Patents

Literature

46results about How to "Uninterrupted processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

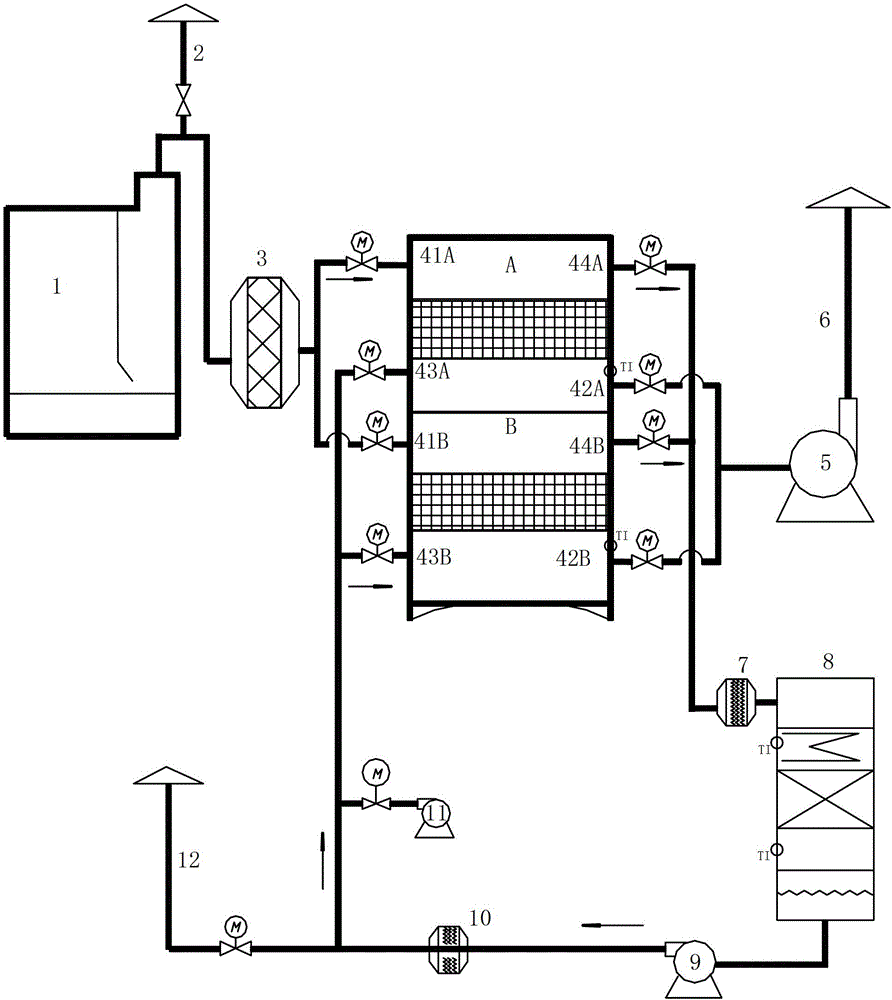

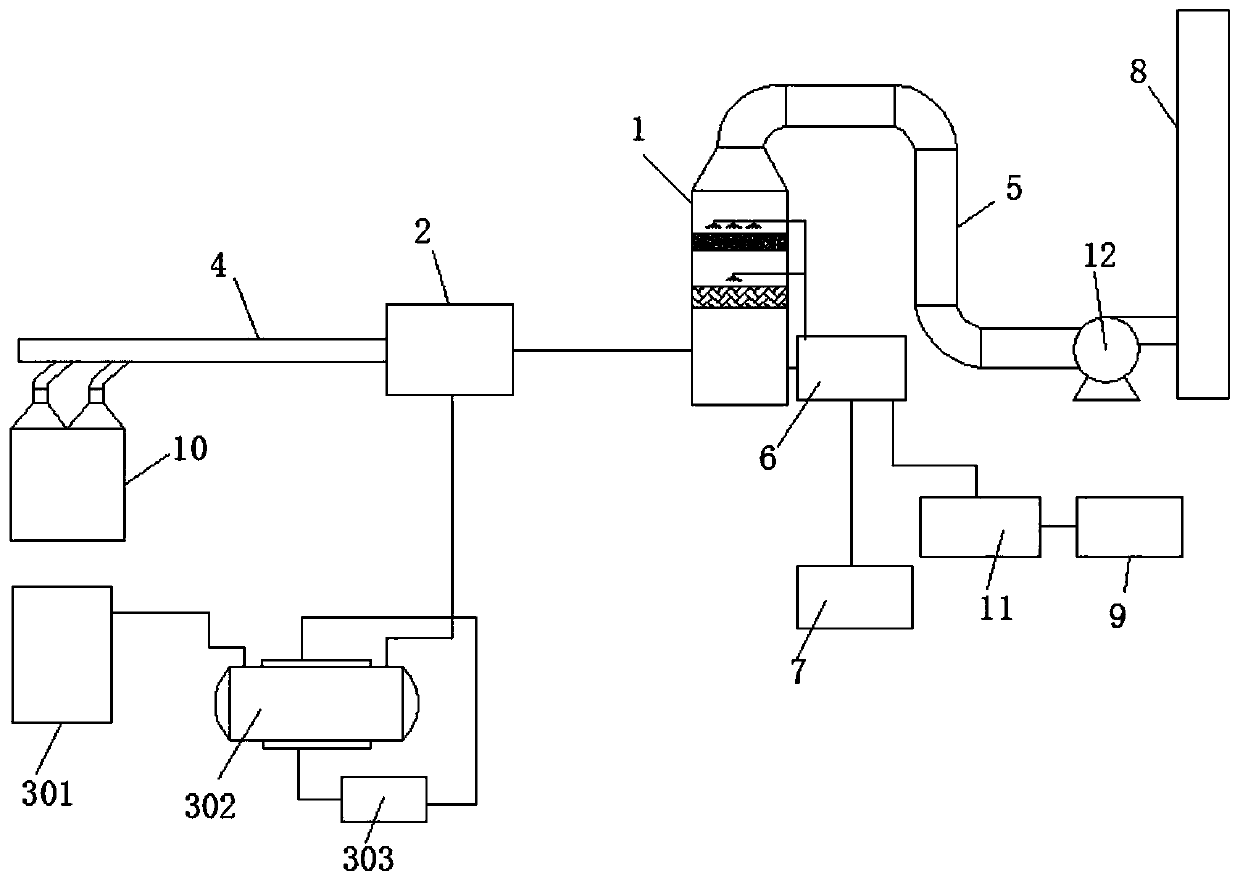

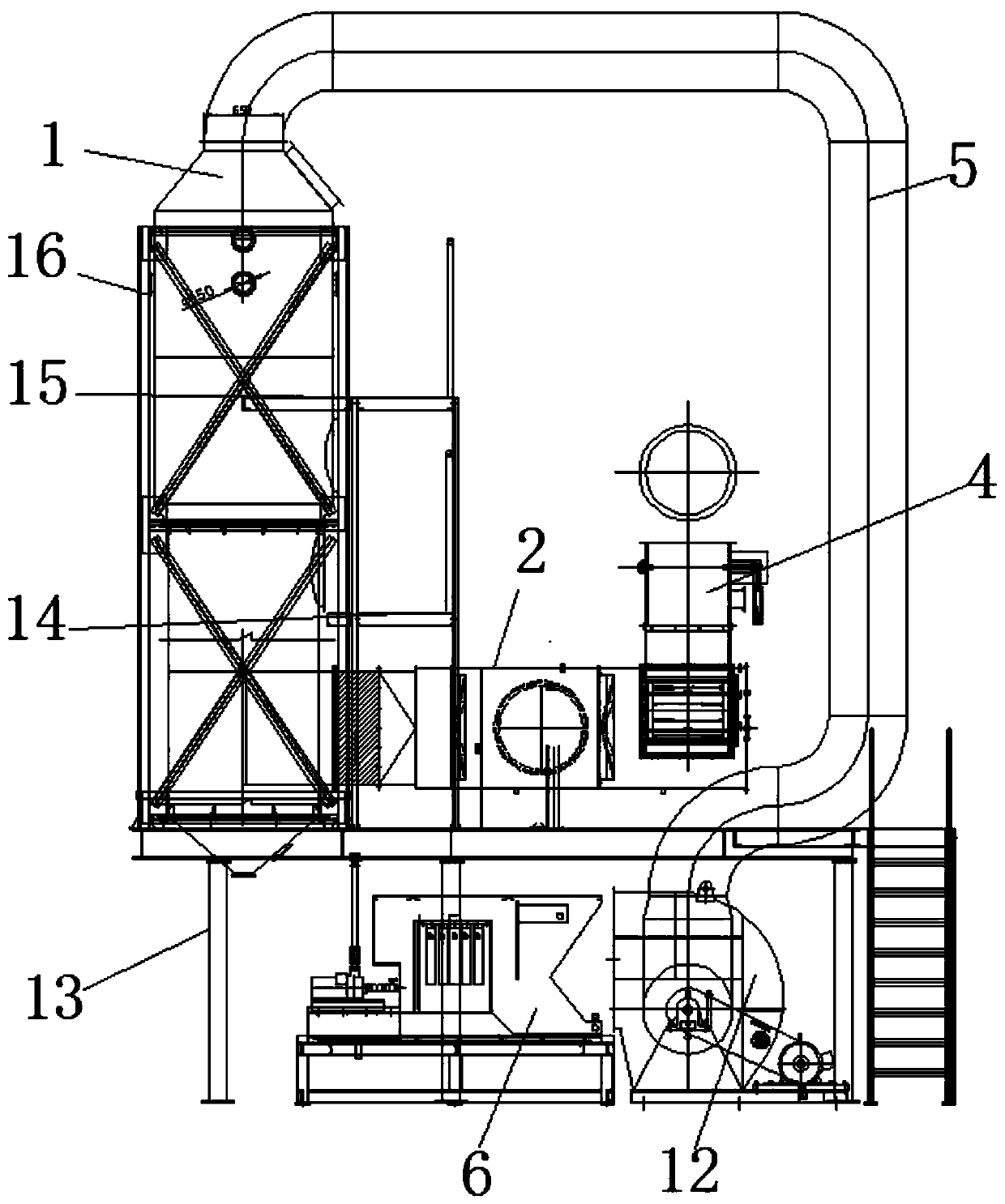

Organic waste gas multifunctional integral processing device

InactiveCN102941000AExtended service lifeLow running costDispersed particle separationIncinerator apparatusActivated carbonProgrammable logic controller

The invention discloses an organic waste gas multifunctional integral processing device, which comprises a programmable logic controller (PLC) control system, a dust filter device, active carbon adsorption beds A and B which are connected in parallel and a catalytic combustion bed. When organic waste gas is adsorbed, the organic waste gas firstly enters into the dust filter device to remove suspended solid; then enters into the active adsorption beds to remove organic substances; finally the purified waste gas is pumped through an adsorption exhaust fan and discharged on standard through an adsorption high-altitude discharge branch. When active carbon is desorbed and regenerated, the hot gas generated by the catalytic combustion bed is pressurized through a desorption fan, and then enters into the active absorption beds to reversely desorb and regenerate the saturated active carbon; the desorbed waste gas enters into the catalytic combustion bed; organics are burned to generate water and carbon dioxide; the hot gas generated at the same time is used for desorbing the active carbon. The processing device is controlled by the PLC, thereby realizing automatic switch between the two absorption beds, so that adsorption and desorption are carried out at the same time. The invention combines two technologies of adsorption and catalytic combustion organically and has complementary advantages.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

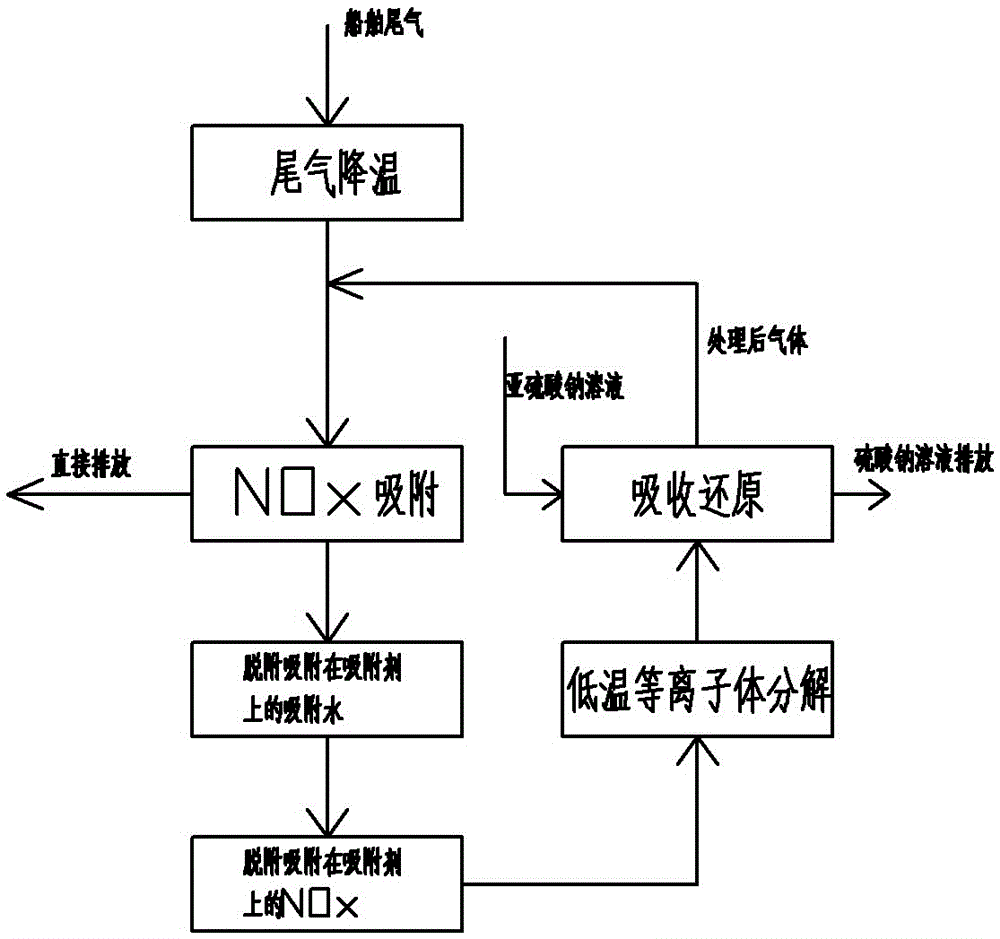

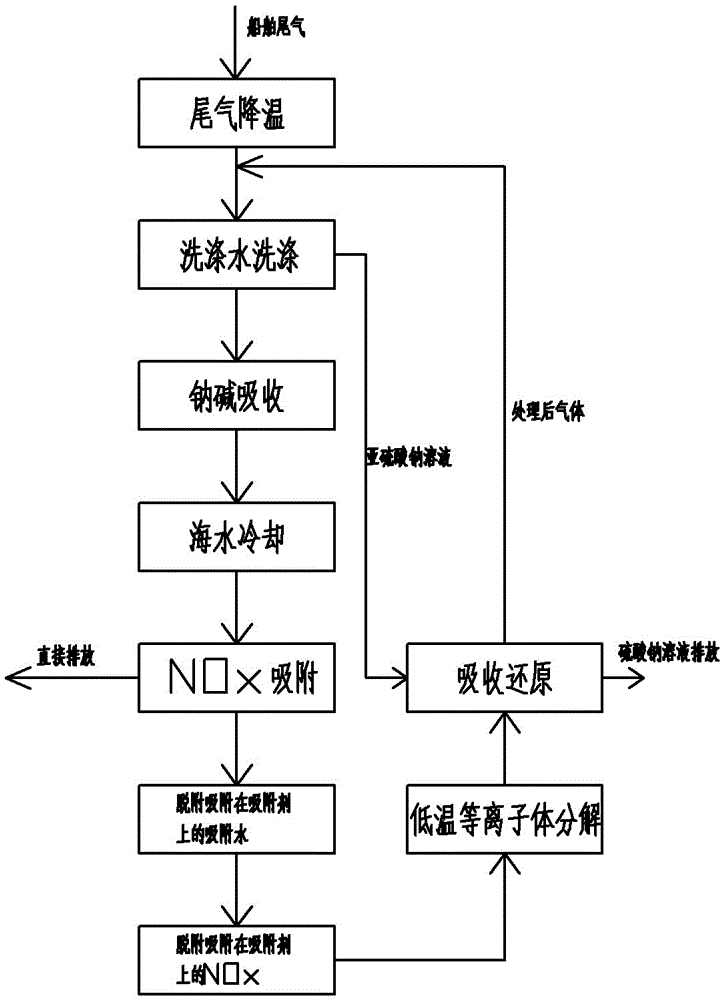

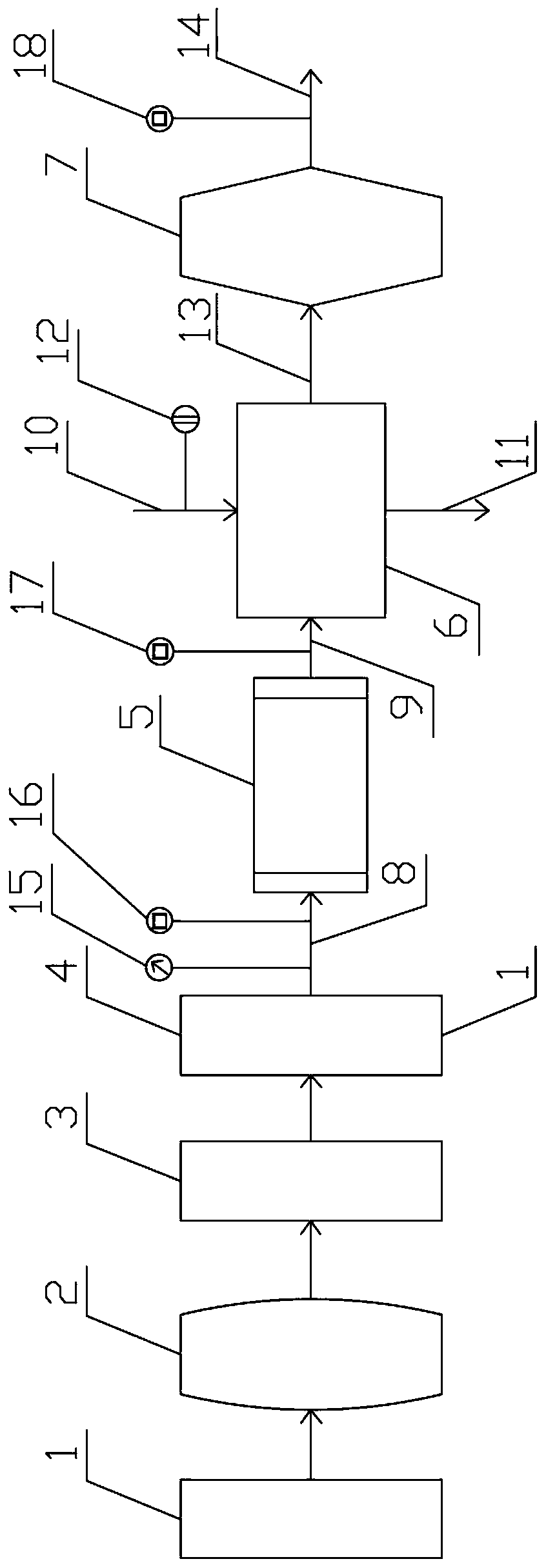

Ship tail gas denitration technology and system and desulfurization and denitrification integrated technology and system

