Apparatus for filling containers having a magnetically operated closing cap

A container and conveying device technology, applied in the field of devices for filling containers, can solve problems such as inability to insert CIP caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

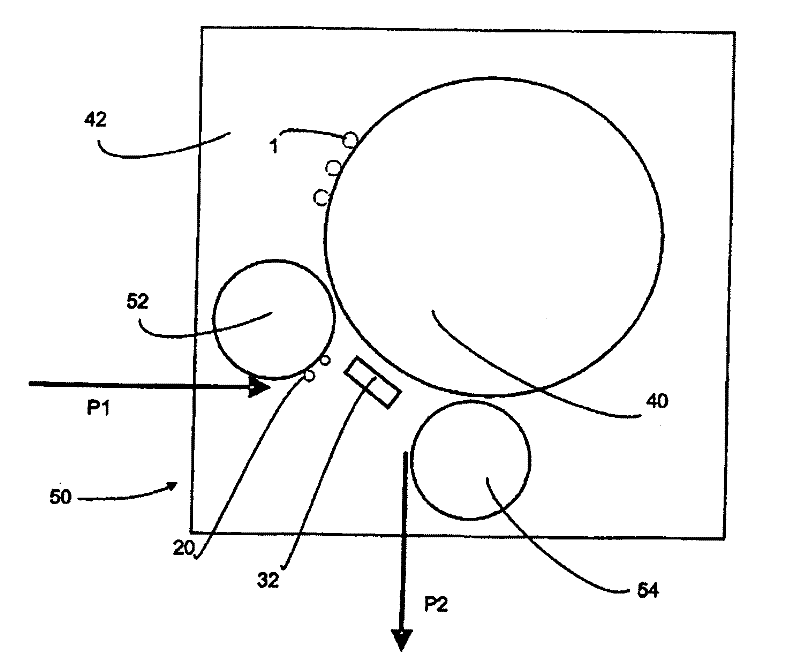

[0036] figure 1 A system 50 for filling containers 20 according to the invention is shown. The system 50 has a feeding device 52 which feeds the containers 20 to the transfer device 40 (cf. arrow P1 ). In this case, the feeding device 52 is a transfer star wheel or transfer wheel on which a plurality of gripping elements, such as tongs, are arranged for gripping the containers and transferring them to the transfer device 40 . A plurality of devices 1 for filling containers 20 with liquid are provided on a conveyor device 40 . In this case, storage means (not shown) are provided, from which liquid is filled into the container 10 .

[0037] Reference numeral 54 designates a removal device for removing the container from the combination device 50, as indicated by arrow P2. In this case, the transfer device 40 and the respective device 1 , supply device 52 and removal device 54 are arranged in a clean room 42 which is only diagrammatically shown. In this way, the filling of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com