Patents

Literature

292results about "Filling device cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

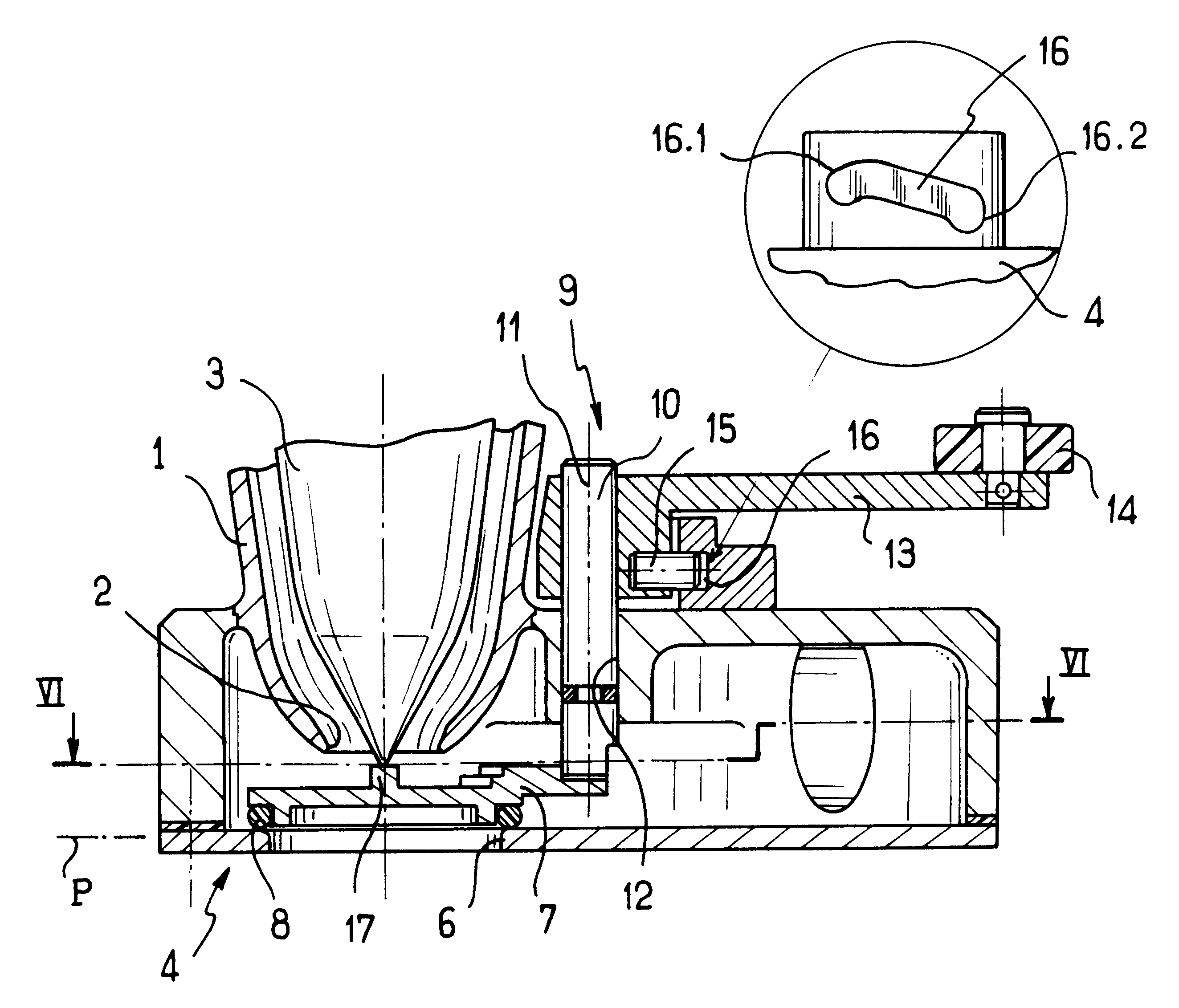

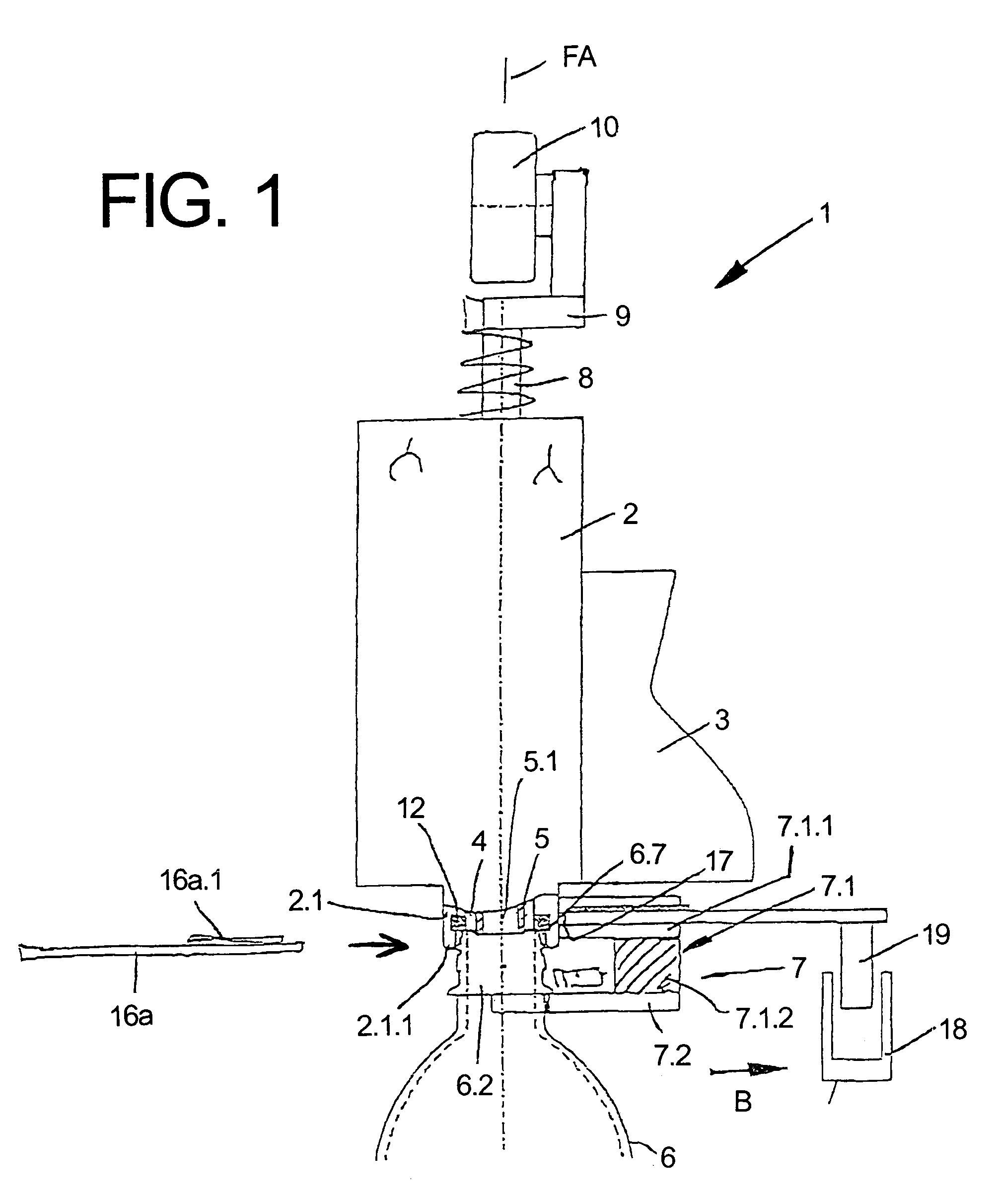

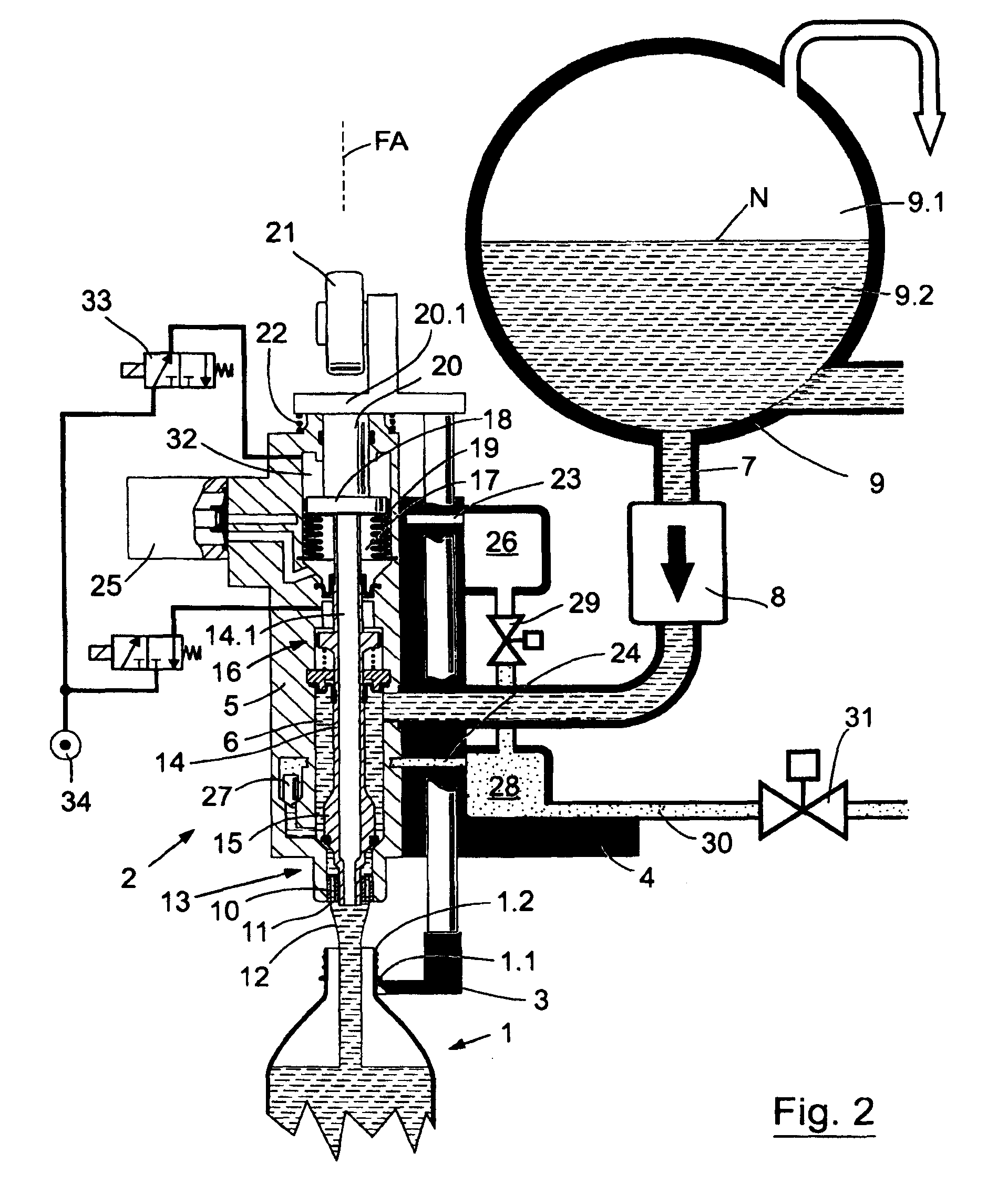

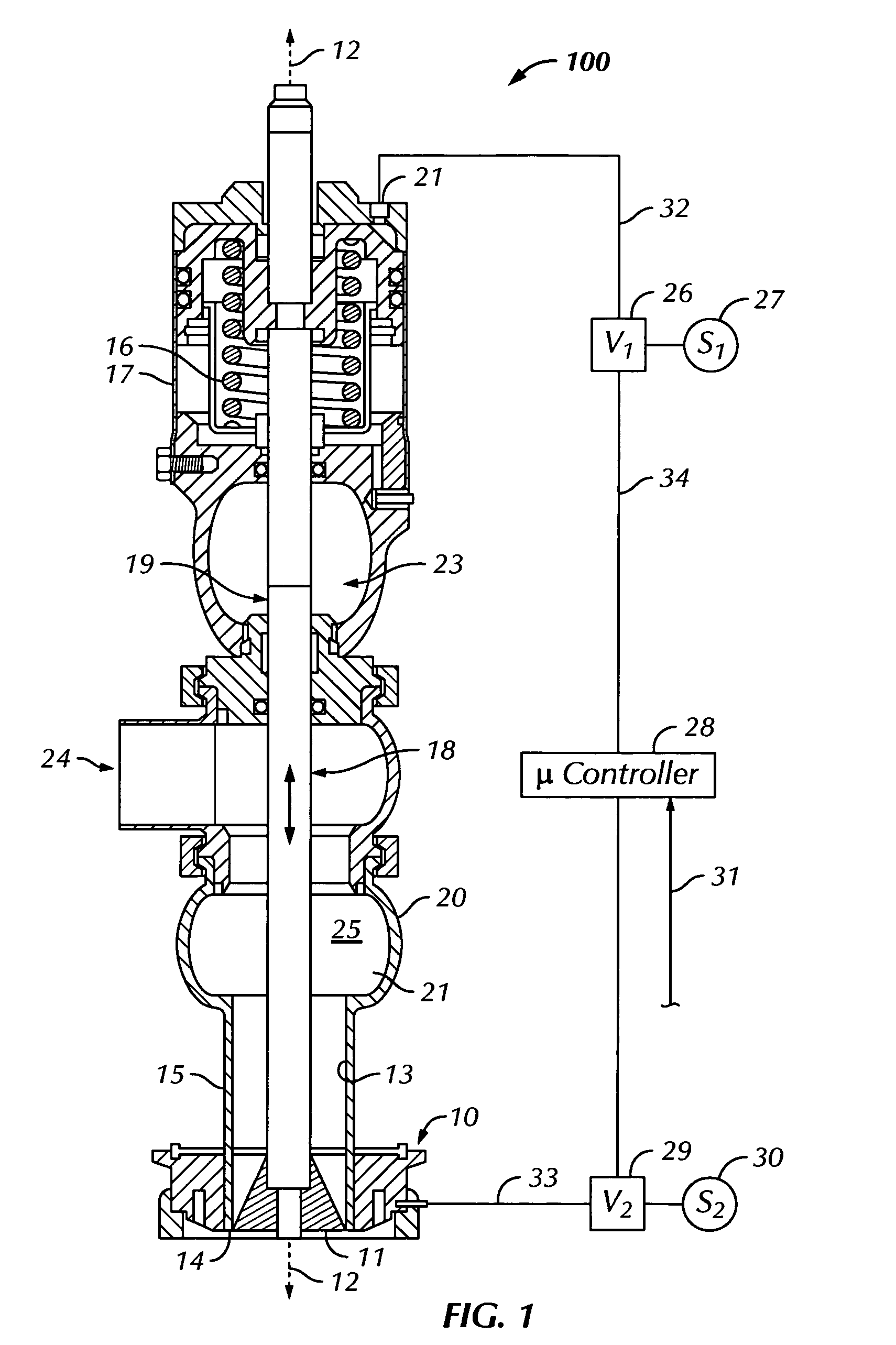

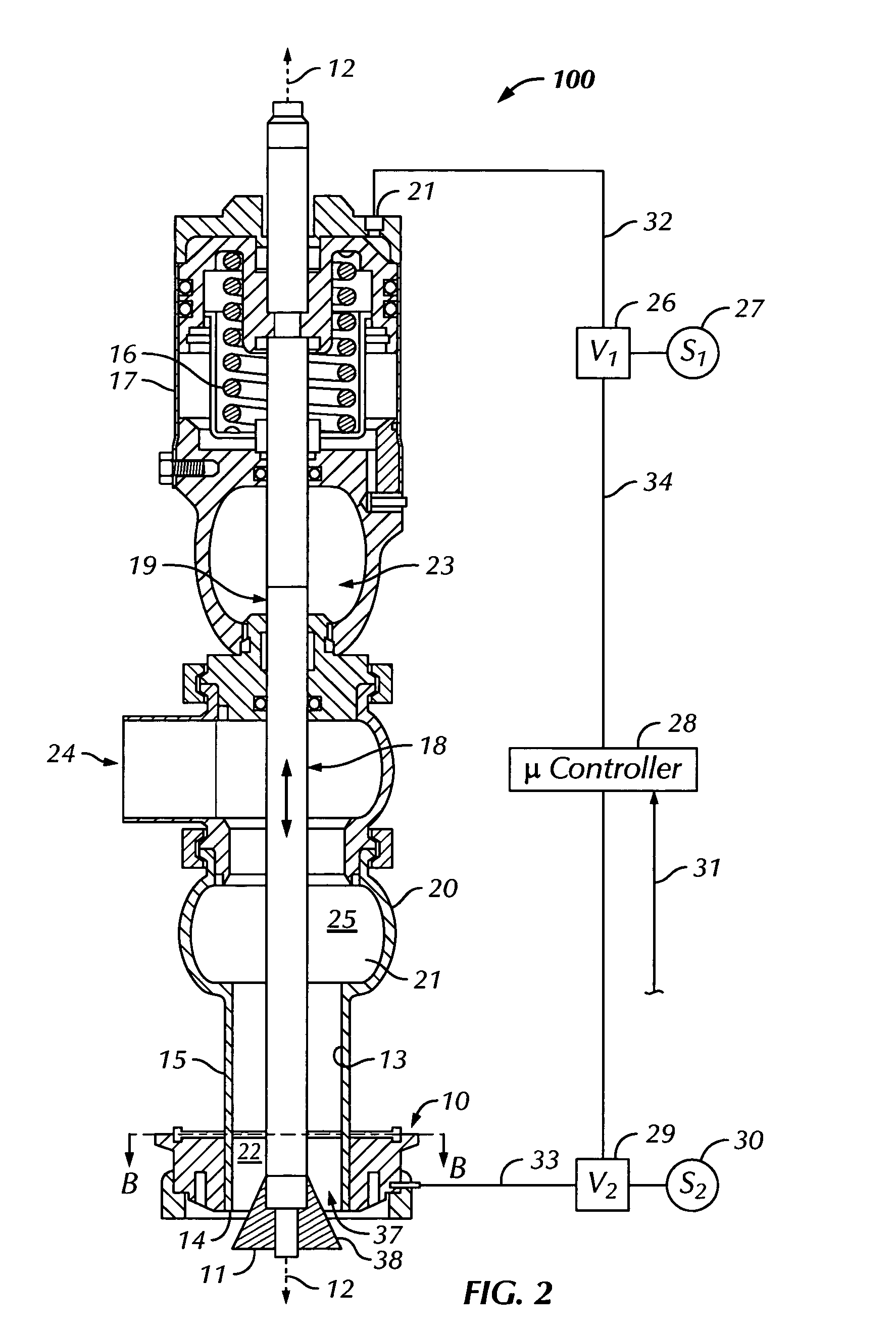

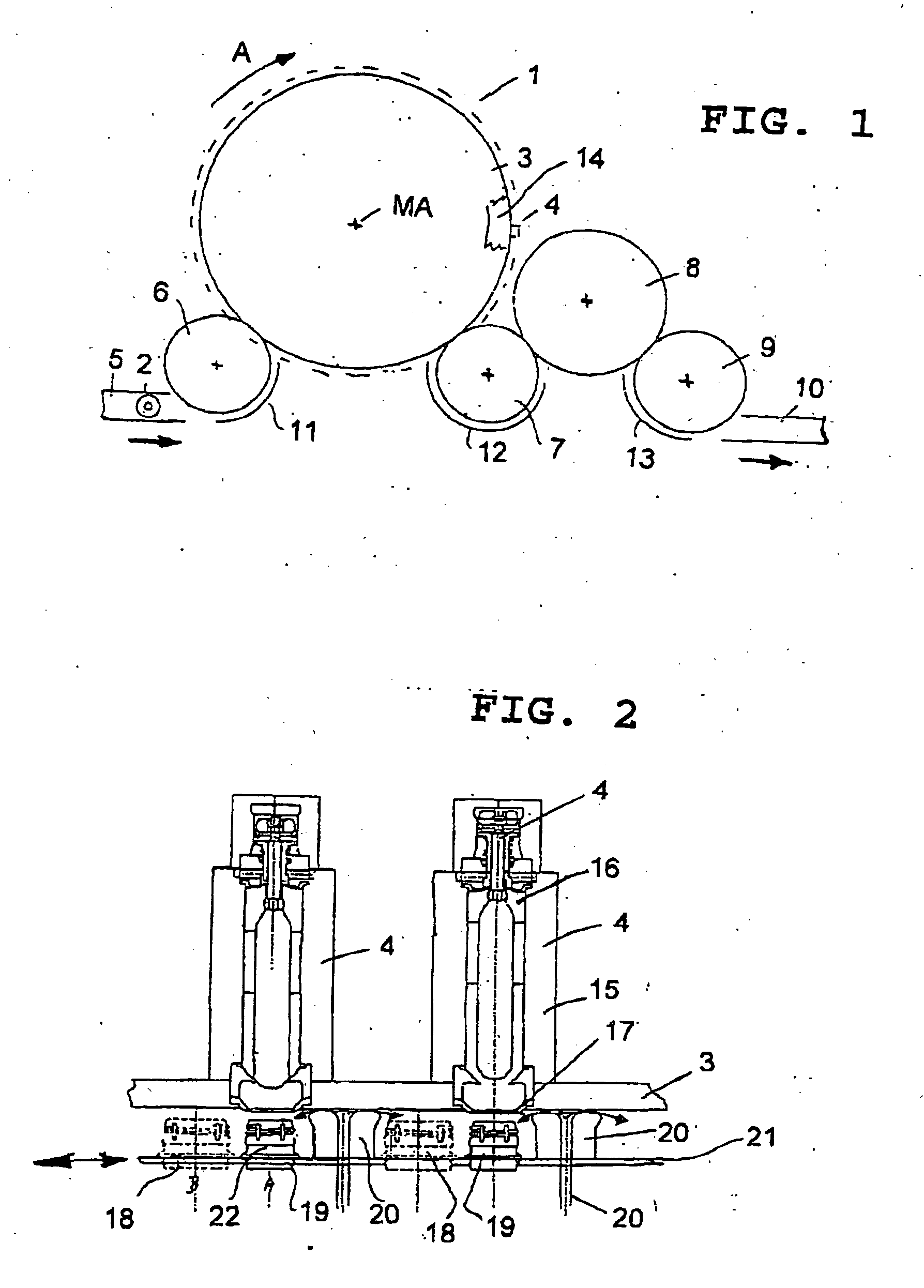

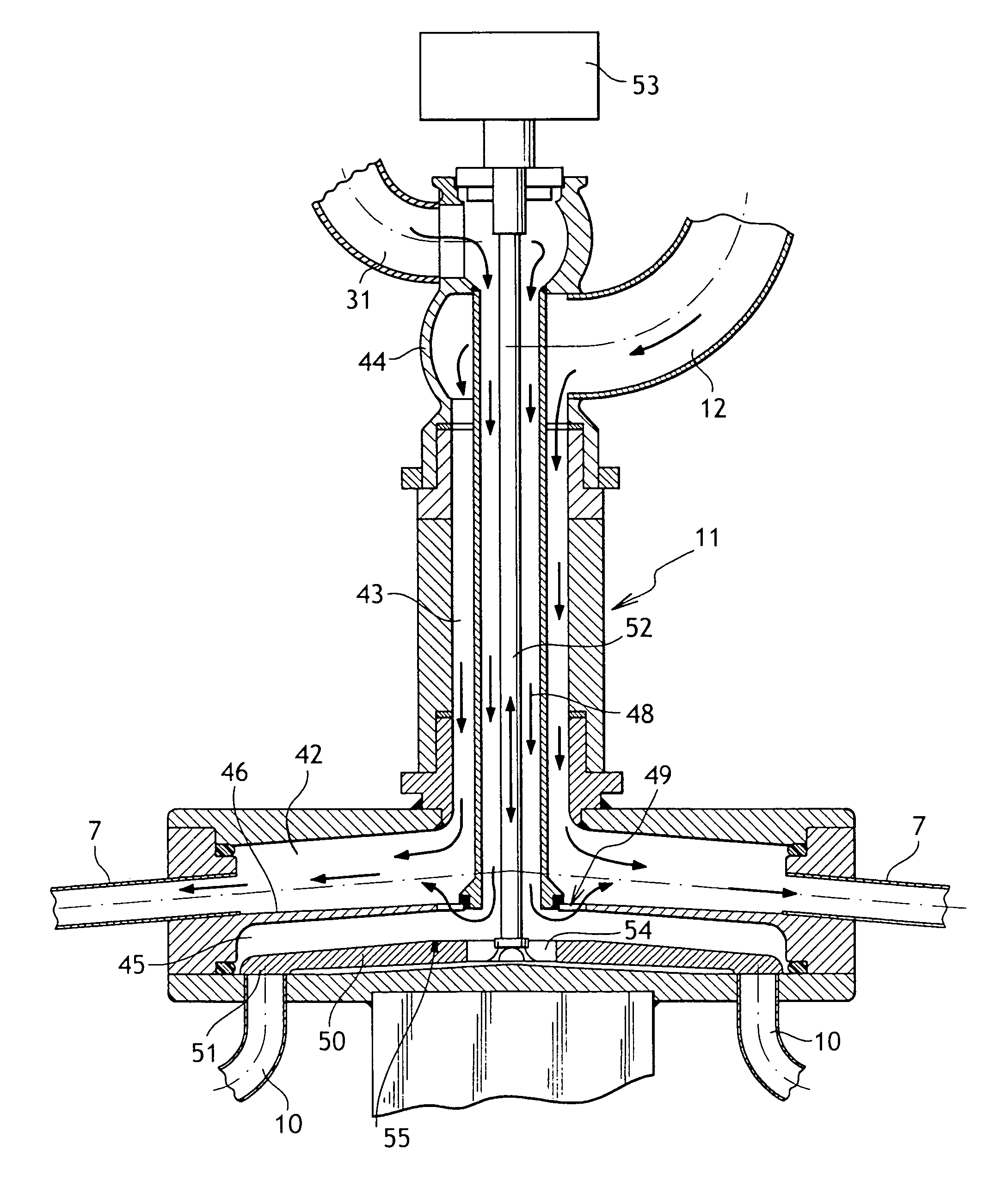

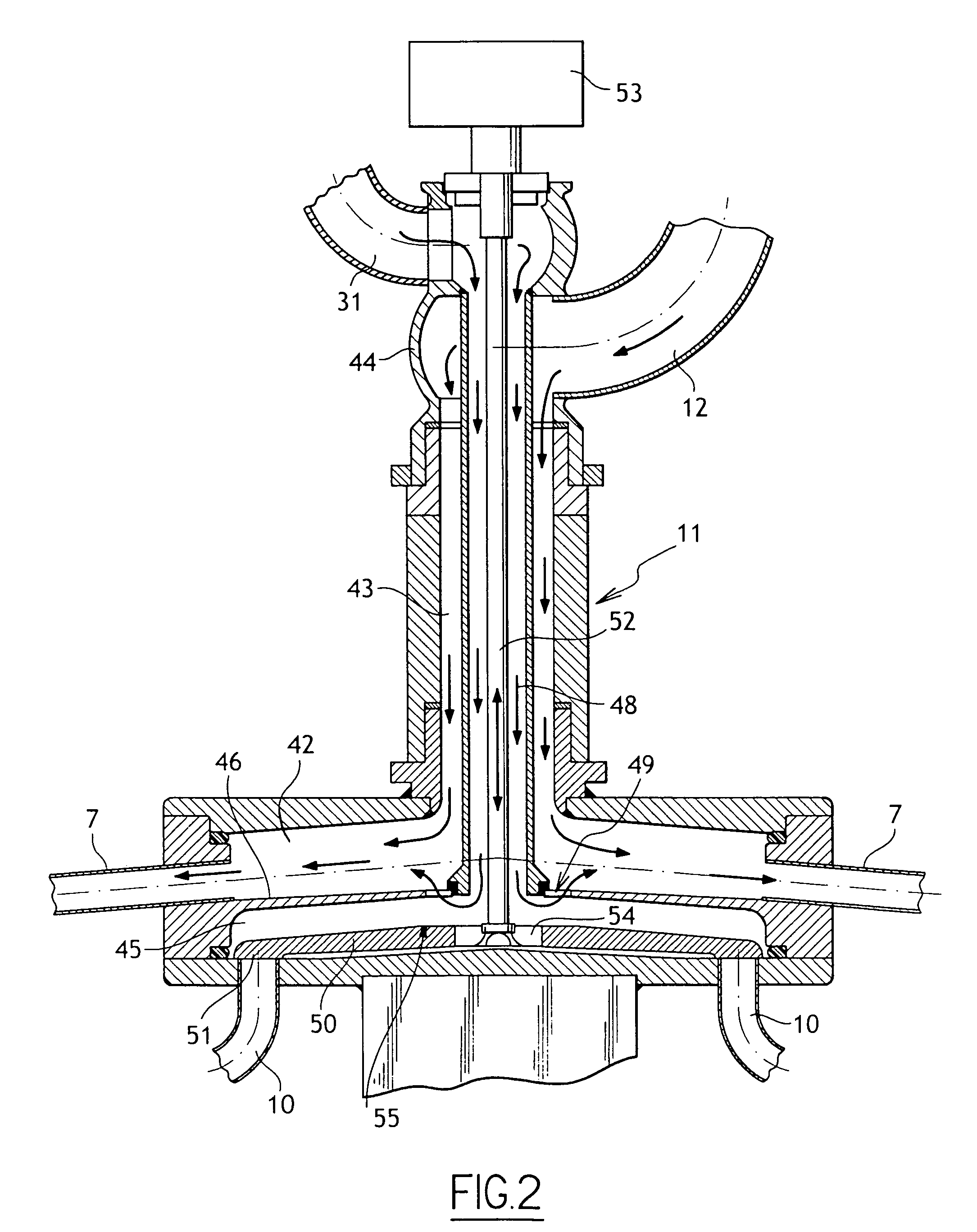

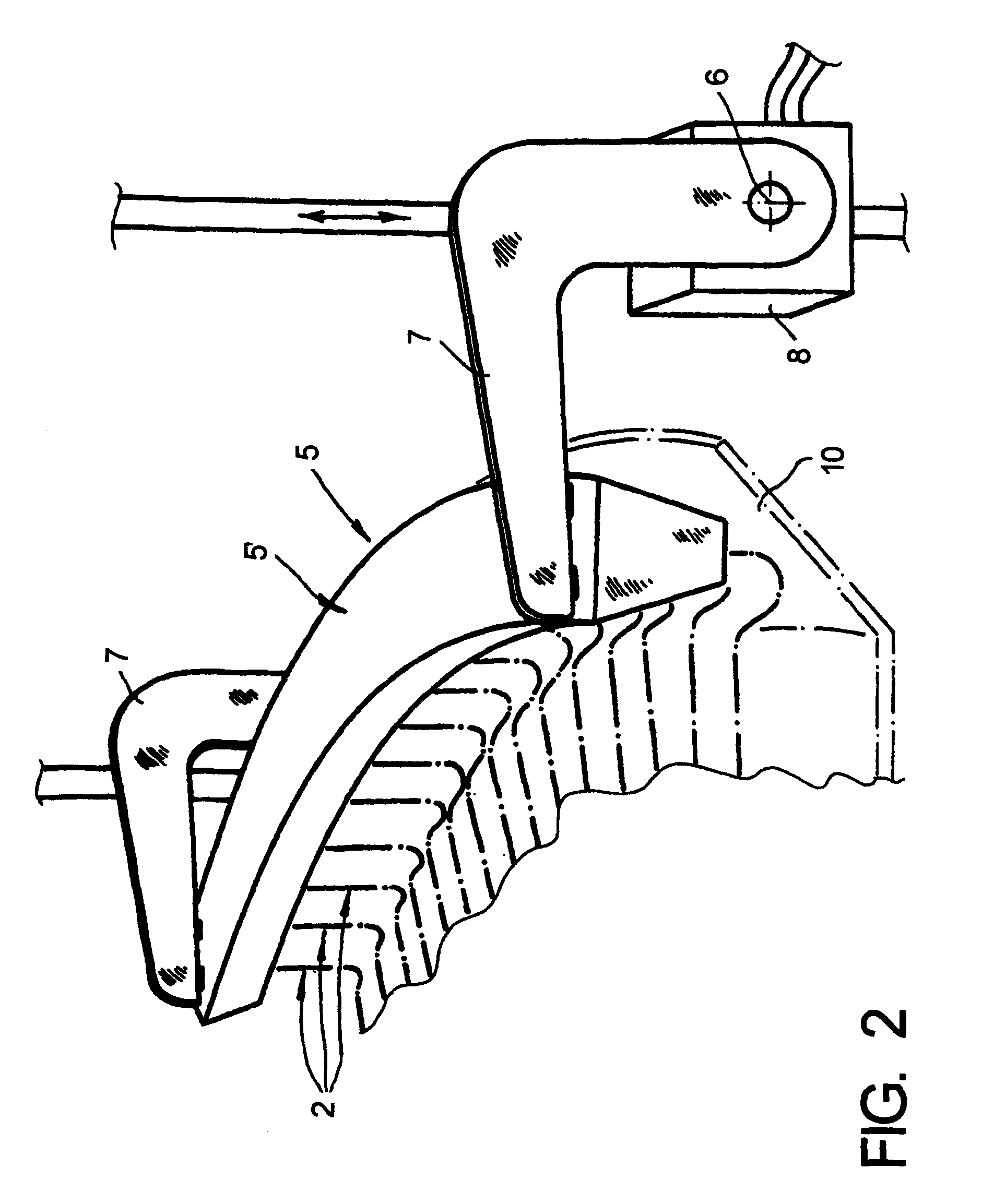

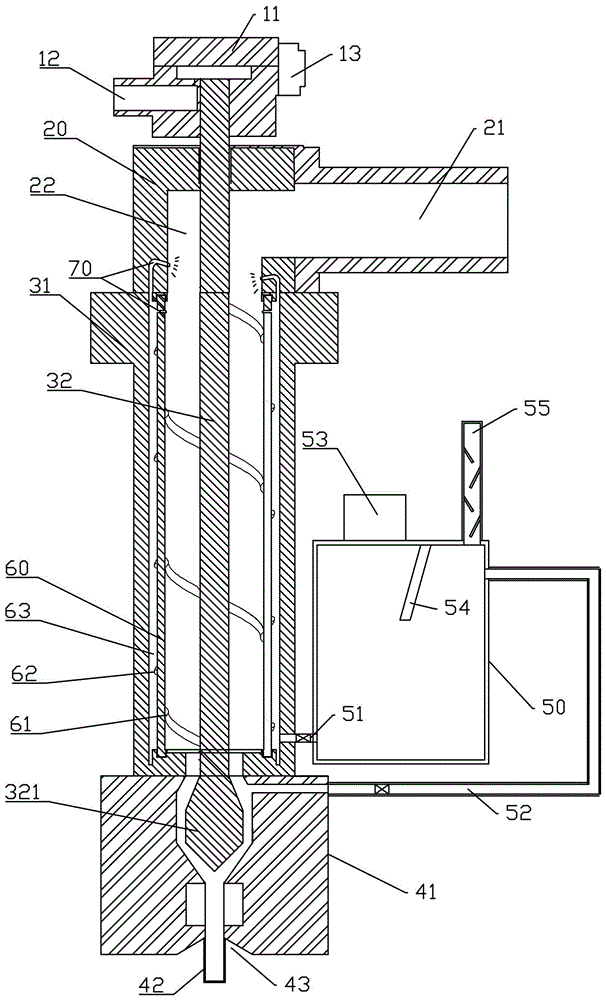

Device for filling receptacles and fitted with an integrated cleaning device

InactiveUS6267157B1Improve sealingImprove efficiencyLiquid fillingSpraying apparatusEngineeringActuator

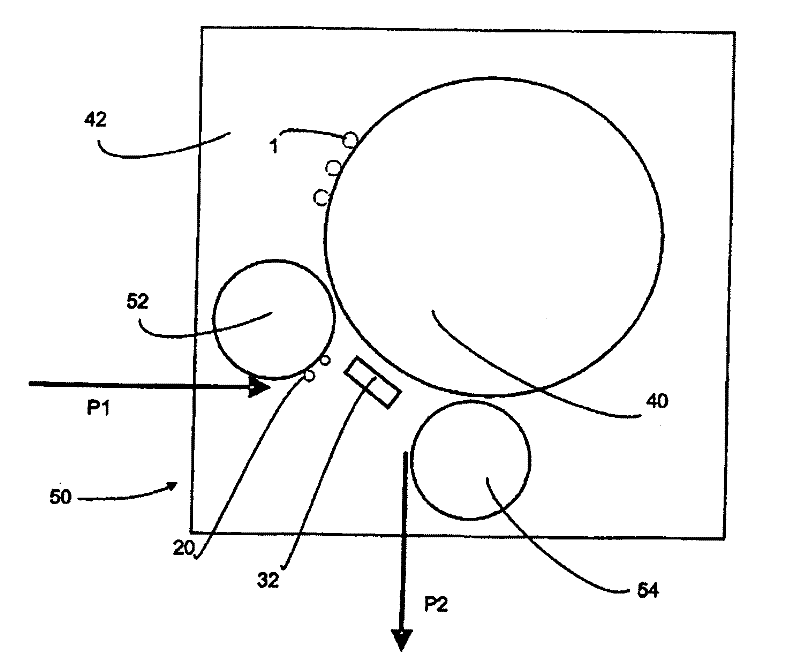

The filling device comprises a delivery duct having a flow orifice associated with a plug, and a cleaning device comprising a collector pan fixed in leakproof manner to the delivery duct in the vicinity of the flow orifice and having a through orifice vertically in register with the flow orifice and a shutter member fixed to an actuator member so that together they form a rigid assembly which is mounted to move with helical motion about an axis normal to a plane containing the through orifice, the shutter member being off said axis.