ActiveCN105536486AEfficient use ofEfficient regenerationNitrous oxide captureGas treatmentSorbentDecomposition

The invention belongs to the field of ship tail gas treatment, energy conservation and environment protection, and particularly relates to a ship tail gas denitration technology and system and a desulfurization and denitration integrated technology and system. When low sulfur oil is used for a ship, the ship tail gas denitration technology and system can achieve high denitration efficiency and reduce energy consumption; when high sulfur content is used for the ship, desulfurization and denitration are combined together, high desulfurization and denitration efficiency is achieved, meanwhile, the cost is greatly saved, and the tail gas exhaust standards are met. The ship tail gas denitration technology comprises the steps of 1, tail gas cooling, 2, NOX adsorption, 3, desorption of NOX adsorbed on an adsorbent, 4, low-temperature plasma decomposition and 5, absorption and reduction. The ship tail desulfurization and denitration integrated technology comprises the steps of 1, tail gas cooling, 2, washing performed through washing water, 3, soda absorption, 4, NOX adsorption, 5, desorption of adsorption water adsorbed on an adsorbent, 6, desorption of NOX adsorbed on an adsorbent, 7, low-temperature plasma decomposition and 8, absorption and reduction.

Owner:张拿慧

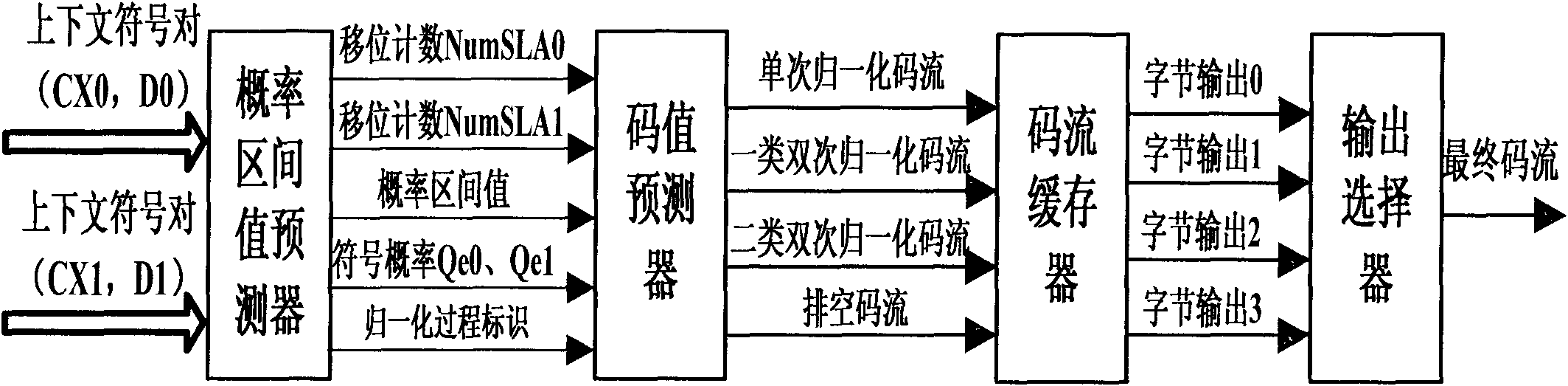

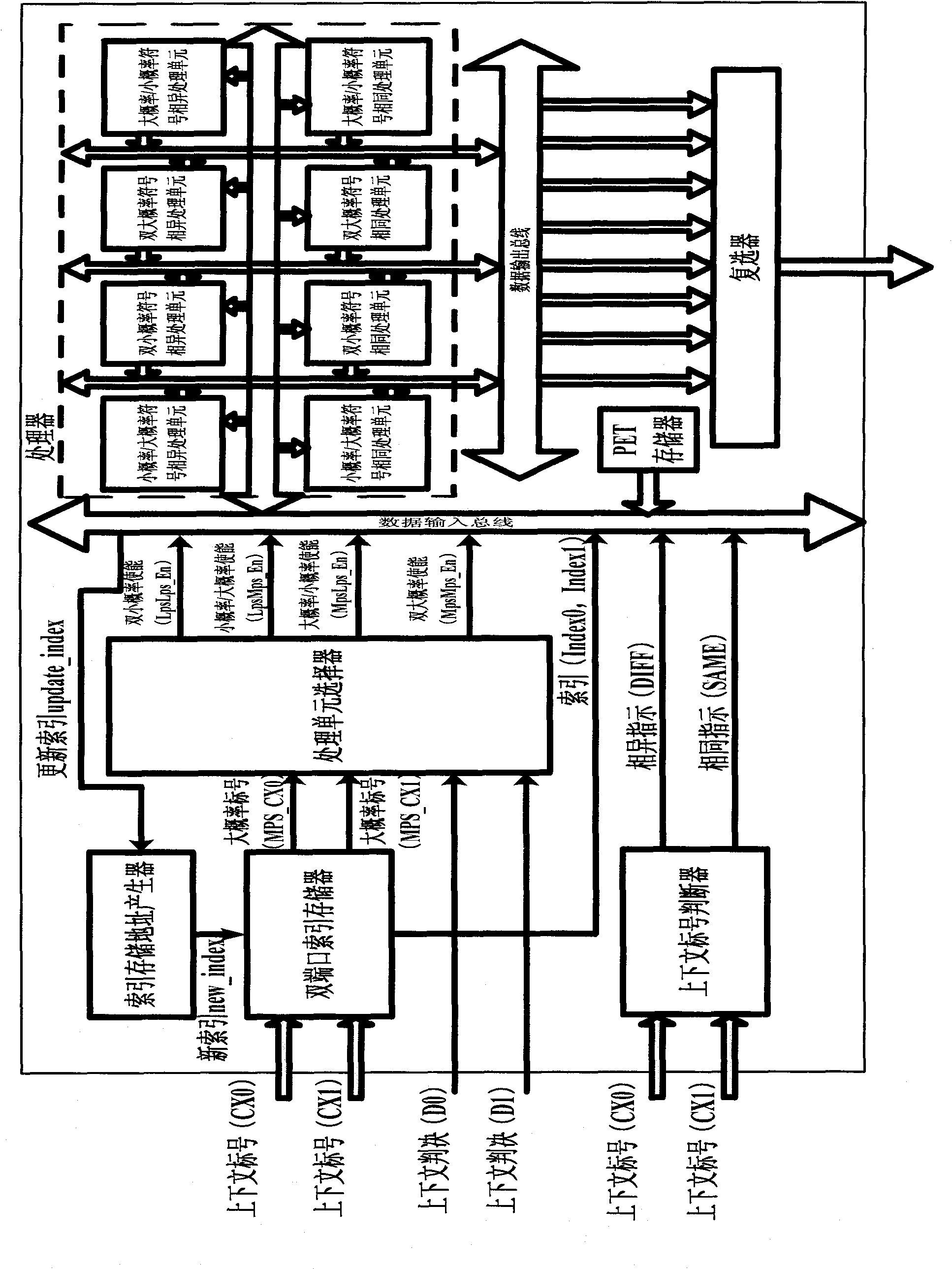

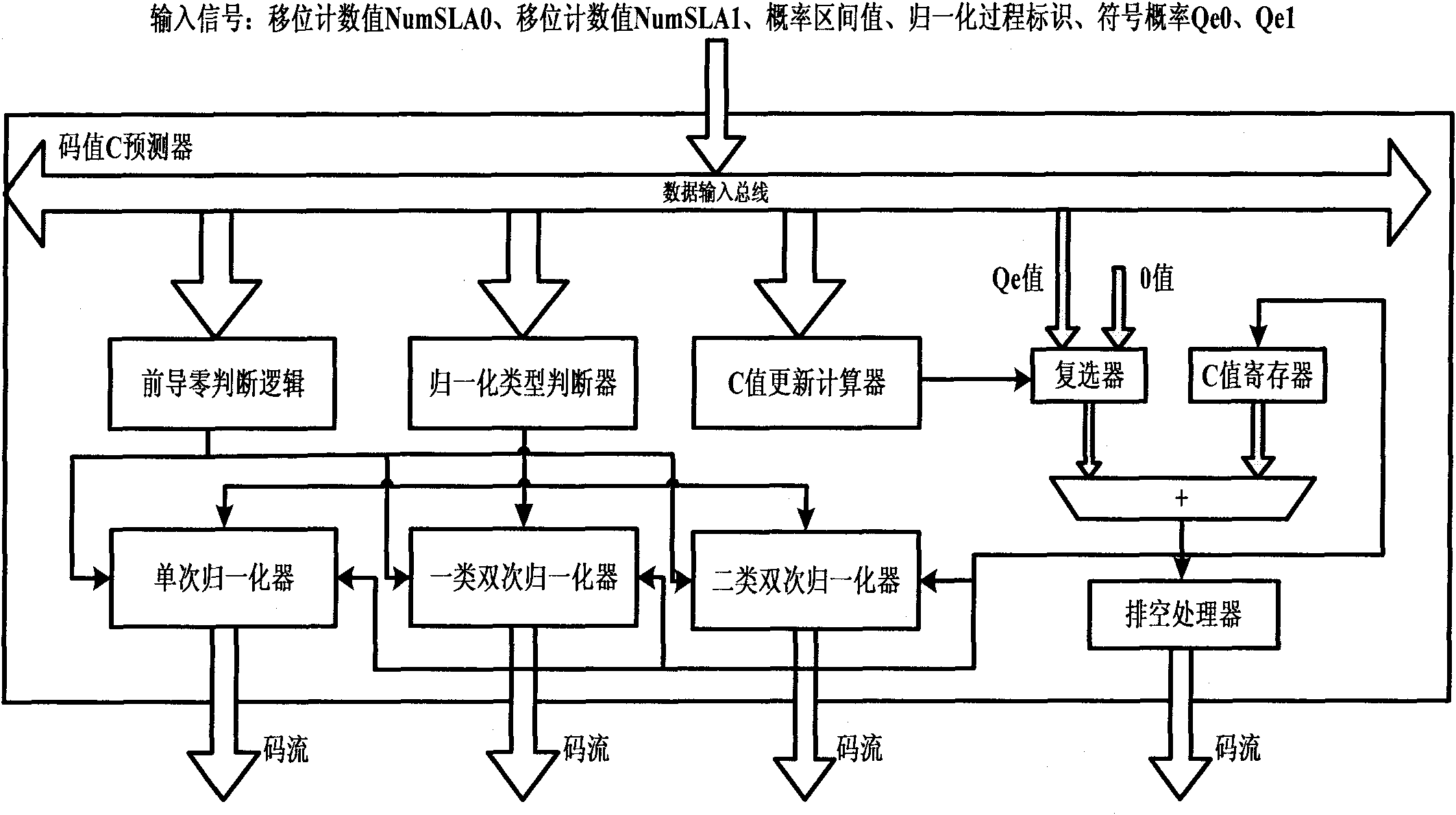

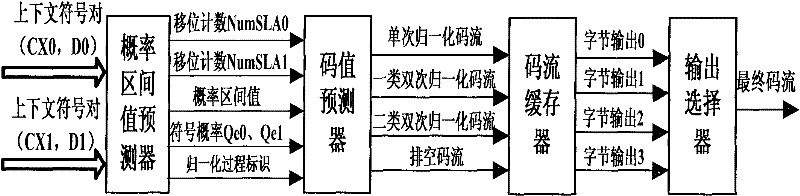

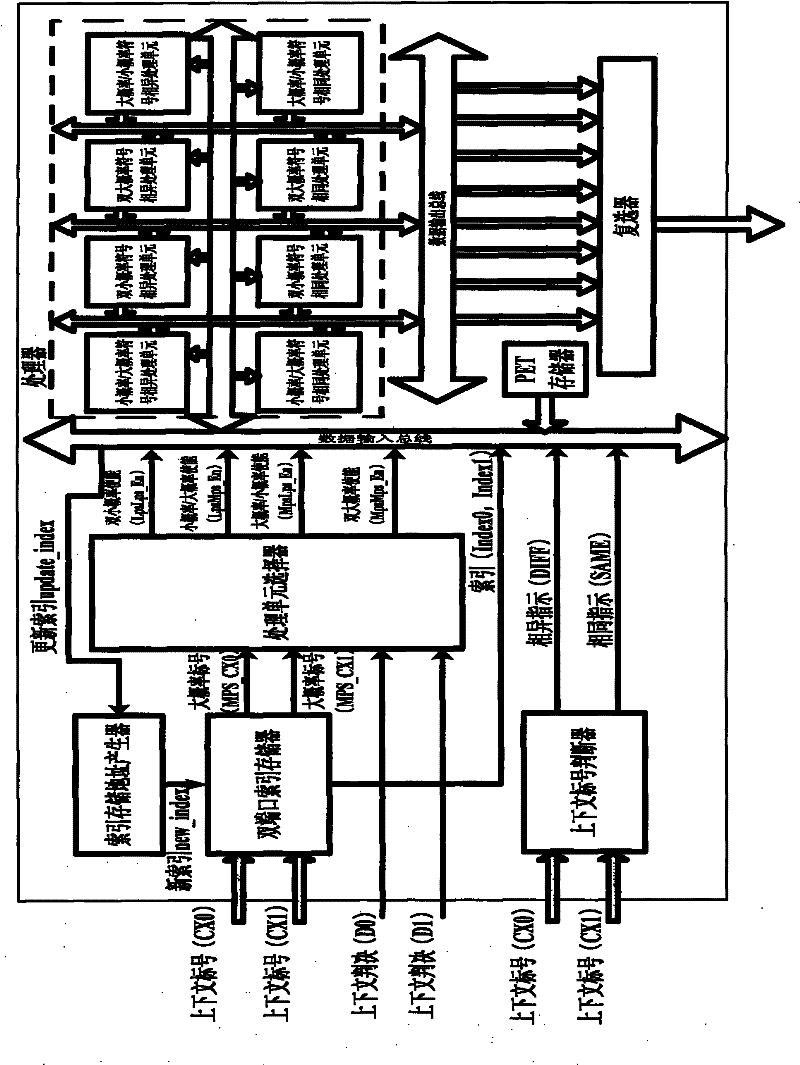

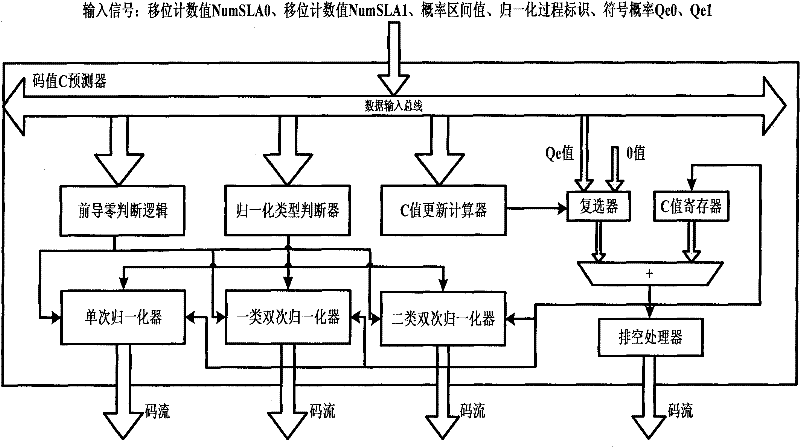

High-speed real-time processing arithmetic entropy coding system based on JPEG2000

InactiveCN101820549AAvoid pauseUninterrupted processingTelevision systemsDigital video signal modificationParallel computingImage compression

The invention discloses a high-speed real-time processing arithmetic entropy coding system based on JPEG2000, mainly solving the problem that the traditional coding system has high complexity and low coding speed. The coding system comprises a probability interval value predictor, a code value predictor, a code stream cache and an output selector, wherein the probability interval value predictor judges the type of a coded identification according to input dual context code pairs and sends an updated probability interval value and a code necessary parameter to the code value predictor; the code value predictor updates the code value, judges a current uniformization type, selects different uniformization processors for uniformization operation, respectively caches four types of code streams into the code stream cache according to bytes, and sequentially serially outputs the parallel input code streams according to a special priority order through the output selector. The invention has the advantages of high coding speed and low complexity and can be used for image compression coding of various high-speed digital equipment, particularly for the coding of a high-speed real-time satellite remote sensing image.

