Method for cleaning beverage bottling apparatus

A technology for filling devices and beverages, applied in beverage preparation devices, chemical instruments and methods, and cleaning of filling devices, etc., can solve the problems of production time (long downtime, low production efficiency, poor production efficiency, etc.), and shorten the production period Time, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

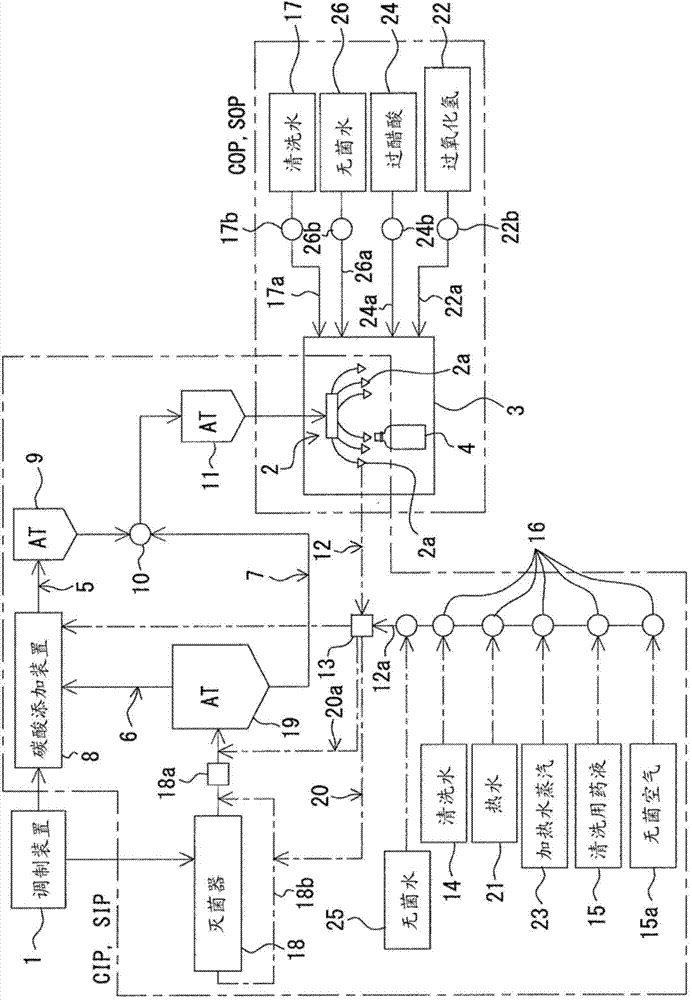

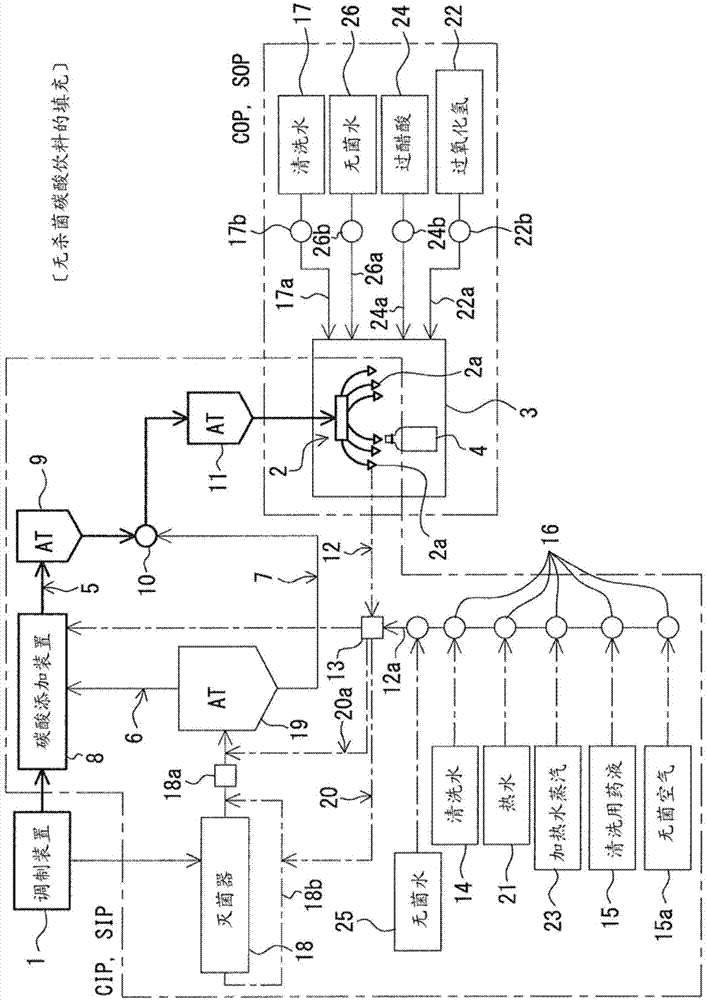

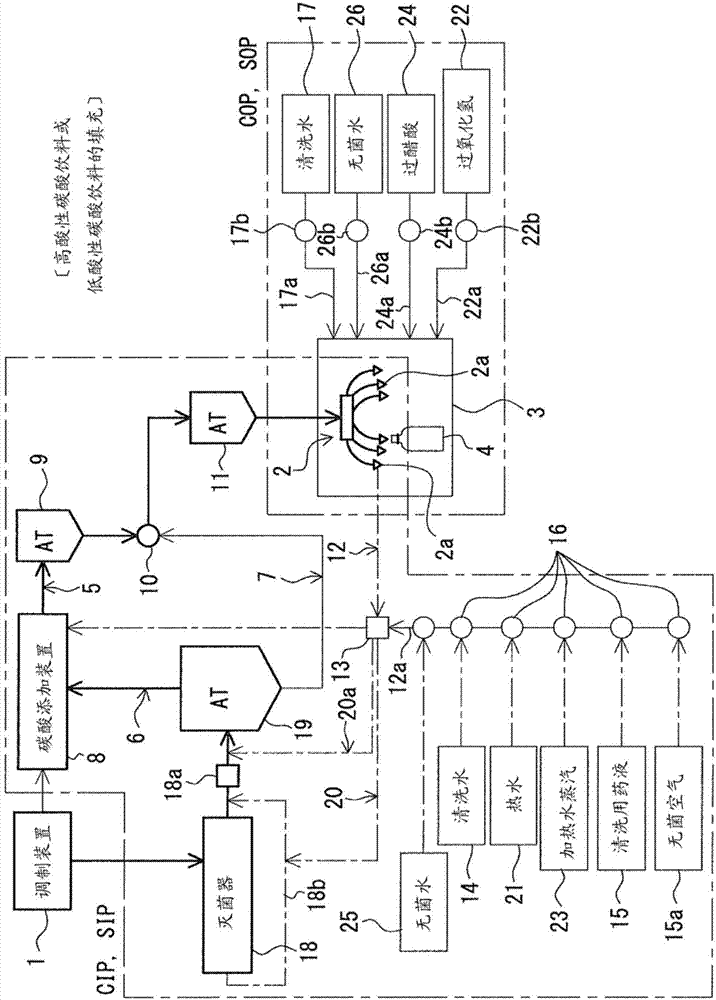

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0037] First, the structure of the beverage filling device will be described, and second, a cleaning method for the device will be described.

[0038] Such as figure 1 As shown, the beverage filling device includes a beverage preparation device 1 and a filling machine 2 for filling beverages into containers such as bottles. The brewing device 1 and the filling machine 2 are connected by piping of a beverage supply system. Furthermore, the filling machine 2 is surrounded by a sterile chamber 3 .

[0039] The preparation device 1 is a device for preparing beverages such as tea beverages and fruit beverages in desired compounding ratios, and is a well-known device, so a detailed description thereof will be omitted.

[0040] The filling machine 2 is a device in which a plurality of filling nozzles 2a are arranged around a high-speed rotating wheel (not shown) in a horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com