Patents

Literature

67results about How to "Avoid drawing phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

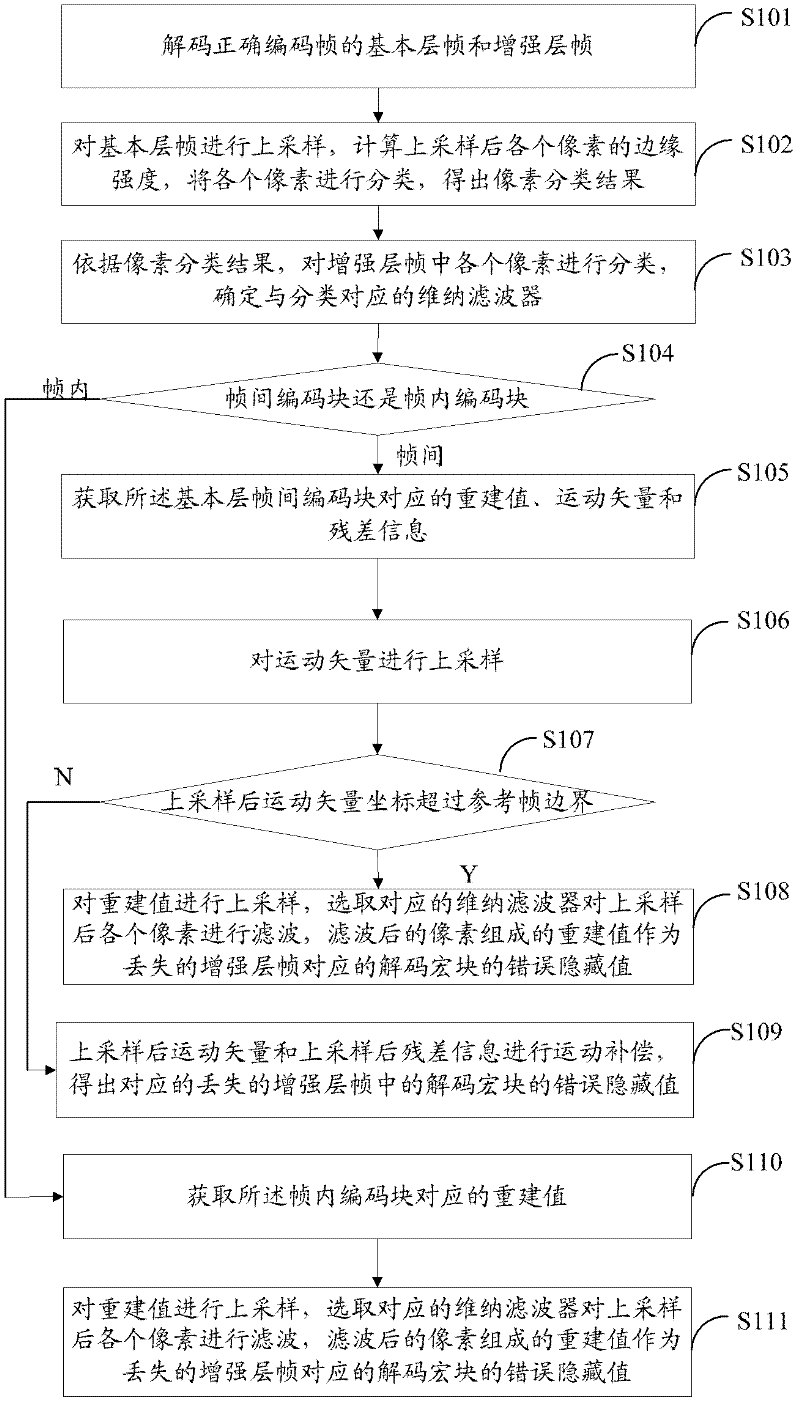

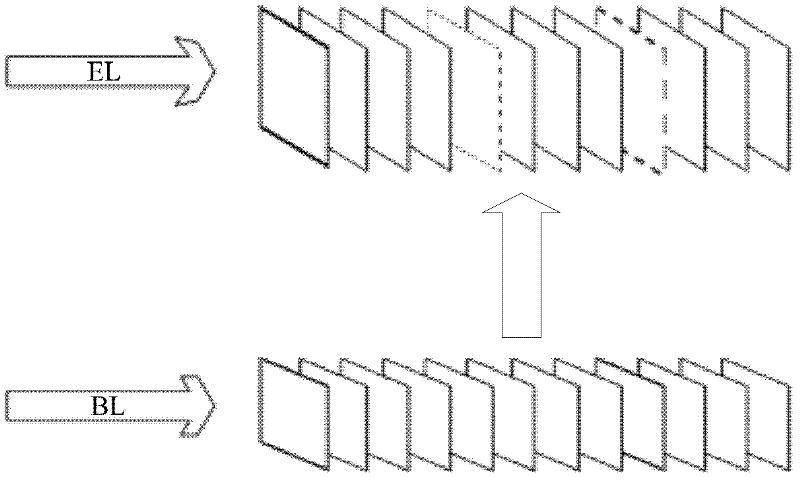

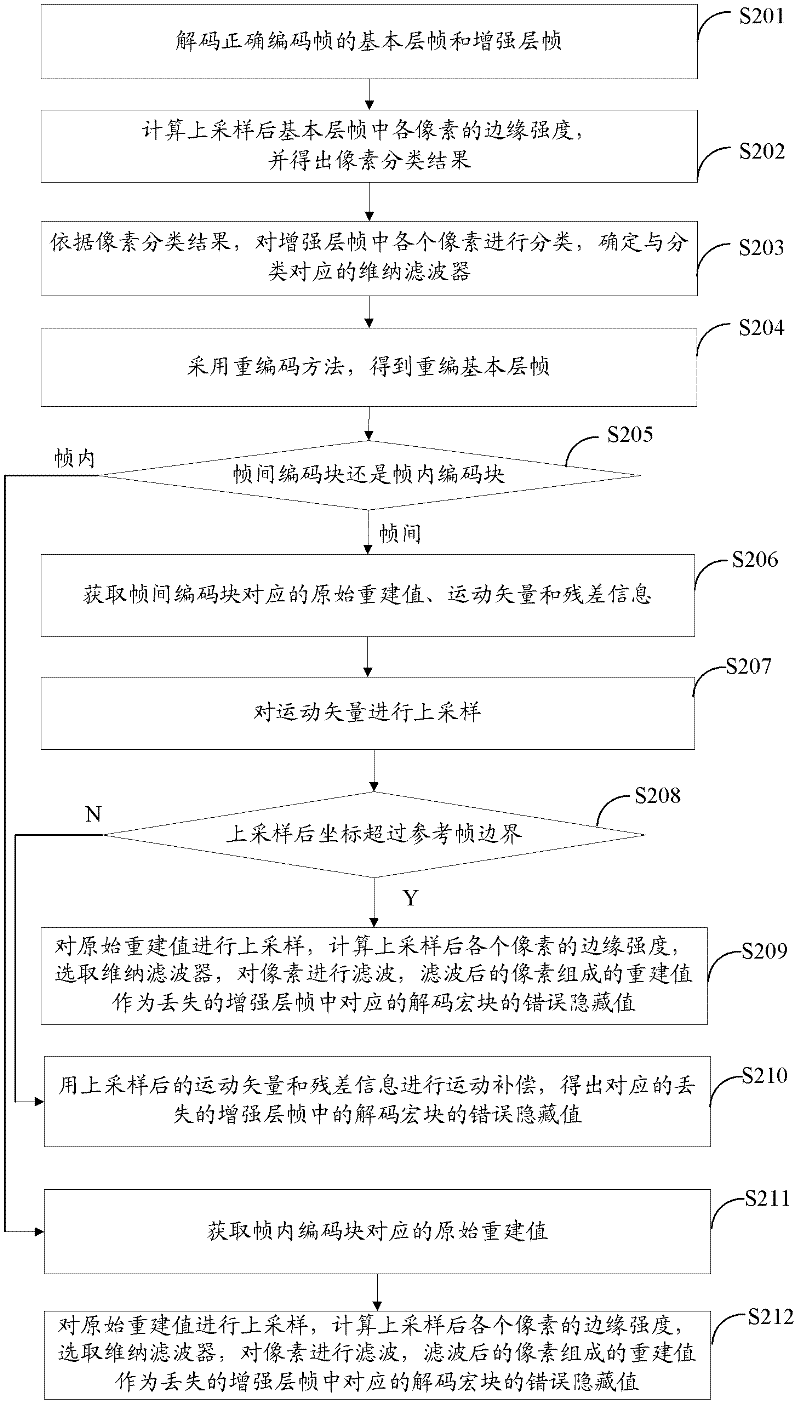

Extensible video coding error hiding method, decoder and system

ActiveCN102547282AQuality improvementImprove clarityTelevision systemsDigital video signal modificationCoding blockComputer hardware

The invention discloses an extensible video coding error hiding method, a decoder and a system. The extensible video coding error hiding method comprises the steps of carrying out different processing when a decoding macroblock in an interframe coding frame is an interframe coding block or an intra-frame coding block under the conditions that a basic layer frame corresponding to a lost enhancement layer frame serves as the interframe coding frame and frame losing times do not exceed a preset times, and obtaining an error hiding value of a reconstructed enhancement layer frame; and under the conditions that the basic layer frame corresponding to the lost enhancement layer frame serves as the interframe coding frame and the frame losing times exceed the preset times or the basic layer frame corresponding to the lost enhancement layer frame serves as an intra-frame coding frame, adopting a recoding method to obtain a recoding base layer frame, carrying out different processing when a decoding macroblock in the recoding base layer frame is an interframe coding block or an intra-frame coding block, and obtaining an error hiding value of a reconstructed enhancement layer frame. Compared with the prior art, quality of the reconstructed enhancement layer frame is improved, thereby improving video definition and avoiding video drawing.

Owner:UNIV OF SCI & TECH OF CHINA

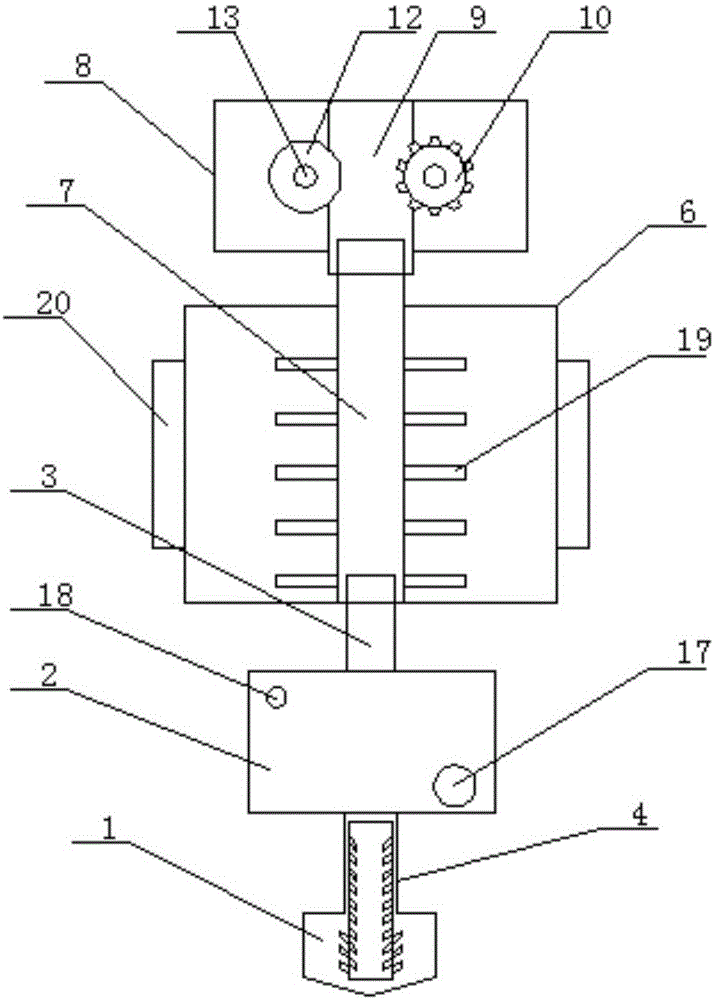

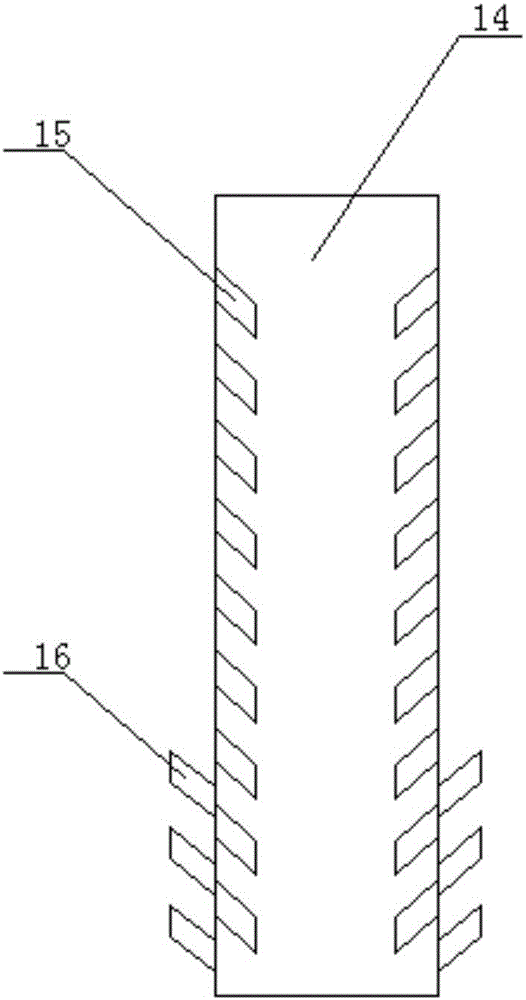

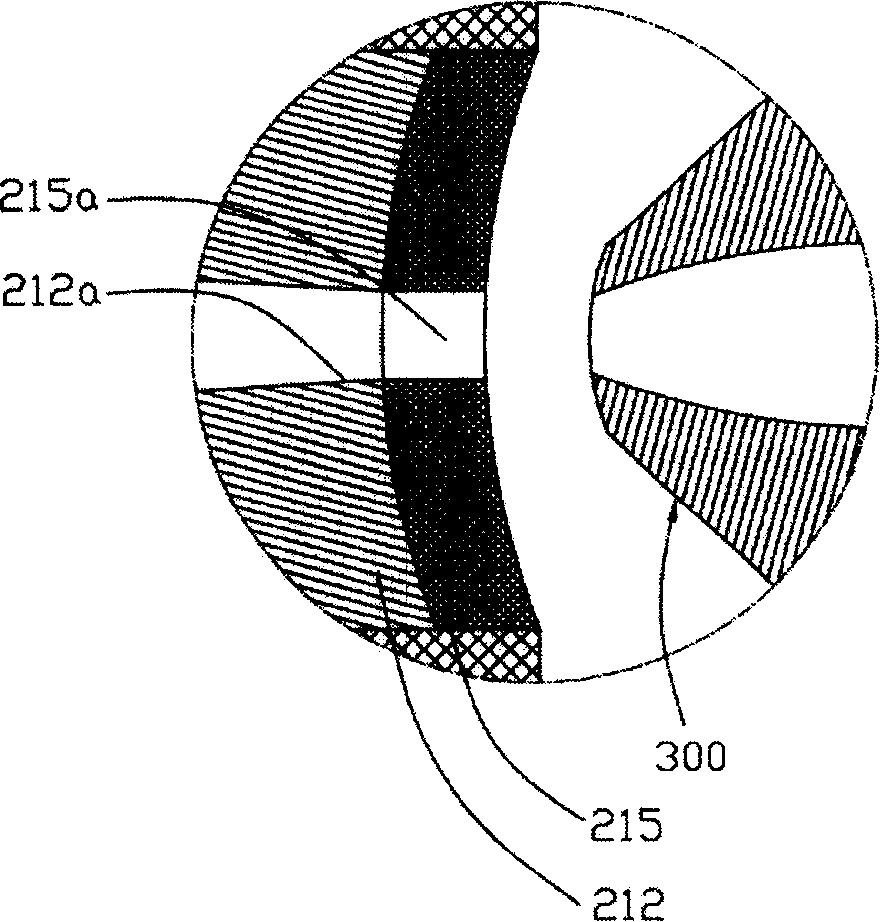

3D printing head capable of solving wire drawing phenomenon effectively

ActiveCN106738914AIngenious designHigh feasibilityManufacturing heating elements3D object support structuresThroatEngineering

The invention relates to a 3D printing head capable of solving the wire drawing phenomenon effectively. The 3D printing head comprises a jet nozzle, a heating block, a throat pipe, a heat dissipation mechanism, a feeding mechanism and a drawing-back assembly. The heat dissipation mechanism comprises a first shell and a heat dissipation pipe. The feeding mechanism comprises a second shell, a feeding pipe, a feeding assembly and an adjusting assembly. The feeding assembly comprises a feeding gear and a feeding motor. The adjusting assembly comprises a press roller and a rotary shaft. The drawing-back assembly comprises a drawing-back pipe, first stop chips and second stop chips. According to the 3D printing head capable of solving the wire drawing phenomenon effectively, the distance between the feeing gear and the press roller can be adjusted through the feeding mechanism so as to adapt to raw wires of different dimensions, the heat dissipation mechanism is high in heat dissipation efficiency, molten raw materials can be prevented from flowing back into the heat dissipation pipe, and the phenomenon that when two independent units are printed, wire drawing is caused can be prevented through the drawing-back assembly.

Owner:长春市交大增智技术创新中心有限公司

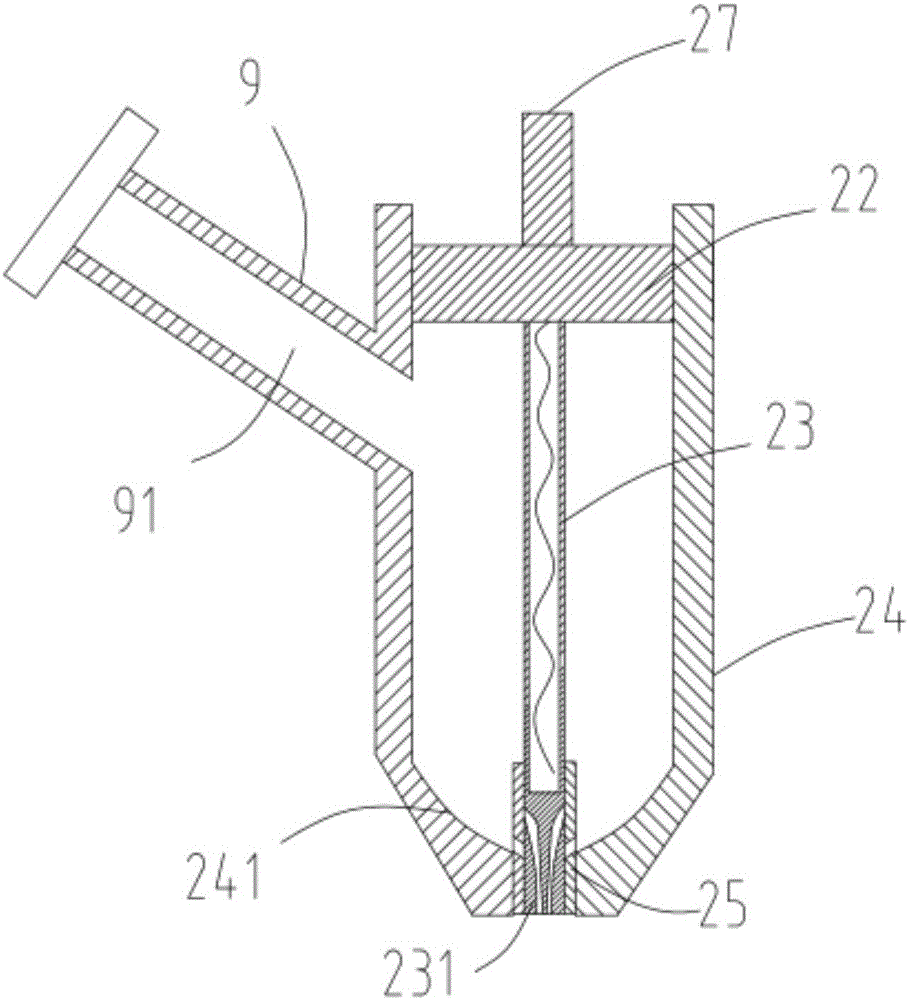

Glue dispensing equipment for processing soft packaged lithium-ion battery

ActiveCN110216042AAvoid affecting work efficiencyPrevent solidificationLiquid surface applicatorsSpraying apparatusElectrical batteryEngineering

The invention discloses glue dispensing equipment for processing a soft packaged lithium-ion battery. The glue dispensing equipment comprises a support column, wherein a top plate is fixed on the topof the support column through a bolt; a box body is fixed at the top of the top plate through the bolt; a motor is fixed on the outer wall of one side of the box body through the bolt; a driving rod is welded with one end of the output shaft of the motor and is positioned in the box body; and a plurality of stirring pieces are fixed on the outer wall of one side of the driving rod through the bolts. The glue dispensing equipment can drive the stirring pieces to rotate to stir and rotate glue, so that the glue can continuously work to prevent solidification of glue so as to avoid influence to the working efficiency; the glue and gas can be extracted and are sprayed out through a glue dispensing head, so that the glue dispensing speed is increased, opening and closing of the glue dispensinghead can be controlled to avoid waste and the wiredrawing phenomenon; and the redundant glue can be collected in a collecting box for recycling through an exhaust fan and cooperation of a connecting pipe and a recycling pipe to save the raw material.

