Combination of a golf club head and a weight member

a golf club head and weight technology, applied in the field of golf club head and weight member combination, can solve the problems of adverse effects on the overall structural strength and toughness of the golf club head, and high cost of brazing, so as to achieve rapid and simplified the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

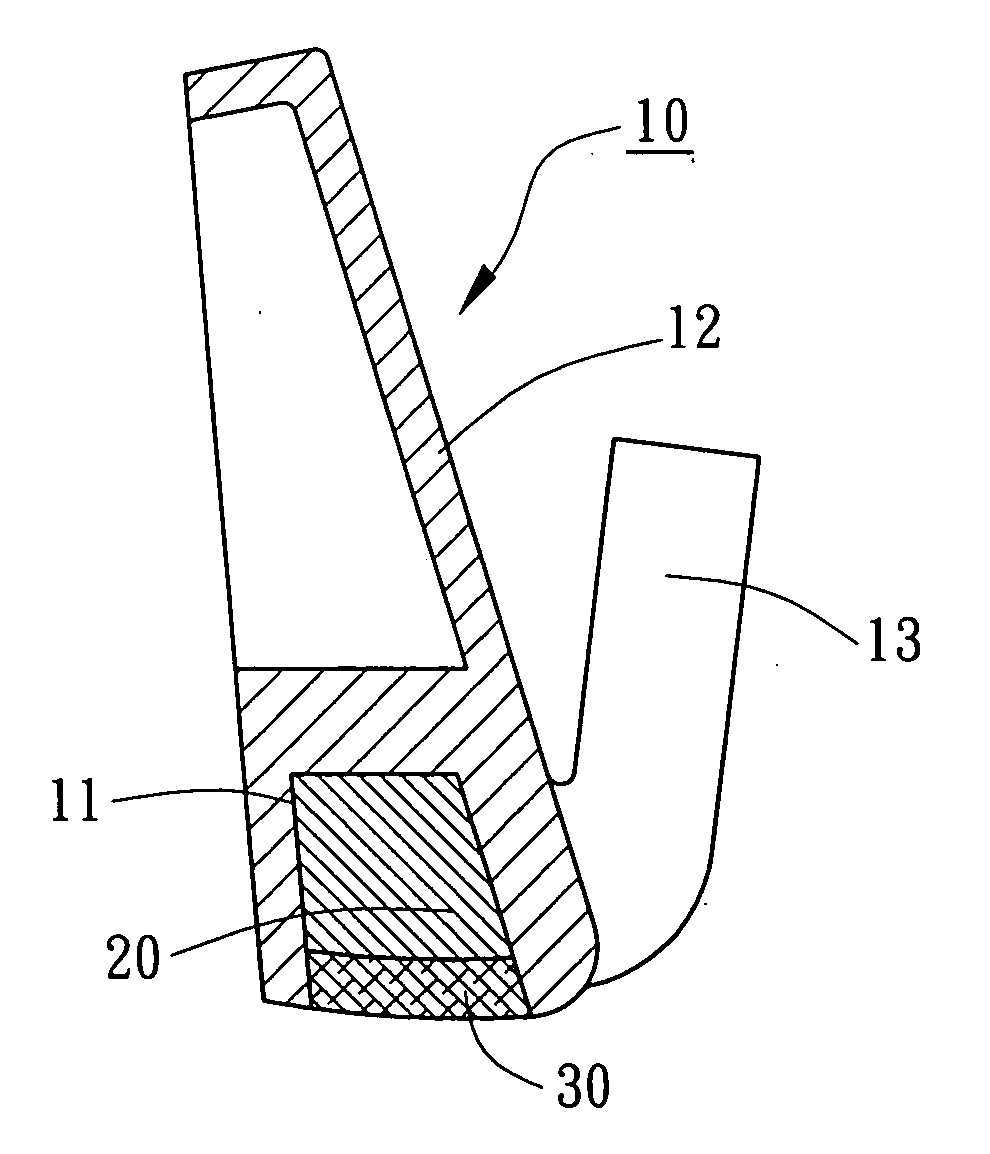

[0021] Referring to FIG. 3, a golf club head 10 in accordance with the present invention is a club head of an iron club and made of a metal having a low specific gravity, such as a titanium alloy, stainless steel, Fe—Mn—Al alloy, soft iron alloy, or other iron alloy. The golf club head 10 includes a recession 11 in a sole (not labeled) thereof. A weight member 20 is inserted into the recession 11. The recession has an opening (not labeled) that faces upward and that is sealed by the filling material 30.