Owner:SERAC GROUP

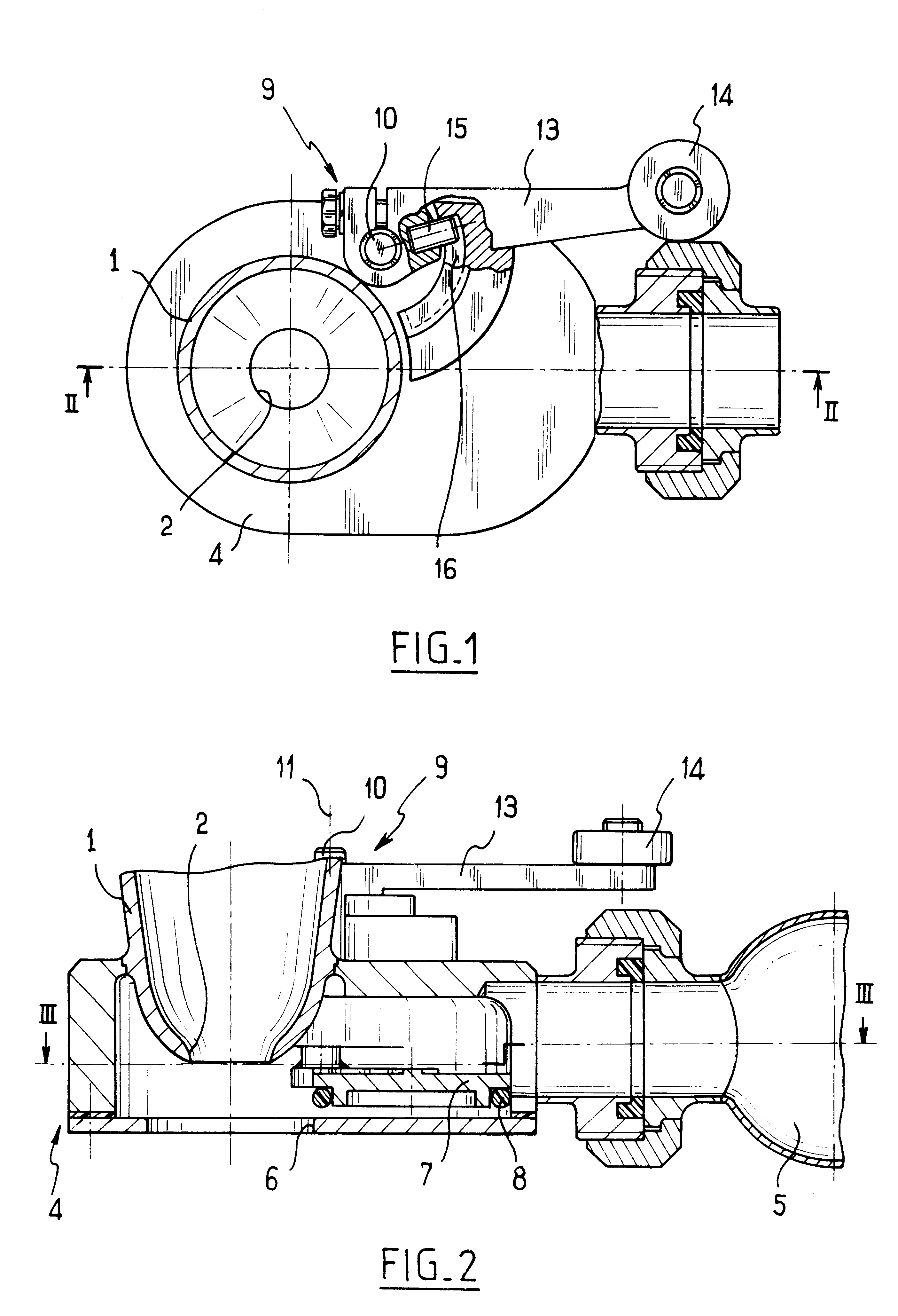

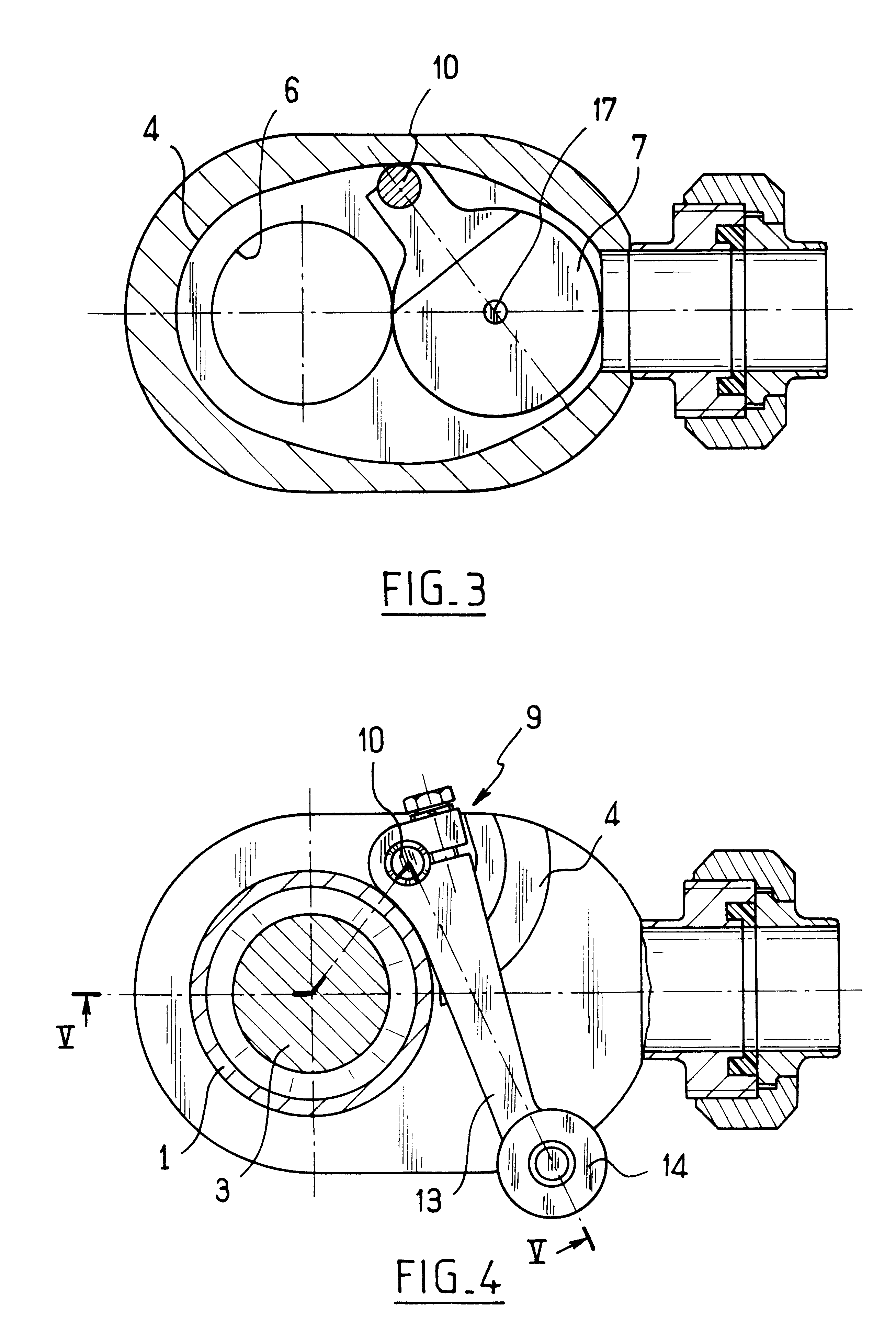

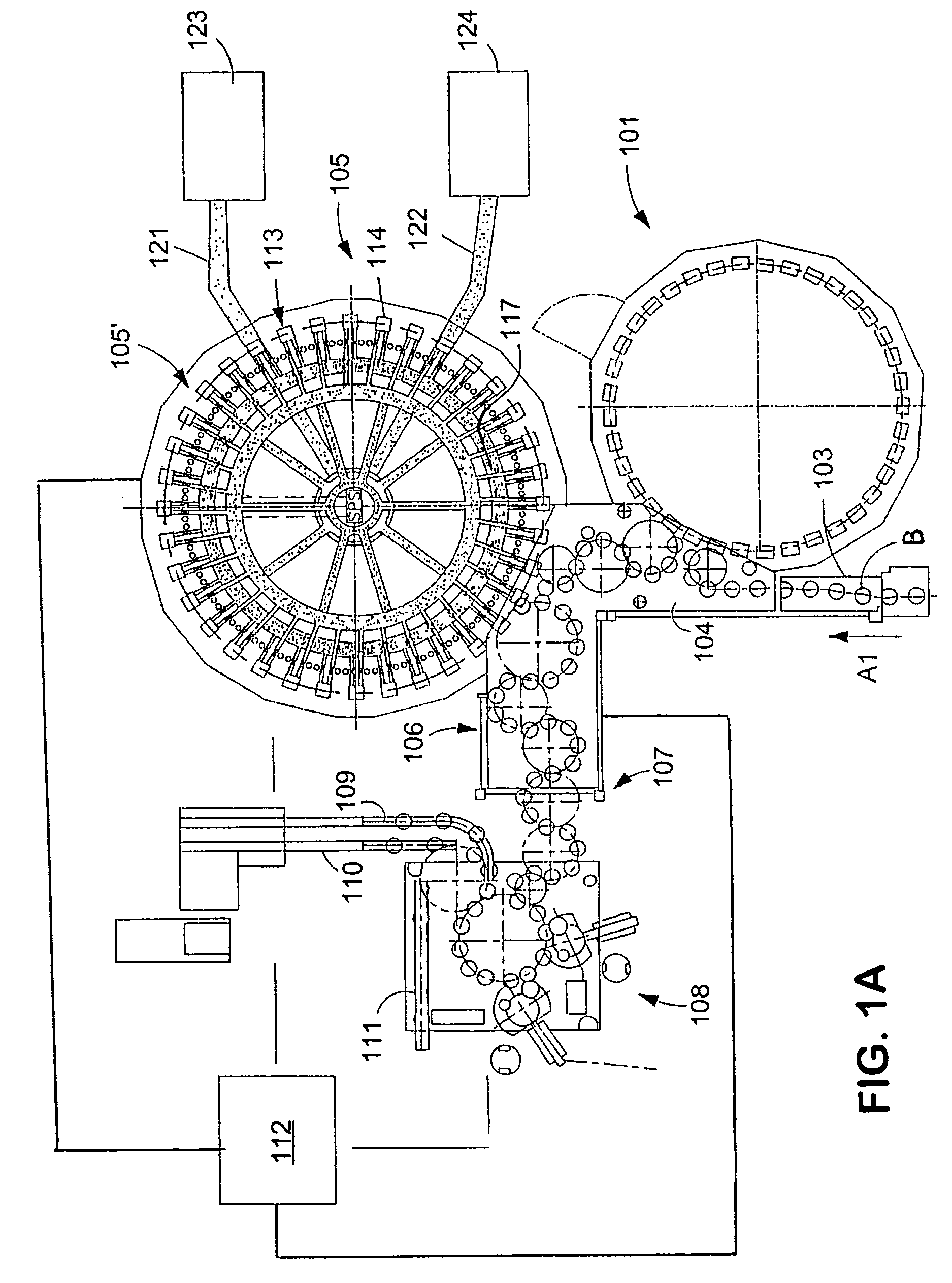

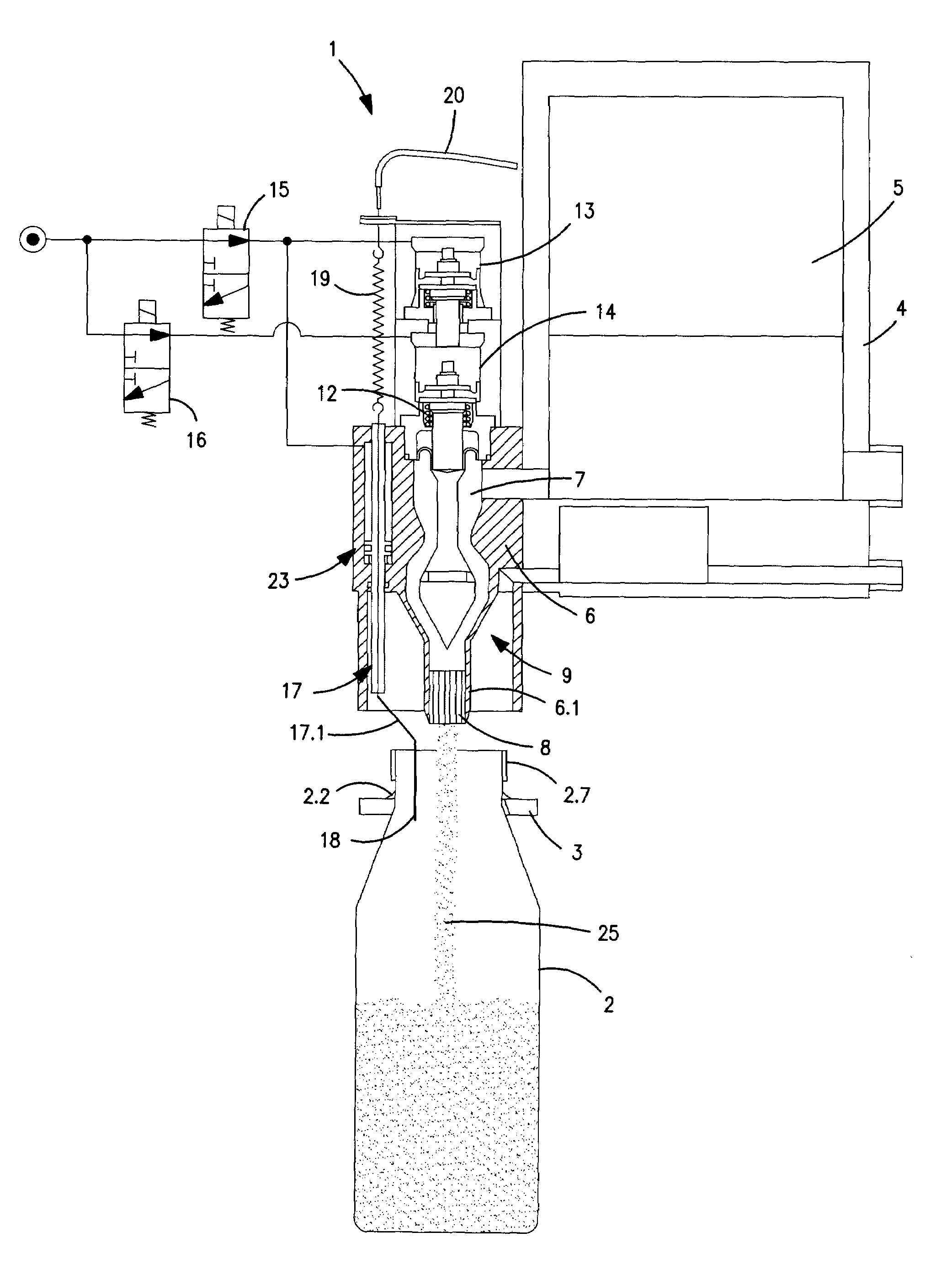

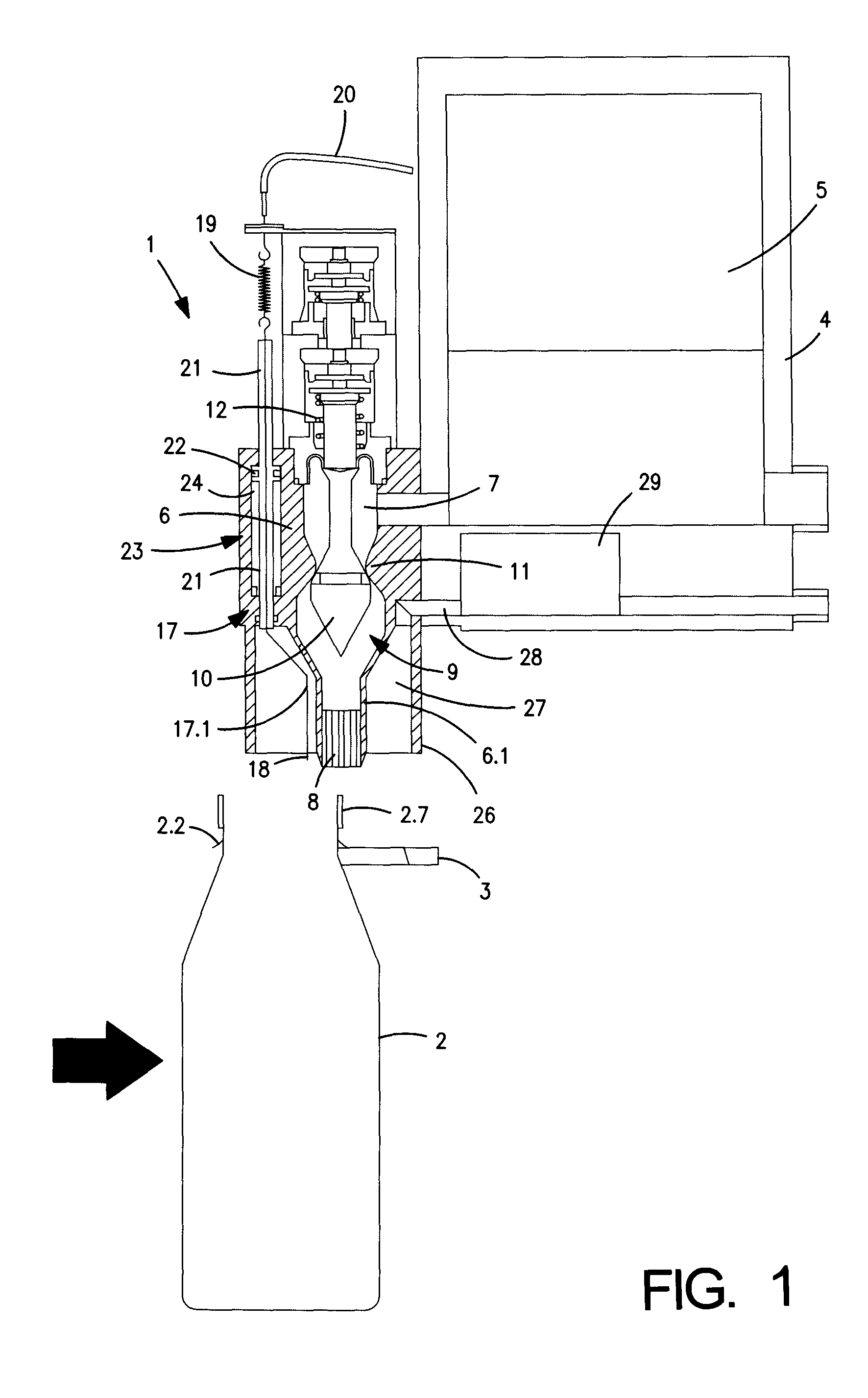

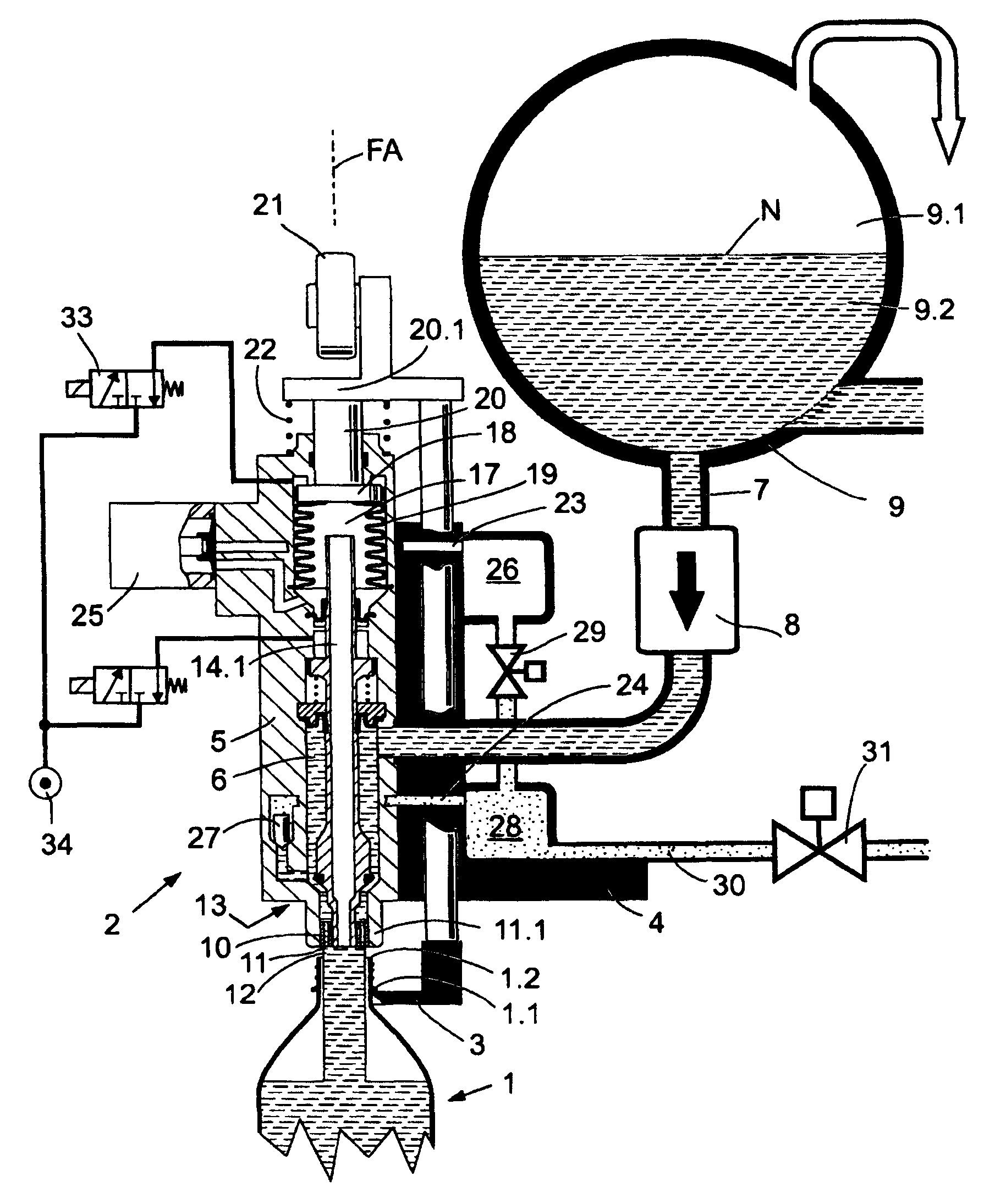

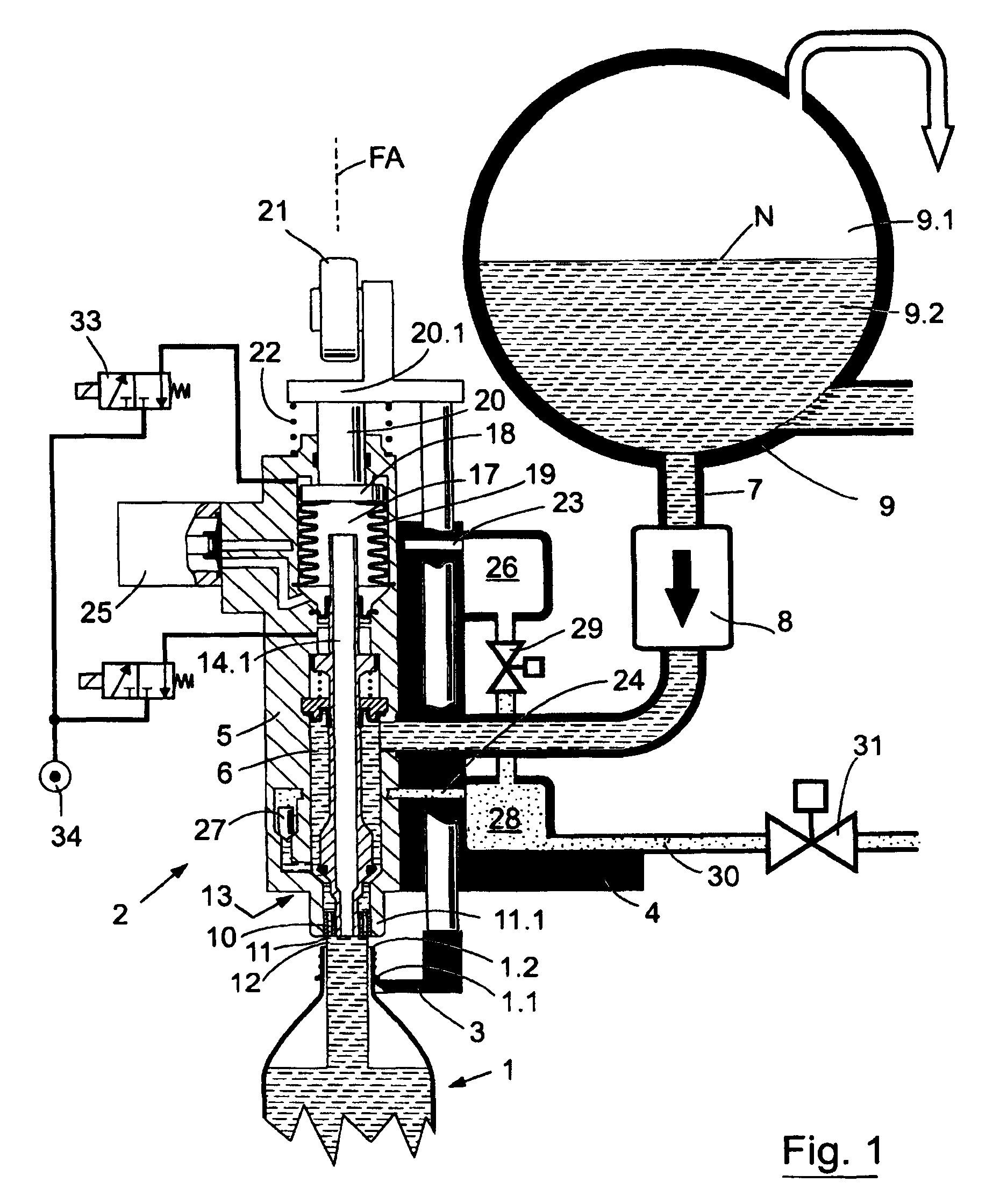

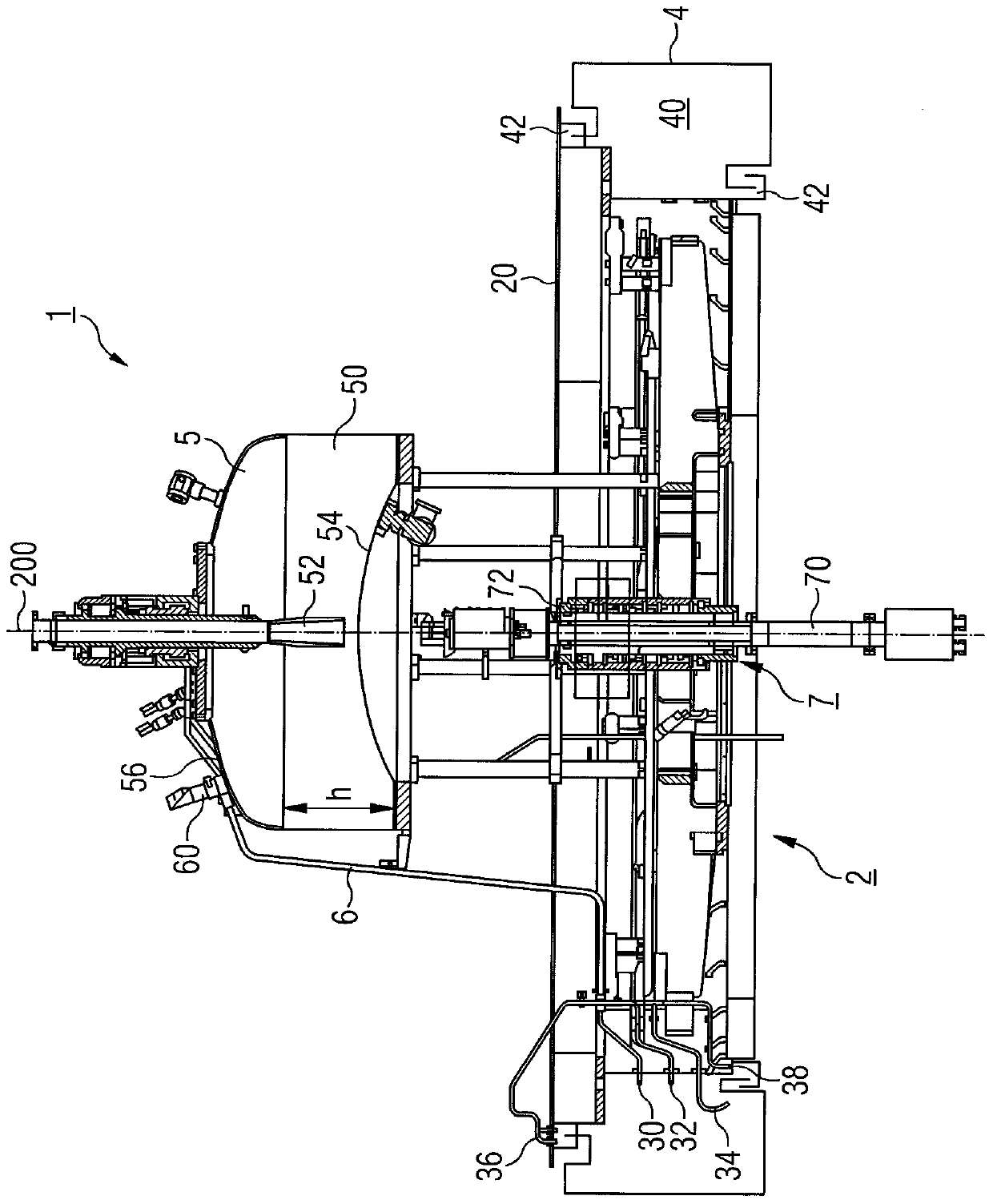

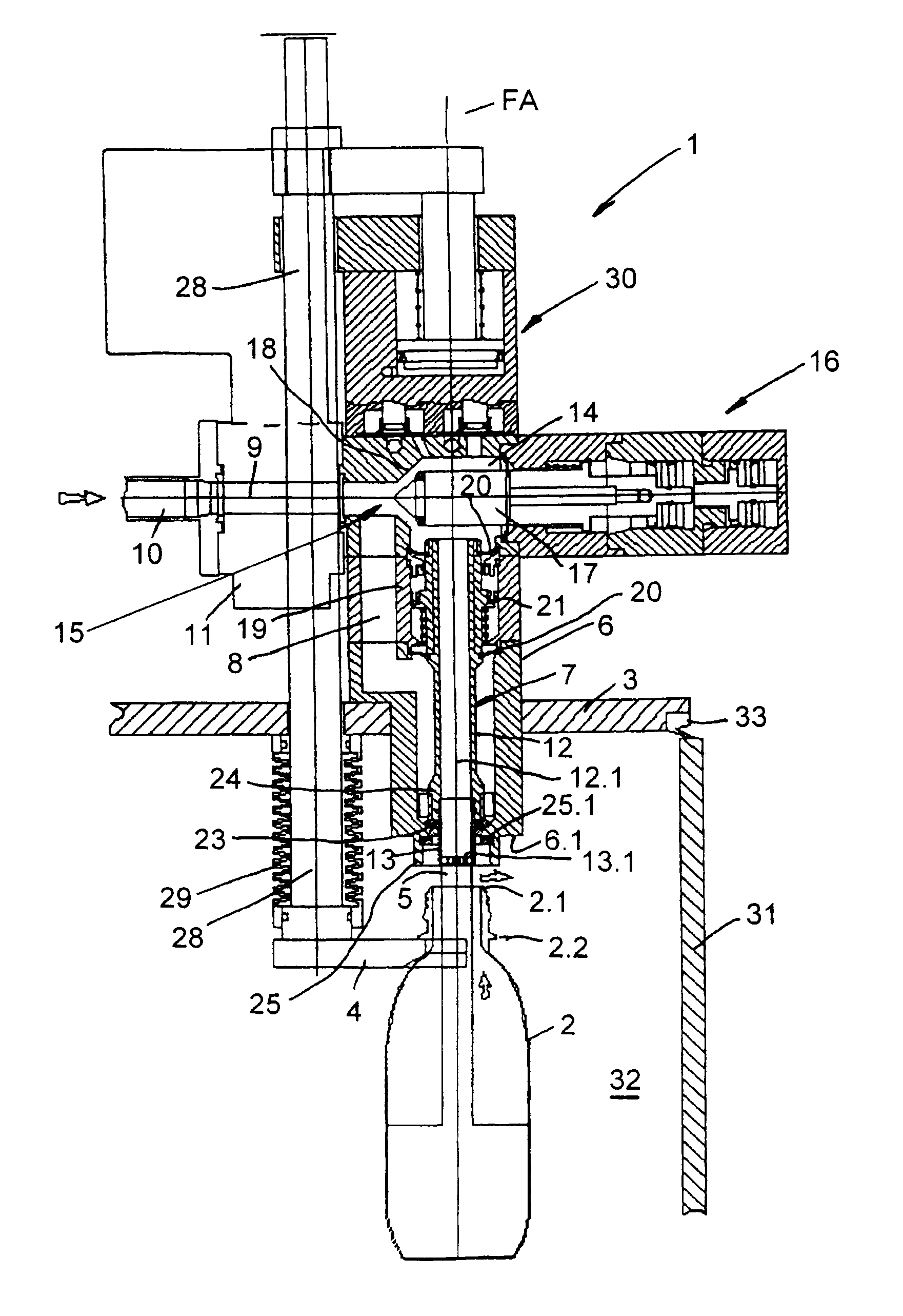

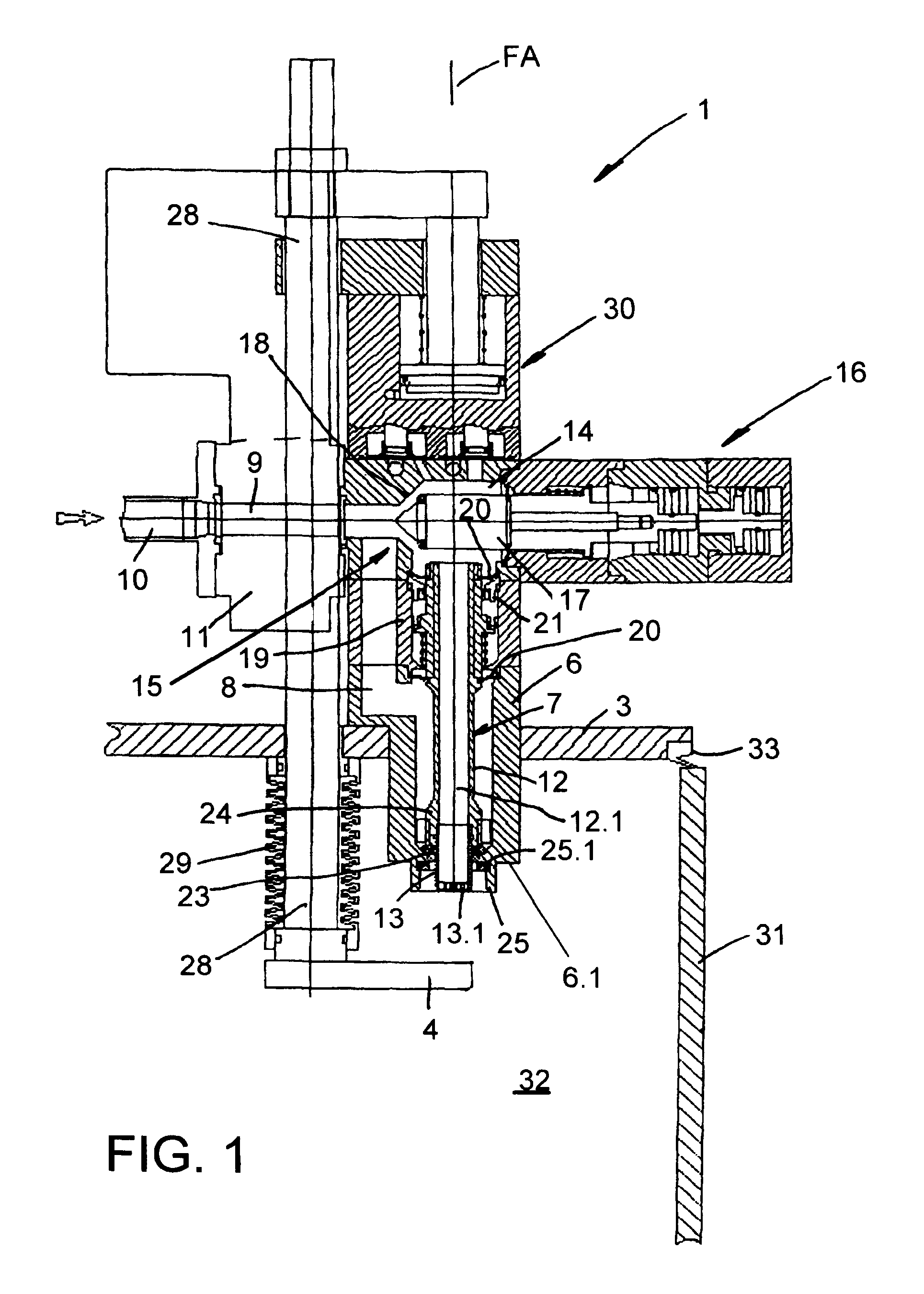

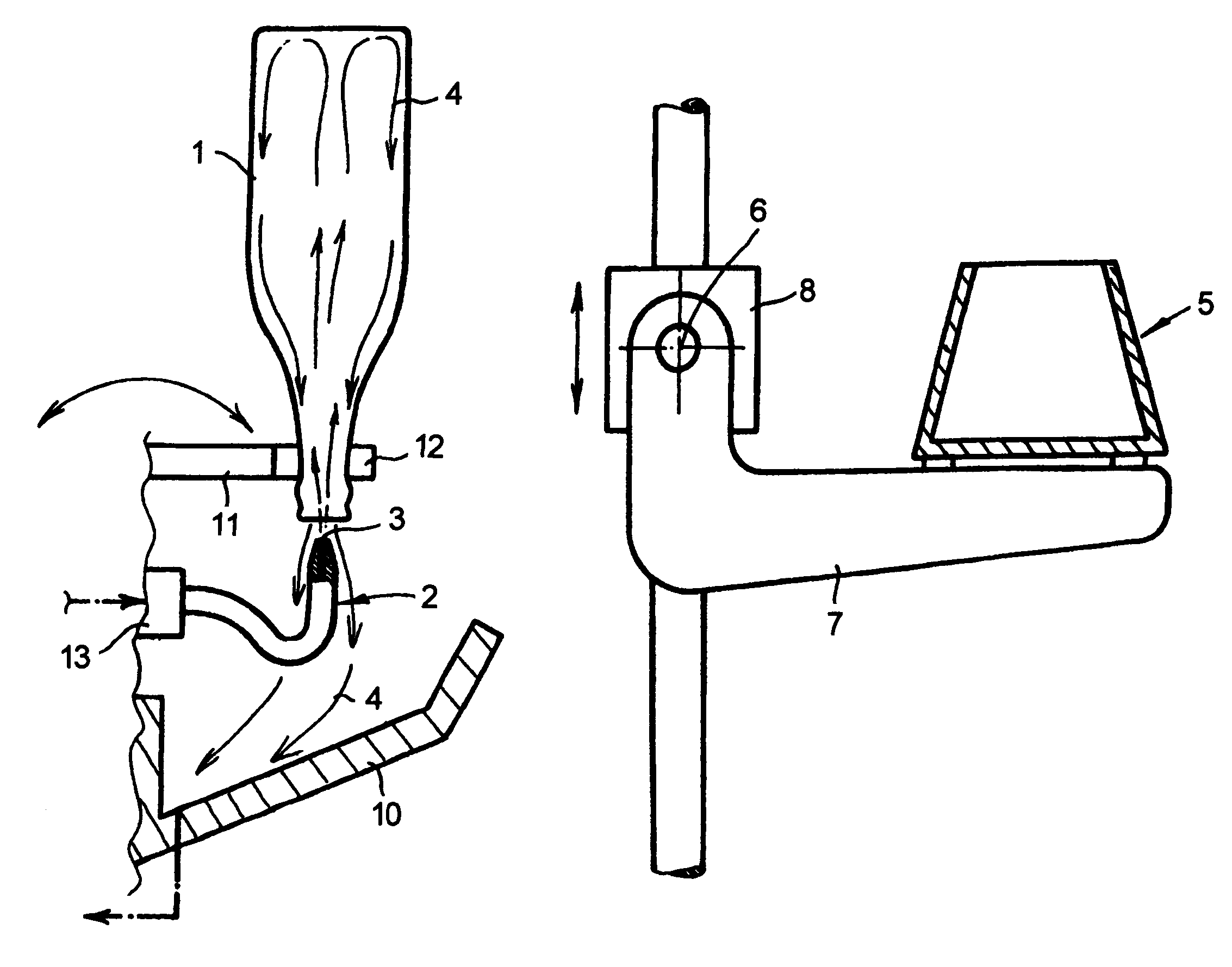

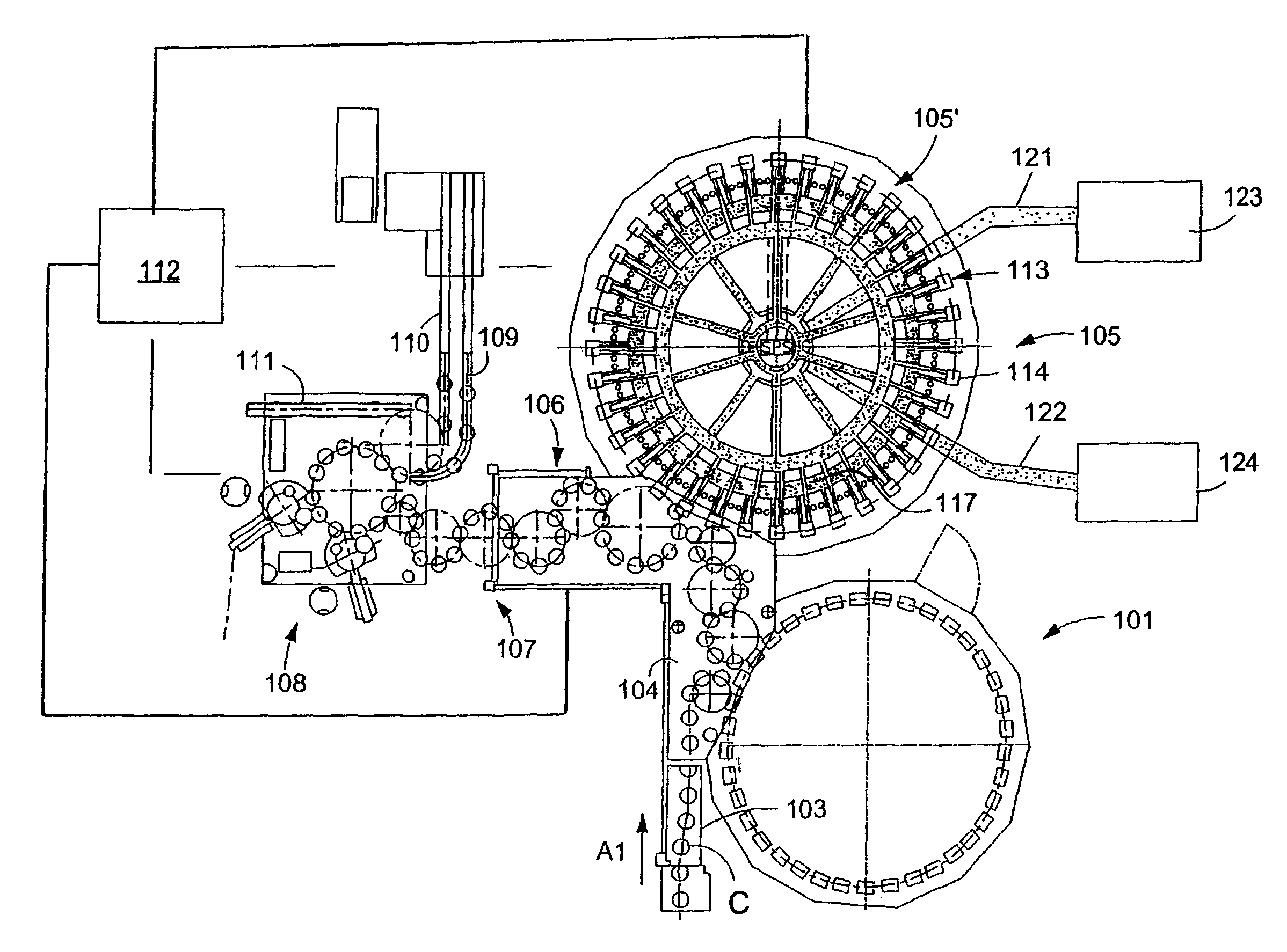

Beverage bottling plant for filling bottles with a liquid beverage, having a filling element and filling machine with such filling elements

A beverage bottling plant for filling bottles with a liquid beverage, having a filling element of a filling machine with a rotary construction for filling bottles or similar containers with a liquid has, in a filling element housing, a liquid duct for the controlled dispensing of a liquid at a dispensing opening. The dispensing opening is located in a recess into which the respective container extends with its container mouth during the filling, and into which at least one additional duct of the filling element empties. During a cleaning or rinsing phase, the recess can be closed by a plate-shaped closing element.

Owner:KHS GMBH

