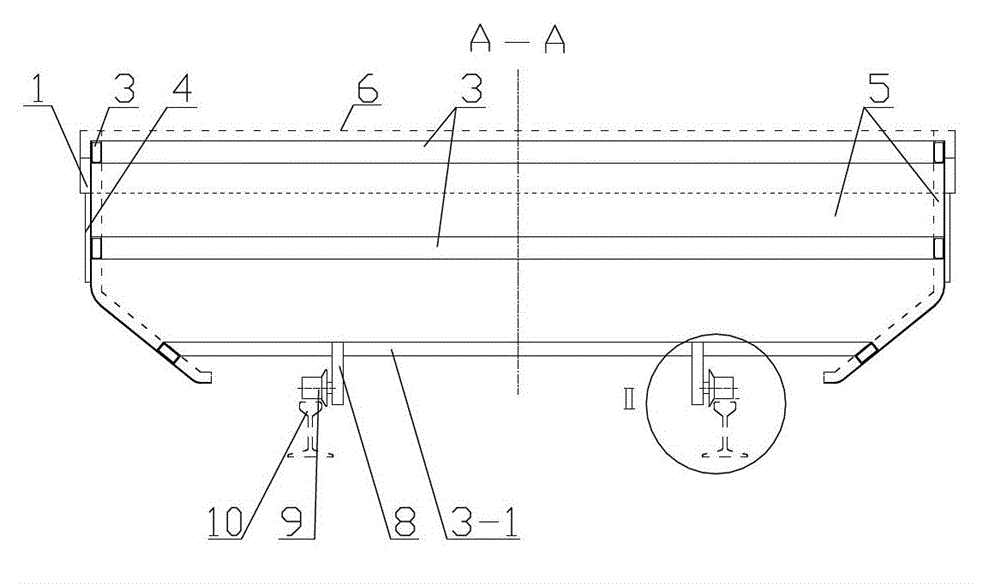

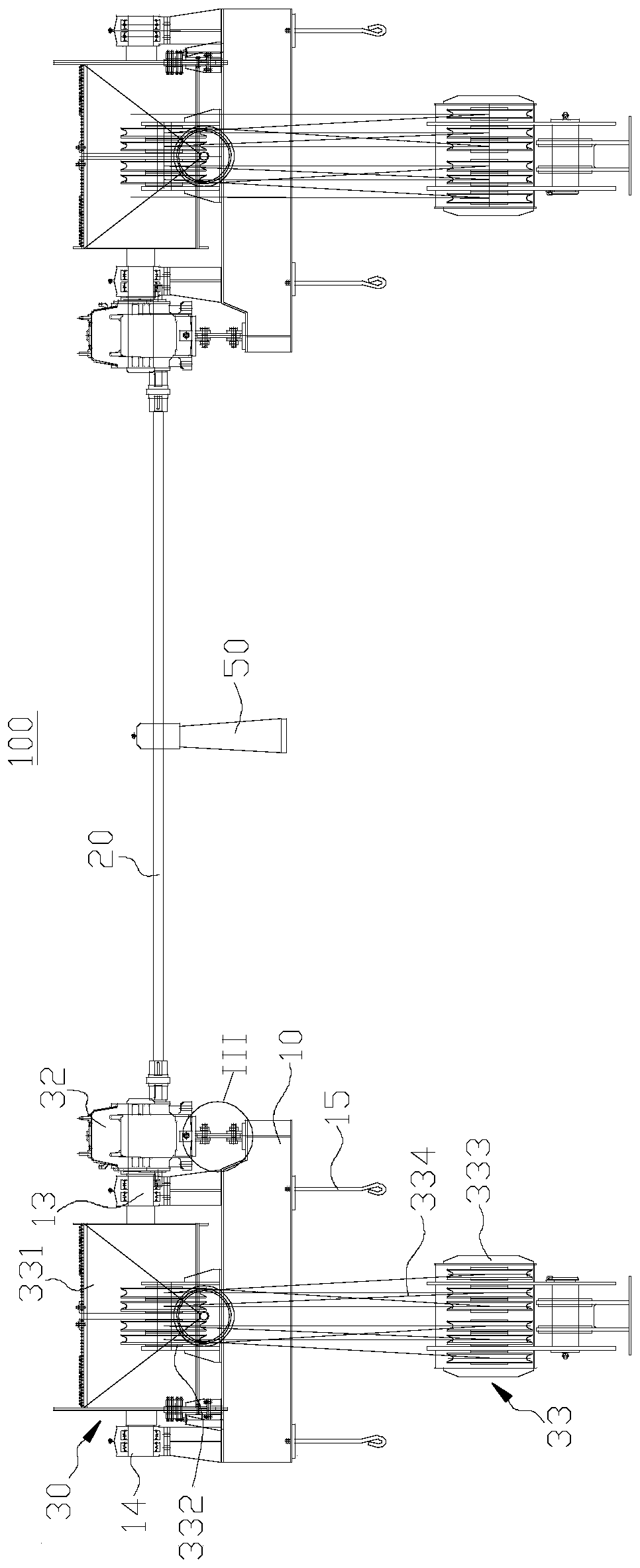

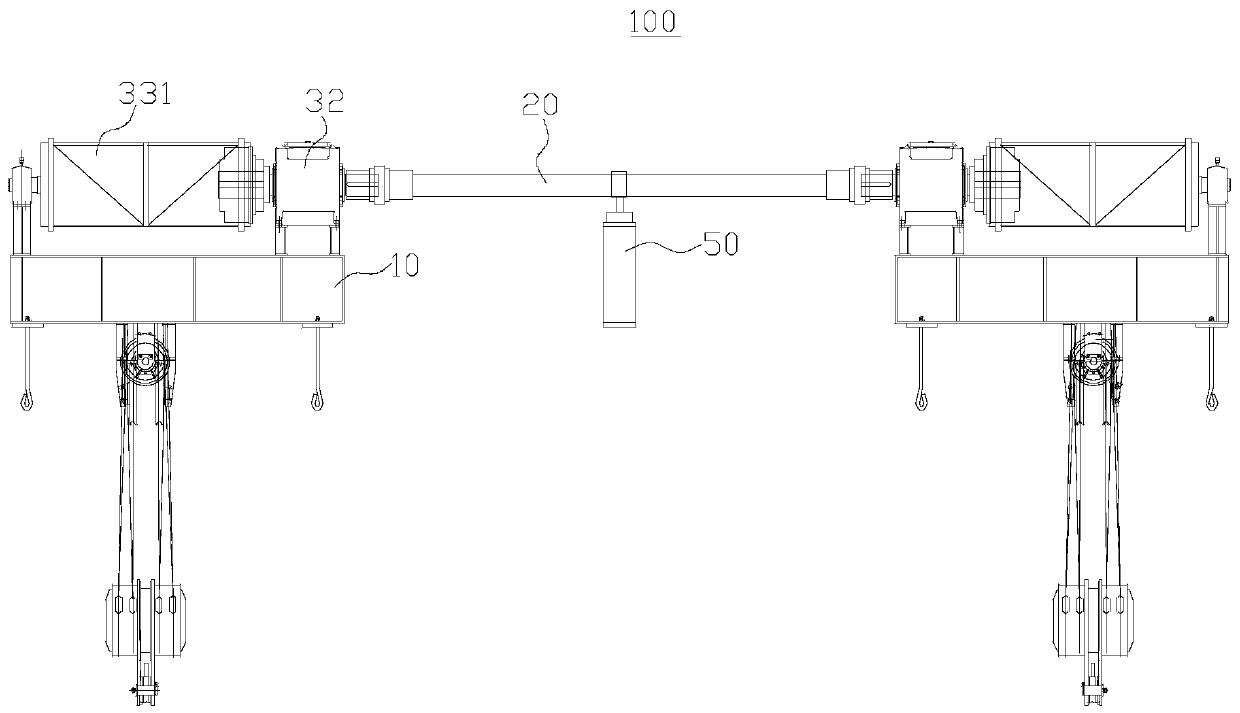

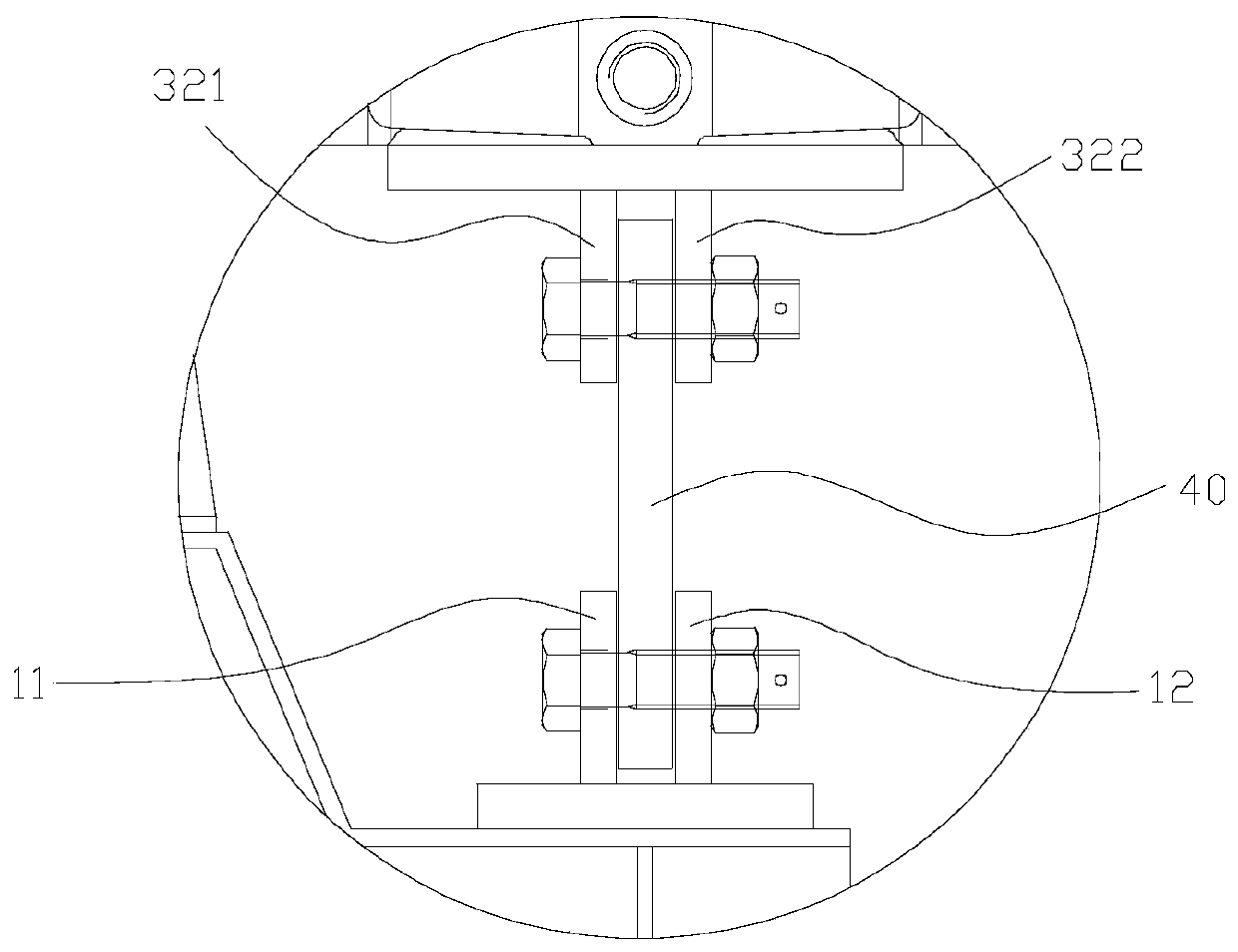

Winch hoist

PendingCN111457144AAvoid disagreementGuaranteed synchronous rotationOperating means/releasing devices for valvesDry-docksReduction driveControl engineering

The invention provides a winch hoist, and relates to the field of water conservancy and hydropower mechanical equipment. The winch hoist comprises a rack, a synchronous connecting shaft and two hoisting point components arranged on the rack at an interval, wherein the two hoisting point components are connected through the synchronous connecting shaft. Each hoisting point component comprises a motor, a speed reducer, a torque arm and a lifting mechanism for lifting; the motors are arranged on the rack; each lifting mechanism comprises a winding drum; power input shafts of the speed reducers are connected with the motors; power output shafts of the speed reducers are connected with the winding drums; the speed reducers are supported above the rack through the torque arms; and the torque arms are located right under the power input shafts of the speed reducers. The motors are used for driving the winding drums to rotate through the speed reducers so as to enable the lifting mechanisms tolift. The speed reducers are supported above the rack through the torque arms, and the torque arms are arranged right under the power input shafts of the speed reducers, so that the speed reducers only bear rotating loads through the arrangement of the torque arms, the transmission of the winch hoist can be stable, and the safety in lifting is realized.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

Glass cup bottom-sealing machine

ActiveCN107382042AThe connection structure is stableGuaranteed synchronous rotationGlass reforming apparatusEngineeringMechanical engineering

The invention relates to a glass cup bottom-sealing machine. Two sides of a frame between a three-jaw chuck and a rotating rod are oppositely provided with flame projectors. The two flame projectors are respectively fixed on two cranks arranged on the upper end surface of the frame. One end of each one of the cranks far away from the flame projectors is rotatably connected to a locking bolt which can be adjusted up and down and is located on the upper end surface of the frame. A rotating shaft is slidingly provided with a sliding sleeve. Two sides of the sliding sleeve are symmetrically provided with rotatably connected rocking bars. The end of each one of the rocking bars is hinged to the corresponding crank. The glass cup bottom-sealing machine can realize synchronous movement of the flame projectors in two sides of a glass tube, realizes heating of opposite positions of two sides of the glass tube, guarantees flatness of the glass cup bottom melt at a high temperature and has a high glass cup production qualification rate.

