Wood-plastic guard bar processing device

A processing device and guardrail technology, applied in the field of wood-plastic guardrail processing devices, can solve problems such as screw eccentricity and product air pockets, and achieve the effects of ensuring quality, simple processing, and ensuring performance and appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

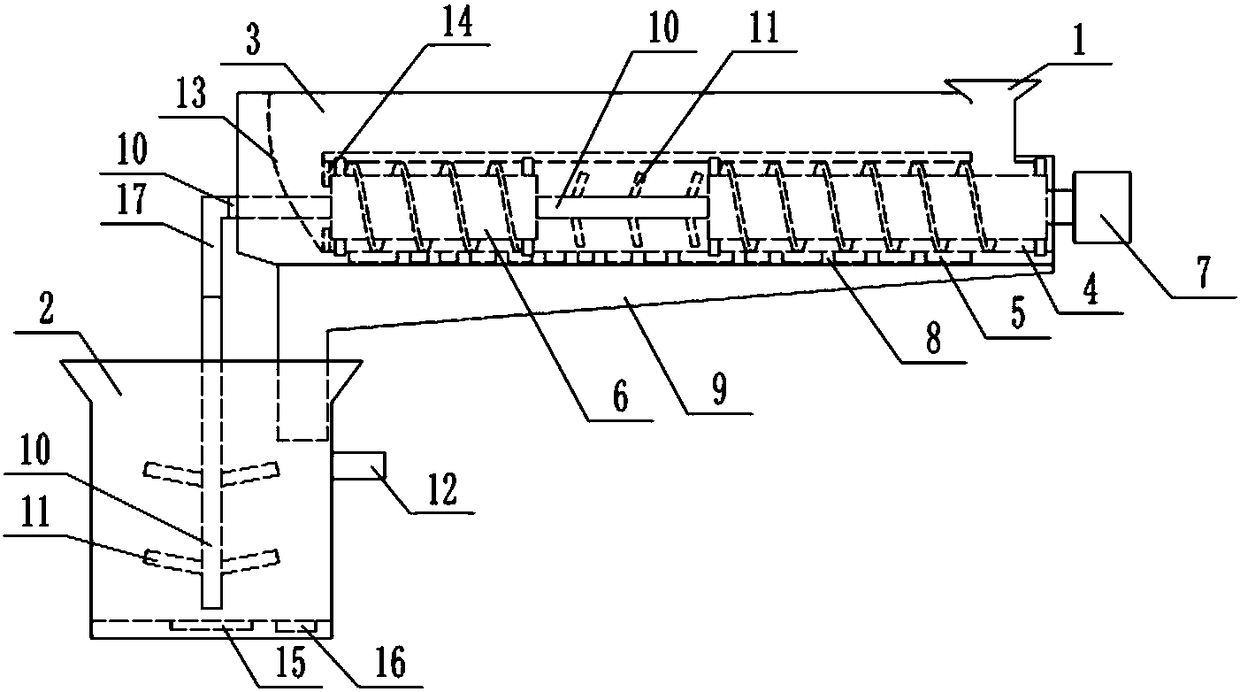

[0015] The reference signs in the drawings of the description include: feeding port 1, mixing barrel 2, recovery chamber 3, melt glue pushing chamber 4, heating plate 5, screw rod 6, motor 7, glue outlet hole 8, melt glue collection chamber 9, Rigid connecting shaft 10, stirring blade 11, melt glue outlet 12, elastic extruding plate 13, elastic extruding block 14, ultrasonic generator 15, ultrasonic transducer 16, corner flexible shaft 17.

[0016] like figure 1 As shown, a wood-plastic guardrail processing device includes a melting glue device provided with a feed inlet 1 and a mixing barrel 2. The melting glue device includes an upper recycling chamber 3 and a lower melting glue pushing chamber 4, and the melting glue pushing chamber 4 It communicates with both ends of the recovery chamber 3, and a heating plate 5 is embedded in the side wall of the melt glue pushing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com