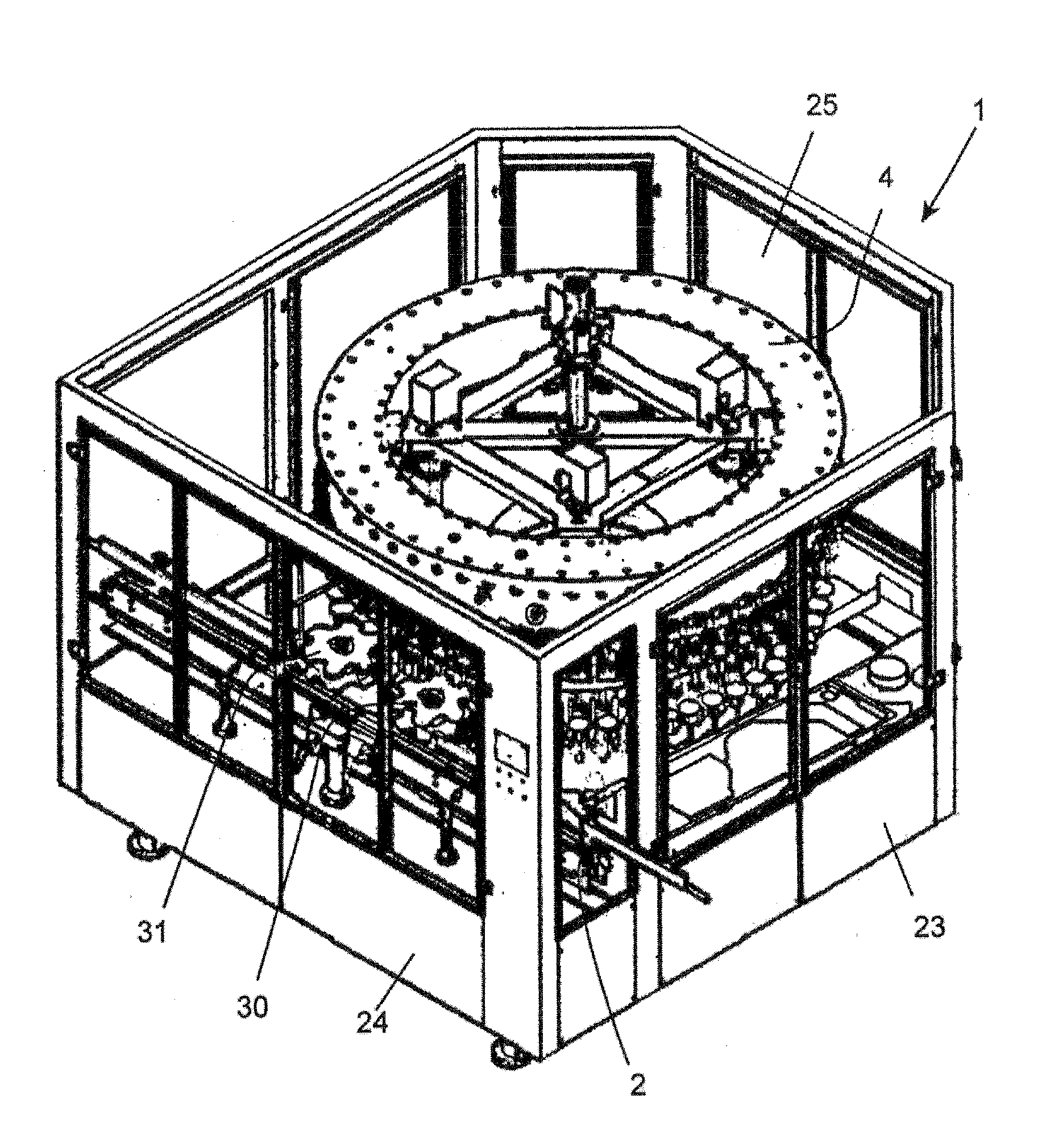

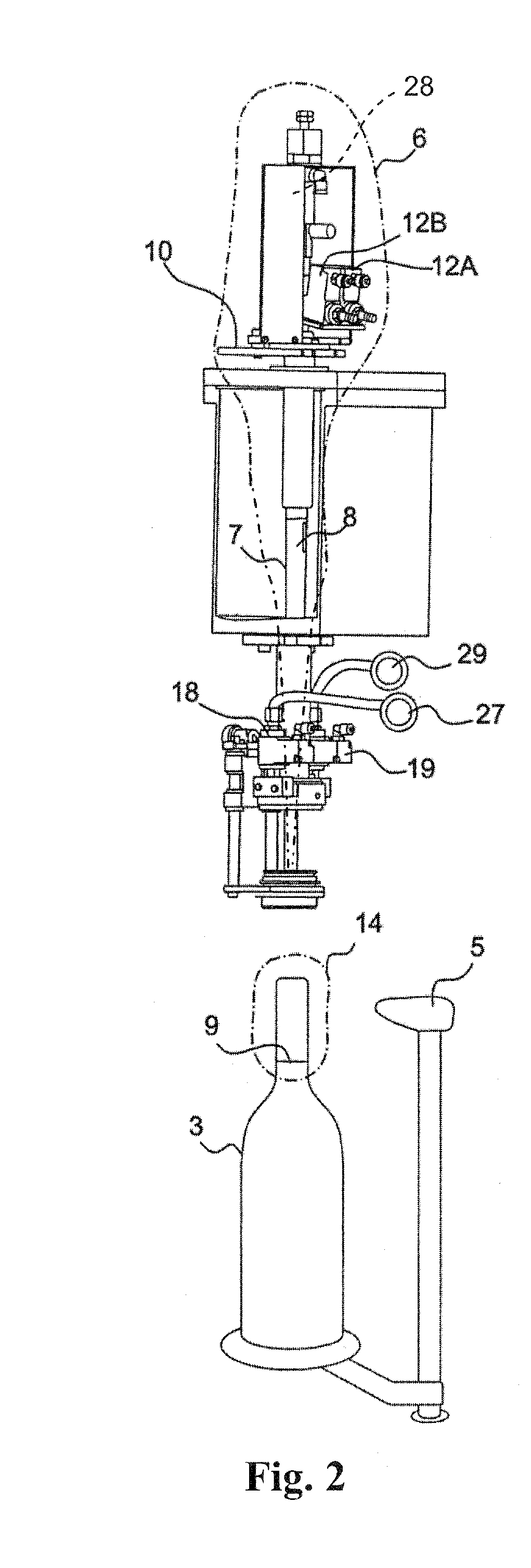

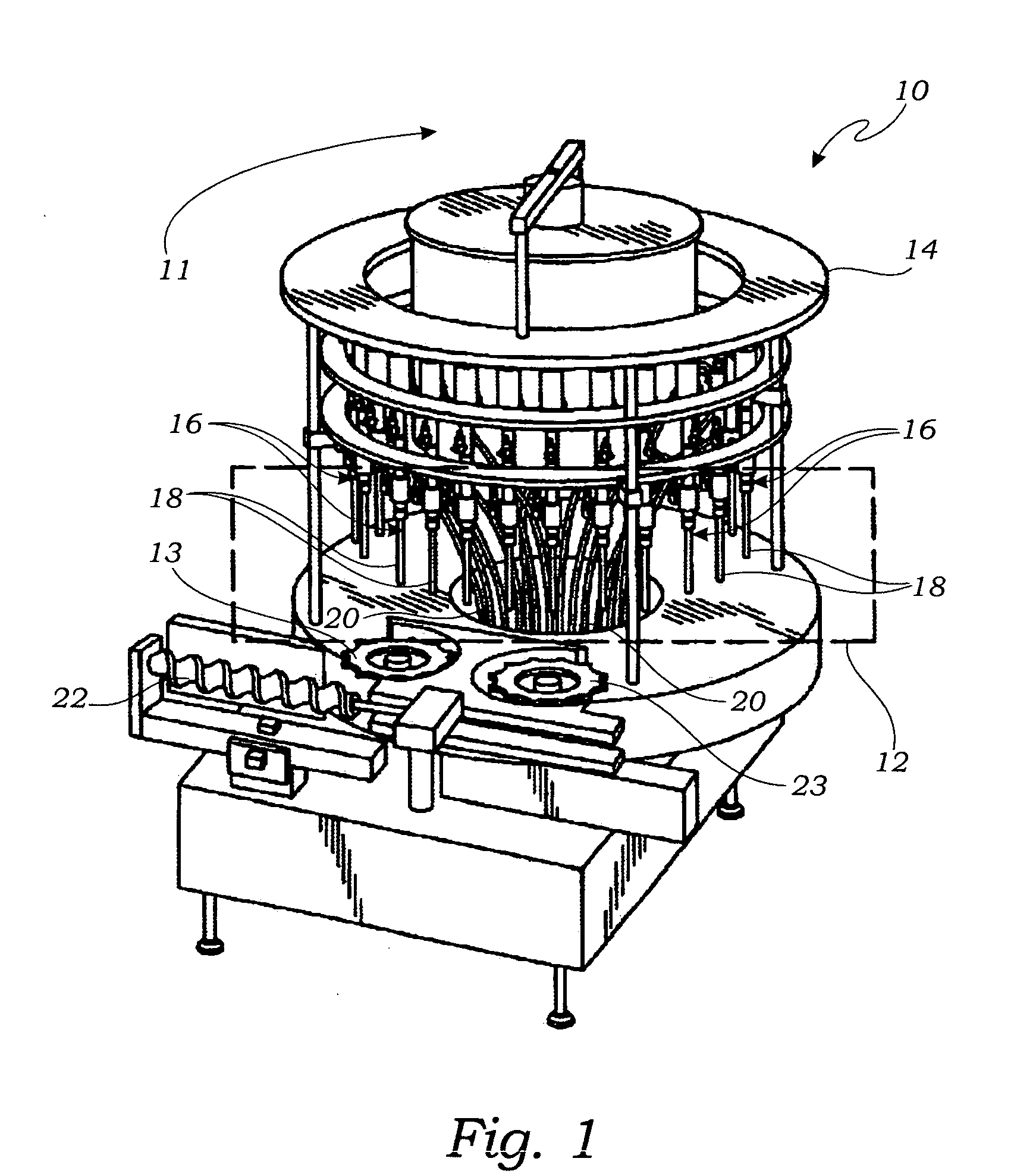

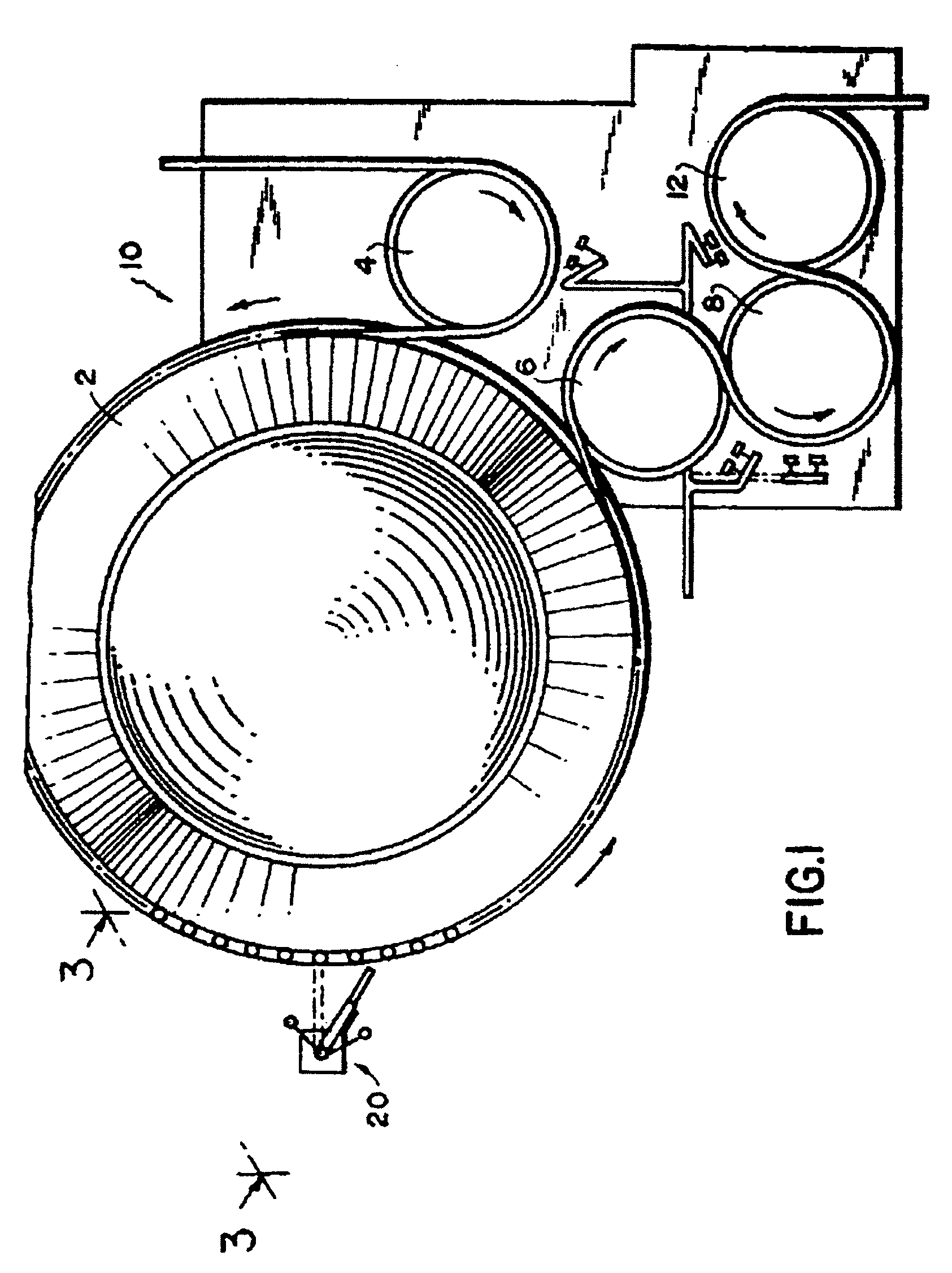

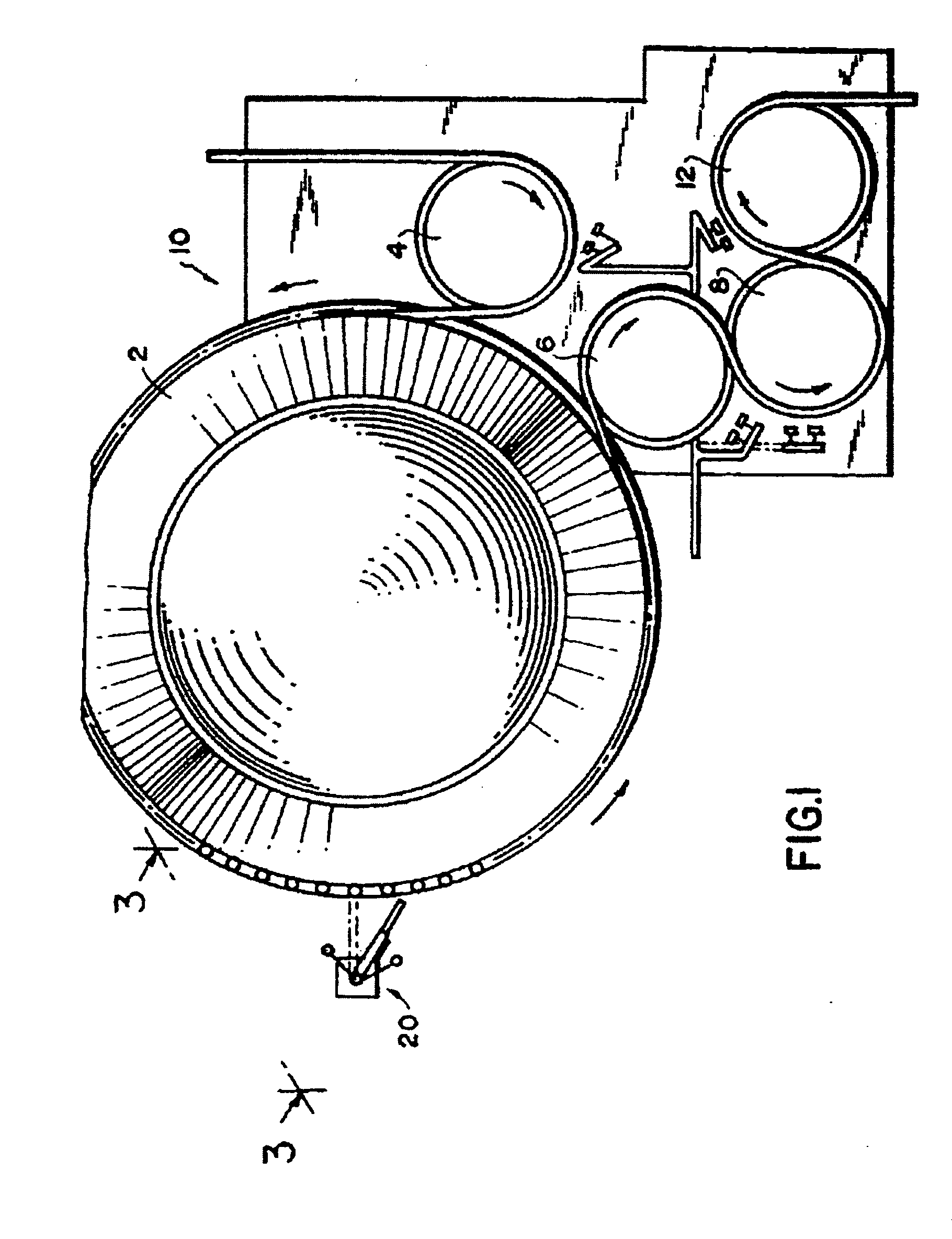

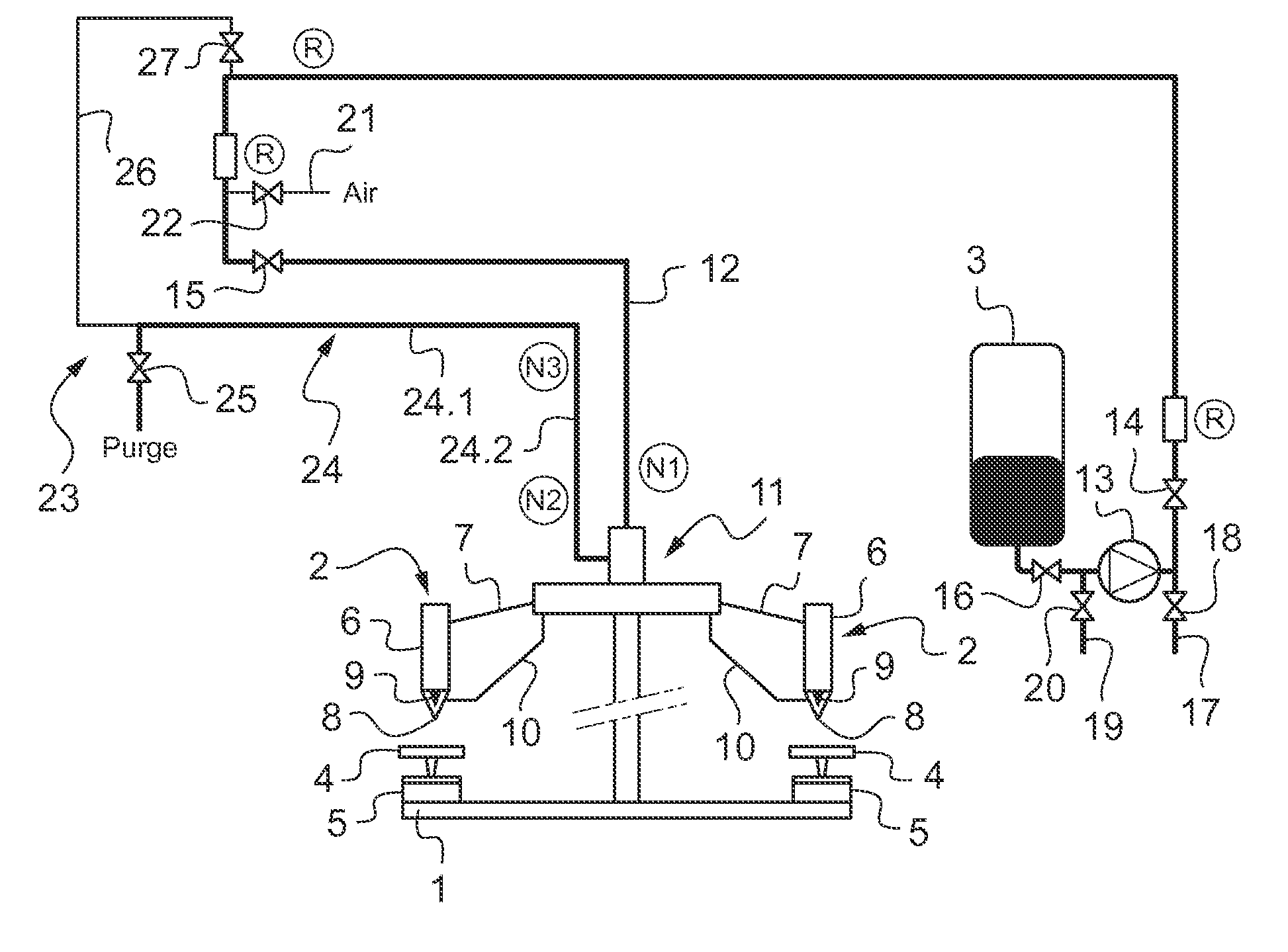

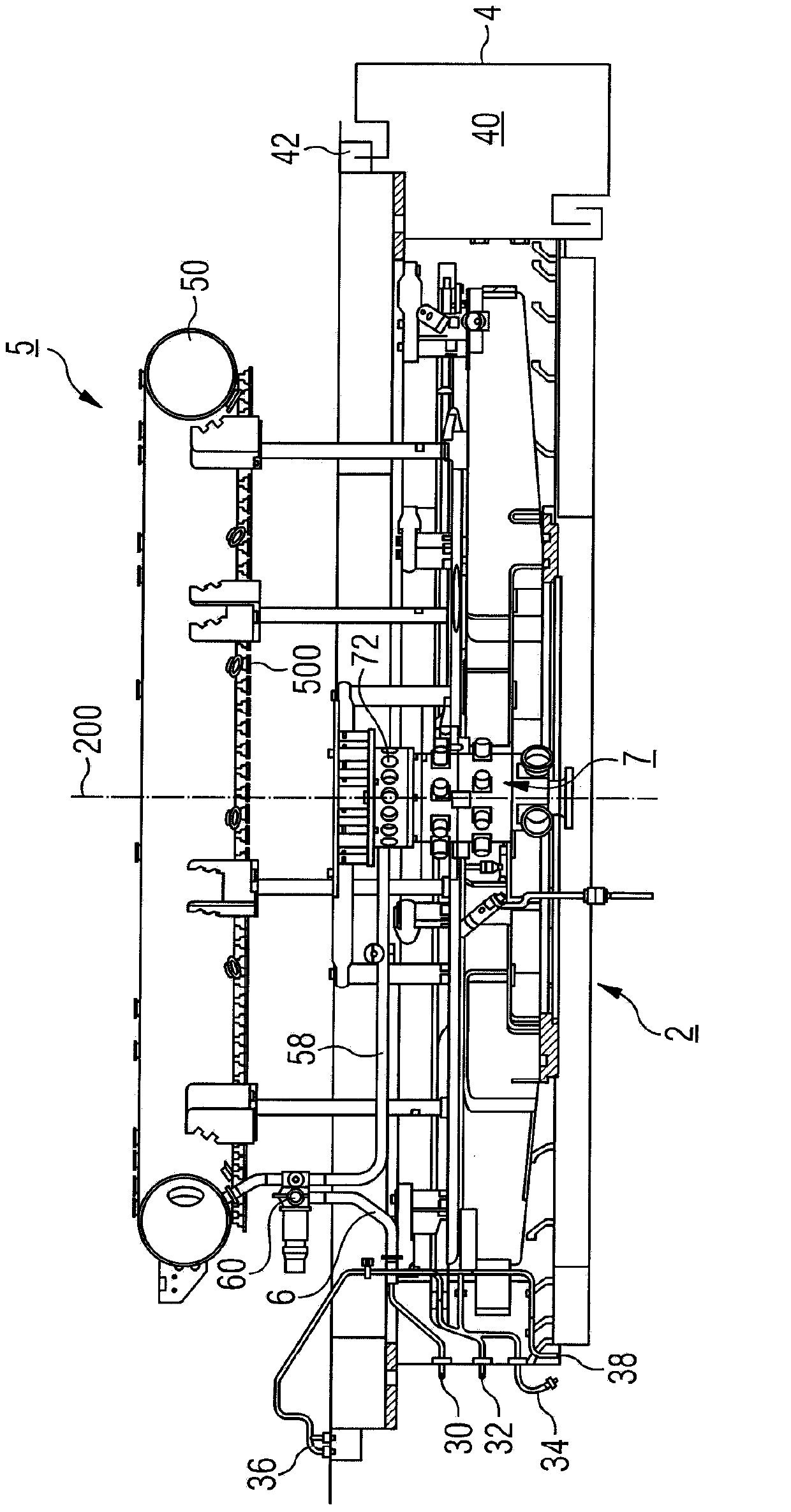

Rotary filling machine for filling containers with liquids

InactiveUS20080271812A1Format has been changedPerformed simply and rapidlyPackaging by pressurising/gasifyingSolid materialActuatorStorage tank

Rotary filling machine for filling containers with liquids, which comprises a rotating carousel (4) having, mounted along its periphery, a plurality of filling valves (6). Each filling valve (6) has an outer pipe (7) for supplying the liquid from a storage tank (20) to a container (30) to be filled with said liquid, and an inner compensation pipe (8) for defining the liquid level inside said container (3) mounted concentrically with the outer pipe (7). Actuator means are envisaged for each filling valve (6) and, by means of transmission means (101), vary simultaneously and in an adjustable manner the vertical position of the compensation pipes (8) of all the filling valves (6) with respect to the position of a seal (13) mounted underneath the tank (20) so as to receive against it the mouth of the containers (3).