Owner:重庆欣维尔玻璃有限公司

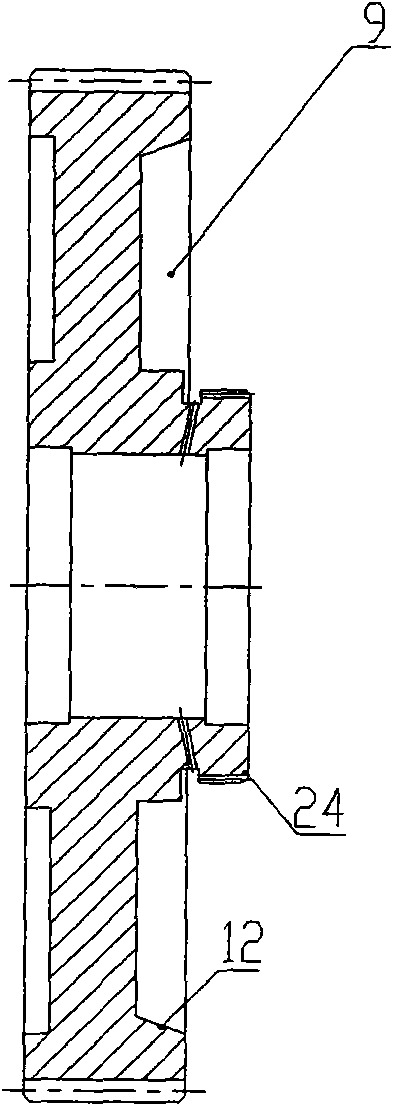

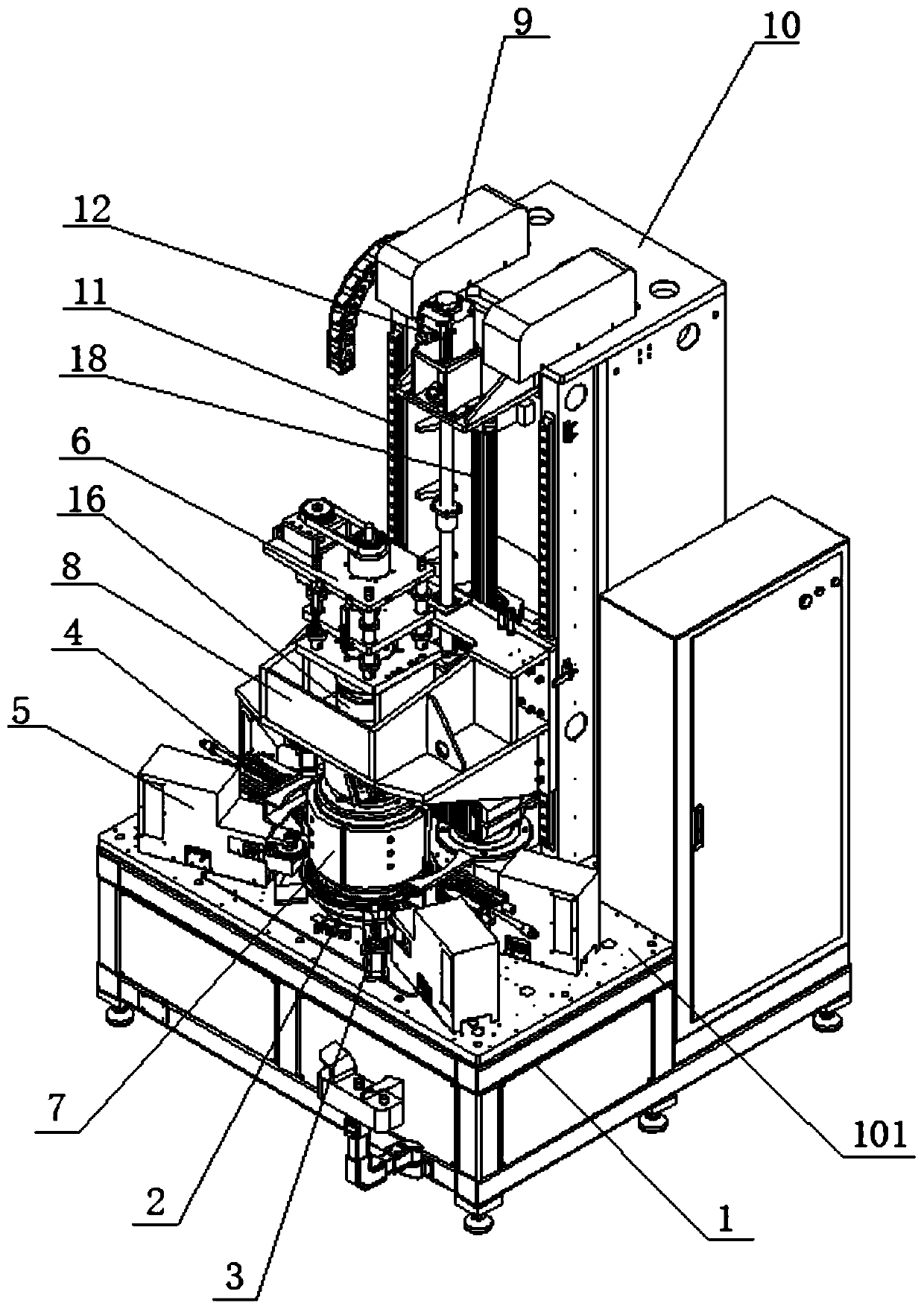

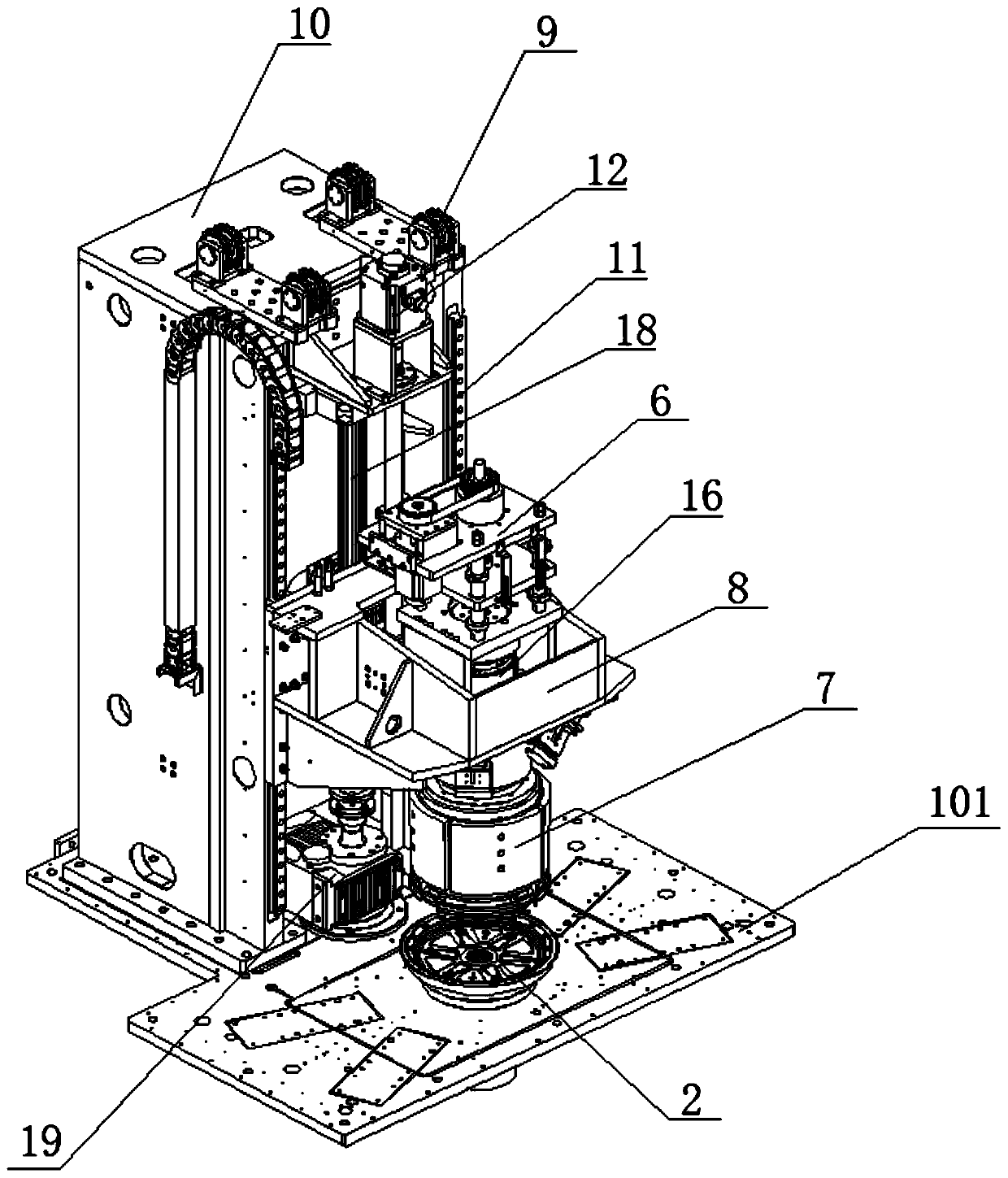

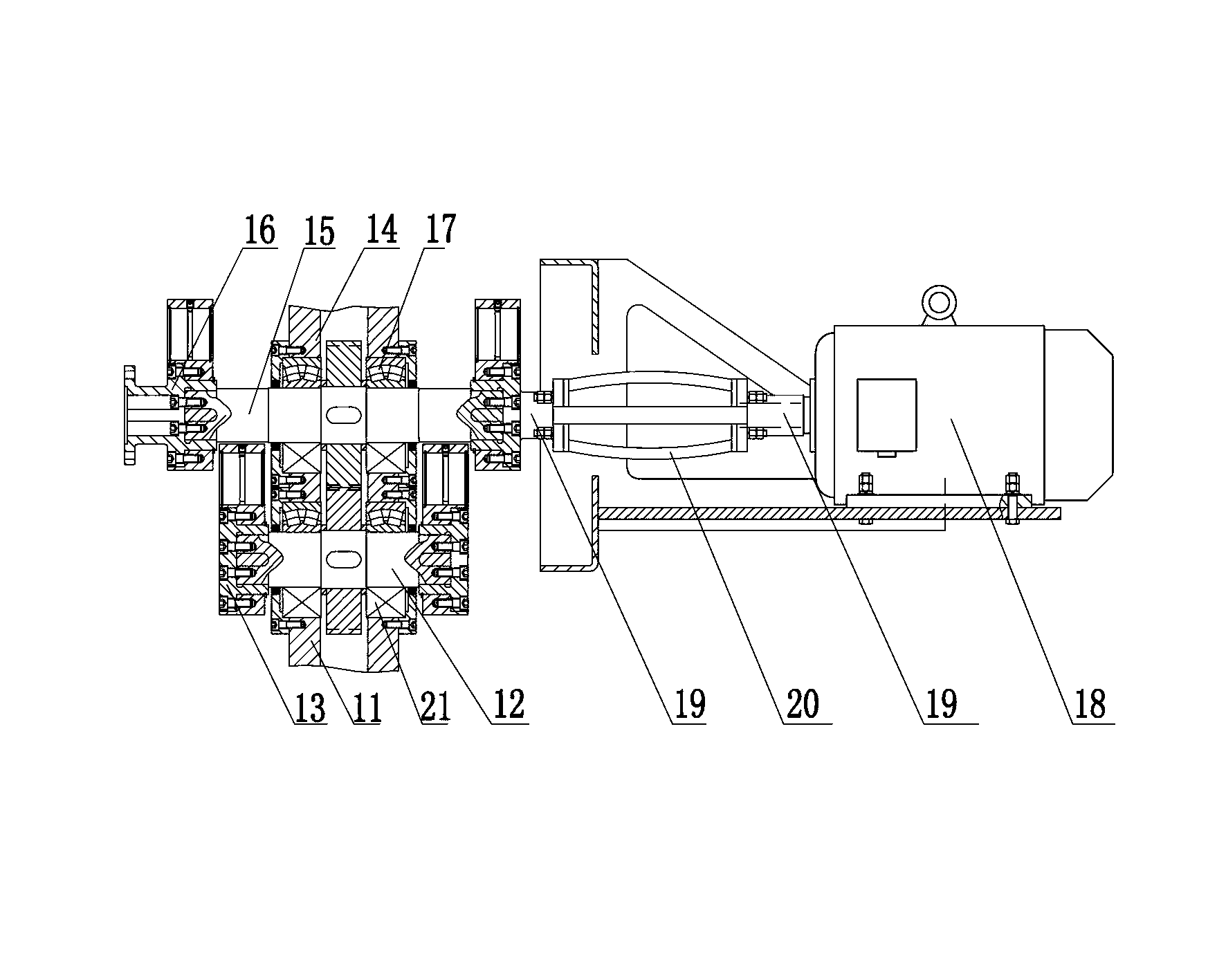

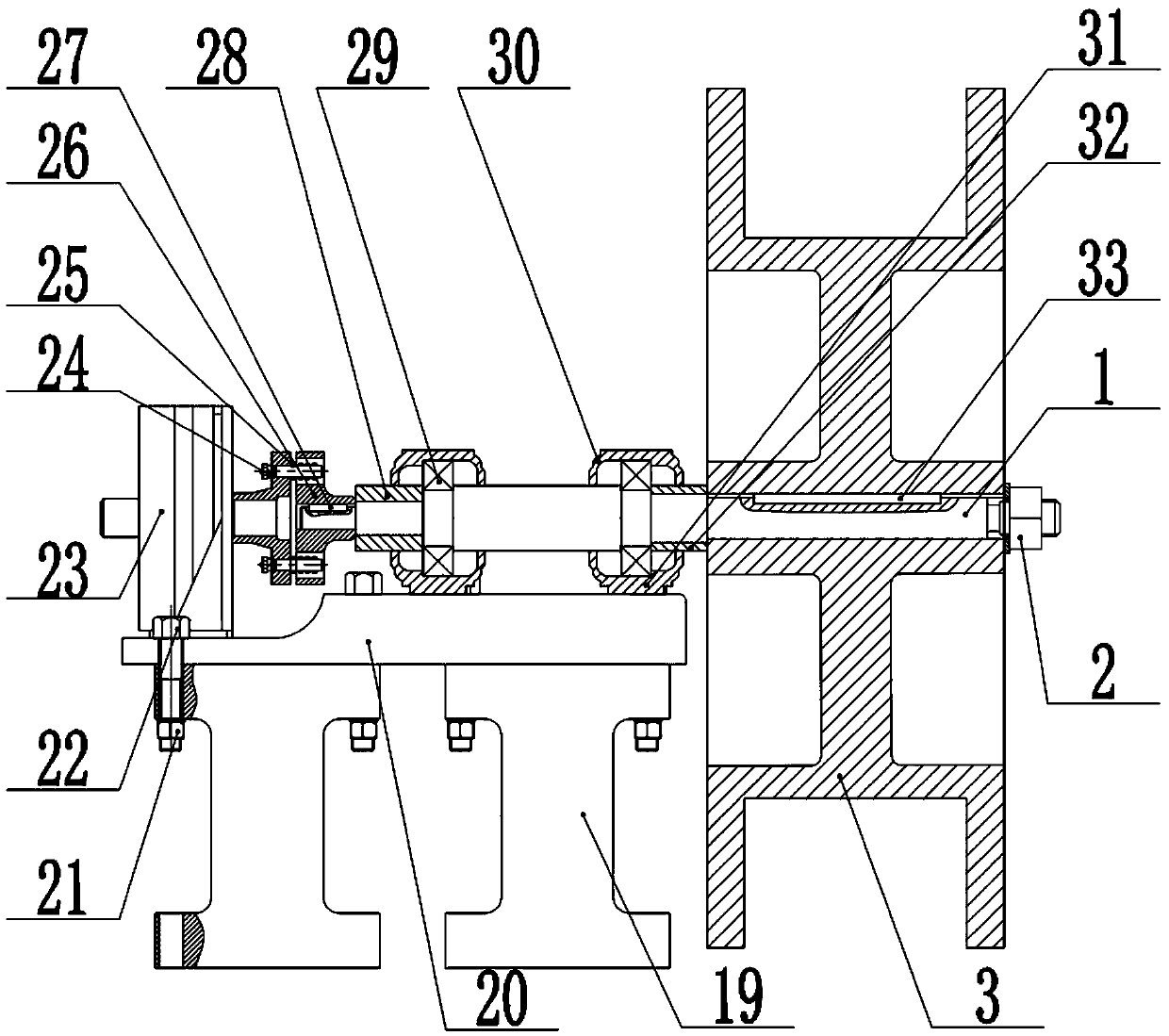

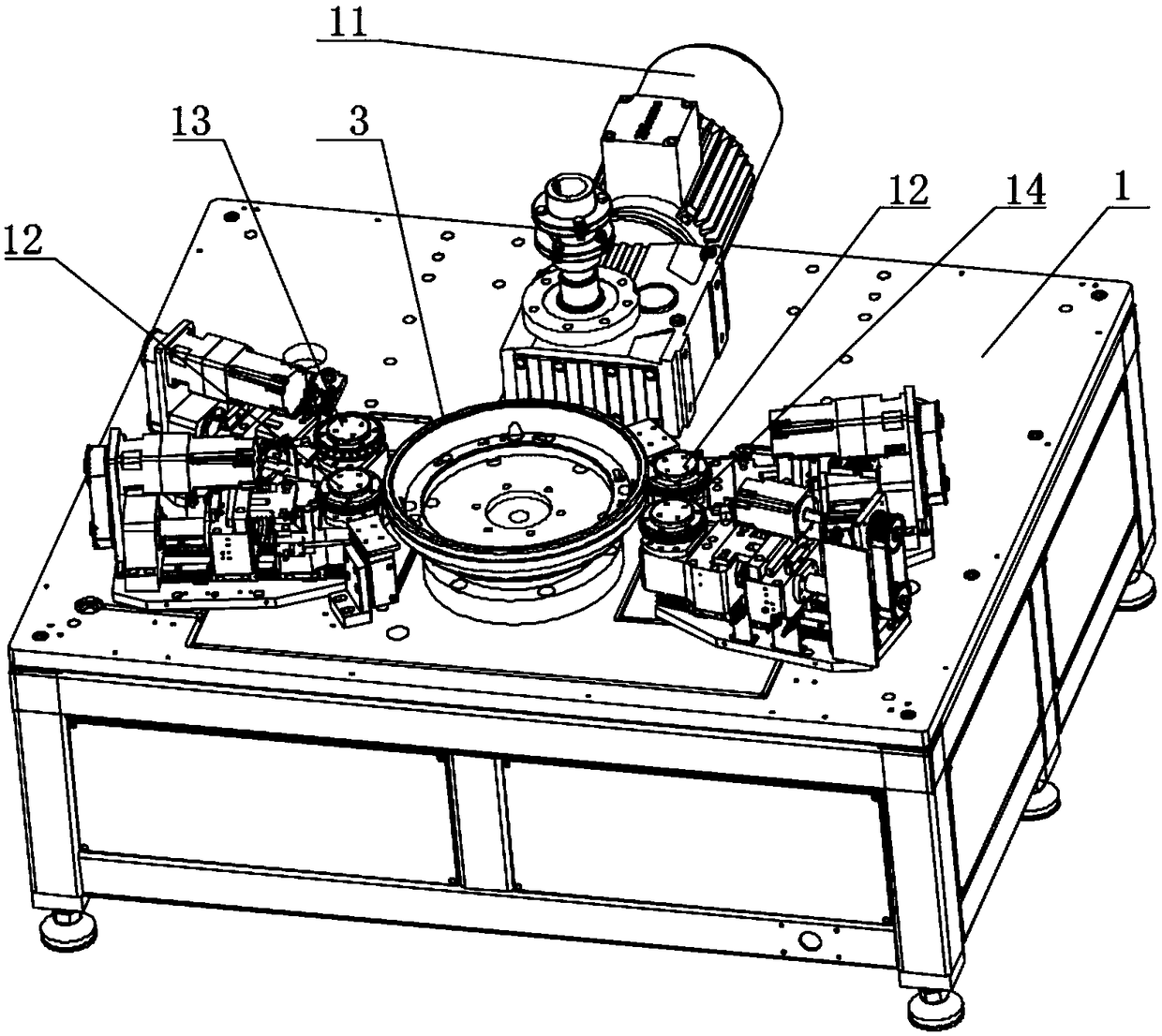

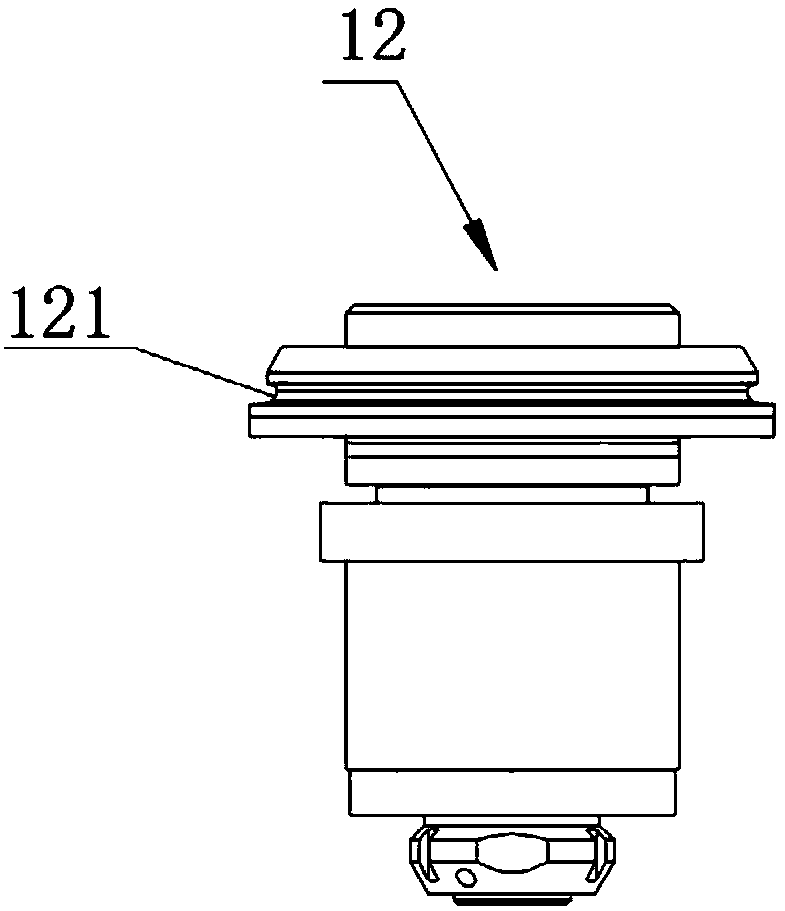

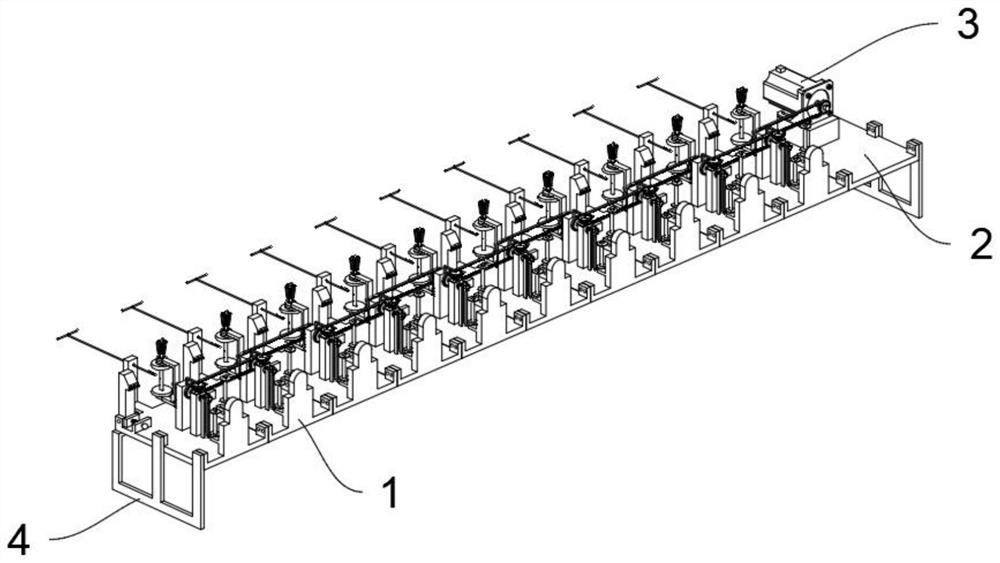

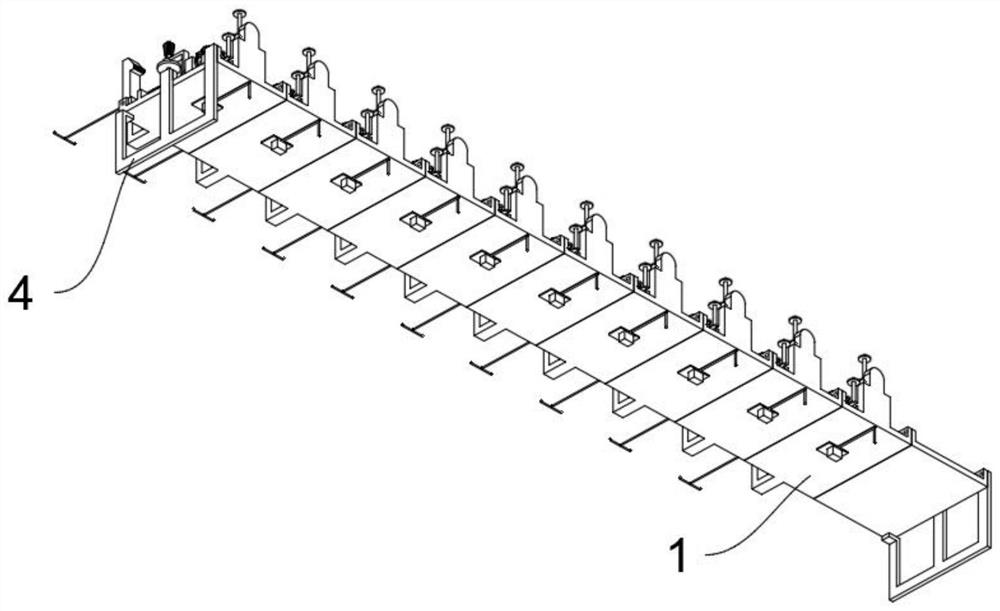

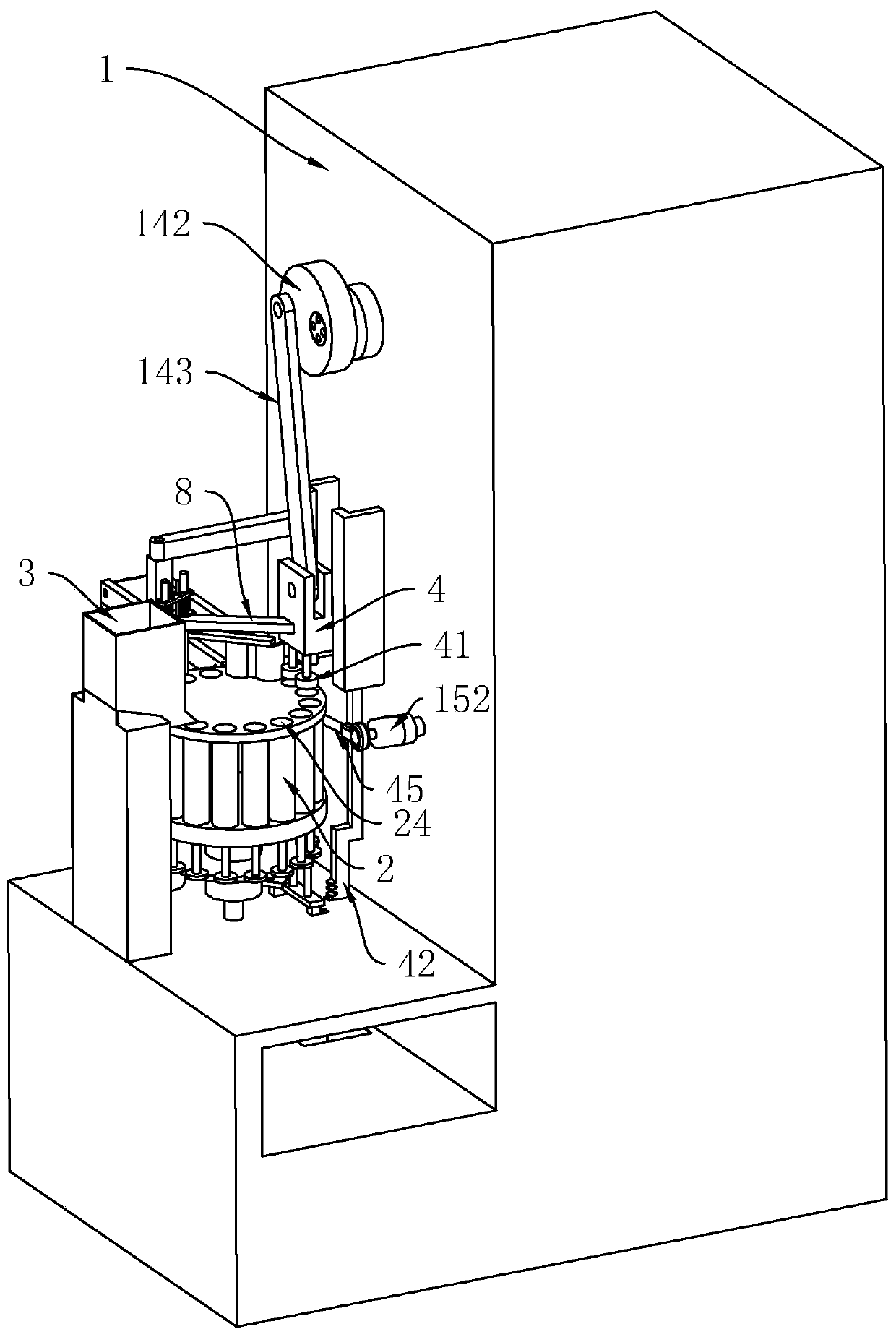

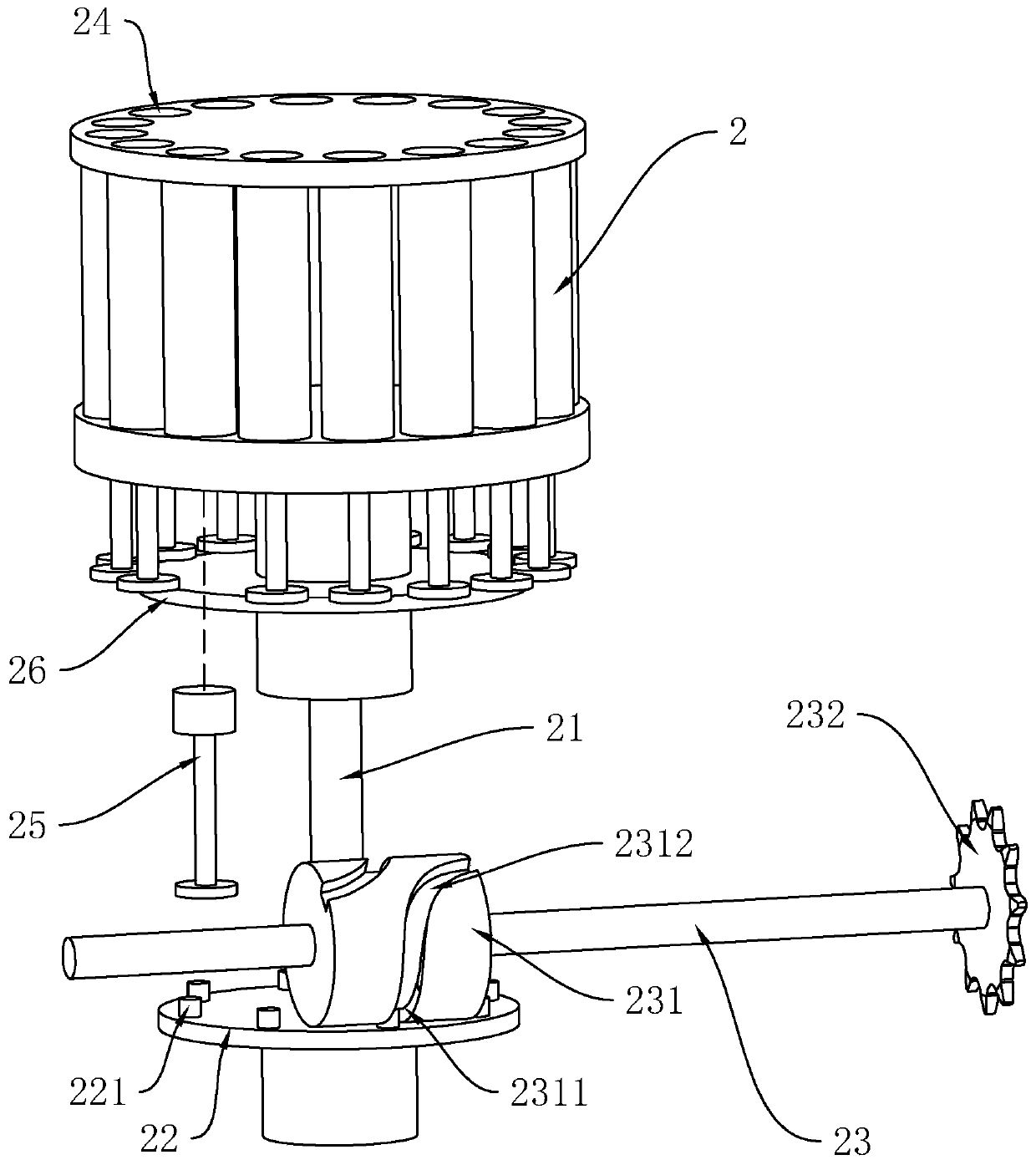

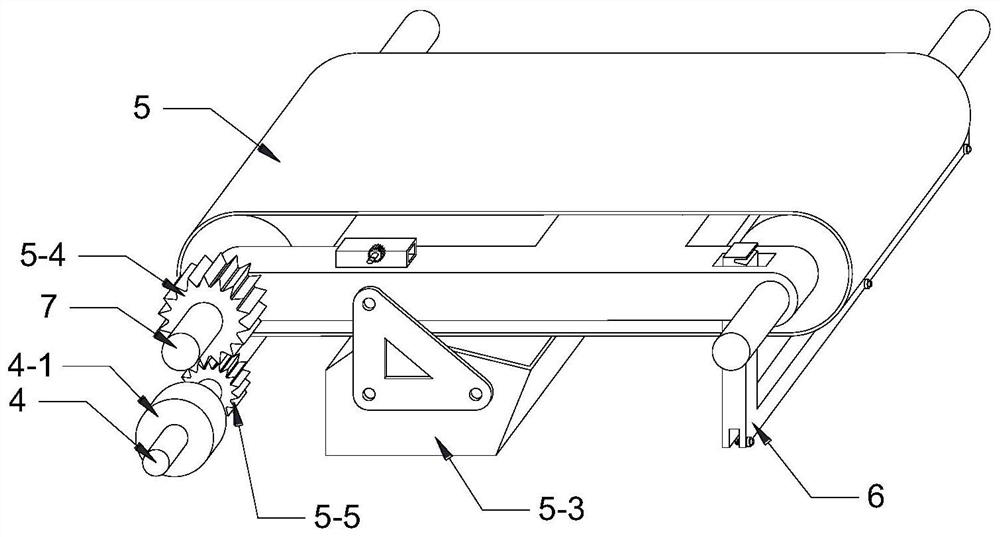

