Ejection shaping die

An injection molding and mold technology, applied in the field of injection molding molds, can solve the problems of limited effect, difficulty in production and preparation, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

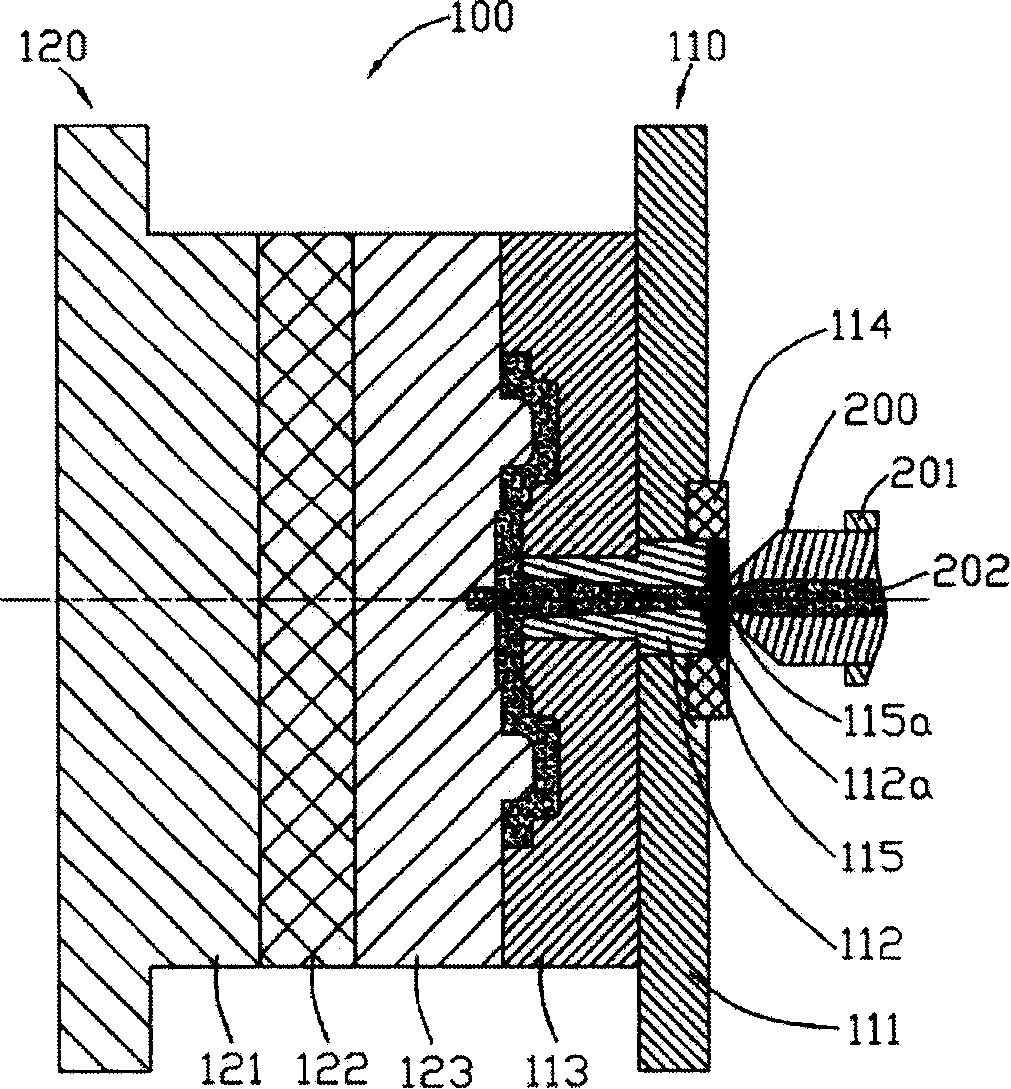

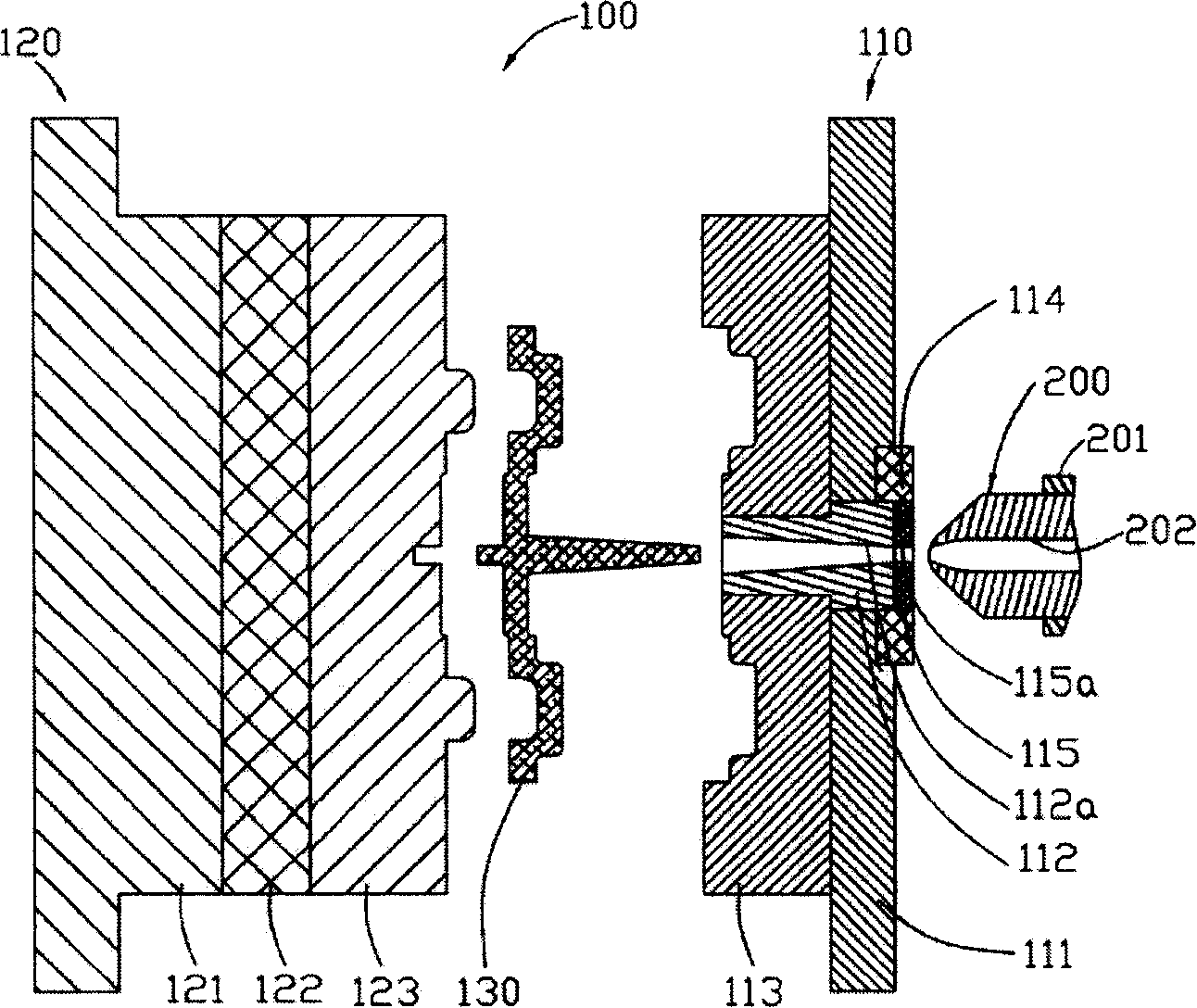

[0015] see figure 1 and figure 2 , the injection molding mold 100 of this embodiment includes a first half-mold 110 and a second half-mold 120. When the first half-mold 110 and the second half-mold 120 cooperate, an injection cavity can be formed for molding the corresponding structure. product. The first half-mold 110 and the second half-mold 120 can move relatively, that is, when the first half-mold 110 is fixed, the second half-mold 120 can be controlled to move toward the first half-mold 110 to cooperate to form a mold cavity. Of course, when the second half-mold 120 is fixed, the first half-mold 110 can be controlled to move toward the second half-mold 120 to cooperate to form the mold cavity. When manufacturing a molded product, after the first half-mold 110 and the second half-mold 120 are closed to form a mold cavity, the nozzle 200 fixed on the spray gun is injected into the mold cavity through the sprue 112a in the sprue bushing (Sprue Bush) 112 The molten plast...

