Automatic filling system for radioactive isotope medicament

A radioactive isotope and automatic filling technology, which is applied in the direction of synchronization device, perfusion device cleaning, perfusion device safety device, etc., can solve the problem of easy error caused by the control of subpackaging dose, affect the effect of clinical diagnosis and treatment, and increase the radiation exposure of patients. To solve problems such as radiation, to achieve accurate and reliable precision data, realize unmanned operation, and reduce the risk of radiation exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

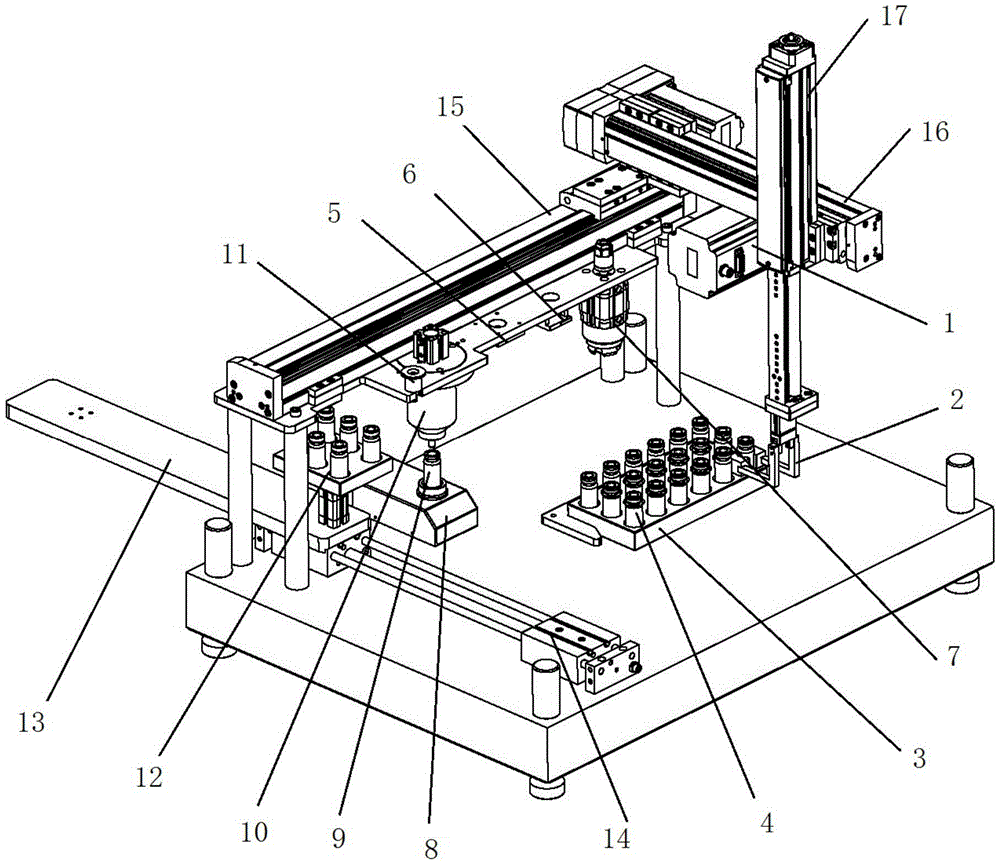

[0026] Such as figure 1 As shown, a radioactive isotope drug automatic filling system includes a filling workbench and a console, the filling workbench is set in a protective box, the protective box is a lead protective box, and the filling work There are movable doors on the protective box corresponding to the feed inlet and outlet of the platform, and the movable doors are respectively connected to the control console. When the system is running, unmanned operation is realized, away from radiation, and safety is improved. The console is arranged outside the protective box and connected with the filling workbench. The system also includes a medicine tank storage module set at the inlet of the filling workbench, an automatic grabbing module on the filling workbench, a medicine tank processing module and a weighing filling module, and the outlet of the filling workbench Each module is connected to the console respectively; first, the automatic grabbing module grabs the medicin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com