Owner:TAIZHOU UNIV

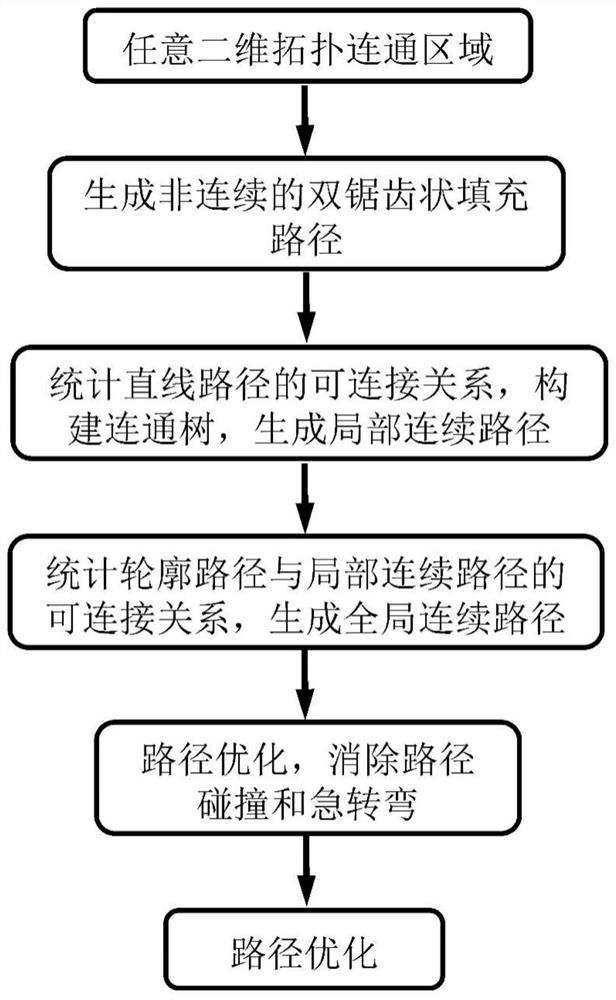

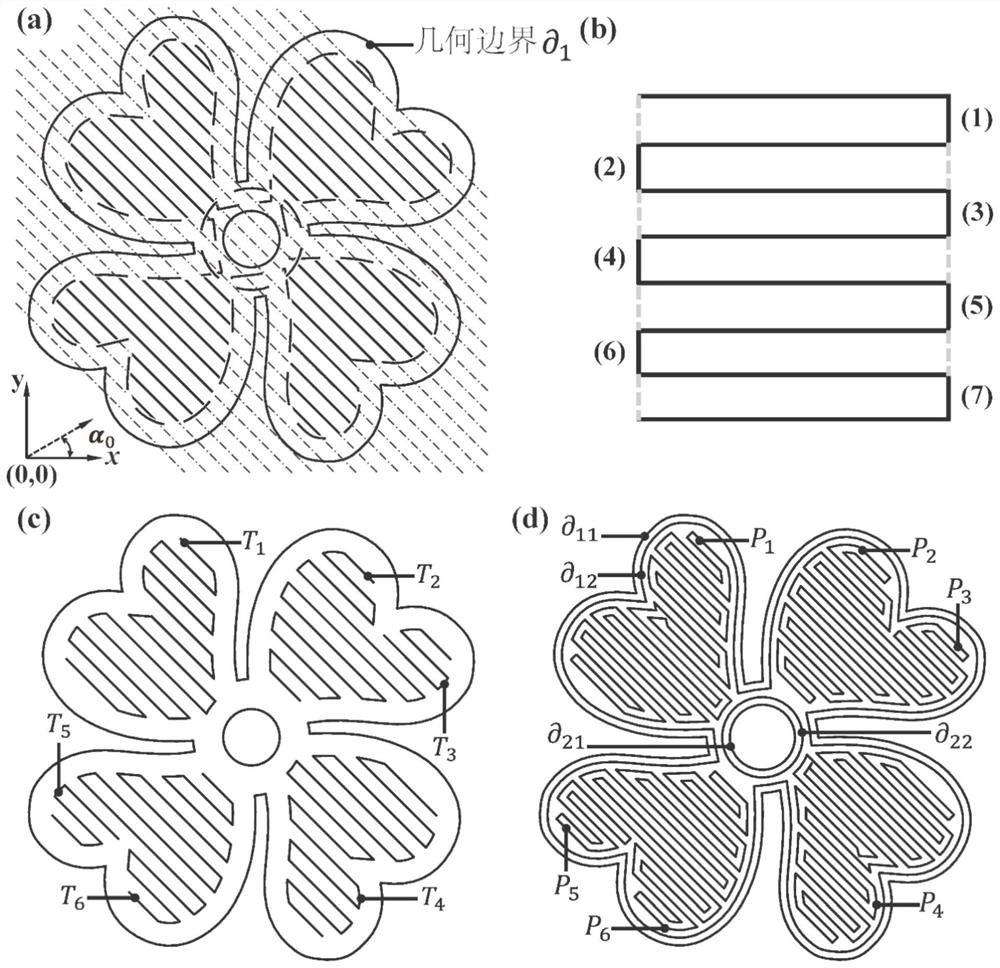

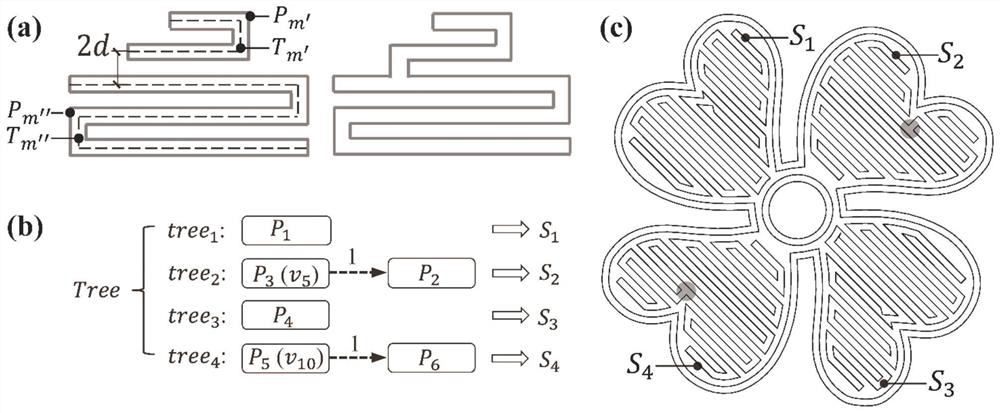

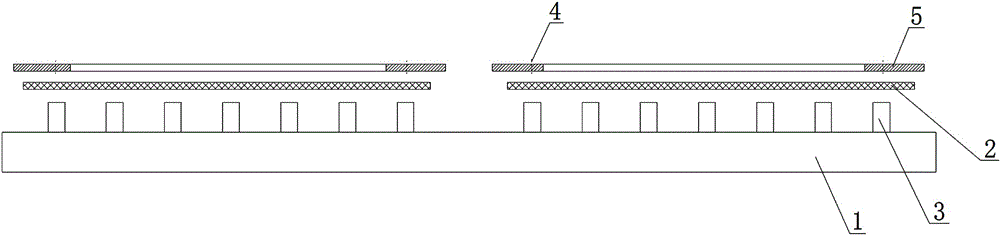

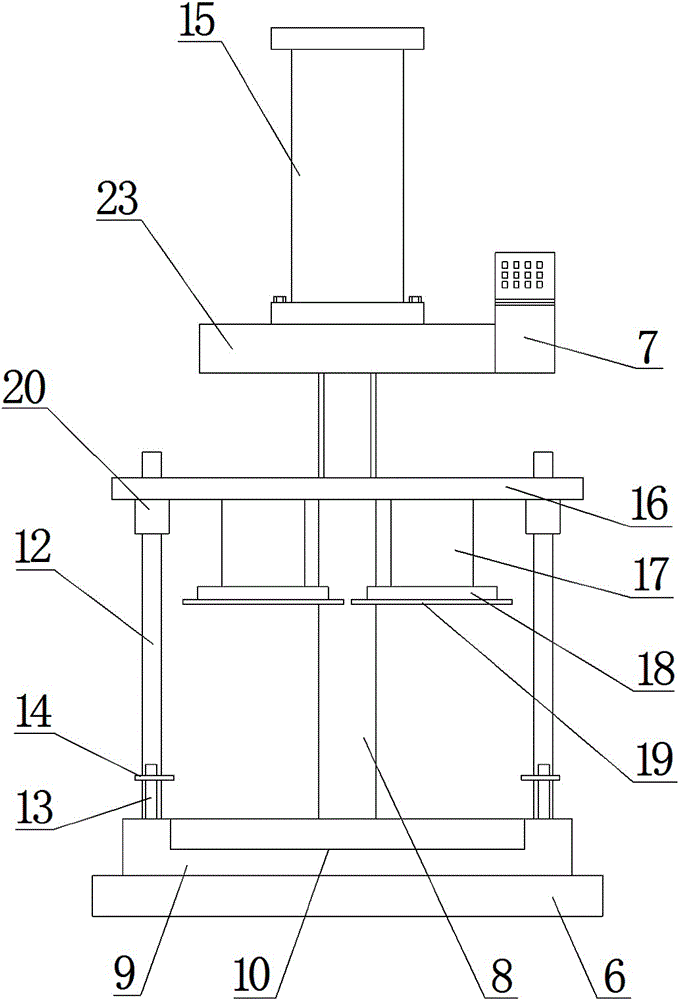

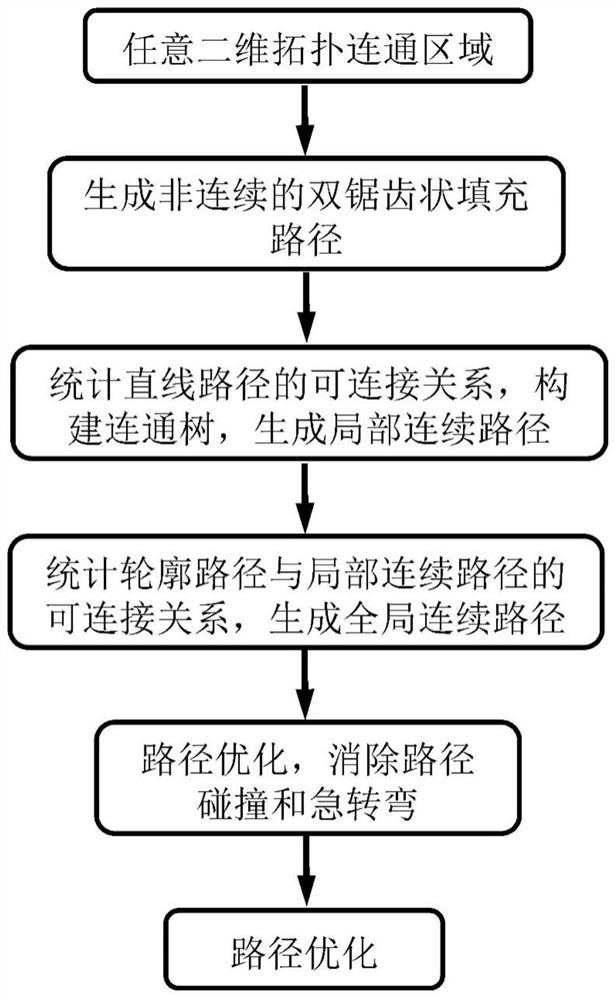

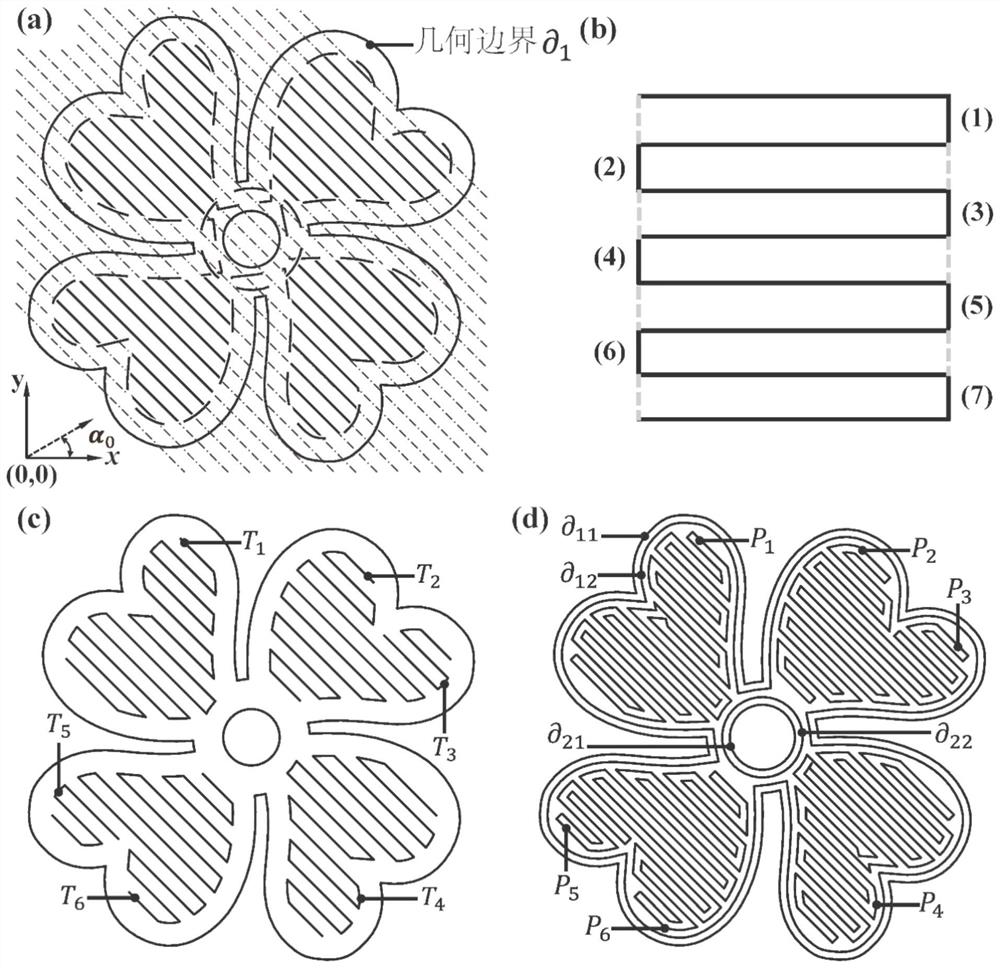

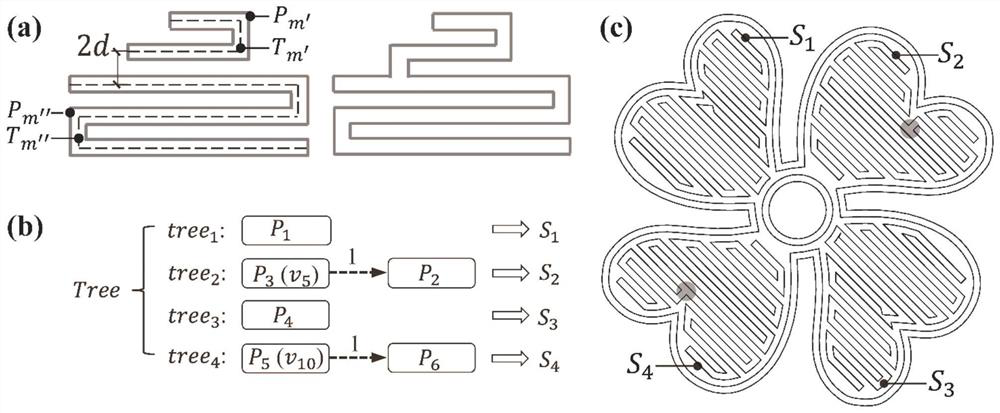

Continuous double-serrated path filling method for deposition modeling

ActiveCN112848309APrevent openingAvoid closingAdditive manufacturing apparatus3D object support structuresGraphicsExternal bias

The invention provides a continuous double-serrated path filling method for deposition modeling. The method comprises the following steps that under the condition of not conducting graphic decomposition, discontinuous single-serrated paths at the interval equal to the diameter d of a nozzle are generated in a slice according to a given angle, and internal and external bias is conducted to generate discontinuous double-serrated paths; the discontinuous double-serrated filling paths are connected into a local continuous double-serrated path according to the connectable relation between the discontinuous double-serrated filling paths; all paths are connected in sequence according to the connectable relation between a double-layer contour and the local continuous double-serrated path a global continuous path; and finally path optimization is conducted. For an arbitrary connected area without islands, one continuous double-serrated linear filling path can be generated according to the set angle under the condition of not conducting polygonal decomposition, opening, closing and jumping of the nozzle are avoided in the printing process, the printing time is shortened, and the printing directions of the paths on different layers can be adjusted as required to achieve the effect of interlayer enhancement.

Owner:HEBEI UNIV OF TECH

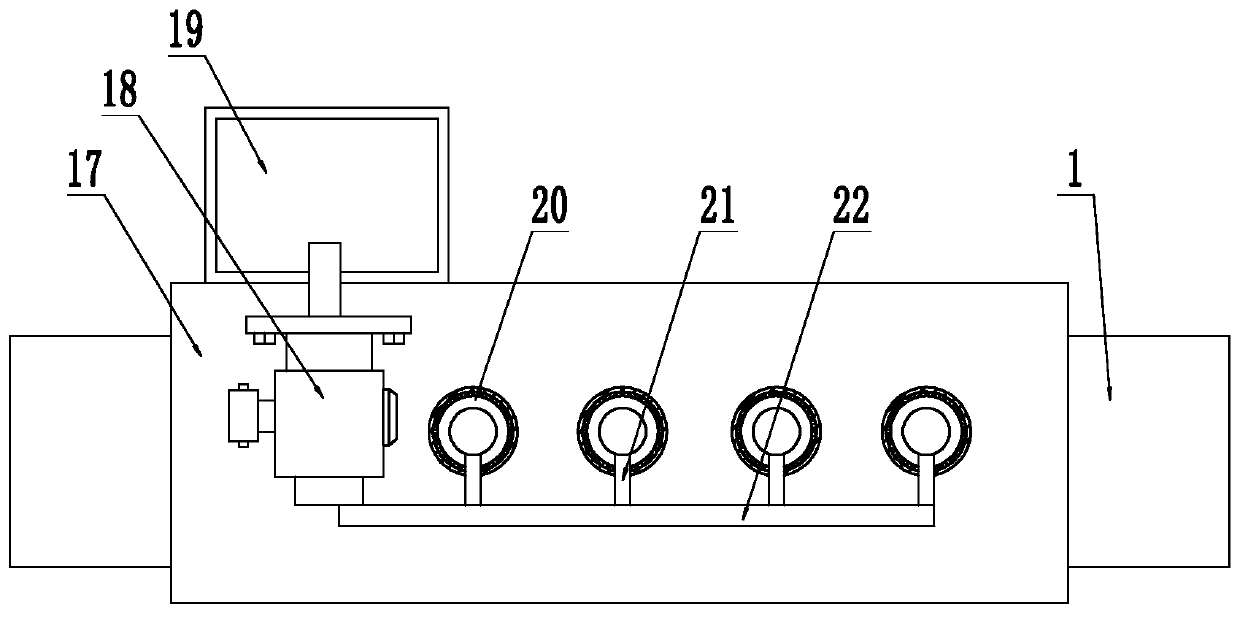

Multi-spray-head three-dimensional printer

InactiveCN107225762ADelicacy guaranteedGuaranteed accuracy3D object support structuresApplying layer meansSpray nozzleEngineering

The invention provides a multi-spray-head three-dimensional printer. The multi-spray-head three-dimensional printer comprises a material dividing plate, a baffle, a first drive mechanism and a spray nozzle assembly; the material dividing plate is of an annular shape, the material dividing plate is internally provided with a plurality of material dividing cavities, and the bottom end of each material dividing cavity is provided with a material discharging hole; the baffle is located under the material dividing plate and is rotatably connected with the material discharging plate, and the baffle is provided with a first material guiding hole which can communicate with the multiple material discharging holes and penetrates through the upper surfaces and the lower surfaces of the material discharging holes; the spray nozzle assembly comprises a connection plate, a second drive mechanism and a plurality of spray nozzles of different diameters, the connection plate is located under the baffle and is rotatably connected with the baffle, the connection plate is provided with a plurality of second material guiding holes which can communicate with the first material guiding hole and penetrate through the upper surface and the lower surface of the first material guiding hole, and the multiple spray nozzles are all installed on the connection plate. Through the arrangement of the multiple spray nozzles of different diameters, different use demands can be met; and the baffle can prevent printed materials in other material dividing cavities which are not used from being leaked out and falling on the surface of a printed object, the wiredrawing phenomenon is avoided, and the delicate degree of a printed product is guaranteed.

Owner:芜湖赛司自动化科技有限公司

Silk-screen printing ink

The invention discloses silk-screen printing ink. The silk-screen printing ink is prepared from, by weight, 15-25 parts of pigments, 25-40 parts of a binder, 45-70 parts of solvent, 1-3 parts of calcium carbonate, 1-3 parts of a defoaming agent, 1-3 parts of a leveling agent, 2-7 parts of a 5A molecular sieve, 1-3 parts of fumed silica, 2-7 parts of a dispersing agent, 0.5-1.5 parts of an adhesion promoter, 2-5 parts of gummy oil, 1-3 parts of a slipping agent, 1-4 parts of barium sulfate, 1-3 parts of hydrotalcite and 1-3 parts of a light stabilizer. According to the silk-screen printing ink, adhesion of ink can be enhanced, the ink penetration and ink fusion phenomena of the ink are prevented, the chemical stability is high, the storage time is long, the printing property is stable, the uvioresistant capacity and the antioxidant capacity are high, and wear resistance is achieved.

Owner:SUZHOU ANJIE TECH

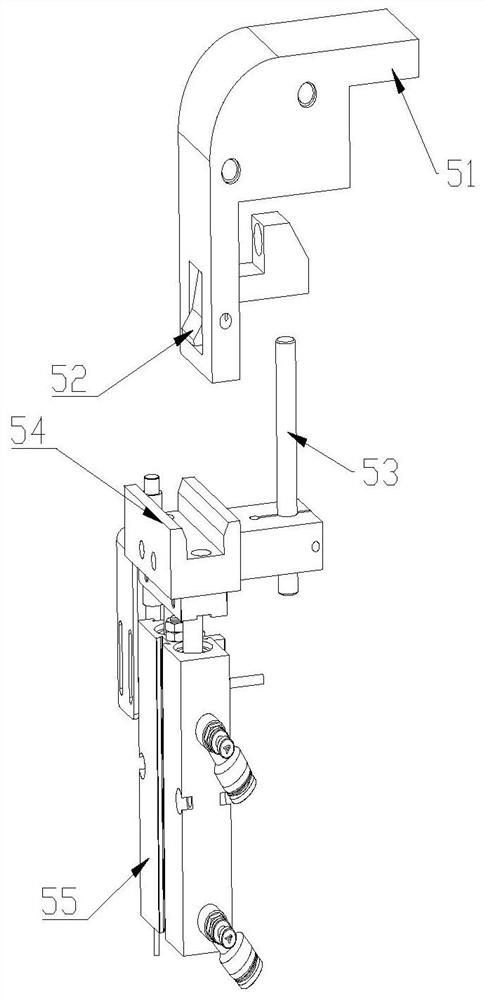

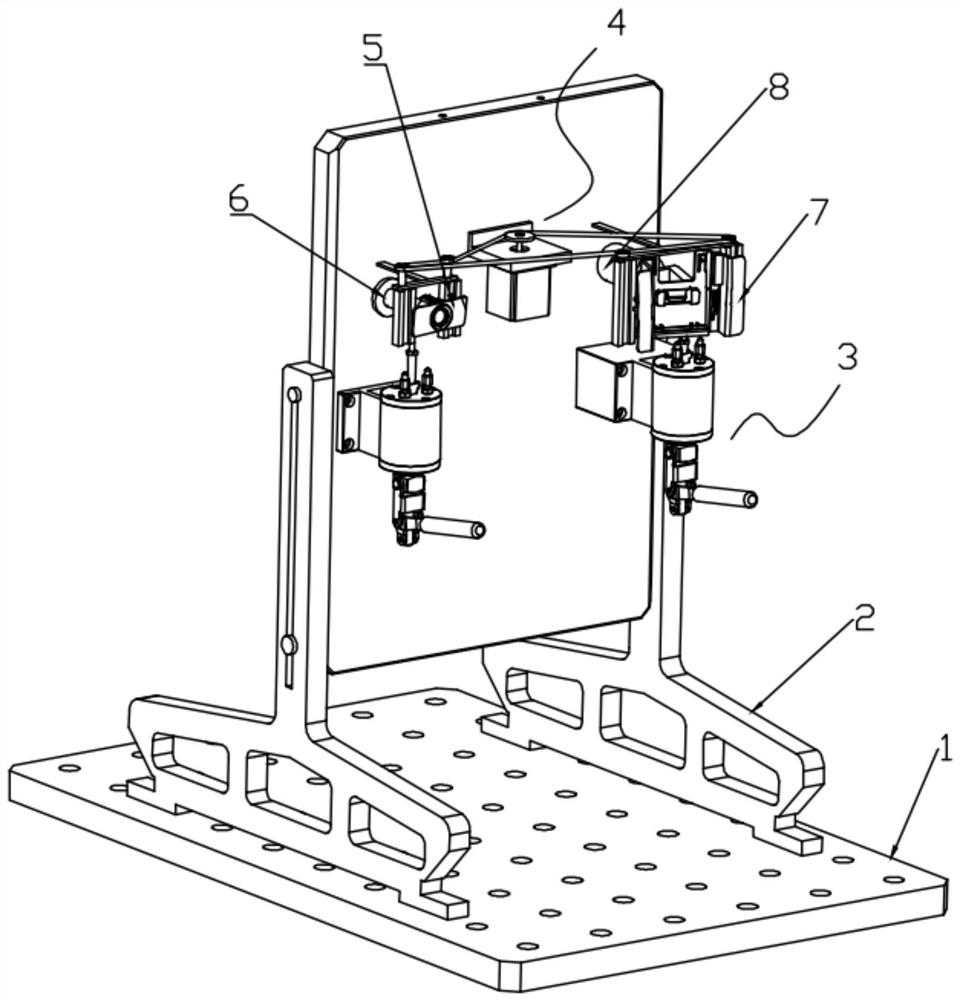

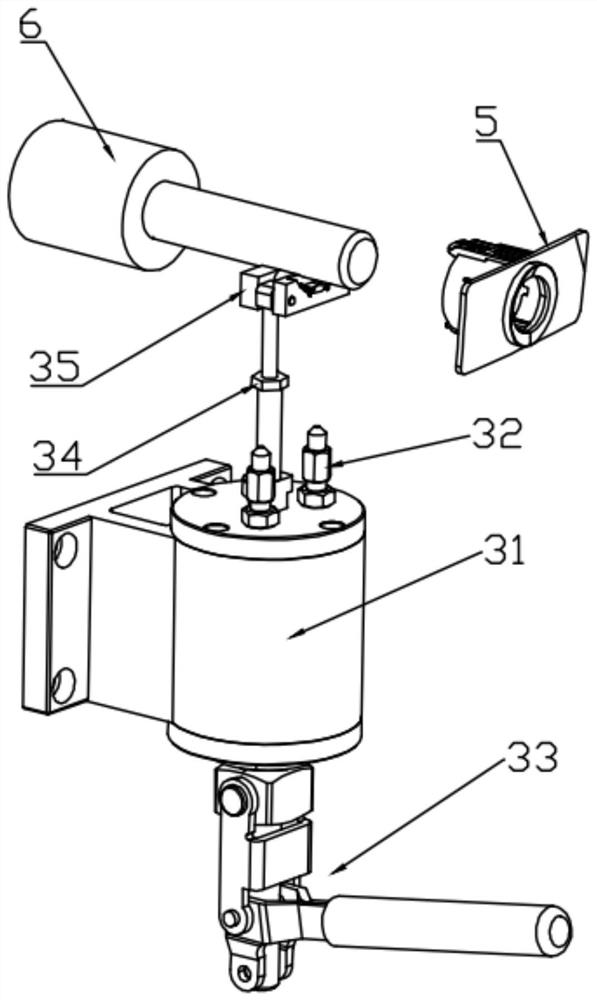

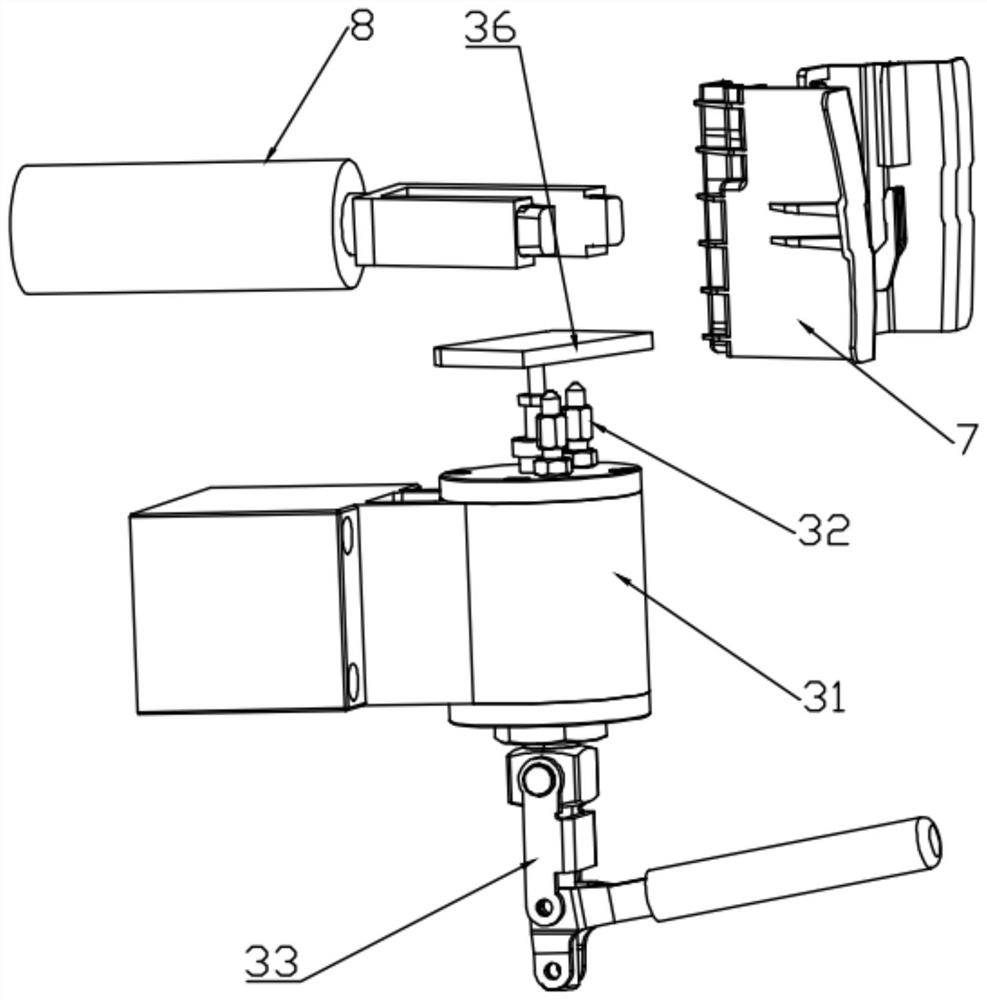

Robotic greasing system

The invention relates to the technical field of machining, in particular to a robotic greasing system and solves the problems that existing greasing equipment has low efficiency, greasing quantity andgreasing position deviations are large, non-uniform bearing lubrication is caused, poor appearance quality is caused, and stringing occurs after greasing. A greasing robot is arranged on one side ofa belt conveyor; a bearing clamp is arranged on the belt conveyor; a greasing working head is mounted at the executing end of the greasing robot; the bearing clamp corresponds to the greasing workinghead in position; a grease pipeline mounting groove is arranged in an upper cross beam of a gantry along its length, a grease pipeline is mounted on the upper cross beam of the gantry, one end of thegrease pipeline is connected with a grease outlet of a grease box of a greasing unit, the other end of the grease pipeline is connected with a grease inlet of the greasing working head, and a suck-back device is arranged on one side of the grease pipeline close to the greasing unit. The robotic greasing system is applied to precise and continuous greasing production for grease lubricated bearings.

