Shower gel preparation system and shower gel preparation method

A technology for preparing a system and shower gel, applied in the directions of bottle filling, liquid bottling, packaging, etc., can solve problems such as wire drawing, and achieve the effects of improving cleanliness, improving work efficiency and cleanliness, and preventing waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

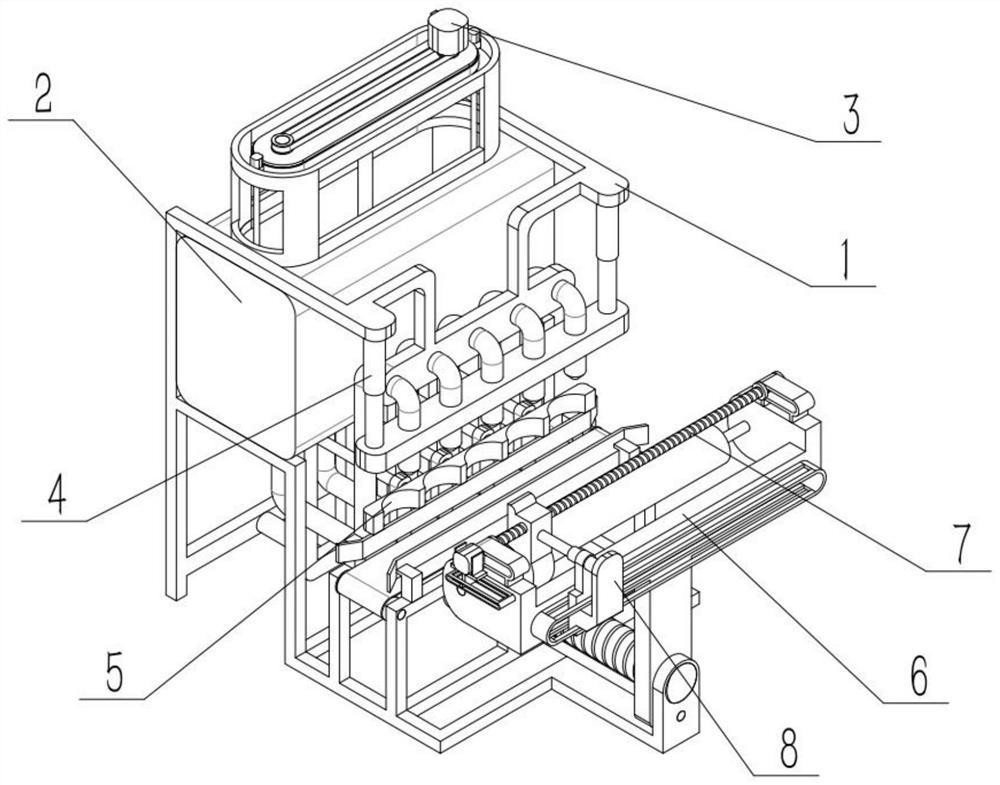

[0039] Such as Figure 1-12 As shown, a shower gel preparation system includes a preparation frame 1, a filling mechanism 2, a scraping mechanism 3, a lifting mechanism 4, an auxiliary device 5, a wire removal mechanism 6, a power mechanism 7 and a material taking mechanism 8. The loading mechanism 2 is connected to the upper end of the left end of the preparation frame 1, the scraping mechanism 3 is connected to the middle of the filling mechanism 2, the lifting mechanism 4 is connected to the upper end of the preparation frame 1, the auxiliary device 5 is connected to the lower end of the left end of the preparation frame 1, and the wire removal mechanism 6 Connected to the right end of the preparation frame 1, the power mechanism 7 is connected to the upper end of the wire-removing mechanism 6, and the retrieving mechanism 8 is connected to the upper end of the wire-removing mechanism 6.