Owner:XIDIAN UNIV

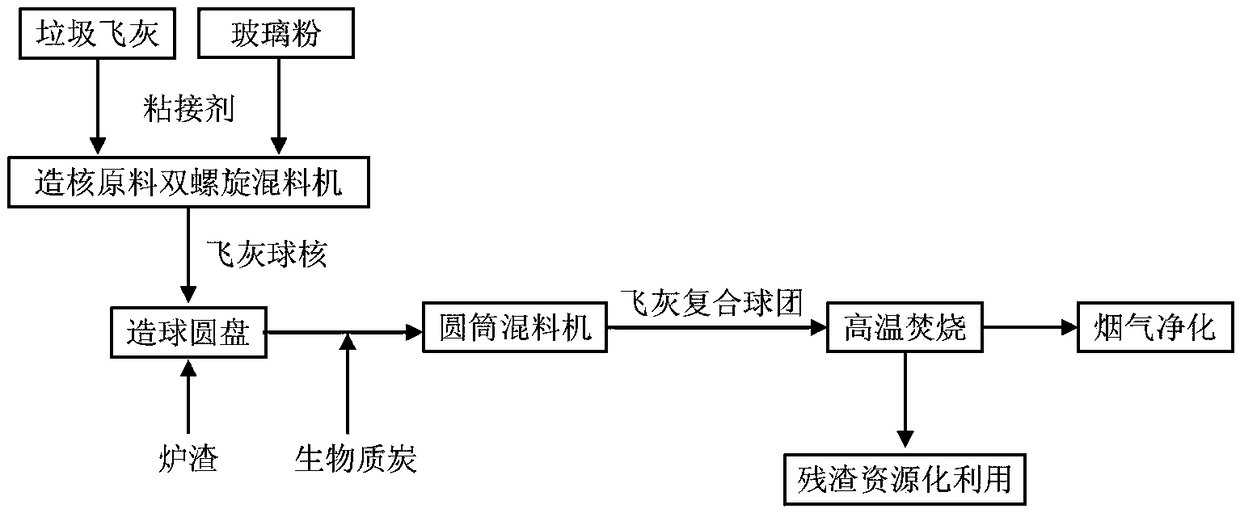

Garbage incineration fly ash high-temperature melting innocuous treatment process

ActiveCN109404916AShorten and simplify the balling processRealize nearby processingIncinerator apparatusBiomass carbonSlag

The invention relates to a garbage incineration fly ash high-temperature melting innocuous treatment process. The garbage incineration fly ash high-temperature melting innocuous treatment process comprises the steps that (1) garbage fly ash and glass powder are mixed to prepare fly ash ball cores; (2) fly ash composite pellets are obtained by adding slag to coat the surfaces of the ball cores; (3)the fly ash composite pellets are mixed with biomass carbon to obtain mixtures; and (4) the mixtures are directly accessed into an incineration device of an existing garbage incineration plant for high-temperature incineration, flue gas generated by incineration is purified by flue gas purification equipment of the garbage incineration plant, and incineration residue is subjected to residue treatment. According to the garbage incineration fly ash high-temperature melting innocuous treatment process, only the garbage fly ash and the glass powder are adopted to prepare the ball cores, the ballcores are coated with slag substances, and the obtained composite pellets are mixed with biomass carbon particles to form the mixtures, so that the ball forming process of the garbage fly ash is shortened and simplified, solid melting of heavy metals in the fly ash is facilitated, glass melts are formed, and leaching toxicity requirements are met; and meanwhile, the required equipment is less, andthe process is matched with the existing garbage incineration plant for implementation, so that nearby treatment of the garbage fly ash can be realized.

Owner:CHONGQING ANGRUIYUE SCI & TECH +1

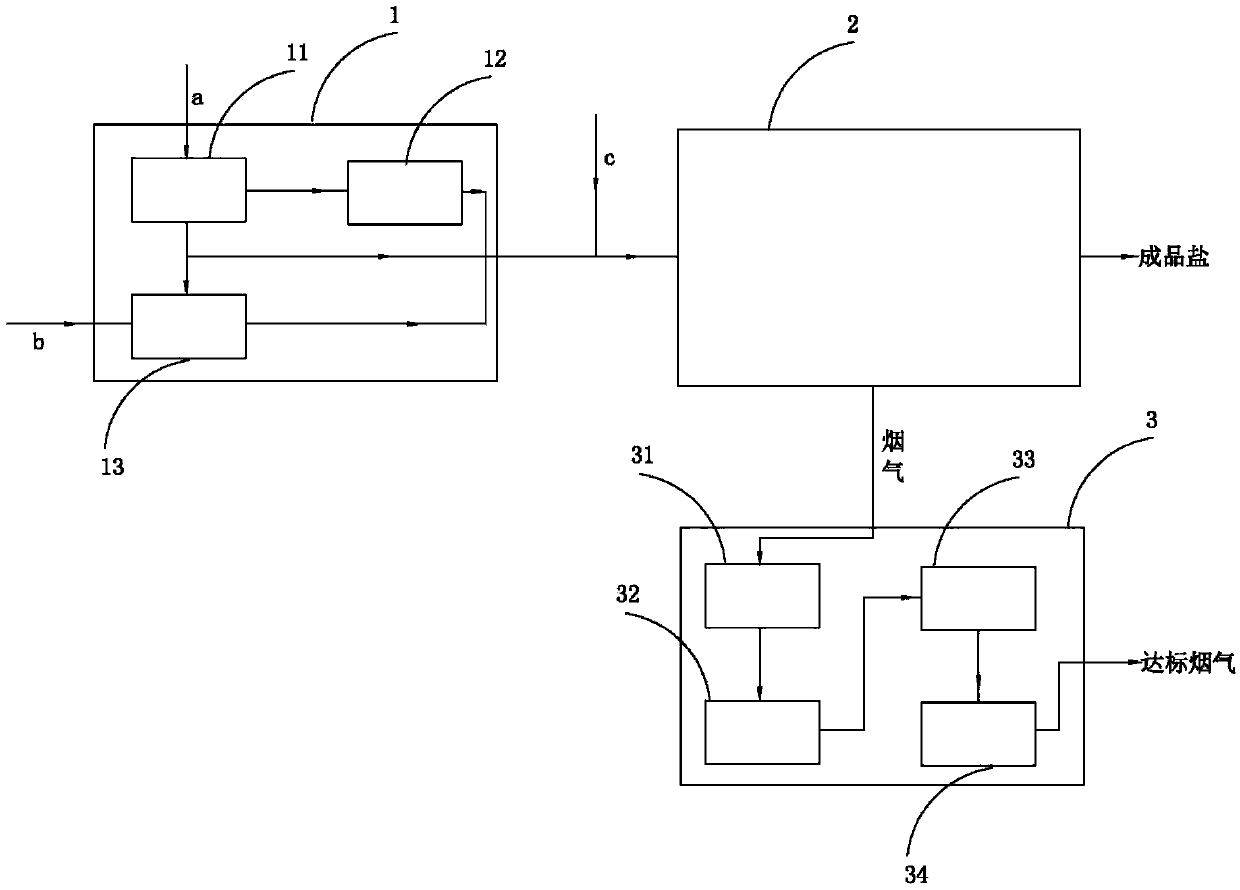

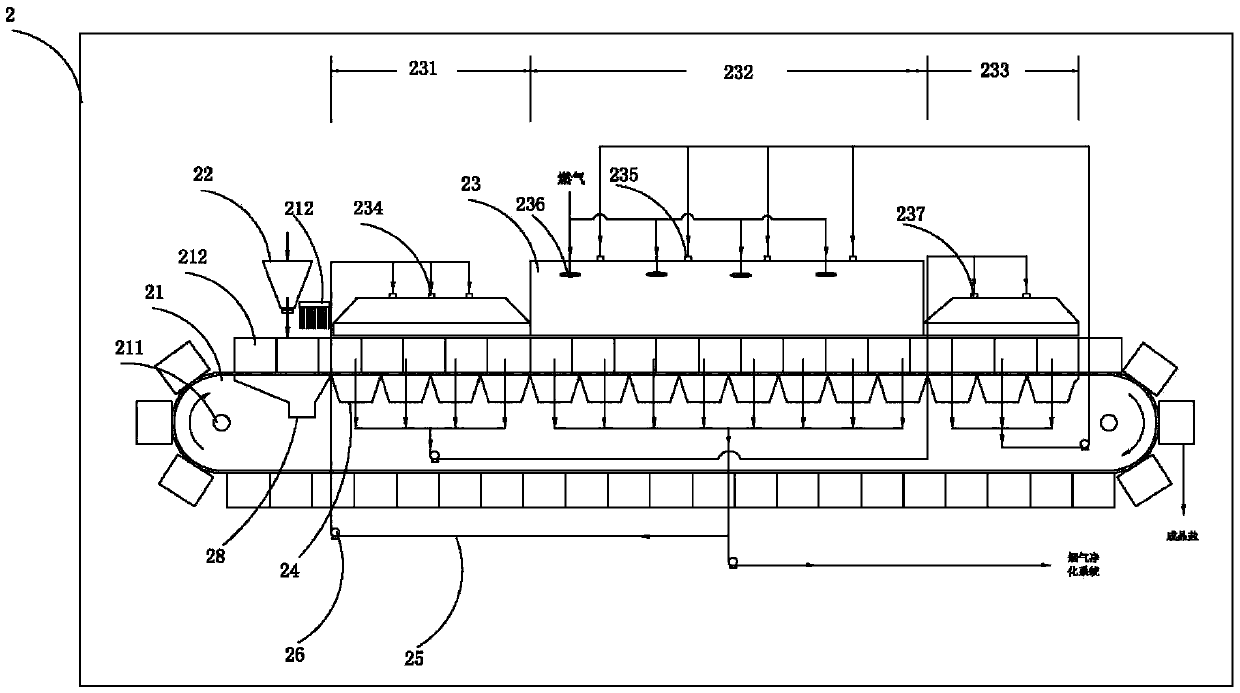

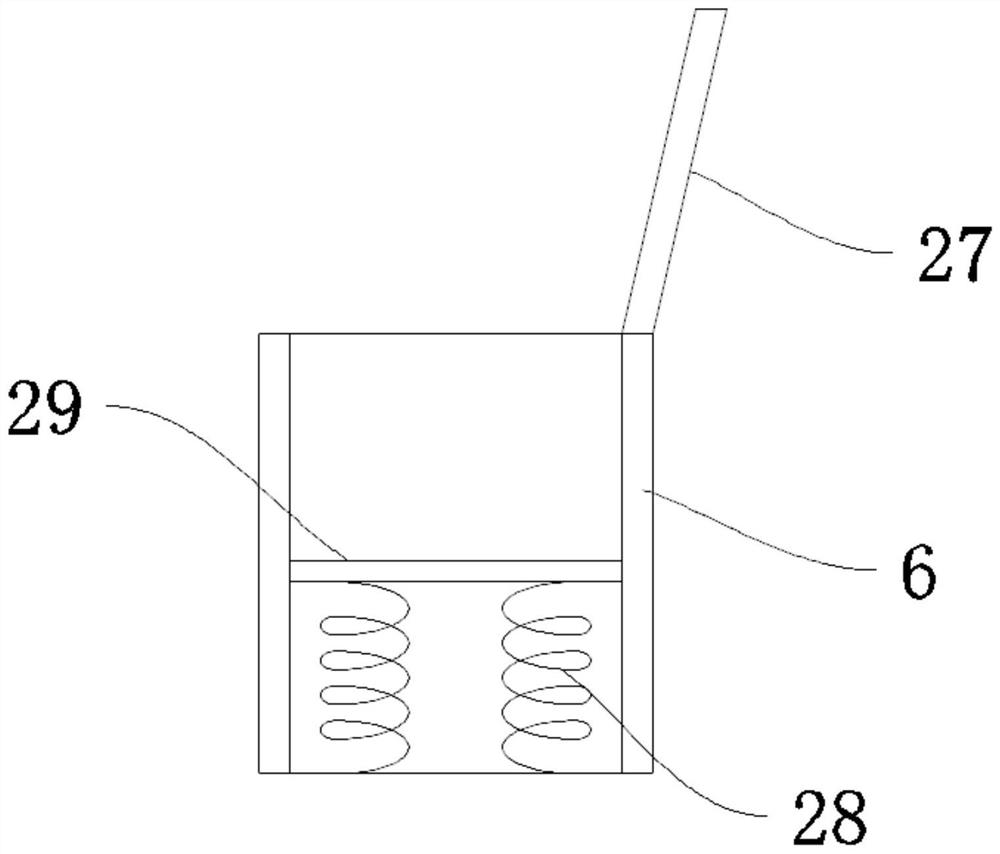

Method and system for treating chemical abraum salt containing organic matter through self-propagating pyrolysis method

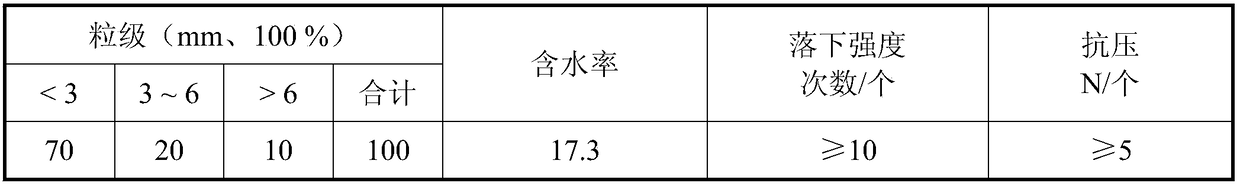

PendingCN109519928AStable and controllable pyrolysis temperatureUniform temperature distributionIncinerator apparatusPelletizingPre treatment

The invention relates to the field of solid waste treatment, in particular to a method and system for treating chemical abraum salt containing organic matter through a self-propagating pyrolysis method. The method comprises the following steps that pretreatment is carried out in a pelletizing or washing or treating-free mode according to particle size distribution of chemical abraum salt; 2, materials are distributed; 3, pyrolysis treatment is carried out, and particularly organic matter in a material layer is pyrolyzed into a gas compound through a self-propagating pyrolysis method; 4, the pyrolyzed material layer is cooled to obtain finished salt; and 5, flue gas treatment is carried out, and particularly flue gas containing the gas compound is introduced into a flue gas purifying treatment system for purifying treatment. The finished salt obtained from the abraum salt treated through the method has no melting and agglomeration phenomenon, the TOC content is as low as 10.00ppm, and the requirements of ionic membrane caustic soda can be met. The invention further provides a treating system adopting the method, a self-propagating pyrolysis device in the system can sufficiently utilize heat, can stably control pyrolysis temperature and is suitable for treatment various kinds of abraum salt.

