Winch hoist

A hoist and winch-type technology, which is applied in the direction of hoisting devices, mechanical equipment, engine components, etc., can solve the problem of complex stress on the reducer, and achieve the effects of reducing procurement costs, low torque, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

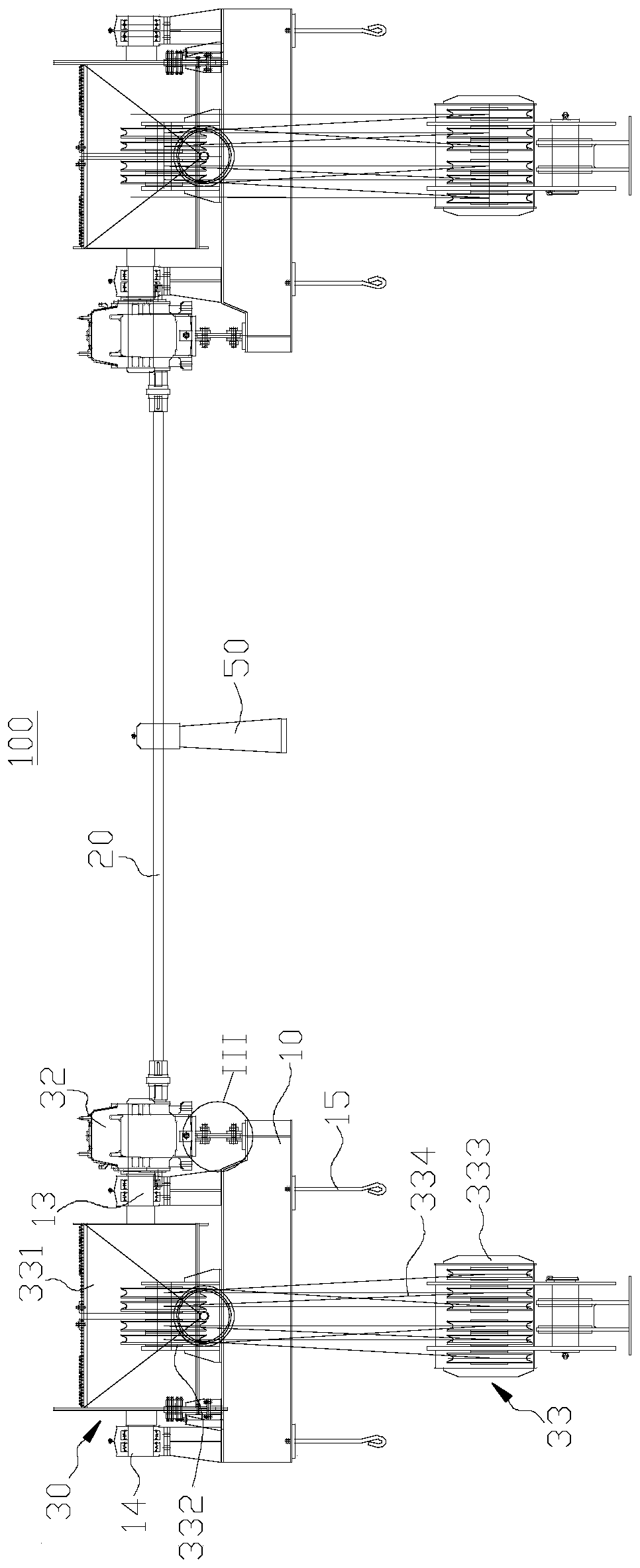

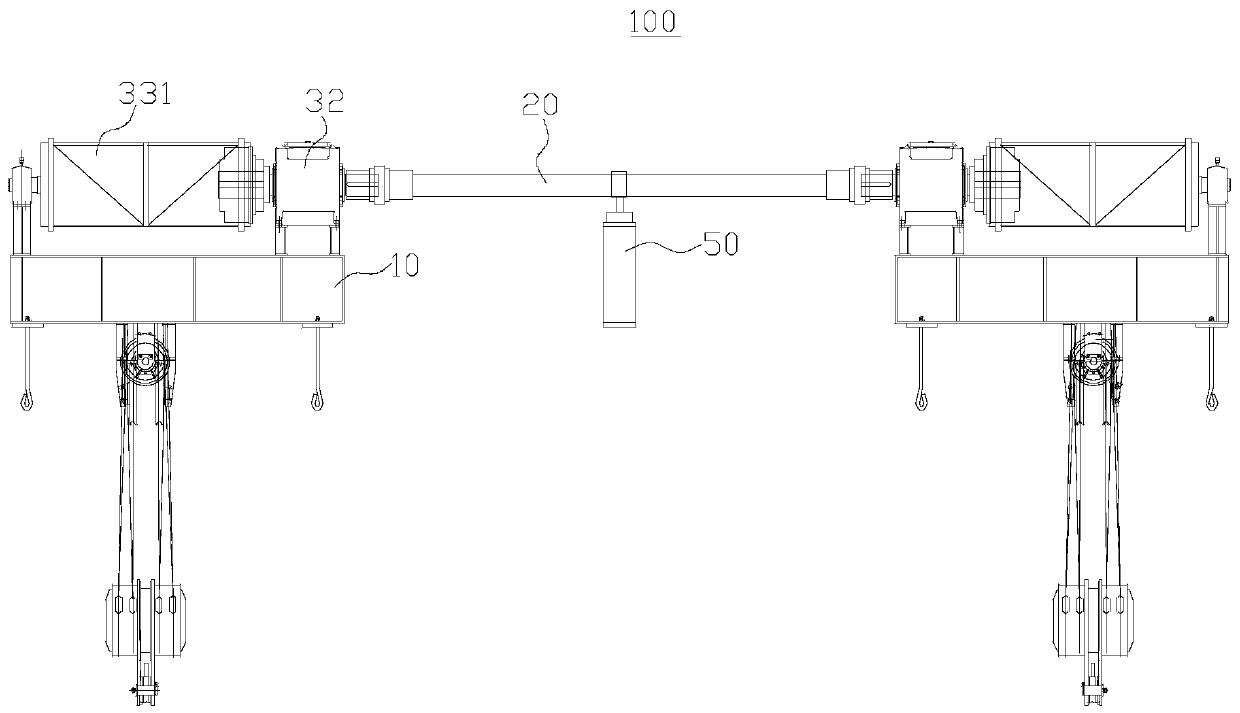

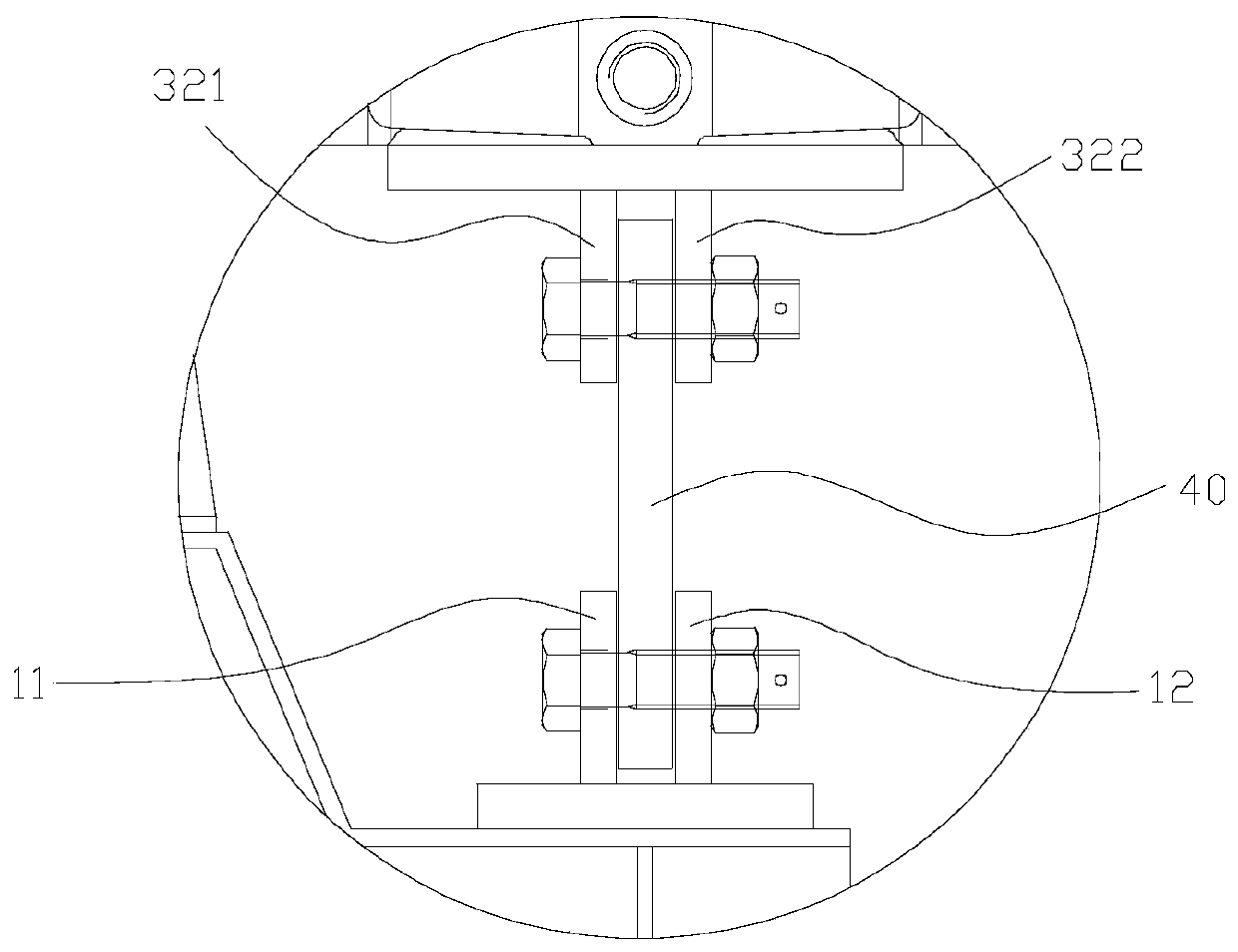

[0039] Such as figure 1 As shown, the embodiment of the present application provides a hoist hoist 100. The hoist hoist 100 includes a frame 10, a synchronous connection shaft 20 and two lifting point assemblies 30 arranged at intervals on the frame 10. Two lifting point assemblies 30 are connected through a synchronous connection shaft 20; each lifting point assembly 30 includes a motor 31, a reducer 32, a torque arm 40 and a lifting mechanism 33 for lifting; the motor 31 is installed on the frame 10. The lifting mechanism 33 includes a reel 331, the power input shaft of the speed reducer 32 is connected with the motor 31, the power output shaft of the speed reducer 32 is connected with the reel 331, the speed reducer 32 is supported on the top of the frame 10 through the torque arm 40, and the torque arm 40 is located directly below the power input shaft of the reducer 32; the motor 31 is used to drive the reel 331 to rotate through the reducer 32, so that the lifting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com