no. 2 example

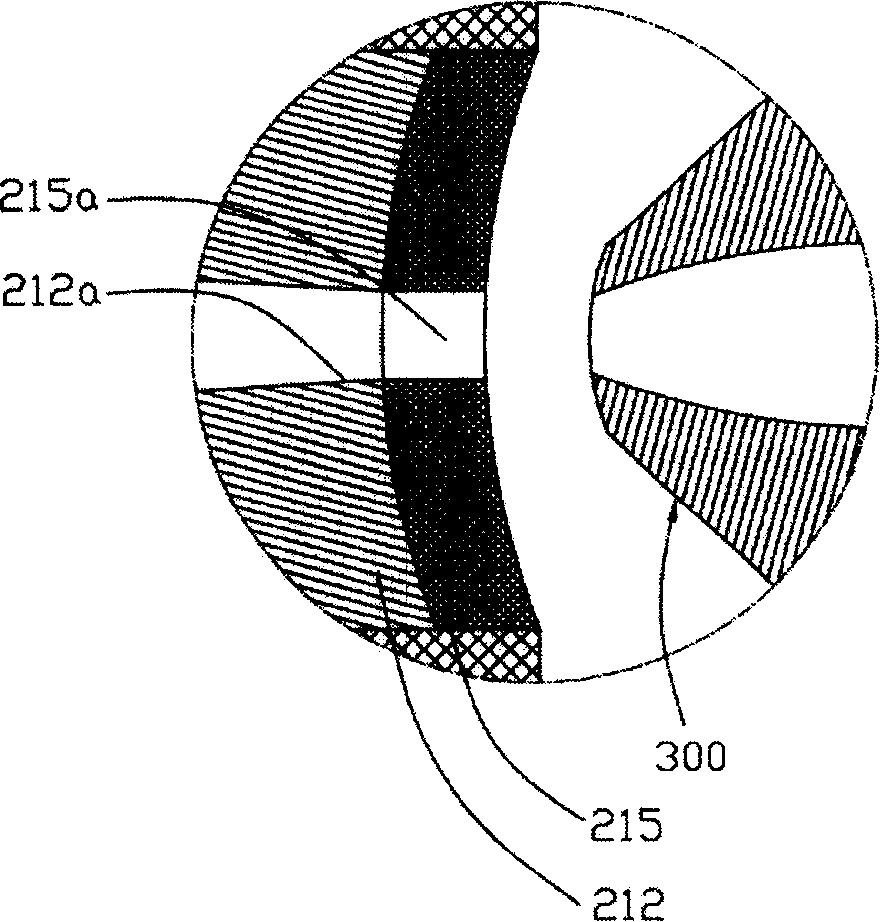

[0023] See image 3 , The mold structure of the second embodiment of the technical solution is basically the same as that of the first embodiment, except for the sprue bushing. In order to match the shape of the nozzle 300, the end of the sprue bushing 212 of the second embodiment that matches the nozzle 300 is a bowl-shaped structure, and the surface that matches the nozzle 300 is a bowl-shaped concave surface. The thermal insulation layer 215 is adapted to the structure of the sprue bushing 212, that is, the thermal insulation layer 215 also has a bowl-shaped structure, and the surface in contact with the sprue bushing 212 is the same bowl-shaped concave surface as the surface of the sprue bushing 212 . The heat insulating layer 215 has a hole 215a, and the diameter of the hole 215a is similar to the diameter of the sprue 212a. Preferably, the diameter of the hole 215a ranges from 95% to 105% of the diameter of the sprue 212a.

no. 3 example

[0025] Of course, the structure of the heat insulating layer does not necessarily need to be exactly the same as that of the nozzle, as long as the shape and structure of the heat insulating layer and the sprue bushing corresponding to the outer surface of the nozzle are consistent and fully in contact. For example, see Figure 4 The heat insulation layer 315 of the third embodiment of the technical solution includes a first heat insulation part 315a and a second heat insulation part 315b, the first heat insulation part 315a is a bowl-shaped structure corresponding to the nozzle 400, and the structural shape of the second heat insulation part 315b Not limited thereto, for example, it may be a ring structure surrounding the first heat insulating portion 315a. The first heat insulating portion 315a has a hole 315c whose diameter is similar to that of the sprue 312a. Preferably, the diameter of the hole 315a ranges from 95% to 105% of the diameter of the sprue 312a.

[0026] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com