specific Embodiment approach 2

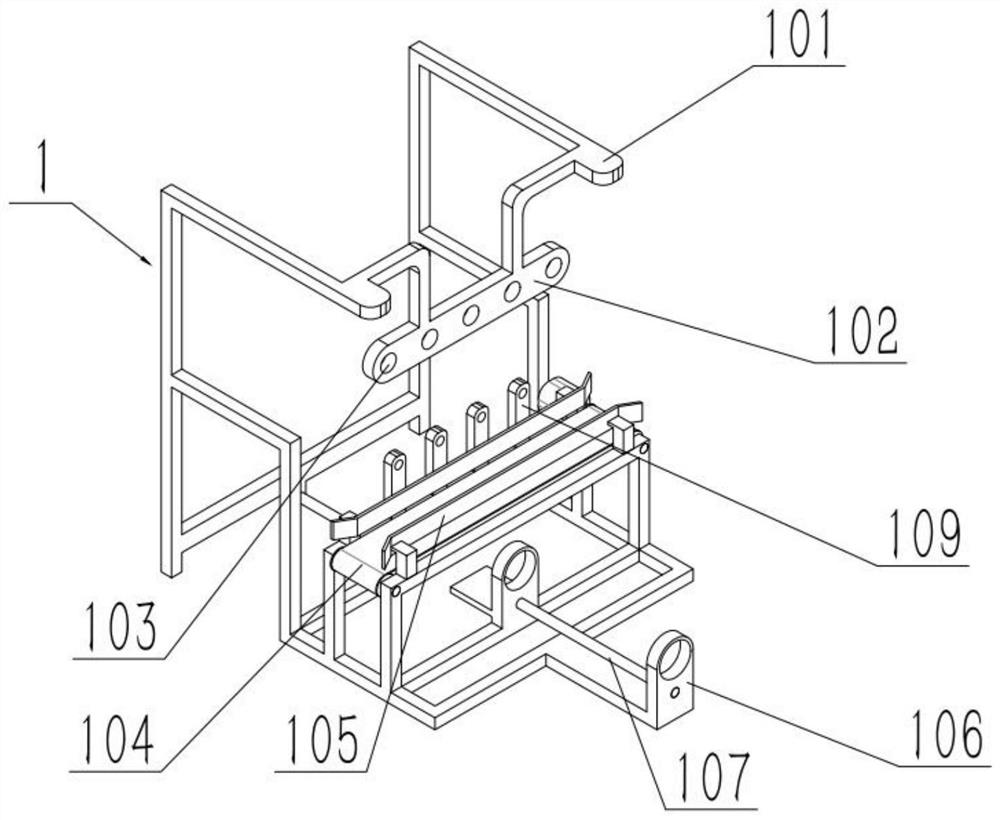

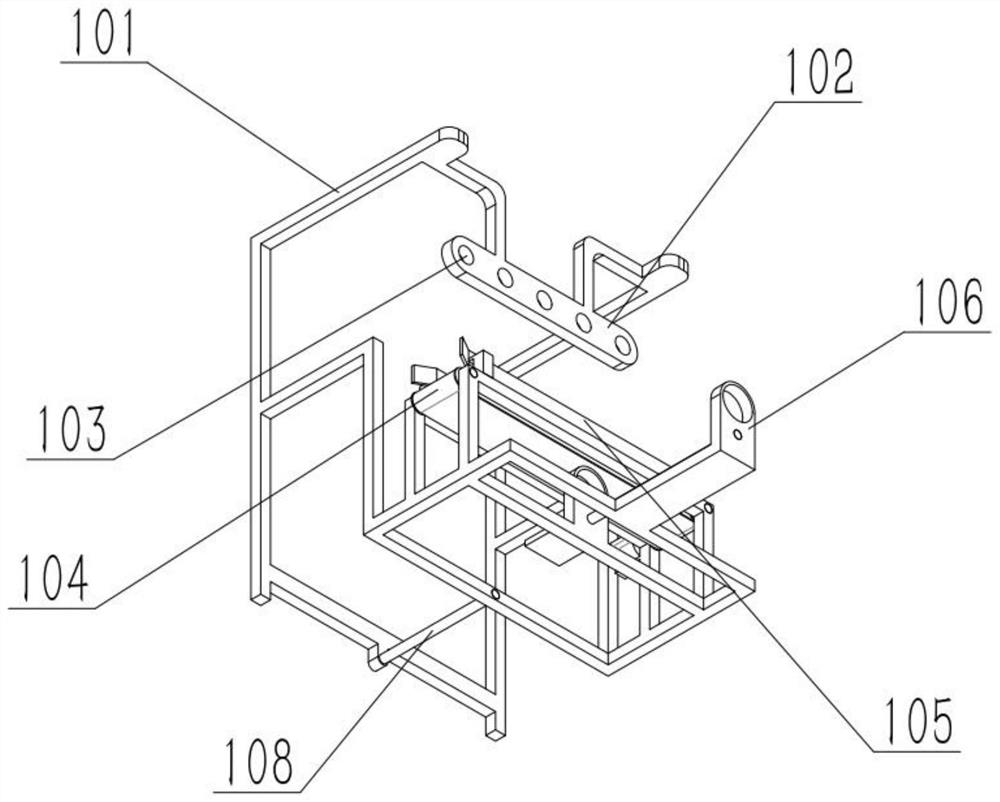

[0041] Such as Figure 1-12 As shown, the preparation frame 1 includes a frame 101, a fixing frame 102, a fixing hole 103, a belt conveyor 104, a deflector frame 105, a boss 106, a right slide bar 107, a left slide bar 108 and an auxiliary seat 109. The frame 102 is fixedly connected to the lower end of the right end of the frame 101, five fixing holes 103 are provided, and the five fixing holes 103 are evenly arranged on the fixing holes 103 in turn, the belt conveyor 104 is fixedly connected to the right end of the frame 101, and the guide frame 105 is set There are two, the guide frame 105 is fixedly connected to the left and right ends of the upper end of the right side of the frame 101, the left and right ends of the middle part of the right end of the frame 101 are respectively fixedly connected to a convex seat 106, and the left and right ends of the right slide bar 107 are connected to the two convex seats. The inner end of 106 is fixedly connected, and left slide bar ...

specific Embodiment approach 3

[0043] Such as Figure 1-12 As shown, the filling mechanism 2 includes a filling box 201, a filling pipe 202, a top seat 203, a rotating seat 204 and a rotating hole 205, and five filling pipes 202 are provided, and the five filling pipes 202 are respectively fixed in turn. Parallel communication is at the lower end of the filling box 201, the top seat 203 is fixedly connected to the upper end of the filling box 201, the rotating seat 204 is fixedly connected to the middle part of the inner end of the filling box 201, and the front and rear ends of the rotating seat 204 are respectively provided with a rotating hole 205. The packing box 201 is fixedly connected to the upper end of the left end of the frame 101, and the upper ends of the five filling pipes 202 are respectively slidingly connected in the five fixing holes 103 in turn. When the shower gel is prepared, the shower gel filling raw materials are placed in the filling box 201, which is convenient for filling the showe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com