Owner:HARBIN BEARING GROUP CORP

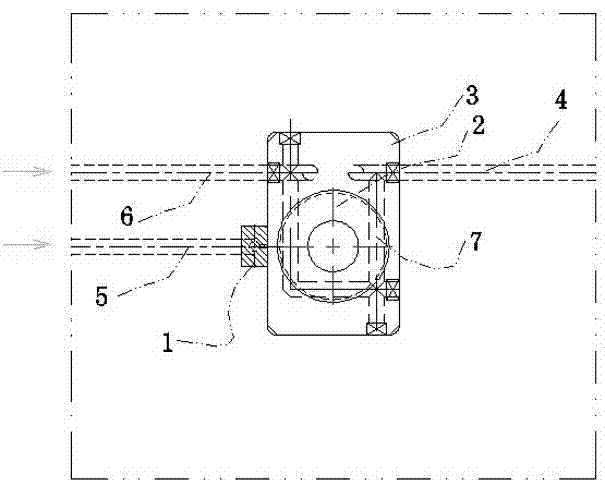

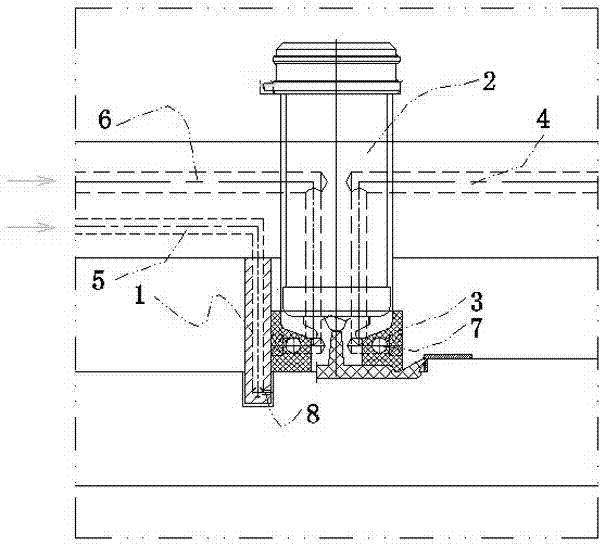

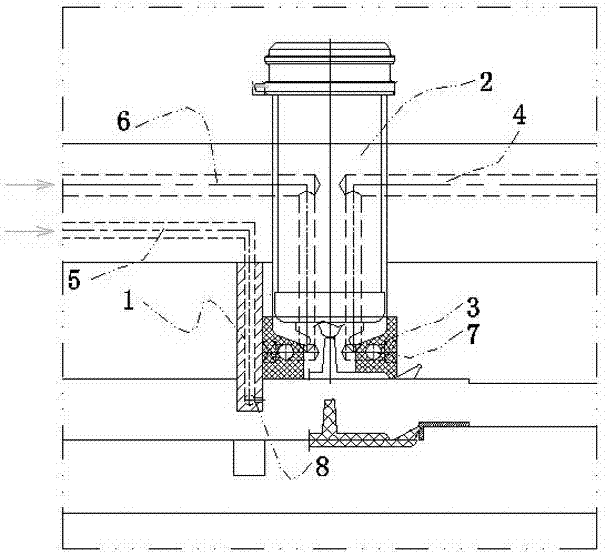

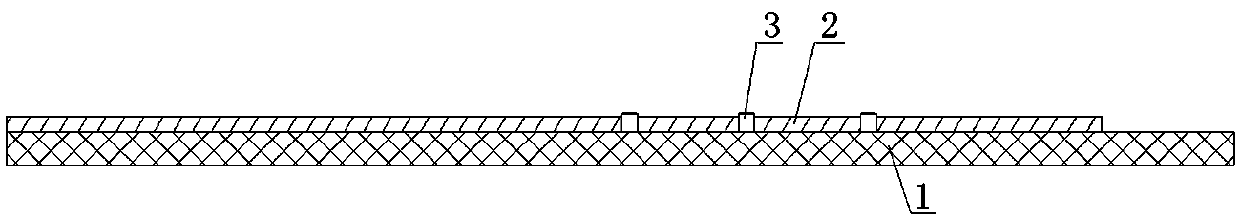

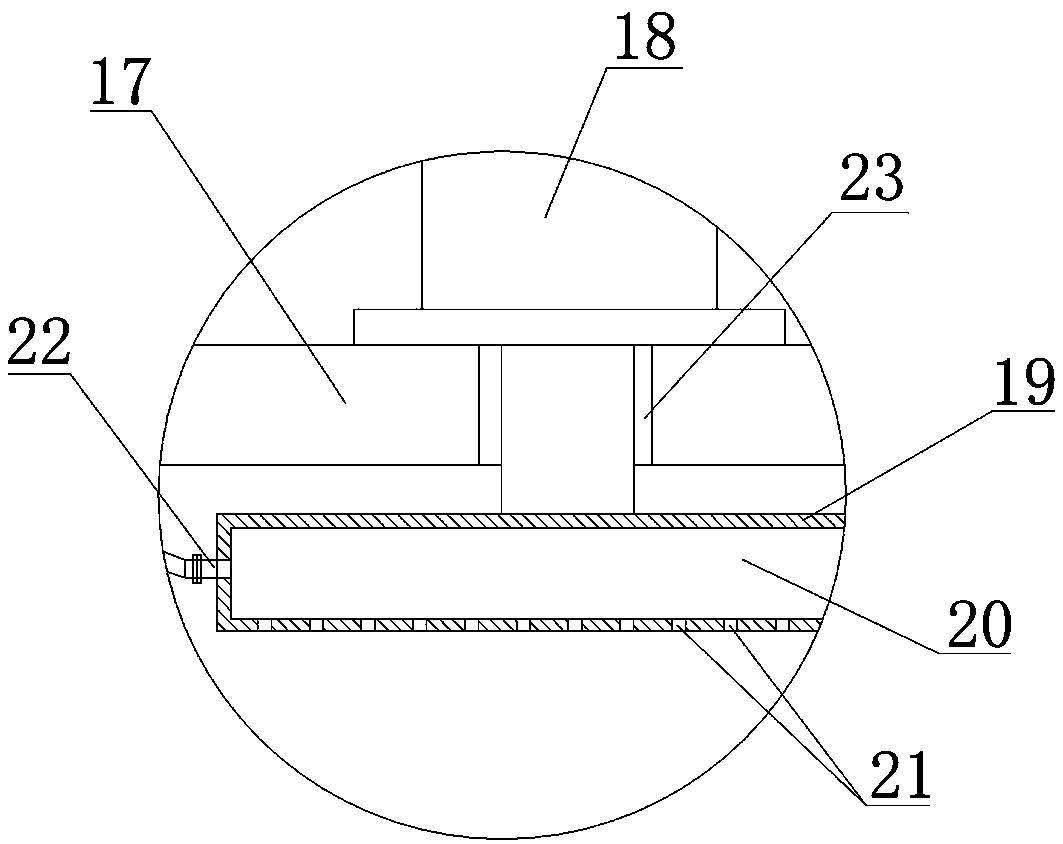

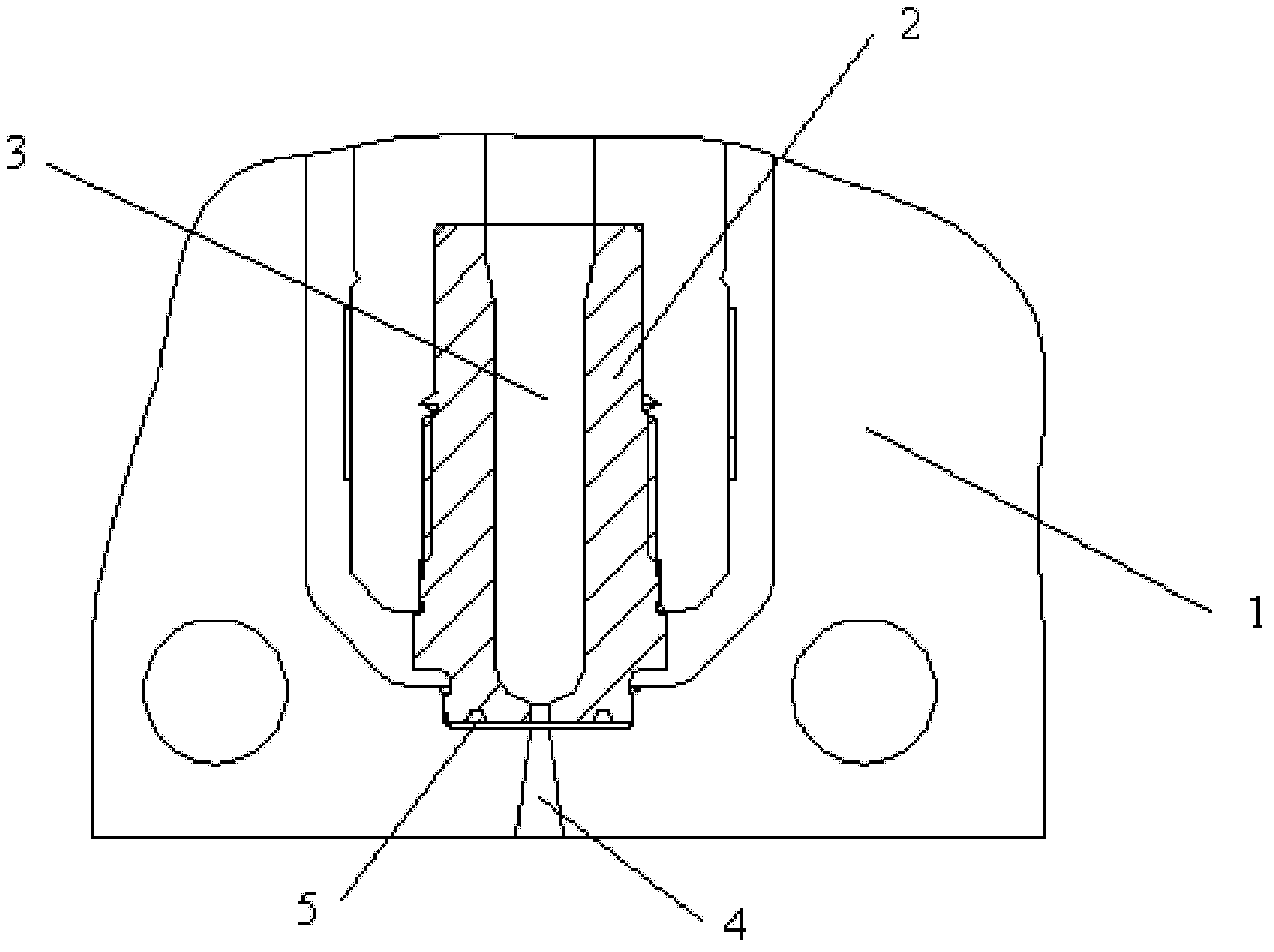

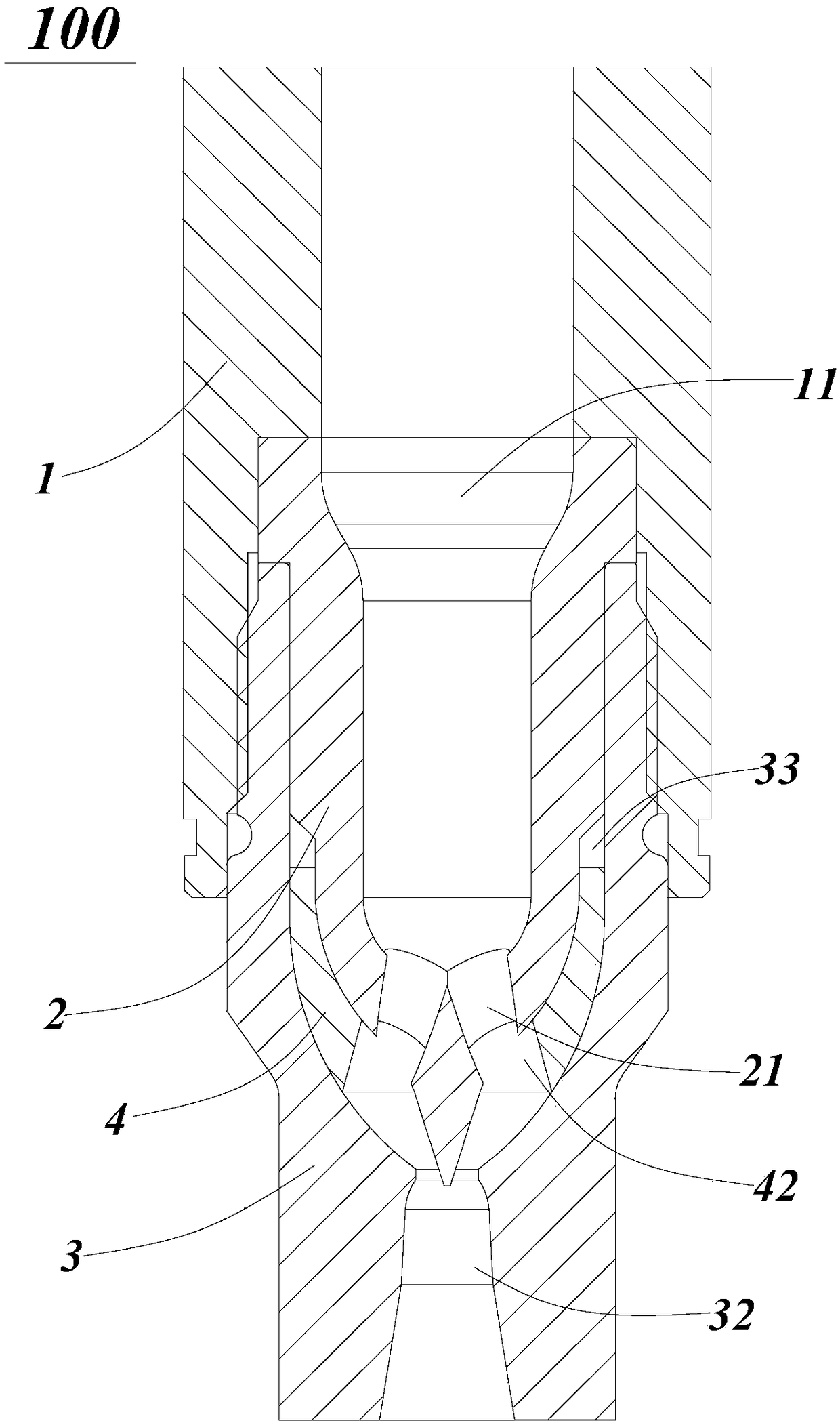

Anti-drawing and quick-break device at the glue inlet point of the mold

The invention belongs to the technical field of plastic die, and especially relates to an anti-wiredrawing and quick-break-proof device for die dispensing points. The device provided by the invention comprises a cooling insert block 3 near a heat spout 2, wherein the cooling insert block 3 is provided with two anti-wiredrawing and quick-break-proof technical schemes: the first one is characterized in that the cooling insert block 3 is equipped with an air blowing block 1or is connected with the air blowing block 1, one end of which communicates with an air inlet pipe 5 inside the die, and theair blowing direction of a blow hole 8 is corresponding to an outlet of the heat spout 2; the second one is characterized in that a water conveying pipe 7 is disposed inside the cooling insert block 3, one end of the water conveying pipe 7 communicates with an inlet pipe 6 inside the die, the other end of the water conveying pipe 7 communicates with an outlet pipe 4 inside the die, and the water conveying pipe 7 is arranged near the outlet of the heat spout 2. The two technical schemes are preferably combined. According to the invention, cooling water flows inside the water conveying pipe to rapidly lower the temperature of the heat spout, and compressed air again blows air to cool a cast gate and breaks wire drawing in initial stage. Therefore, the wiredrawing phenomenon can be completely avoided by the dual functions.

Owner:思柏精密科技股份有限公司

Toothpaste containing polygonum cuspidatum and preparation method of toothpaste

InactiveCN109381350AEfficient extractionIncrease profitCosmetic preparationsToilet preparationsAdditive ingredientGlycerol

The invention belongs to the field of daily chemical products, in particular to toothpaste containing polygonum cuspidatum and a preparation method of the toothpaste. The toothpaste containing the polygonum cuspidatum comprises the following ingredients by weight percentage: 0.5-8% of polygonum cuspidatum extract, 15-25% of friction silicon oxide, 3-10% of thickening silicon oxide, 10-18% of glycerol, 40-52% of sorbitol solution, 1-3% of sodium carboxymethylcellulose, 1.5-3% of lauryl sodium sulfate, 0.1-0.5% of saccharin sodium, 0.2-0.4% of sodium benzoate, 0.3-0.5% of menthol, 0.2-0.4% of citric acid and the balance of deionized water. The prepared toothpaste containing the polygonum cuspidatum is uniform and transparent in character, has a pH (potential of hydrogen) close to that of human saliva, and can prevent anthraquinone and tannin active ingredients from being oxidized, keep a better antibacterial and anti-caries effect, whiten teeth, refresh breath and the brain and regain consciousness.

Owner:HUBEI UNIV OF CHINESE MEDICINE

Automatic two-end gluing machine

ActiveCN113289866AShorten the timeImprove work efficiencyLiquid surface applicatorsCoatingsEngineeringMachine

The invention discloses an automatic two-end gluing machine, and relates to the field of gluing. The automatic two-end gluing machine comprises a rack, a dust cover and a control mechanism, wherein the rack is sequentially provided with a feeding mechanism, a conveying mechanism and a discharging mechanism in the flowing direction of products; a material distributing mechanism is arranged between the feeding mechanism and the conveying mechanism; the rack is sequentially provided with a terminal plug opening mechanism and two gluing mechanisms at one side of the conveying mechanism in the flowing direction of the products; the two gluing mechanisms are symmetrically arranged along the conveying mechanism; jacking mechanisms are arranged at the positions, located on the gluing mechanisms, of the inner side of the conveying mechanism; and the rack is provided with first sensors located at one sides of the gluing mechanisms. According to the automatic two-end gluing machine, glue dispensing can be carried out on two ends of the products, a plurality of glue dispensing mechanisms are arranged, and a plurality of products can be glued at the same time, so that the working efficiency is improved; and a glue pushing mechanism and a glue amount precision control table are used, so that the glue outlet amount can be more precisely controlled, gluing is more uniform, and the gluing quality is improved.

Owner:苏州博奕精工科技有限公司

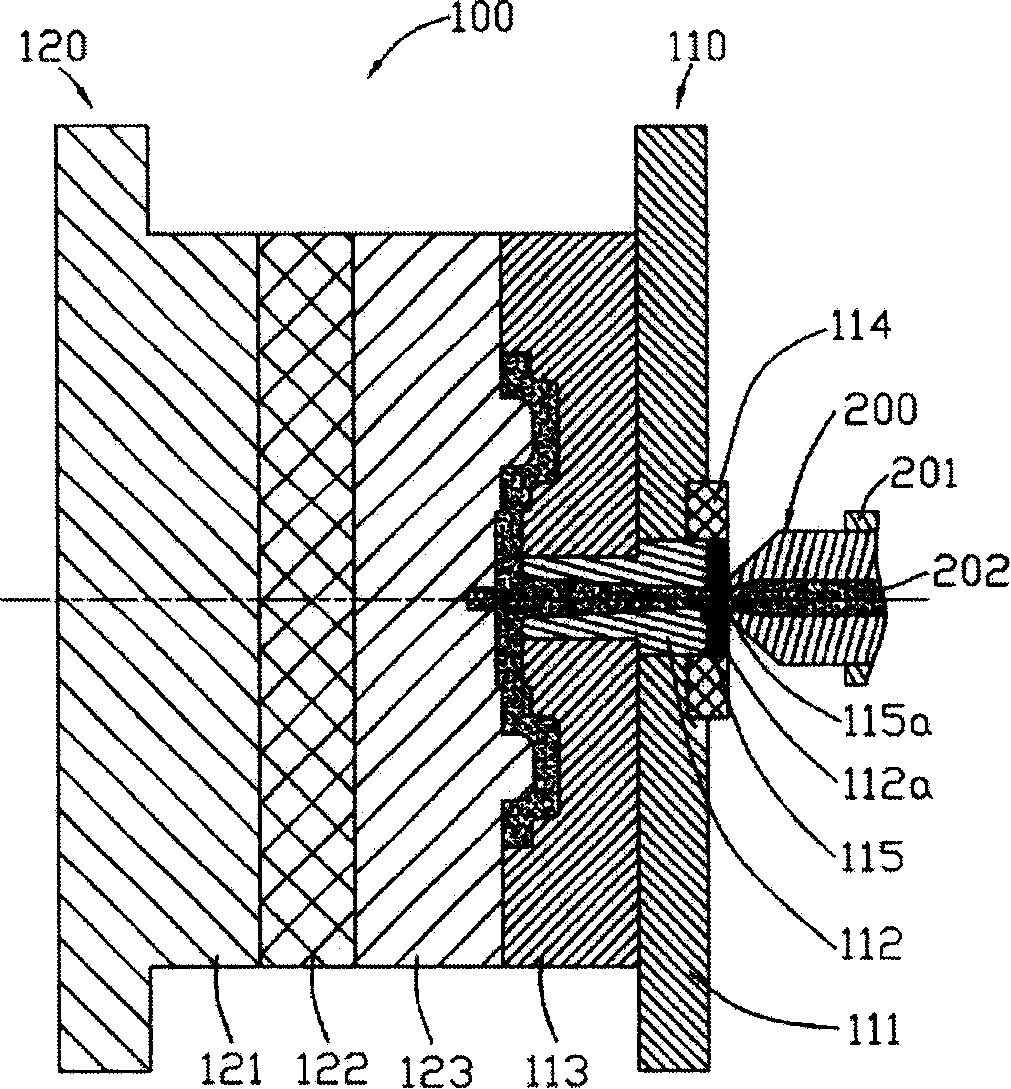

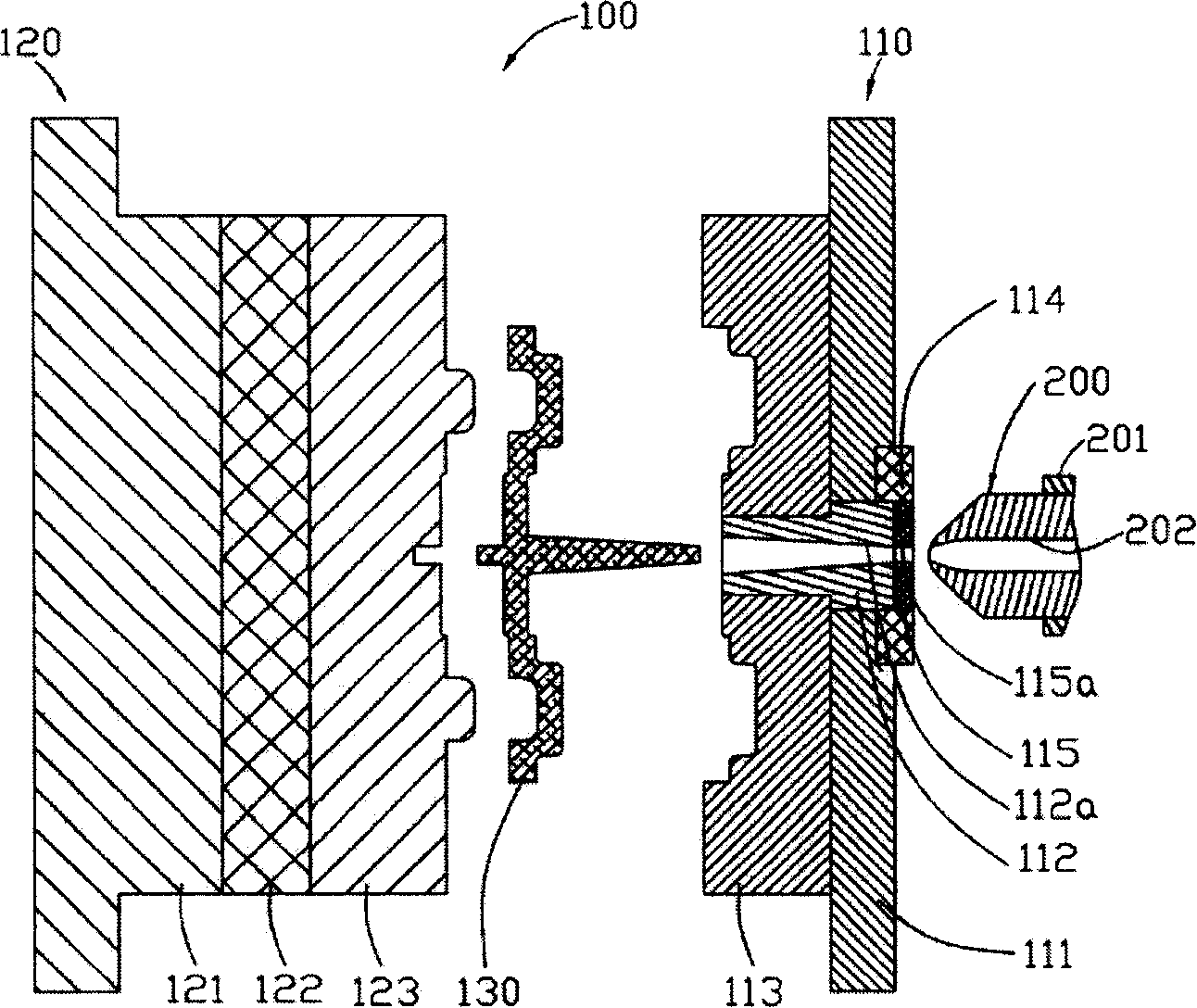

Ejection shaping die

The present invention provides an ejection forming mould. Said mould includes a mould base body, said mould base body possesses an injection channel liner, on the external surface of said injection channel liner which is used for matching with ejection machine nozzle a heat-insulating layer is set. In the invented technical scheme said heat-insulating layer can isolate most of heat quantity released from nozzle and transferred to the mould and can ensure cooling effect of mould cooling system, therefore it can avoid the production of superhigh temperature in mould injection channel and can prevent the moulded product from producing wire-drawing phenomenon.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Dispensing machine for semiconductor

