Glue dispensing equipment for processing soft packaged lithium-ion battery

A power battery and soft-packed lithium technology, which is applied in the direction of spraying devices, coatings, and devices for coating liquid on the surface, can solve the problems of low work efficiency, save raw materials, increase dispensing speed, and facilitate dispensing work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

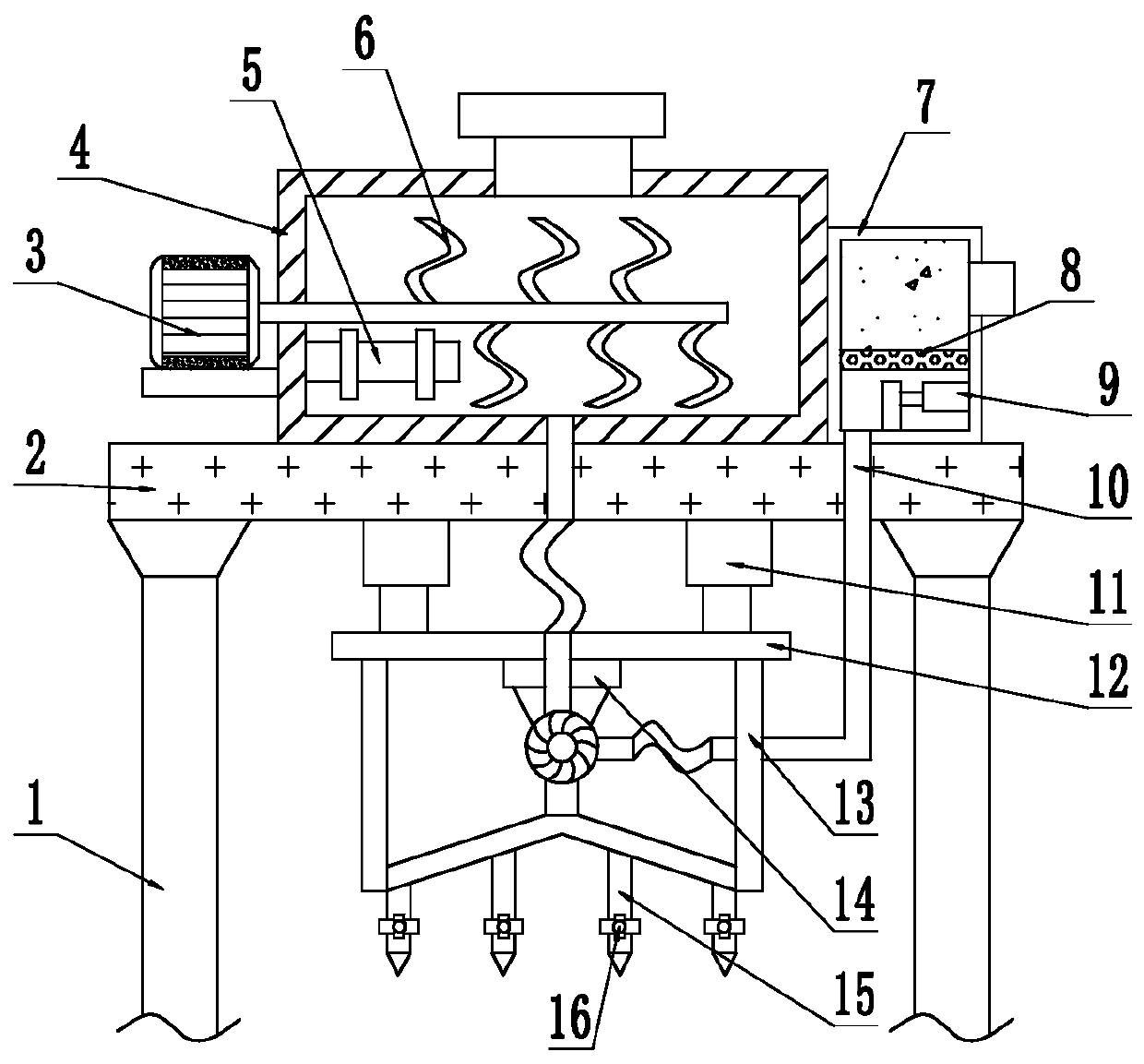

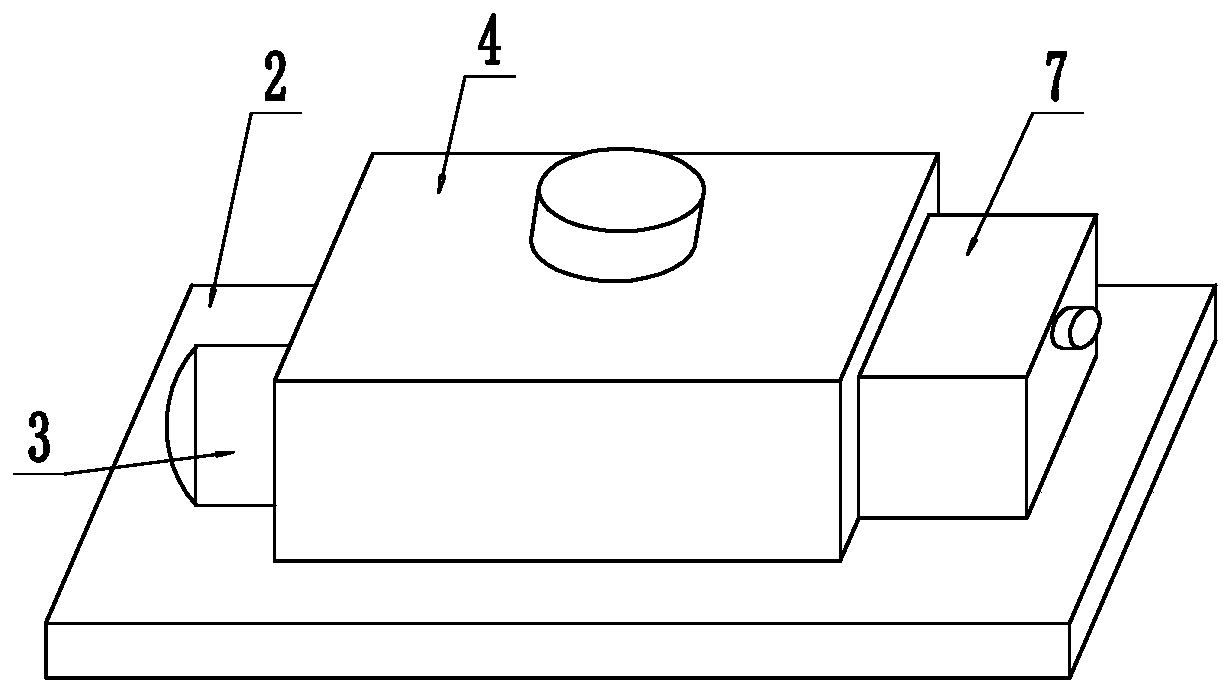

[0025] refer to figure 1 and figure 2 , a kind of dispensing equipment for processing soft-pack lithium-ion power batteries, including a support column 1, the top of the support column 1 is fixed with a top plate 2 by bolts, the top of the top plate 2 is fixed with a box body 4 by bolts, and one side of the box body 4 The motor 3 is fixed on the outer wall by bolts, and one end of the output shaft of the motor 3 is welded with a transmission rod. It can drive the stirring plate 6 to rotate, stir it, and drive the glue to rotate. On the inner wall of one side of the casing 4, a first heater 5 is fixed by bolts, and the raw materials in the casing 4 are heated by the first heater 5. To prevent it from solidifying, the bottom of the top plate 2 is fixed with a plurality