Owner:GRUPPO BERTOLASO

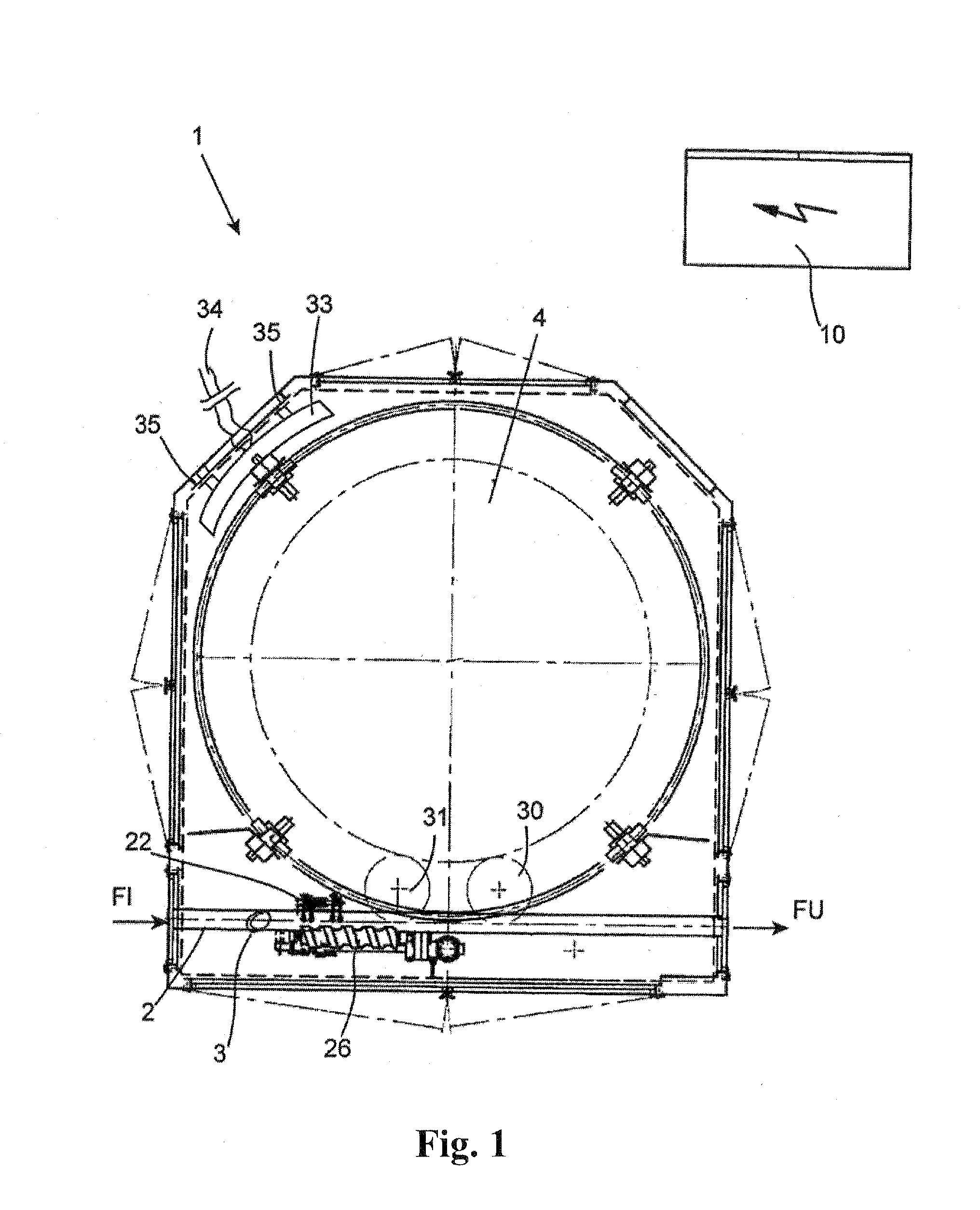

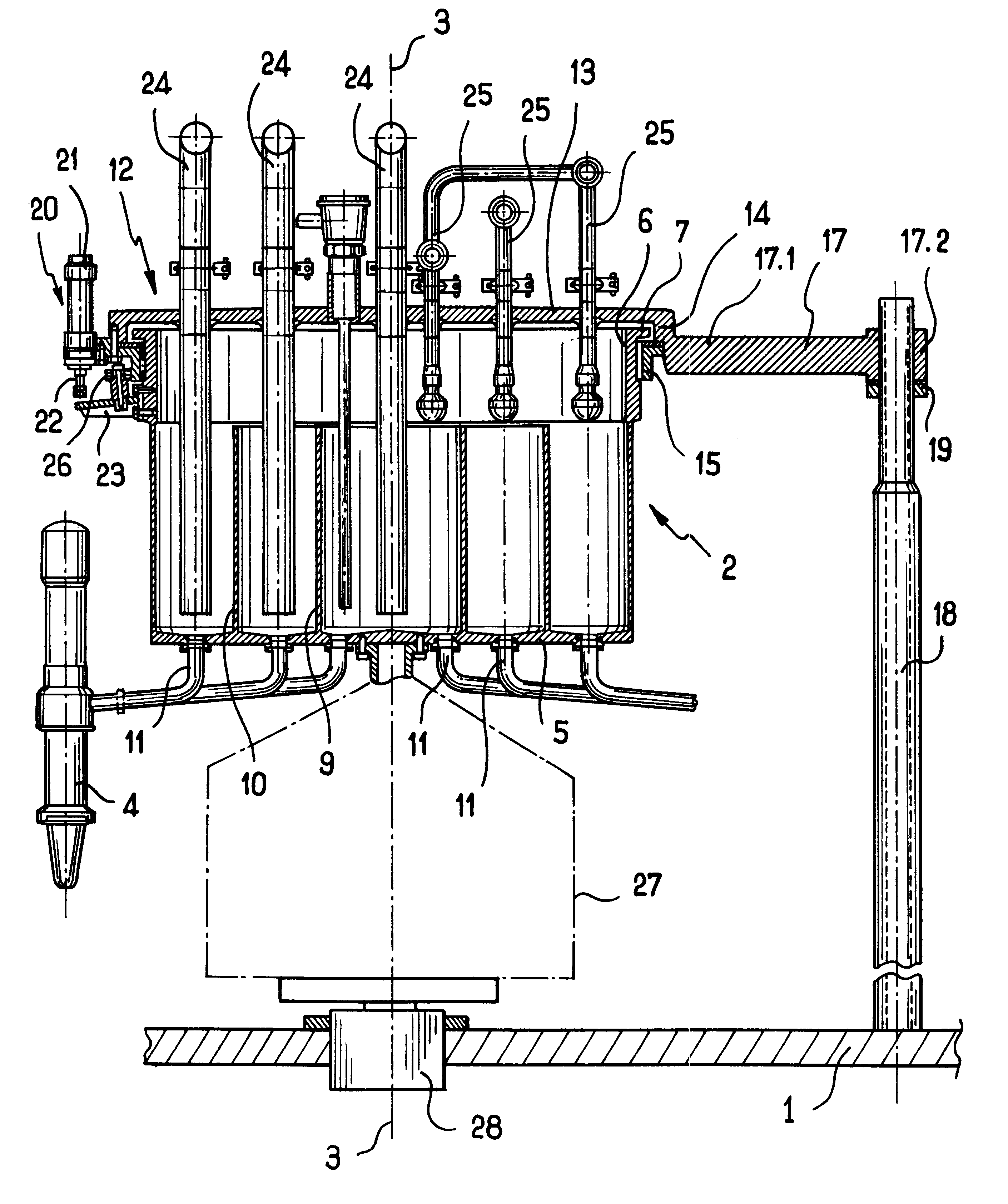

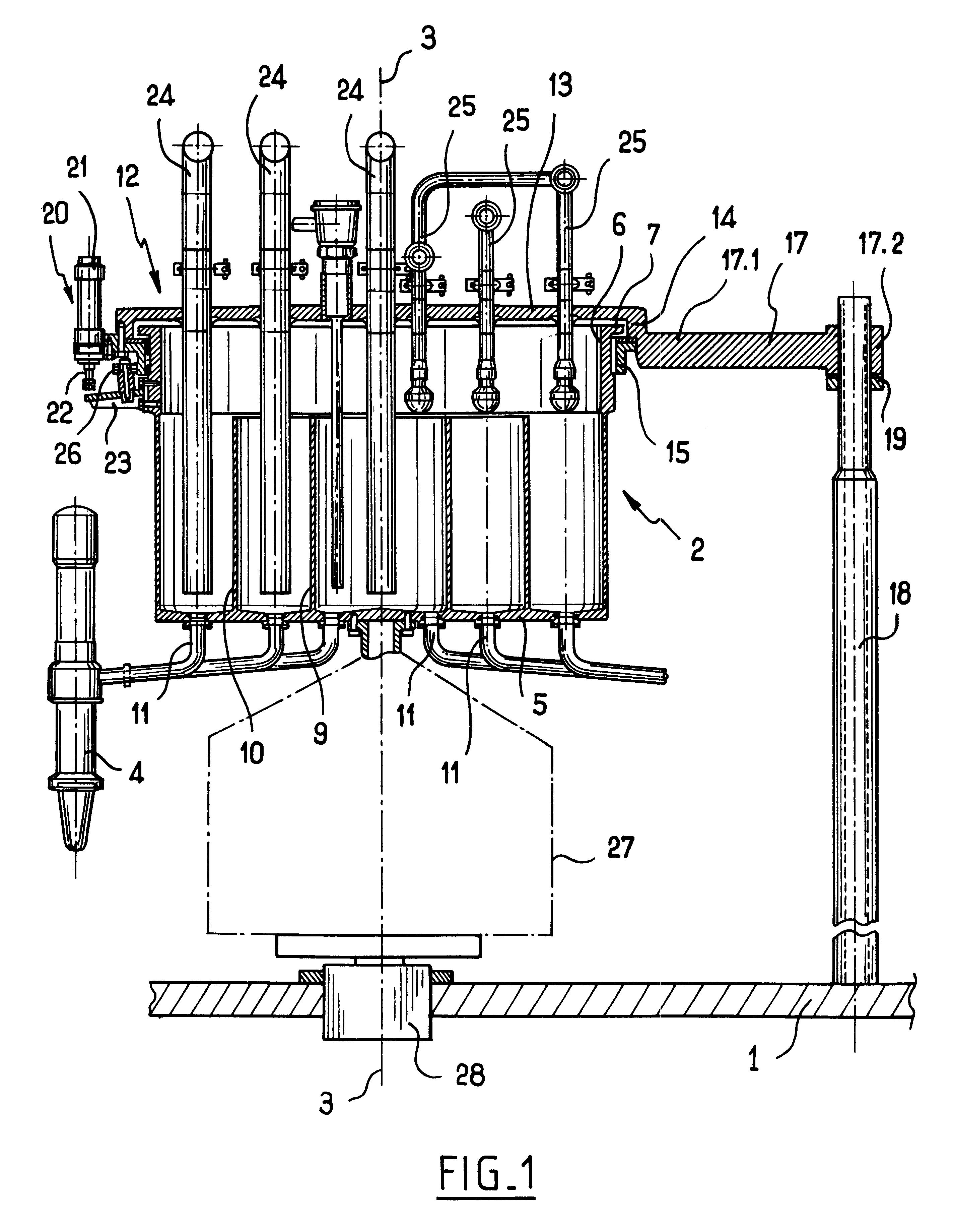

Installation for filling containers

InactiveUS6334473B1Keep the distancePrevent rotationFilling without pressureSolid materialFixed frameEngineering

A filling installation comprising a fixed frame, a tank mounted on the fixed frame so as to rotate about an axis, and a lid associated with the tank and provided with a feed pipe, positioning means being fixed to the lid, and being mounted on the fixed frame to slide parallel to the axis of rotation between a position in which the lid is applied against an edge of the tank so as to close off said tank and a position in which the lid is spaced apart from the edge of the tank.

Owner:SERAC GROUP

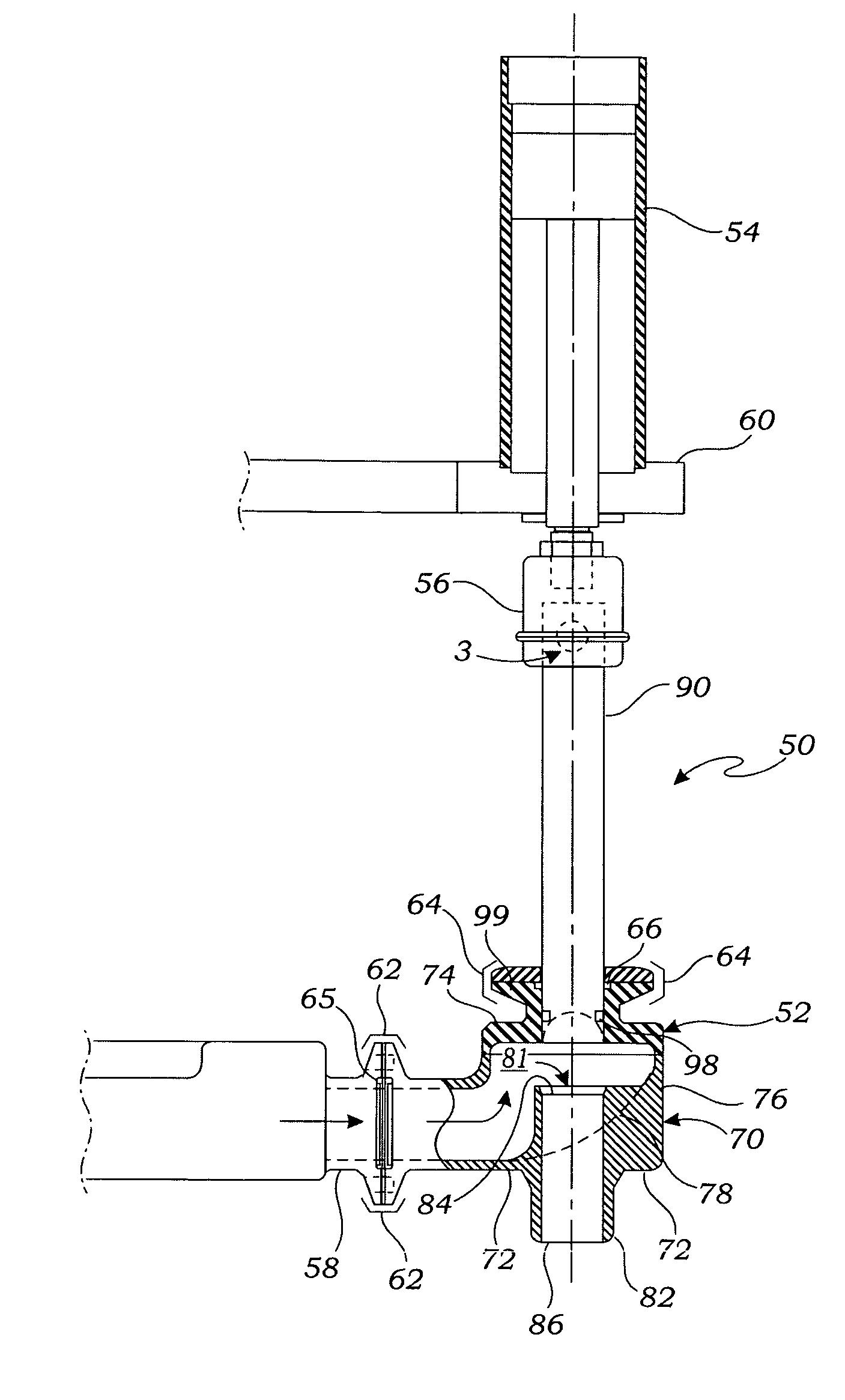

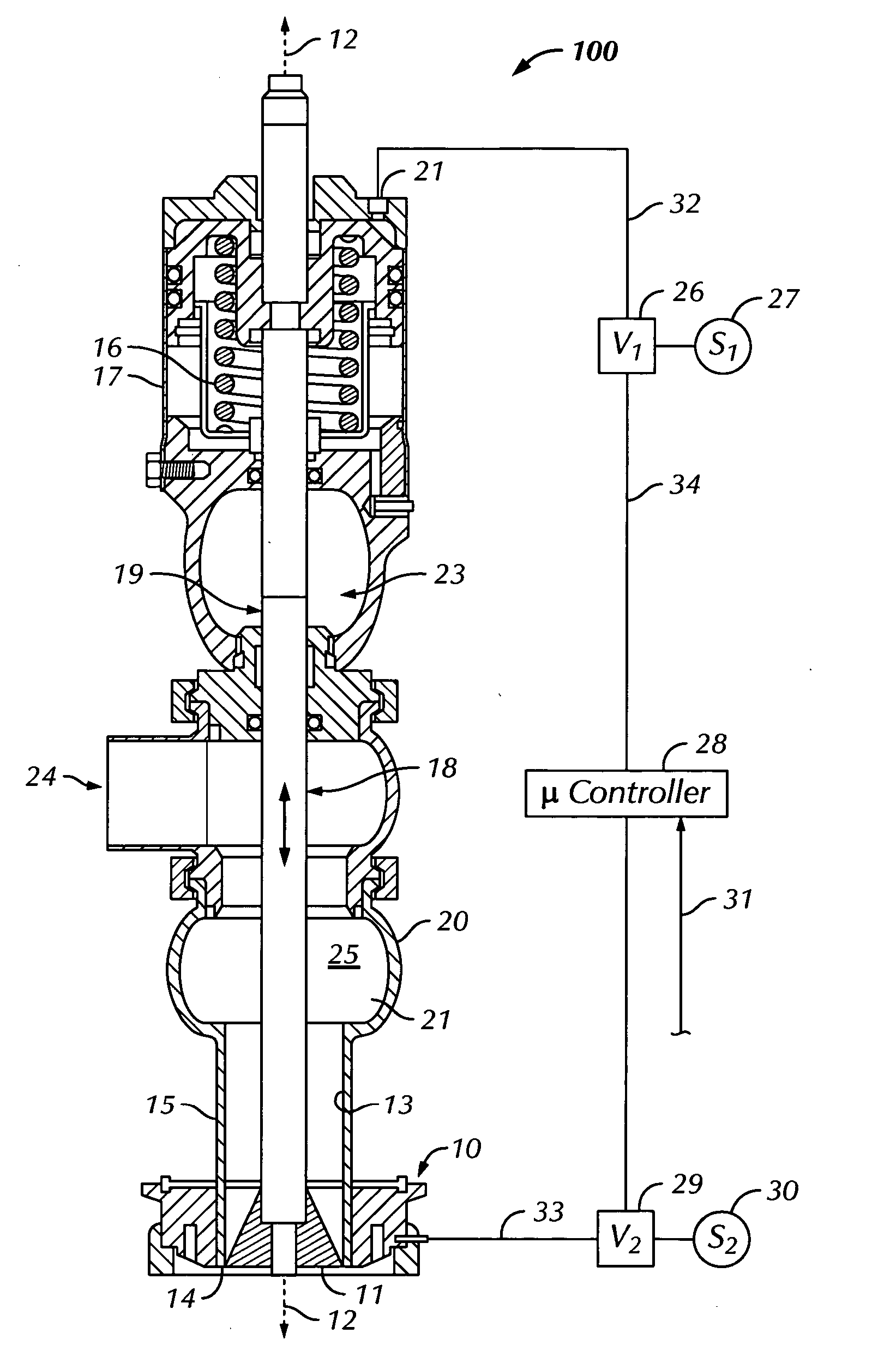

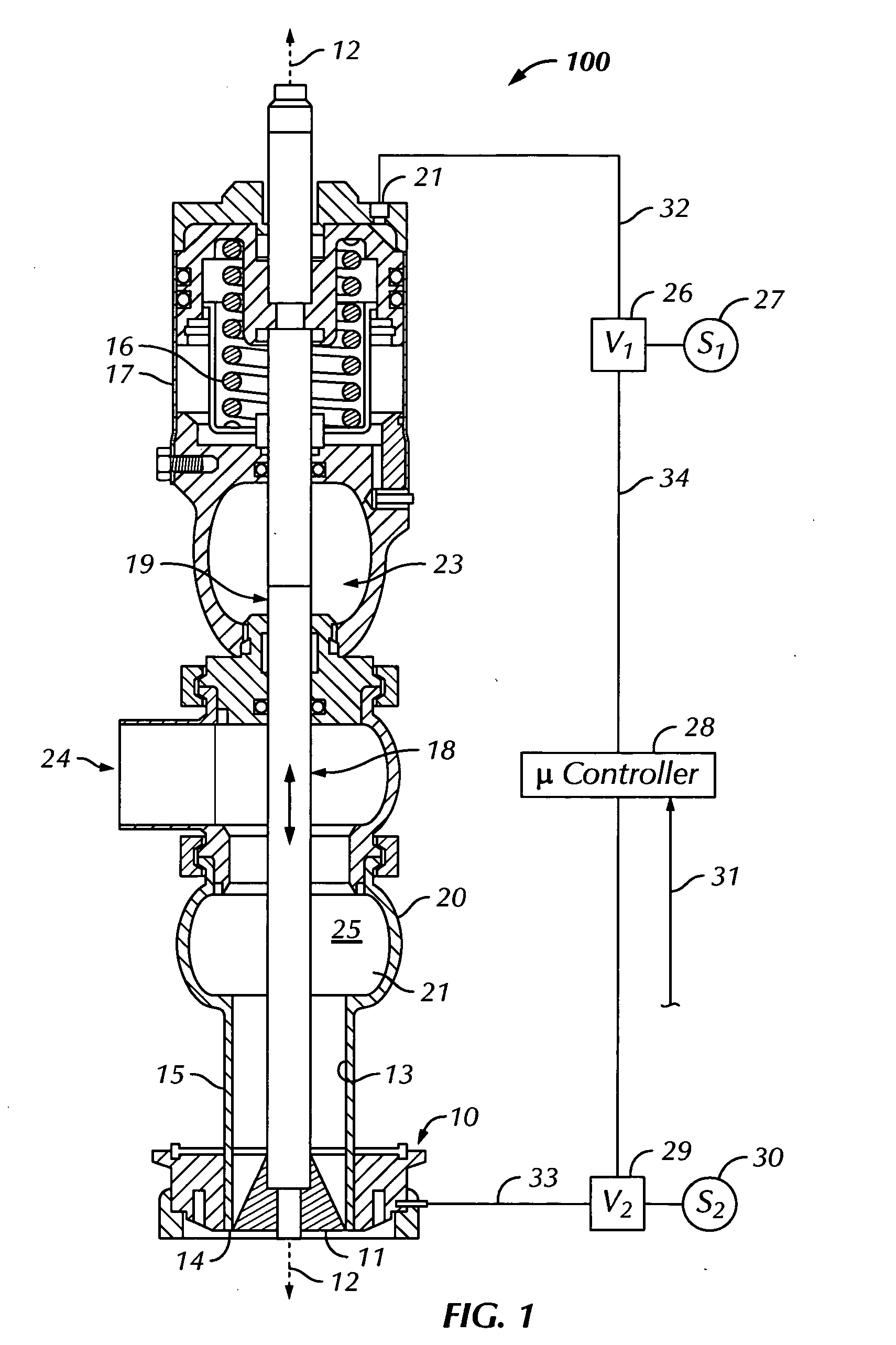

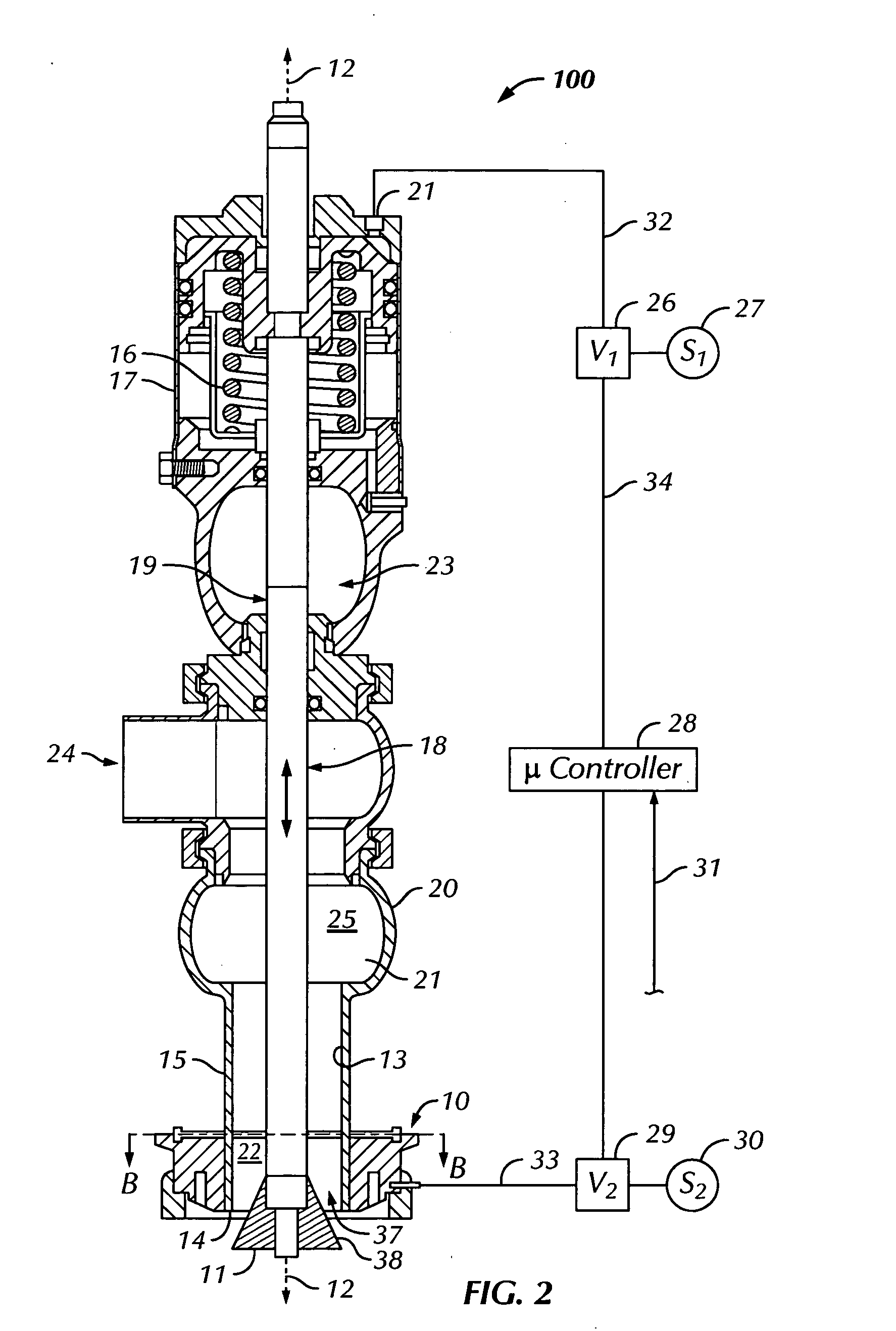

Filling valve

ActiveUS7011117B1Tight tolerance fitImprove sealingLiquid fillingCheck valvesLiquid productEngineering

An improved filling valve and liquid filling machine comprising such valve are herein disclosed. The filling valve comprises a housing having a base, a cap and a sidewall extending between the base and the cap thereby defining a chamber. The base has a ramp which slopes from a bottom surface of the base toward the cap. An outlet tube extends from said housing and has an inlet opening in fluid communication with the chamber. An inlet port extends through the sidewall to allow liquid product to enter the chamber. A plunger guide having an opening is provided on the cap with the opening extending through the cap. A plunger is slidably received in the outlet tube and the opening in the plunger guide. The plunger is movable between a position in which the plunger seals the outlet tube thereby closing the valve and a position in which the plunger is withdrawn from the outlet tube thereby unsealing the outlet tube and thereby opening the valve. The filling valve may be utilized on a liquid filling machine to fill containers with liquid product.

Owner:PROMACH FILLING SYST LLC

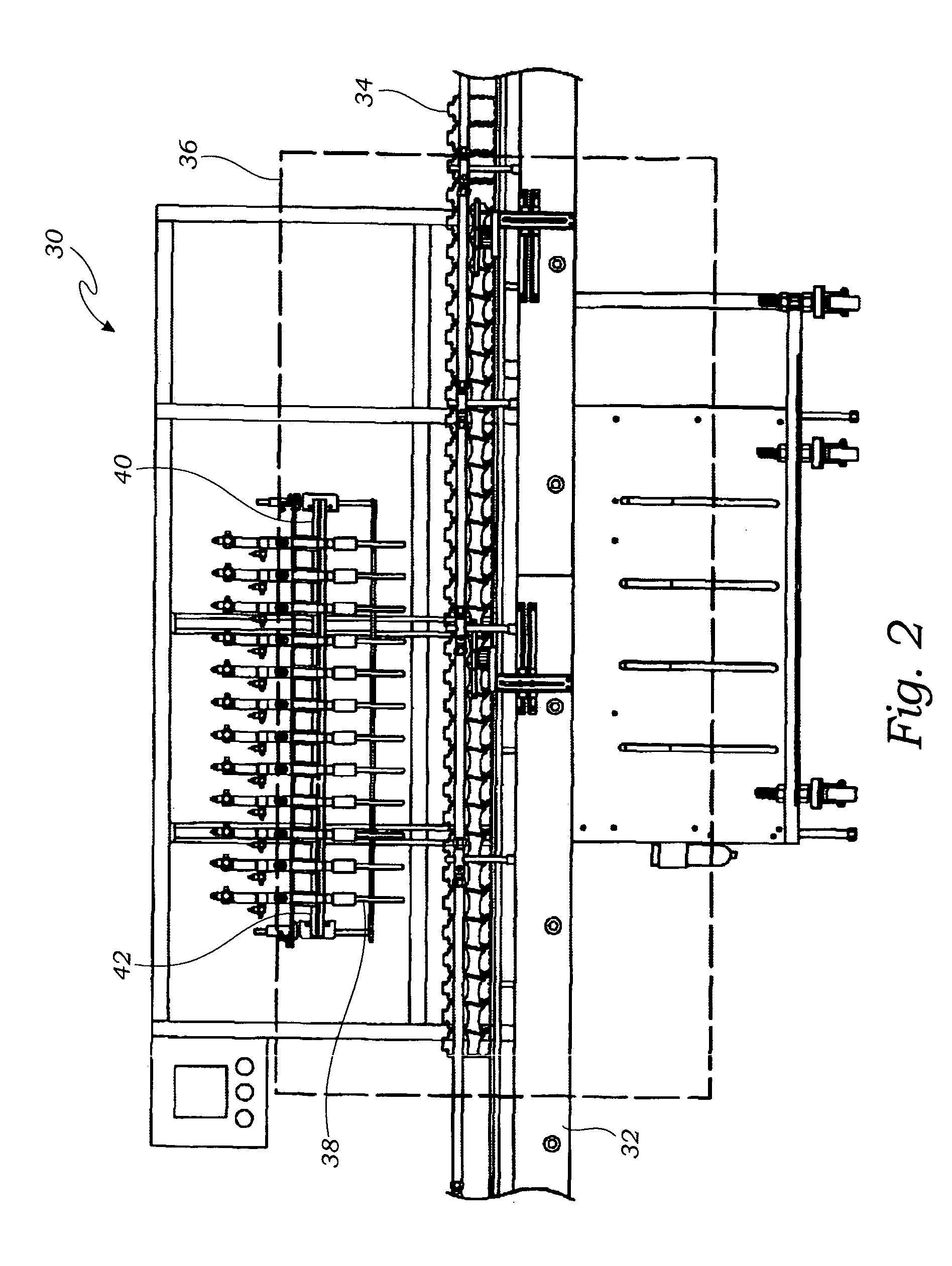

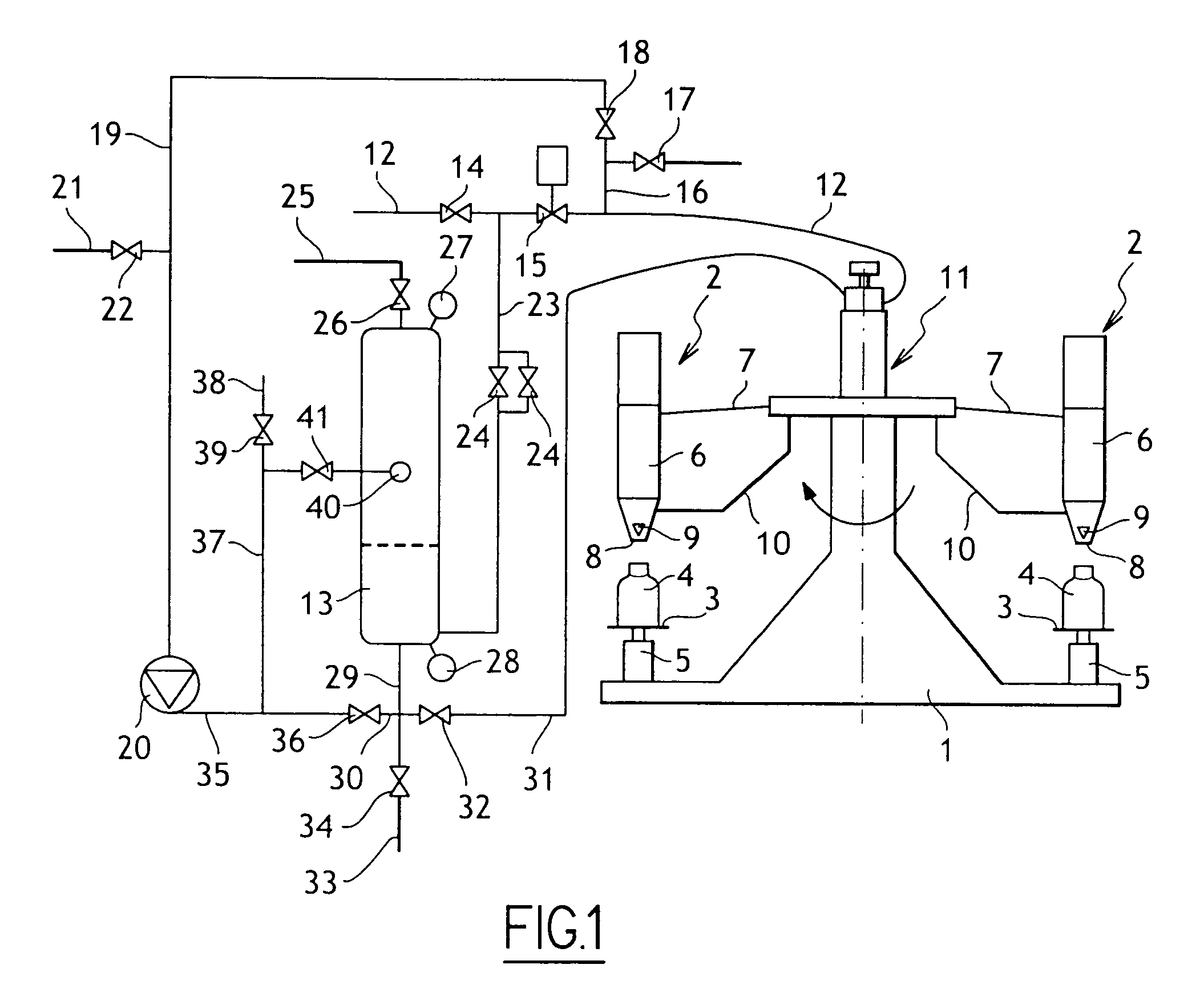

Liquid filling system with improved set-up and fill weight calibration/verification capabilities

InactiveUS6941981B2Improve system securityImprove accuracyLiquid fillingSolid materialProduction rateEngineering

An improved method and apparatus for a liquid filling system is herein disclosed incorporating means for generating greater overall production rate efficiencies (i.e. number of filled containers per minute per filling station) for automatic systems utilizing diverter valve and / or walking beam (i.e. continuous-motion) filling technologies with, for example, non-traditional ratios between the number of filling stations and the number of filling nozzles. The methods / apparatus disclosed herein also incorporate means to more efficiently changeover and clean up, in either a clean-in-place (CIP) or clean-out-of-place (COP) configuration, the product contact parts that become “dirty” when used in a production environment. Finally, an improved method and apparatus designed to provide a means for priming and air purging the product contact path of liquid filling machinery, a fill volume calibration procedure, and a fill weight verification cycle is also herein described.

Owner:ROSEN ROBERT A

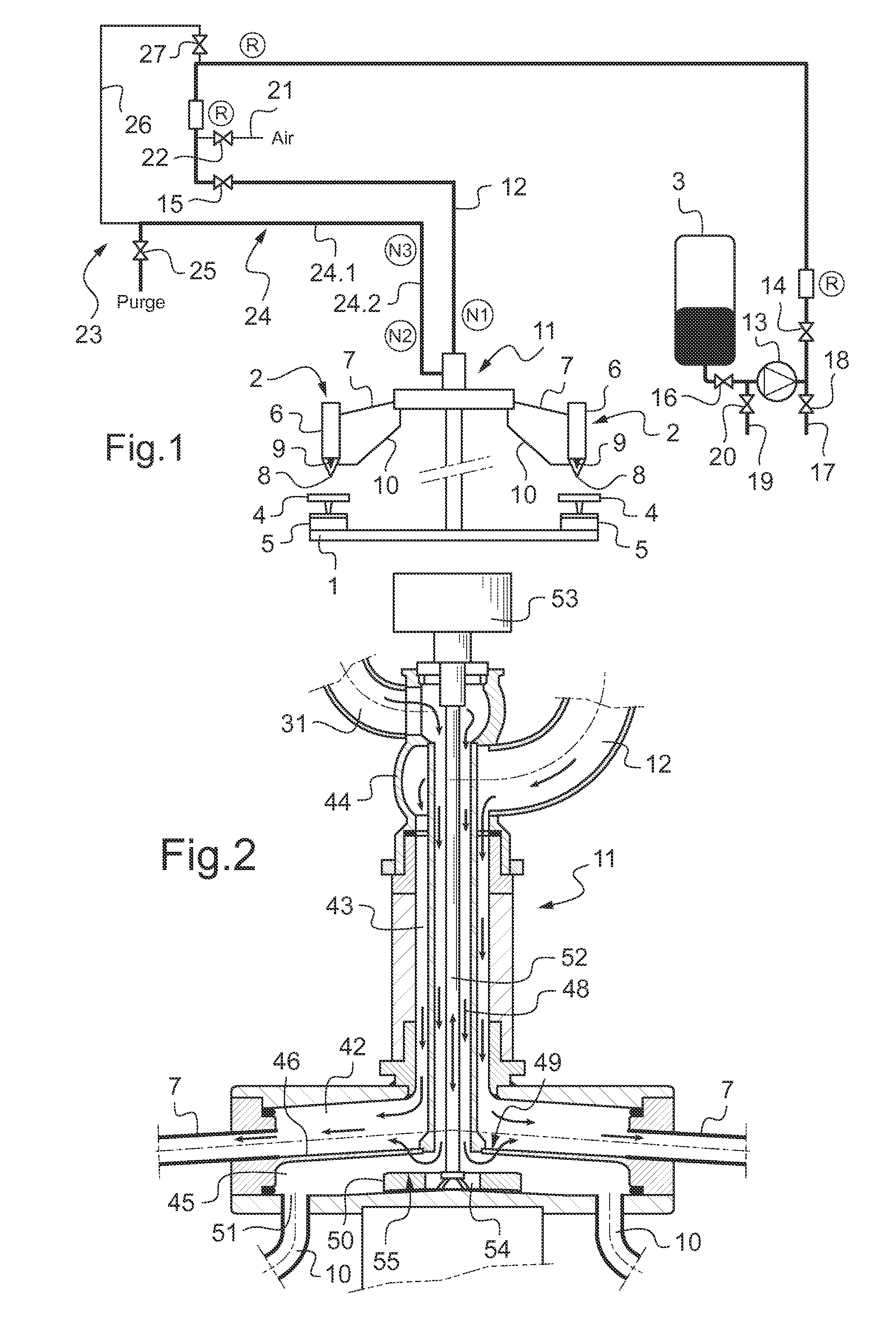

Container filling element for open-filling of containers

A beverage bottling plant for filling bottles with a liquid beverage material having a filling element and a filling machine having such filling elements. The filling elements each have a movable probe which may be moved into a bottle or container to be filled in order to detect the level of liquid, such as a beverage, in the bottle or container.