ActiveCN114042601AEasy to fallAvoid self-fallPretreated surfacesCoatingsAdhesive glueMechanical engineering

The invention relates to the technical field of semiconductor processing equipment, and particularly relates to a dispensing machine for a semiconductor. The machine comprises a machine body, a conveyor is mounted on the top surface of the machine body, a support is fixedly connected to the top of the machine body, a dispensing device is mounted on one side of the support, and a supporting sleeve is fixedly connected to the bottom surface of the dispensing device. And a glue dispensing column is slidably connected into the supporting sleeve, a plurality of glue dispensing pipes are arranged in the glue dispensing column, and the bottom surfaces of the glue dispensing pipes communicate with a glue dispensing nozzle. According to the invention, glue is pushed and injected through air pressure and moves to the glue dispensing nozzle through the glue dispensing pipes, the glue dispensing nozzle moves out of the supporting sleeve to achieve glue dispensing, after glue dispensing is finished, the glue dispensing column drives the glue dispensing pipe and the glue dispensing nozzle to return to the initial position under driving of the reset mechanism, and at the moment, the transmission mechanism drives the opening and closing mechanism to be closed to achieve the purpose that the glue dispensing nozzle is protected in the supporting sleeve; and the glue dispensing nozzle is protected, direct contact between the glue dispensing nozzle and the surface of a device is reduced, and the phenomenon of glue wire drawing is reduced.

Owner:江苏卓远半导体有限公司

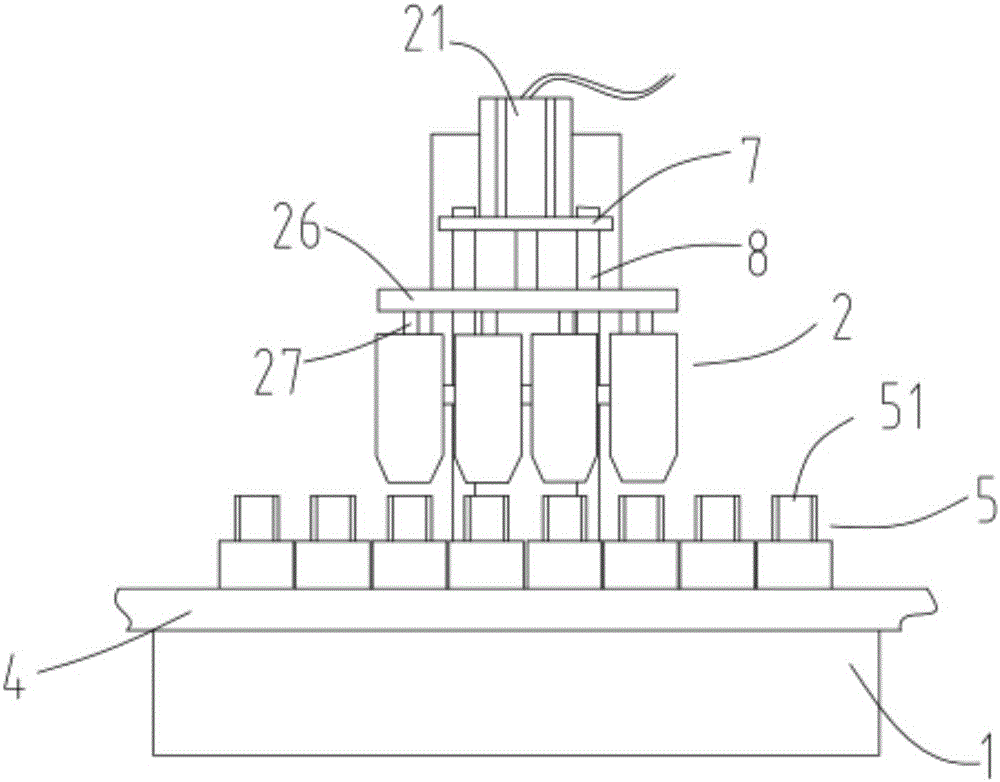

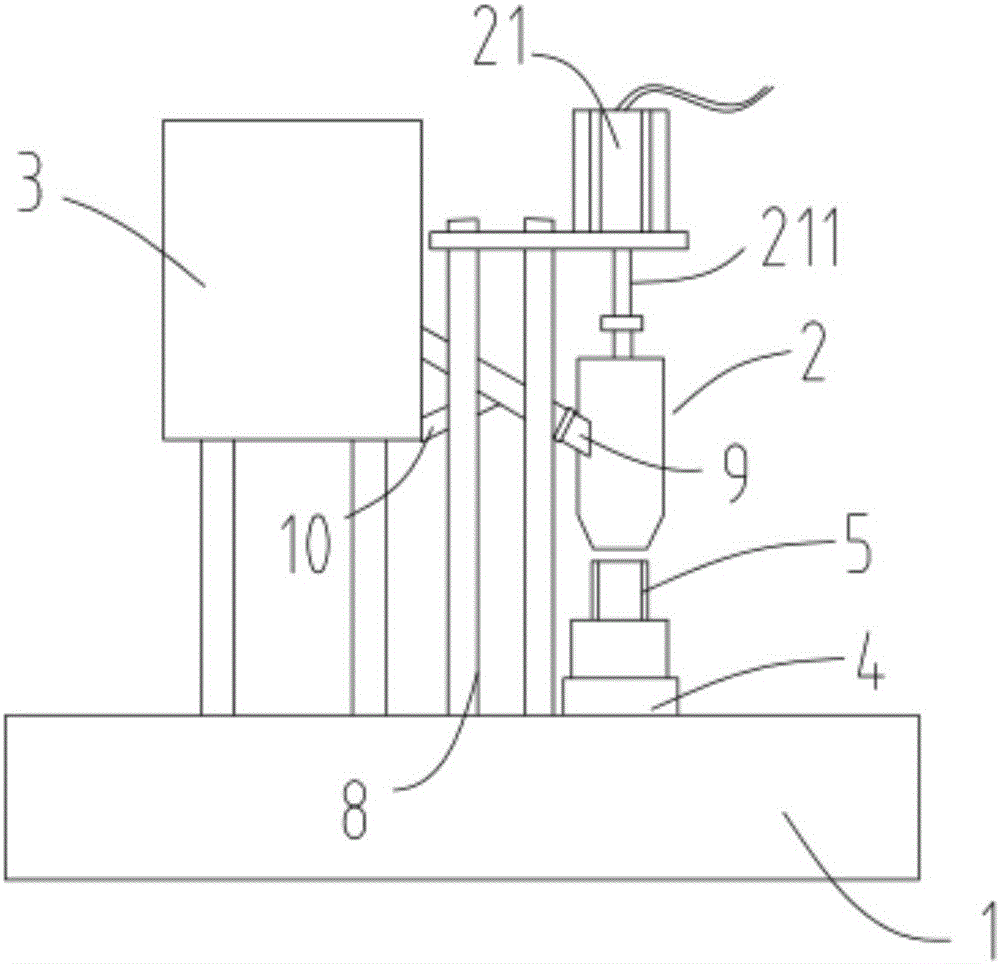

Equipment for uniformly injecting glue into battery

ActiveCN105789649AAvoid drippingReduce length of stayPrimary cell manufactureCell sealing materialsInjectorEngineering

The invention relates to equipment for uniformly injecting glue into a battery. The equipment comprises a bearing platform, a plurality of glue injecting components, a tank and an incoming material component, wherein the plurality of glue injecting components are arranged in parallel at equal intervals; the tank is used for storing glue; the incoming material component carries a plurality of battery steel shells; the glue injecting components vertically correspond to glue injecting openings of the battery steel shells; each of the glue injecting components comprise a power part, a pressing plate, a discharge rod, a glue injecting bucket and a material guide column; the pressing plates are arranged on top rods of the power parts; the discharge rods are arranged on the pressing plates; the material guide columns are arranged at the end parts of the discharge rods in a sleeving manner; the discharge rods can slide upwards and downwards relative to the inner walls of the material guide columns; the material guide columns are fixed on the glue injecting buckets; a semicircular material guide hole is formed in the end part of each discharge rod; a discharge hole is formed in each material guide column. By adopting the equipment, the problems that in the battery glue injecting process, the sealing property of a battery can be affected as the flowability is poorer as glue can be relatively greatly affected by the external environment, the glue injecting process is slow, the glue cannot be uniformly injected and distributed, and an injector can be easily blocked, are overcome.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

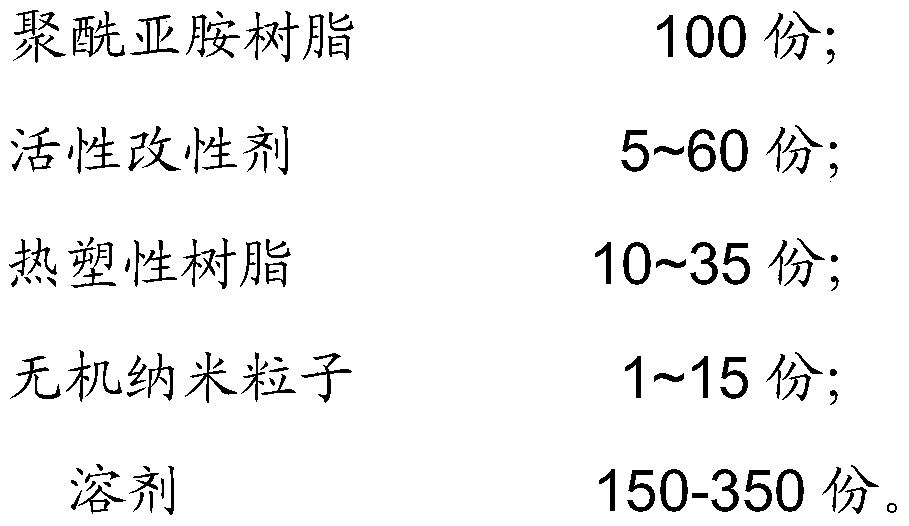

High-temperature-resistant honeycomb core strip adhesive and preparation method and application thereof

ActiveCN111574953AGood workmanshipReduce energy consumptionNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesHoneycombPolymer chemistry

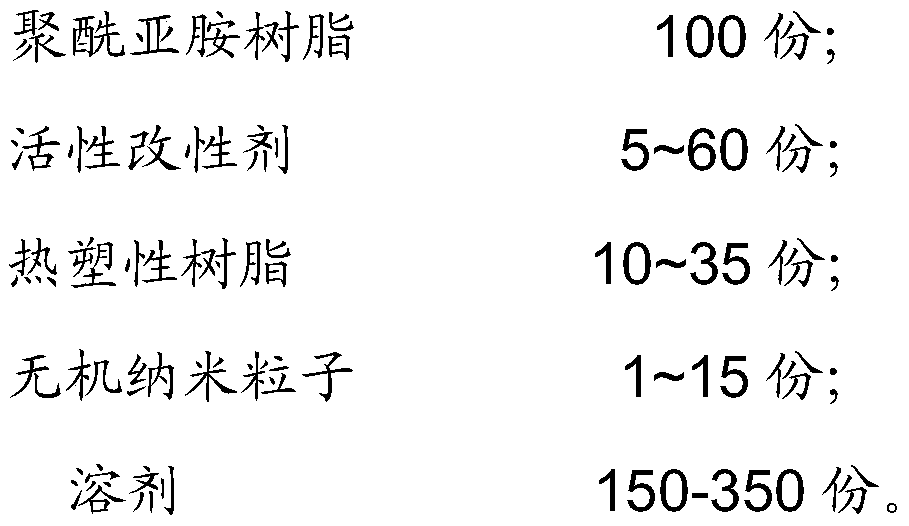

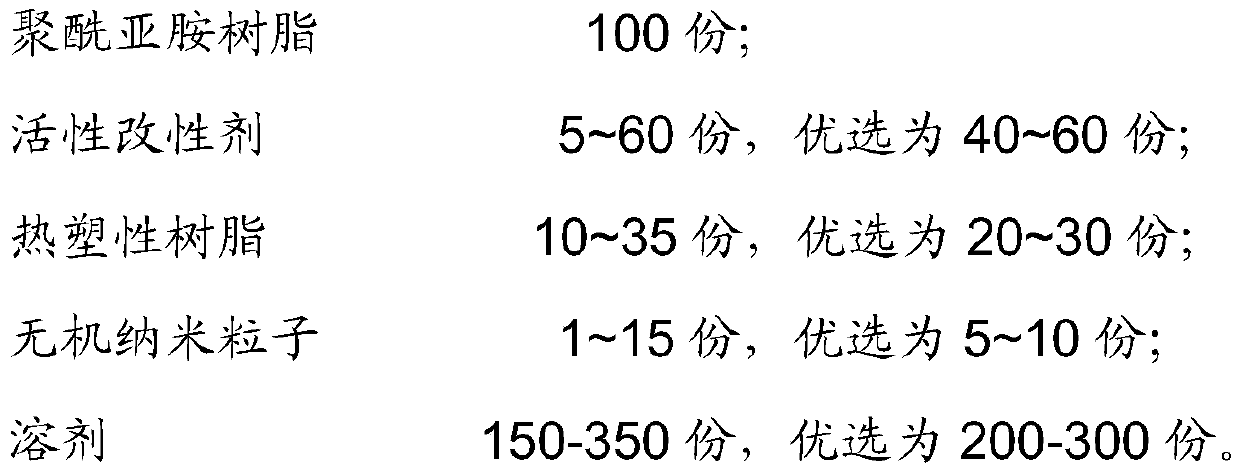

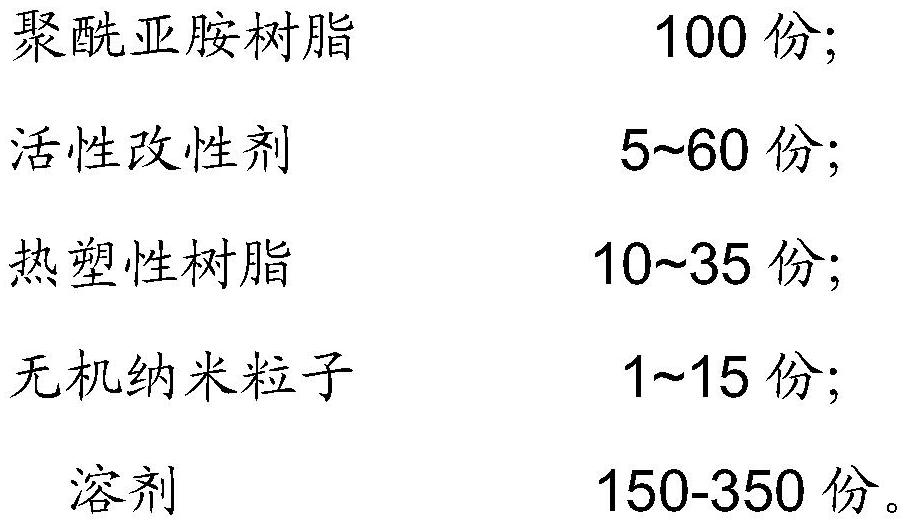

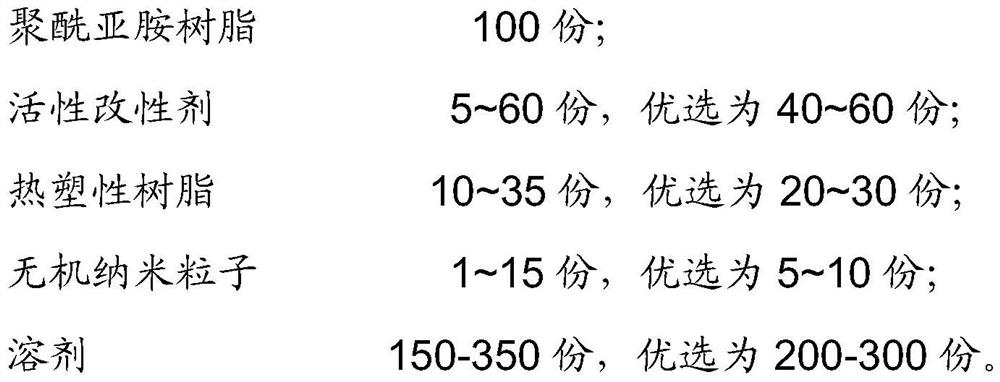

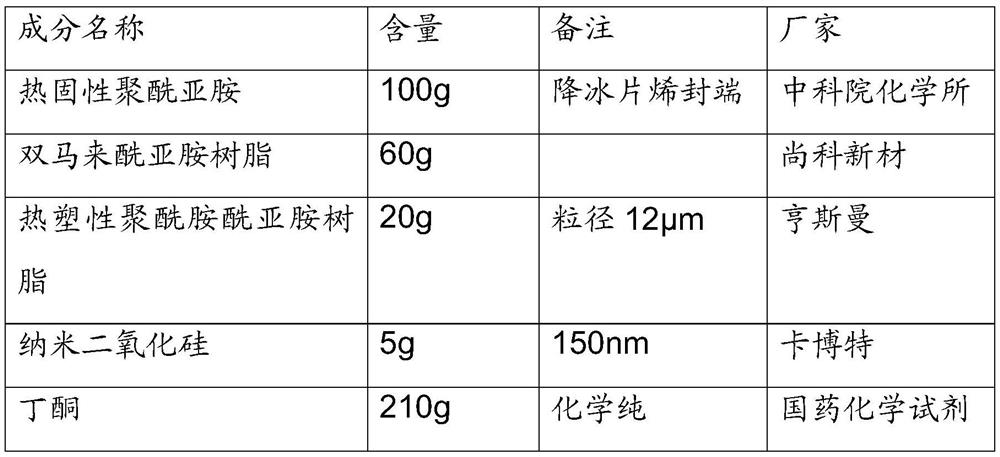

The invention provides a high-temperature-resistant honeycomb core strip adhesive and a preparation method and application thereof, and belongs to the technical field of honeycomb core material preparation. The core strip adhesive is prepared from the following components in parts by mass: 100 parts of polyimide resin; 5-60 parts of an active modifier; 10-35 parts of thermoplastic resin; 1-15 parts of inorganic nanoparticles; 150-350 parts of solvent. The preparation method comprises the following steps: adding 1 / 4-1 / 3 of the thermoplastic resin into the active modifier, dissolving at 100-150DEG C, cooling to below 80 DEG C, adding the remaining thermoplastic resin and inorganic nanoparticles into the active modifier, and stirring and dispersing to obtain a component A; and adding polyimide resin and the component A into a solvent for dissolving and dispersing under a room-temperature stirring condition to obtain the uniform and stable honeycomb core strip adhesive. The core strip adhesive has the characteristics of good manufacturability, low curing temperature, high temperature resistance, excellent mechanical properties and the like, and is especially suitable for preparation of ultrathin glass cloth honeycombs.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

