Method for cleaning beverage filling lines

A filling line, beverage technology, applied in the direction of cleaning device, filling device cleaning, packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The method according to the invention is described in more detail below by way of working examples.

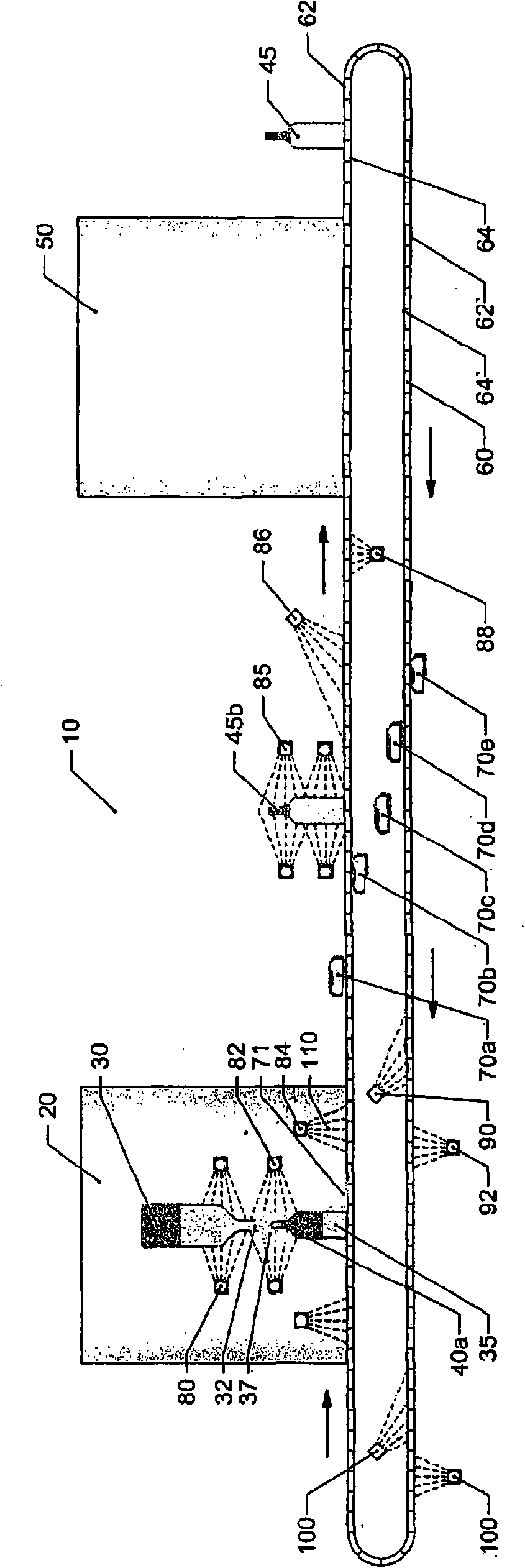

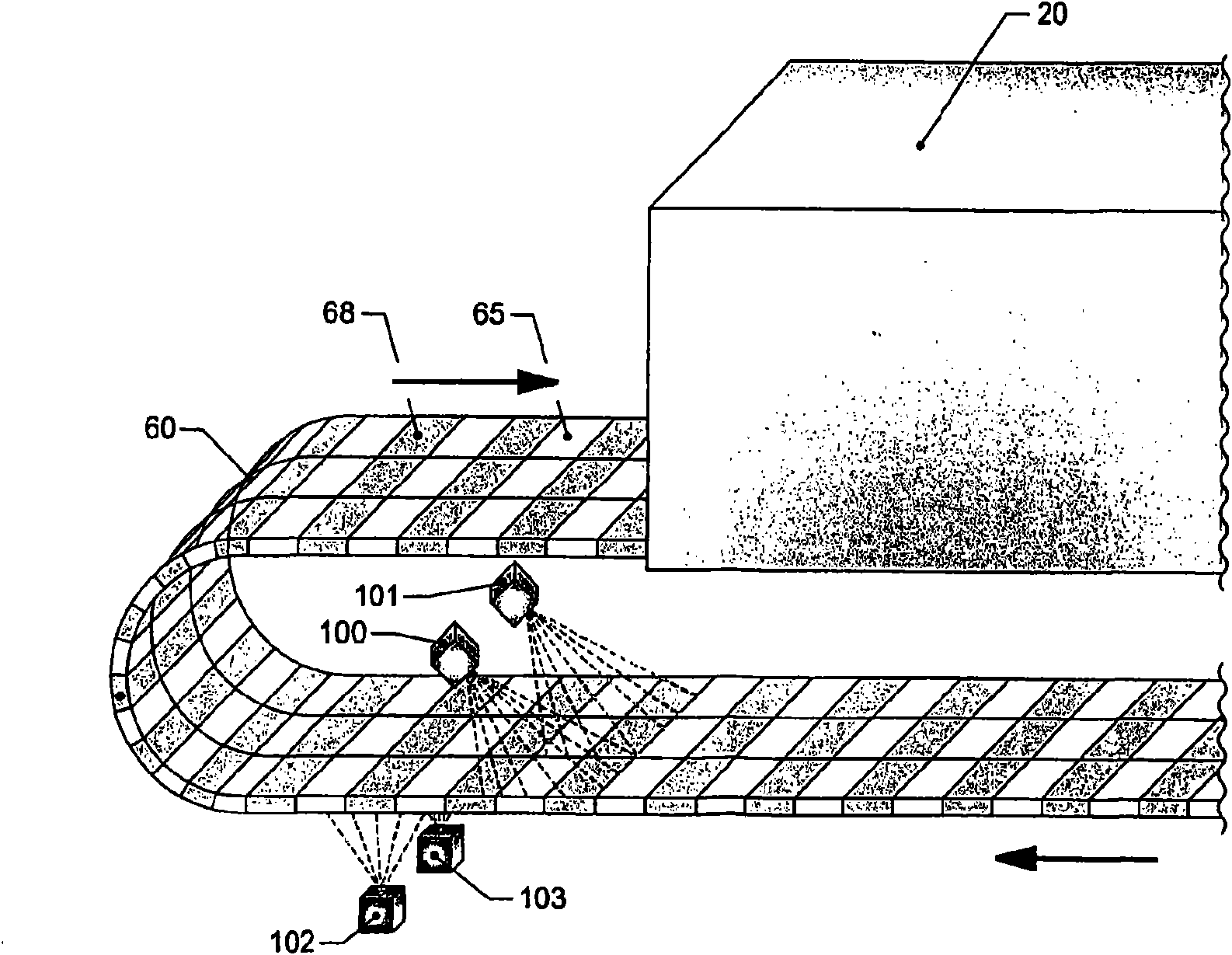

[0041] Beverage filling equipment 10 such as figure 1 shown schematically. In the beverage filling chamber 20 (often transparent) is accommodated a beverage filling device 30 by means of which a beverage 35 is filled into a bottle 40a (or another container) through a filling head 32 . During this process, the beverage 35 or foam 37 may splash from the bottle ( 40 a ), causing contamination 71 of the conveyor belt 60 . Subsequently, beverage dripping from the filling head 32 may also contaminate the conveyor belt during the process in which filled bottles 40b are conveyed forward from the filling head 32 while empty bottles (not shown) are advanced below the filling head 32 .

[0042] During the filling process, cleaning agent 110 is sprayed continuously through nozzles 80 , 82 , 84 , which may be wide-mouth nozzles, onto filling device 30 , its filling head 32 as well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com