Rotary riveting equipment for inner drum of washing machine

The invention relates to rotary riveting equipment for an inner drum of a washing machine. The rotary riveting equipment comprises a workbench. A lower flange plate is arranged in the middle of the upper surface of the workbench, and a plurality of first roller assemblies are arranged at intervals in the circumferential direction of the lower flange plate. Each first roller assembly comprises rollers fed by servo drive, and the axes of the rollers are parallel to the axis of the lower flange plate. A counterweight box is mounted on the rear side of the upper surface of the workbench, and a guide rail is arranged on the front side surface of the workbench. A fixing cover sliding along the guide rail is arranged on the guide rail. The fixing cover is connected with a counter weight in the counterweight box through a transmission chain. The fixing cover is driven by a servo motor at the top of the counterweight box. An upper flange plate rotating synchronously with the lower flange plateis arranged on the lower surface of the fixing cover. A plurality of second roller assemblies are arranged at intervals in the circumferential direction of the upper flange plate. The second roller assemblies and the first roller assemblies correspond to each other one by one in the vertical direction and are of the same structure. By the adoption of the rotary riveting equipment for the inner drum of the washing machine, the technical problems of uneven press-fit, poor press-fit quality, low efficiency and asynchronous rotation of the upper end and the lower end of the inner drum during rotary riveting are solved.