Owner:CHONGQING ANGRUIYUE SCI & TECH

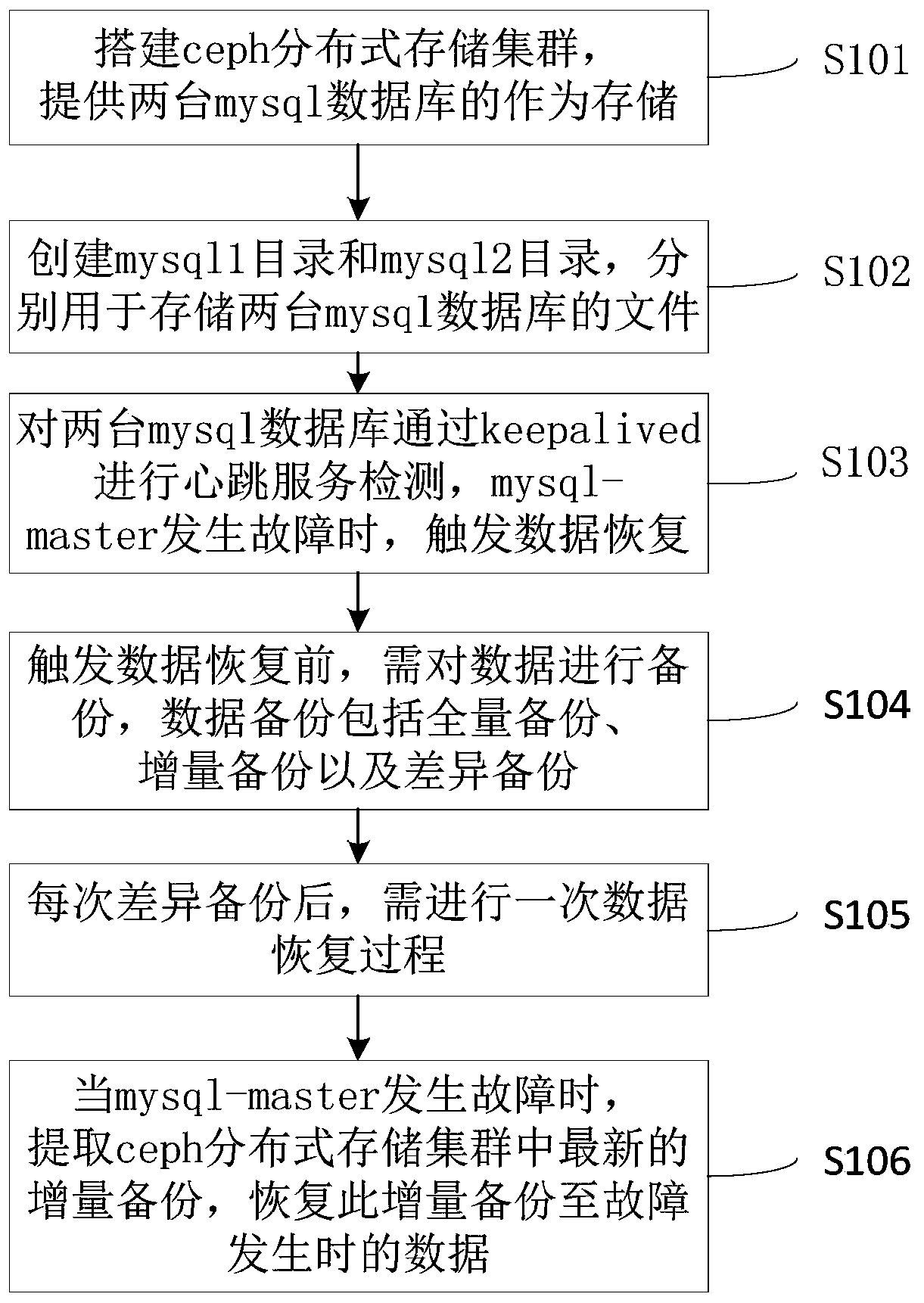

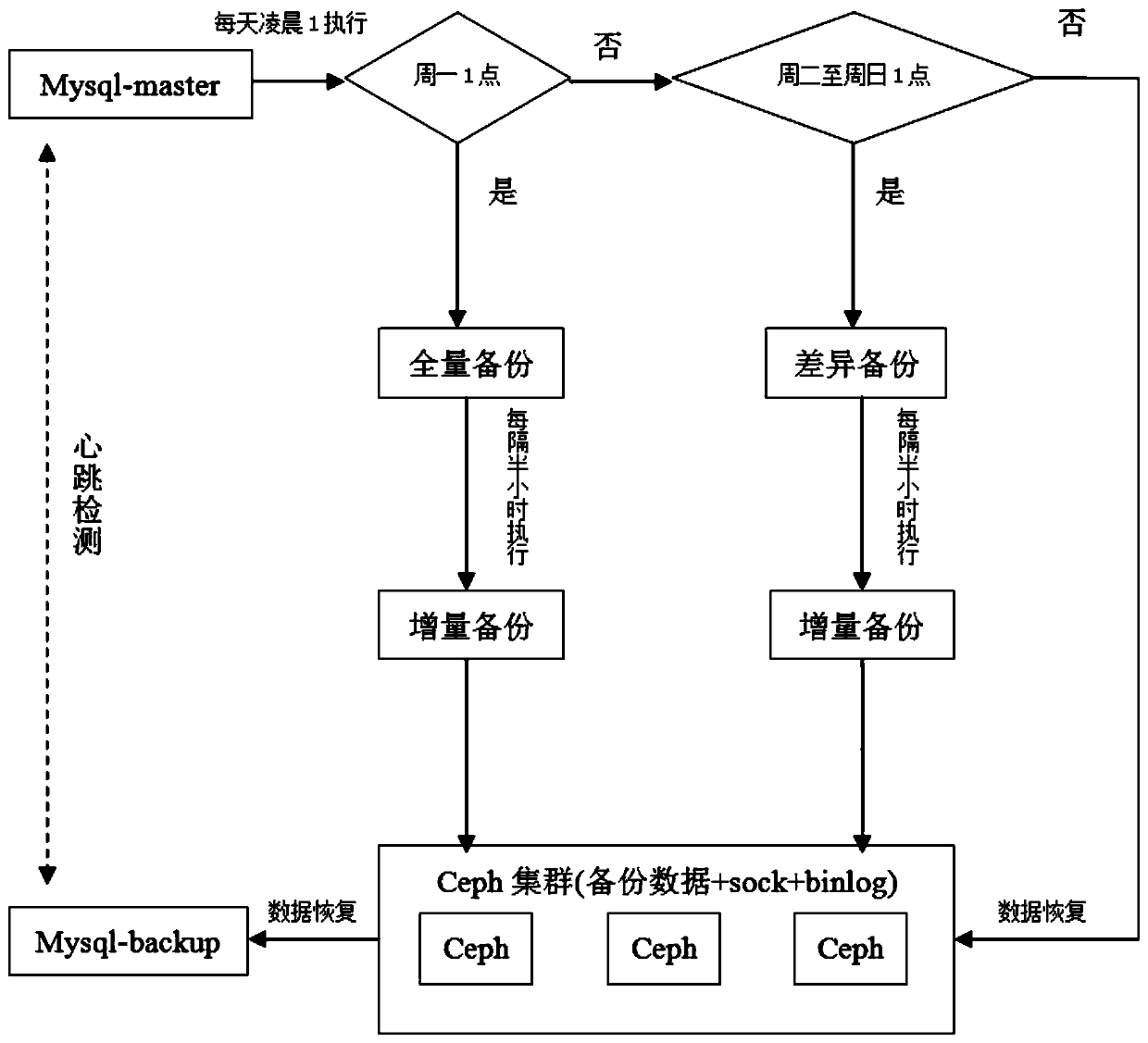

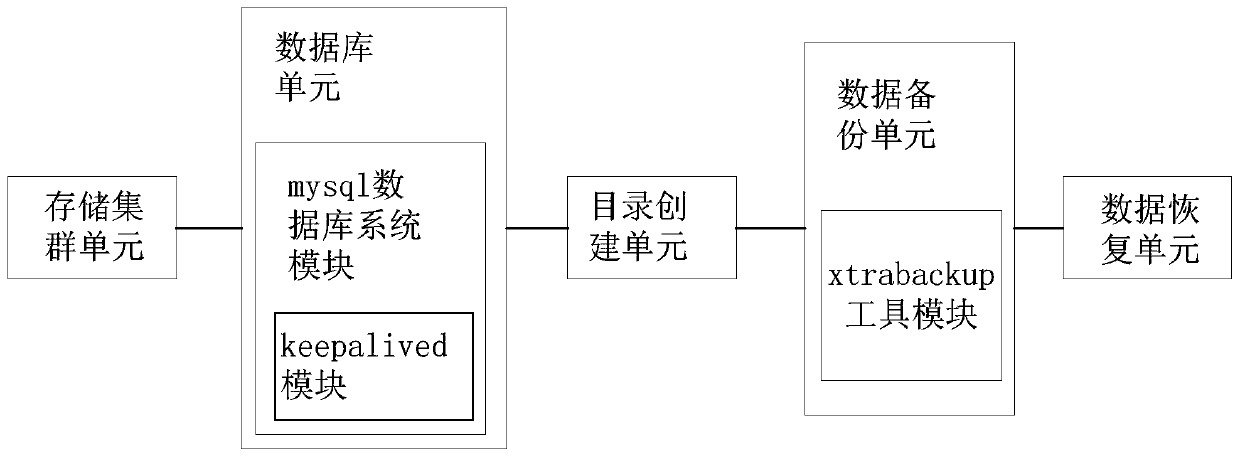

Shared mysql database backup and recovery method and device

InactiveCN110673982ARelieve pressureNot lostDatabase distribution/replicationRedundant operation error correctionDatabase backupData needs

The invention discloses a shared mysql database backup and recovery method and device, and the method comprises the steps: a ceph distributed storage cluster is built, and two mysql databases are provided for storage; a mysql1 directory and a mysql2 directory which are respectively used for storing files of the two mysql databases are created; the two mysql database systems adjust mysql configuration files, and the positions, used for being stored on a cephfs system catalogue, of a lock and a binary log binlog of each mysql database system are modified respectively; heartbeat service detectionis carried out on the two mysql databases, and when the mysql-master fails, data recovery is triggered; before data recovery is triggered, data needs to be backed up, wherein data backup comprises full backup, incremental backup and differential backup; after each time of differential backup, a data recovery process needs to be carried out once; and when the mysql-master breaks down, the mysql-master is immediately switched to the mysql-backup to continue to serve, and the latest incremental backup in the ceph distributed storage cluster is extracted. According to the method, the reliabilityof backup is improved, the integrity of data recovery is ensured, and the data recovery time is shortened.

Owner:GUANGDONG EFLYCLOUD COMPUTING CO LTD

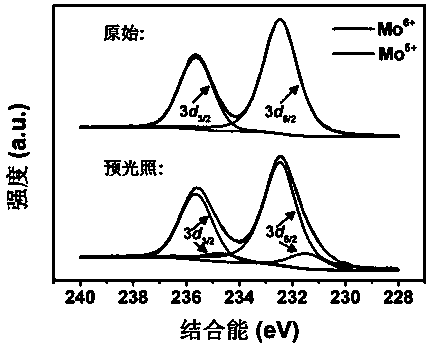

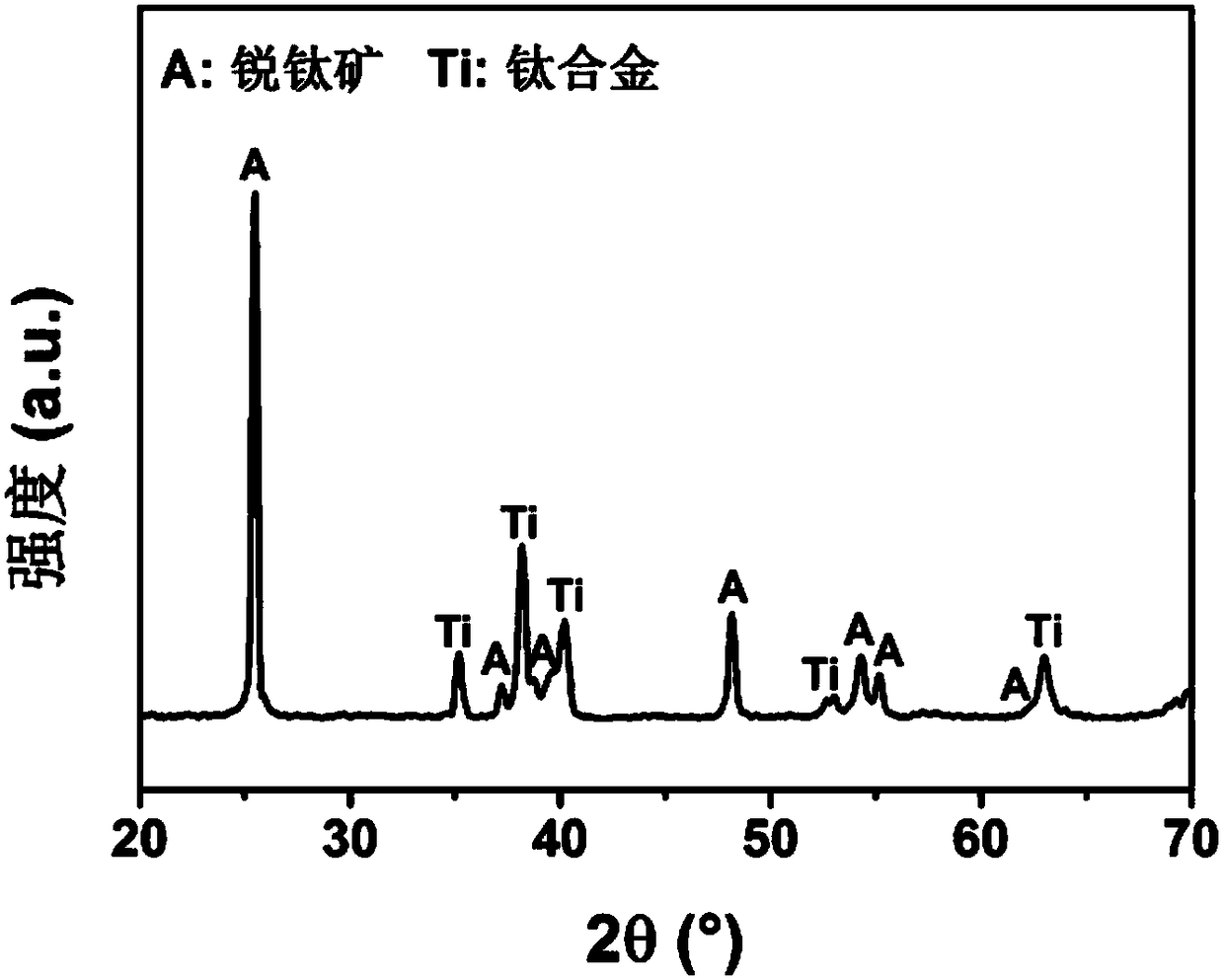

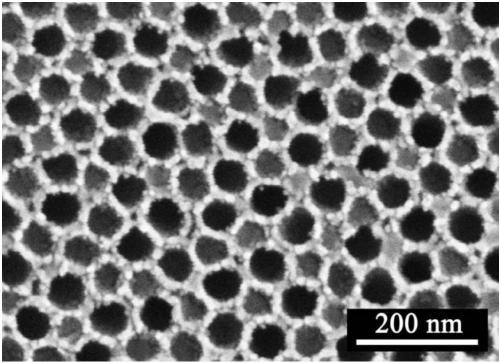

Bulk-phase doped nano-photocatalysis material, preparation method thereof and application of material

InactiveCN109482173AAvoiding the Difficulties of Building Complex HeterojunctionsKeep aliveWater/sewage treatment by irradiationWater contaminantsTherapeutic effectElectron

The invention discloses a bulk-phase doped nano-photocatalysis material, a preparation method thereof and an application of the material, and belongs to the technical field of inorganic non-metallic nano-material preparation, solar energy utilization and environmental protection. The bulk-phase doped nano-photocatalysis material is a single-phase titanium dioxide material, doped ions with electroncapturing and storing capability are uniformly dispersed in a bulk-phase of titanium dioxide, so that doped elements keep activity for a long time without illumination in such a manner that the dopedelements store photo-generated charge under illumination and release the photo-generated charge after illumination is closed to generate active groups, pollutants in environments are continuously treated by sunlight in a full time manner, the nano-photocatalysis material solves the problem that the reaction activity of an existing photocatalysis material is rapidly lost after energy supply of anoutside light source is lost, treatment effects of a photocatalysis technique on environmental pollution are greatly improved, and treatment cost and energy consumption are reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

