Fruit juice filling valve

A technology for filling valves and fruit juices, which is applied in the cleaning, packaging, and valve raising of filling devices, and can solve problems such as inability to clean thoroughly, quantitative filling valves that cannot be cleaned, quantitative filling valves that cannot be fully cleaned, etc. , to increase the service life and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

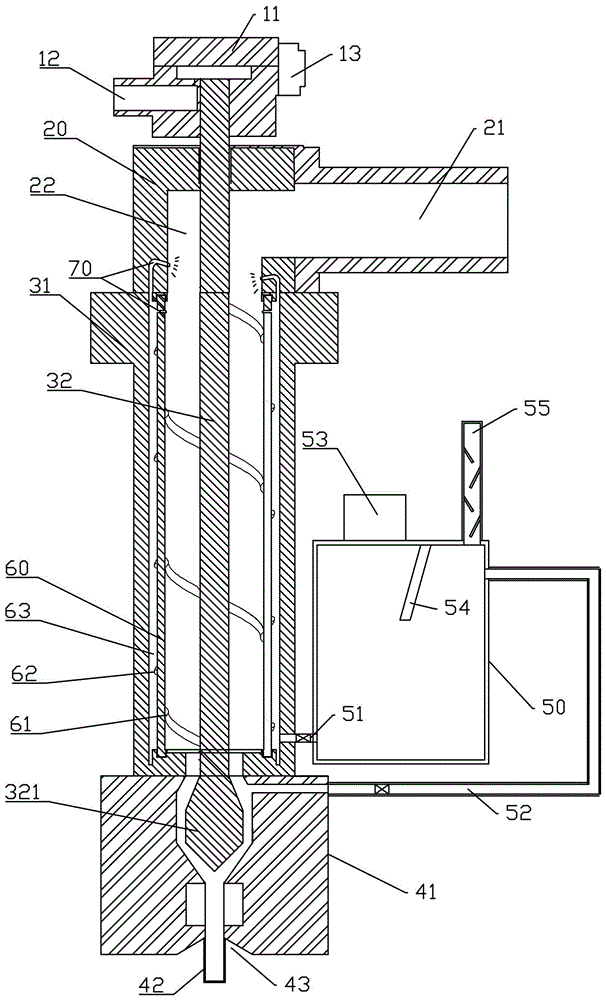

[0019] The reference signs in the drawings of the description include: valve cover 11, exhaust port 12, filling cylinder 13, valve body seat 20, liquid inlet 21, material chamber 22, liquid guide valve seat 31, valve stem 32, valve core 321, valve seat head 41, filling port 43, filling pipe 42, liquid storage tank 50, liquid inlet pipe 51, recovery pipe 52, liquid inlet cover 53, separation plate 54, separation pipe 55, rotary pipe 60, positive rotation Ring rib 61, anti-rotating impeller 62, cleaning channel 63, nozzle 70.

[0020] Such as figure 1 The juice filling valve shown includes a valve cover 11, a filling cylinder 13, a valve body seat 20, a valve stem 32, a valve core 321 and a valve seat head 41. The valve cover 11 is installed on the filling cylinder 13, and the valve cover 11 There is an exhaust port 12 on the top, the filling cylinder 13 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com