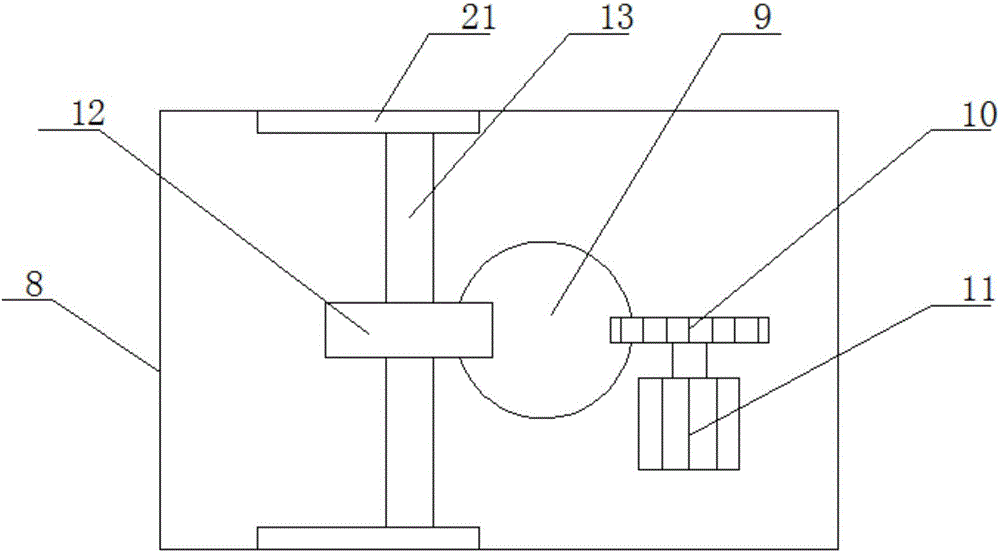

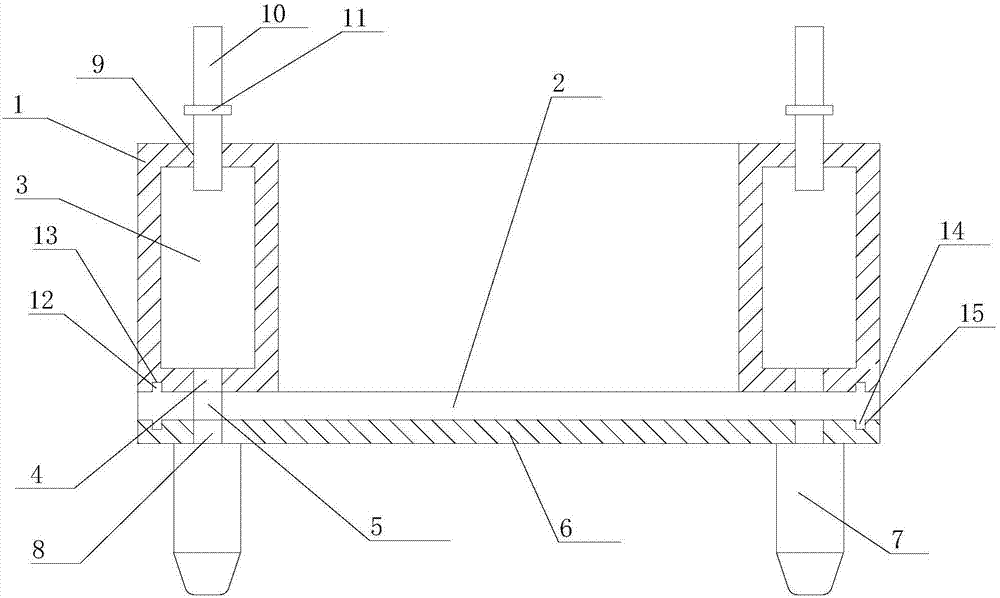

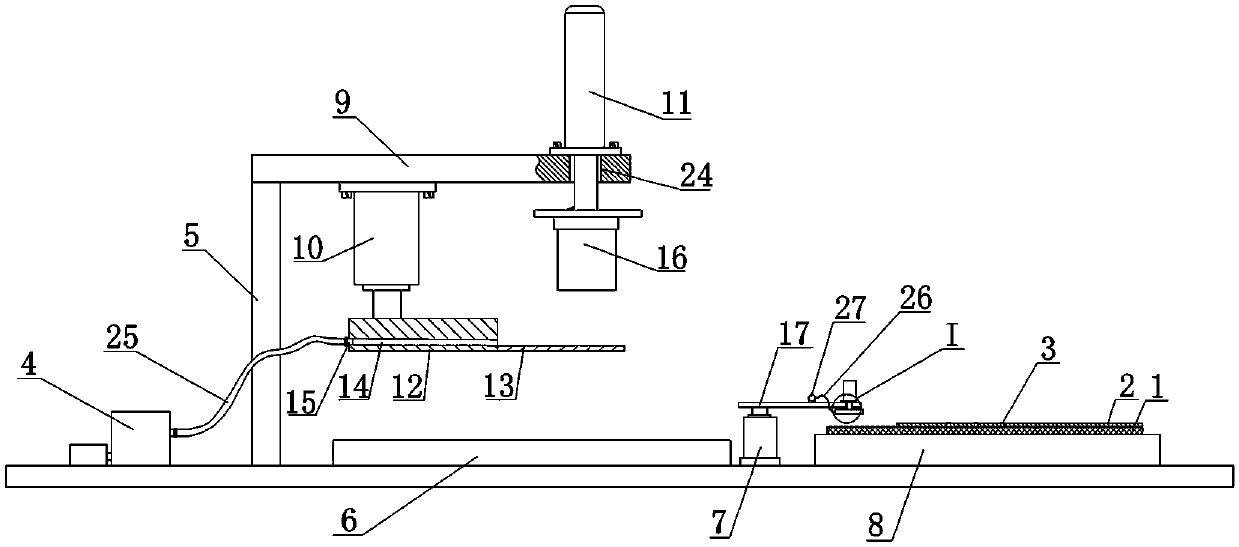

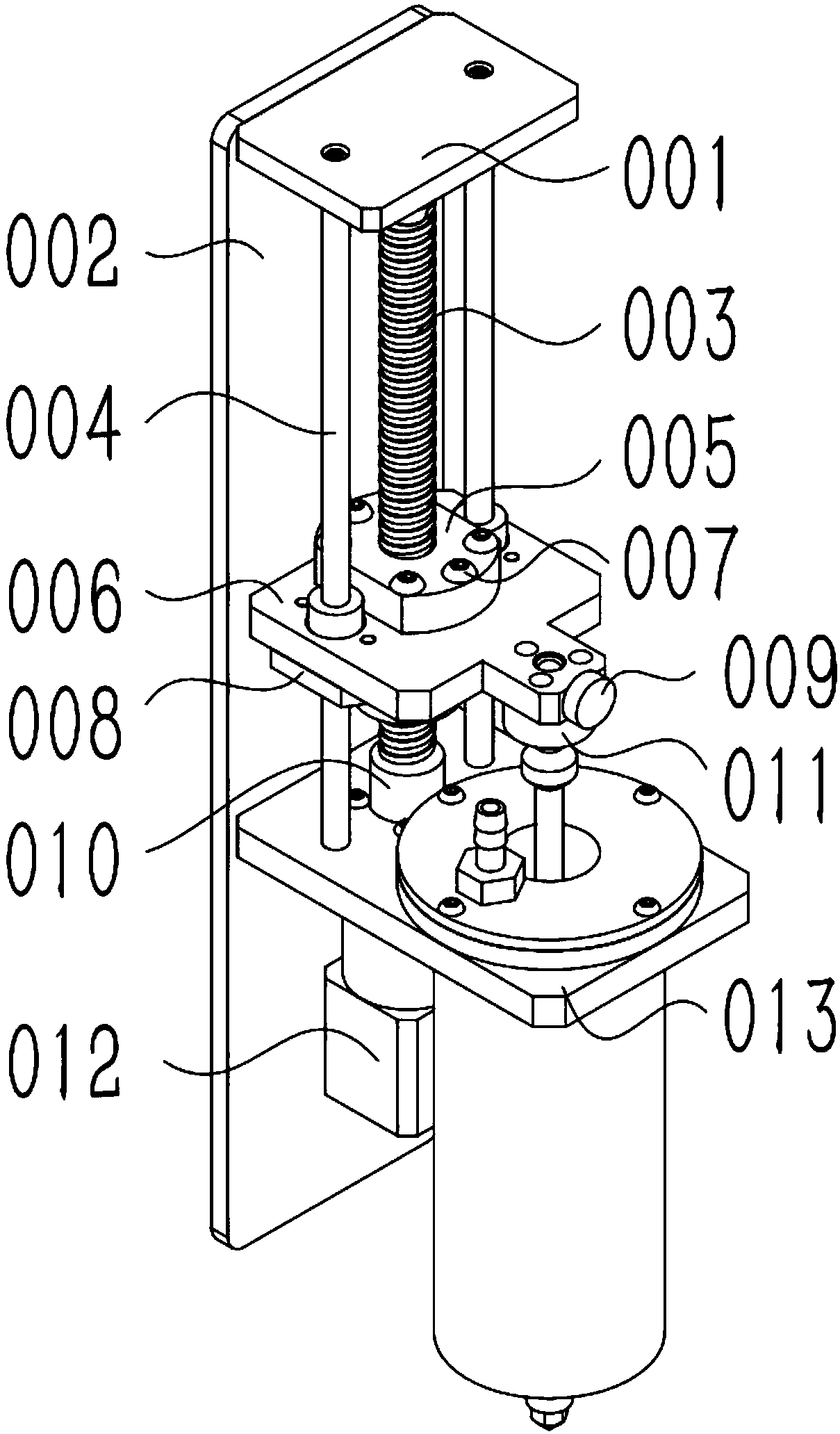

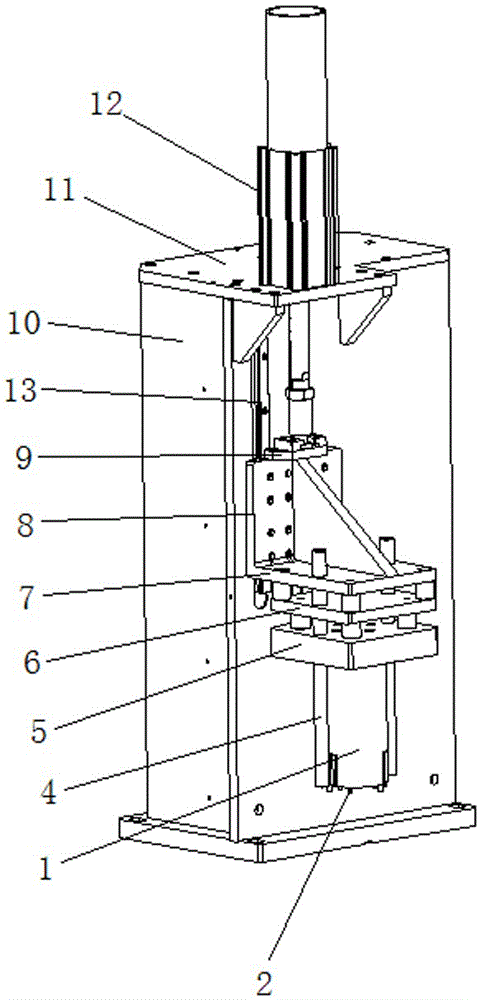

Heat-conduction riveting equipment

The invention discloses heat-conduction riveting equipment. The equipment comprises an air compressor (4), a machine frame (5), a workbench (6), a rotating air cylinder (7) and a loading platform (8)which are arranged successively from left to right; the top of the machine frame (5) is provided with a cross beam (9) on which a vertically arranged cylinder A (10) and a cylinder B (11) are fixedlyinstalled, a piston rod of the cylinder A (10) is provided with a pressure head (12), the bottom surface of a copper sheet (13) is flush with the bottom surface of the pressure head (12), the pressurehead (12) is internally provided with an air flow passage (14) formed in the upper portion of the copper sheet (13), the air flow passage (14) tilts down to the right, the left end of the air flow passage (14) is provided with a joint I (15), the joint I (15) is connected with the outlet end of the air compressor (4) through a pipe clamp. The equipment has the advantages of not cutting off a power supply of a heating head, saving energy consumption, improving the processing efficiency, effectively avoiding the occurrence of a drawing phenomenon, and being safe and reliable.

Owner:CHENGDU HOMIN TECH

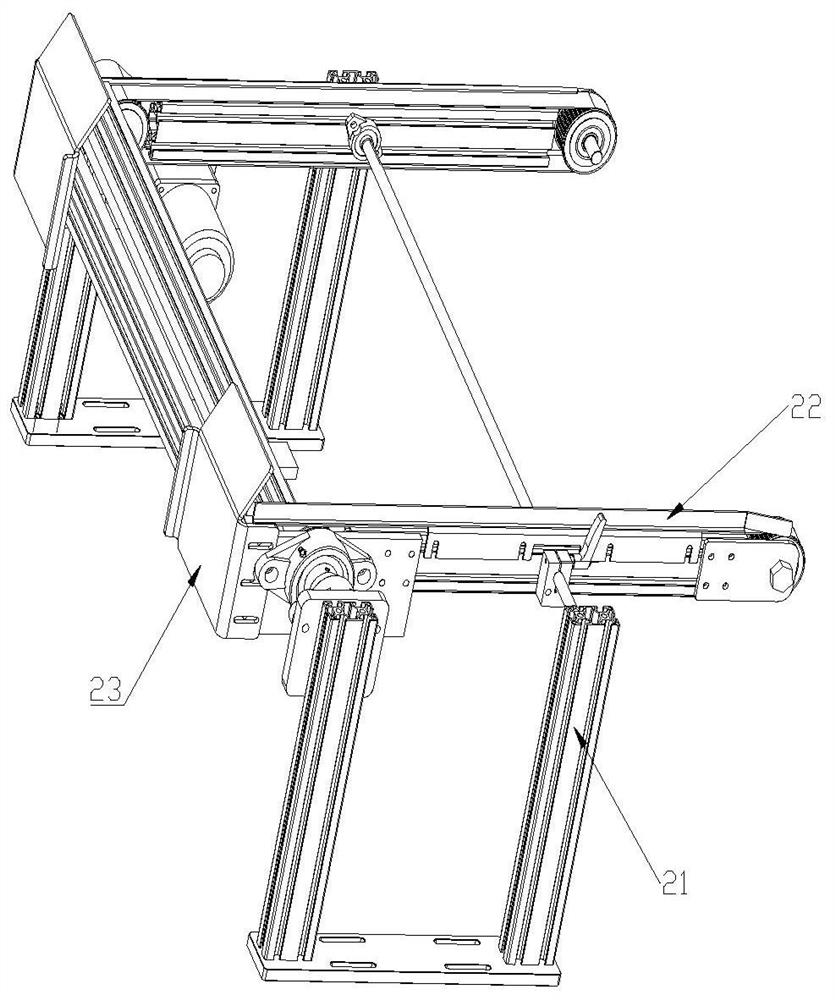

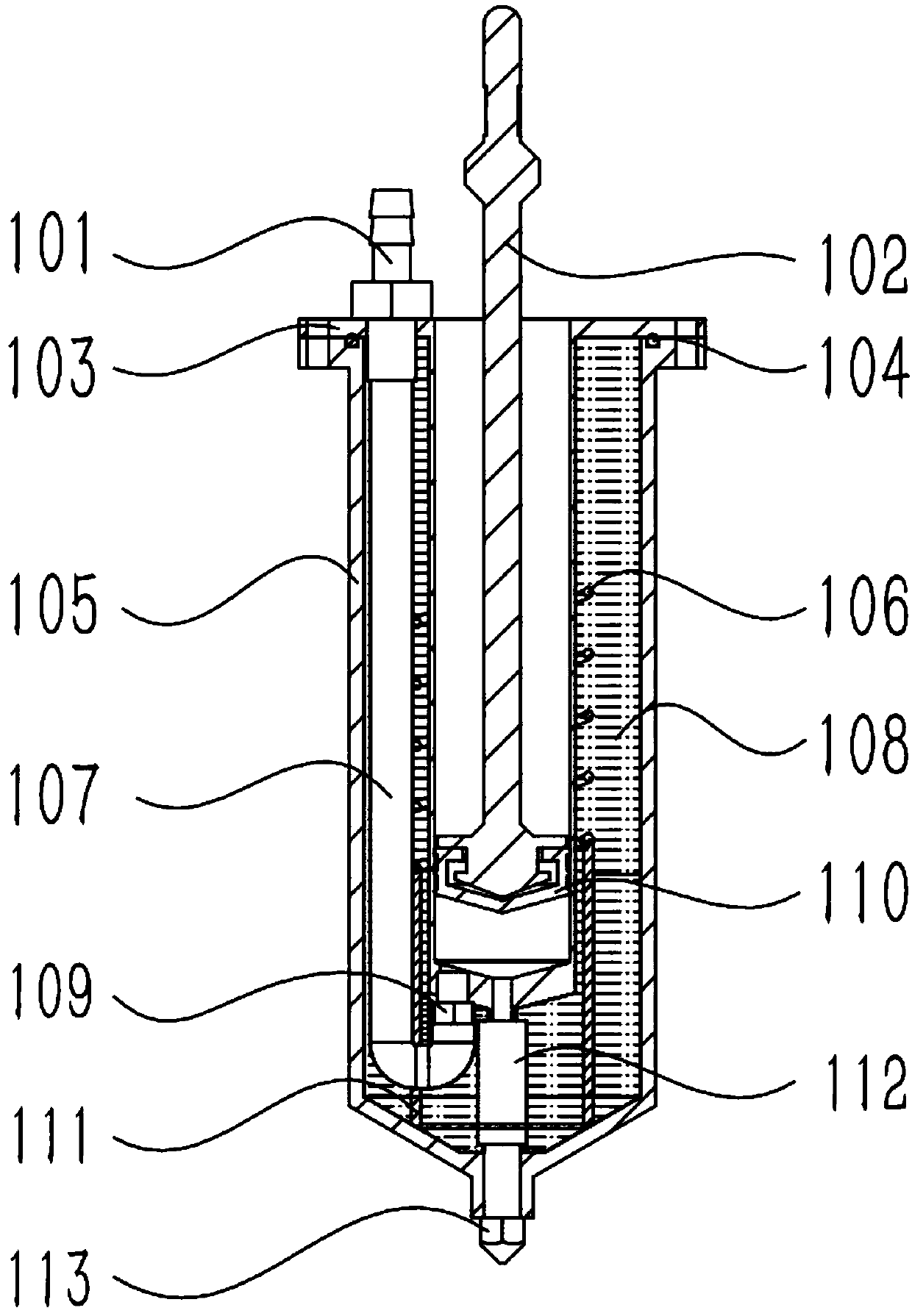

Half-fluid food 3D printer extrusion system

ActiveCN107752113APrecise temperature controlNot prone to cloggingFood shapingTemperature controlComputer printing

The invention relates to the technical field of 3D printing and in particular relates to a half-fluid food 3D printer extrusion system which comprises a power conveying module, a power conveying module, a pull type conveying module, a temperature control module, a screw rod fixing plate, a motor fixing base and an extrusion system back plate, wherein the upper end of the power conveying module isconnected with the screw rod fixing plate; the lower end of the power conveying module is connected with the motor fixing base; the screw rod fixing plate is fixedly connected with the upper end of the extrusion system back plate; the motor fixing base is fixedly connected with the lower end of the extrusion system back plate; the power conveying module is connected with the pull type conveying module; and the pull type conveying module is connected with the temperature control module. The invention provides the half-fluid food 3D printer extrusion system which is capable of feeding materialscontinuously, precise in temperature control and not liable to cause nozzle blocking phenomena.

Owner:深圳翱诺科技有限公司

Ultrasonic hot melting device and method

The invention discloses an ultrasonic hot melting device and method. The ultrasonic hot melting device comprises a surrounding-type heating assembly and an ultrasonic molding assembly. The surrounding-type heating assembly comprises a heating mould; one or more heating mould heads are arranged at the bottom of the heating mould; each heating mould head is a tubular body with the inside hollowed and the periphery closed; the dimension of the hollowed part of each tubular body is matched with the external dimension of a hot melting part of a workpiece; and before preheating, surrounding-type preheating is conducted after the hot melting part of the workpiece is sleeved with one tubular body from top to bottom. The ultrasonic molding assembly comprises an ultrasonic vibrator and a hot melting mould. The bottom of the ultrasonic vibrator is connected with the hot melting mould, and the bottom of the hot melting mould is provided with a plurality of hot melting mould heads used for press molding. The hot melting mould heads along with the hot melting mould are driven by the ultrasonic vibrator to conduct press molding. The ultrasonic hot melting device and method have the advantages that the heating is even without blind angles, the heating speed and the efficiency are high, the melting penetration effect is good, the hot melting mould is durable and long in service life, the surface of a product is full and good in degree of finish, and the tensile force of the product is sufficient.