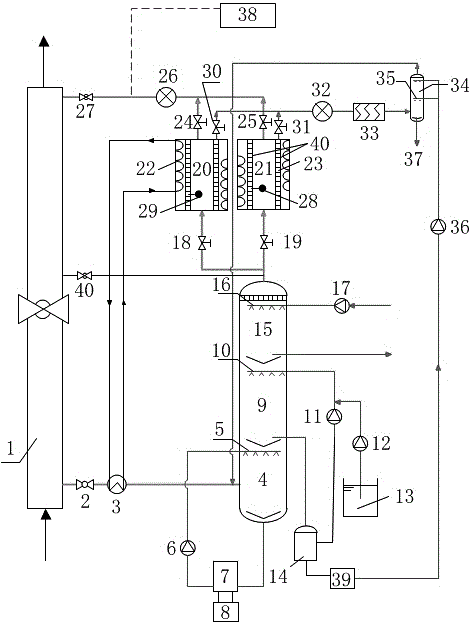

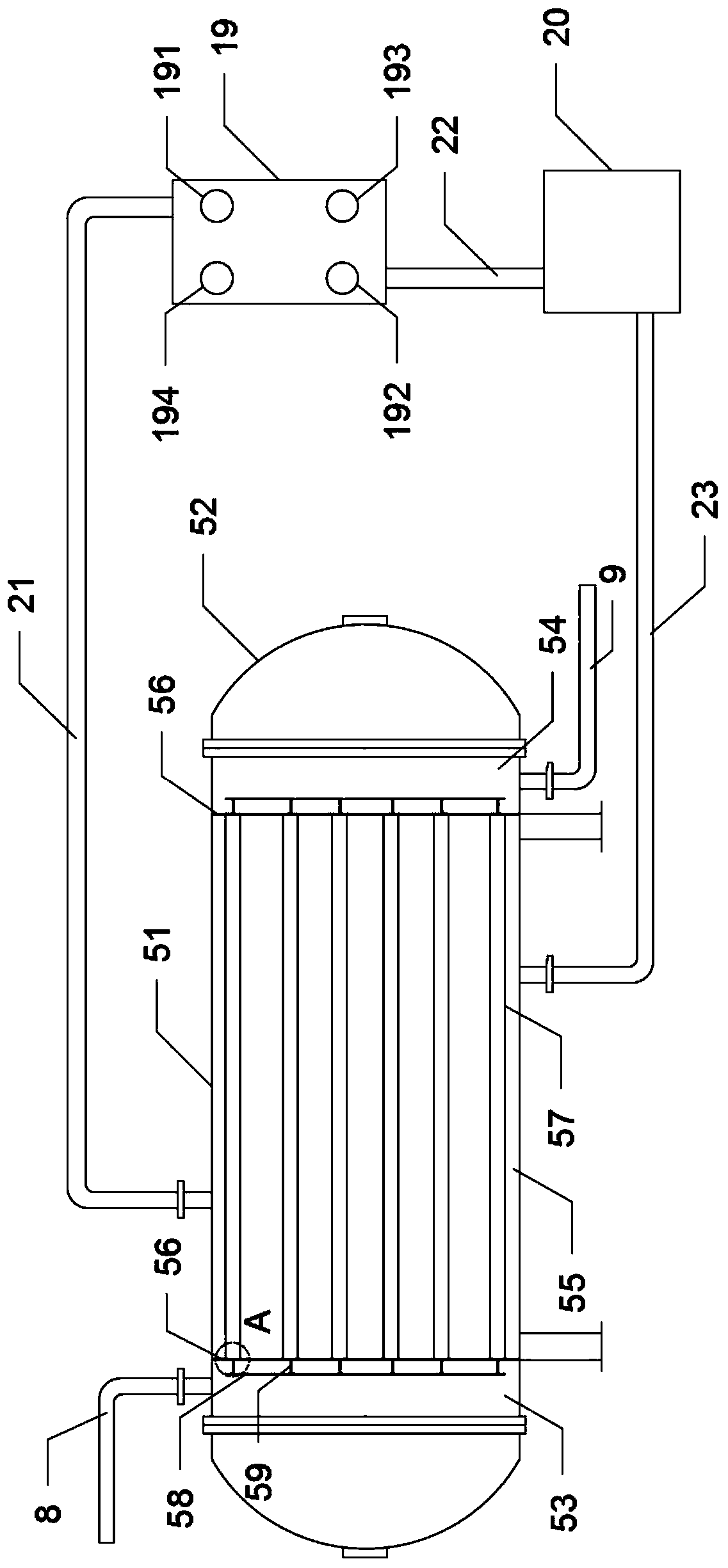

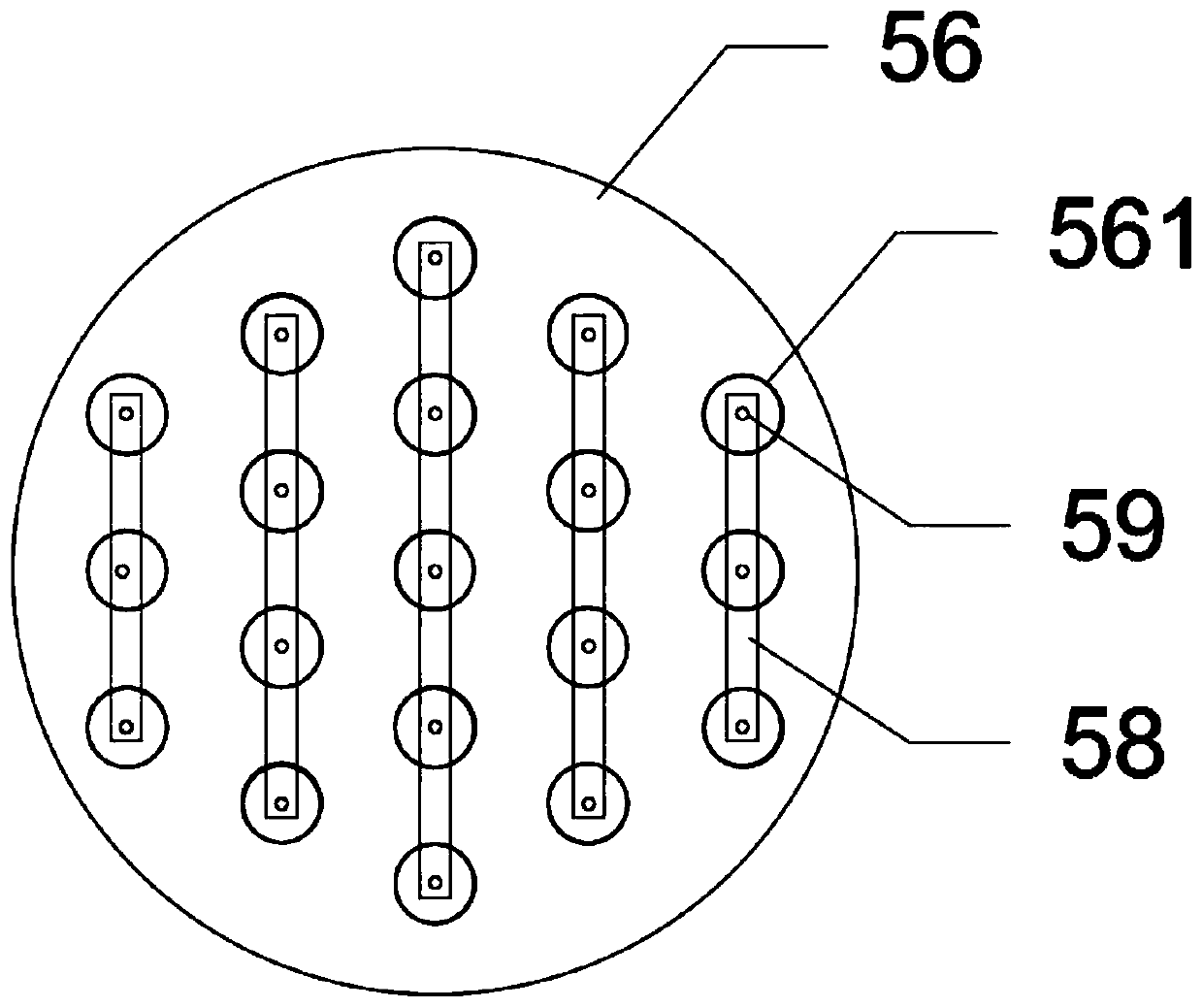

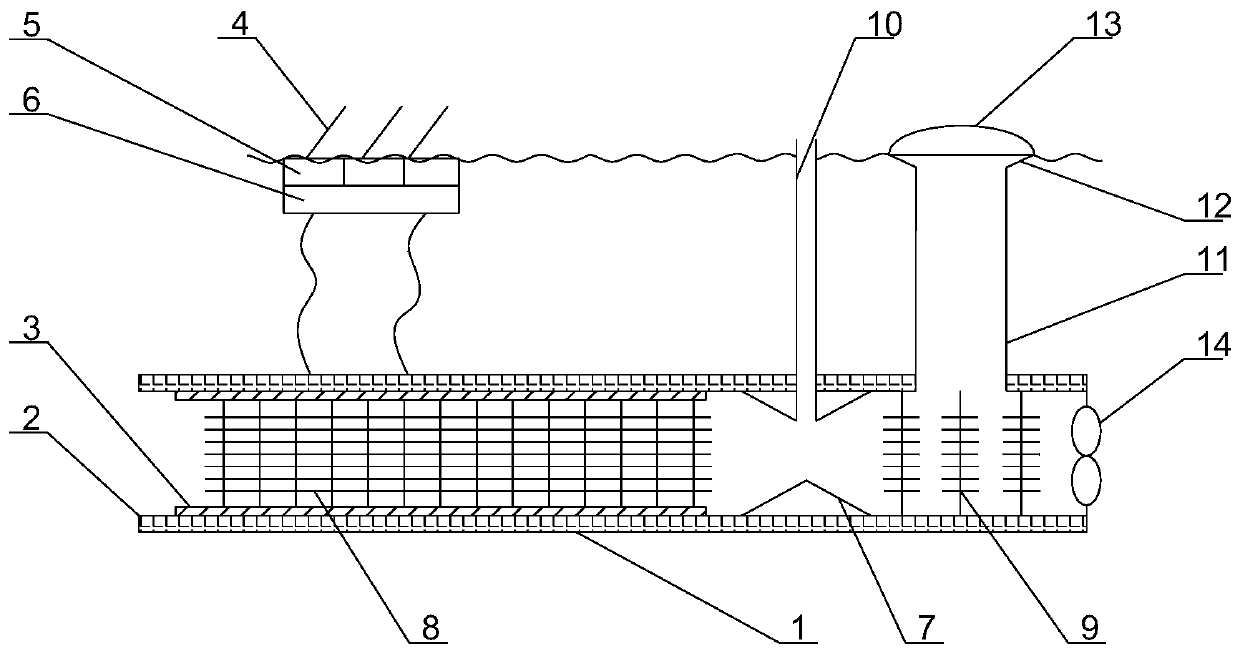

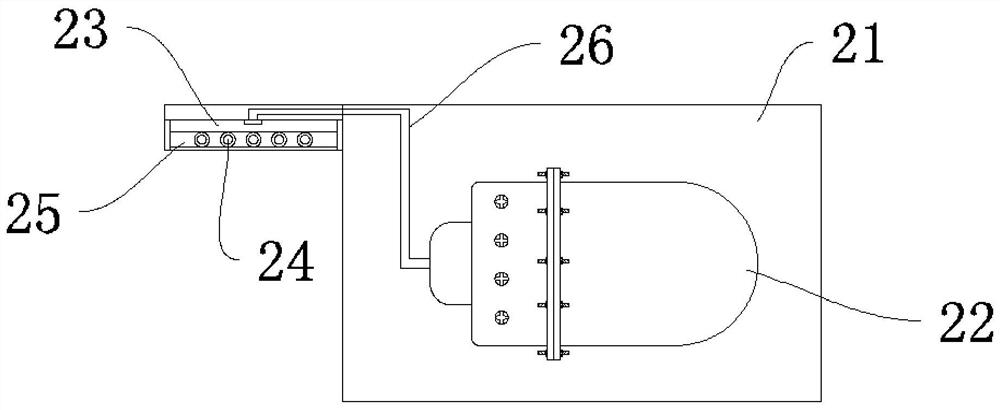

High-efficiency ozone water treatment system and continuous ozone preparation and water treatment method

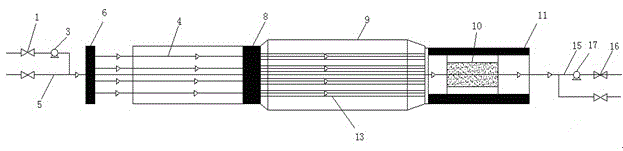

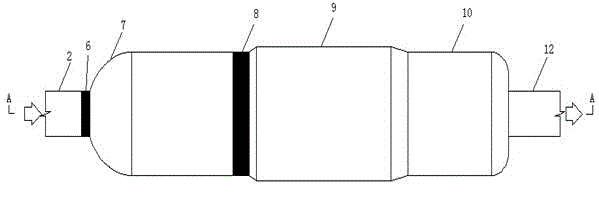

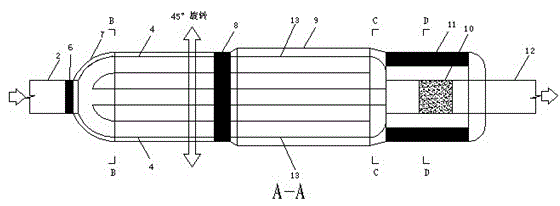

PendingCN109704449AHigh densityHigh purityOzone preparationWater/sewage treatment by oxidationOzone generatorWater treatment system

The invention relates to a high-efficiency ozone water treatment system, and belongs to the field of water treatment equipment. The system comprises a gas source preparation system, an ozone generator, an ozone contact pool and a tail-gas destroyer; the gas source preparation system comprises an air compressor, a gas storage tank, a refrigerated dryer and an adsorption dryer which are connected insequence through a pipeline; and the adsorption dryer is connected with the ozone generator, the ozone generator is connected with the ozone contact pool, and the ozone contact pool is connected withthe tail-gas destroyer through a tail-gas discharging pipeline. The invention also provides a continuous ozone preparation and water treatment method. The system and method provided by the inventioncan solve the problem that a gas prepared by a gas source preparation system has a higher water content, the efficiency of the ozone generator is improved, the gas distribution in the ozone contact pool is uniform, and the system is convenient to maintain.

Owner:JIANGSU FANGYANG WATER

Small drinking water emergency treatment device

InactiveCN103332814AMeet the needs of lifeSimple and effective filter disinfectionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentCotton gauzeEmergency treatment

The invention discloses a small drinking water emergency treatment device, and relates to the technical field of drinking water purification devices. The small drinking water emergency treatment device comprises a water inlet segment, a rotary tube head, an ultra-filter tube segment, an activated-charcoal column tube segment and a water drainage segment, which are sequentially connected. Filter head cotton gauze is arranged between the water inlet segment and the rotary tube head, and a sealing ring is arranged between the rotary tube head and the ultra-filter tube segment. The small drinking water emergency treatment device has a simple structure and can purify water in time to cause residents to use safe water when the local is polluted.

