Looseness-preventing mechanism in reversion of pump impeller

A pump impeller and impeller technology, applied in the field of pump impeller reversal anti-loosening structure, can solve the problems of impeller damage, impeller loosening, impeller forward movement, etc., and achieve the effect of prolonging the service life, protecting the impeller and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

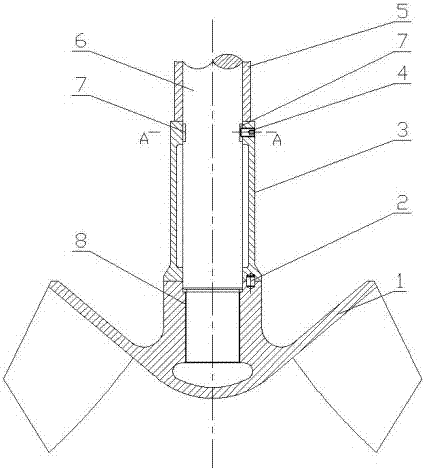

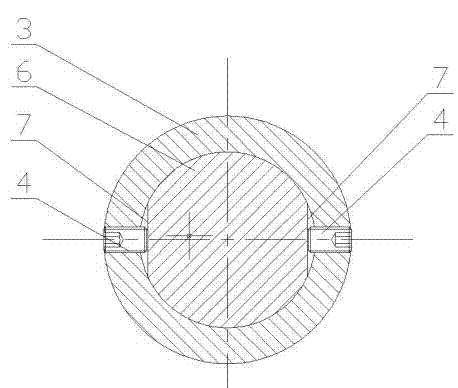

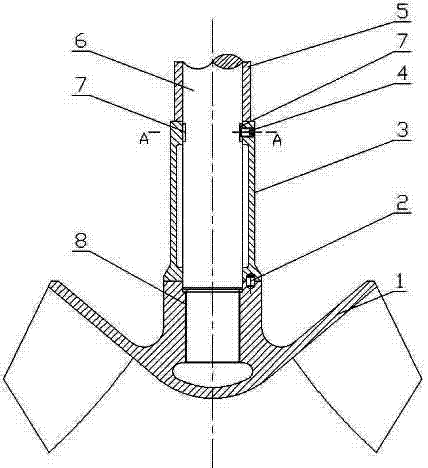

[0010] With reference to the accompanying drawings, its structure includes an impeller 1, a cylindrical pin 2, an axle sleeve 3, an inner hexagon screw 4, an upper axle sleeve 5, a main shaft 6, a plane 7, and a connecting thread 8. Among them, the impeller 1 is screwed on the main shaft 6 through the connecting thread 8, the impeller 1 withstands the shaft sleeve 3, and the shaft sleeve 3 withstands the upper shaft sleeve 5, thereby limiting the axial movement of the impeller 1, and the impeller 1 connects with the shaft sleeve 3 through the straight pin 2 The connection limits the relative movement of the impeller 1 and the sleeve 3 in the circumferential direction, thereby ensuring the synchronous rotation of the impeller 1 and the sleeve 3, and the hexagon socket screw 4 is screwed on the sleeve 3 to withstand the plane 7 on the main shaft 6, The relative movement between the shaft sleeve 3 and the main shaft 6 in the circumferential direction is limited, thereby ensuring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com