Article identification and sorting device and method thereof

An article and image technology, applied in the field of automated non-destructive testing, can solve problems such as non-compliance with quality requirements, consumers eating by mistake, affecting food quality, etc., to reduce the risk of radiation radiation, reduce labor costs, and improve the effect of production line efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

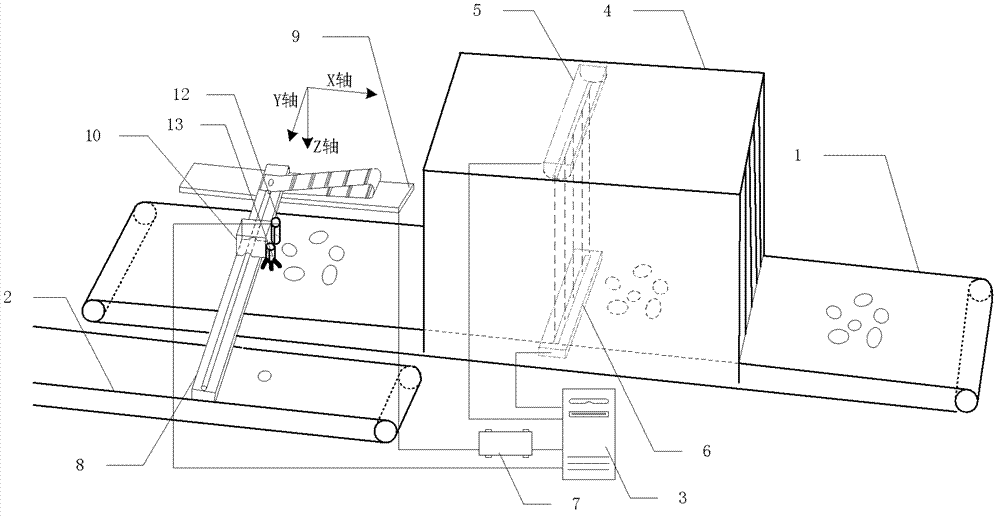

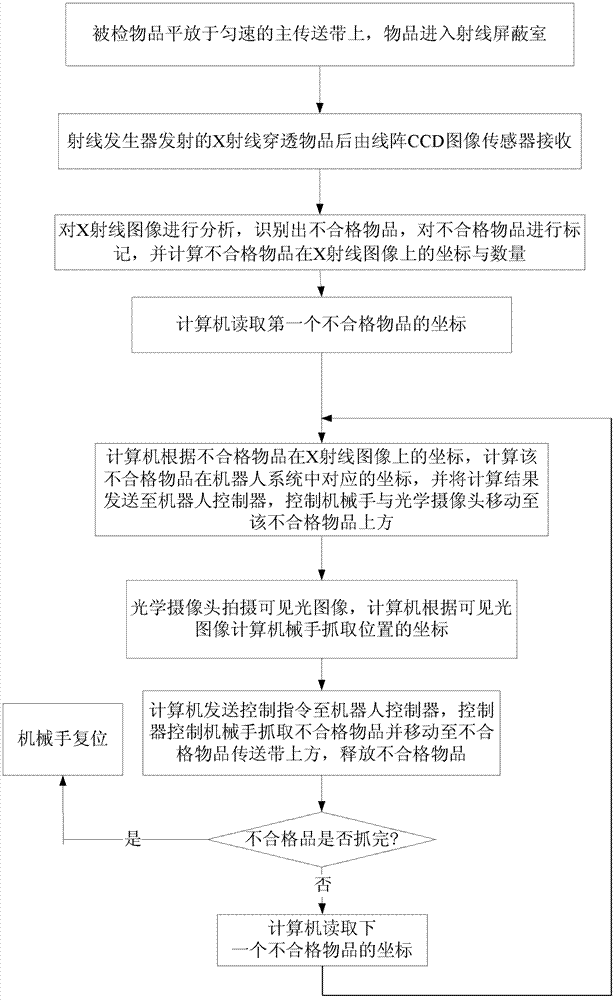

[0051] Such as figure 1 As shown, an article identification and sorting device according to the present invention includes a main conveyor belt 1, a conveyor belt for unqualified articles 2, a robot system and a computer 3;

[0052] The main conveyor belt 1 and the unqualified article conveyor belt 2 are located on the same level and parallel to each other;

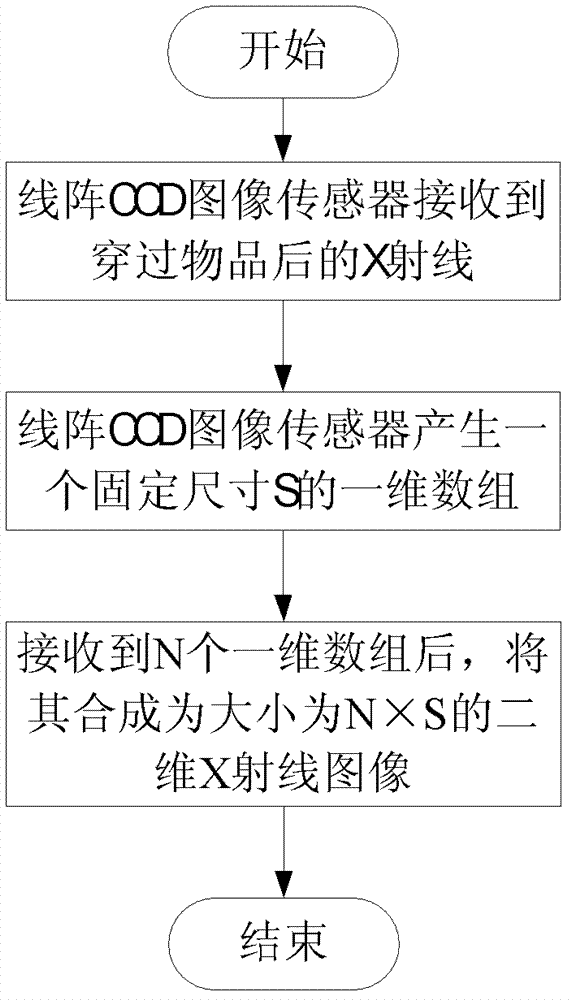

[0053] The main conveyor belt 1 is provided with a radiation shielding chamber 4, the top of the radiation shielding chamber 4 is provided with an X-ray generator 5, and the bottom of the radiation shielding chamber 4 is provided with a linear array CCD image sensor 6, and the linear array CCD Image sensor 6 is connected with computer 3;

[0054] The robot system includes a robot controller 7, a Y-axis chute 8 arranged above the main conveyor belt 1 and the unqualified article conveyor belt 2 and perpendicular to the conveying direction, and a Y-axis chute 8 arranged on one side of the Y-axis chute 8 and parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com