Efficient ash removal device and method suitable for garbage furnace

A waste furnace and high-efficiency technology, applied in combustion methods, chemical instruments and methods, incinerators, etc., can solve the problems of reducing the service life of furnace components, large loss of working medium, and high operating costs, and achieve structural stability and stability. The effect of high reliability, low operation and maintenance cost, and simple structure system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

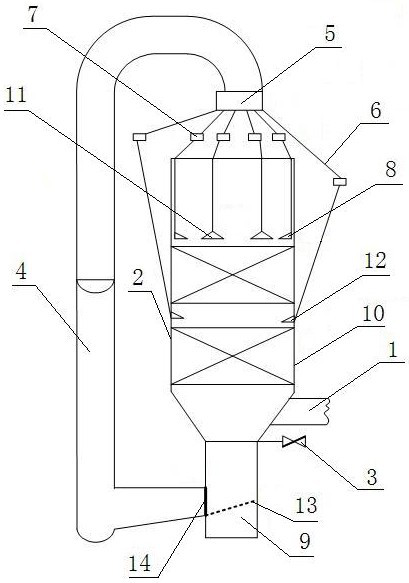

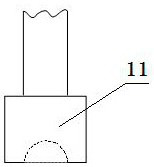

[0029] A high-efficiency ash removal device suitable for garbage furnaces. Its composition includes: a tail flue 1, the upper and lower sides of the tail flue are respectively equipped with a high-temperature heating surface 2 and a low-temperature heating surface 10, and the bottom opening of the tail flue is installed with Electromagnetic gate valve 3, a fly ash steel ball separator 9 is installed under the electromagnetic gate valve, a sorting screen 13 is installed obliquely in the middle of the fly ash steel ball separator, and a sorting screen 13 is installed on the lower end of the sorting screen. Selecting door 14, the sorting door is connected to the sealing hoist 4, the outlet of the sealing hoist is connected to the steel ball storage box 5, the bottom of the steel ball storage box 5 has a set of openings, and the openings are connected to the descending passage 6. The descending passages are respectively connected to the high-temperature side diffuser 8 , the high-t...

Embodiment 2

[0031] According to the high-efficiency ash removal device suitable for garbage furnaces described in Example 1, the high-temperature side diffuser, the high-temperature central diffuser, and the low-temperature side diffuser are arranged above the high-temperature heating surface , wherein the high-temperature side diffuser and the high-temperature central diffuser are arranged around and in the middle of the tail flue, and the low-temperature side diffuser is arranged on the high-temperature heating surface and the between the low-temperature heating surfaces, and distributed around the tail flue.

Embodiment 3

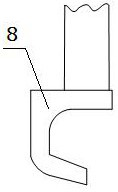

[0033] According to the high-efficiency ash removal device suitable for garbage furnaces described in Example 1, the steel balls spread around the high-temperature side diffuser and the tail flue at an angle of 180°, and the high-temperature central diffuser is arranged at In the middle of the flue, the bottom is ring-shaped, with a boss in the middle, and the steel ball spread angle is 360°. The low-temperature side spreader is arranged on the rear flue furnace wall, and the steel ball spread angle is 180°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com