Owner:KHS GMBH

Method for cleaning beverage filling lines

Owner:AQUAGROUP AG

Cleaning attachment for fluid dispenser nozzles and fluid dispensers using same

InactiveUS20050056707A1Easy to assembleEasy to disassembleSpraying apparatusLiquid transferring devicesEngineeringVALVE PORT

A nozzle attachment for removing residual material retained on the dispensing nozzle of a fluid dispenser, having a retainer adapted to releasably attach the nozzle attachment to a dispensing nozzle, and a pair of hollow-bodied nozzle attachment components that define, when nested together, an intervening space useful as a gas passageway for pressurized gaseous fluid introduced and directed to a discharge opening at a lower axial end of the nested nozzle attachment components. The gas passageway is adapted to emit gas introduced into the gas passageway as a gas stream in a manner effective to remove residual material clinging to the nozzle. Dispensers using the nozzle attachment are presented, including one using a truncated valve head.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Cleaning system for a filling machine

An automatic cleaning apparatus and / or method for periodically cleaning a filling machine during a filling cycle without the need for human interaction to initiate the cleaning process. In some embodiments, a controller automatically initiates a cleaning sequence at predetermined intervals. The predetermined intervals can be a time interval, such as every thirty minutes for example, or based upon filling characteristics, such as after a predetermined number of containers are filled or a predetermined amount of product has flowed through the filling machine. In some embodiments, the controller performs many operations during the cleaning process. For example, the controller can prevent containers from entering the filling machine and control the operation of a cleaning manifold. Upon completion of the cleaning operation, the controller waits a predetermined period while filing operations commence before automatically initiating the next cleaning operation.

Owner:JOHNSONDIVERSEY INC

Cleaning system for a filling machine

InactiveUS20060185755A1Avoid paddingLiquid fillingSolid materialHuman interactionMechanical engineering

An automatic cleaning apparatus and / or method for periodically cleaning a filling machine during a filling cycle without the need for human interaction to initiate the cleaning process. In some embodiments, a controller automatically initiates a cleaning sequence at predetermined intervals. The predetermined intervals can be a time interval, such as every thirty minutes for example, or based upon filling characteristics, such as after a predetermined number of containers are filled or a predetermined amount of product has flowed through the filling machine. In some embodiments, the controller performs many operations during the cleaning process. For example, the controller can prevent containers from entering the filling machine and control the operation of a cleaning manifold. Upon completion of the cleaning operation, the controller waits a predetermined period while filing operations commence before automatically initiating the next cleaning operation.

Owner:JOHNSONDIVERSEY INC

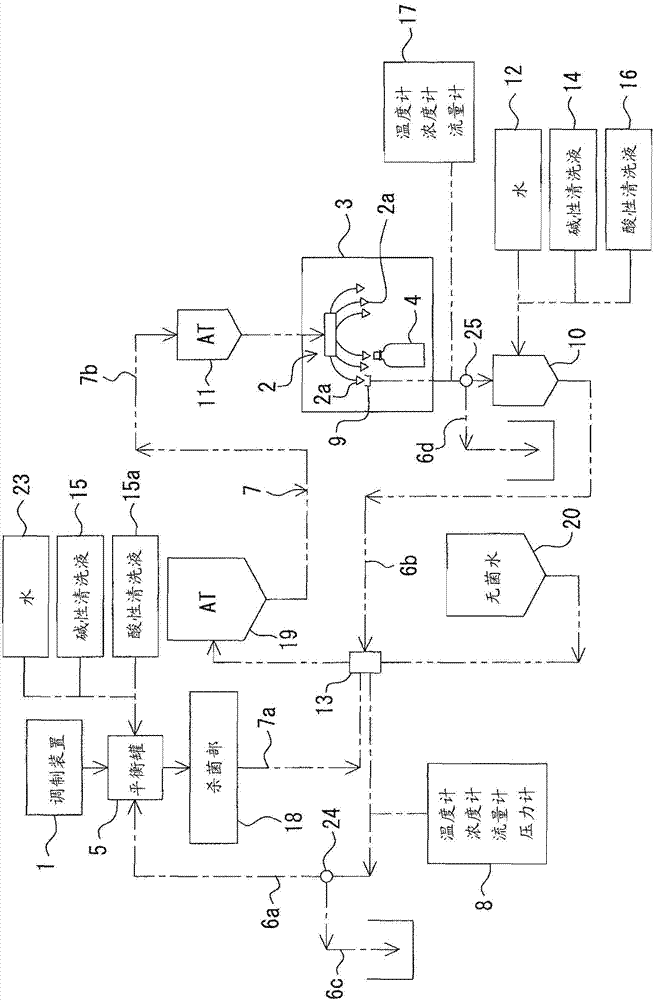

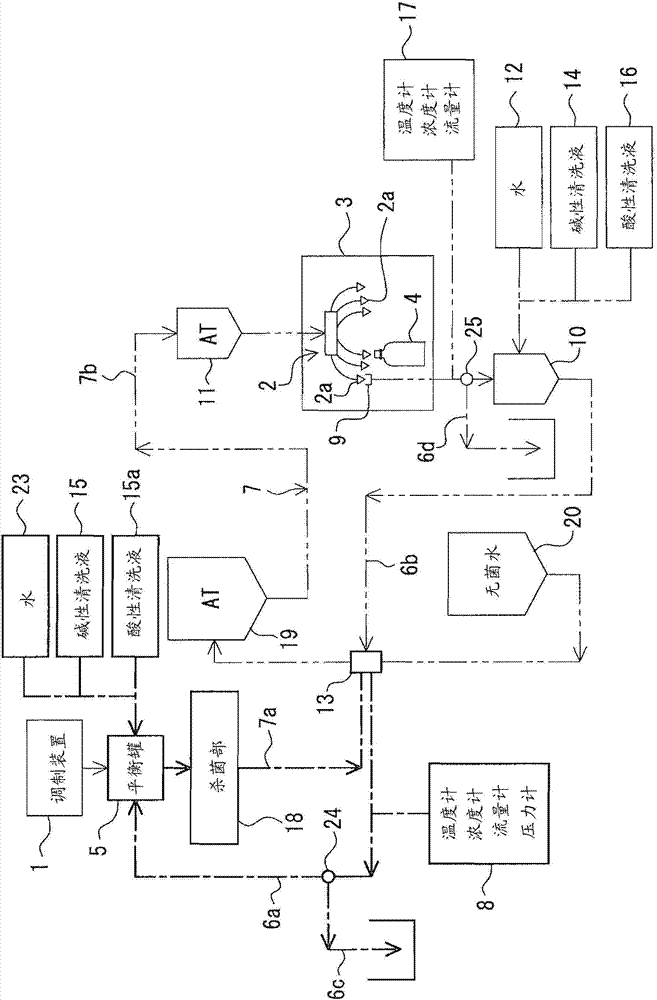

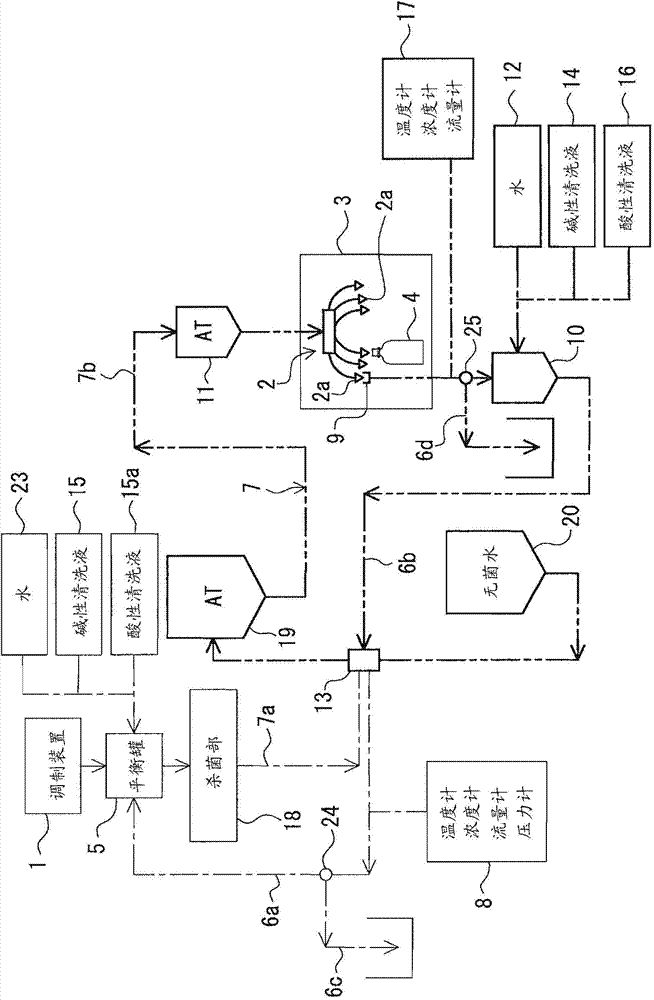

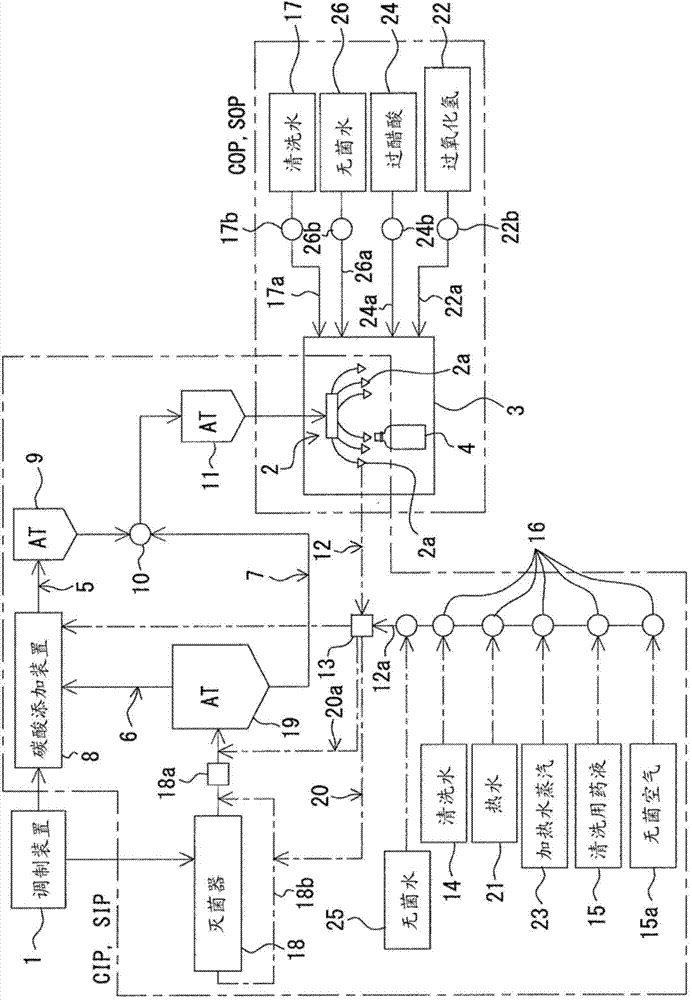

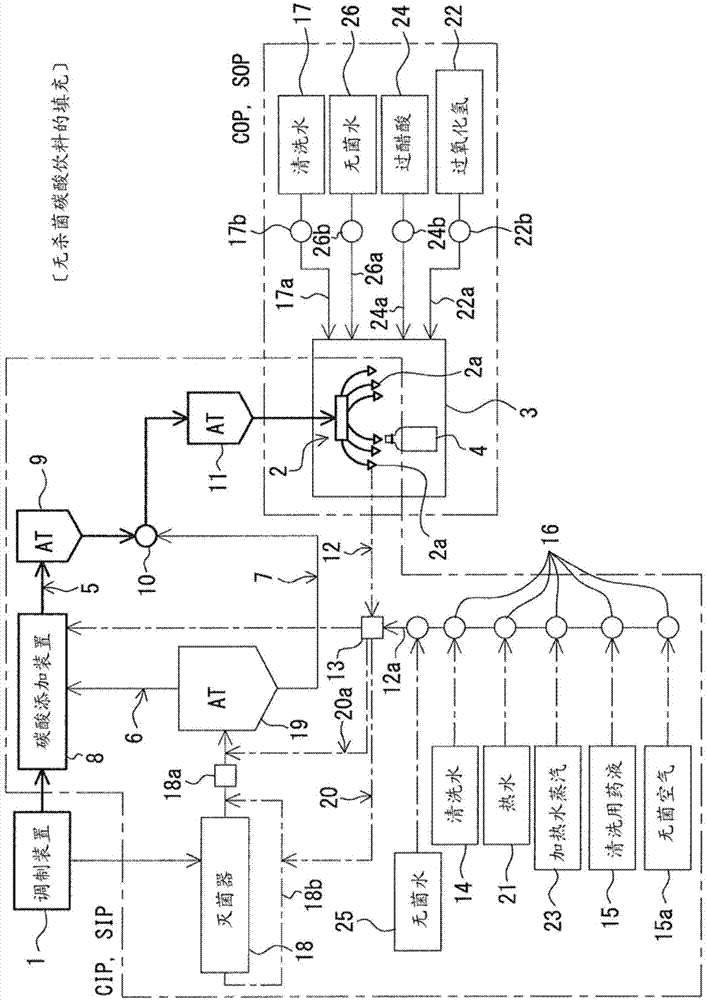

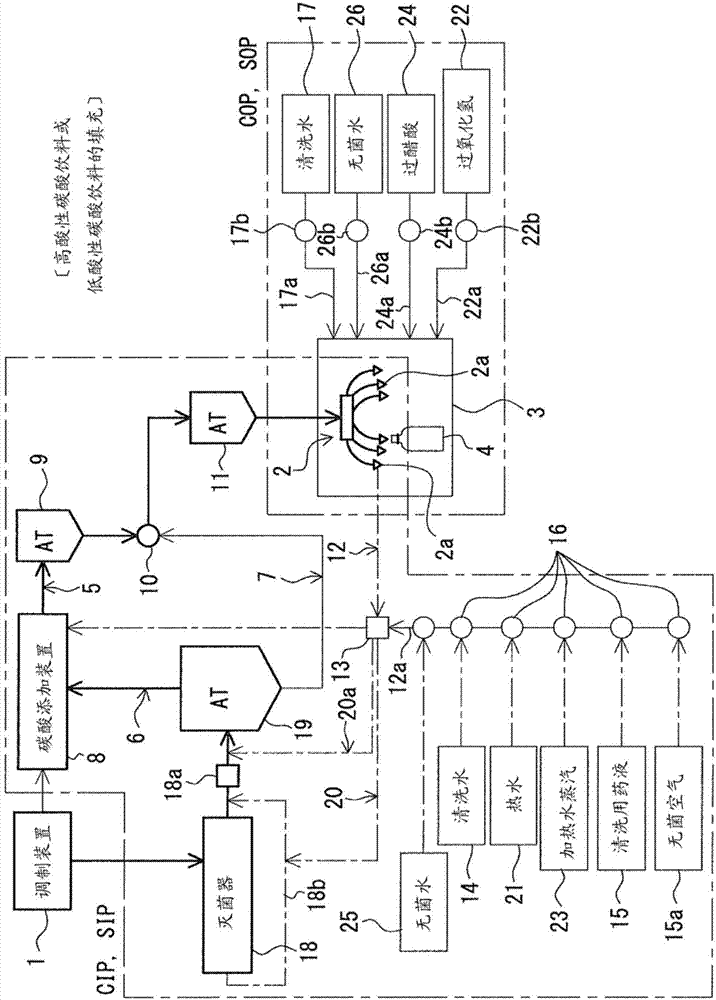

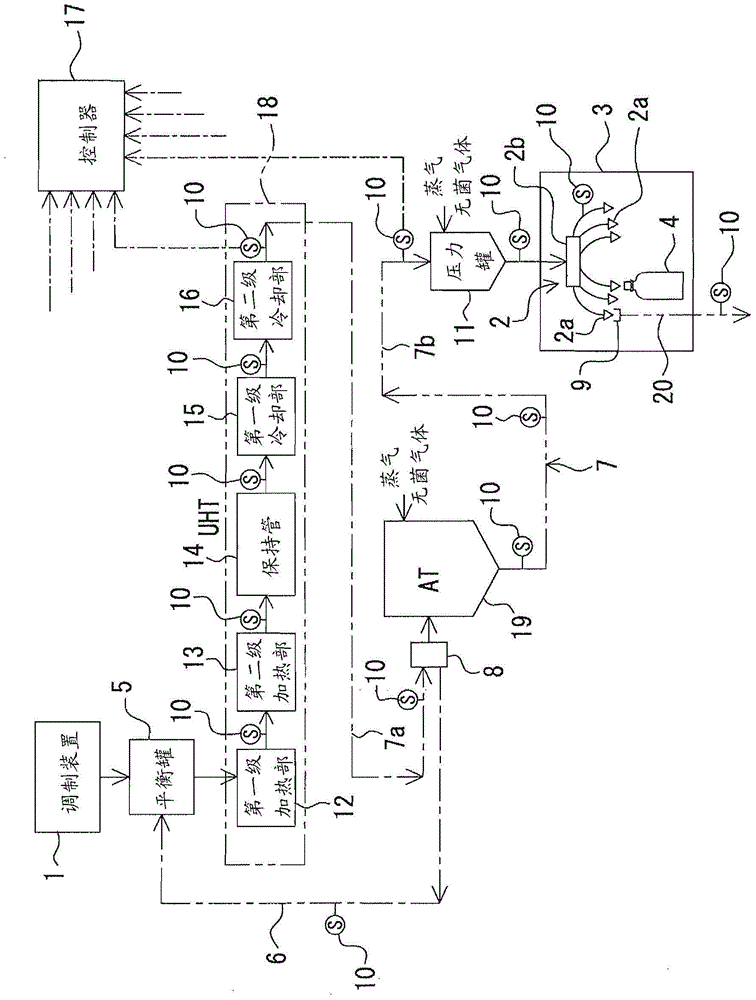

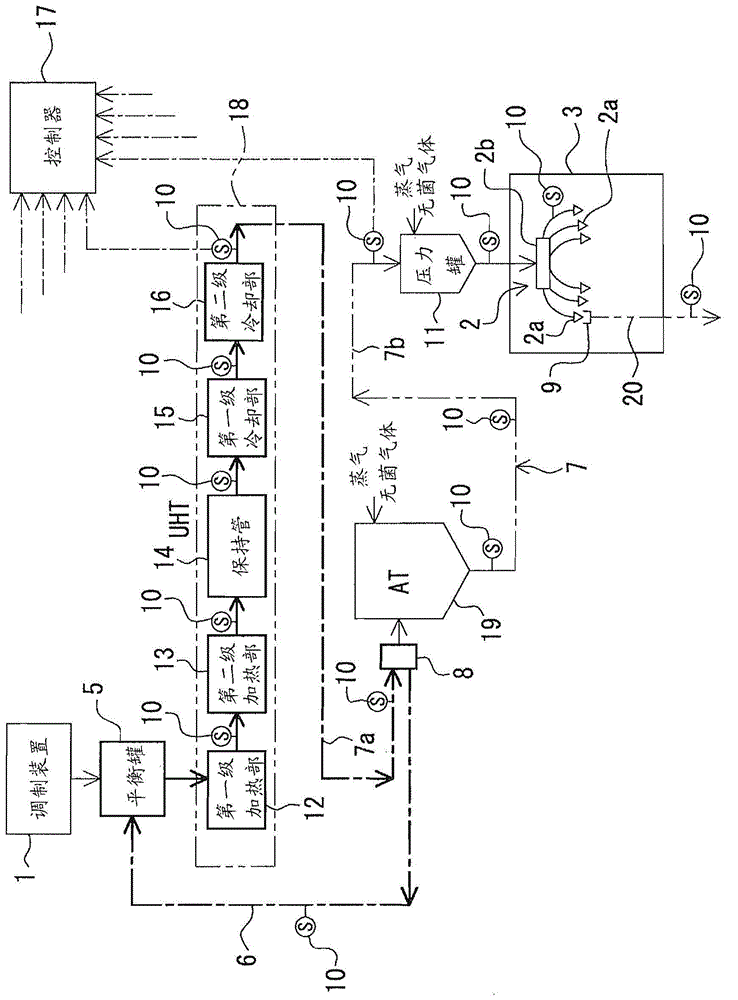

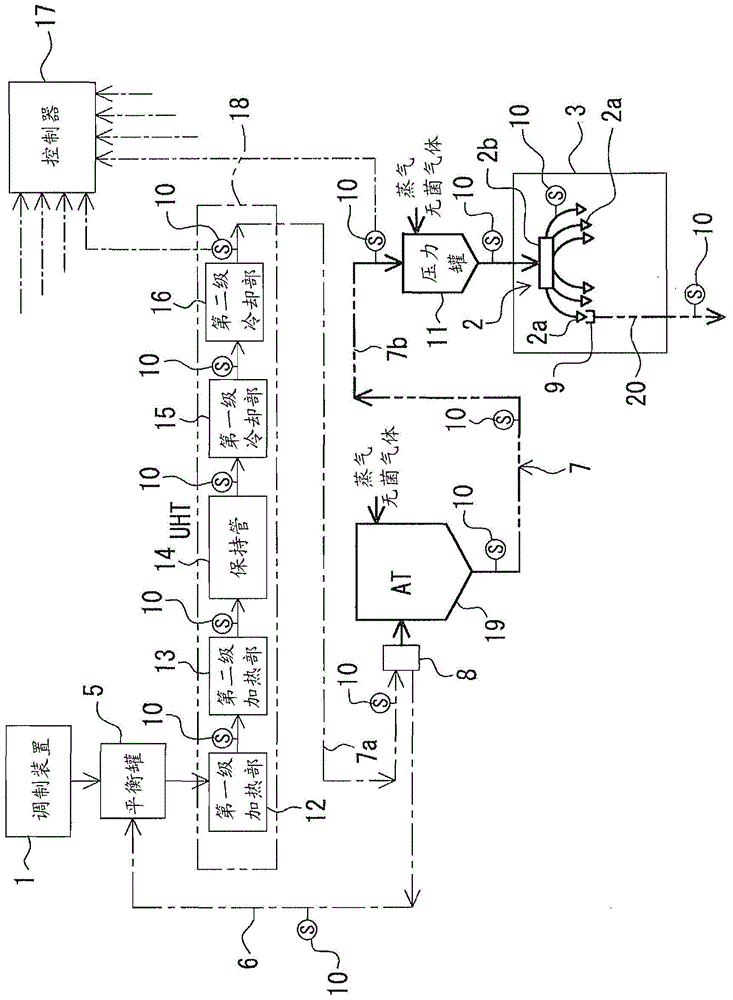

Beverage filling method

ActiveCN104755411ASimple and fast decontaminationSimple and rapid sterilizationHollow article cleaningFilling device cleaningSterile waterReturn channel

The present invention reduces either a production interval or the amount of time it takes until a beverage filling process can be started. In this beverage filling method, in which sterilized containers (4) are filled with a sterilized beverage via beverage-supply-system tubing (7) and said containers are sealed after said beverage-supply-system tubing, through which the beverage is delivered from a heat-sterilization unit (18) to the interior of a filling machine (2), is sterilized, an upstream tubing section (7a), said upstream tubing section (7a) being the part of the beverage-supply-system tubing that passes through the sterilization unit, is provided with an upstream return channel, forming an upstream circulation channel (6a); and a downstream tubing section (7b), said downstream tubing section (7b) being the part of the beverage-supply-system tubing that extends from the downstream side of the aforementioned upstream tubing section to the interior of the filling machine, is provided with a downstream return channel (6b), forming a downstream circulation channel. The process of filling the abovementioned containers with the abovementioned beverage is started after the following: first, an alkaline cleaning solution is circulated through the upstream circulation channel and the downstream circulation channel to clean and sterilize the inside of the beverage-supply-system tubing; and said beverage-supply-system tubing is then rinsed with sterile water.

Owner:DAI NIPPON PRINTING CO LTD

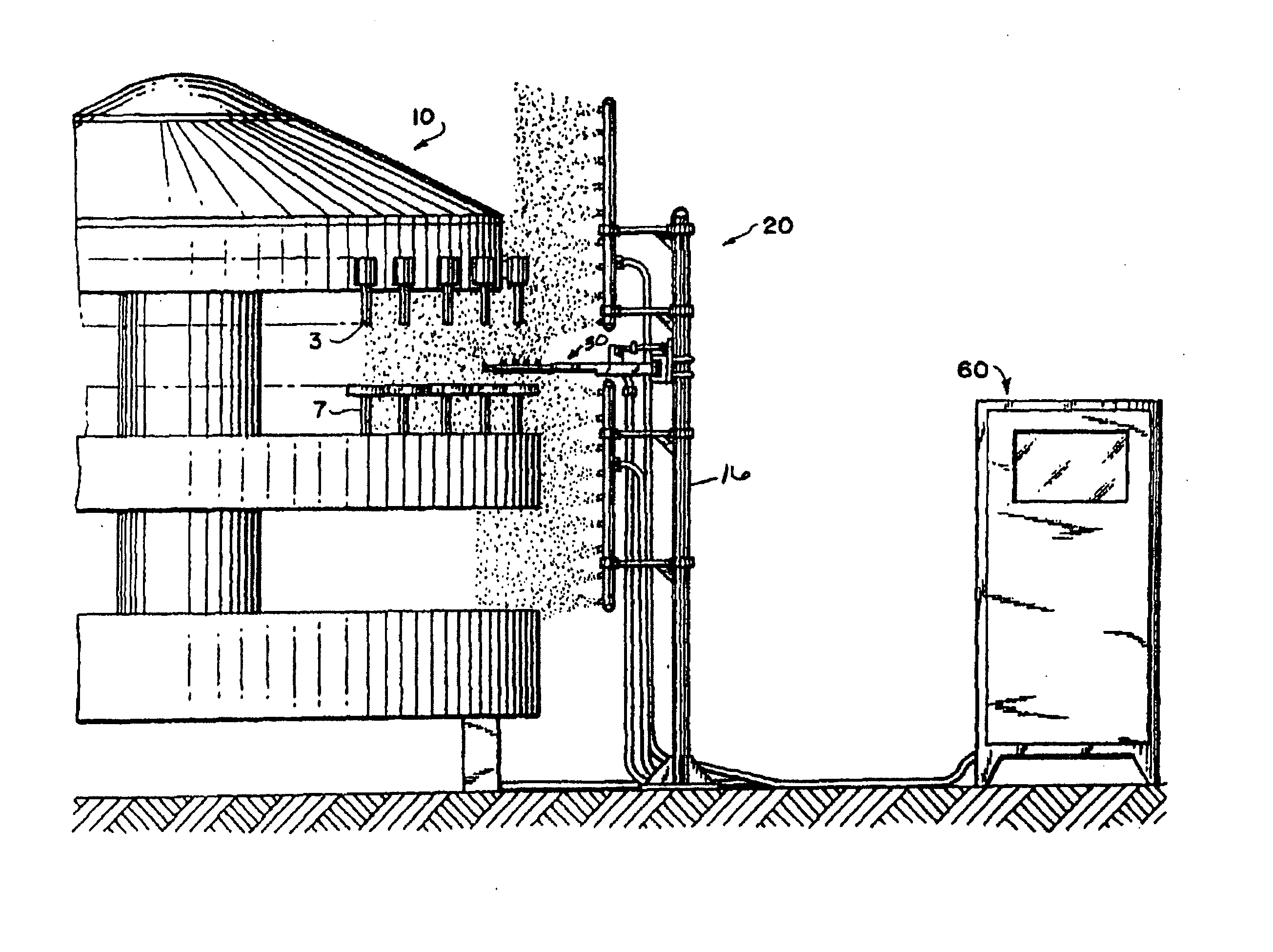

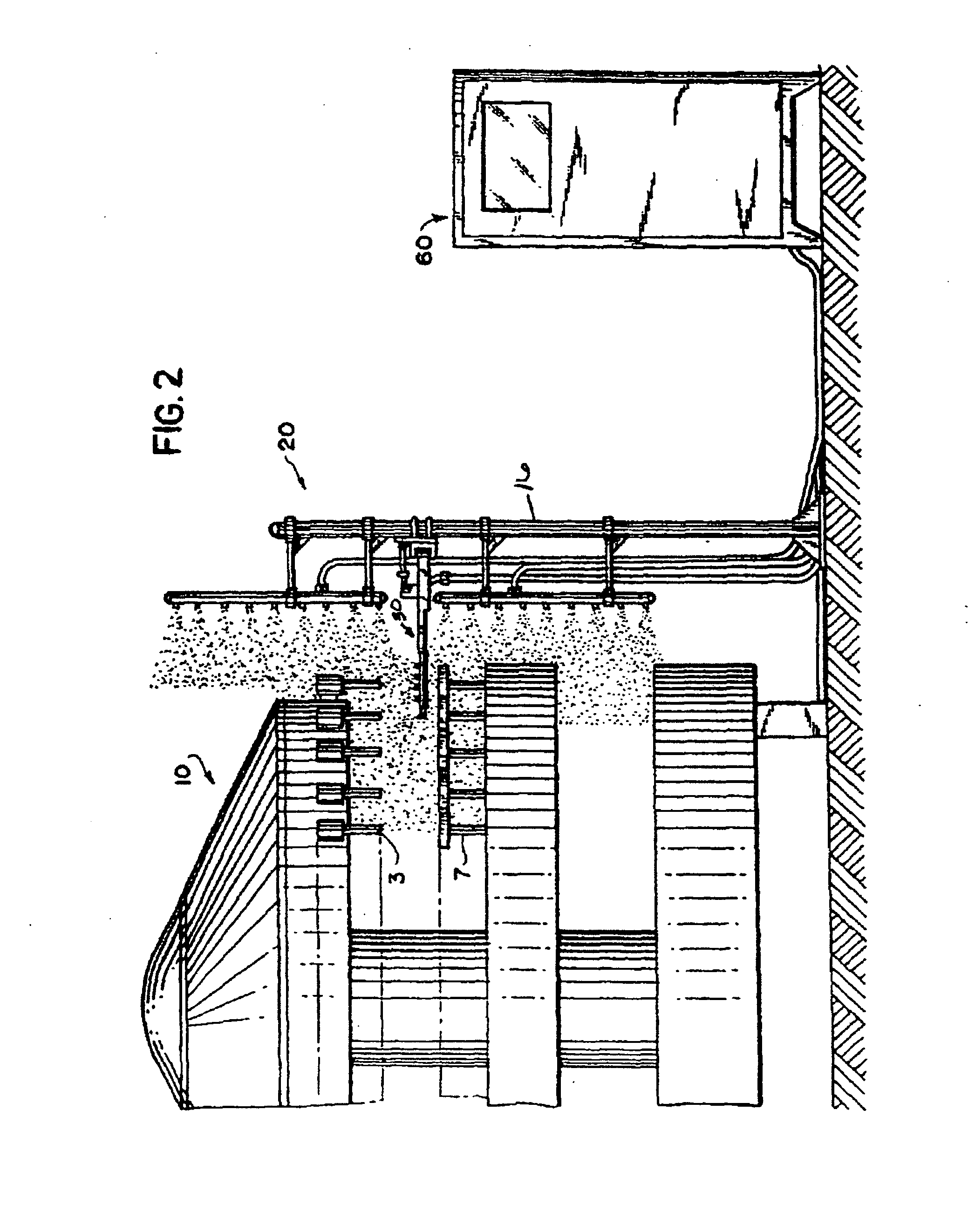

Method of treating a beverage bottle filling machine in a beverage bottling plant, method of cleaning a container filling machine in a container filling plant, and arrangements therefor

A method of treating a beverage bottle filling machine in a beverage bottling plant, method of cleaning a container filling machine in a container filling plant, and arrangements therefor. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Bottling installation including filler spouts fitted with feed-back ducts from the spout bodies

ActiveUS20130000779A1Reliable bottling installationMinimize of amountLiquid fillingSolid materialEngineeringControl valves

Owner:SERAC GROUP

Cleaning attachment for fluid dispenser nozzles and fluid dispensers using same

InactiveUS6957781B2Easy to assembleEasy to disassembleSpraying apparatusLiquid transferring devicesEngineeringAirflow

A nozzle attachment for removing residual material retained on the dispensing nozzle of a fluid dispenser, having a retainer adapted to releasably attach the nozzle attachment to a dispensing nozzle, and a pair of hollow-bodied nozzle attachment components that define, when nested together, an intervening space useful as a gas passageway for pressurized gaseous fluid introduced and directed to a discharge opening at a lower axial end of the nested nozzle attachment components. The gas passageway is adapted to emit gas introduced into the gas passageway as a gas stream in a manner effective to remove residual material clinging to the nozzle. Dispensers using the nozzle attachment are presented, including one using a truncated valve head.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

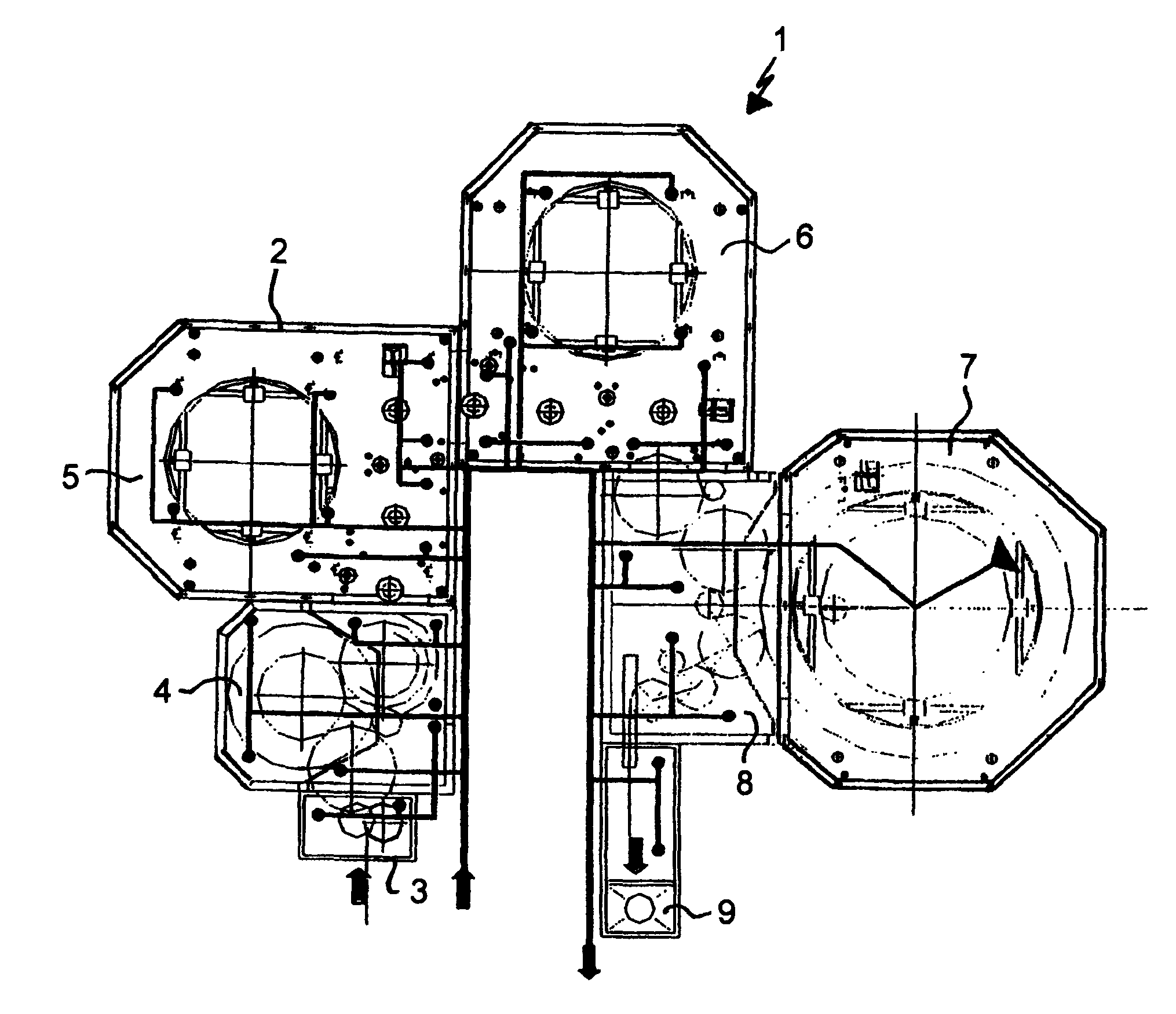

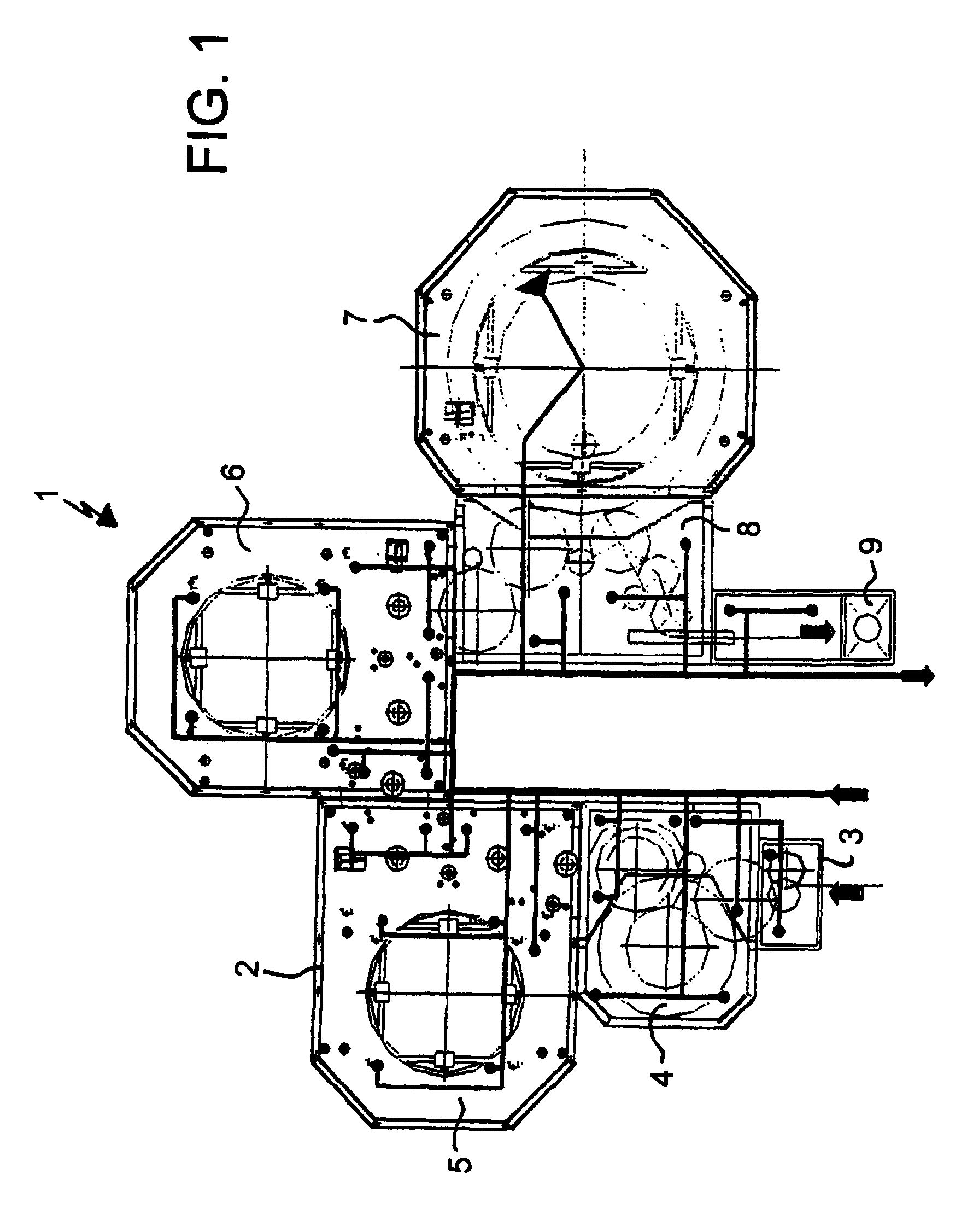

Aseptic beverage bottle filling plant with a clean room arrangement enclosing the aseptic beverage bottle filling plant and a method of operating same, and an aseptic container filling plant with a clean room arrangement enclosing the aseptic container filling plant, and a method of operating same

InactiveUS20100043915A1Increase heightEnables and promotes effective cleaningLiquid fillingHollow article cleaningTrademarkEngineering

An aseptic beverage bottle filling plant with a clean room arrangement enclosing the aseptic beverage bottle filling plant and a method of operating same, and an aseptic container filling plant with a clean room arrangement enclosing the aseptic container filling plant, and a method of operating same. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Method for cleaning beverage bottling apparatus

ActiveCN104718151AShorten production timeIncrease productivityHollow article cleaningPackage sterilisationEngineering

The purpose of the present invention is to shorten the time between production runs when switching between types of beverages for bottling. Provided is a method for cleaning a beverage bottling apparatus equipped with a beverage supply line for delivering a beverage to a bottling machine (2), and a sterile chamber (3) enclosing at least the bottling machine, wherein the method has at least two programs selected from among: a first program adapted to untreated carbonated beverages, for executing COP on the sterile chamber interior, and CIP on the beverage supply line interior; a second program adapted to high-acidity beverages, for executing COP and SOP on the sterile chamber interior, and CIP and SIP on the beverage supply line interior; and a third program adapted to low-acidity beverages, for executing COP and SOP on the sterile chamber interior, and CIP and SIP on the beverage supply line interior; and has a function for selectively executing any one thereof. By selecting the first program when the beverage is an untreated carbonated beverage, selecting the second program when the beverage is a high-acidity beverage, and selecting the third program when the beverage is a low-acidity beverage, corresponding cleaning processes are performed on the beverage supply line interior and the sterile chamber interior, prior to initiating bottling of the corresponding beverage.

