Anti-blocking water intake pump used at construction site

An anti-clogging, water pump technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of reducing water flow, reducing pump life, easy blockage, etc., to improve work efficiency, improve service life, and remove impurities. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

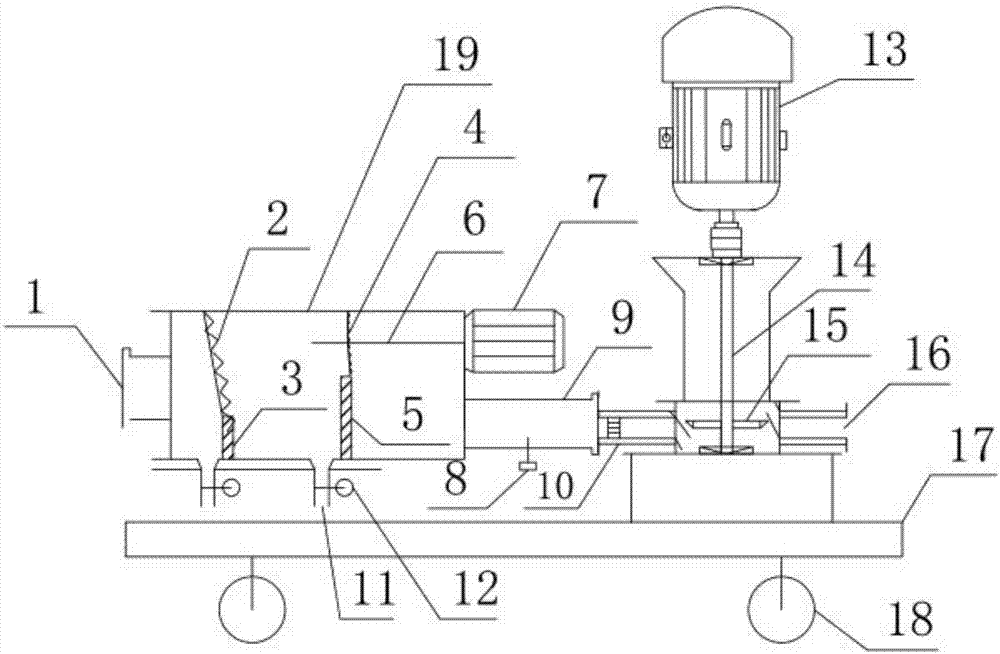

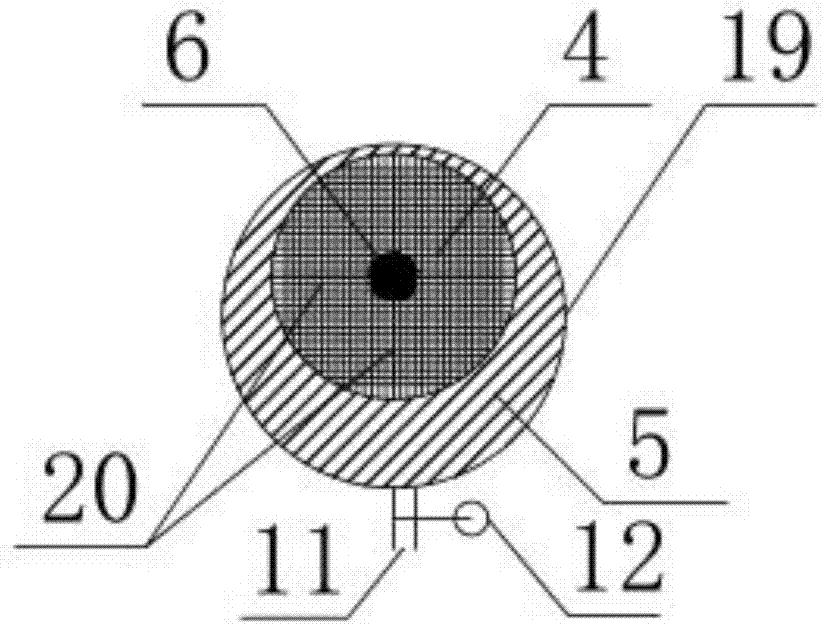

[0017] Such as figure 1 , figure 2 As shown, the present invention comprises a water pump, and the front end of the water inlet of the water pump is equipped with a decontamination device; and pressure sensor 8; the decontamination device and the water pump are all installed on the top of the support frame 17, and the coarse filter screen 2, the first water guide sheet 3, the fine filter screen 4, and the second water guide sheet 5 are all installed on the shell of the decontamination device In the body, the coarse filter 2 is installed on the inner side of the water inlet 1 of the decontamination device, and the first water guide piece 3 is located below the coarse filter 2; There are sewage outlets 11;

[0018] The fine filter 4 is installed on the side of the coarse filter 2 away from the water inlet 1 of the decontamination device, and the second water guide 5 is installed under the fine filter 4; between the first water guide 3 and the second water guide 5 There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com