Owner:HOHAI UNIV

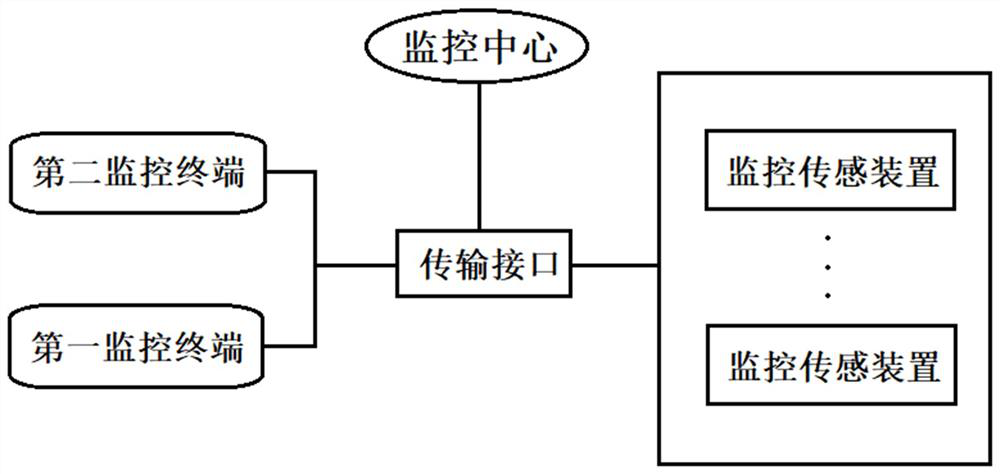

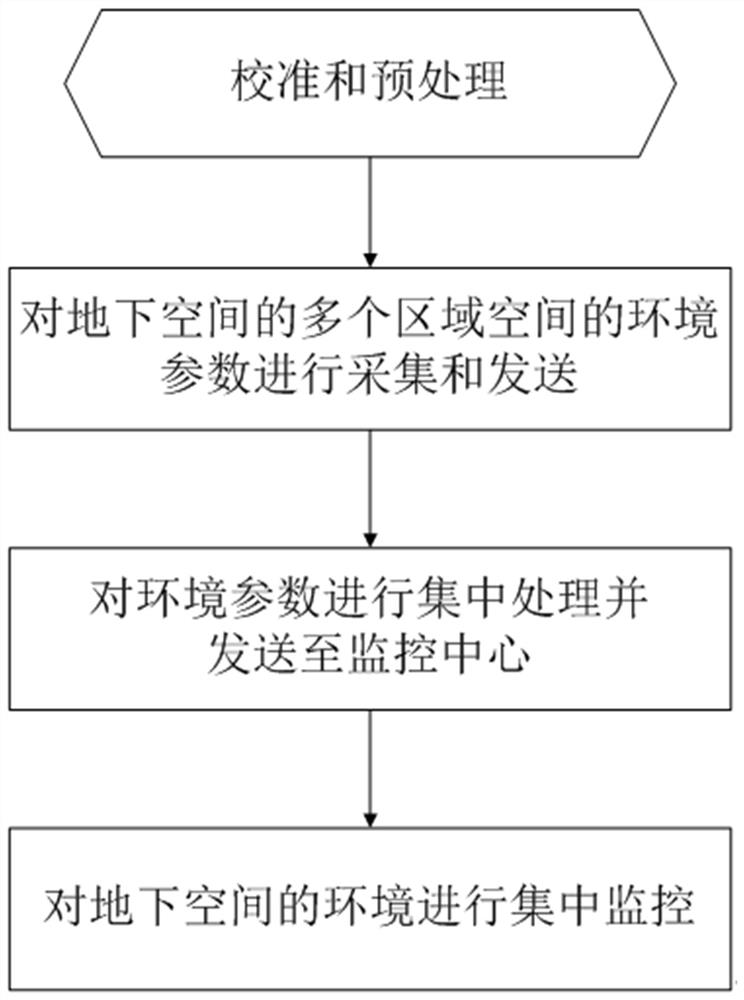

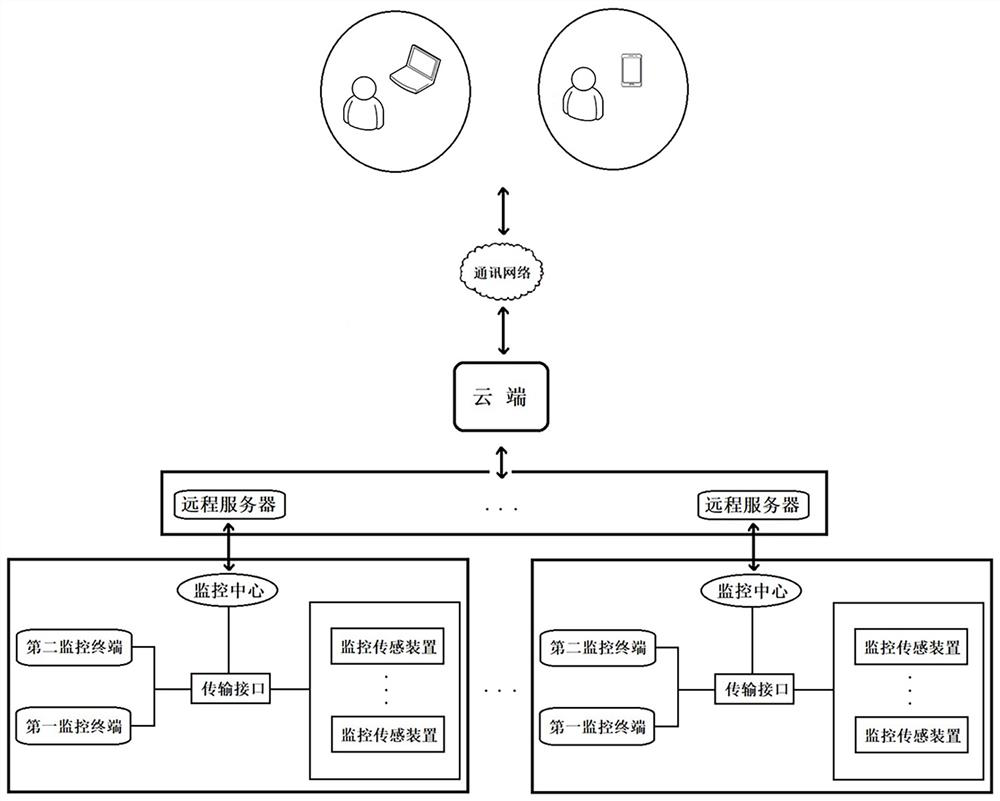

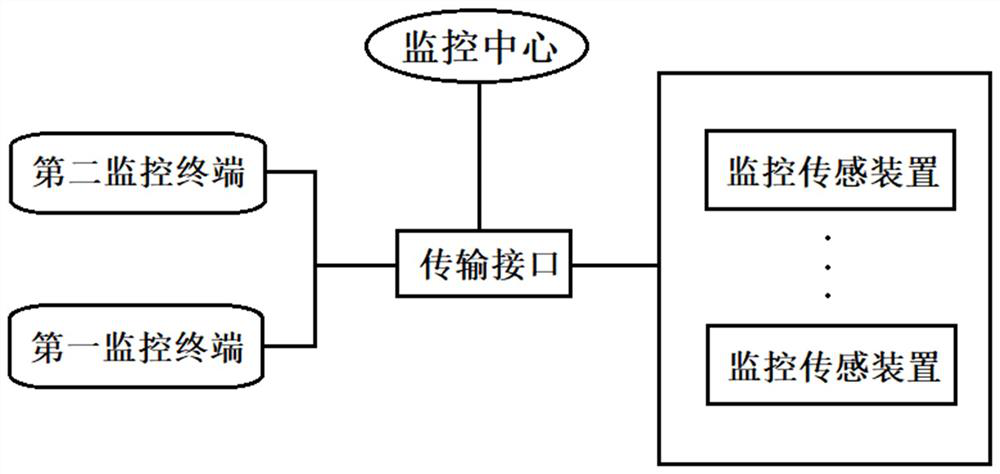

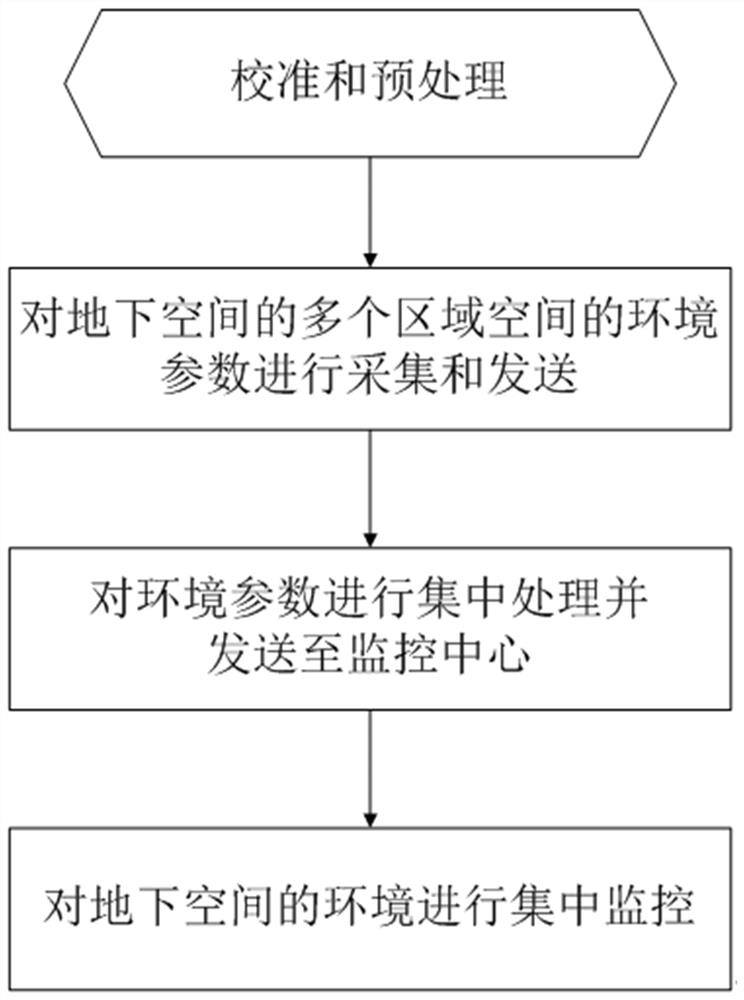

Underground space environment monitoring system and method

ActiveCN114689129AAchieve no lossImplement updateMeasurement devicesTotal factory controlTelecommunications linkDynamic monitoring

An underground space environment monitoring system and method relate to the field of underground environment monitoring and are applied to underground space environment monitoring, the system is set and applied to a server, the server is connected with a terminal device through a network, and the network is used for providing a communication link between the terminal device and the server; the system comprises a monitoring center, a monitoring terminal, a multi-channel transmission interface, a standard sensing device and a plurality of monitoring sensing devices, and the monitoring center, the monitoring terminal and the plurality of monitoring sensing devices are respectively connected with the multi-channel transmission interface. Uninterrupted continuous data processing is rapidly and efficiently achieved, the efficiency is improved, meanwhile, the cost is saved, and the problems that in the prior art, the function is single, and rapid and accurate dynamic monitoring cannot be achieved are solved.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队 +2

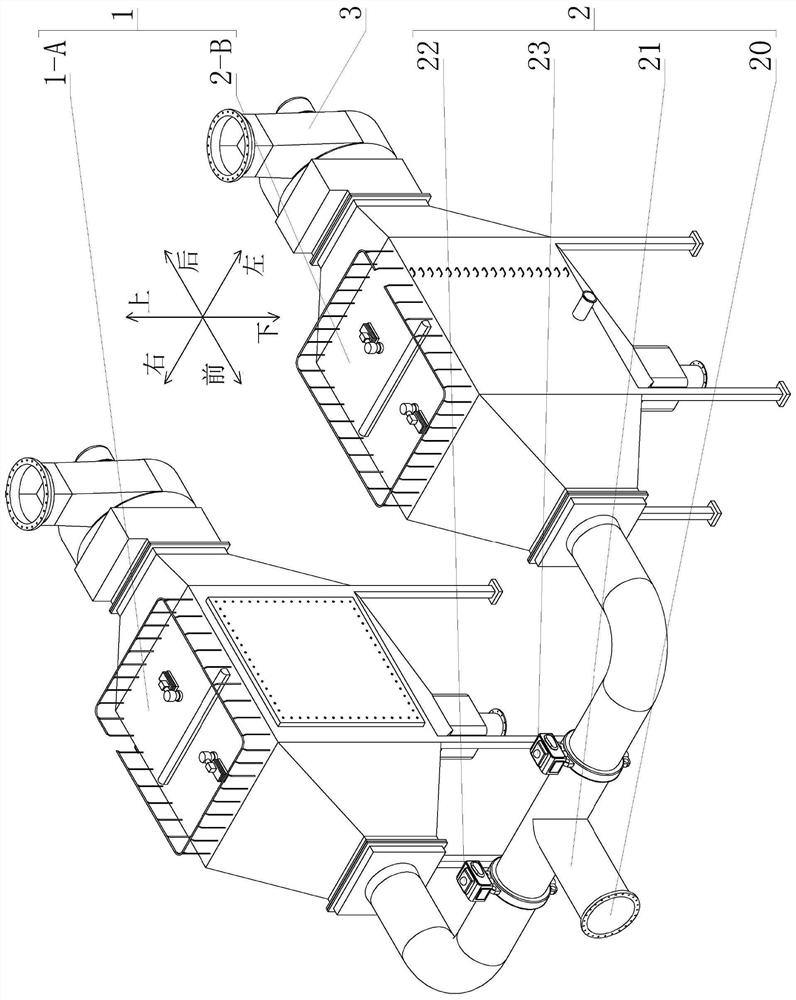

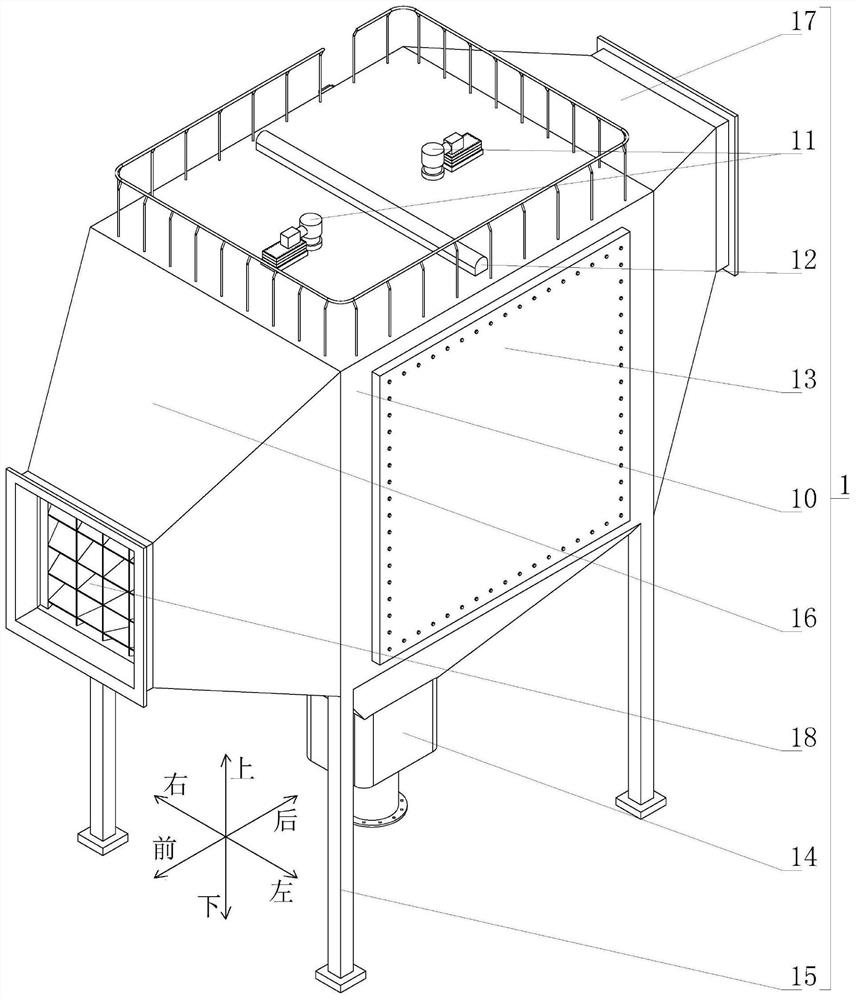

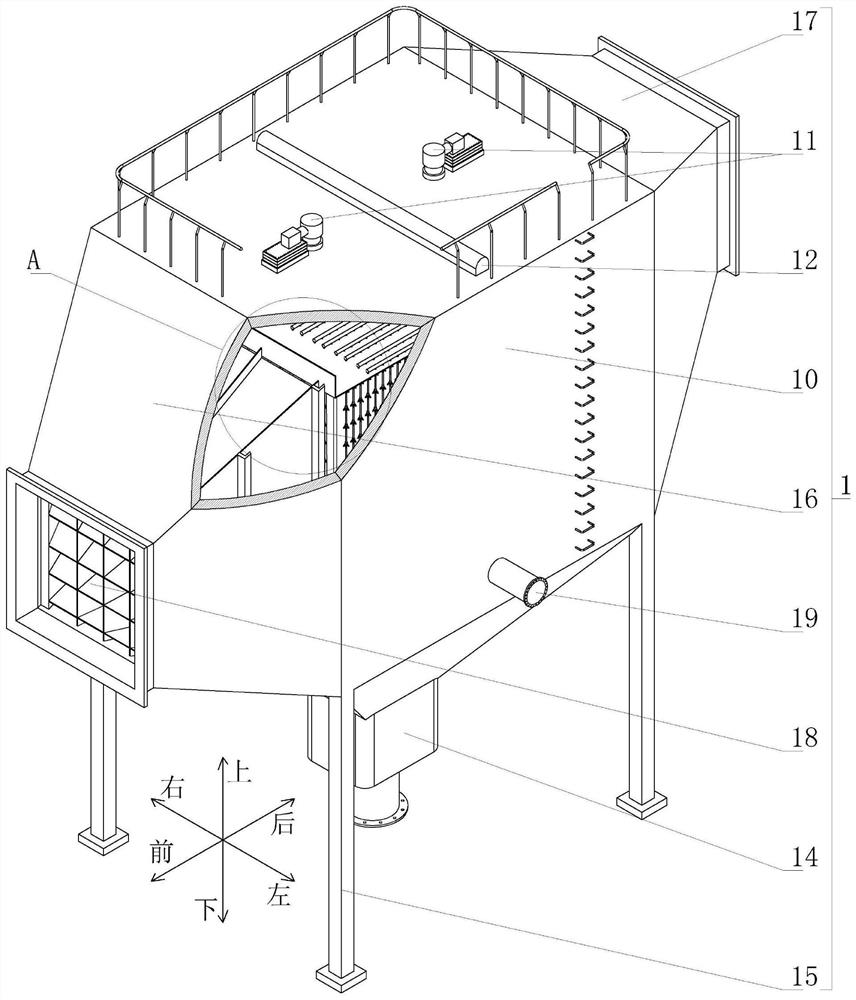

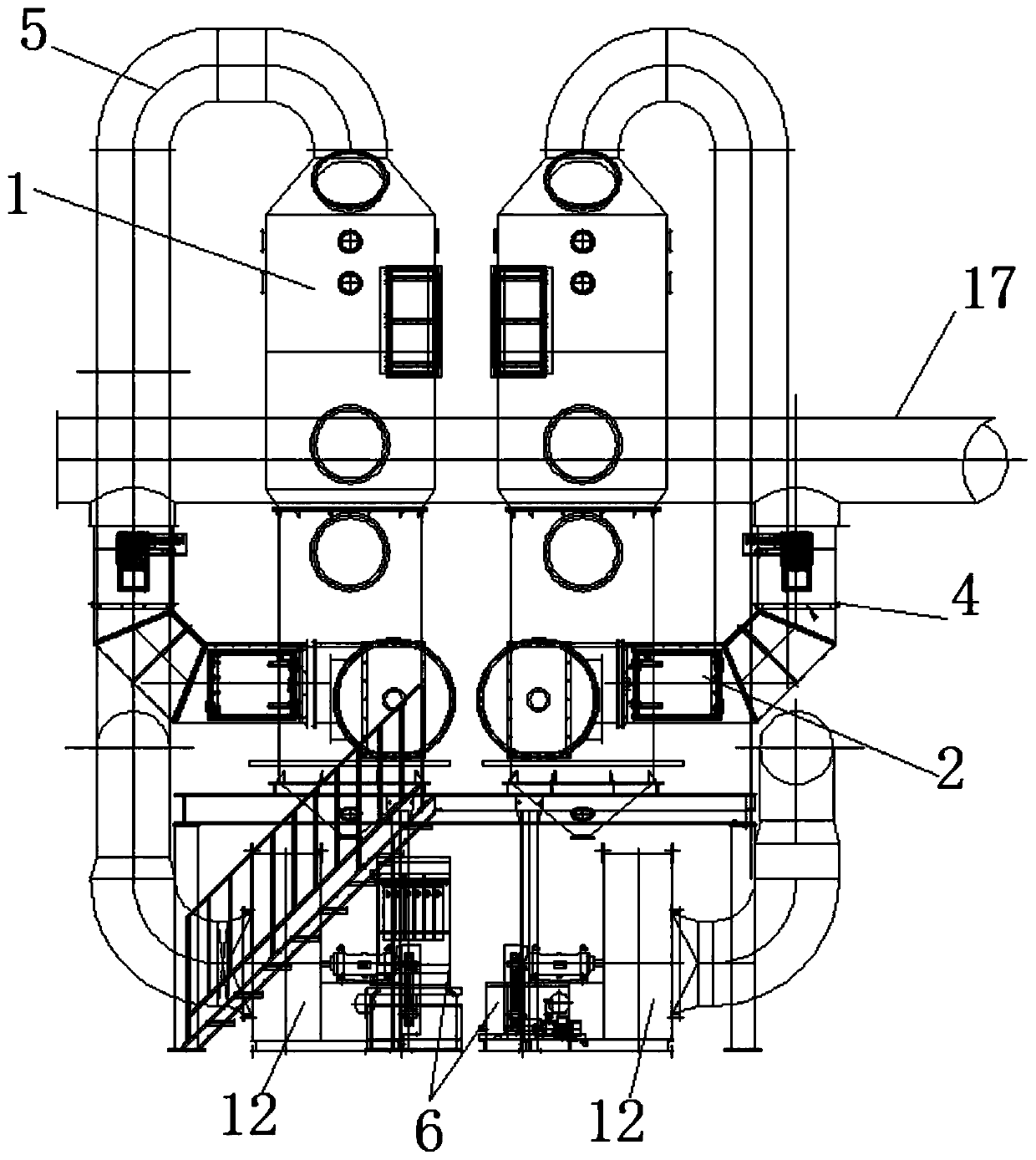

Wet type electrostatic dust collector

ActiveCN113751200AIncrease contactImprove vacuuming effectHuman health protectionExternal electric electrostatic seperatorVentilation tubeThermodynamics