Owner:DAI NIPPON PRINTING CO LTD

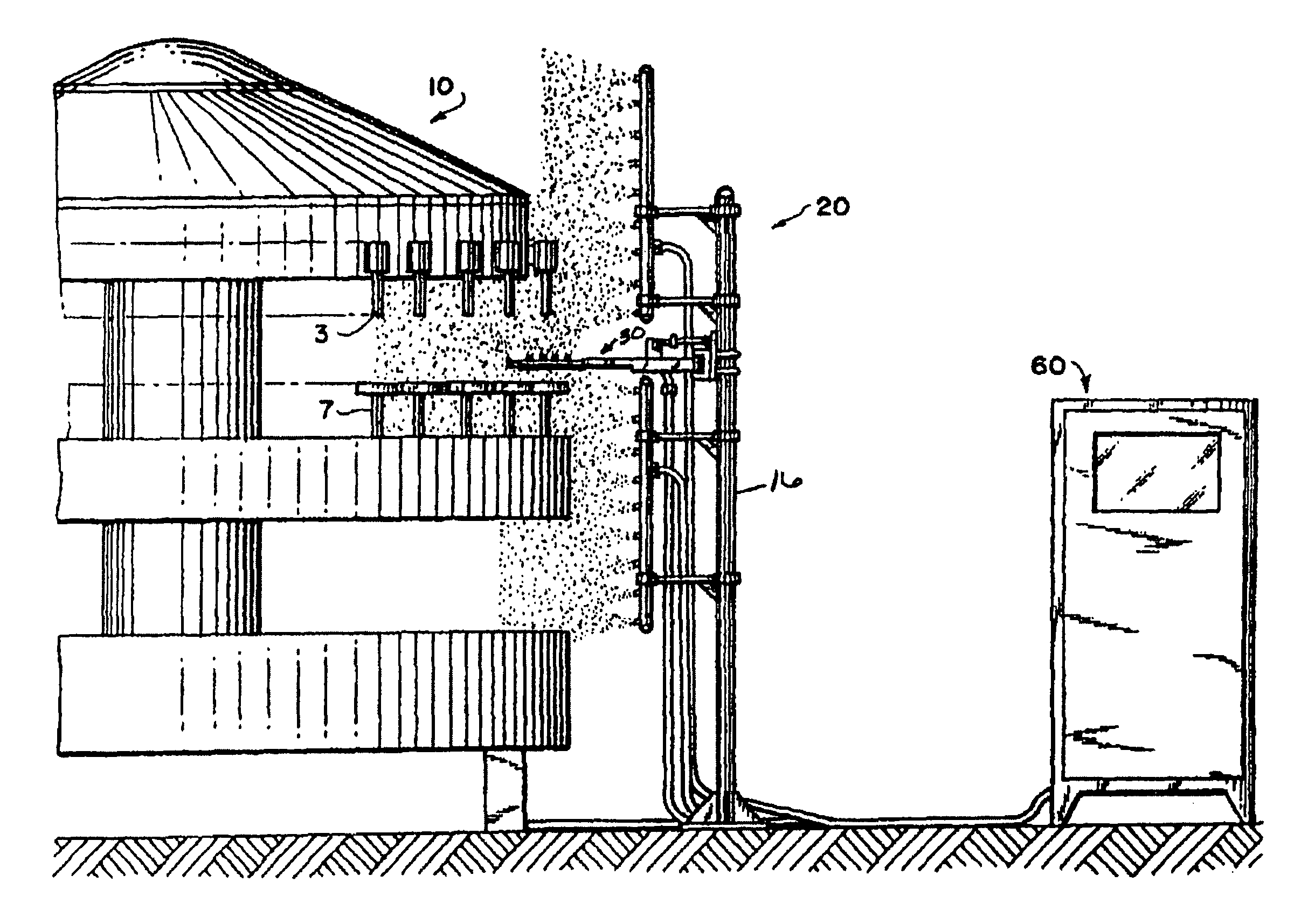

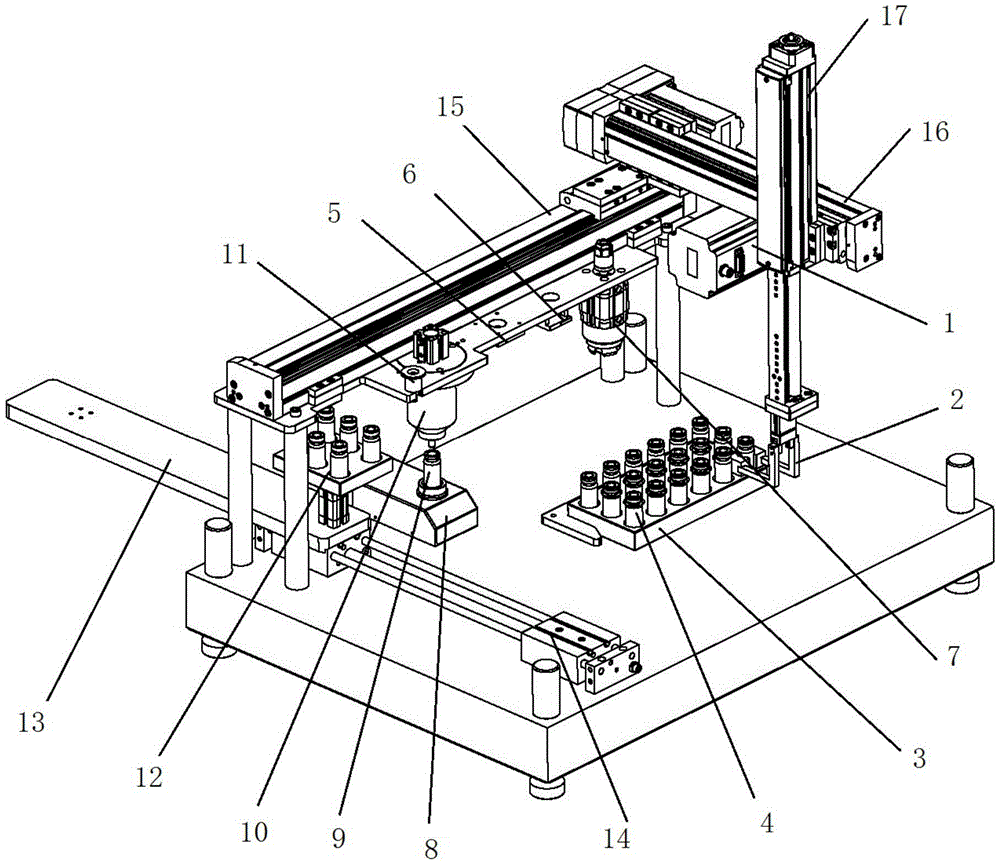

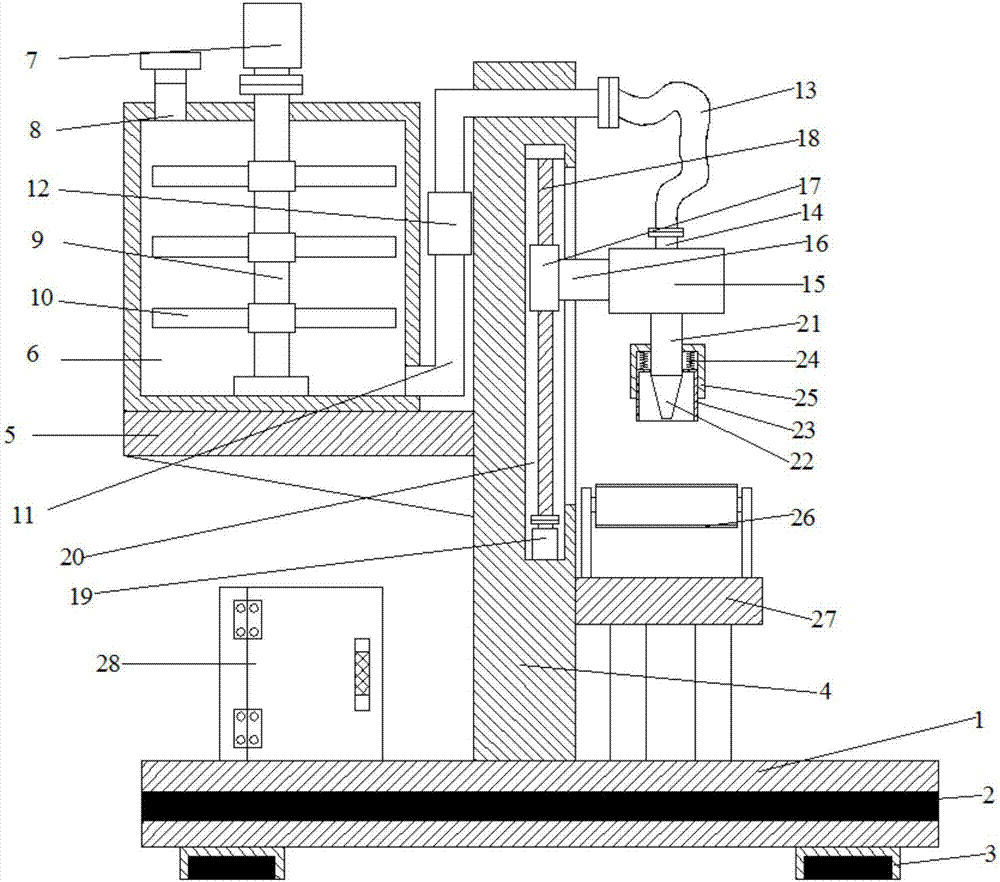

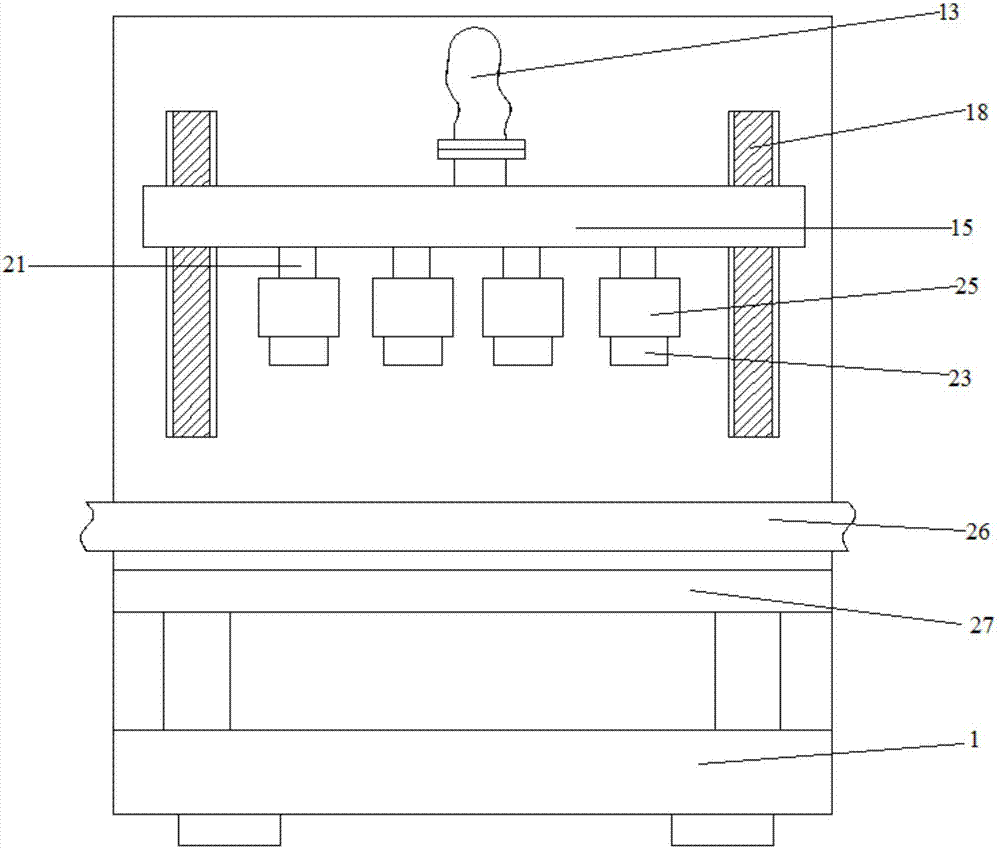

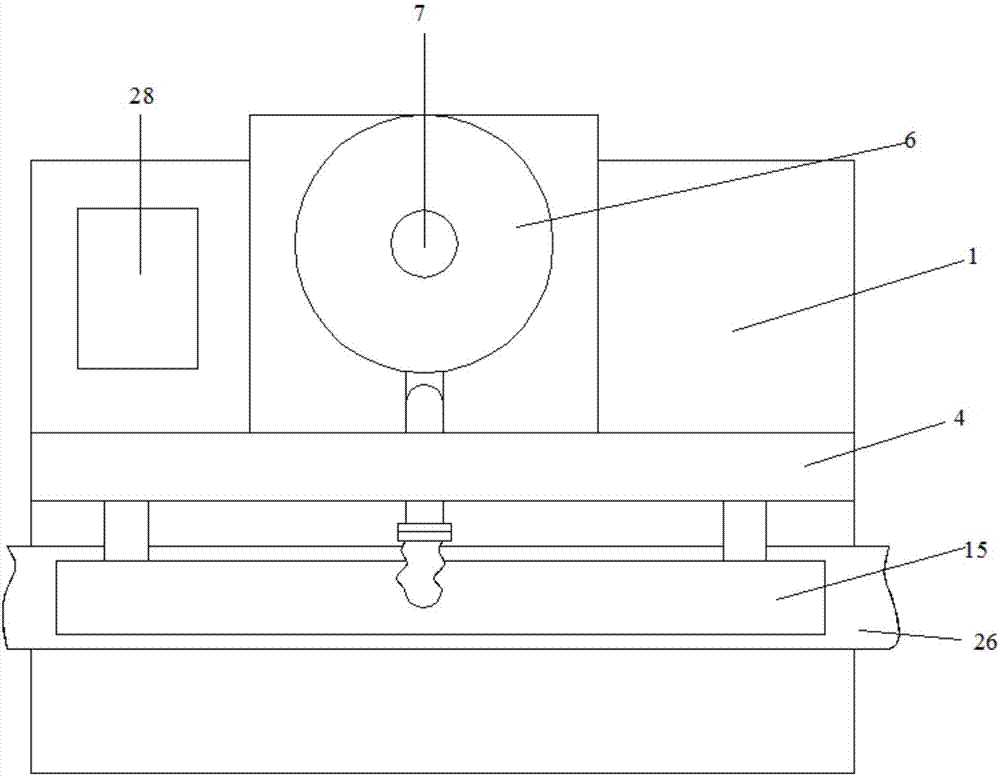

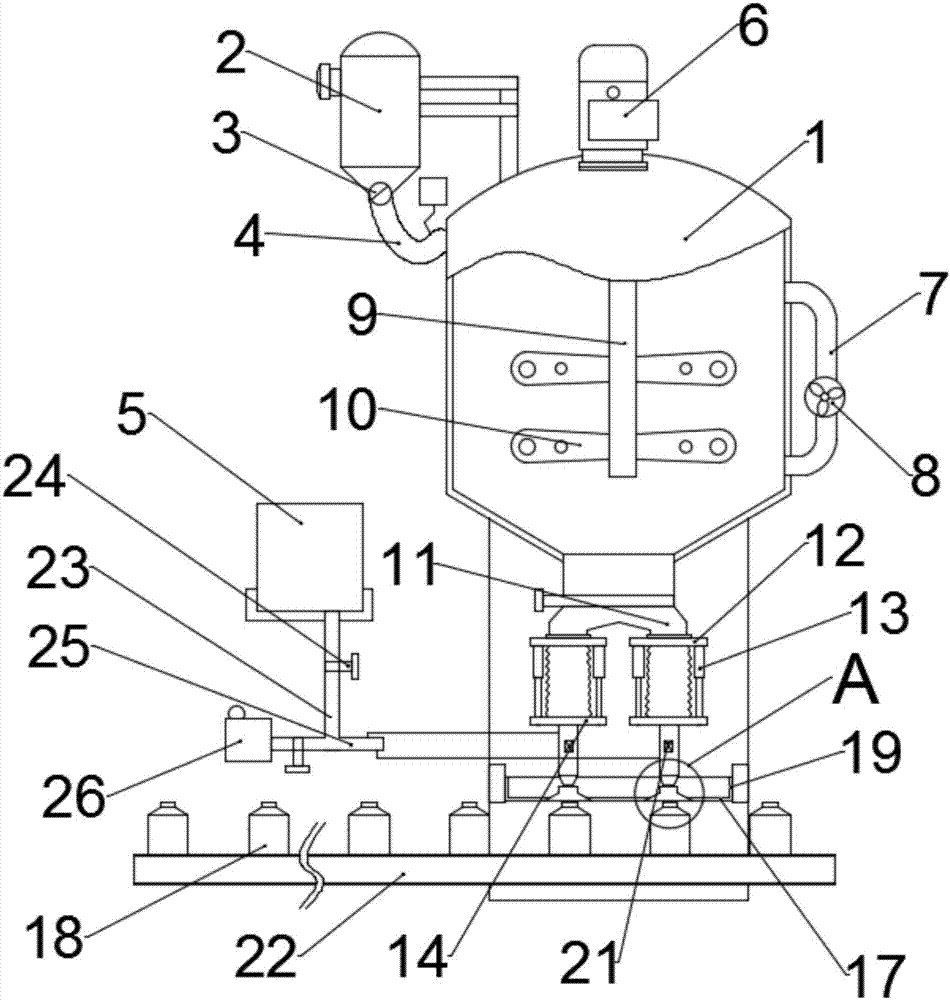

Automatic filling system for radioactive isotope medicament

ActiveCN106800268AReduce the risk of radiation exposureFully automatedCapsSynchronising machinesIsotopeMechanical engineering

The invention relates to an automatic filling system for a radioactive isotope medicament. The automatic filling system comprises a filling worktable and a control table. The filling worktable is arranged in a protective box. The control table is arranged outside the protective box and connected with the filling worktable. The automatic filling system further comprises a medicament pot storage module arranged at a feeding inlet of the filling worktable, an automatic grabbing module, a medicament pot processing module, a weighing and filling module and a finished product conveying module, wherein the automatic grabbing module, the medicament pot processing module and the weighing and filling module are arranged on the filling worktable, the finished product conveying module is located at a discharging outlet of the filling worktable, and all the modules are connected with the control table. Firstly, the automatic grabbing module grabs a medicament pot in the medicament pot storage module to the medicament pot processing module to be unsealed, next, the medicament pot is conveyed to the weighing and filling module to be filled automatically, then, the medicament pot is conveyed to the medicament pot processing module to be sealed, and finally, the medicament pot is conveyed to the finished product conveying module for conveying process. Compared with the prior art, the automatic filling system has the advantages of high filling accuracy, safety, reliability and the like.

Owner:SHANGHAI ATOM KEXING PHARMA +1

Beverage filling device and pasteurization method for same

ActiveCN104903229AFast filling operationShorten production intervalsHollow article cleaningFilling device cleaningEngineeringPasteurization

A pasteurization method for a beverage filling device comprising a beverage supply system piping (7) that sends a beverage through a heating pasteurizing unit (18) into a filling device (2), sends hot water or heated steam through the beverage supply system piping (7), calculates an F value while detecting, at prescribed time intervals, the temperature at a plurality of locations on the beverage supply system piping (7), and finishes a pasteurization step when the smallest of the F values reaches a target value. Thus, the time until starting the beverage filling operation or the time between production cycles can be shortened.