Owner:WUXI IDO SCI & TECH CO LTD

Mouse with high applicability

InactiveCN111290639ASmooth rotationGuaranteed stabilityInput/output processes for data processingEngineeringStructural engineering

The invention discloses a mouse with high applicability that comprisesa first body; one side of the first body abuts against a second body; a mounting groove is provided on one side of the second body; bearing grooves are provided at the lower end of the first body and the lower end of the second body; the upper end of one of the bearing grooves is communicated with the mounting groove; the mounting groove corresponds to the first body; a power mechanism is arranged on the side wall of one end in the mounting groove; and a connecting pipe and a first shaft sleeve are arranged on the power mechanism. The distance between the two bodies can be adjusted, and the distance between the bodies and the U-shaped plate can also be adjusted, therefore, the application range of the mouse can be well expanded; the adjustable mouse is simple in structure and convenient to use, can be well suitable for different users, can guarantee the stability of the adjusted mouse, improves the use comfort of theusers, can well avoid the situation that the palm and the arm of some users are prone to fatigue when the existing mouse is used due to the fact that the mouse cannot be adjusted, and facilitates prolonging of the use time of the users.

Owner:长沙凯泽工程设计有限公司

Original yarn weaving device with threading function based on textile industry

InactiveCN111793895AGood automation effectFast and fixed installation functionFibre cleaning/openingBraidYarnRotational axis

The invention discloses an original yarn weaving device with a threading function based on a textile industry, and relates to the technical field of textile processing. The original yarn weaving device solves the problem that an original yarn weaving device used at present mainly weaves original yarns through a simple mechanism and does not have an automatic take-up function while weaving. The original yarn weaving device with the threading function based on the textile industry comprises a main seat stand; connecting buckles are integrally arranged on the two sides of the main seat stand, themain seat stand can be fixedly connected with the other set of main seat stand through the connecting buckles, a linkage effect is provided for the knitting device by arranging a rotating shaft frameand a linkage bevel gear, original threads can be knitted through rotation of the rotating shaft frame, and the rotation of the linkage bevel gear can rotate a take-up wheel during knitting, so thatthe knitted original yarn is continuously taken up, the automation effect is good, and the yarn can be automatically taken up during knitting.