[0022] The weight member 20 is made of a material having a high specific gravity, such as a W—Fe—Ni alloy. The weight member 20 has a sectional area substantially the same as that of the recession 101 of the golf club head 10. Thus, when the weight member 20 is mounted in the recession 11, a perimeter of the weight member 20 is in contact with a perimeter wall delimiting the recession 11, and a bottom face of the weight member 20 is in intimate contact with a bottom wall delimiting th...

second embodiment

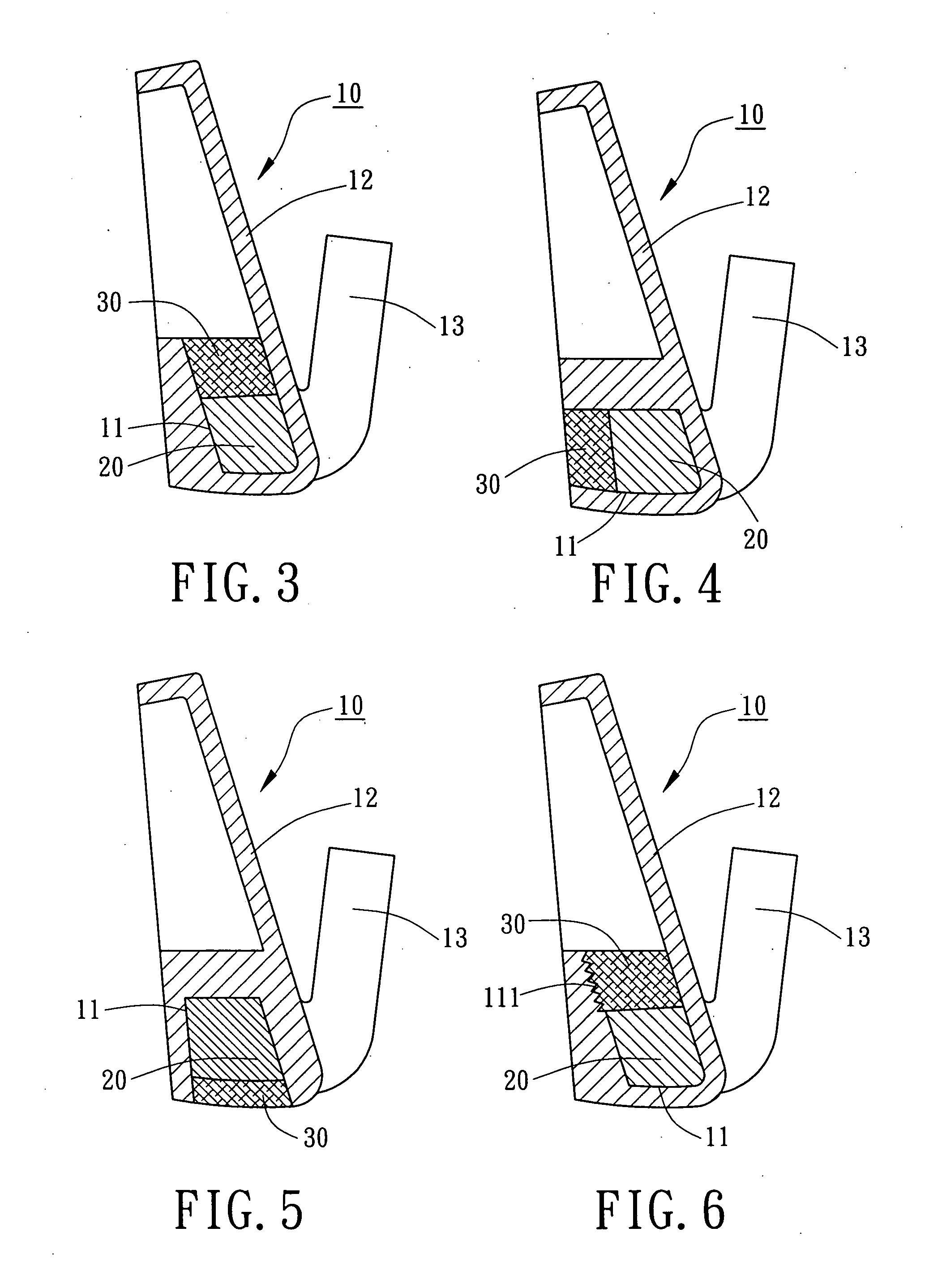

[0026]FIG. 4 shows the invention, wherein the opening of the recession 11 faces rearward. Further, the shape of the opening of the recession 11 may vary to match the appearance of the golf club and to match the shape of the weight member 20. For example, the opening of the recession 11 may be circular, oval, polygonal, or star-like. Further, the type and color of the filling material 30 can be selected. Alternatively, filling materials 30 of different types and colors can be used at the same time. Thus, in addition to burying the weight member 20 and absorbing vibrations generated as a result of striking a golf ball, the filling material 30 provides an aesthetic appearance on the back of the golf club head 10.

third embodiment

[0027]FIG. 5 shows the invention, wherein the opening of the recession 11 faces downwardly. The filling material 30 is, e.g., a polyurethane elastomeric filling material or rubber to provide a buffering effect and anti-sliding effect while burying the weight member 20 and absorbing vibrations as a result of striking a golf ball.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com