Owner:DAI NIPPON PRINTING CO LTD

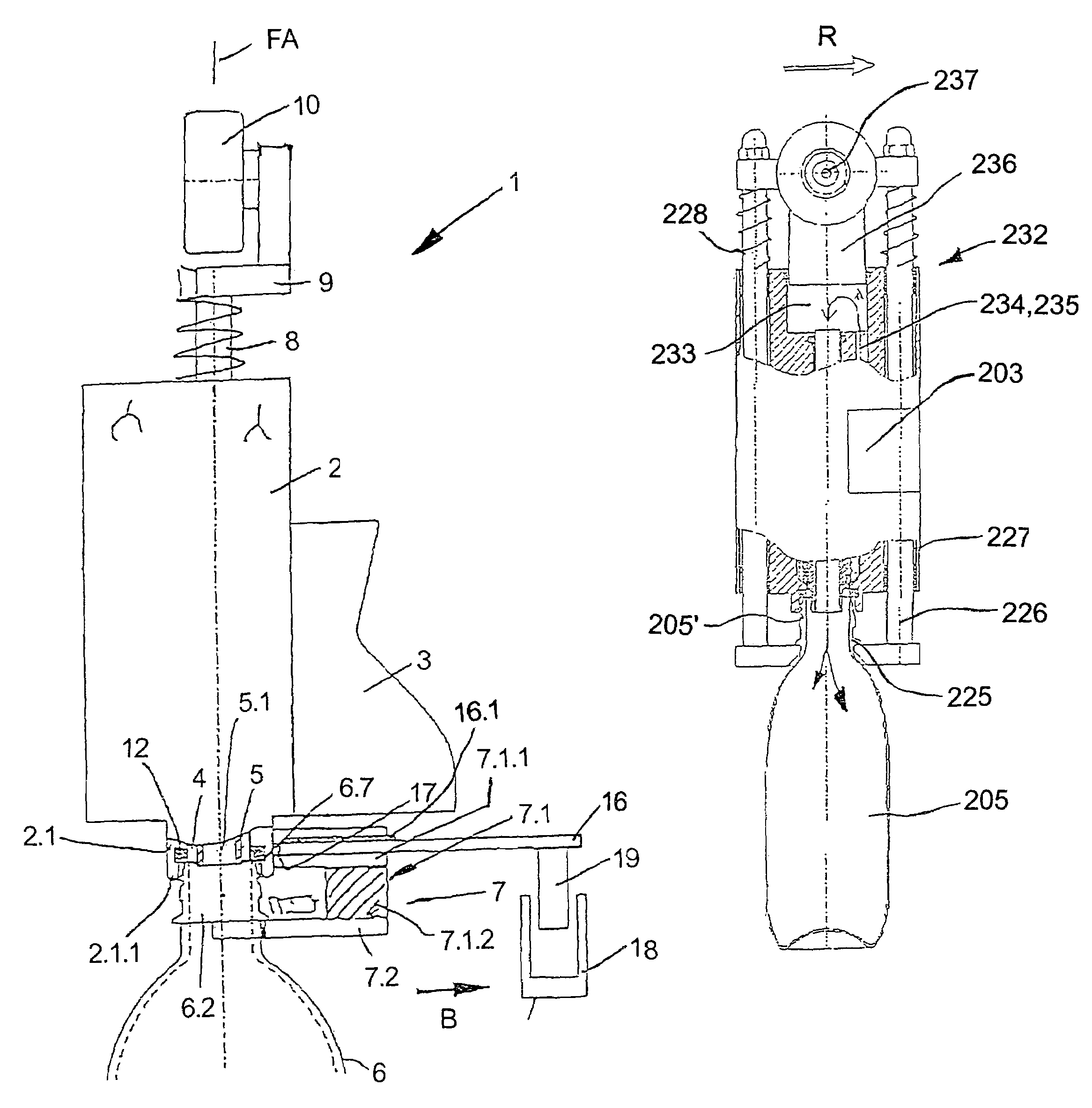

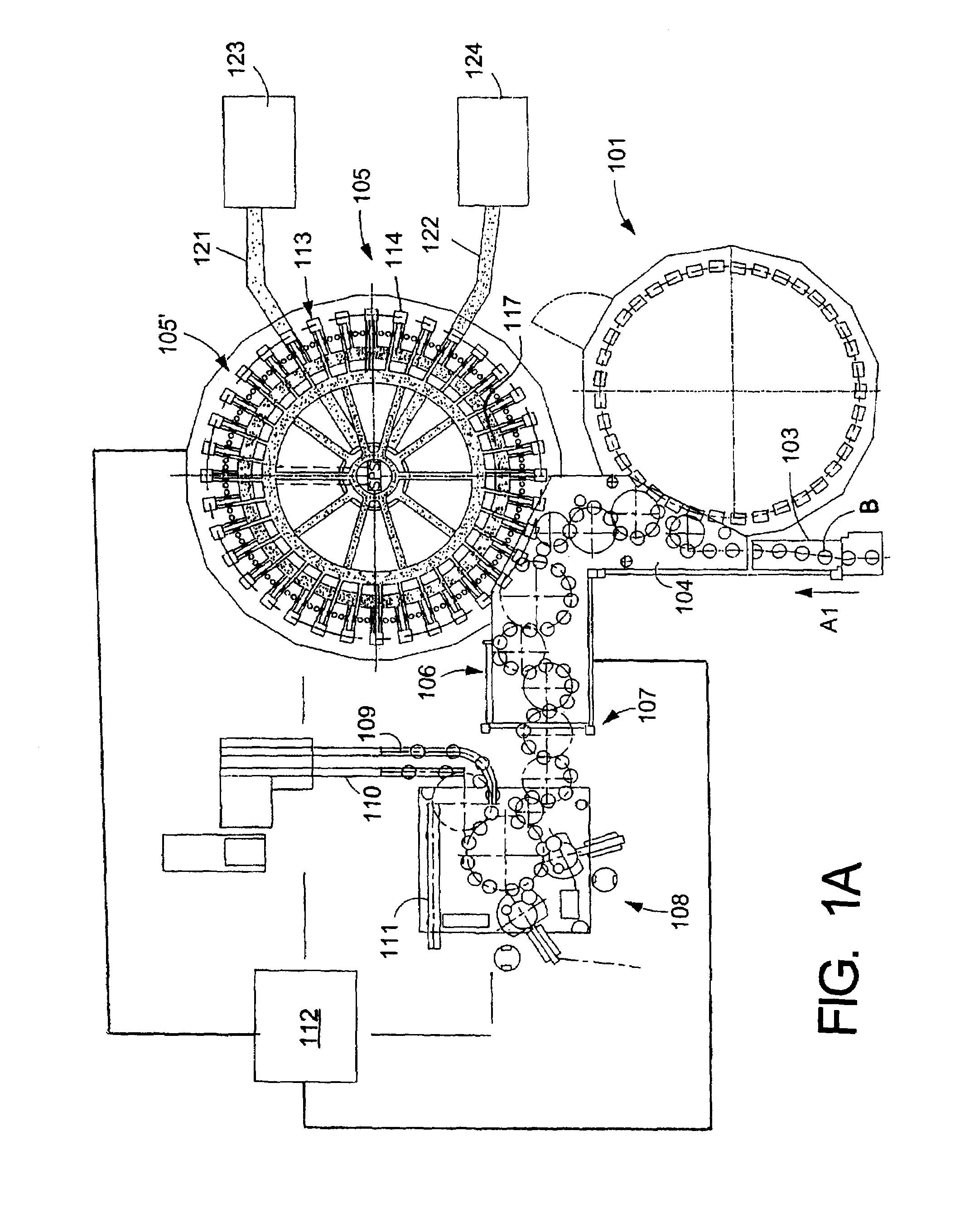

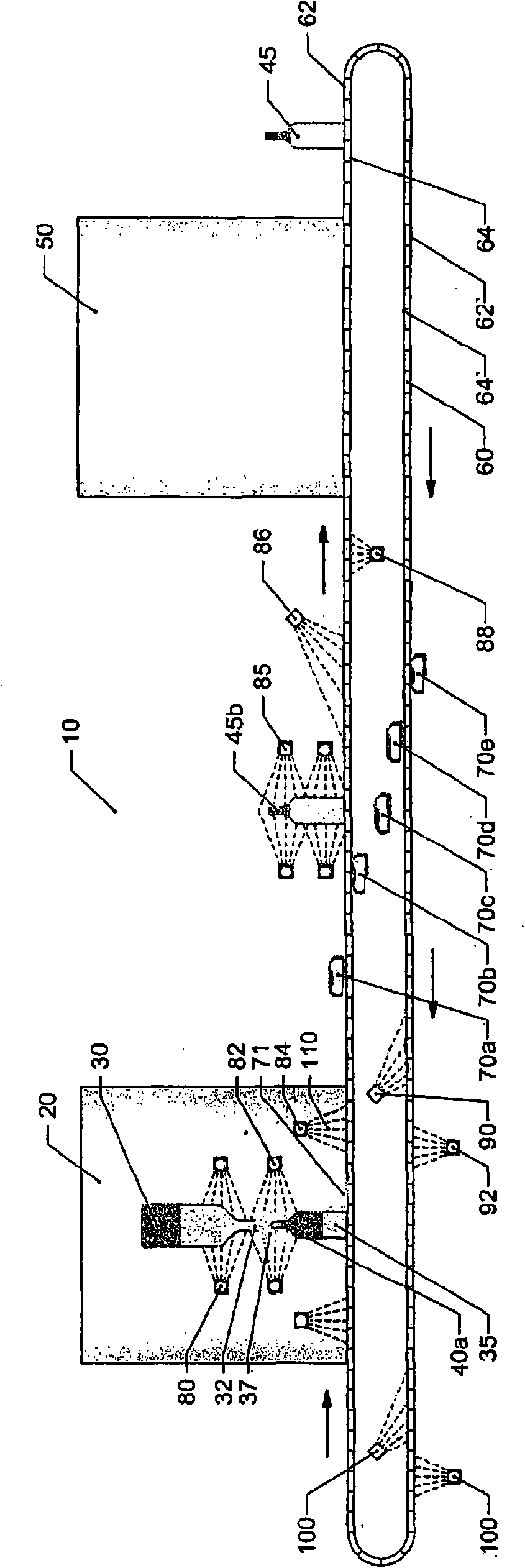

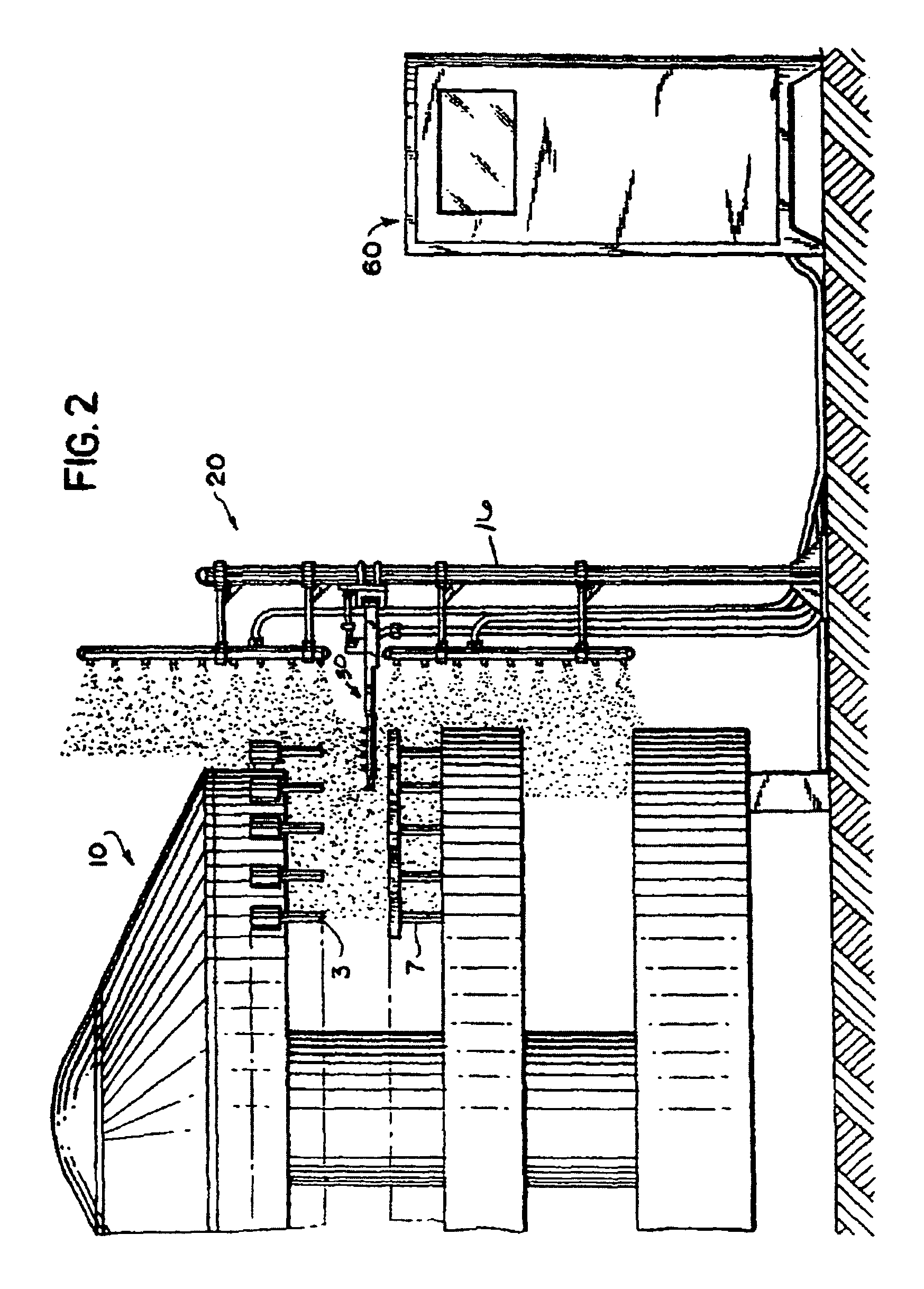

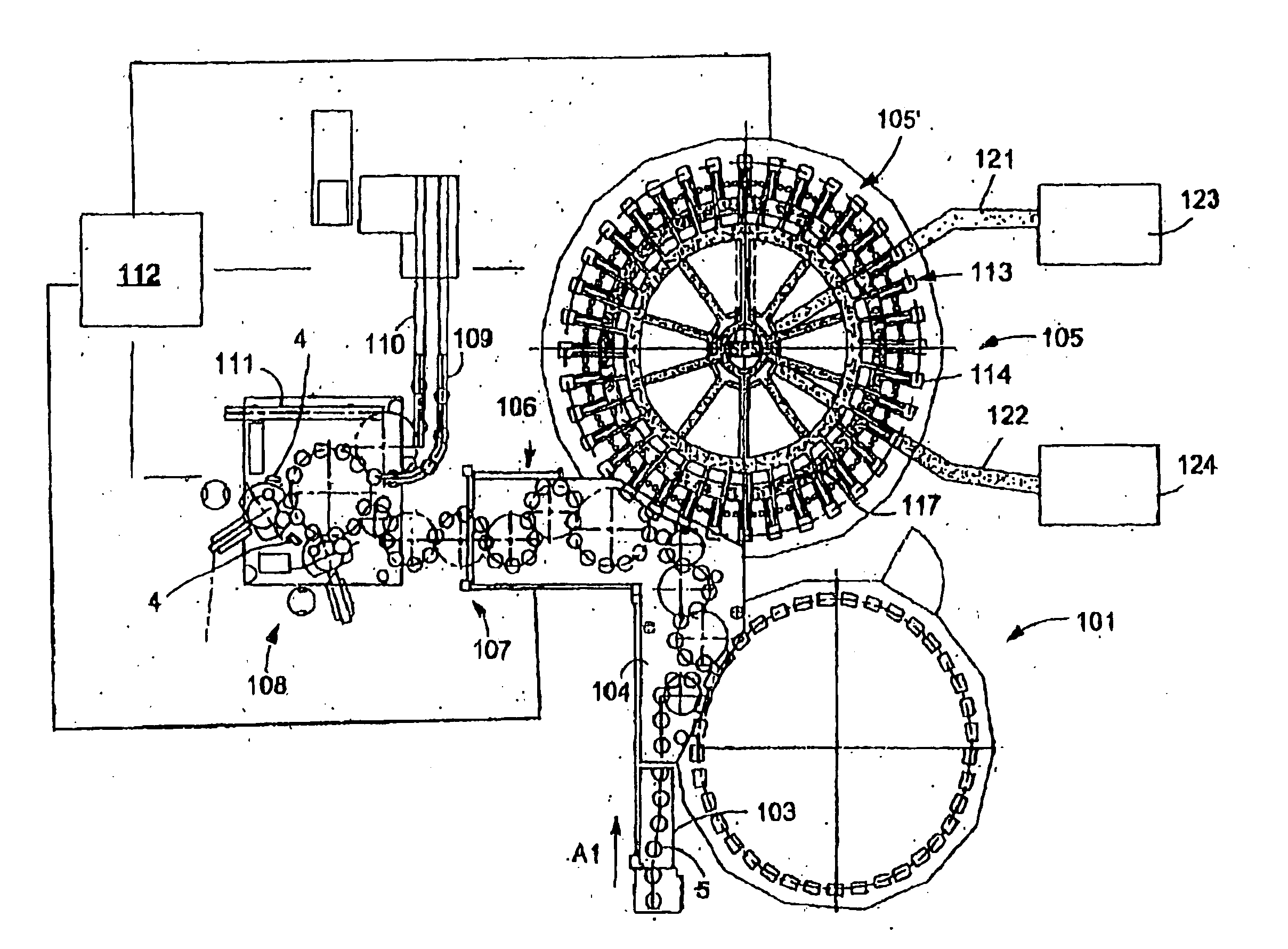

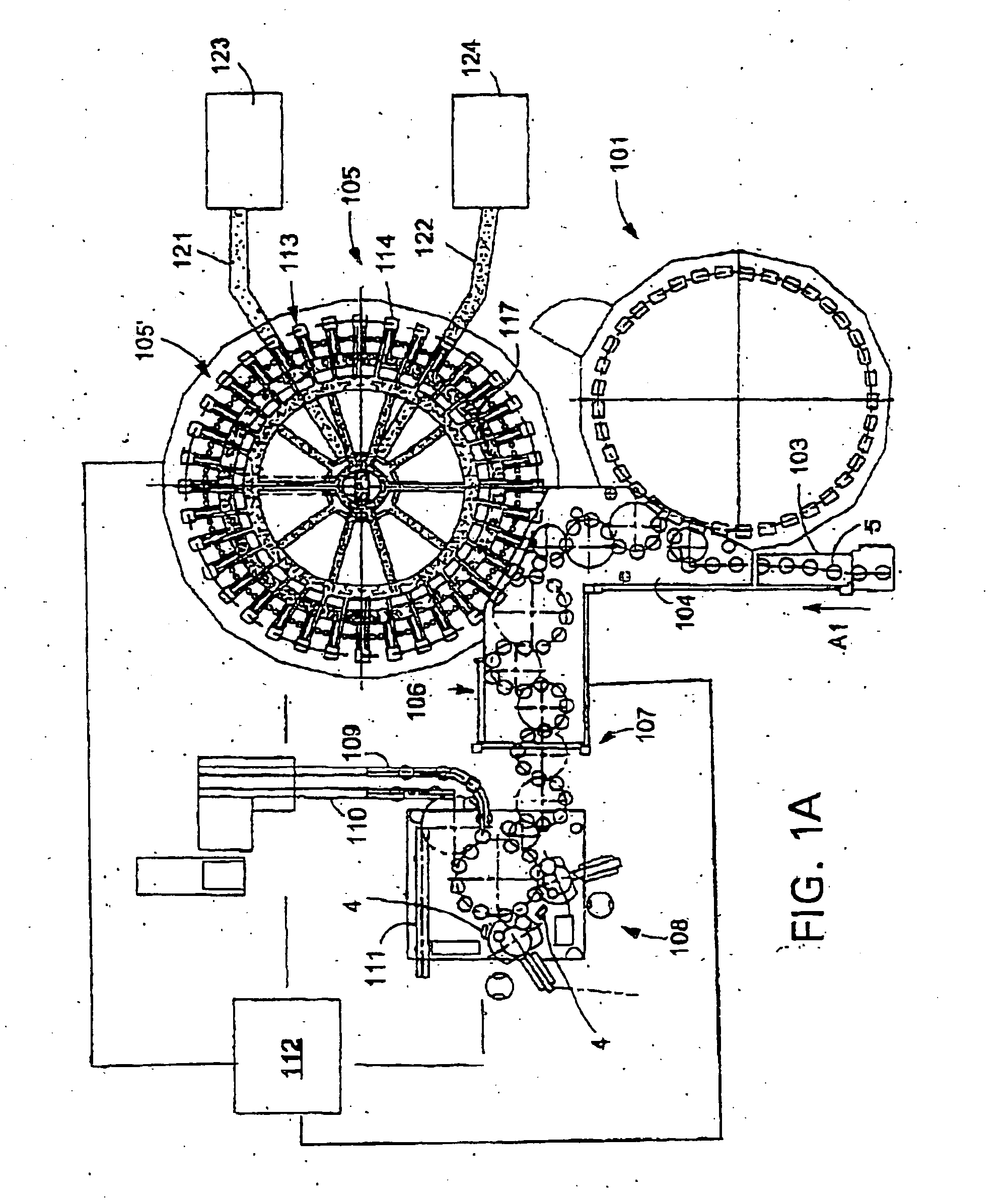

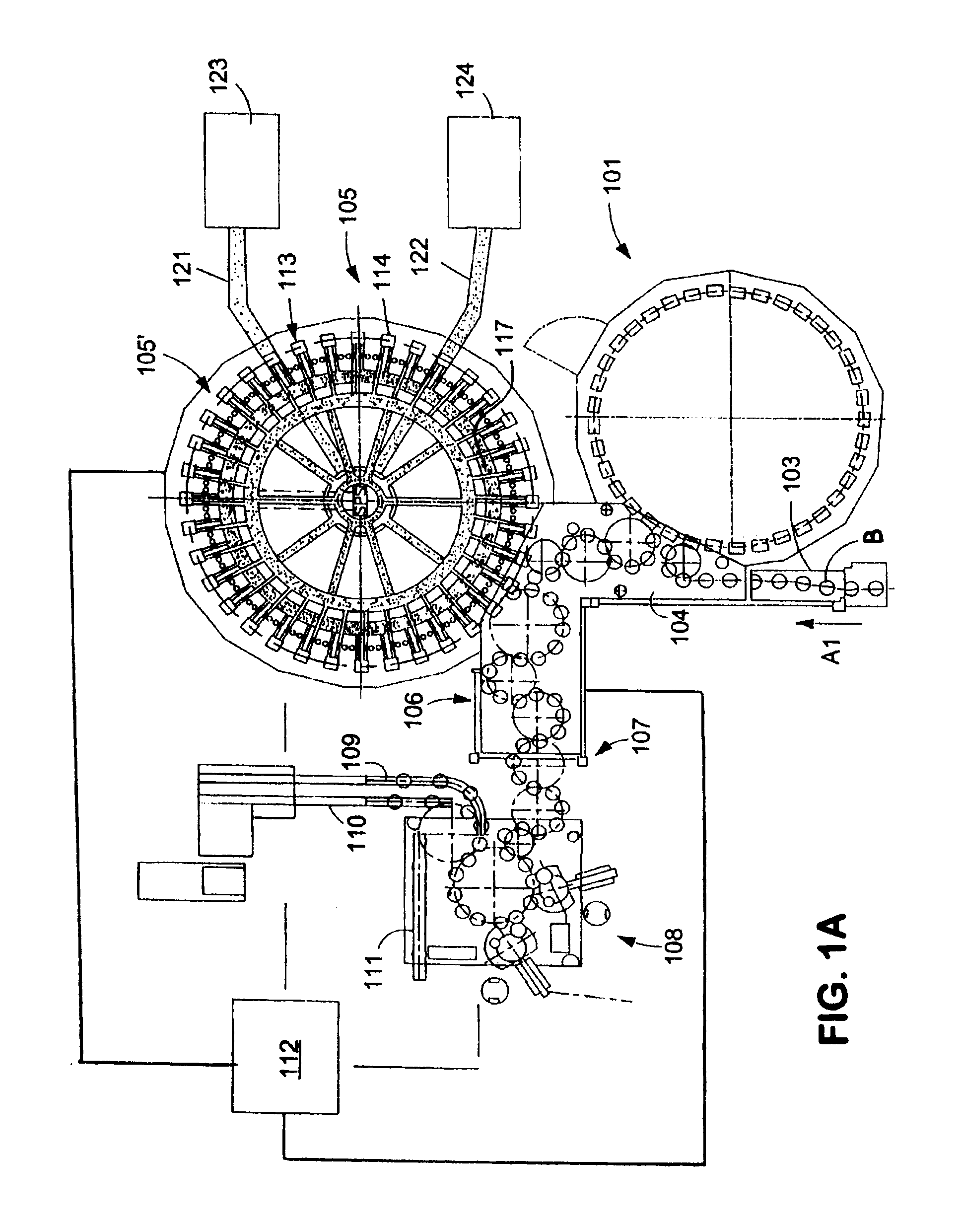

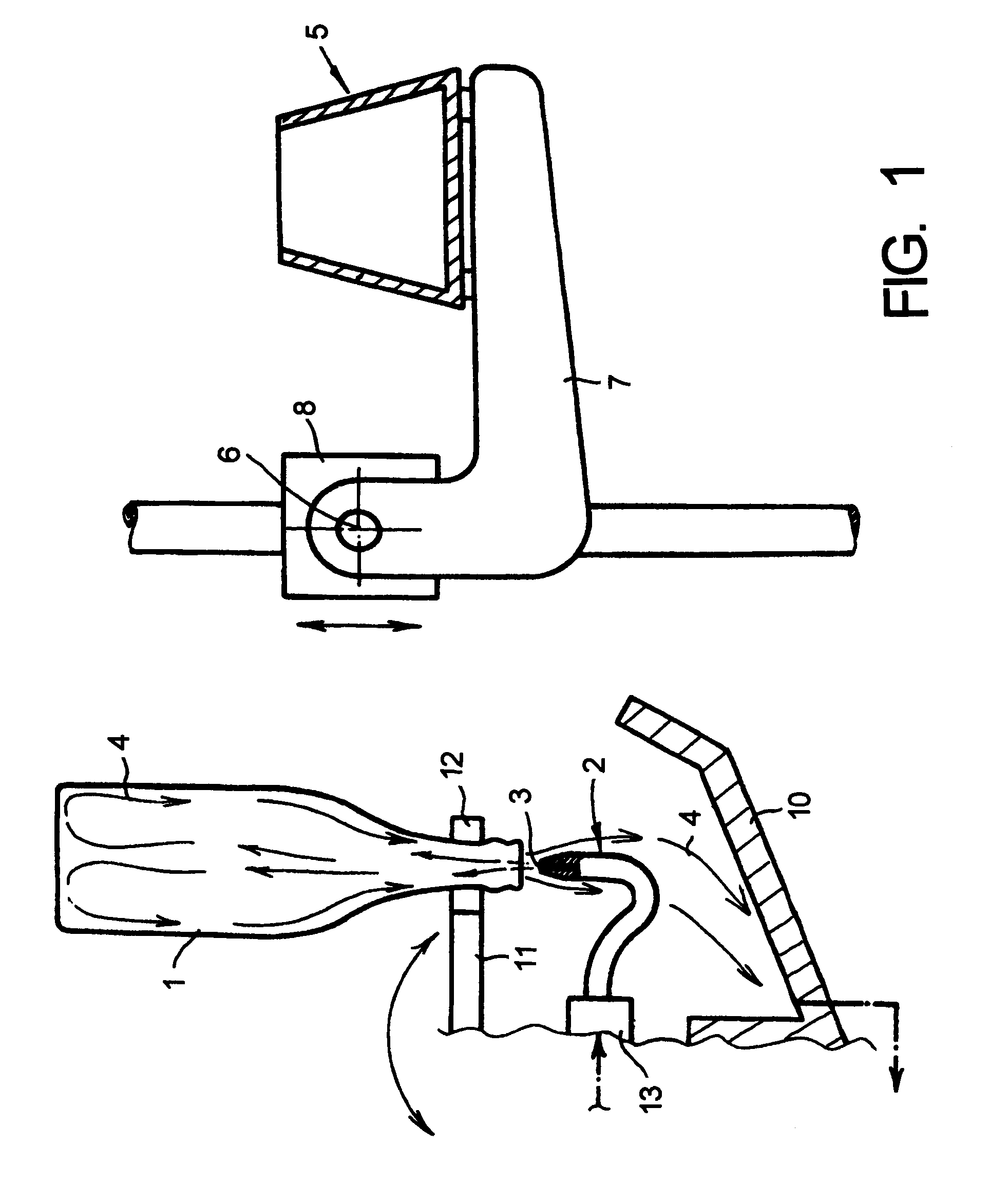

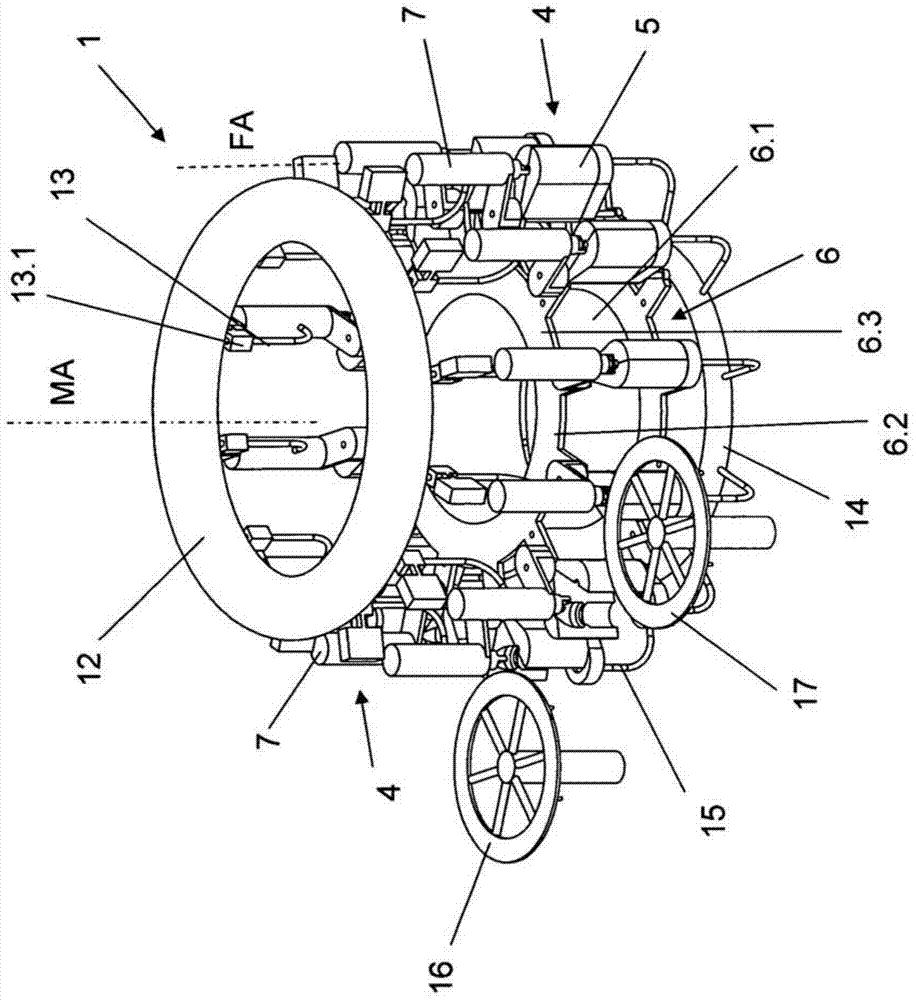

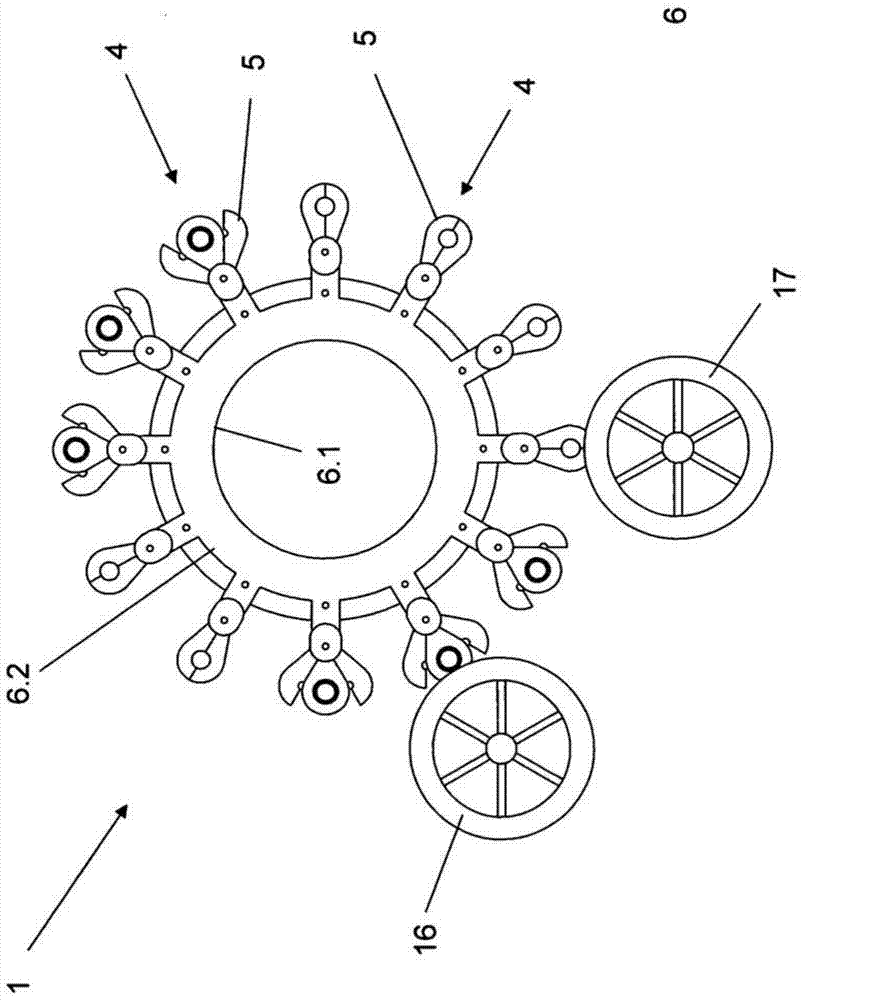

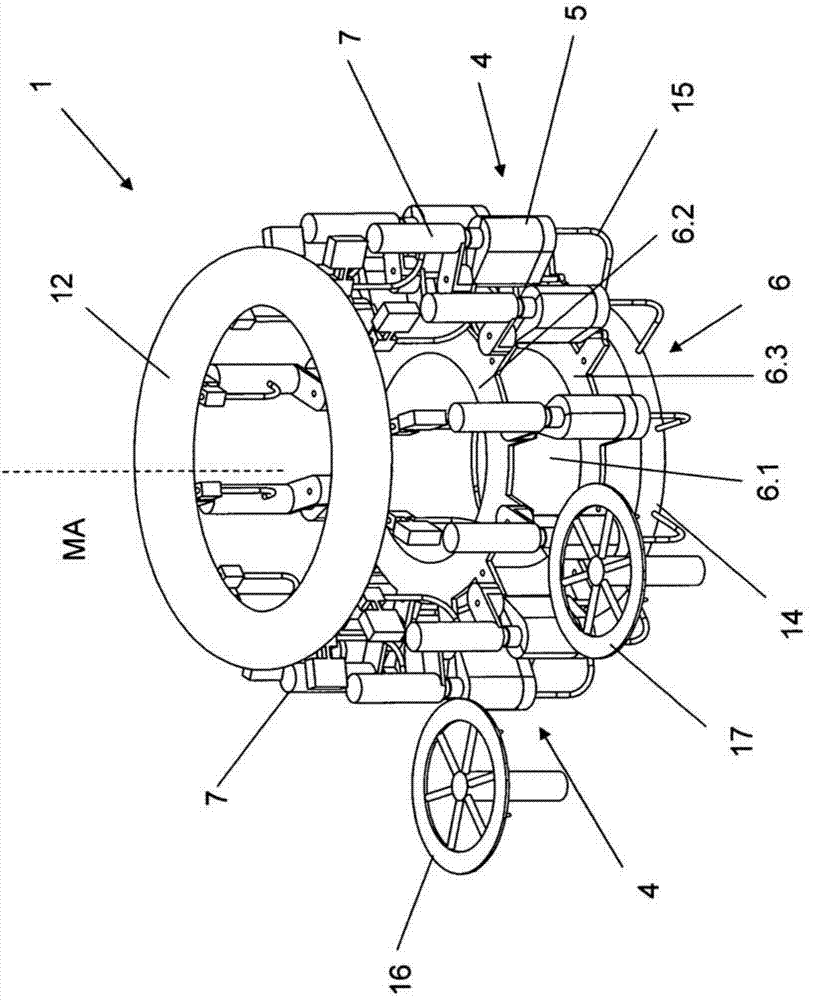

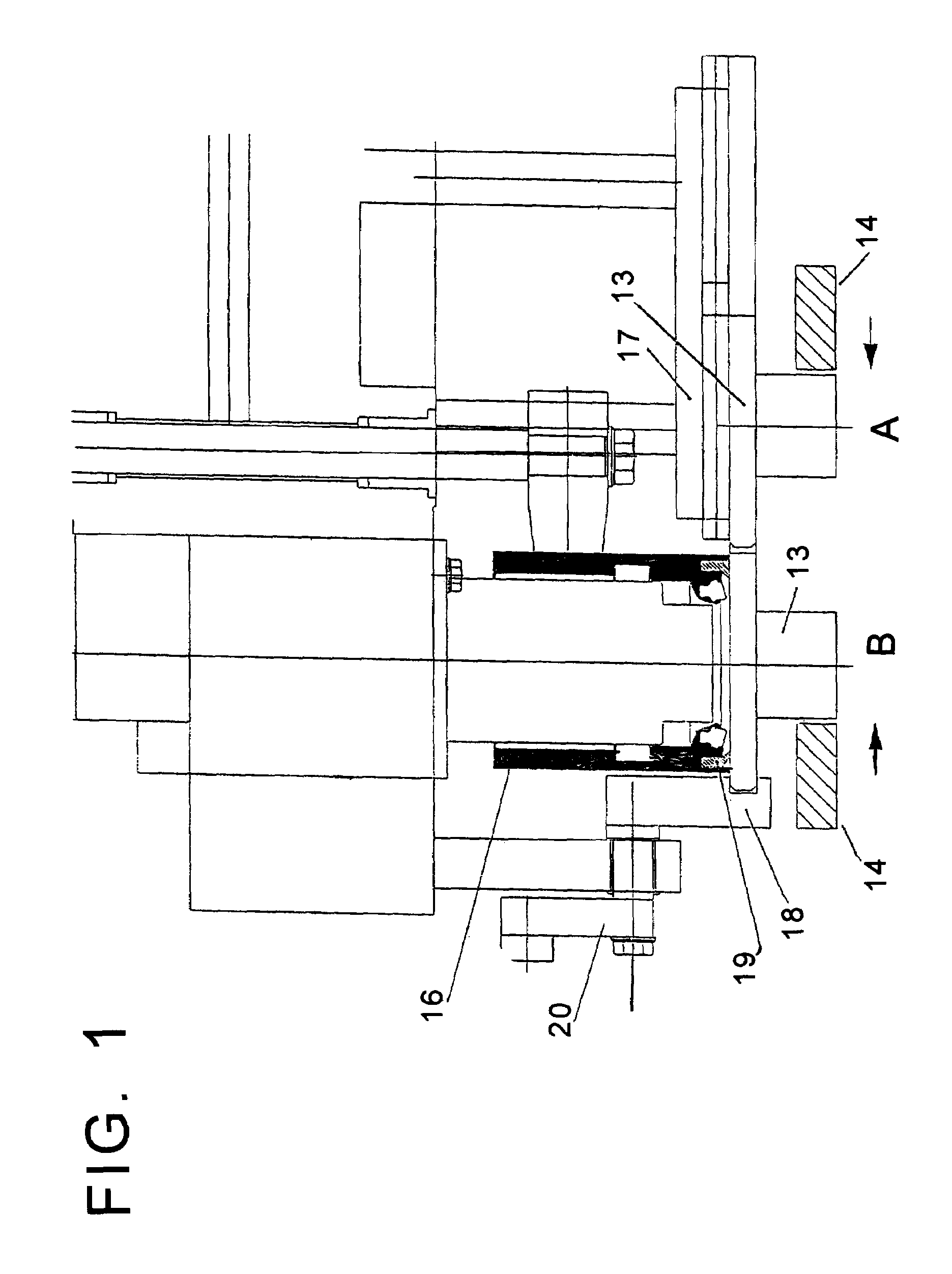

Beverage bottling plant for filling bottles with a liquid beverage filling material, having an apparatus for exchanging operating units disposed at rotating container handling machines

ActiveUS20050086909A1Shorten the timeRapid and simplified exchange/adaptationSolid materialFilling device cleaningFilling materialsTrademark

An apparatus for exchanging operating units disposed at rotating container handling machines, particularly upper handling components for varying the filling program, the cleaning program, and / or the closing program, wherein units are removed and replacement units are mounted in place of the removed units, it being proposed that each upper operating head (for example, filling element) {4}is associated with a plurality of replacement units {18, 19, 20} and these replacement units can be attached during a replacement at all operating heads {4} at the same time and / or exchanged at the same time and / or can be brought into the operative position with / connected to these operating heads {4}. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Device for the treatment of containers and cleaning method for such a device

ActiveCN103723666AEasy to manufactureReduce risk of leakageHollow article cleaningPackage sterilisationEngineeringDevice Subassembly

The invention relates to a device (1) for the treatment of containes by a processing medium in beverage filling equipment, preferably a filler, a rinser or a sterilizer. The device comprises the components of: a rotor (2) which is used for processing surrounding movement of the container to be processed, at least one cleaning nozzle which is used for applying cleaning medium and / or sterilizing medium on equipment assembly that surrounds the rotor (2) along with surrounding movement of the rotor (2), and a processing medium accommodating part (5) which performs surrounding movement along with the rotor (2), wherein a fluid connecting part (6) is arranged between at least one cleaning nozzle (30-38) and a processing medium accommodating part (5).

Owner:KRONES AG

High-efficiency liquid filling machine

InactiveCN107500222AEffective protectionPrevent fallingRotary stirring mixersControl devices for conveyorsEngineeringElectric control

The invention discloses a high-efficiency liquid filling machine. The high-efficiency liquid filling machine comprises a base. A supporting plate is arranged in the middle of the upper side of the base. The lower end of the left side of the supporting plate is provided with a fixed plate. The front end of the lower side of the fixed plate is provided with an electric control cabinet. A liquid storage cavity is arranged on the upper side of the fixed plate. The right side of the liquid storage cavity is provided with a first connecting pipe. The lower end of the right side of the first connecting pipe is provided with a connecting hose. The lower side of the connecting hose is provided with a second connecting pipe. The lower side of the second connecting pipe is provided with a connecting cavity. The front and rear sides of the left side of the connecting cavity are provided with connecting rods. The left sides of the connecting rods are provided with a sliding block. The sliding block is internally provided with a lead screw. The lower side of the lead screw is provided with a second motor. The lower side of the connecting cavity is provided with a liquid adding pipe. The lower side of the liquid adding pipe is provided with a nozzle. The outer side of the nozzle is provided with a connecting cover. The four corners of the rear side of the connecting cover are provided with springs. The outer sides of the springs are provided with a fixing cover. A conveyor belt is arranged under the nozzle. A connecting plate is arranged under the conveyor belt. The high-efficiency liquid filling machine can effectively and conveniently conduct liquid filling and can effectively prevent the nozzle from being damaged during liquid filling.

Owner:朱淑君

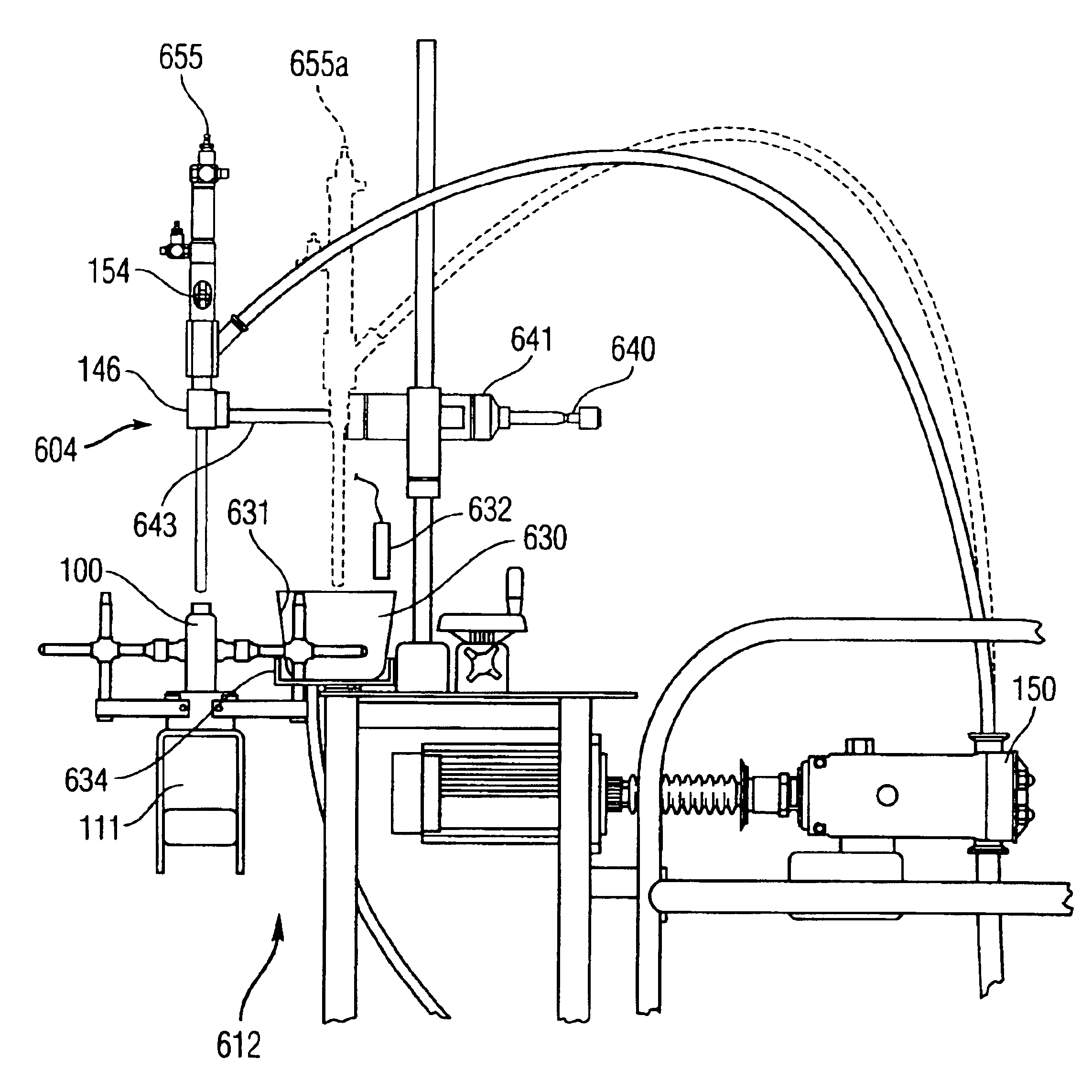

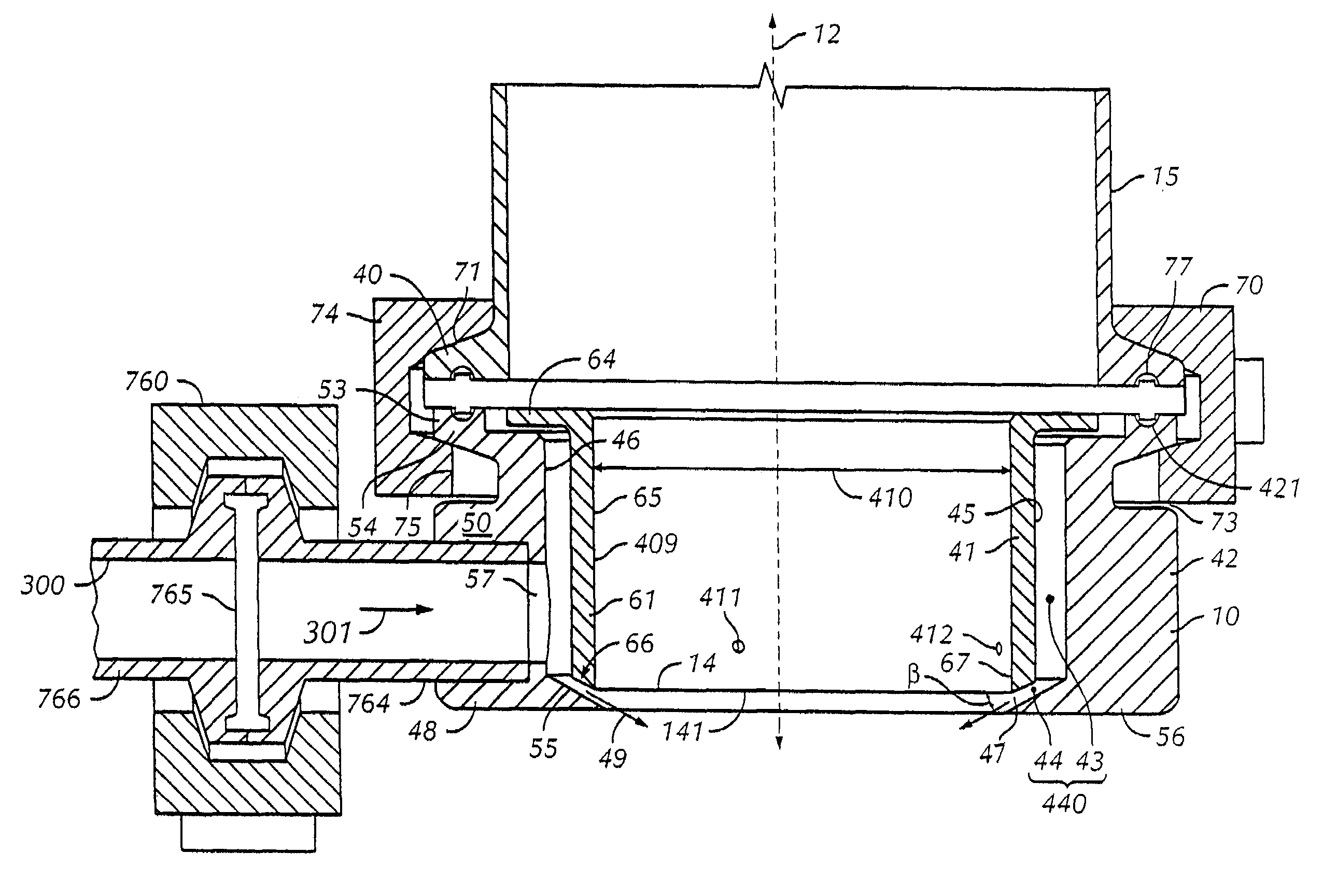

Installation for packaging a liquid product in receptacles

InactiveUS7942170B2Quantity minimizationQuick changeLiquid fillingLarge containersLiquid productIsolation valve

An installation for packaging a product in receptacles. The installation includes a series of filler stations each having a filler spout having a spout body with a top end connected to a filler spout feed duct and a bottom end provided with an orifice fitted with a controlled valve. The filler spout is fitted with a looping duct opening into the spout body above the controlled valve and connected by a link member to a general feed duct at a point between a stop valve and an isolation valve. A purge valve is connected to the general feed duct between the isolation valve and the link member.