The invention relates to a wet type electrostatic dust collector which comprises a dust collector body composed of a first dust collector and a second dust collector and a control mechanism. The dust collector body comprises a cavity, a charging device, a washing header pipe, a dust hopper air inlet hopper, an air exhaust hopper and a steam pipe orifice; a dust collecting mechanism, a discharging mechanism and a flushing mechanism are arranged in the cavity; a diffusion plate is arranged in the air inlet hopper; an air inlet mechanism is arranged at an outer opening of the air inlet hopper and comprises a first air inlet pipe, a second air inlet pipe, a first valve, a second valve, a third valve, a fourth valve, a fifth valve, a sixth valve, a first exhaust pipe, a second exhaust pipe, a first ventilation pipe and a second ventilation pipe. An induced draft fan electrically connected with the control mechanism is arranged at an outer opening of the exhaust hopper. According to the wet type electrostatic dust collector, high-dust-content flue gas can be better diffused in the cavity of the dust collector, the dust-containing flue gas is continuously treated, and the dust collection effect after cleaning is improved.

Owner:山东首丰智能环保装备有限公司

Device for improving water quality of river bottom

InactiveCN109928502APromote growthPromote degradationBatteries circuit arrangementsTreatment with aerobic and anaerobic processesLarge mouthInsulation layer

The invention discloses a device for improving the water quality of a river bottom. The device comprises a horizontal reaction tube placed at the river bottom and a cavity floating on the surface of the river, a storage battery is arranged in the cavity, the external of the cavity is fixedly provided with solar battery panels connected to the storage battery, and the outer wall of the reaction tube is provided with a heat insulation layer; the inner wall of the reaction tube is provided with a constant temperature heater connected with the storage battery, an anaerobic reaction section, a throat tube, an aerobic reaction section and electric blades are sequentially arranged in the reaction tube, the throat part of the throat tube is provided with an upward vertical thin tube, and the top end of the thin tube is located above the river surface; the upper part of the pipeline of the aerobic reaction section is provided with an opening connected with a vertically upward cylinder, the inside of the cylinder is a mirror surface, the top of the cylinder is a bell mouth, and the top large-mouth end cover of the bell mouth is provided with a convex lens; and the electric blades connected with the storage battery are arranged at the end part of the reaction tube. The device has a very good treatment effect on river pollutants, can continuously perform the treatment in an all-weather manner, and can realize the degradation of the entire river pollutants.

Owner:CHANGZHOU UNIV

High-speed real-time processing arithmetic entropy coding system based on JPEG2000

InactiveCN101820549BAvoid pauseUninterrupted processingTelevision systemsDigital video signal modificationParallel computingImage compression

The invention discloses a high-speed real-time processing arithmetic entropy coding system based on JPEG2000, mainly solving the problem that the traditional coding system has high complexity and low coding speed. The coding system comprises a probability interval value predictor, a code value predictor, a code stream cache and an output selector, wherein the probability interval value predictor judges the type of a coded identification according to input dual context code pairs and sends an updated probability interval value and a code necessary parameter to the code value predictor; the code value predictor updates the code value, judges a current uniformization type, selects different uniformization processors for uniformization operation, respectively caches four types of code streamsinto the code stream cache according to bytes, and sequentially serially outputs the parallel input code streams according to a special priority order through the output selector. The invention has the advantages of high coding speed and low complexity and can be used for image compression coding of various high-speed digital equipment, particularly for the coding of a high-speed real-time satellite remote sensing image.