of electric telescopic rods 11 by bolts, and the bottom of the electric telescopic rods 11 is fixed with a mounting plate 12 by bolts, and the bottom of the mounting plate 12 is fixed with a piston pump 14 by bo...

Embodiment 2

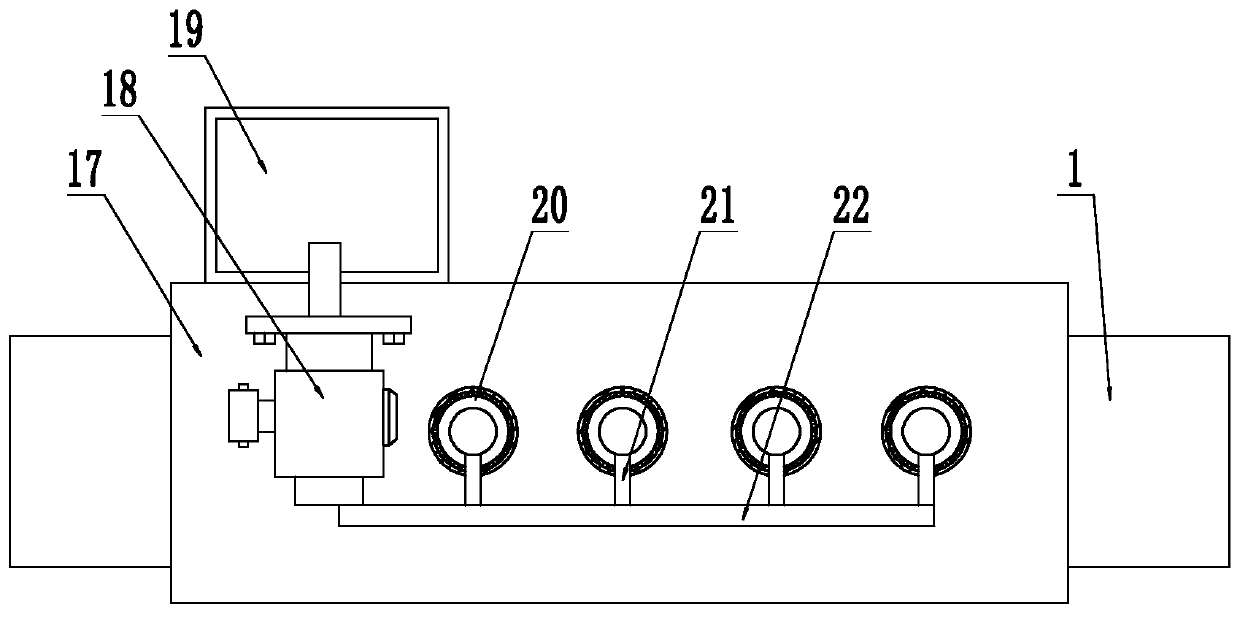

[0031] refer to image 3 and Figure 4 , a kind of dispensing equipment for processing soft-pack lithium-ion power batteries. Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, one side of the support column 1 is fixed with a fixed plate 17 by bolts, and the fixed plate 17 Located below the dispensing head 15, the top of the fixing plate 17 is provided with a plurality of fixing holes, and the filter head 20 is fixed by bolts in the fixing hole, and the filter heads 20 are all located directly below the dispensing head 15, and the bottom of the filter head 20 It is a hollow conical structure, and the bottom of the filter head 20 has a through hole, which is convenient for scraping off the excess glue on the dispensing head 15. One side of the filter head 20 is welded with a connecting pipe 21, and one end of the connecting pipe 21 is welded with a recovery pipe 22 , the top of the fixed plate 17 is fixed with an exhaust fan 18 by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com