Owner:HUIZHOU YIPIN TECH CO LTD

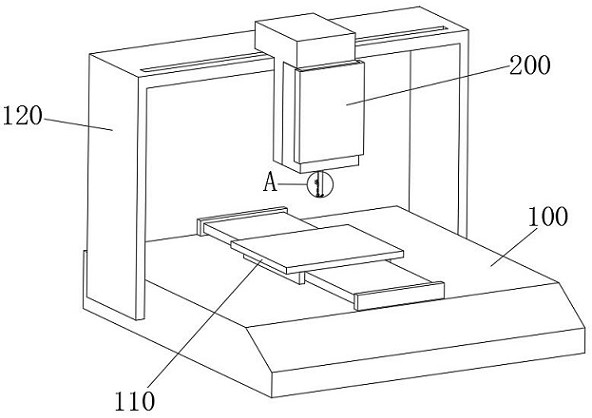

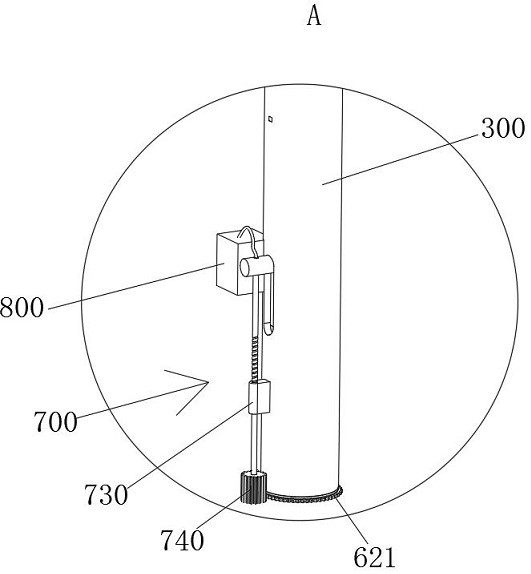

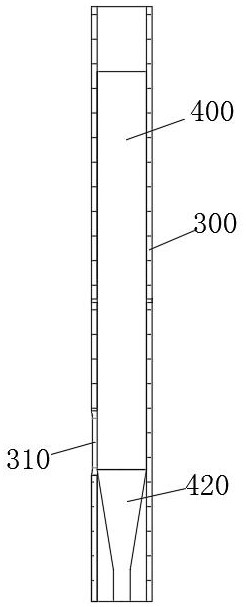

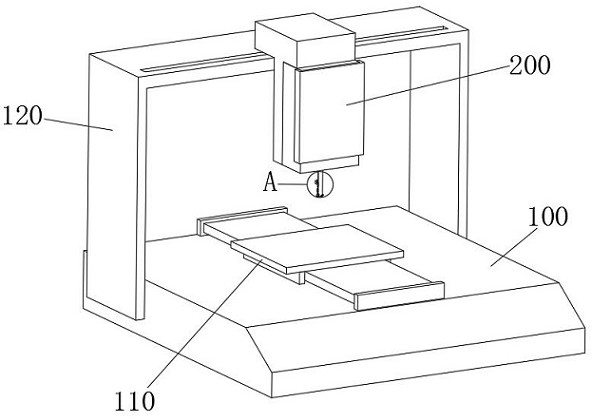

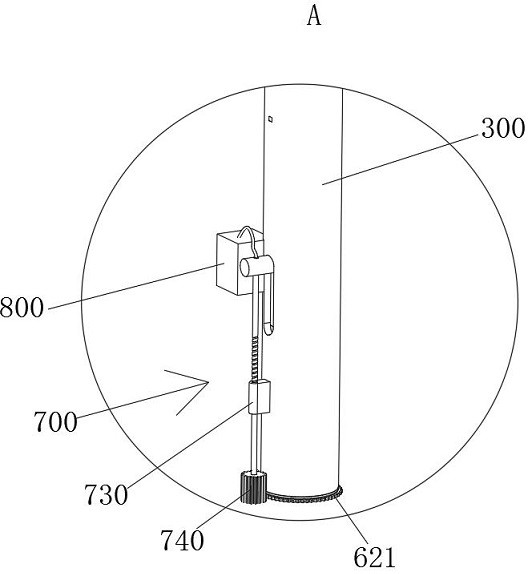

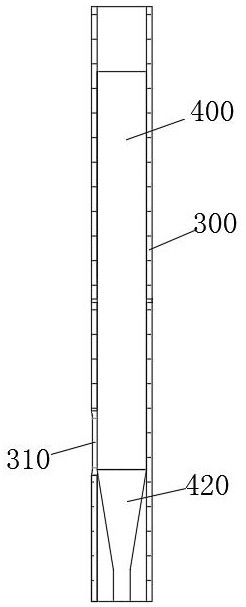

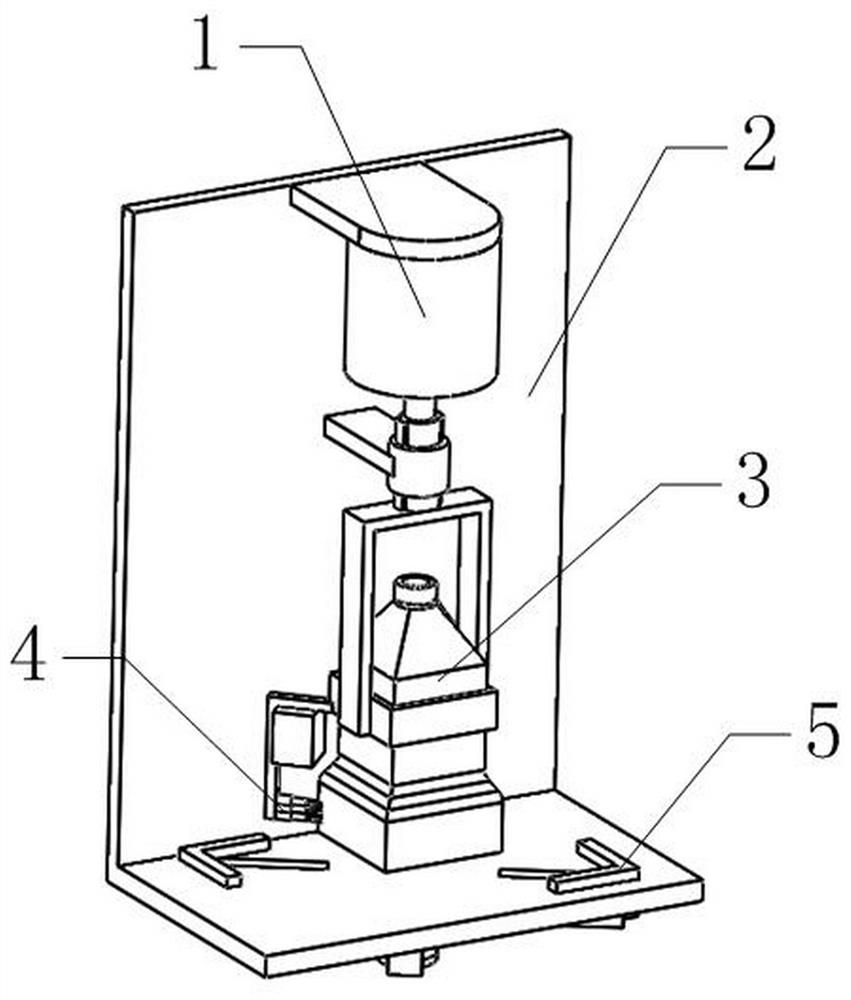

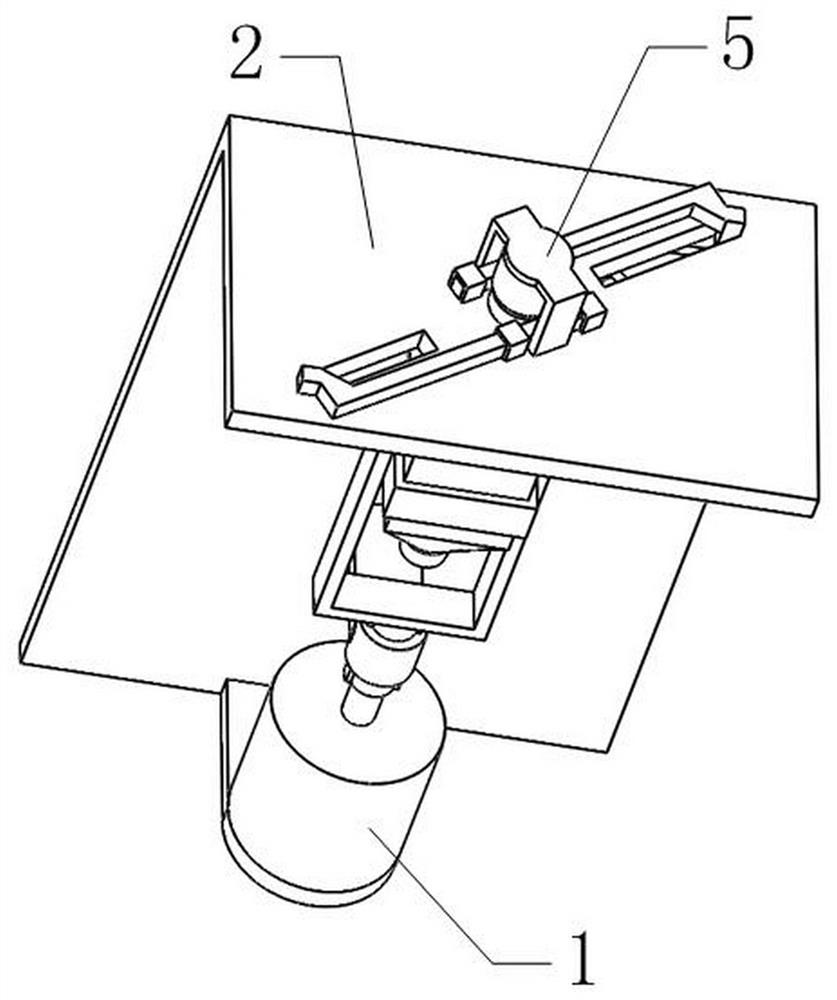

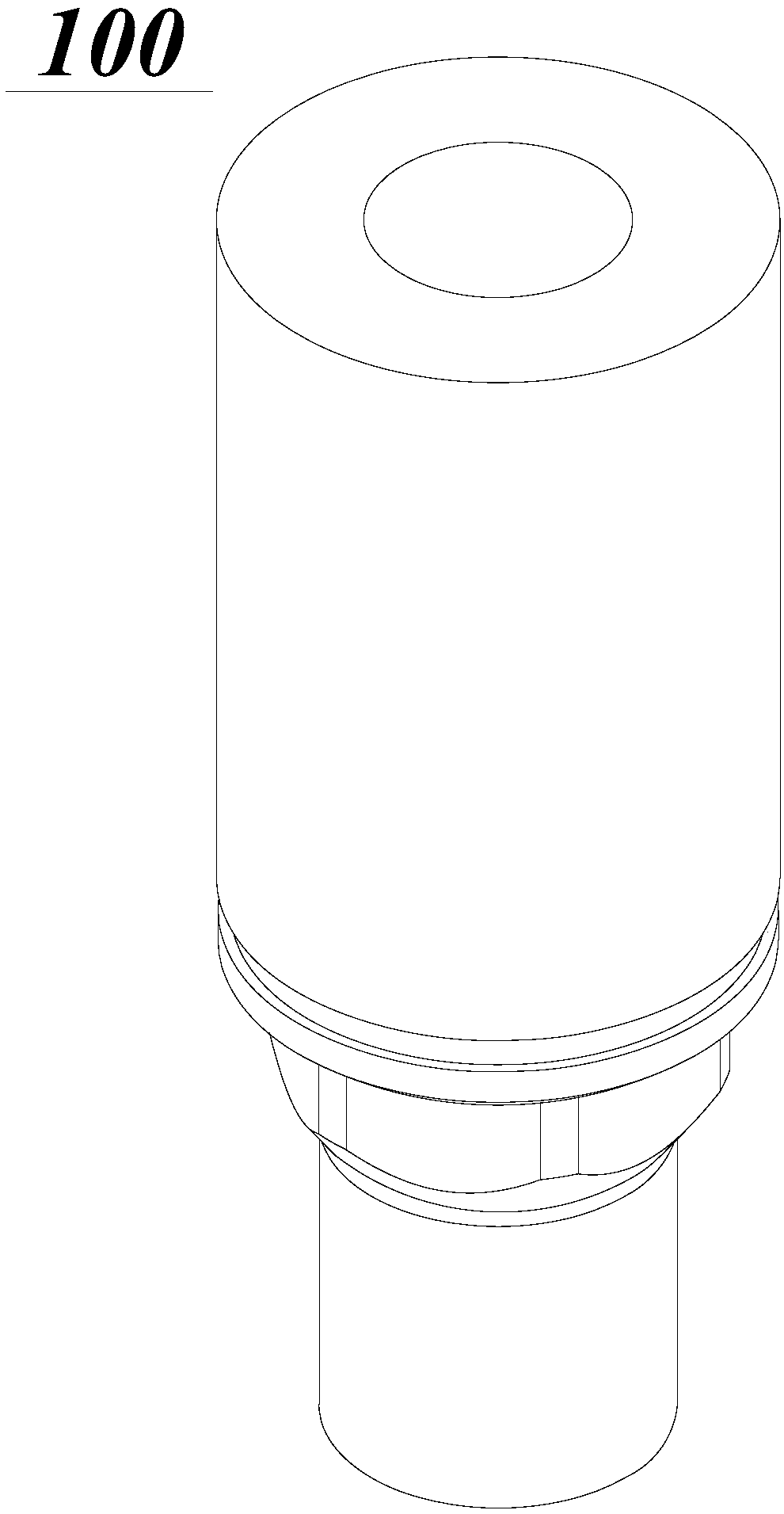

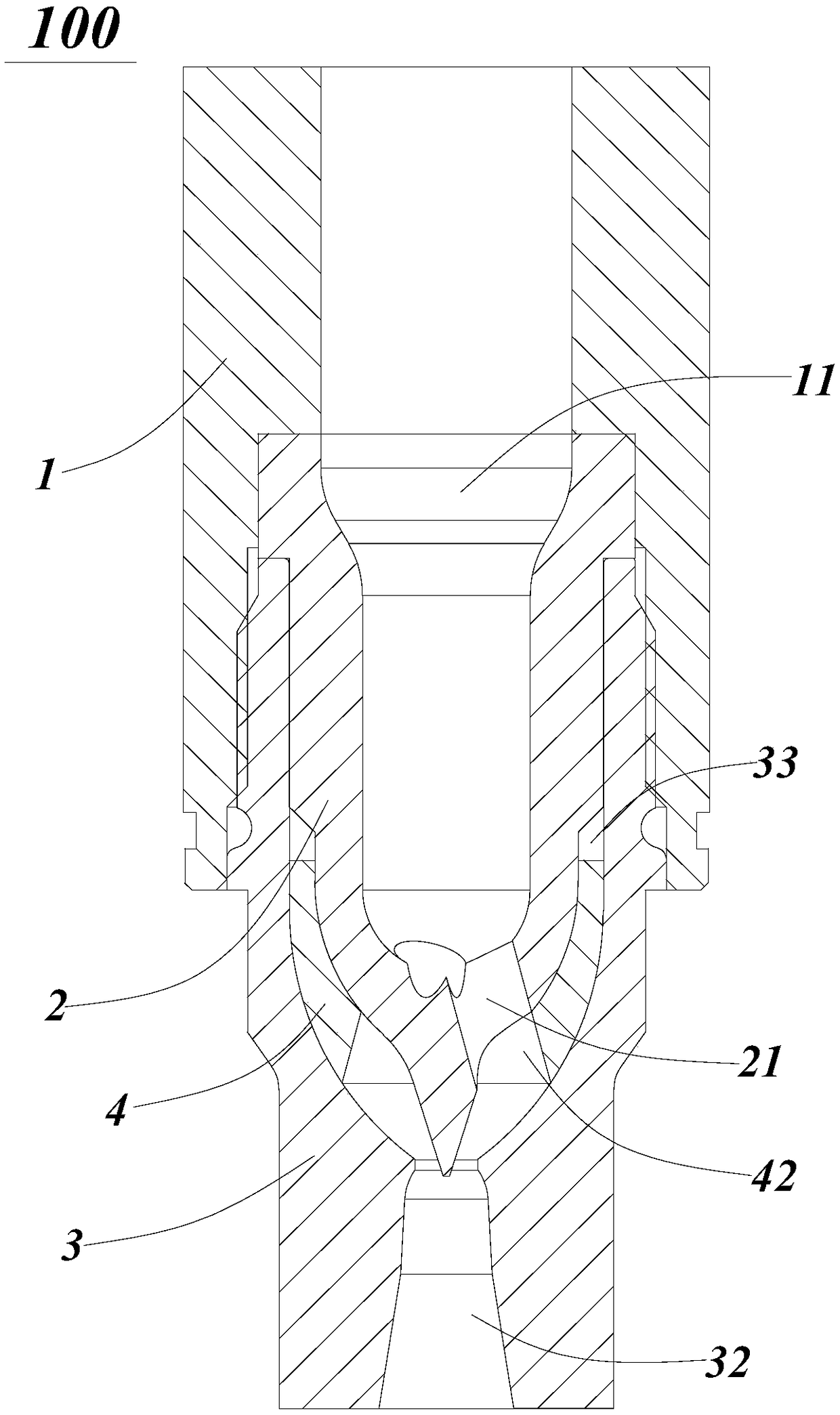

A 3D printing nozzle to prevent material leakage

ActiveCN106915074BAvoid passingAvoid drawing phenomenonAdditive manufacturing with liquids3D object support structuresEngineeringMonomer

Owner:宿州市徽腾知识产权咨询有限公司

Preparation method of transfer glue used for coating and coating method of transfer glue

ActiveCN103059803AReduce adhesionGood peeling effectLiquid surface applicatorsMacromolecular adhesive additivesEmulsionAdhesive

The invention relates to a preparation method of transfer glue used for coating and a coating method of the transfer glue. The preparation method is characterized by including the following steps: 1) mixing alcohol and water with a proportion of 1:1, stirring evenly and forming diluent; 2) mixing emulsion resin and organic heat curing poly methylurea resin with a proportion of 1: 0.005, stirring evenly and forming transfer glue adhesive; 3) mixing the diluent and the transfer glue with a proportion of 1:20, stirring evenly and obtaining the transfer glue. The coating method is characterized in that an anilox roller is adopted to feed the glue when coating is conducted, coating pressure is 0.2 MPa, pressure of a cooling cylinder is 0.3 MPa, and pressure of a drying tunnel is 0.2 MPa. The preparation method of the transfer glue used for the coating and the coating method of the transfer glue have the advantages that adhesive force of the transfer glue is poor, a peeling effect of an aluminum layer of transfer products is enhanced, integrity of patterns is protected, a phenomenon of silk drawing in the coating process is completely eradicated, and due to the fact that the way of feeding the glue through the anilox roller is adopted, the coating is even and easy to control.

