Spin riveting equipment for bottom of pulsator drum of washing machine and spin riveting method of spin riveting equipment

A washing machine and tube bottom technology, which is applied in the washing machine pulsator tube bottom spin riveting equipment and its spin riveting field, can solve the problems affecting product appearance quality, affecting product quality, uneven pressing, etc., and achieve reliability and uniformity High performance, compact structure, ensuring the effect of uniform motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments of the present invention will be described below in conjunction with the drawings.

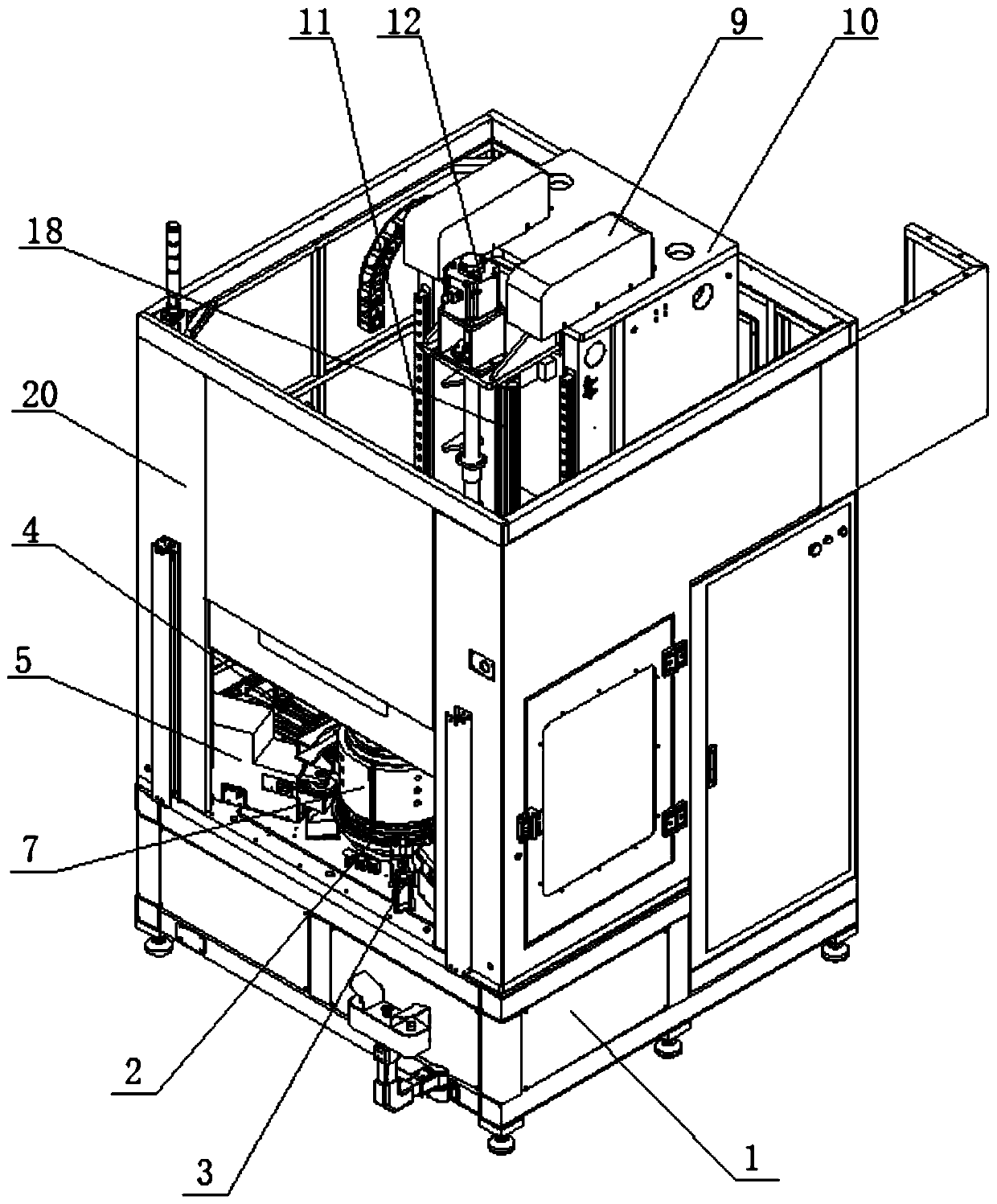

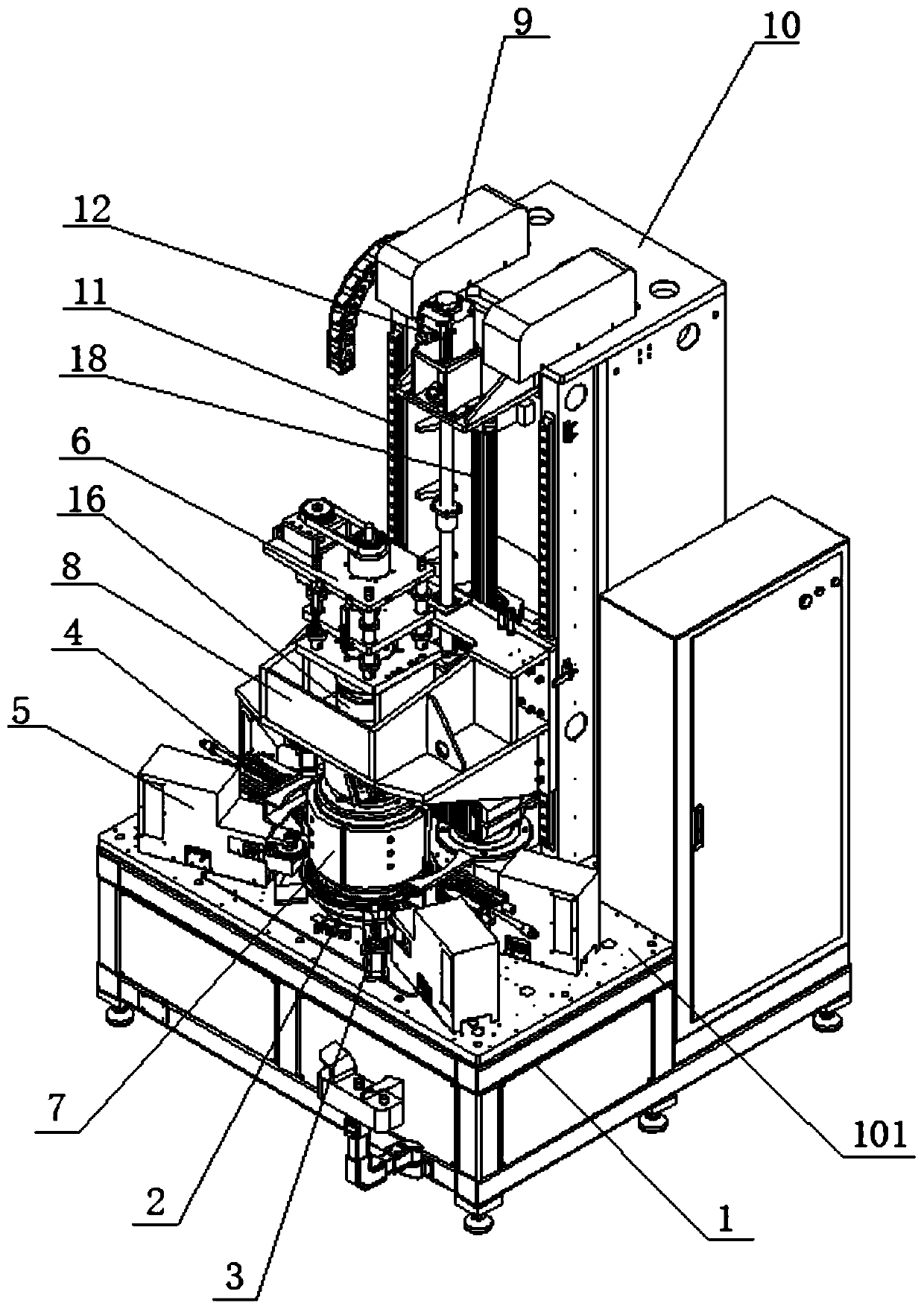

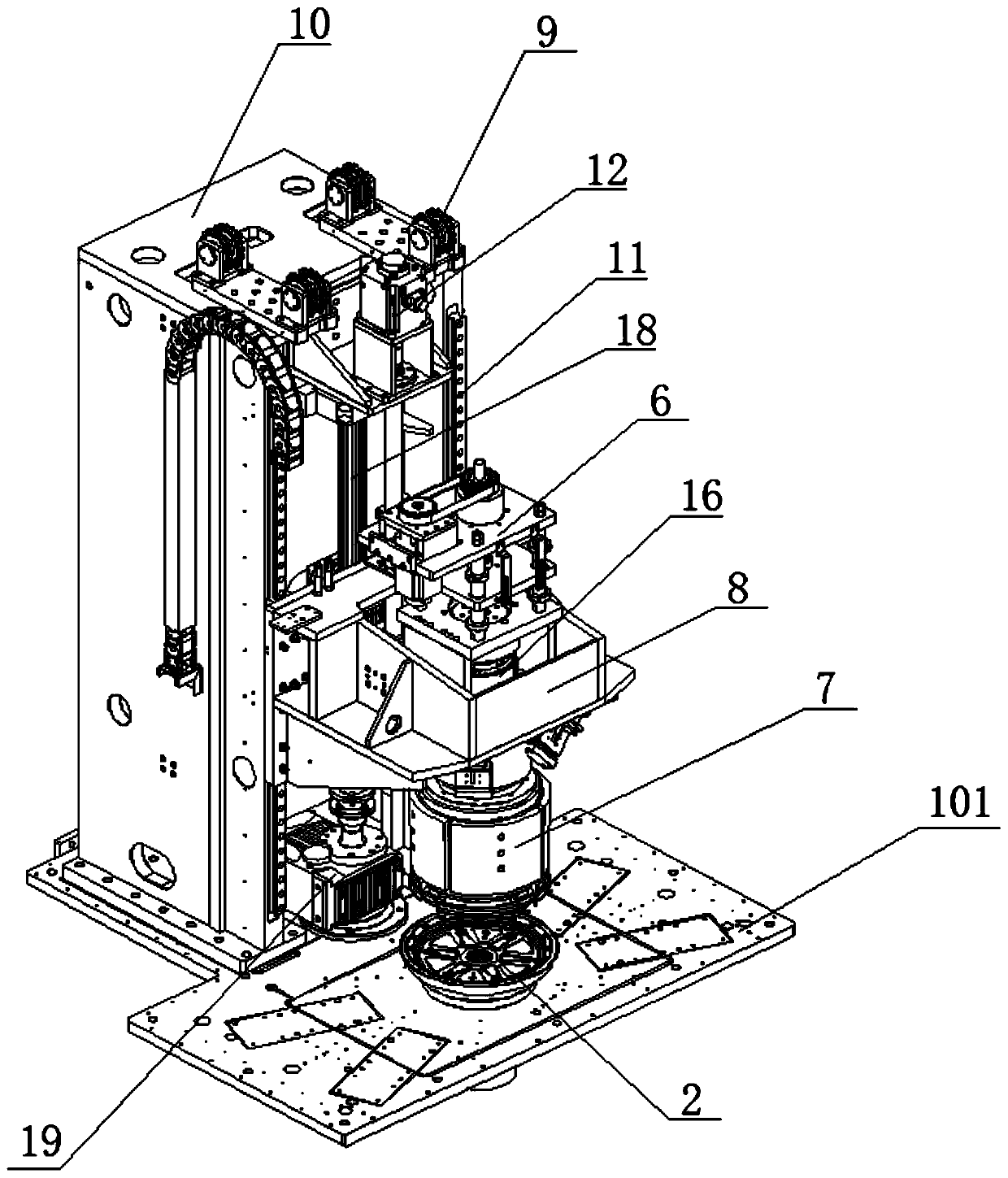

[0050] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the washing machine pulsator drum bottom spin riveting equipment of this embodiment includes a frame 1, a working platform 101 is installed on the top, and a "┏┓"-shaped counterweight box 10 is installed on the rear side of the upper surface of the working platform 101. A guide rail 11 is installed on the front side. The guide rail 11 is installed with a supporting mold assembly 6 that slides along it. The supporting mold assembly 6 is driven by a servo motor 12 mounted on the top of the counterweight box 10, and is driven by a chain and a The counterweight 15 installed in the heavy box 10 is connected, and the lower part of the mold supporting assembly 6 is installed with a mold core 7; the main motor 19 is installed on the working platform 101 directly under the counterweight box 10, and its o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com