Canal type countercurrent regeneration system for catalyst

A countercurrent regeneration and catalyst technology, which is applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of long flushing cycle, low cleaning efficiency, cumbersome operation, etc., and achieve low cost and high efficiency. Regeneration effect, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

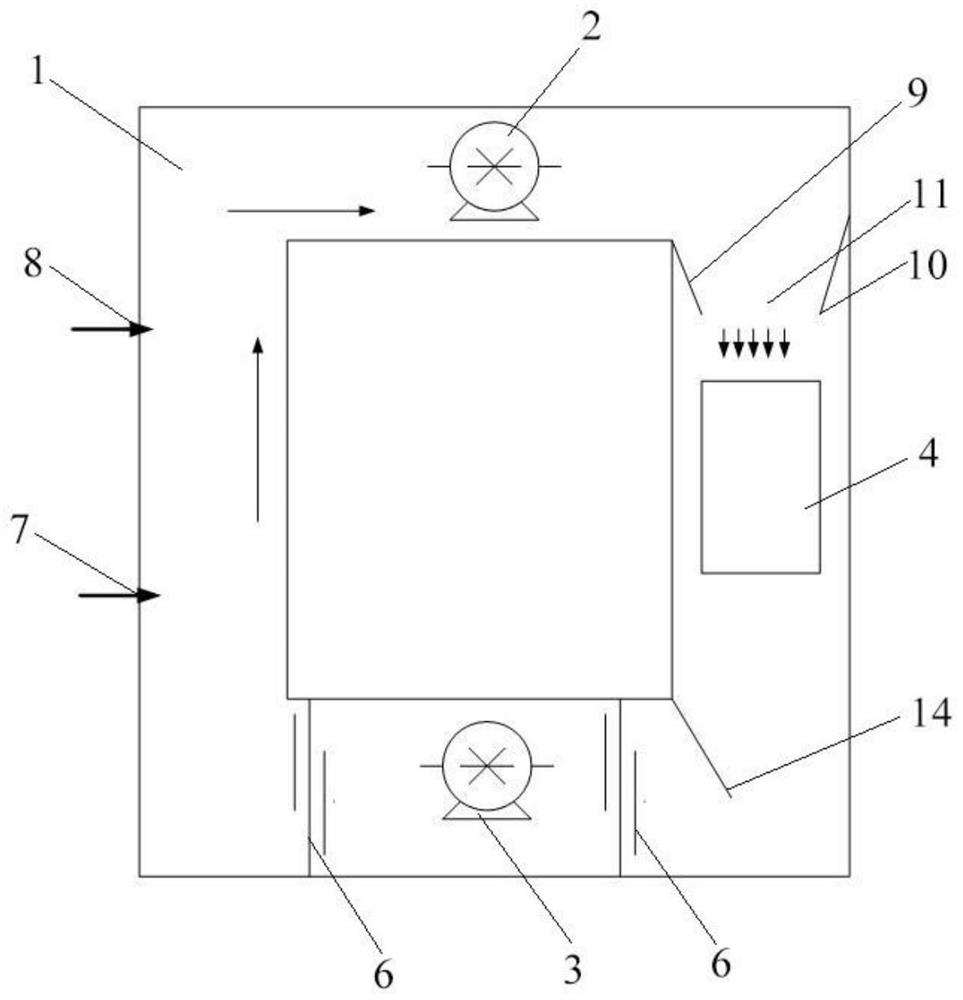

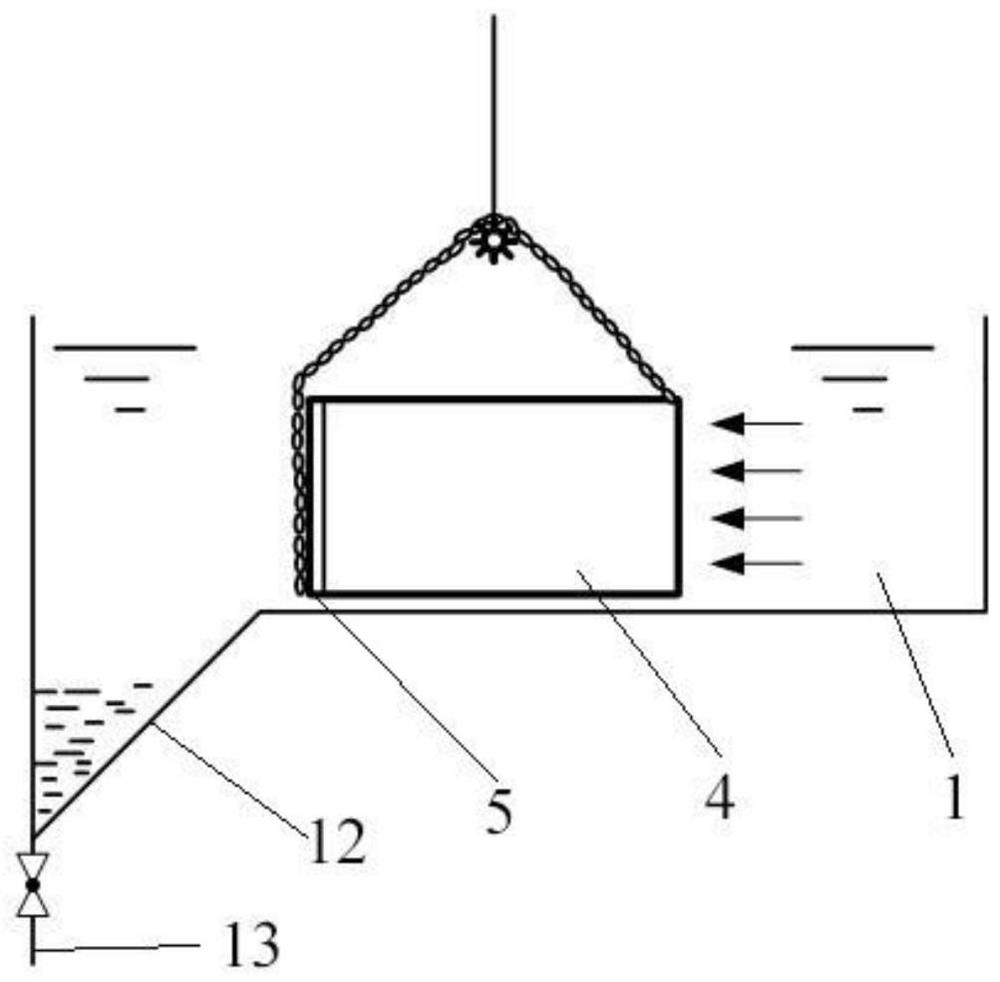

[0018] Such as figure 1 , figure 2 As shown, a channel-type countercurrent regeneration system for catalysts of the present invention includes a cleaning channel 1 arranged in a back shape, and a lifting water pump 2 and a lifting water pump 3 are arranged in the cleaning channel 1, and the lifting water pump 2 and the lifting water pump 3 are respectively arranged On the opposite sides of the cleaning channel 1, to ensure the circulation of the water flow in the cleaning channel 1, it can ensure the continuous operation of cleaning and improve the regeneration effect; the cleaning channel 1 is equipped with a liquid medicine supply device to supply the medicine and liquid to the cleaning channel. In the canal 1; after the catalyst 4 is placed on the cleaning rack 5, it is immersed in the cleaning canal 1, and the hardened end of the catalyst 4 (that is, the end of the catalyst 4 in the conventional flue gas contact direction) is arranged opposite to the direction of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com