Original yarn weaving device with threading function based on textile industry

A technology for the textile industry and raw thread, which is used in woven fabrics, textiles and papermaking, fiber processing, etc. It can solve the problems of inability to quickly remove and collect felt, inability to quickly install the original reel, and inconvenient to quickly disassemble and replace the take-up reel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

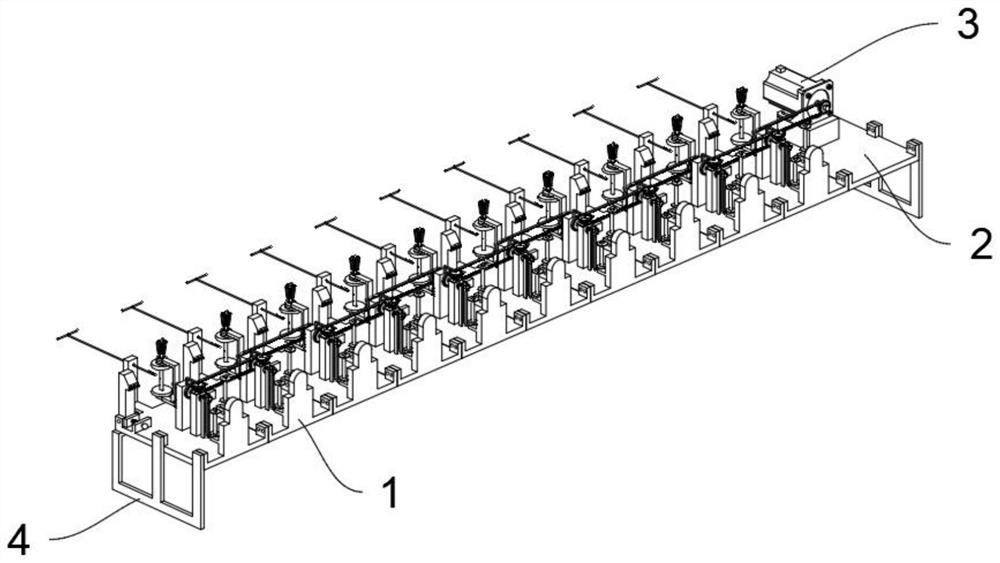

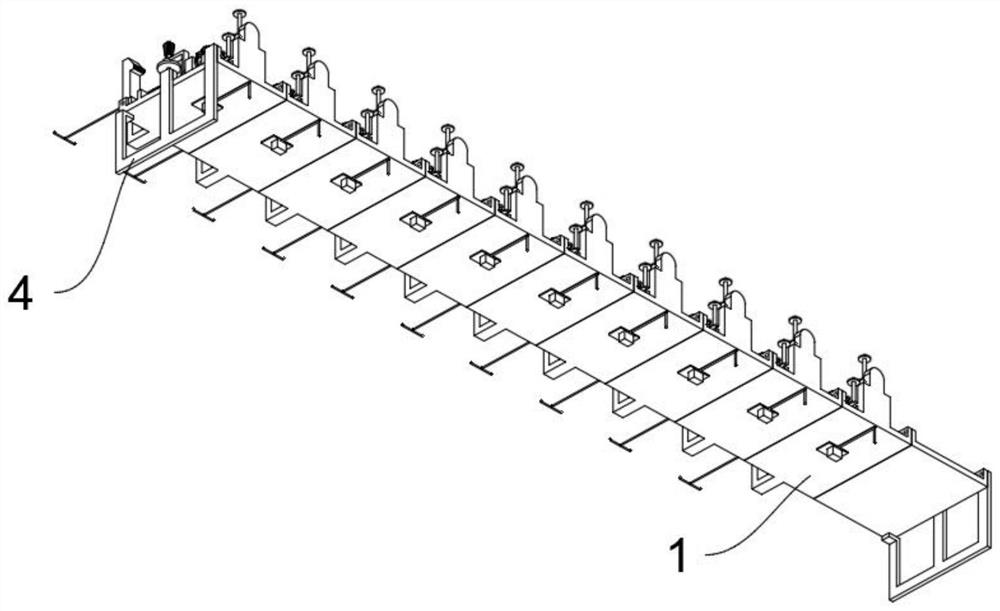

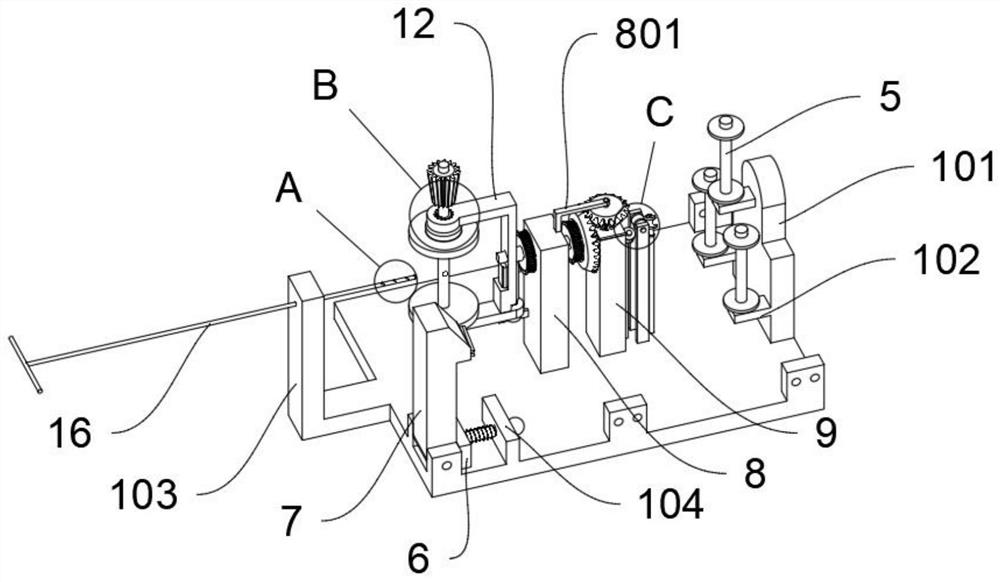

[0034] see Figure 1 to Figure 9 , an embodiment provided by the present invention: a raw thread knitting device with threading function based on the textile industry, including a main seat 1; both sides of the main seat 1 are uniformly provided with connecting buckles, and the main seat 1 It can be fixedly connected with another set of main seat 1 through connecting buckle; main seat 1 also includes original line plate 101, original line roller frame 102, rear crutch frame 103, rebound plate 104; the front top of main seat 1 The middle is integrally provided with the original line plate 101, and the rear side of the original line plate 101 is integrally provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com