Method and device for cleaning and/or disinfecting a device for producing containers filled with a liquid filling material

A sensor device and cleaning technology, applied in the field of container devices, can solve problems such as inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

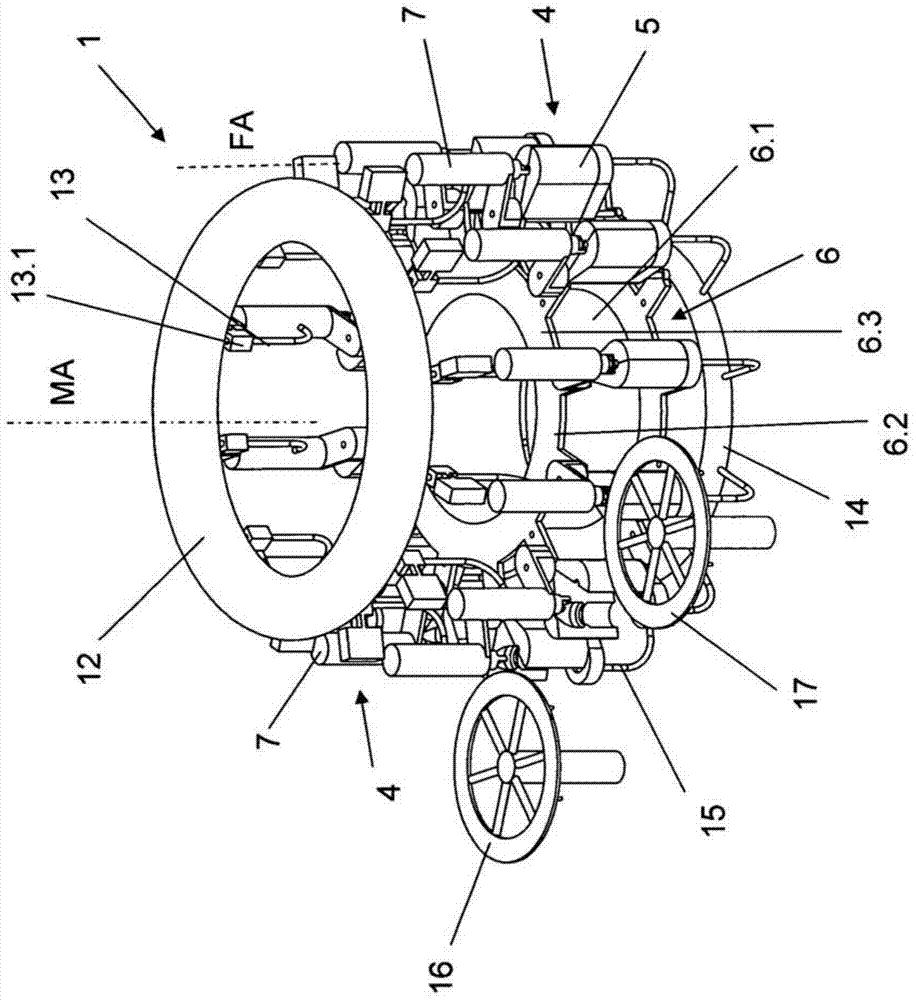

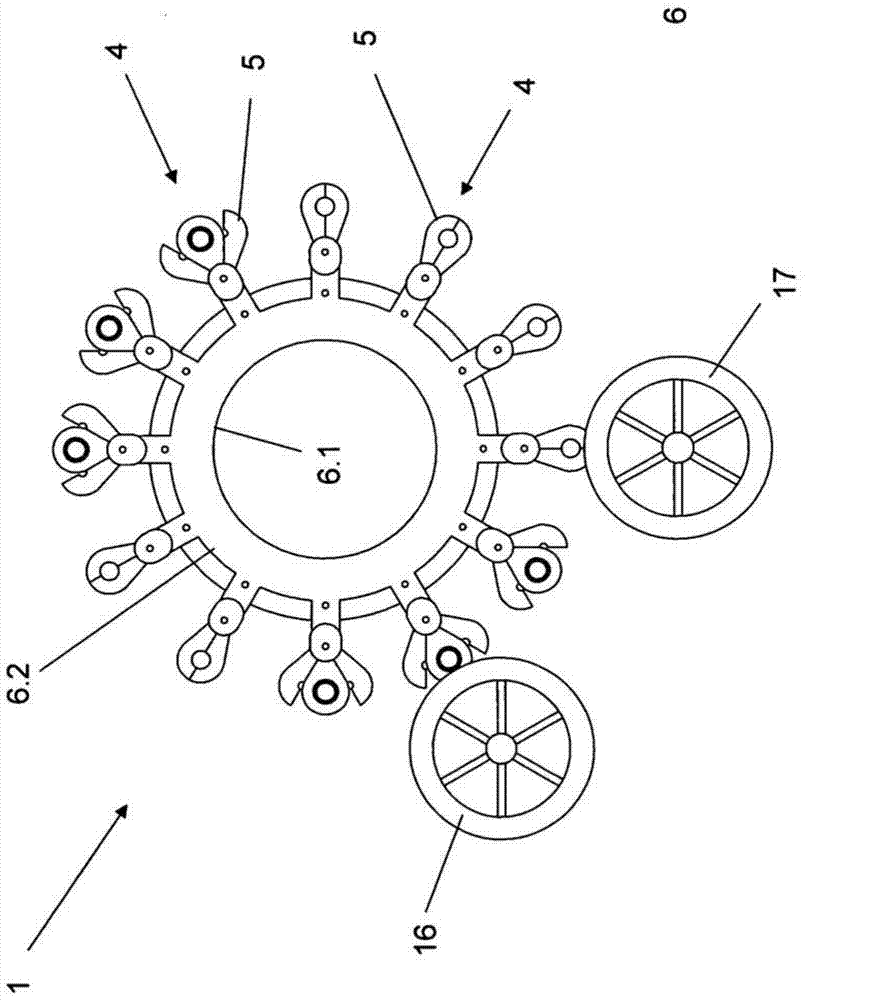

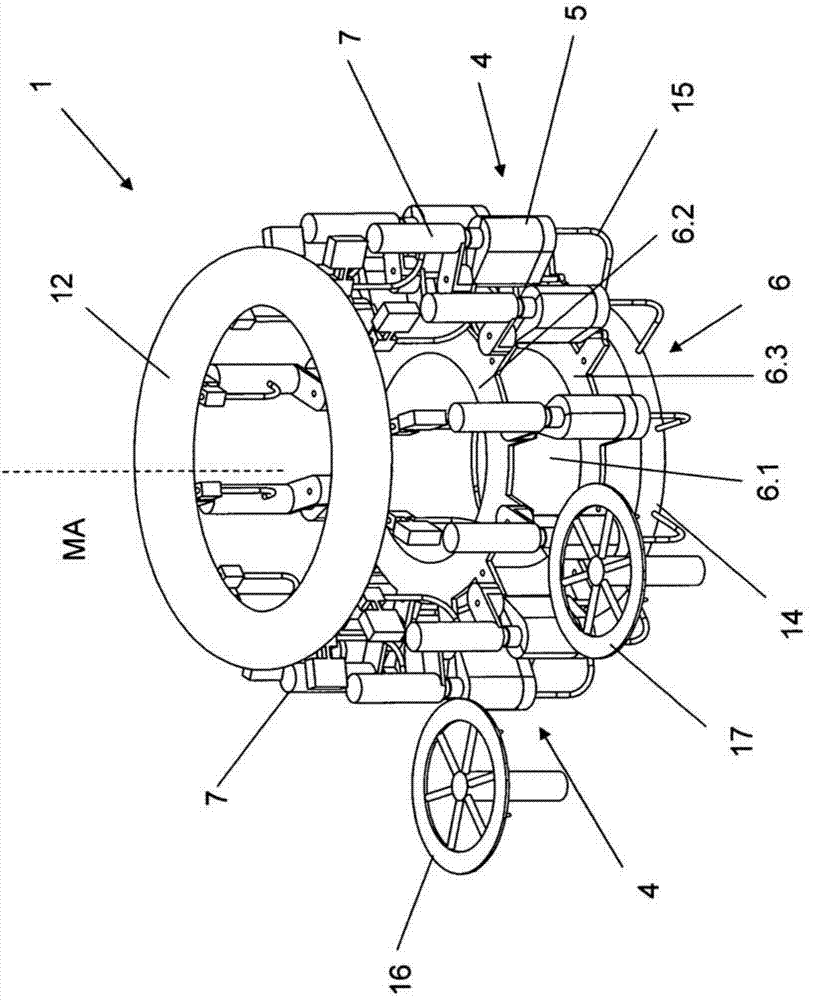

[0024] exist Figure 1-6 The device generally denoted by 1 is used for the manufacture of bottles in the form of preforms 3 (Preforms) ( Figure 4 ) of the filled container 2, the preform is made of thermoplastic material, such as polyethylene terephthalate (PET), polyethylene (PEE), polyethylene naphthalate (PEN) or polyethylene Made of propylene (PP). The preform 3 is configured telescopically in a known manner with an open end forming the later container opening and a closed bottom forming the later container bottom and with a forming the later container bottom. Flange leading to inlet flange (see Figure 5 ).

[0025] The production of the container 2 filled with a liquid filling material proceeds in principle in such a way that each treated, ie at least preheated, preheated mold 5 which is arranged in the closed mold 5 of the forming and filling station 4 The preforms 3 are loaded with filling material which is under high forming and filling pressure and which is heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com