Owner:SHANDONG TAIBAO PACKAGING PROD

Dispensing machine for semiconductor

Owner:江苏卓远半导体有限公司

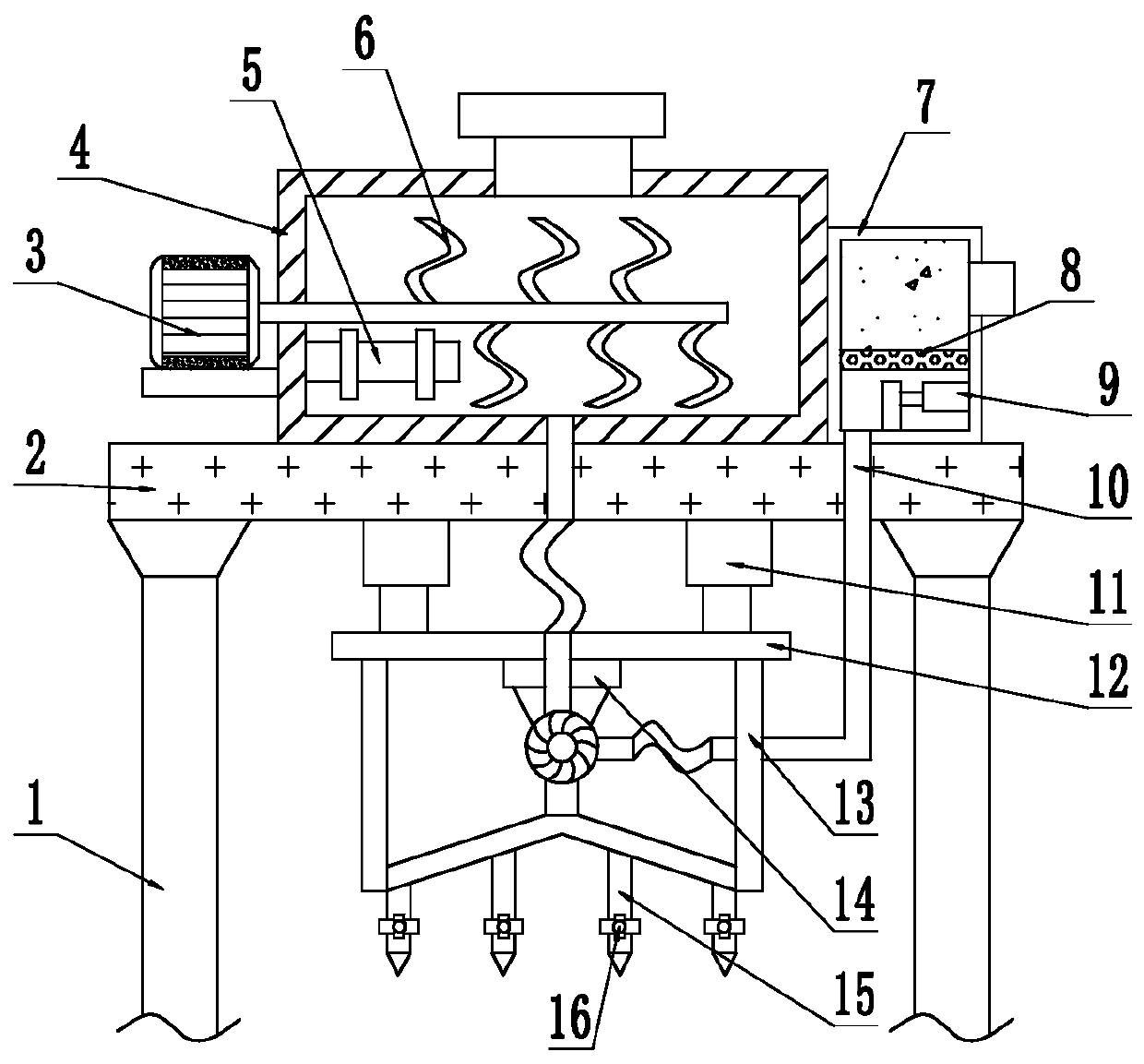

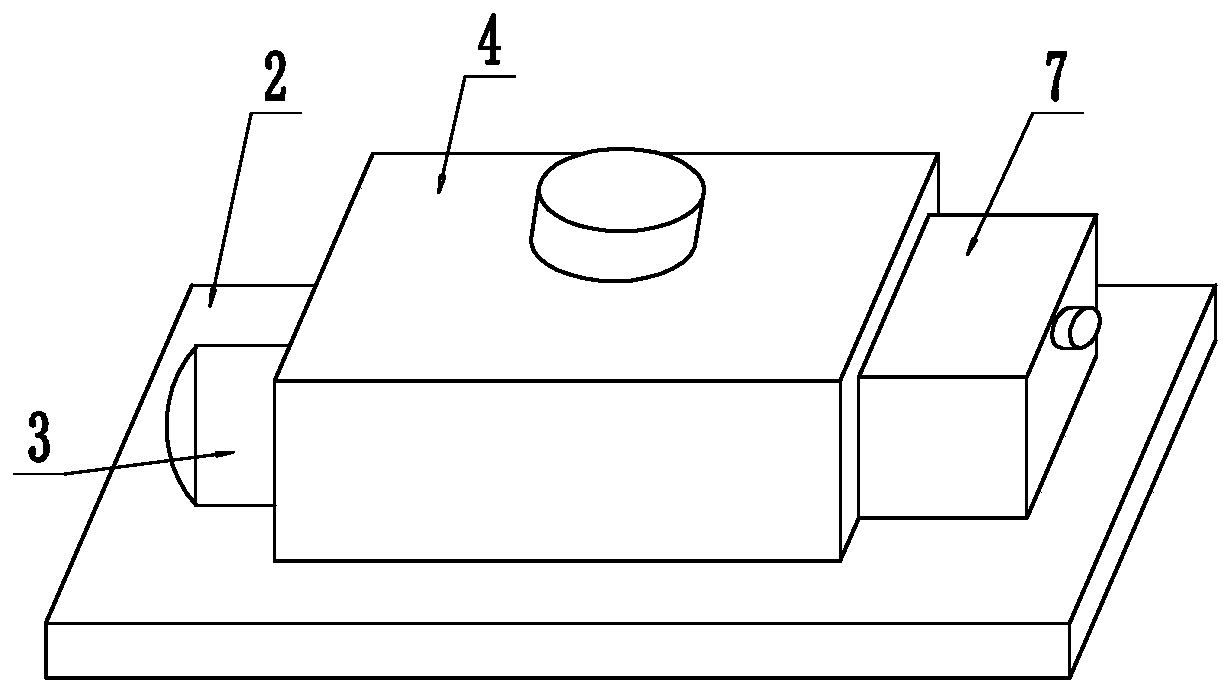

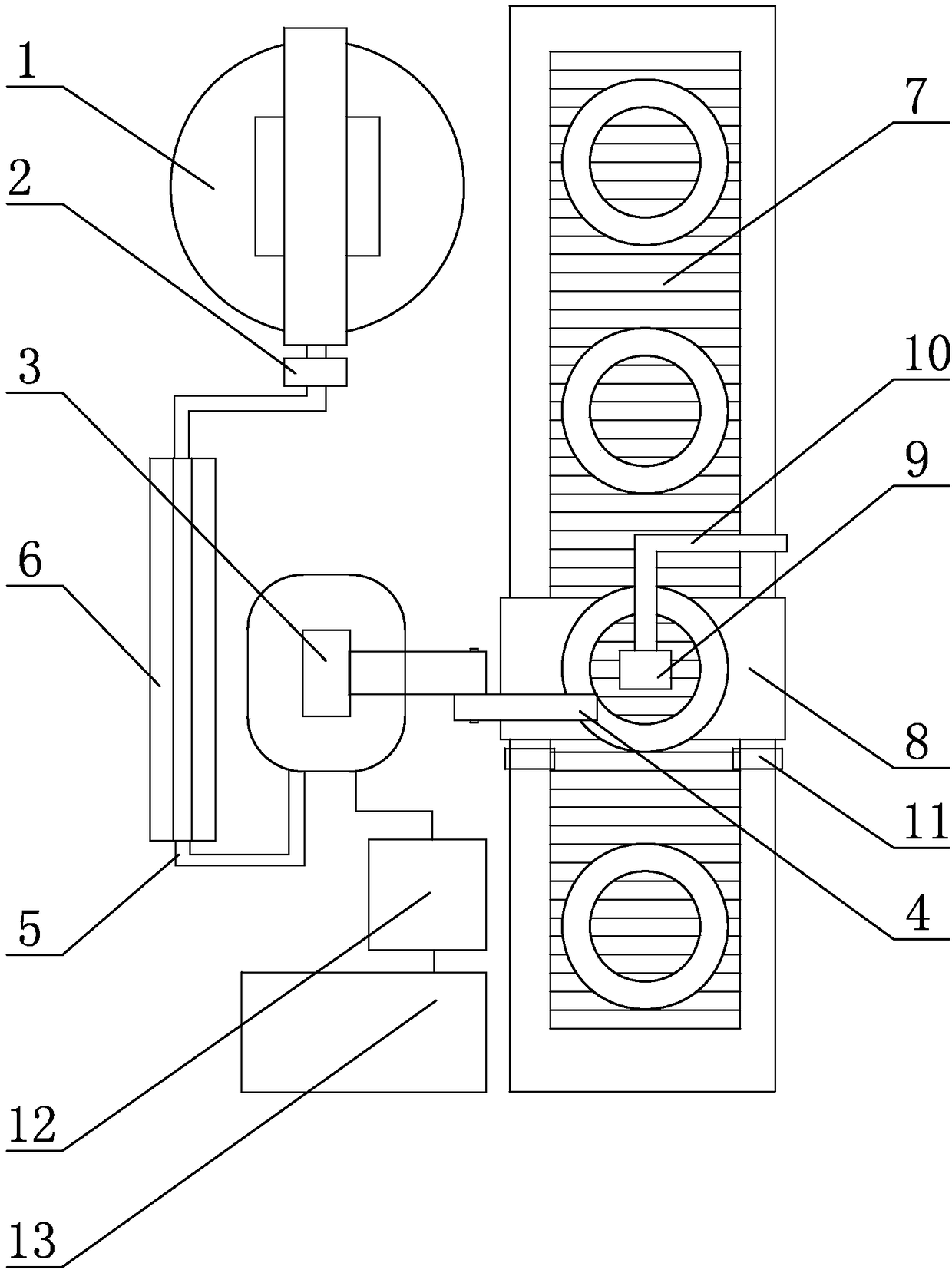

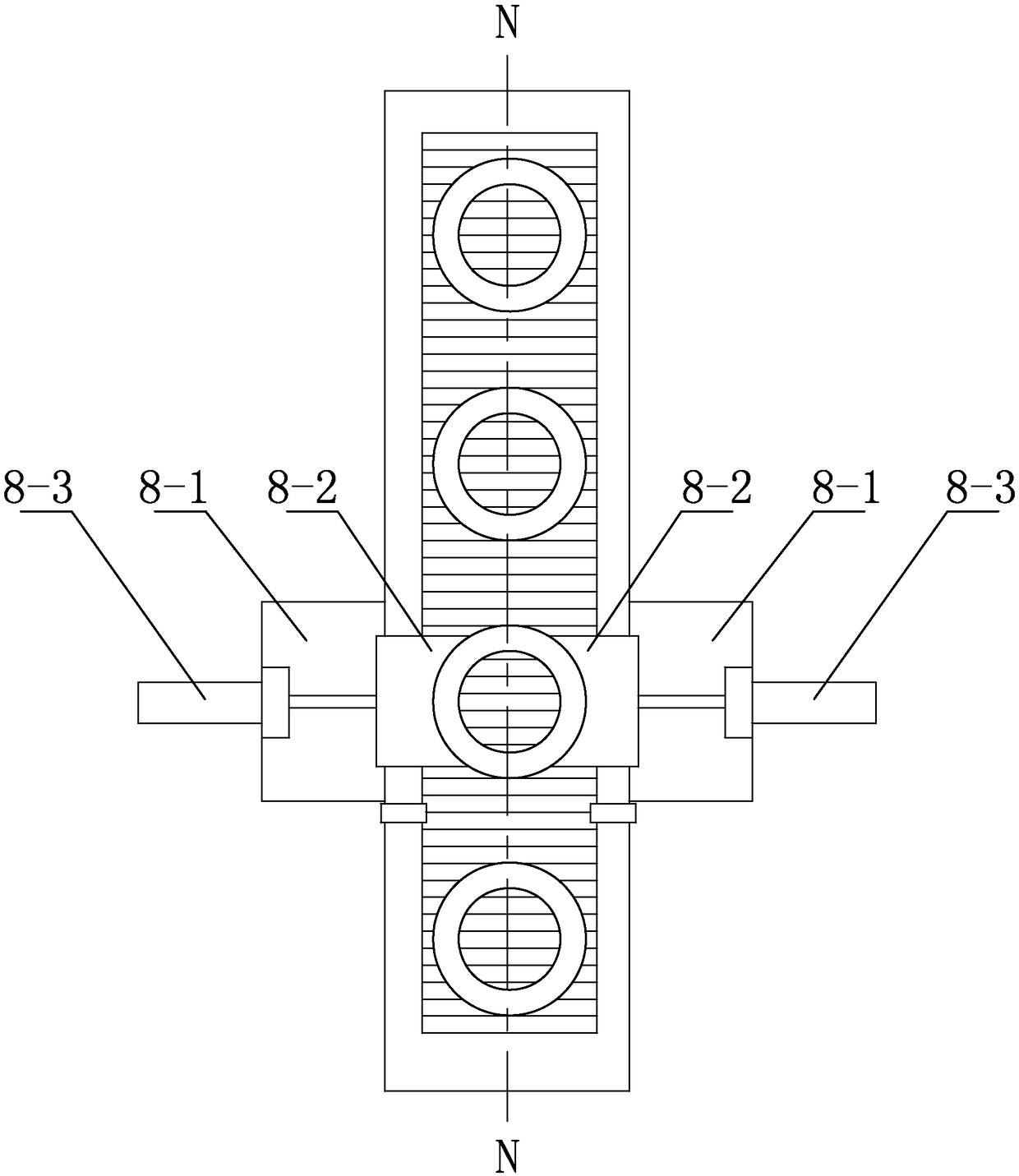

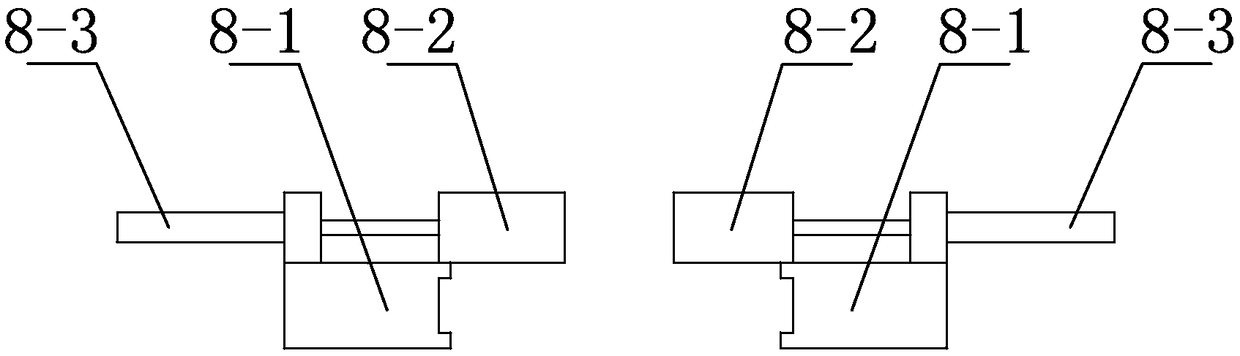

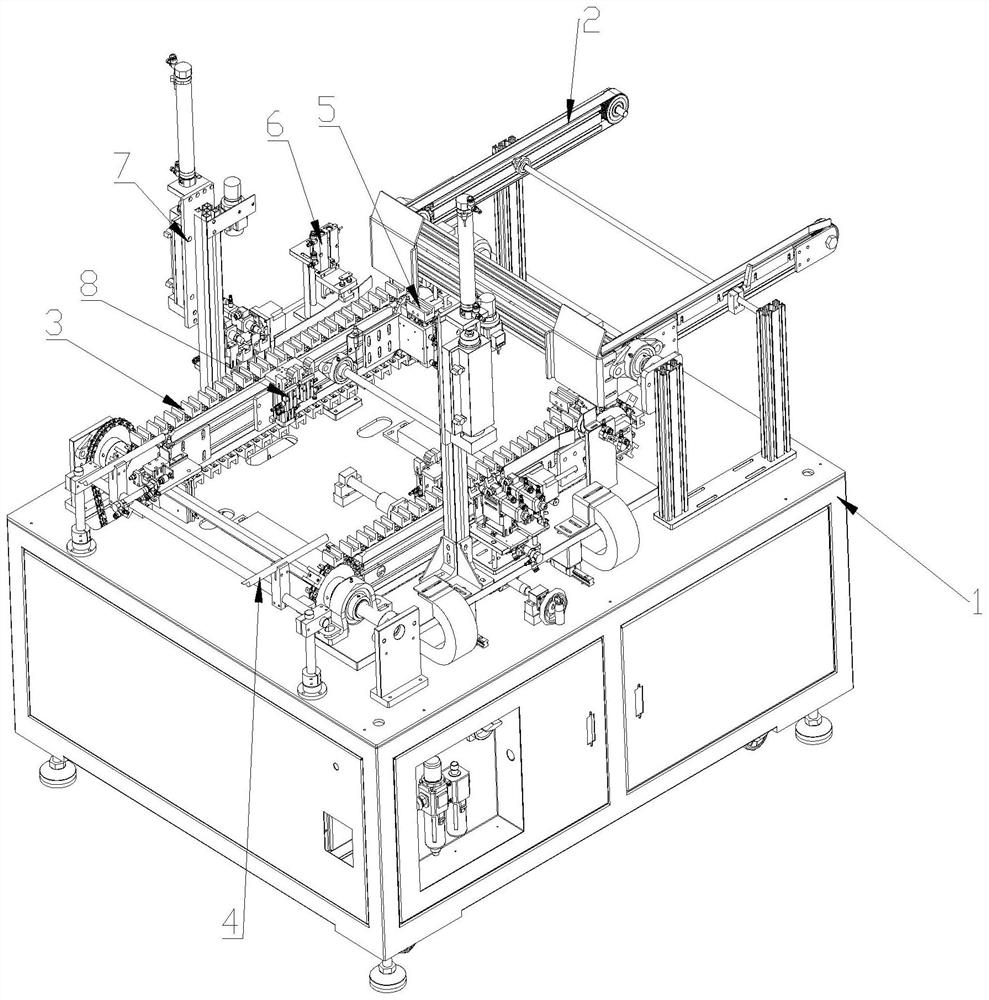

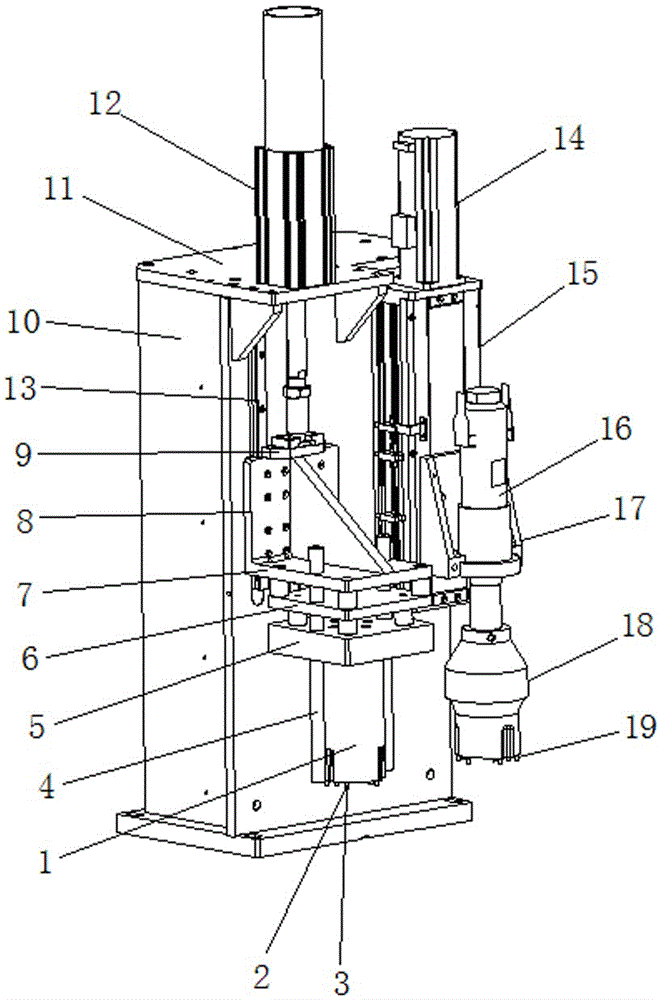

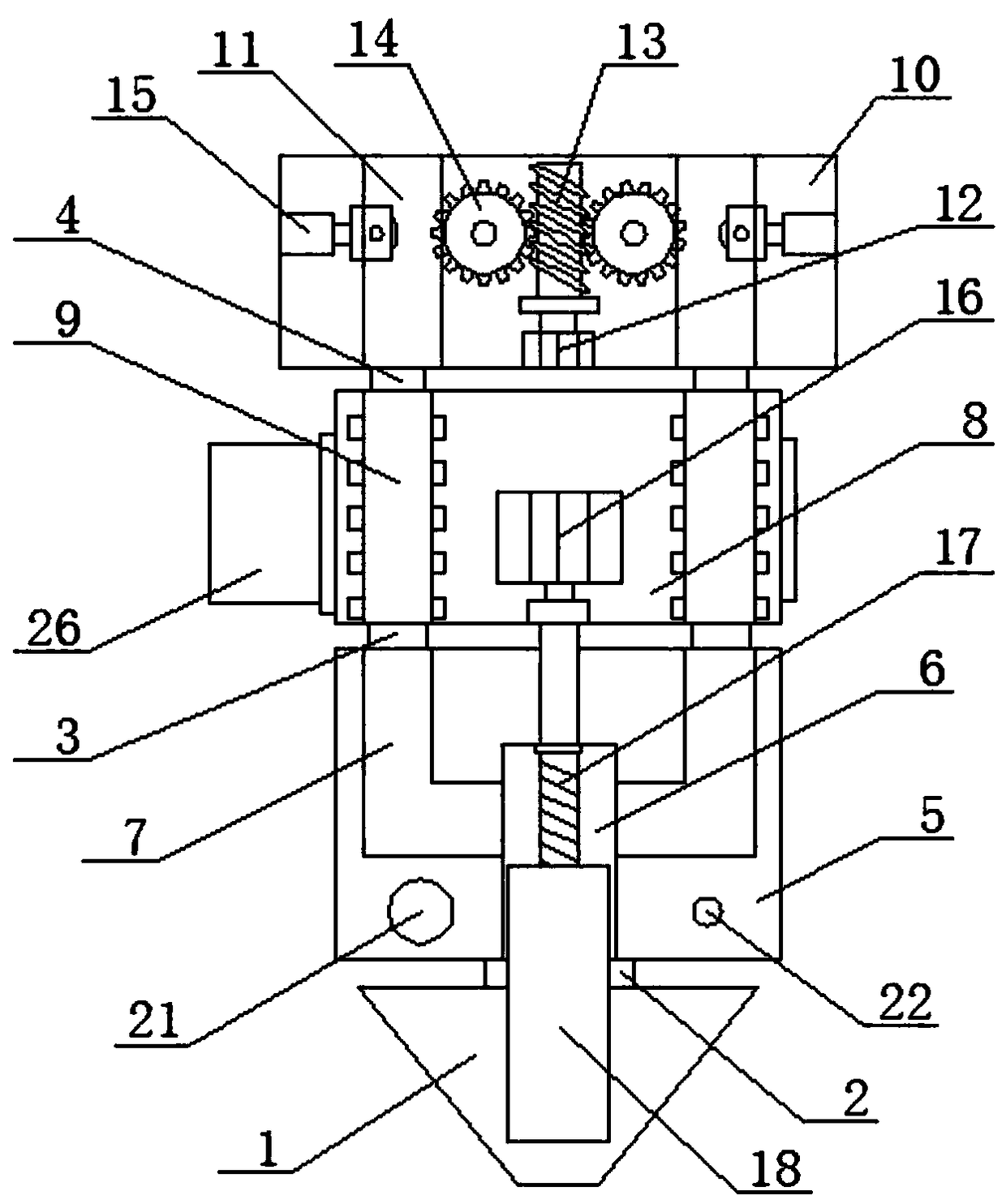

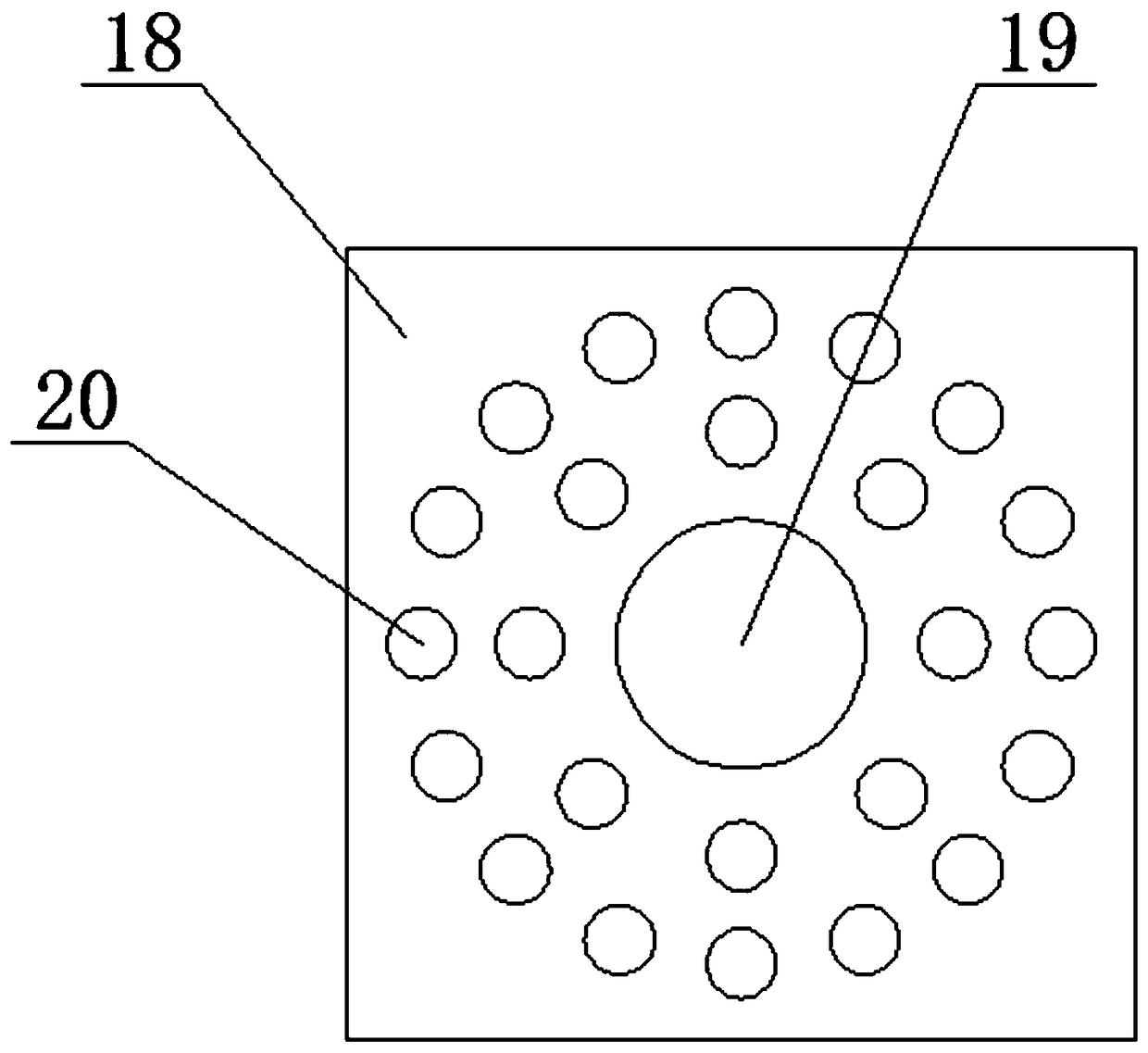

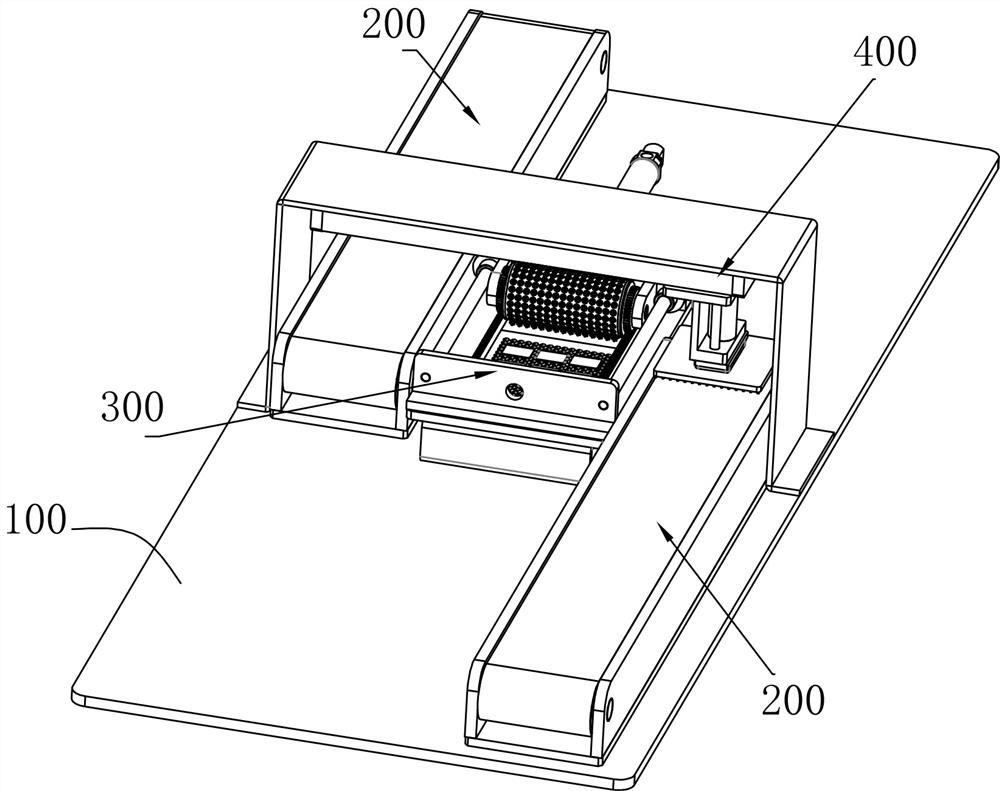

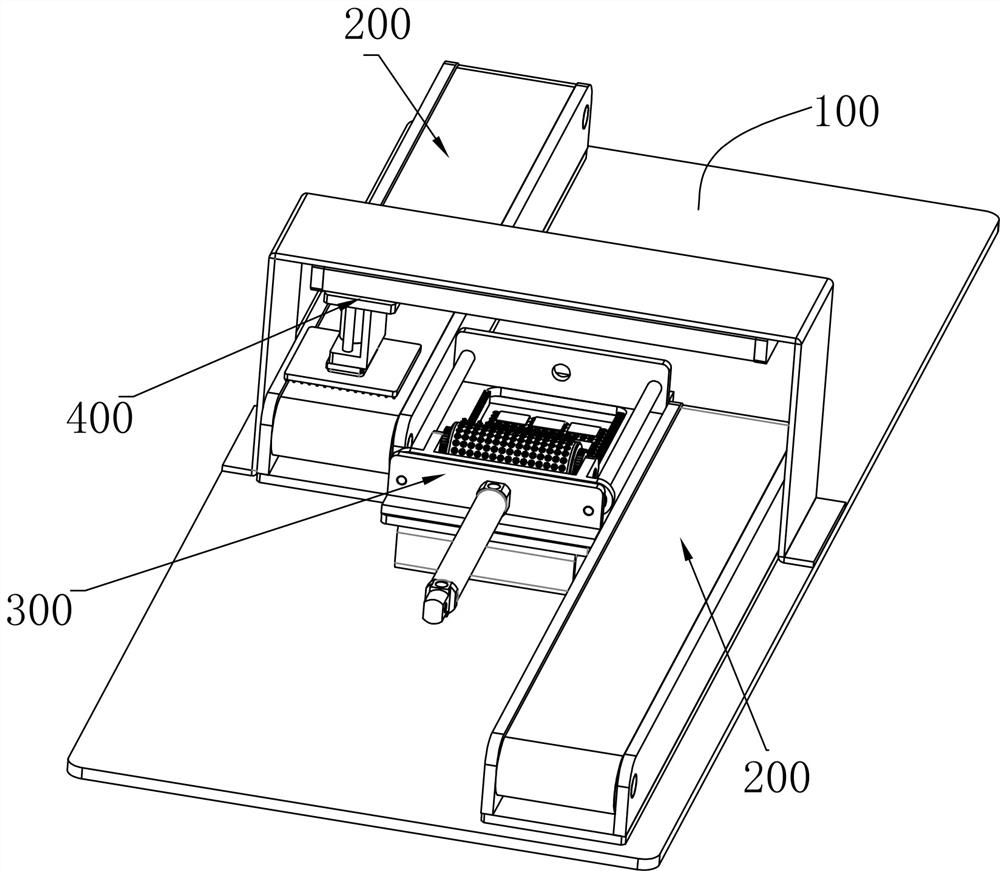

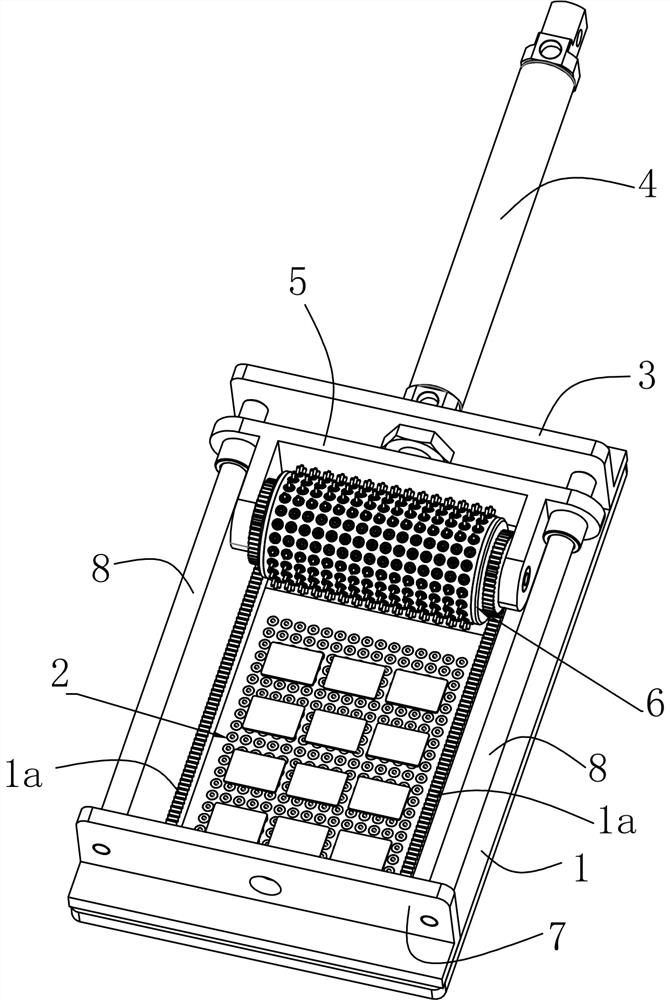

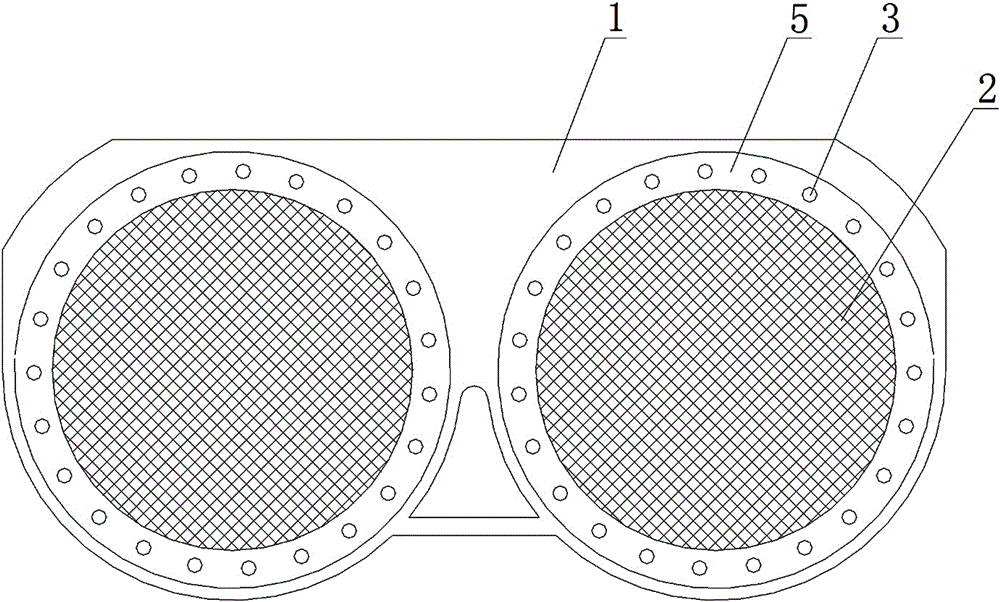

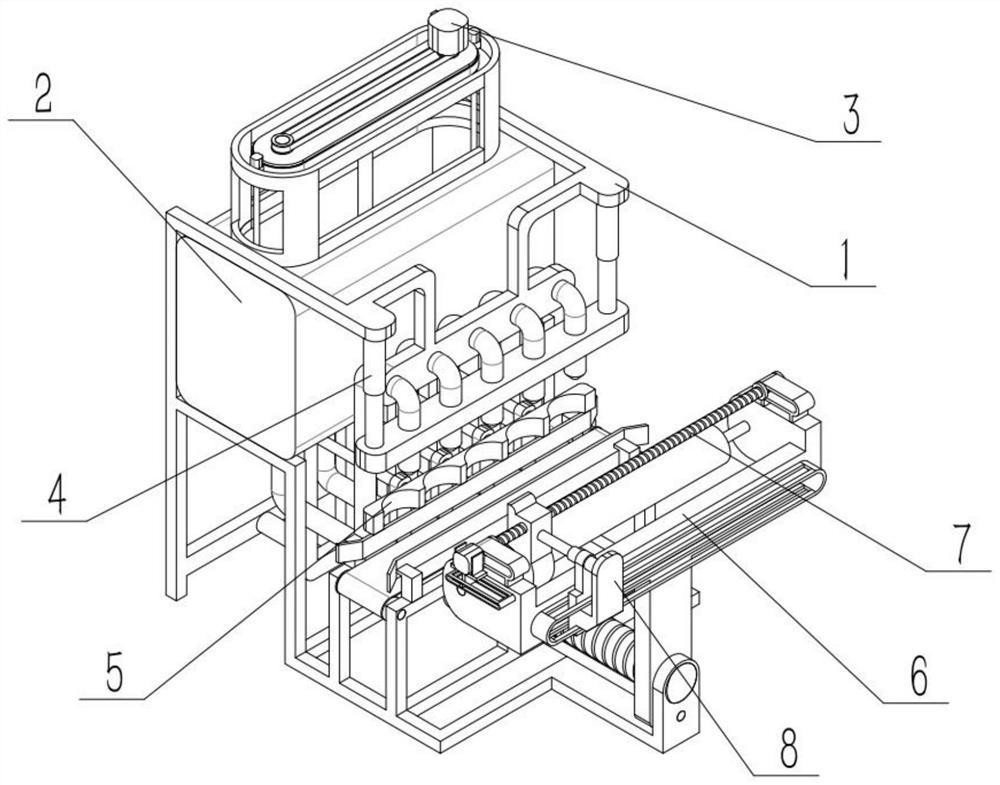

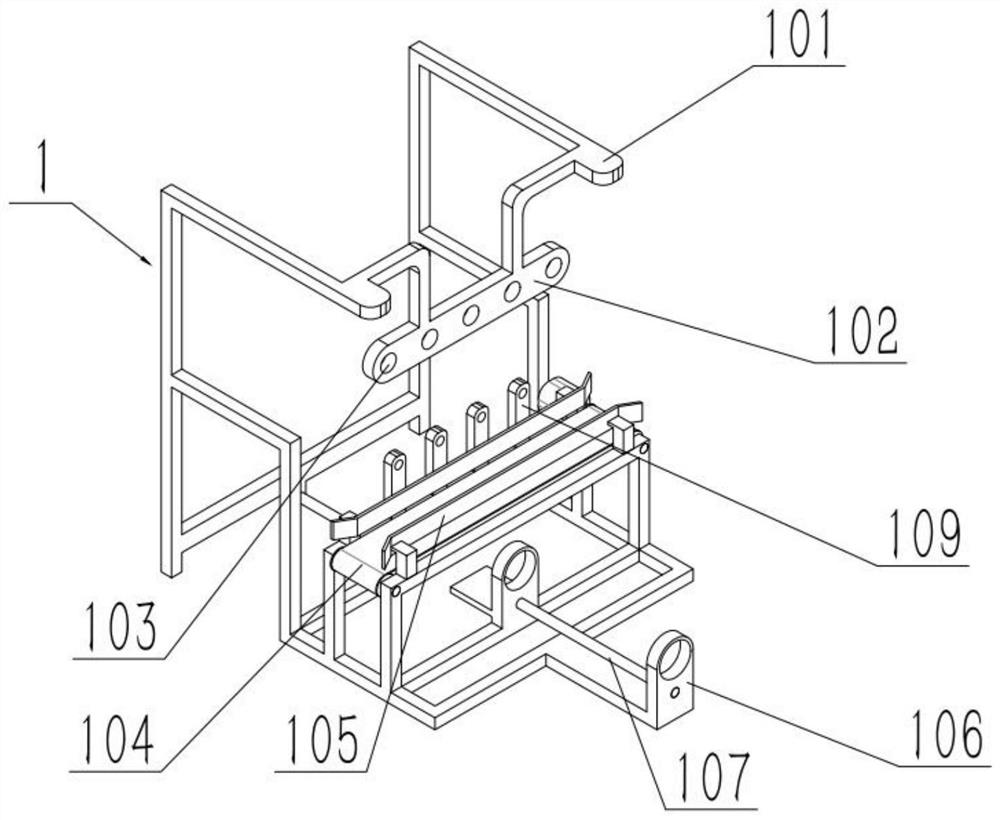

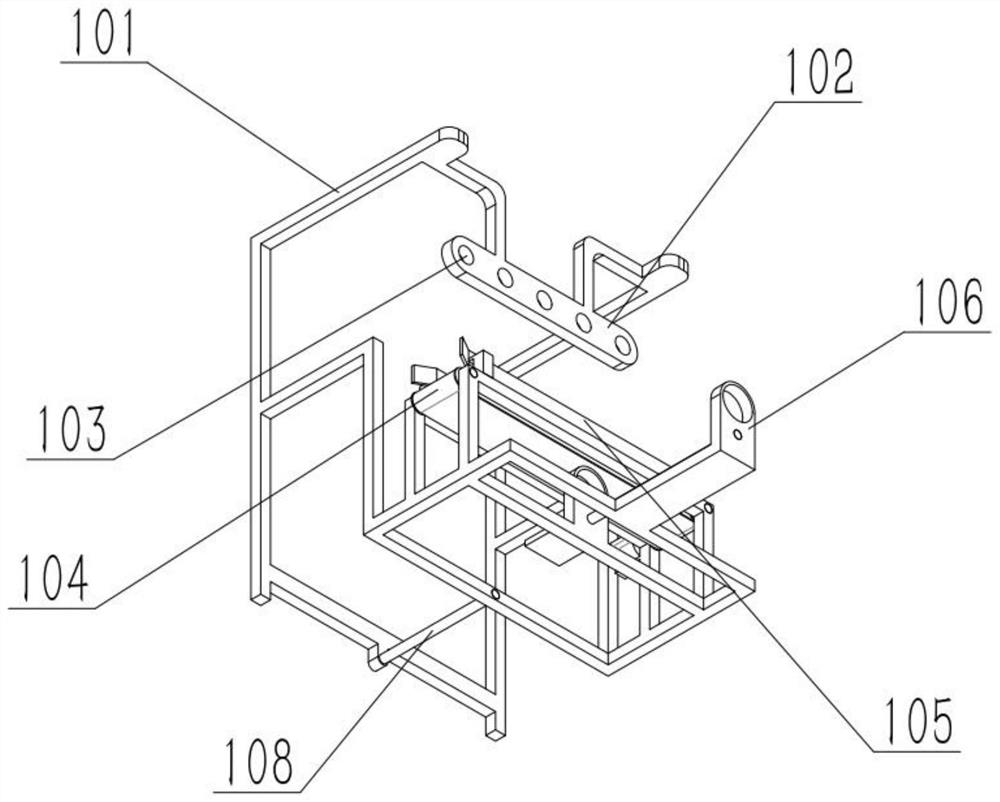

Continuous operation type anti-wiredrawing dispensing robot complete machine

InactiveCN112452650AHigh error tolerance rate of position deviationAvoid drawing phenomenonLiquid surface applicatorsCoatingsControl engineeringMachine

The invention discloses a continuous operation type anti-wiredrawing dispensing robot complete machine. The continuous operation type anti-wiredrawing dispensing robot complete machine comprises a base, two conveying tables, a rolling type dispensing robot and a material transferring mechanical arm; the rolling type dispensing robot comprises a bottom plate, a positioning mechanism, a first support, a thrust driving piece, a dispensing support and a rolling type dispensing mechanism, the positioning mechanism comprises a positioning base, an electrode plate and a plurality of positioning unitsarranged on the positioning base in a matrix array mode, and the positioning units comprise electrostatic adsorption rings, electromagnetic coils, insulating elastomers and conduction probes; and therolling type dispensing mechanism comprises a rolling shaft frame, two side covers and a plurality of dispensing units arranged on the rolling shaft frame in a circumferential array mode, the dispensing units are in one-to-one correspondence with the positioning units, and the dispensing units comprise dispensing bodies, dispensing pistons, permanent magnets, dispensing needles, glue outlet pipesand tension springs. According to the continuous operation type anti-wiredrawing dispensing robot complete machine, a to-be-dispensed chip does not need to be accurately positioned, so that the chipposition deviation error-tolerant rate is high; glue solution is dispersed, so that the wiredrawing phenomenon is avoided; and the mechanical operation is realized, so that the efficiency is high.

Owner:南京欧汉智能设备有限公司

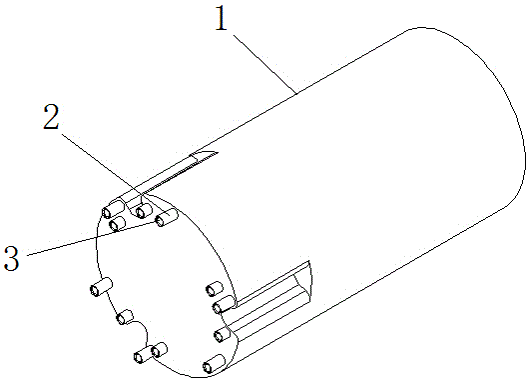

A welding device for crimping rings of end caps with a stripper plate

The invention discloses a welding device for crimping rings of end caps with a stripper plate, which comprises a workbench (6), a heating coil (17), a column (8) arranged on the workbench (6) and a concave The mold (9), the bottom of the groove (10) is provided with a mold cavity (11), the stripper plate (14) is provided between the fixed column (13) and the guide rail (12), and the stripper plate (14) is arranged on the mold Above the chamber (11), a cylinder (15) perpendicular to the workbench (6) is fixedly installed on the support plate (23), and a flat plate (16) is arranged on the acting end of the piston rod of the cylinder (15), and two heating coils ( 17) are provided with disks (18) at the bottom, high-temperature cloth (19) is provided on the bottom surface of the two disks (18), the controller (7) and the cylinder (15) and two heating coils (17) )connect. The invention has the beneficial effects of improving production efficiency, stable movement, high welding precision, effectively avoiding wire drawing, and conveniently taking finished end caps.

Owner:SICHUAN ULUPURE ULTRAPURE TECH

A Continuous Double Zigzag Path Filling Method for Depositional Modeling

ActiveCN112848309BPrevent openingAvoid closingAdditive manufacturing apparatus3D object support structuresGraphicsBi layer

The invention is a continuous double zigzag path filling method for deposition molding, the method includes: generating discontinuous single zigzag paths at a given angle in a slice with a distance of nozzle diameter d without graphic decomposition , and perform internal and external bias to generate discontinuous double zigzag paths; according to the connectable relationship between discontinuous double zigzag filling paths, connect them into local continuous double zigzag paths; The connectable relationship connects all paths in order to generate a global continuous path; finally, path optimization is performed. For any connected area without islands, a continuous double zigzag straight line filling path can be generated according to the set angle without polygon decomposition, avoiding the opening, closing and jumping of the nozzle during the printing process, reducing printing Time, and the printing direction of different layer paths can be adjusted as needed to achieve the effect of interlayer strengthening.

Owner:HEBEI UNIV OF TECH

Welding tool for automobile parts

ActiveCN114750419AAvoid drawing phenomenonObvious springback deformationDomestic articlesElectric machineryEngineering

The invention discloses a welding tool for automobile parts, and relates to the technical field of automobile part welding, the welding tool comprises a base, a mounting frame, a positioning mechanism and a compensation mechanism, and the mounting frame is adjustably mounted on the base. The positioning mechanism and the compensation mechanism are arranged on the mounting frame, and the output end of the driving motor drives the driving synchronizing wheel to rotate at a constant speed and a small angle, so that the welding heads in the welding guide grooves synchronously and dynamically deflect; it is guaranteed that the two sides of each welding guide groove are in a vertical state relative to the corresponding curved surface welding end faces of the front radar support and the angle radar support, a flat puncture welding head is located at any welding point of the curved surface end of a weldment, the two sides can completely penetrate through the weldment, and the wiredrawing phenomenon is avoided; under continuous pushing of the abutting piece and the top plate, complete penetrating welding of the weldment is matched, so that heat generated inside is uniform, heat dissipation outside is uniform, obvious springback deformation does not occur between the weldment and the welding body after welding, and the design precision is guaranteed.

Owner:NANTONG INST OF TECH

Improved structure of hot runner mold

The invention discloses an improved structure of a hot runner mold. The improved structure comprises a hot template, a liner, and a hot runner located on the liner and communicated with a cavity of the mold. A gap is formed between the hot template and the liner, the liner is formed by a main runner liner and a nozzle liner in an integrated mode, one end of the liner towards the cavity is provided with a plurality of round holes, a cold runner is arranged between a nozzle of the hot runner and the cavity, and the cold runner is located on the hot template of the hot runner. According to the improved structure, the diameter of the hot runner can be increased, plastic flowing is benefited, heat in the nozzle of the hot runner can be prevented from being exceedingly dissipated, wire drawing phenomena at the nozzle are avoided, and the quality of the mold is effectively improved.

