Ceramic tile grabbing mechanism and mechanical arm for firmly grabbing ceramic tiles

A grasping mechanism and ceramic tile technology, applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems of low running speed of manipulators, excessive transmission distance, collisions, etc., to avoid weak gripping and large contact area. , The effect of high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Figure 1~14 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~14 The present invention will be further described.

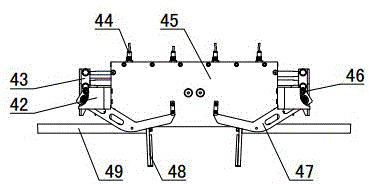

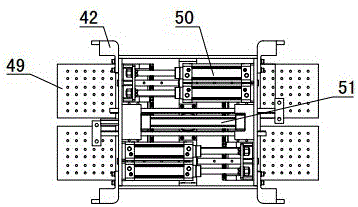

[0048] A tile grabbing mechanism: including a splint power unit and a tile splint 48, the splint power unit is installed in the grabbing mechanism main body 45, the tile splint 48 is arranged below the grabbing mechanism main body 45, and the splint power unit is connected to the tile splint 48;

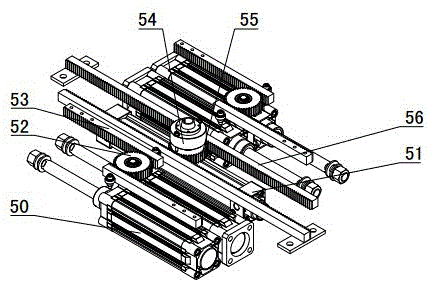

[0049] A splint drive mechanism is arranged between the splint power unit and the tile splint 48, and the splint drive mechanism drives the tile splint 48 to clamp or loosen the tiles through the rack and pinion pairs.

[0050] The tile grabbing mechanism clamps the tiles through the tile splint 48. The tile splint 48 has a large contact area with the tiles. The splint 48 can exert a greater clamping force to clamp the ceramic tile firmly to ensure that the tile will not fall off freely; When opening or clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com