Rotary riveting equipment for inner drum of washing machine

A cylinder spin riveting and washing machine technology, which is applied in the field of spin riveting equipment, can solve the problems of low spin riveting efficiency, asynchronous inner cylinder rotation, and uneven pressing, so as to improve the pressing uniformity and pressing strength, and ensure uniform movement , the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

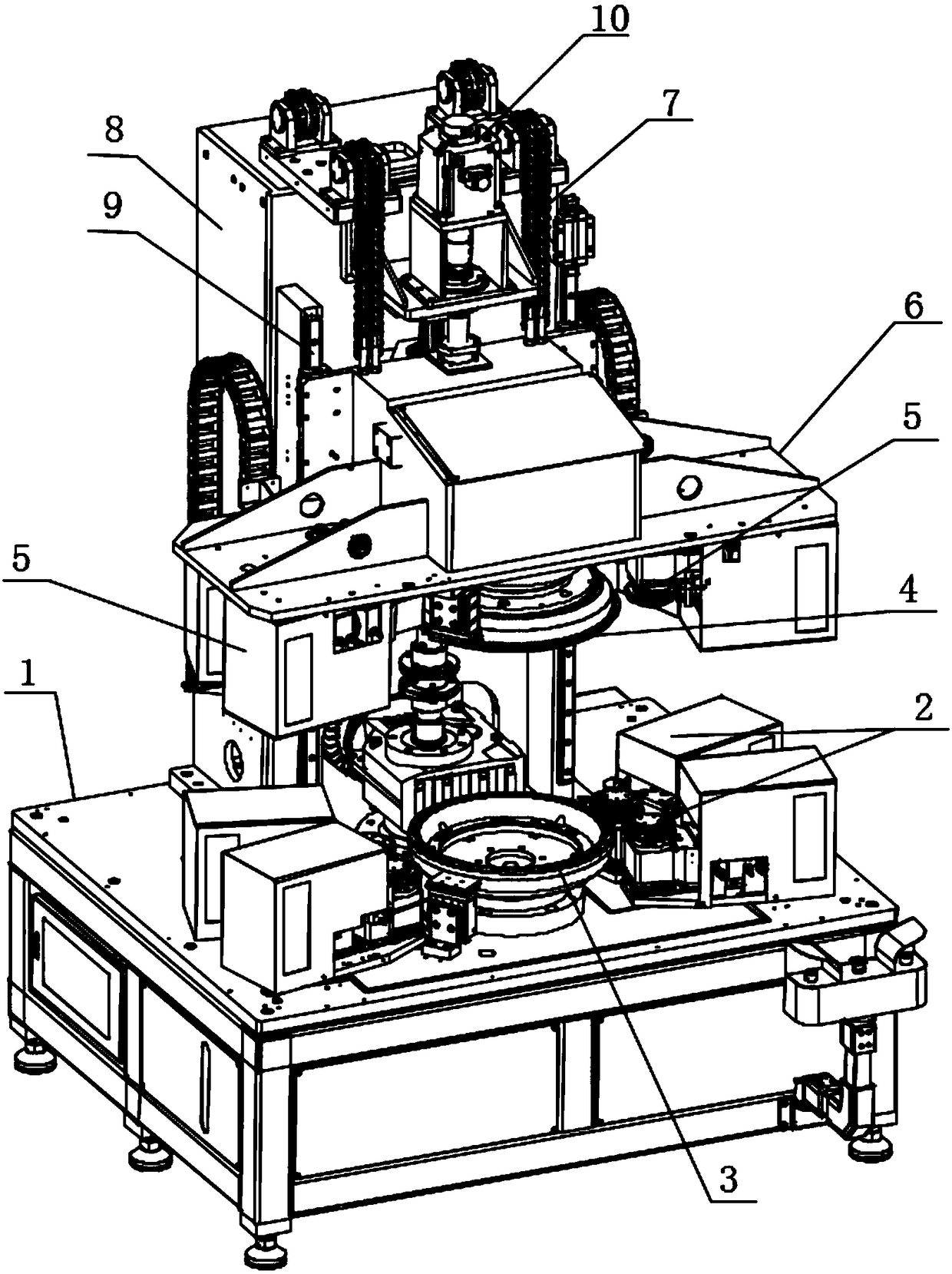

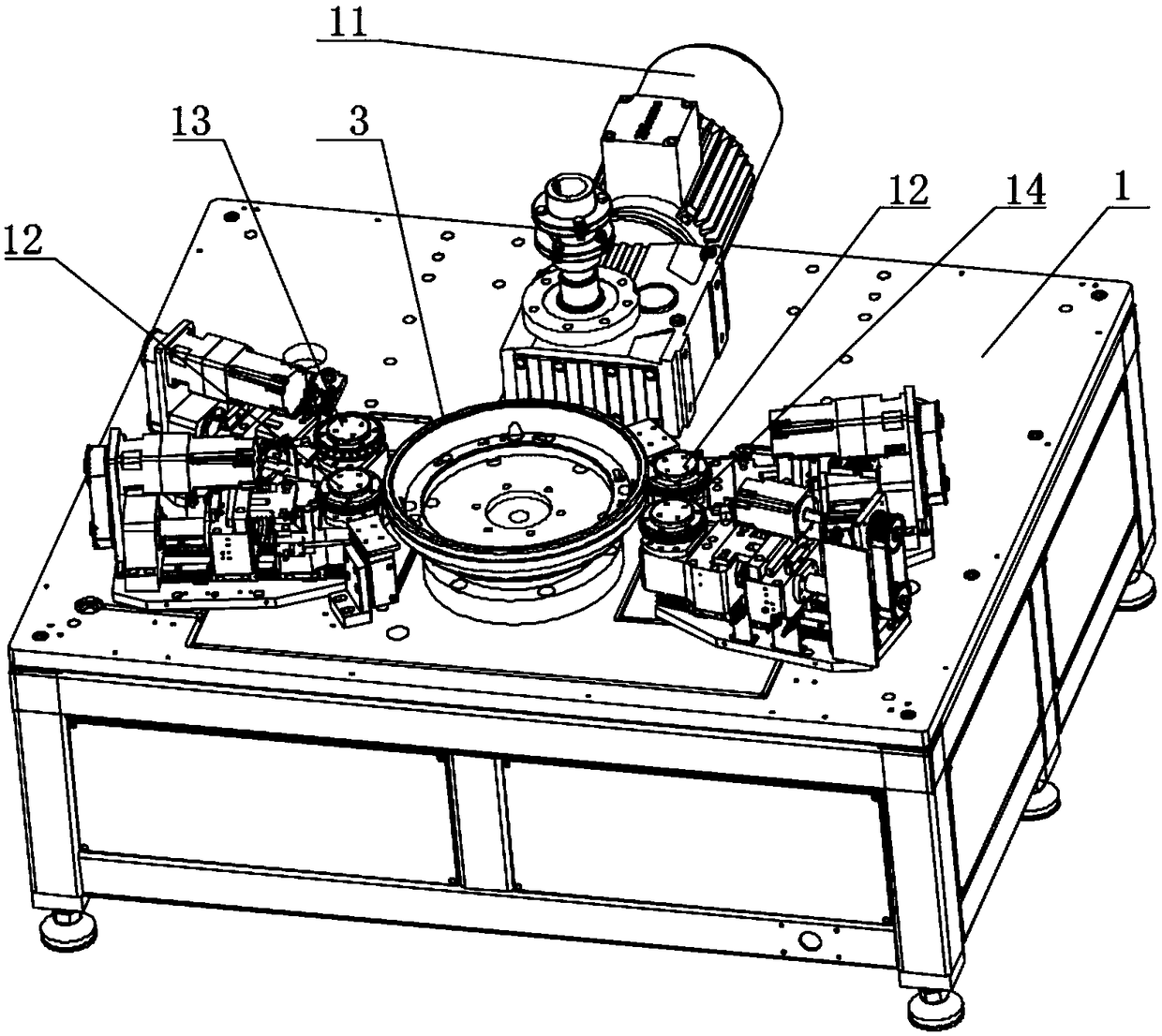

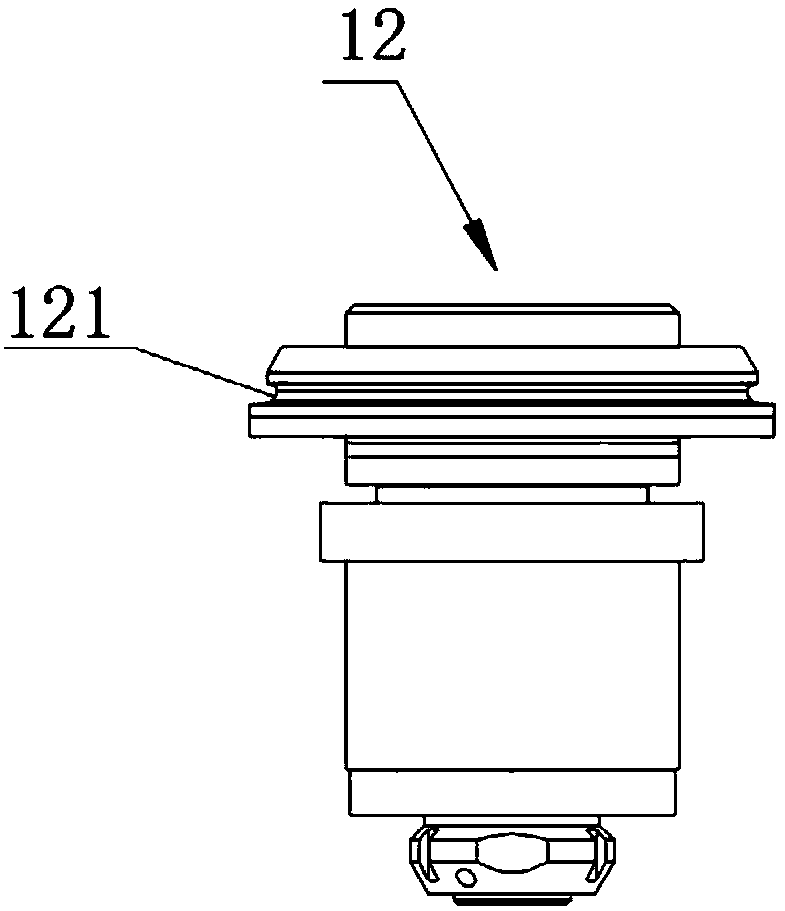

[0023] Such as figure 1 As shown, the spinning riveting equipment for the inner drum of the washing machine in this embodiment includes a workbench 1, a lower flange 3 is installed in the middle of the upper surface, and a plurality of roller assemblies-2 are installed at intervals along the circumference of the lower flange 3, each The roller assembly one 2 includes rollers fed by servo drive, the axis of the rollers is parallel to the axis of the lower flange 3; the counterweight box 8 is installed on the rear side of the upper surface of the workbench 1, and the guide rail 9 is installed on the front side of the workbench. The fixed cover 6 sliding along it is installed on the top, and the fixed cover 6 is connected with the counterweight 15 installed in the counterweight box 8 through the transmission chain 7. The fixed cover 6 is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com