Owner:SERAC GROUP

Industrial uniform material deep processing and filling device

PendingCN107089631ASolution to contaminationSolve cleanlinessRotary stirring mixersFilling device cleaningEngineeringMechanical engineering

The invention discloses an industrial uniform material deep processing and filling device. The industrial uniform material deep processing and filling device comprises a material treatment tank; a raw material temporary storage tank is arranged on the left side of the material treatment tank; the raw material temporary storage tank communicates with a feeding port of the material treatment tank through a material conveying pipeline; a flow meter is arranged on a pipe body of the material conveying pipeline; a driving motor is arranged at the top of the material treatment tank; a stirring rotating shaft is arranged at the bottom end of the driving motor and stretches into the bottom of a tank body of the material treatment tank; and the right end of a pipe body of a water spray guide pipe leads two branches to communicate with a pipeline body of a material filling head correspondingly. According to the industrial uniform material deep processing and filling device, efficient and constant-speed charging is realized, and the actual charging effect is better; the phenomenon of non-uniform materials in the filling cavity caused by the treatment mechanism with the traditional form is avoided, and the materials are treated more completely and reasonably; furthermore, the traditional filling machine head is simpler and more convenient to clean, the work difficulty is reduced, and the practicability of the traditional filling equipment is further enhanced.

Owner:长沙装研智能科技有限公司

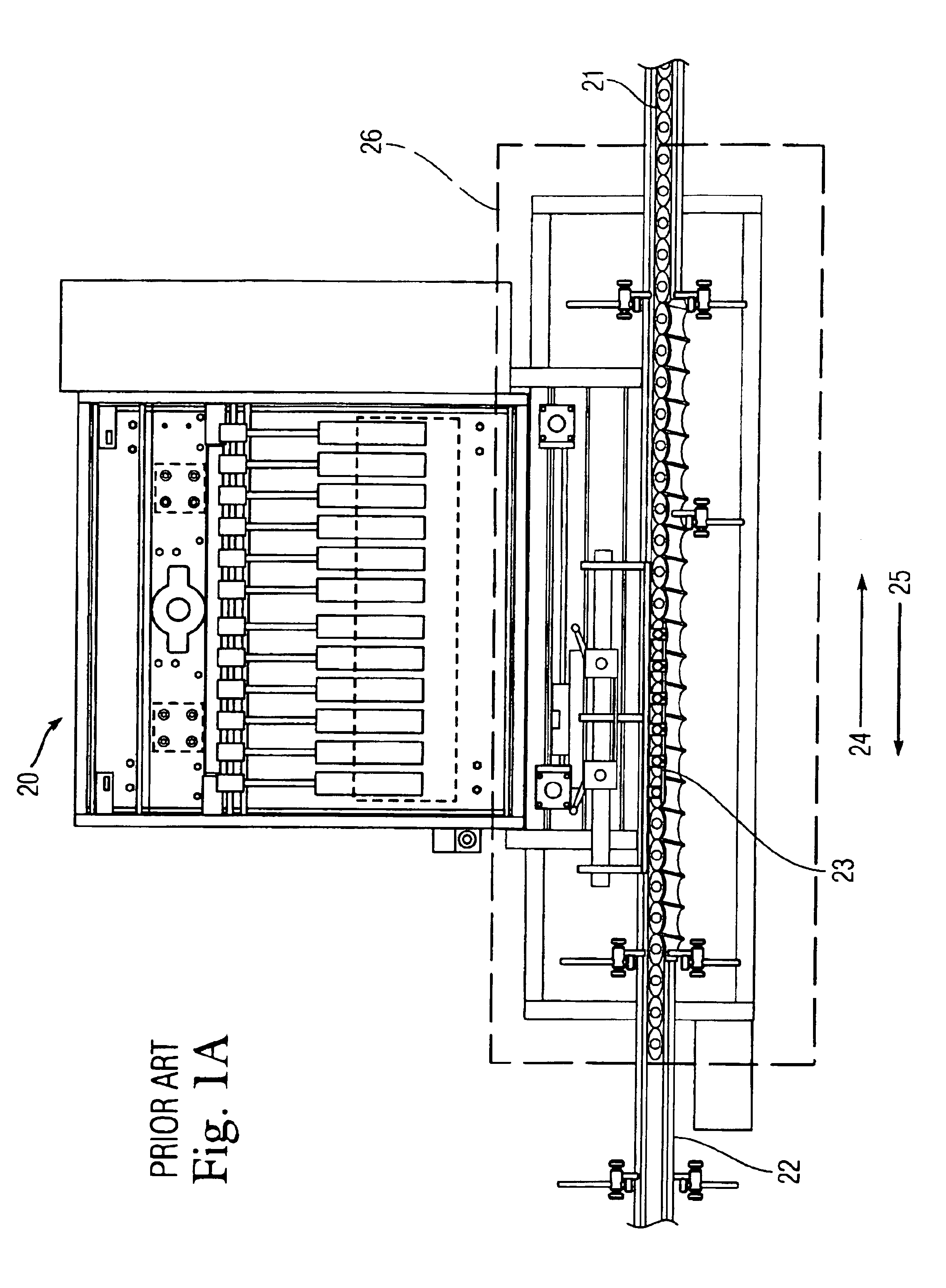

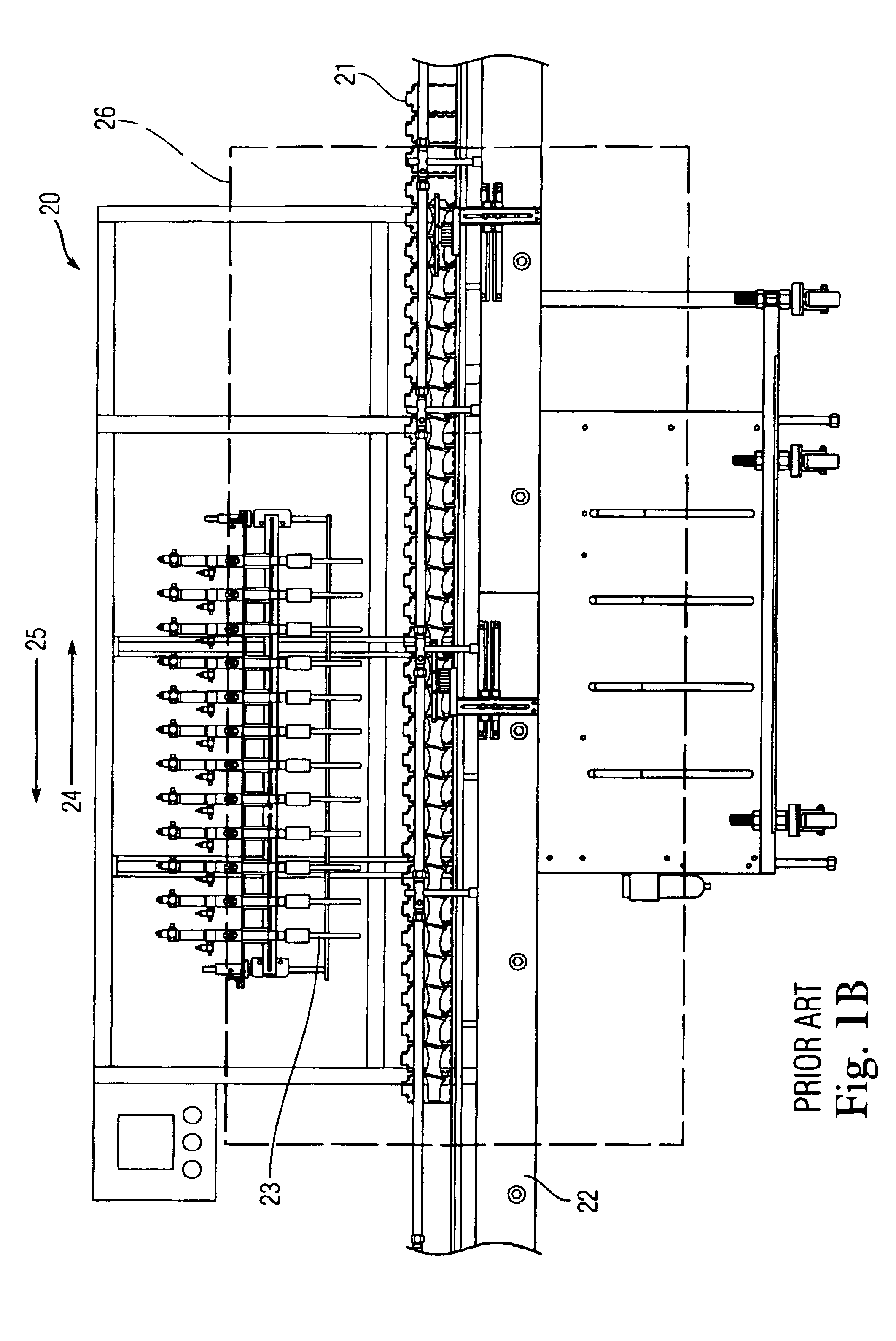

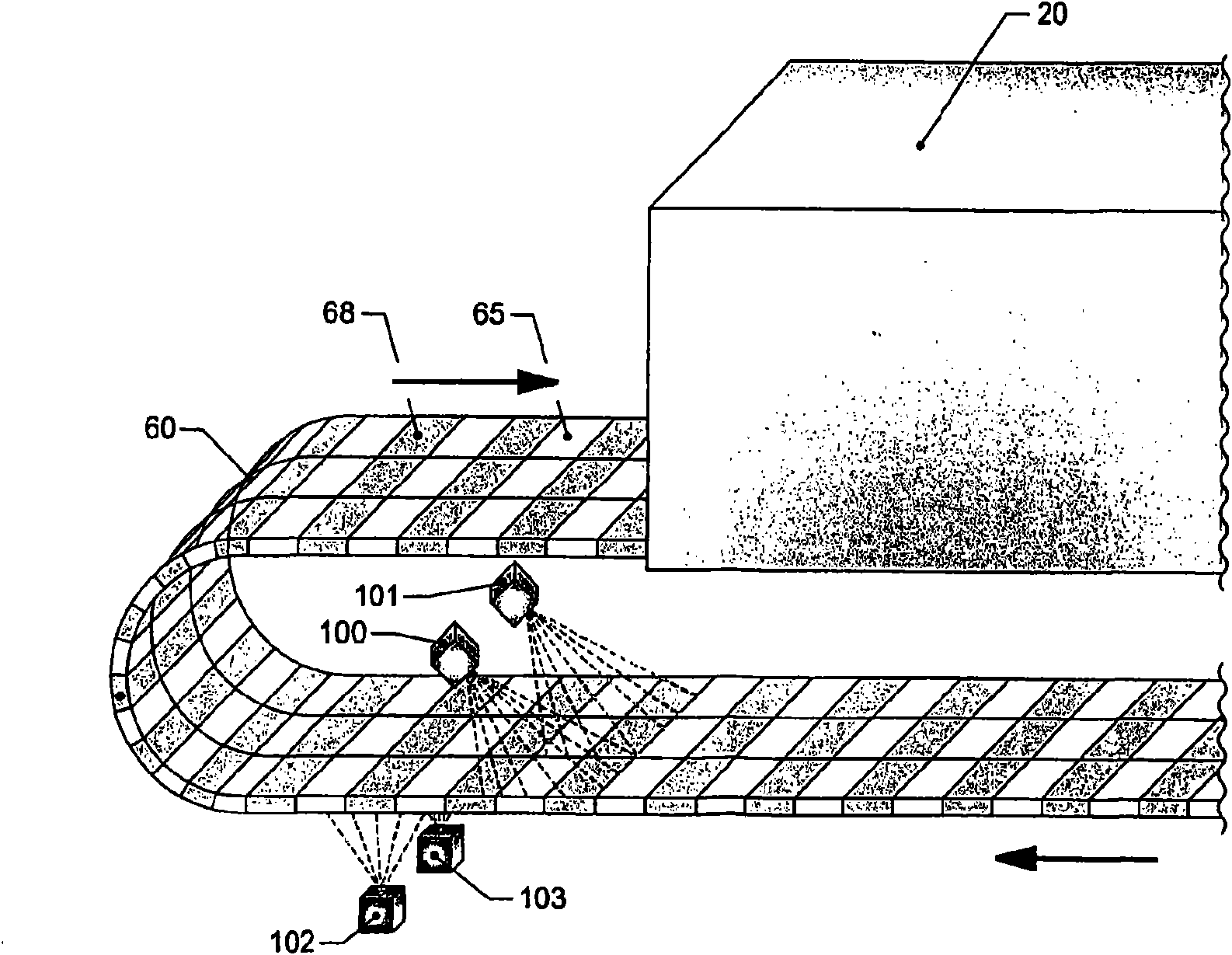

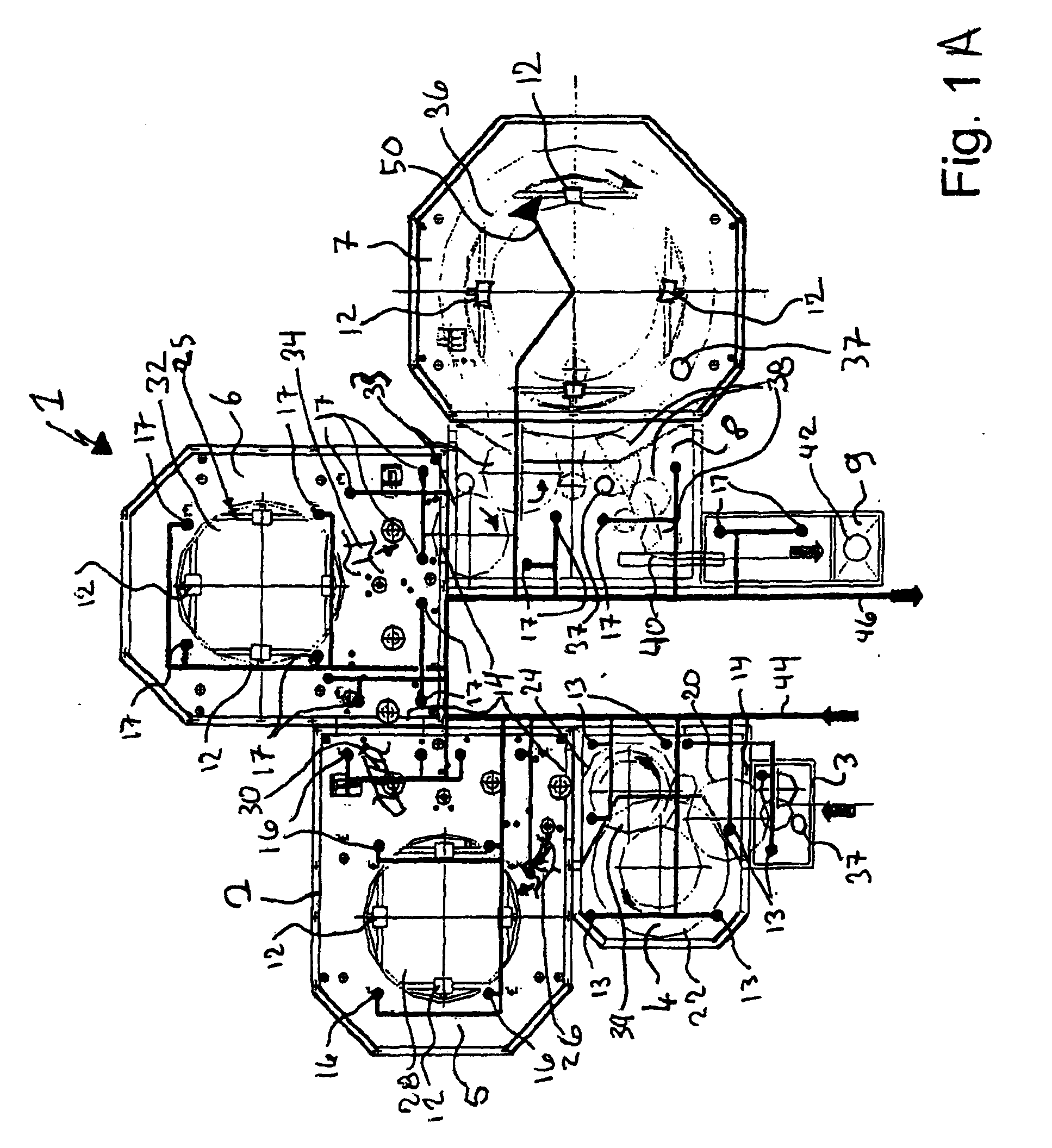

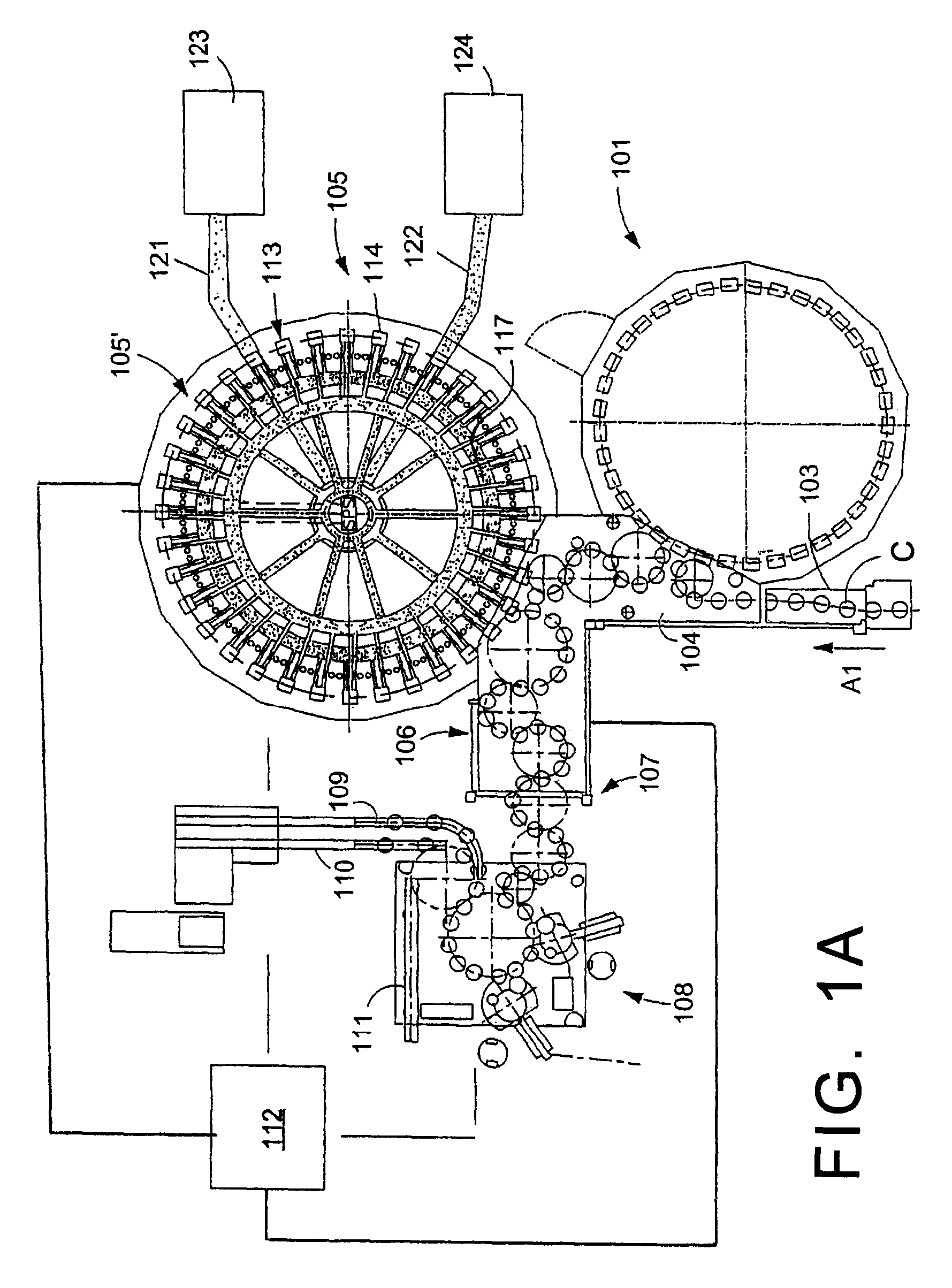

Rotary or linear beverage bottle cleaning machine configured to clean beverage bottles disposed upside-down which machine includes apparatus for cleaning rotary or linear beverage bottle cleaning machine in a filling plant and rotary or linear container cleaning machine configured to clean containers with apparatus for cleaning the container cleaning machine

ActiveUS20100037925A1Easy to cleanEliminates and restricts and minimizes manual interventionHollow article cleaningFilling device cleaningTrademarkEngineering

A rotary or linear beverage bottle cleaning machine configured to clean beverage bottles disposed upside-down which machine includes apparatus for cleaning rotary or linear beverage bottle cleaning machine in a filling plant and rotary or linear container cleaning machine configured to clean containers with apparatus for cleaning the container cleaning machine. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

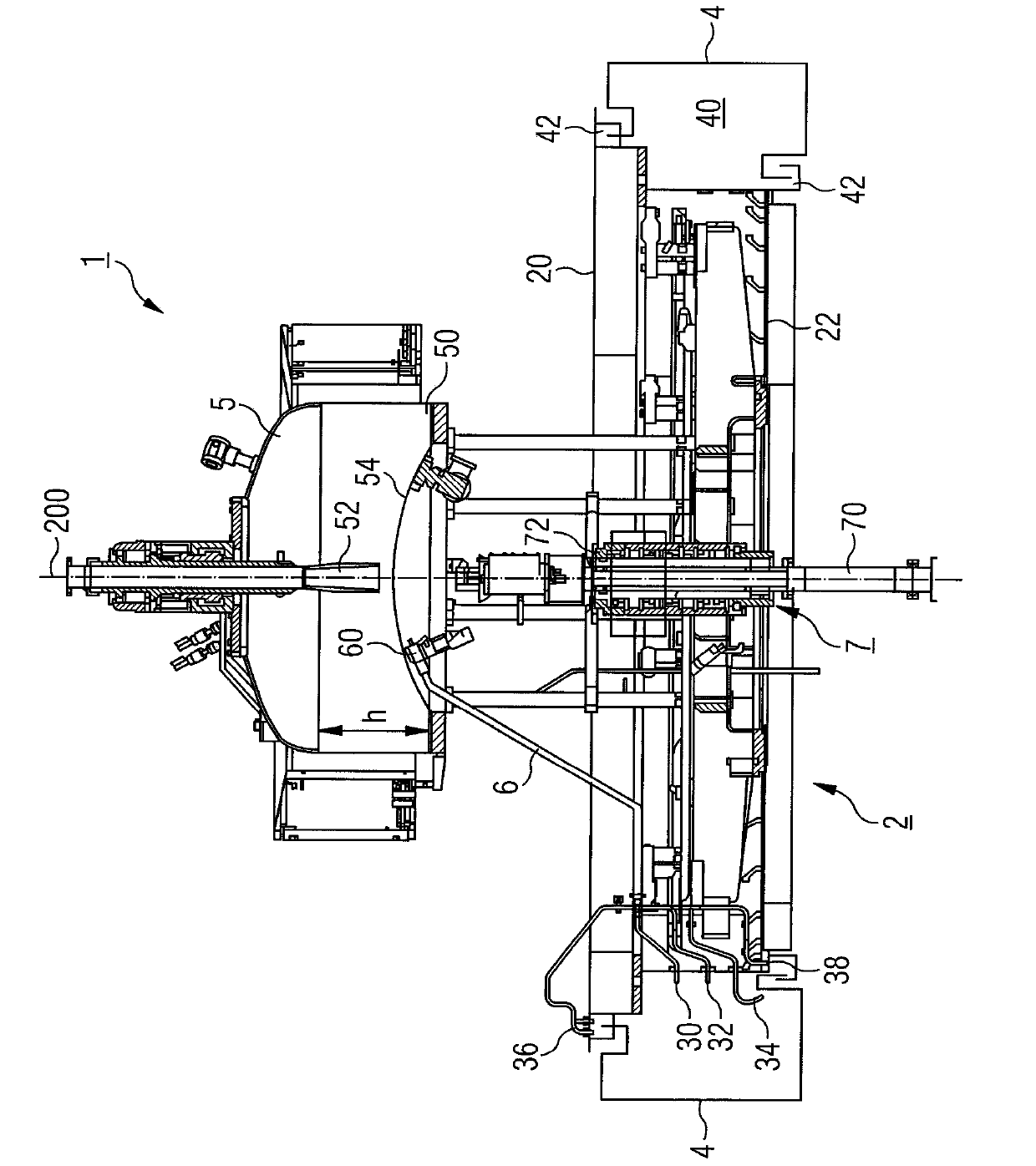

Method and device for cleaning and/or disinfecting a device for producing containers filled with a liquid filling material

ActiveCN103687711AHollow article cleaningFilling device cleaningFilling materialsBiomedical engineering

The invention relates to a device (1) for the integrated production and filling of containers and to a method for cleaning and / or disinfecting at least the mould (5) of at least one molding and filling station (4) of said device (1). During a cleaning and / or disinfecting operation of the device (1), at least the inside of the mould (5) is cleaned and / or disinfected with at least one cleaning and / or disinfecting agent by means of at least one cleaning element, and during the cleaning and / or disinfecting operation, the at least one mould (5) is opened and closed at least once, preferably many times and / or the plunger is moved at least once, preferably many times, between its initial position and end position.

Owner:KHS GMBH +1

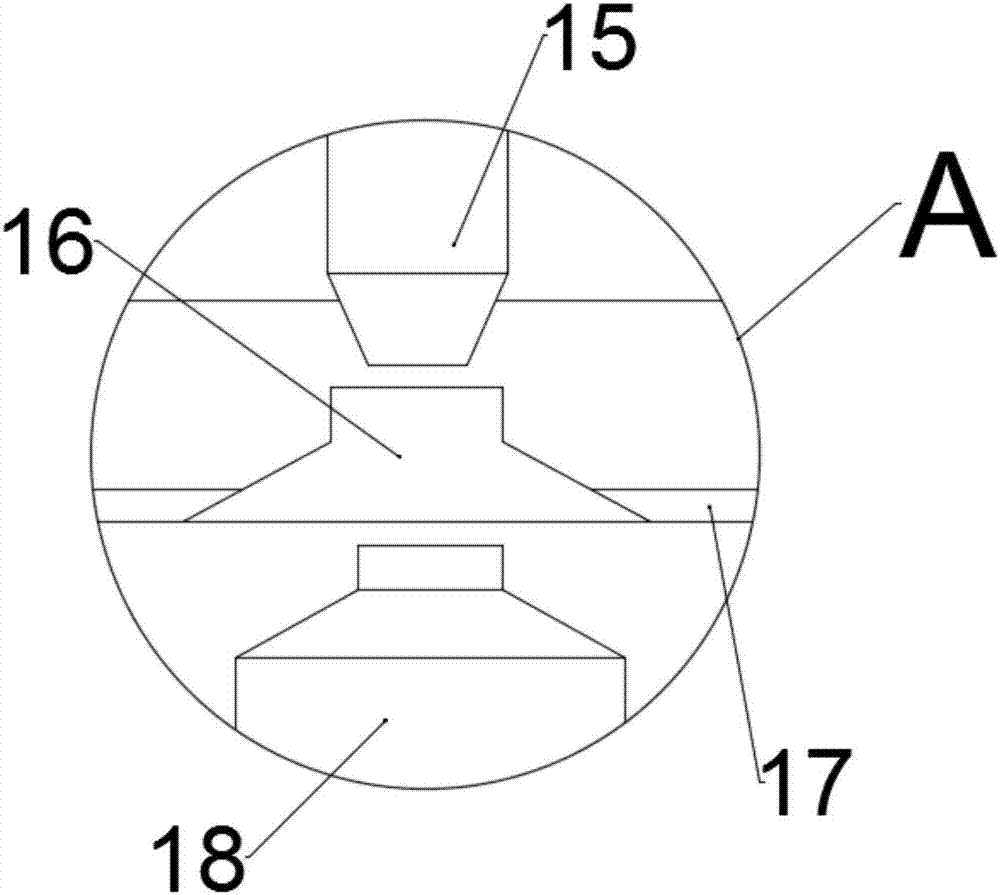

Fruit juice filling valve

ActiveCN106698299ARealize cycle cleaningWith flow rateFilling device cleaningLift valveImpellerFruit juice

The invention relates to a filling valve, in particular to a fruit juice filling valve. A cleaning device is arranged at one end of a liquid guide valve seat and a valve seat head. An inner cavity of the valve seat head communicates with a material cavity to form a flow guide cavity. The cleaning device comprises a rotary pipe, a liquid storing tank and spraying heads, wherein the rotary pipe is located in the flow guide cavity and rotationally connected to the liquid guide valve seat with a valve rod as the rotary axis; a cleaning channel is formed between the outer wall of the rotary pipe and the inner wall of the flow guide cavity; forward-rotation annular ribs are disposed on the inner wall of the rotary pipe; backward-rotation impellers are disposed on the outer wall of the rotary pipe; the liquid storing tank is provided with an air outlet, a liquid inlet pipeline, a recycling pipeline and a liquid inlet cover; the air outlet is formed in the top of the liquid storing tank; the liquid inlet pipeline communicates with the liquid storing tank and the cleaning channel; the recycling pipeline communicates with the inner cavity of the valve seat head and the liquid storing tank; both the liquid inlet pipeline and the recycling pipeline are provided with valves; and the spraying heads are connected with the cleaning channel and arranged on the inner wall of the rotary pipe or in the material cavity. The invention aims to provide the filling valve of which an interior cavity can be comprehensively cleaned.

Owner:重庆市嘉诺食品有限公司

Rotary beverage filling machine for filling cans with a liquid beverage

InactiveUS7513279B2Eliminates and minimizesLeaks can be reliably preventedLiquid fillingSolid materialMechanical engineeringEngineering

Owner:KHS GMBH

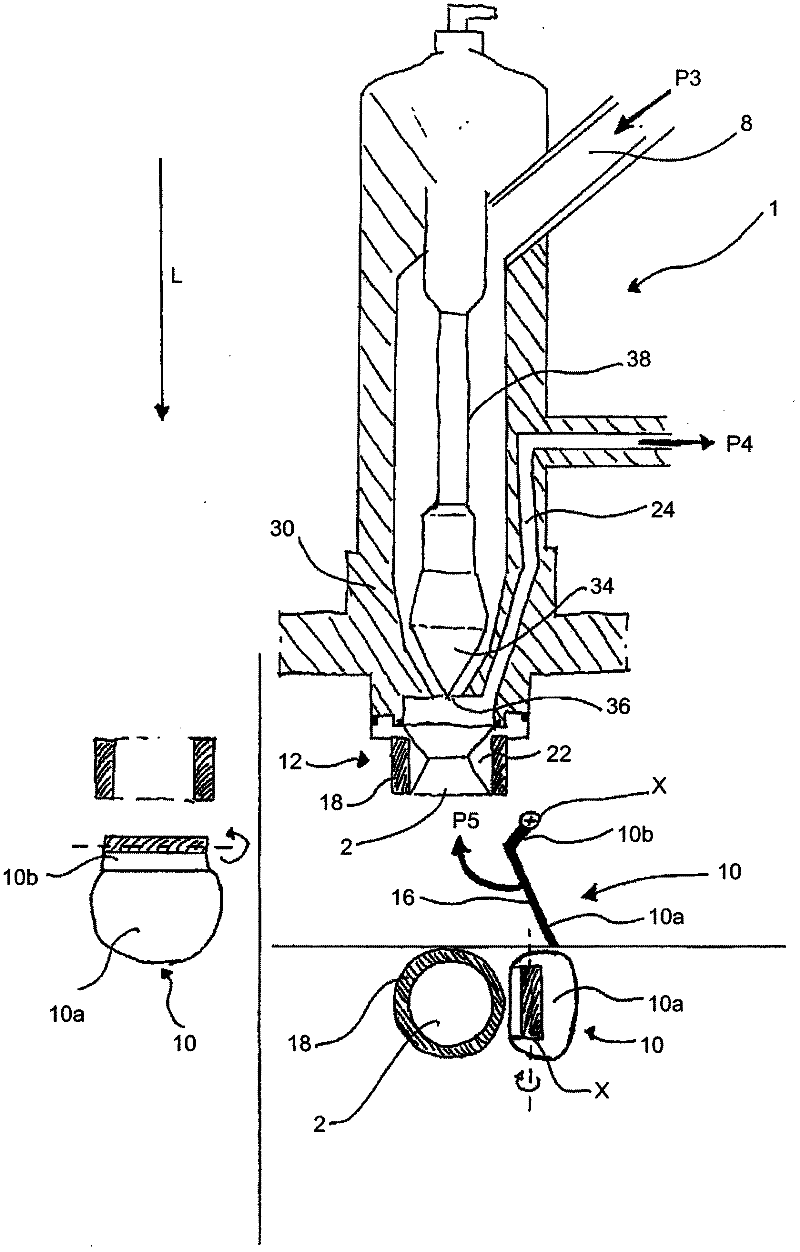

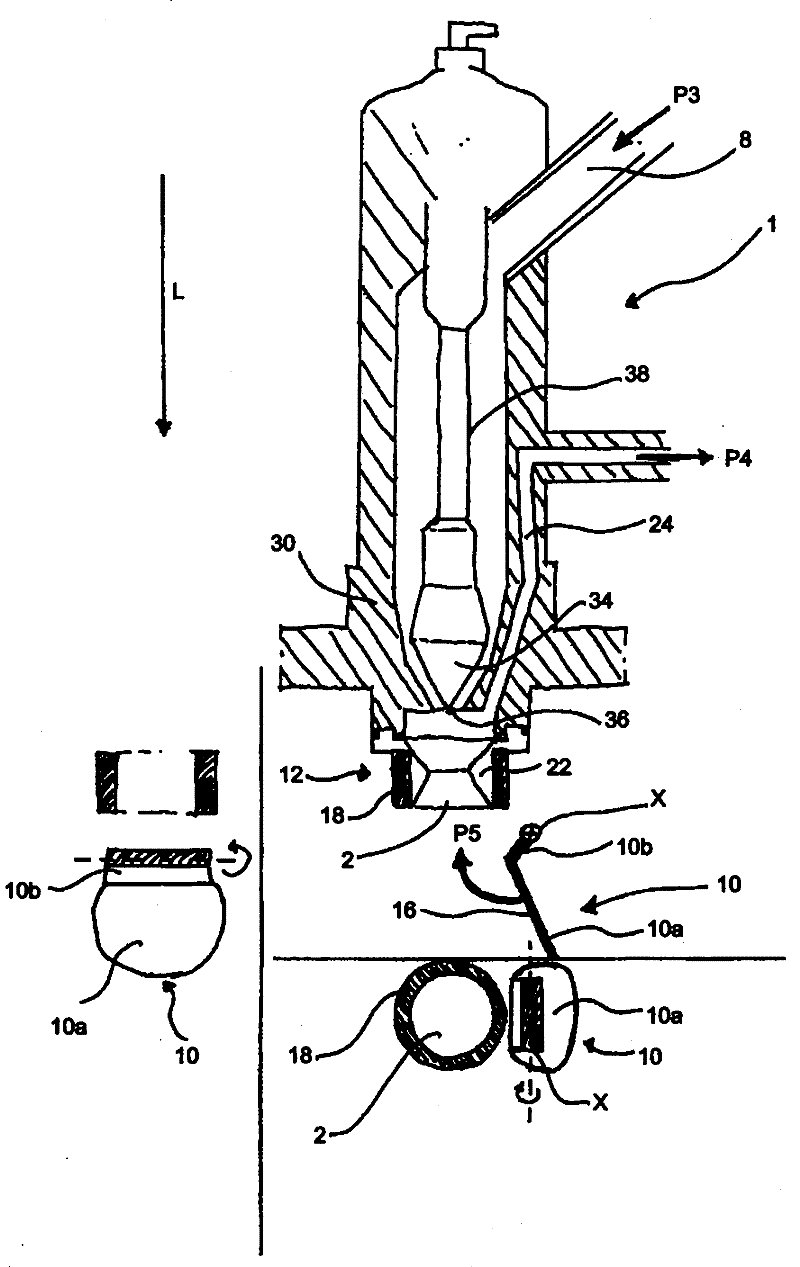

Apparatus for filling containers having a magnetically operated closing cap

An apparatus (1) for filling containers with a liquid, having an outlet opening (2) via which the liquid can be filled into the container, having a liquid line (8) in order to feed the liquid to the outlet opening (2), and having a closing body (10) which can be moved between at least two positions in relation to the outlet opening, wherein the closing body (10) rests against the outlet opening (2) in a first position in order to close said outlet opening. According to the invention, the apparatus (1) has a first magnetic or magnetized element (12) which is arranged in a stationary manner in relation to the outlet opening (2) and interacts with a second magnetic or magnetized region (16) of the closing body (10) in order to move the closing body (10).

Owner:KRONES AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com