Owner:马斯特模具有限公司

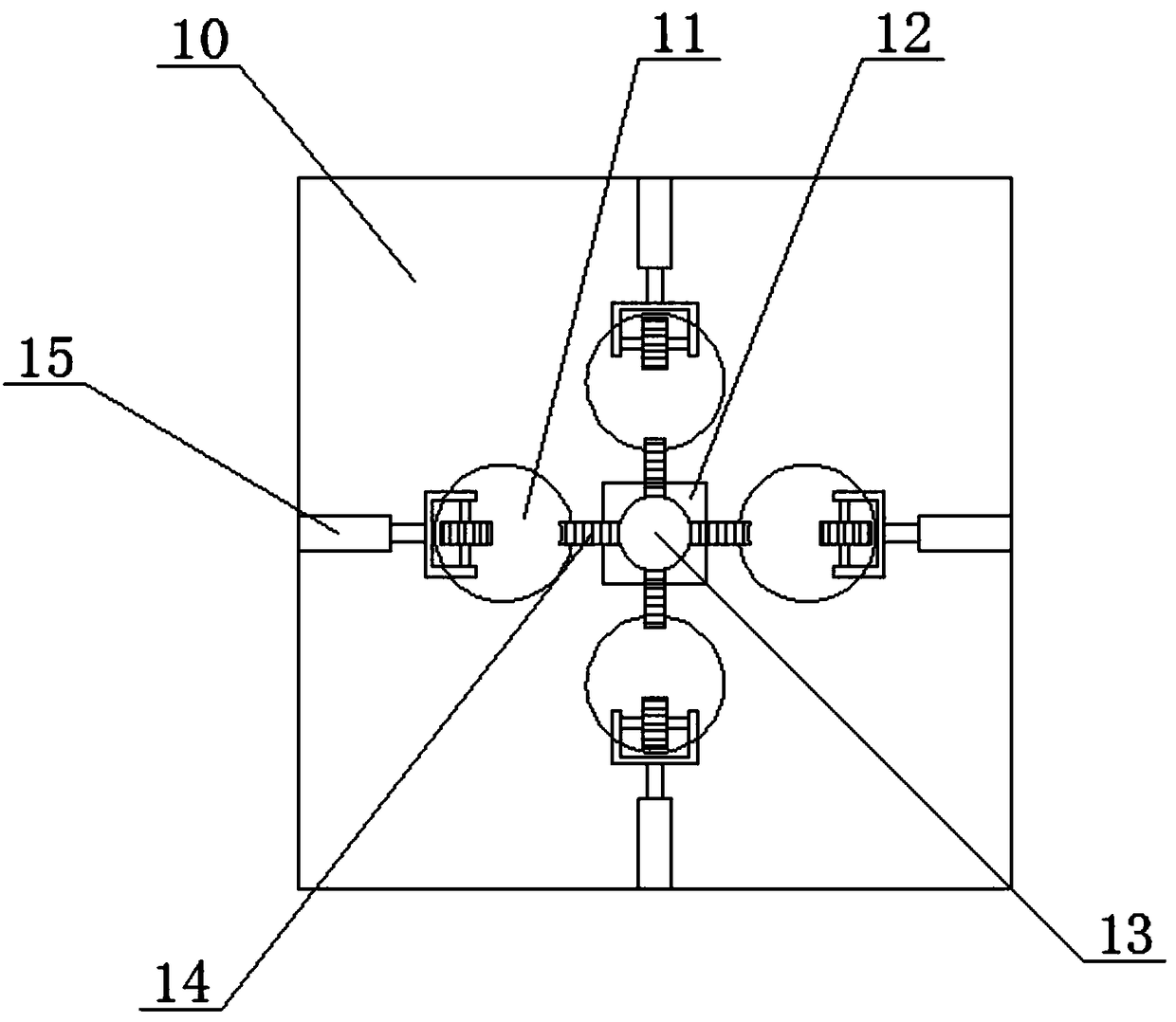

A kind of intelligent chip manufacturing equipment and manufacturing method

ActiveCN112705423BAvoid drawing phenomenonQuick GlueLiquid surface applicatorsSemiconductor/solid-state device manufacturingElectric machineryControl switch

The invention belongs to the technical field of chip manufacturing, and in particular relates to an intelligent chip manufacturing equipment, which includes a motor, a frame, a dispensing head, a control switch, a chip centering mechanism, a screw, a threaded sleeve, and a guide sleeve. The isolation structure, the second isolation structure and the third isolation structure are distributed from top to bottom. By controlling the movement of the three isolation structures, it is possible to control whether the three isolation channels are glued; thus, it can adapt to the gluing of chips of different sizes; After the structure closes the corresponding return channel, the pneumatic module does work and blows air into the isolation structure. After the gas passes through the isolation structure, it blows the glue on the lower side of the isolation structure to make it flow out; blowing the glue out through the gas can prevent the glue from sticking to the back. In the type channel, there is a drawing phenomenon and the gluing can be completed quickly.

Owner:法诺信息产业有限公司 +1

High temperature resistant honeycomb core strip adhesive, preparation method and application thereof

ActiveCN111574953BReduce the initial curing temperatureReduce energy consumptionNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer scienceAdhesive

The invention provides a high-temperature-resistant honeycomb core strip glue, a preparation method and an application thereof, and belongs to the technical field of honeycomb core material preparation. The core strip adhesive is prepared from components including the following mass ratio: 100 parts of polyimide resin; 5-60 parts of active modifier; 10-35 parts of thermoplastic resin; 1-15 parts of inorganic nanoparticles; 150 parts of solvent ‑350 servings. The preparation method is: add 1 / 4 to 1 / 3 of the thermoplastic resin to the active modifier, dissolve it in the range of 100 to 150°C, then lower the temperature to below 80°C, and add the remaining thermoplastic resin and inorganic nanoparticles to the Among the active modifiers, component A is obtained by stirring and dispersing; under the condition of stirring at room temperature, the polyimide resin and component A are added to the solvent to dissolve and disperse to obtain a uniform and stable honeycomb core strip adhesive. The core strip adhesive of the invention has the characteristics of good manufacturability, low curing temperature, high temperature resistance, excellent mechanical properties, etc., and is suitable for the preparation of ultra-thin glass cloth honeycombs.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

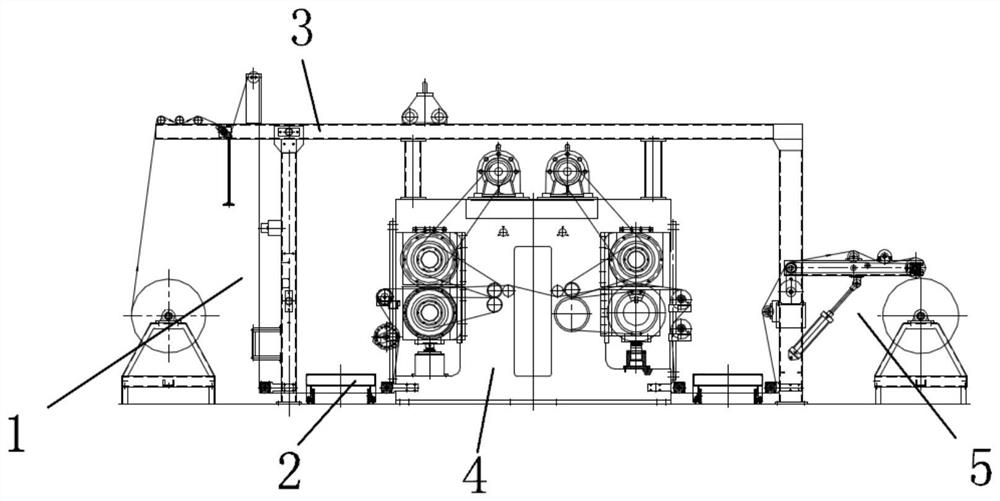

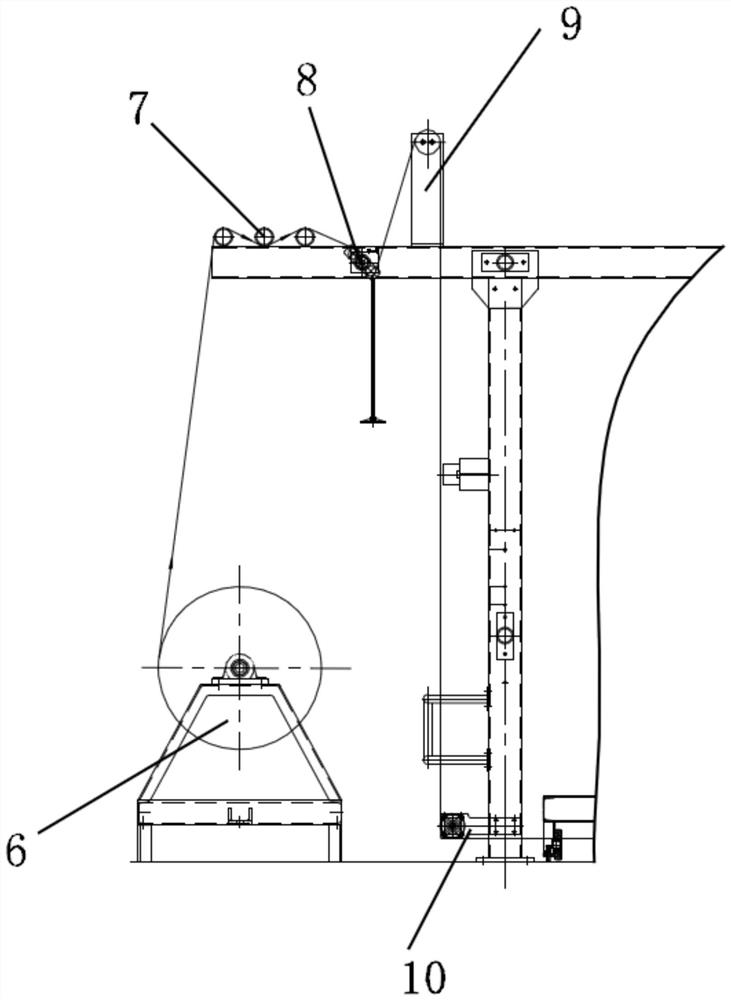

Sunshine fabric calendering process and calendering machine thereof

ActiveCN112281383AEasy to heat pressGuarantee product qualityHeating/cooling textile fabricsProcess engineeringWeft yarn

The invention relates to a sunshine fabric calendering process and a calendering machine thereof. The sunshine fabric calendering process comprises the following steps: firstly, flattening woven sunshine fabric, and conveying the sunshine fabric to an opening of a drying oven through a conveyor; then, feeding the flattened cloth from the opening of the drying oven, leading the cloth out from an outlet after passing through four temperature intervals, and shaping; then, feeding the shaped sunshine fabric into a calender, flattening and calendering silk threads on the fabric through the calender, and thus reducing the aperture ratio between warp and weft and the number of the yarn; and then cooling the calendered sunshine fabric through a cold water roller. The process has the characteristics of reducing the production cost of the sunshine fabric, ensuring the quality of the sunshine fabric, improving the production benefit, reducing the energy consumption and the like.

Owner:PHIFER INC

Hot nozzle assembly and hot runner system

The invention discloses a hot nozzle assembly and a hot runner system. The hot nozzle assembly comprises a hot nozzle body and a nozzle tip arranged at the end part of the hot nozzle body, wherein a runner body is formed inside the hot nozzle body and the nozzle tip in a penetrating mode, a pressing part is arranged outside the nozzle tip in a sleeved mode, an inner cavity is formed in the inner side of the pressing part, a heat insulation sealing cap is arranged in the inner cavity, a through channel is formed inside the heat insulation sealing cap, and the nozzle tip is inserted into the through channel; a discharge port is formed in the end part of the nozzle tip, and a material injection channel is arranged in the pressing part; the runner body,and the discharge port communicate with the material injection channel, the inner wall of the pressing part and the outer wall of the nozzle tip are both tightly attached to the heat insulation sealing cap. The hot nozzle assembly avoids excessive internal material residue of an interior part, so that the cooling speed is increased, and the wire drawing phenomenon is avoided; and in addition, due to the reasonable internal structure, excess materials are prevented from entering between the nozzle tip and the pressing part, so that the residual material can be prevented from remaining in the interior and gradually becomes yellow, theproblem that the yellowing excess materials enter a product is avoided, and the product quality is improved.

Owner:YUDO SUZHOU HOT RUNNER SYST

Shower gel preparation system and shower gel preparation method

ActiveCN112110401AImprove cleanlinessAvoid wasting resourcesFilling device cleaningDischarging meansShower gelPolymer chemistry

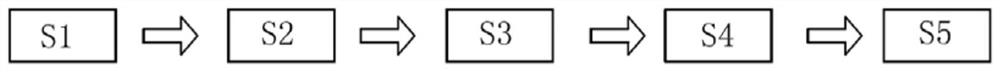

The invention relates to preparation of shower gel, in particular to a shower gel preparation system and a shower gel preparation method. The shower gel preparation method comprises the following steps of S1, preparing shower gel raw materials in a filling mechanism by using a scraping mechanism to obtain a shower gel finished product; S2, conveying the shower gel finished product by using the filling mechanism; S3, adjusting the filling height through a lifting mechanism, and filling a container with the shower gel finished product through the filling mechanism; S4, conducting wiredrawing removing on a bottle opening filling position of the container through a wiredrawing removing mechanism; and S5, collecting wiredrawing residues by using a material pickup mechanism. According to the shower gel preparation system and the shower gel preparation method, when the shower gel is prepared in the filling mechanism, the scraping mechanism further processes the shower gel in the filling mechanism and is capable of preventing the shower gel from adhering to the interior of the filling mechanism at the same time, the interior of the filling mechanism can be cleaner when ingredients of the shower gel in the filling mechanism are replaced, and the situation that different raw materials are mixed, and consequently the smell of the shower gel is mixed is prevented.

Owner:山东文正科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com