Biomass gas production tar circulating cleaning device

A cleaning device and biomass technology, applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc., can solve problems that affect the normal use of pipelines and reduce the efficiency of biomass gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

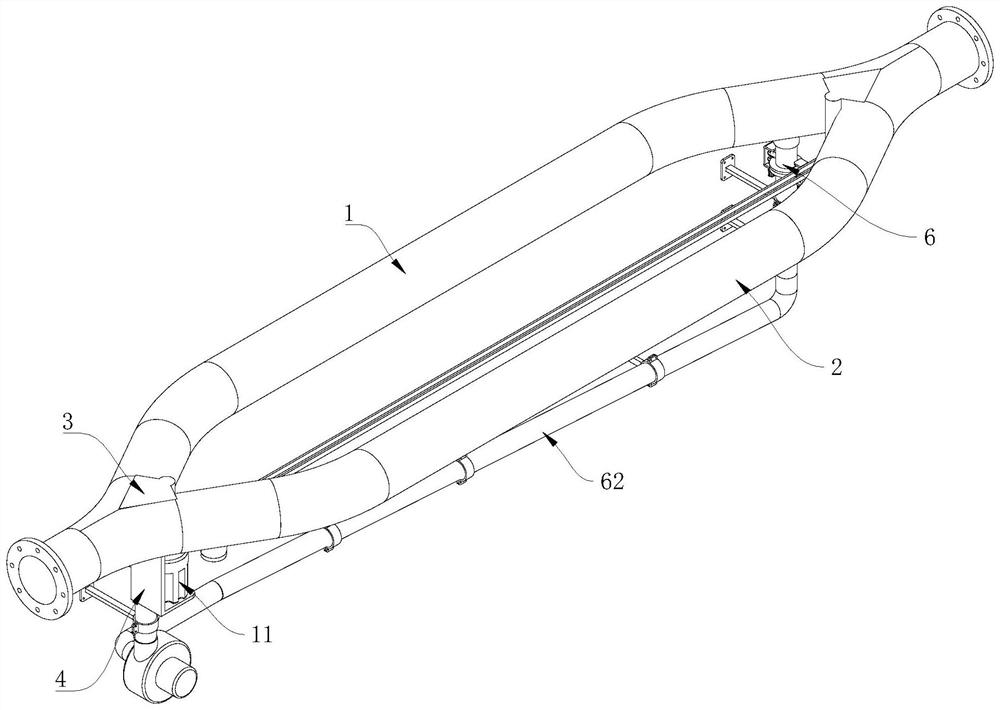

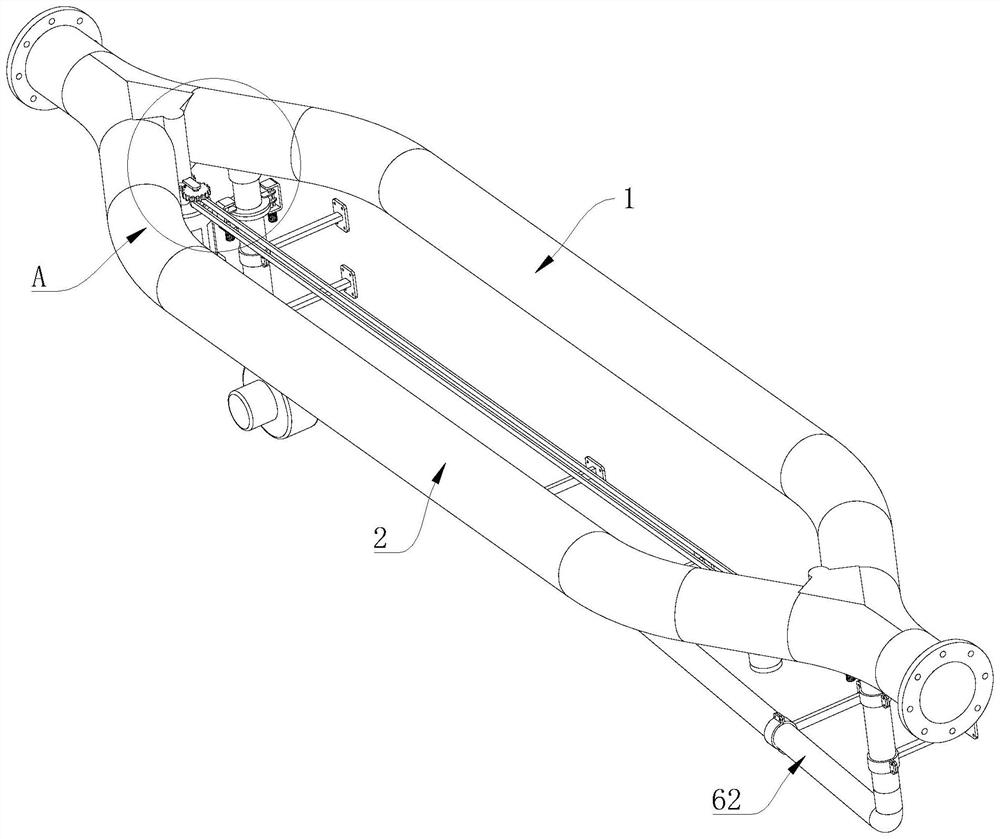

[0033] see Figure 1-9 , the present invention provides a technical solution:

