Portable laser measuring device for wheel circumference surface roughness and non-rounding abrasion

A circumferential surface, laser measurement technology, used in measurement devices, optical devices, instruments and other directions The effect of convenient and fast, fast data transmission, and not easy to lose data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

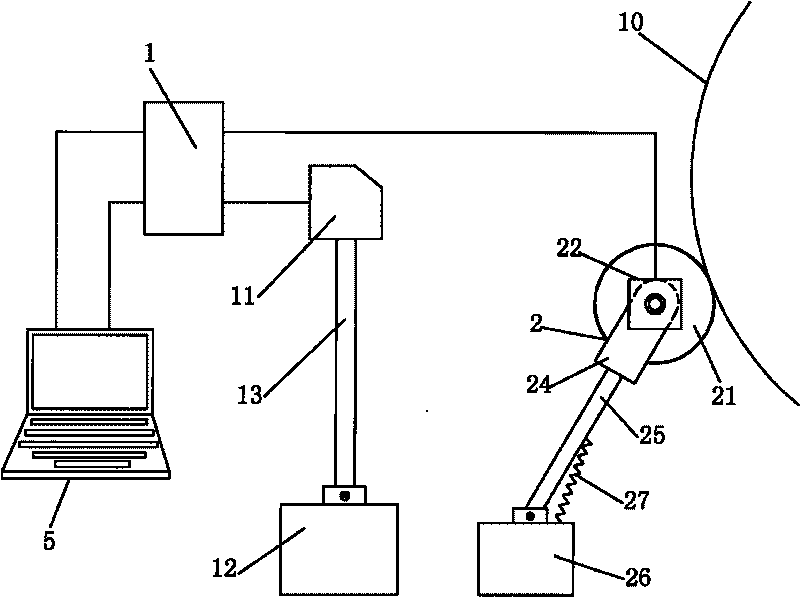

[0031] figure 1 Shown, a kind of specific embodiment of the present invention is:

[0032] A portable laser measuring device for surface roughness and non-circular wear of a wheel, which consists of: the laser head 11 of the laser displacement sensor 1 is fixed on the laser head support seat 12; the serial port and the USB interface of the laser displacement sensor 1 are respectively connected to the computer The serial port of 5 is connected with USB interface;

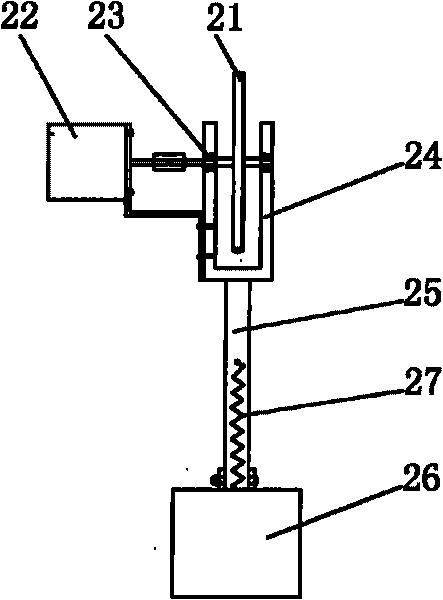

[0033] figure 1 , figure 2 Shown, the specific composition of small wheel mechanism 2 is: small wheel 21 is fixed on the U-shaped support block 24 by bearing 23, and the bottom of U-shaped support block 24 is hinged with support seat 26 through connecting rod 25; The middle part of connecting rod 25 is connected with Tension spring 27, the other end of tension spring 27 is connected with supporting seat 26.

[0034] The specific structure that the laser head 11 is fixed on the laser head support seat 12 is: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com