Owner:张项丽

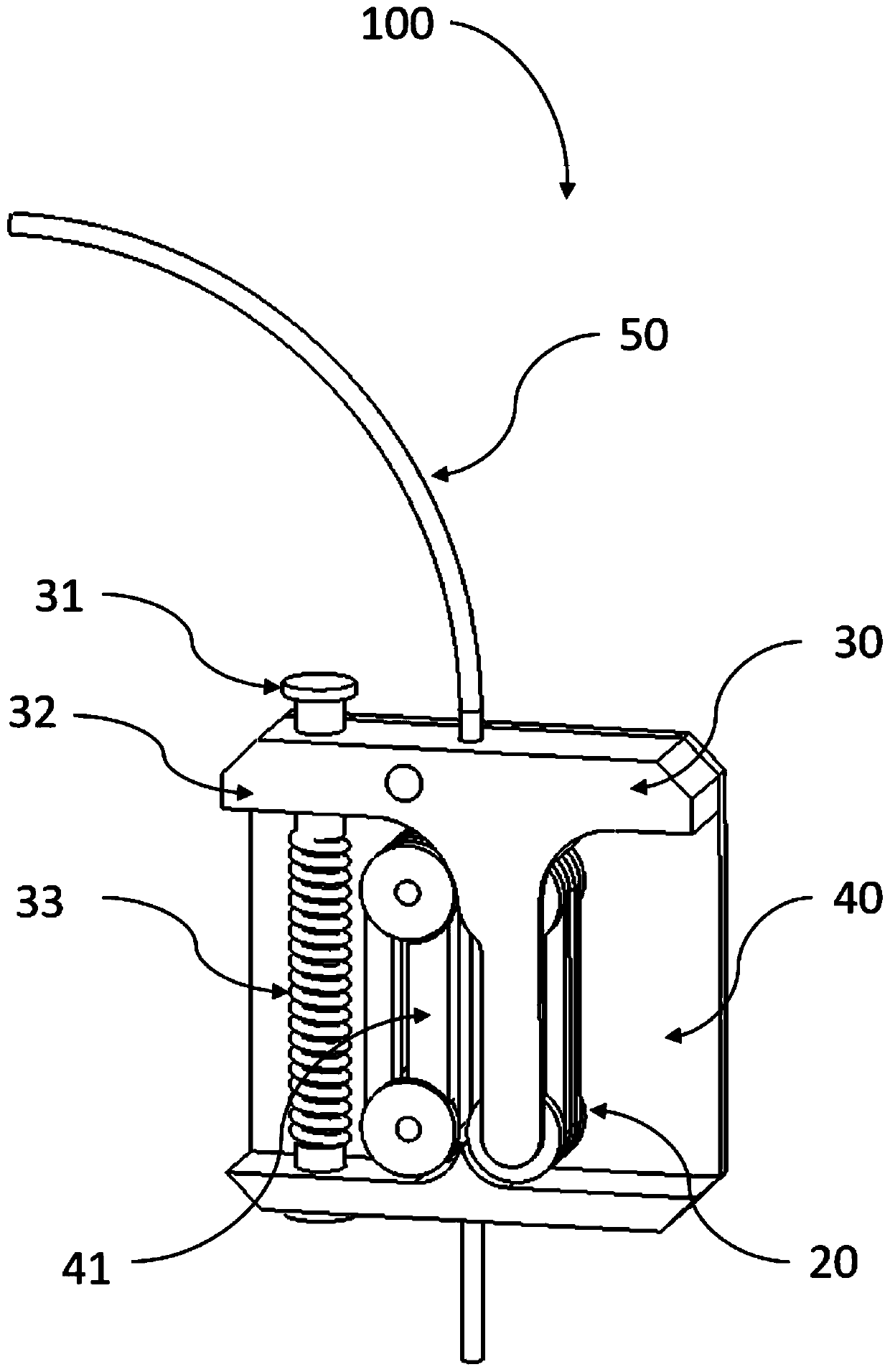

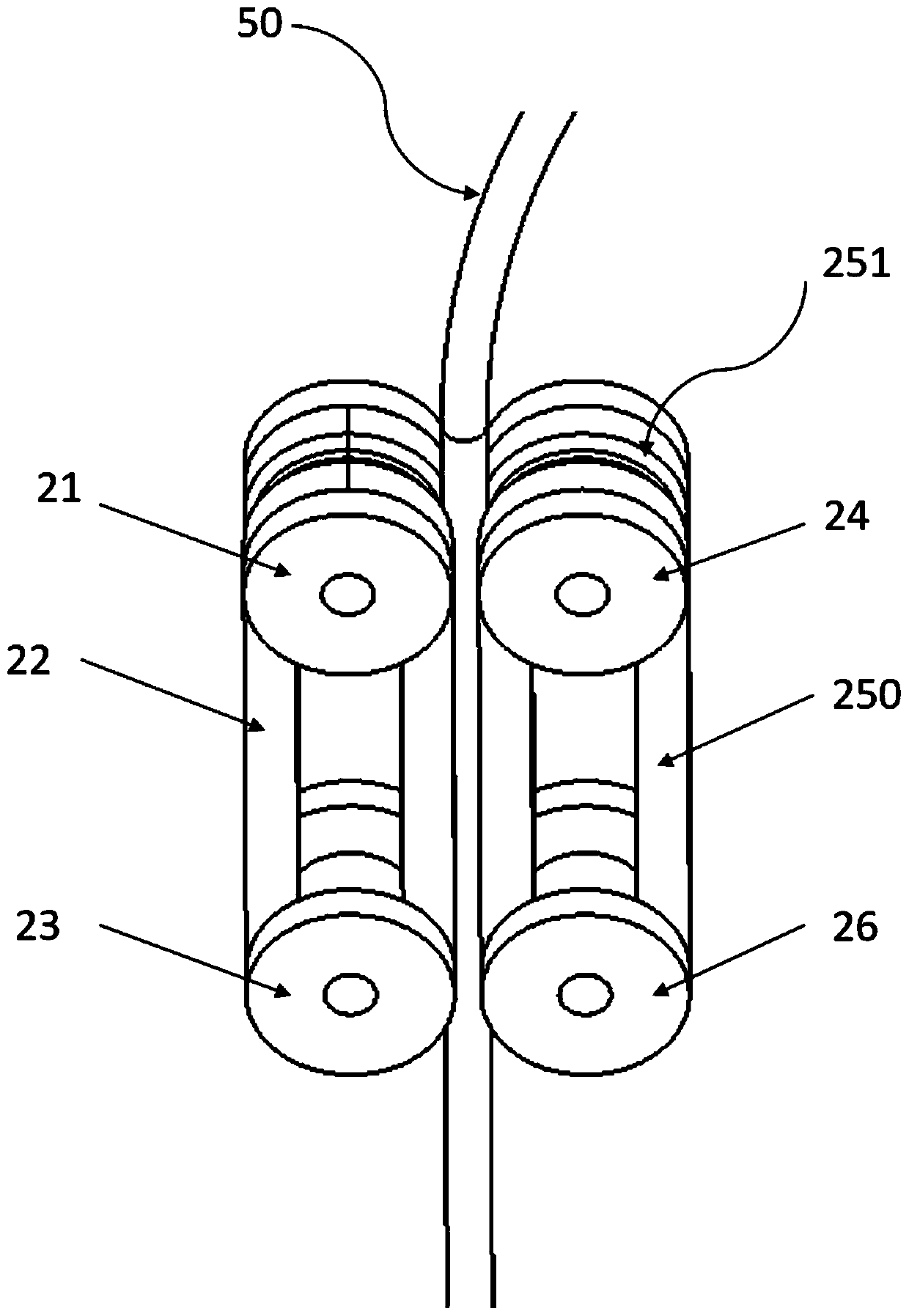

Conveying mechanism for 3D printer

InactiveCN110614771AStable deliveryEasy to installAdditive manufacturing apparatus3D object support structuresEngineeringExtrusion

The invention discloses a conveying mechanism for a 3D printer. The conveying mechanism comprises a first mounting part and a second mounting part, a conveying structure is arranged between the firstmounting part and the second mounting part, a driving part of the conveying structure is mounted on the first mounting part, a driven part of the conveying structure is mounted on the second mountingpart, the second mounting part can rotate relative to the first mounting part, and wire materials are arranged between the driving part and the driven part and conveyed through friction force. According to the conveying mechanism, the wire materials are clamped through a driving belt and a driven belt, the materials are conveyed through the friction force, and destroy and damage to the wire materials are reduced while stable conveying of the wire materials is ensured; guiding is conducted through a guiding groove, and the magnitude and direction of extrusion force are stable; and the guiding groove can achieve the effect of straightening the materials, and the problem of a conveying obstacle caused by wire material folds is reduced.

Owner:XI AN JIAOTONG UNIV

Wax column forming equipment

PendingCN110699187ARealize continuous processingEasy to operateCandle preparation apparatusTransmission beltClassical mechanics

Wax column forming equipment comprises a rack, a rotating body is rotatably connected to the middle of the rack, a plurality of through grooves are evenly formed in the upper surface of the rotating body, and ejection columns are slidably connected to the lower ends of the through grooves; a hopper is fixedly connected above the rack corresponding to the rotating body; a pressing column capable ofbeing inserted into the through groove is arranged at a position, corresponding to one side of the hopper, of the rack. A push rod capable of pushing the corresponding ejection column to move upwardsis arranged at the position, corresponding to the lower side of the pressing column, of the rack. An ejection rod capable of pushing the ejection column to push the wax column in the through groove out of the upper side of the through groove is arranged at the position, corresponding to one side of the push rod, of the rack, a discharging conveying belt is arranged at the position, correspondingto one side of the rotating body, of the rack, and a swing plate capable of pushing the wax column on the upper side of the through groove to the discharging conveying belt is further arranged on therack; the rack is further provided with an inserting rod capable of being inserted into the through groove in the vertical direction to push the jacking column to reset. The wax column forming equipment has the advantages of being easy to operate, low in labor intensity and high in machining efficiency.

Owner:青岛欧亚自动化设备有限公司

Ligament stretching device for aerobics training

PendingCN111111104APlay a stretching effectAvoid damageGymnastic exercisingRoller massagePhysical medicine and rehabilitationEngineering

The invention discloses a ligament stretching device for aerobics training, which comprises a base. A traction seat is arranged at one end of the base, a cushion is arranged at the other end of the body, a sliding groove is reversely formed in the base along the length direction, the traction seat is arranged in the sliding groove in a sliding manner, a traction mechanism used for driving the traction seat to be away from the cushion is arranged between the sliding groove and the traction seat, a grip is arranged on the side wall of the traction seat, positioning frames are arranged on the twosides of the base, a positioning rod is arranged on the positioning frame in the length direction, the positioning rod is arranged on the positioning frame in a rotating mode, a plurality of abuttingidler wheels with gradually-increased diameters are arranged on the positioning rod in a sliding mode, the abutting idler wheels are eccentrically arranged on the positioning rod, a locking piece used for limiting sliding of the abutting idler wheels is arranged on the positioning rod, and a driving piece used for driving the positioning rod to rotate is further arranged on the positioning frame.The device can assist in exercising and stretching of side-by-side stretching and knee bending, and the exercising and stretching effect is improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Wood-plastic guard bar processing device

ActiveCN108162238AAlleviate rotational resistanceGuaranteed working lengthEngineeringMechanical engineering

The invention belongs to the technical field of guard bar processing and particularly discloses a wood-plastic guard bar processing device. The wood-plastic guard bar processing device comprises a melt glue device provided with a feeding inlet and a stirring barrel, the melt glue device comprises a recovery cavity and a melt glue pushing cavity, and a heating plate is inlaid in the side wall of the melt glue pushing cavity. The melt glue pushing cavity is internally provided with at least two screws rotatably connected with the melt glue pushing cavity and used for pushing materials to move forwards, the front end of the melt glue pushing cavity is provided with motors for driving the screws to rotate, and a plurality of glue outlet holes are formed in the bottom of the melt glue pushing cavity. Melt glue collecting cavities communicating into the stirring barrel are formed in the lower portions of the glue outlet holes, rigid communication shafts are arranged between the screws, and astirring mechanism is arranged on the screw located at the tail end of the melt glue pushing cavity. The rigid communication shafts are each provided with a plurality of stirring blades, a squeezingdevice is arranged at the tail end of the melt glue pushing cavity, and a melt glue outlet is formed in the side wall, close to the top wall of the stirring barrel, of the stirring barrel. According to the wood-plastic guard bar processing device, the screws are not prone to being off center, nearly no bubble exists in manufactured guard bars, and performance and appearance are good.

Owner:重庆立帆金属结构有限公司

Scraping device for focus body surface hair in dermatology department

ActiveCN113143490AGuaranteed to scrape and cleanReduce forceDiagnosticsSurgeryDrive wheelDermatology department

The invention relates to the technical field of medical instruments, in particular to a scraping device for focus body surface hair in dermatology department, which comprises a first rotating shaft, second rotating shafts and an I-shaped supporting frame, pulleys are fixedly connected to the front end and the rear end of the first rotating shaft, a driving wheel is fixedly connected to the second rotating shaft on the left side, a driven wheel is fixedly connected to the second rotating shaft on the right side, a conveying belt is sleeved between the driving wheel and the driven wheel, the I-shaped supporting frame is arranged in the conveying belt, and a skin scraping device is arranged at the lower right end of the I-shaped supporting frame. The scraping device disclosed by the invention is reasonable in structural design, force exerted by the thumb and the index finger in the skin scraping process of medical staff is relieved, secondary injury to a patient due to uneven hand force of the medical staff is avoided, synchronous rotation of a pulley and a conveying belt is guaranteed through meshing of a second gear and a first gear, then skin scraping and cleaning are guaranteed, cross infection is avoided, functions are complete, has good popularization prospect.

Owner:殷桂春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com