[0034] A biomass gas production tar cycle cleaning device, comprising a gas production pipeline 1, flanges are arranged at both ends of the gas production pipeline 1;

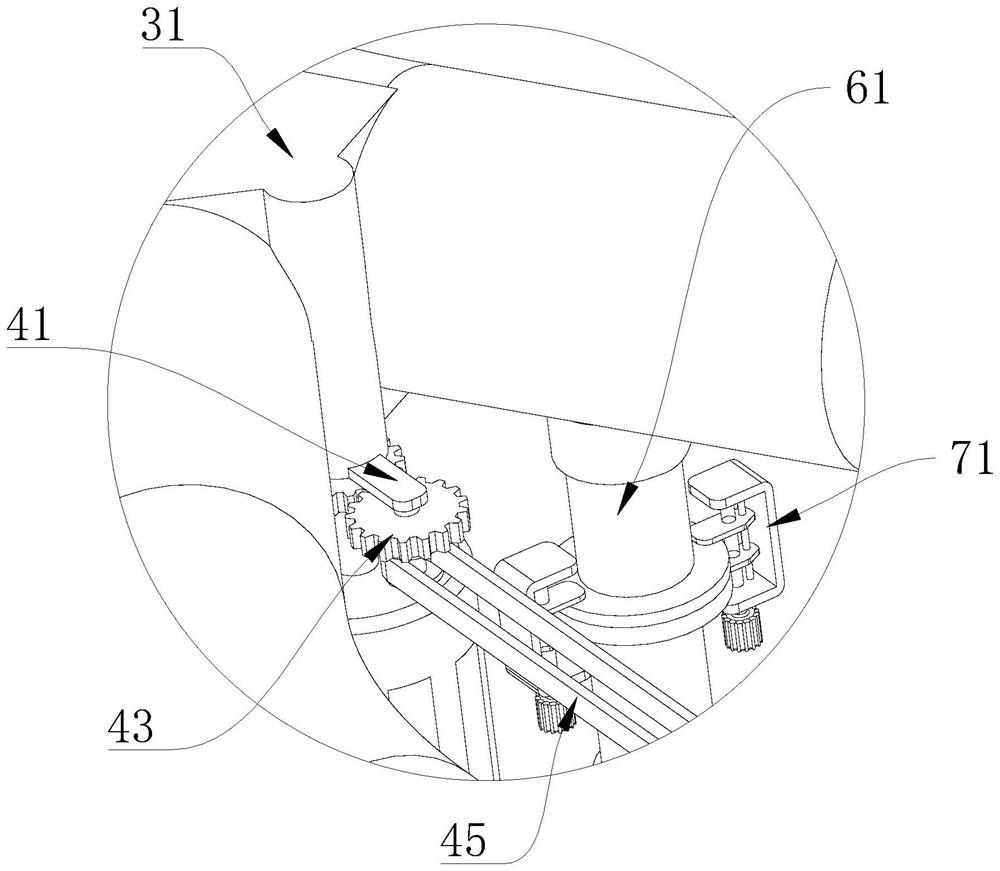

[0035] The gas-making pipeline 1 is provided with an auxiliary pipeline 2 that communicates with each other at both ends. The diameters of the gas-making pipeline 1 and the auxiliary pipeline 2 are the same. 31. The functional chamber 31 communicates with the gas-making pipeline 1 and the auxiliary pipeline 2. A main shaft 32 with one end extending to the outside of the functional chamber 31 is rotated in the functional chamber 31. A sealing plate 33 is arranged outside the main shaft 32. The sealing plate 33 is connected to the gas-making pipeline. Pipe 1 and auxiliary pipe 2 have the same inner diameter;

[0036] Both the inside of the gas pipeline 1 and the auxiliary pipeline 2 are provided with a fixed ring 34, and the sealing...

Embodiment 2

[0050] see Figure 1-10 , the present invention provides a technical solution:

[0051] A biomass gas production tar cycle cleaning device, comprising a gas production pipeline 1, flanges are arranged at both ends of the gas production pipeline 1;

[0052] The gas-making pipeline 1 is provided with an auxiliary pipeline 2 that communicates with each other at both ends. The diameters of the gas-making pipeline 1 and the auxiliary pipeline 2 are the same. 31. The functional chamber 31 communicates with the gas-making pipeline 1 and the auxiliary pipeline 2. A main shaft 32 with one end extending to the outside of the functional chamber 31 is rotated in the functional chamber 31. A sealing plate 33 is arranged outside the main shaft 32. The sealing plate 33 is connected to the gas-making pipeline. Pipe 1 and auxiliary pipe 2 have the same inner diameter;

[0053] Both the inside of the gas pipeline 1 and the auxiliary pipeline 2 are provided with a fixed ring 34, and the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com