Owner:XIDIAN UNIV

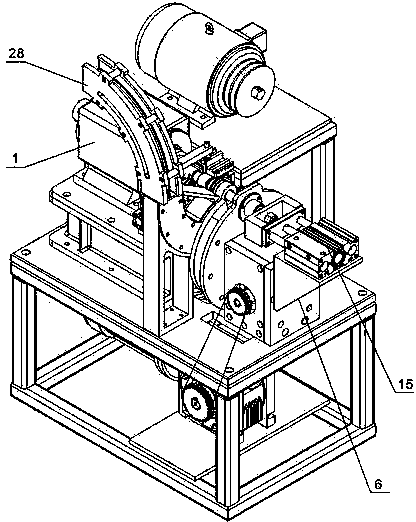

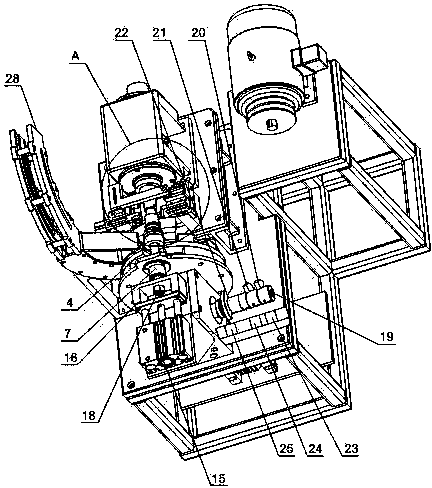

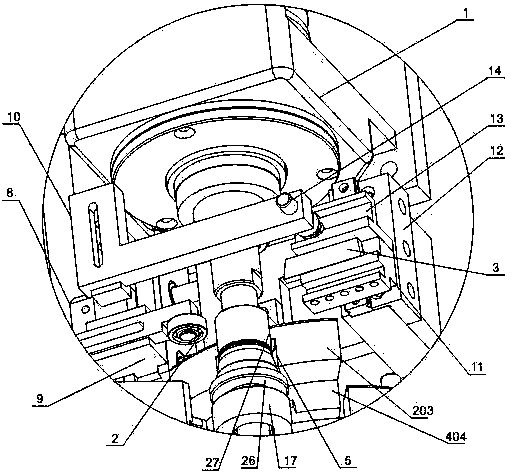

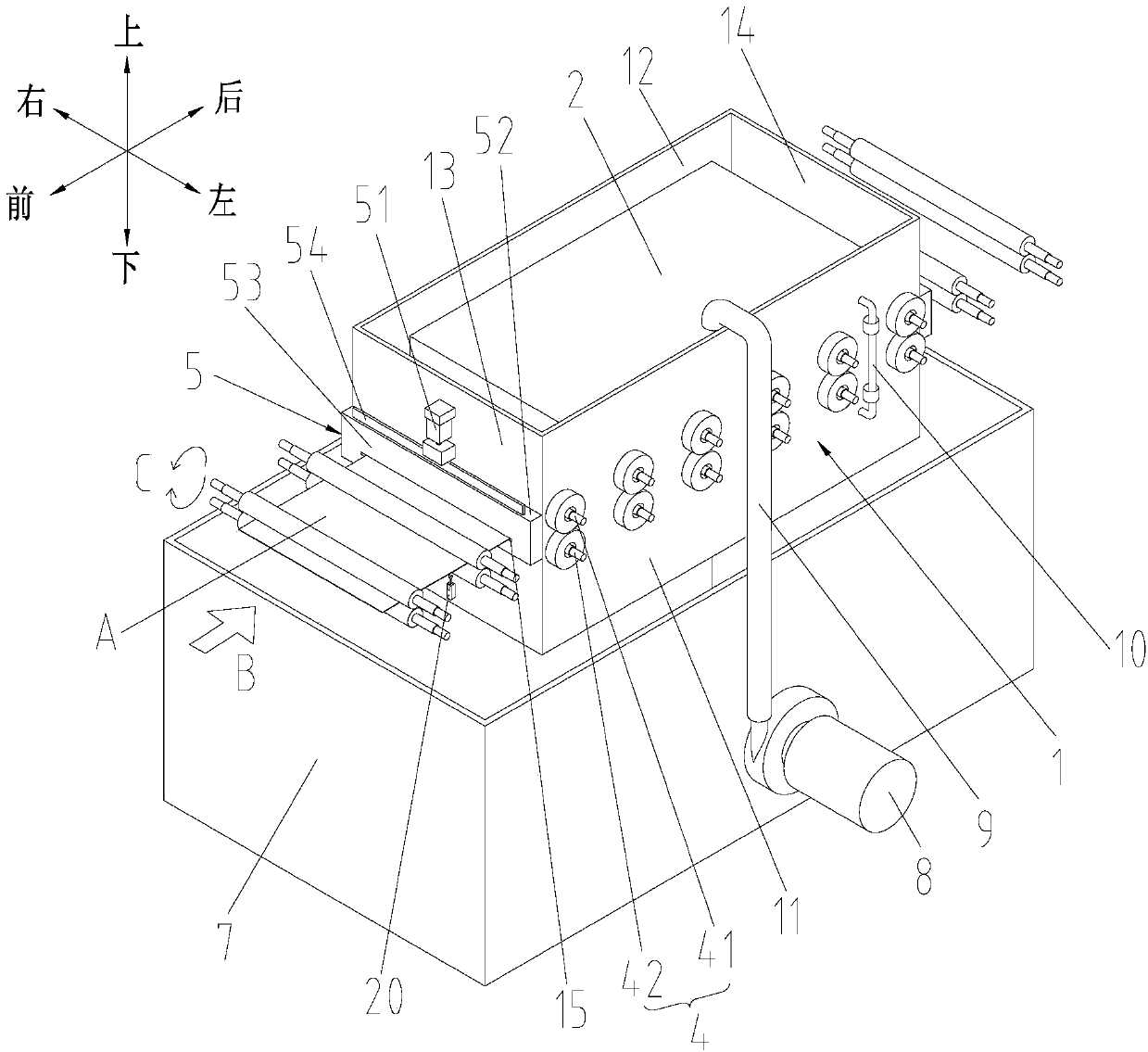

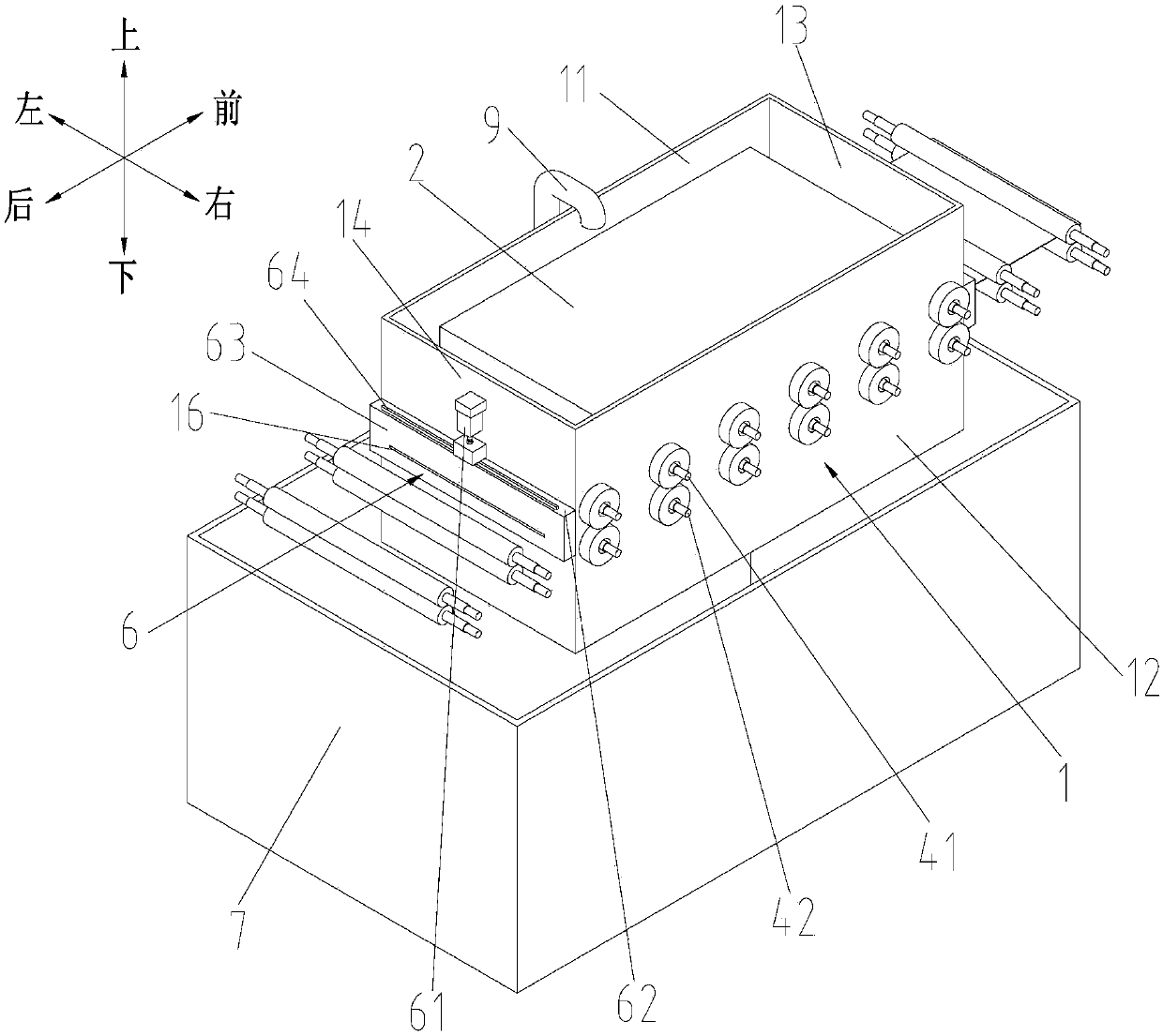

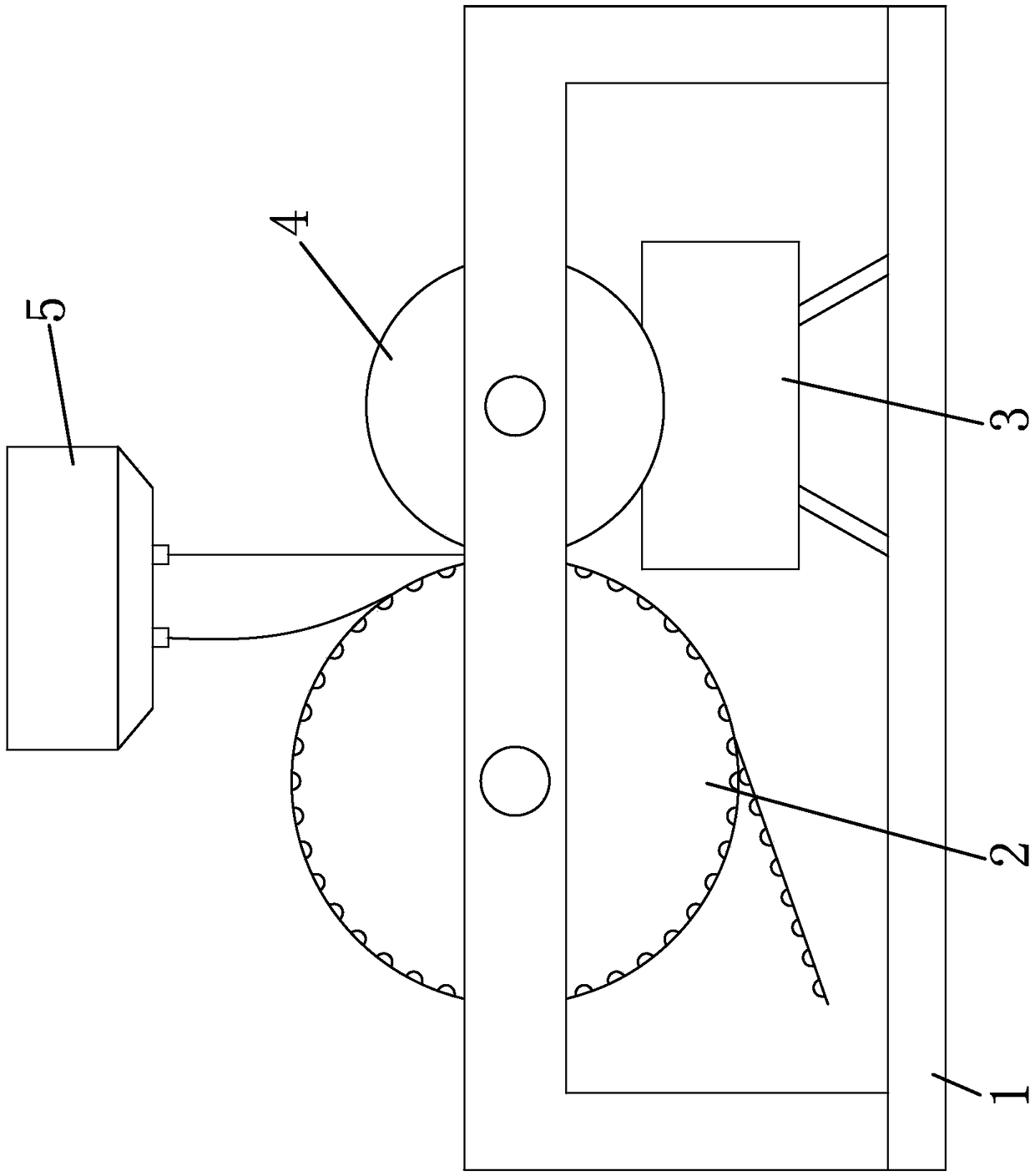

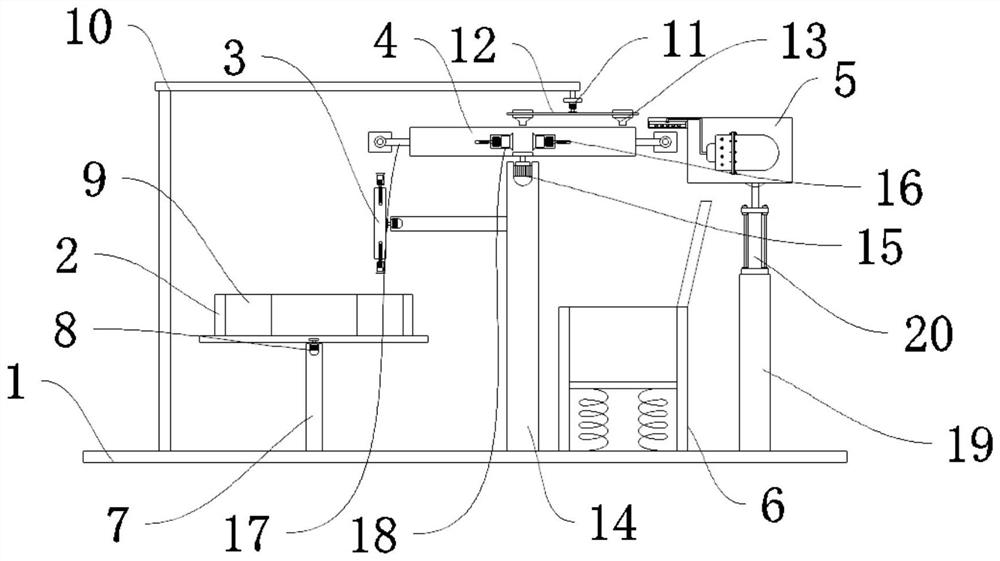

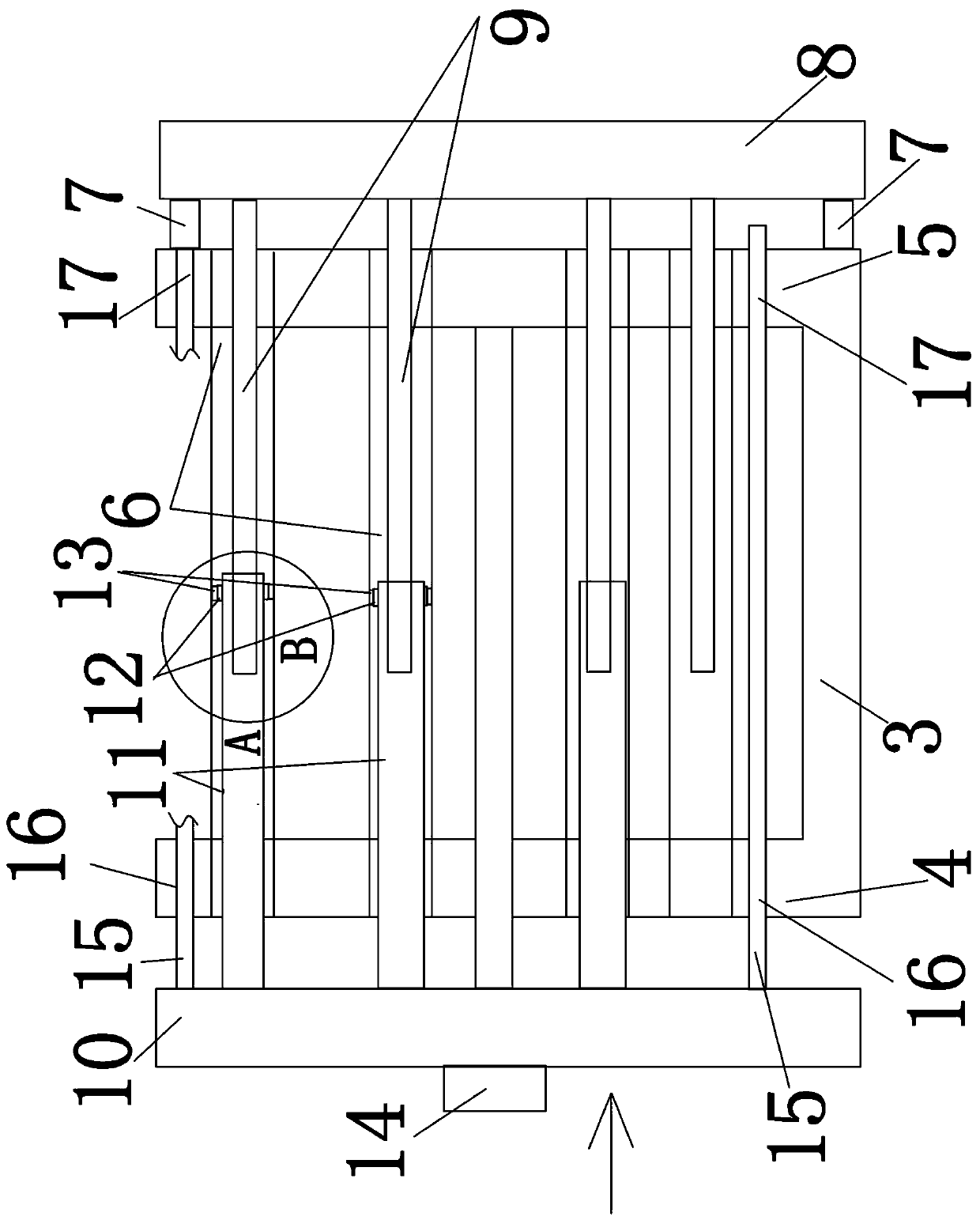

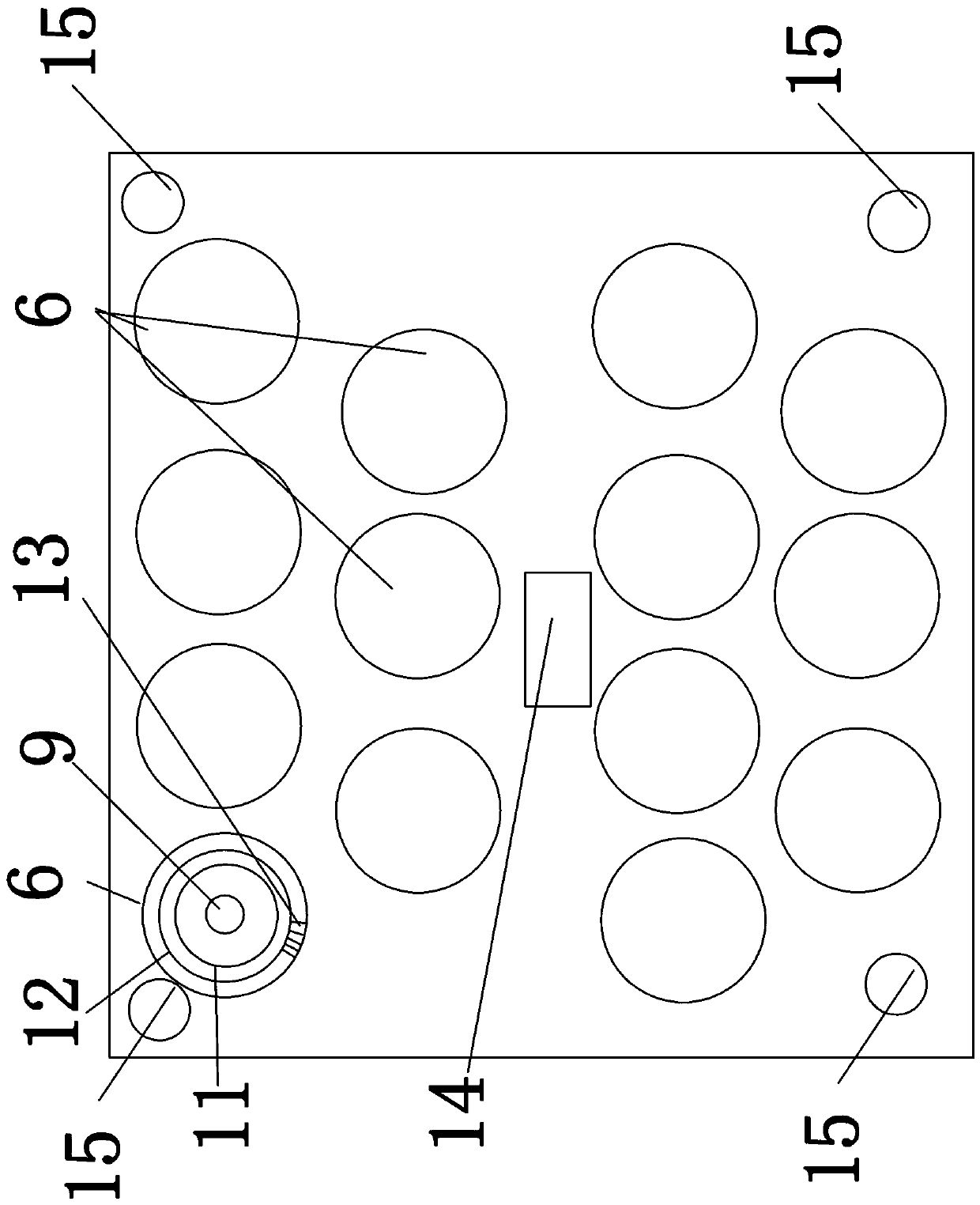

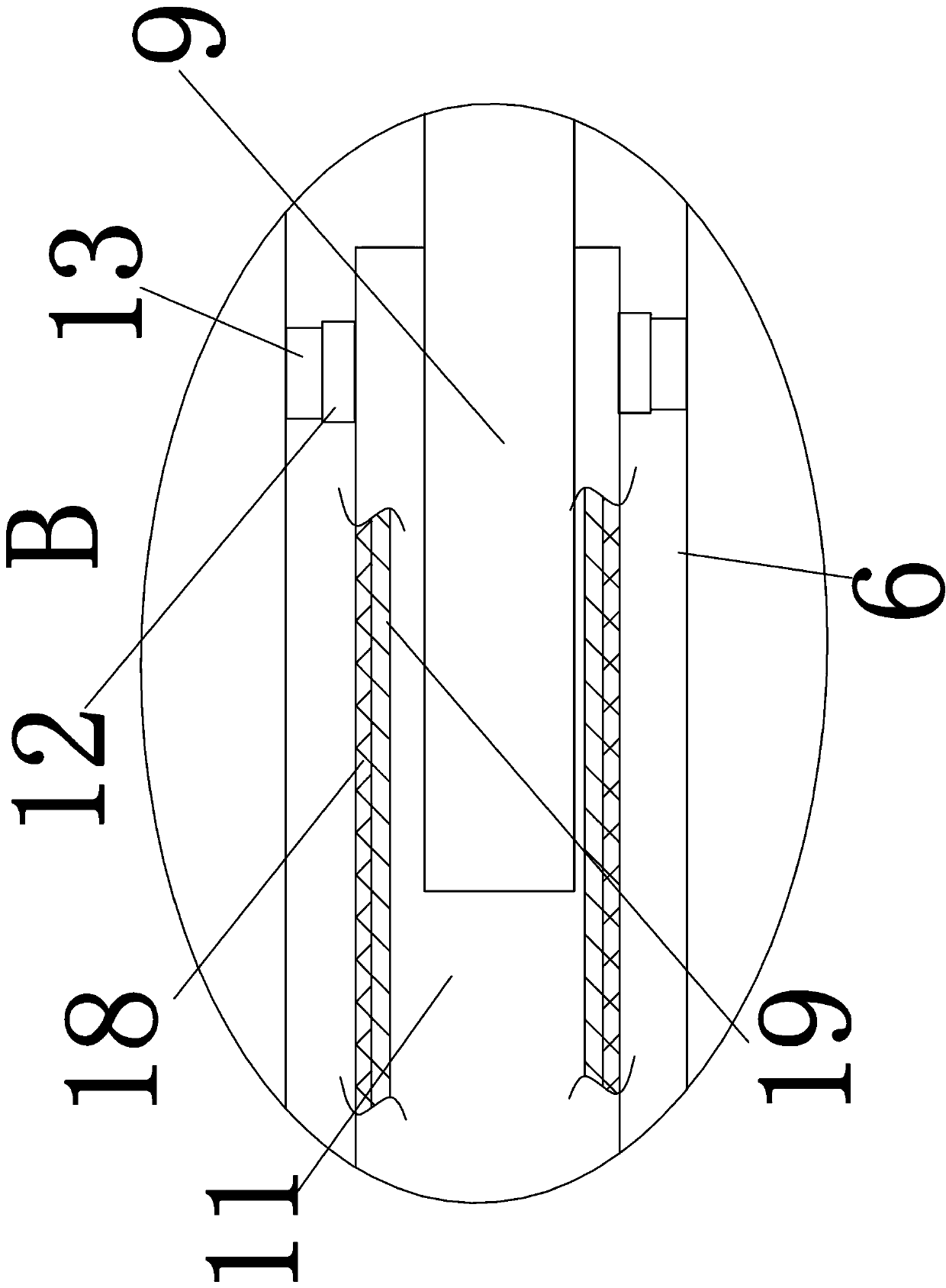

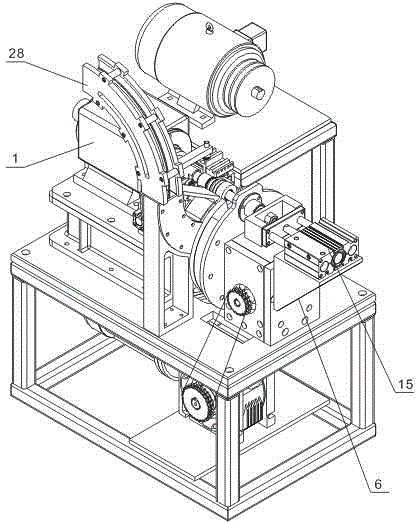

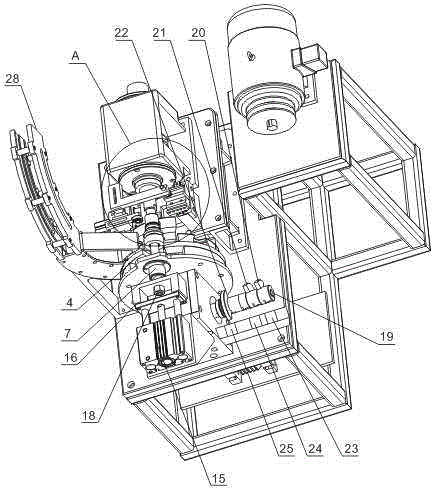

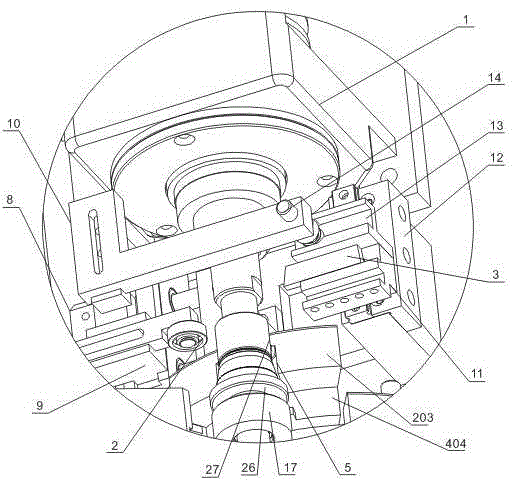

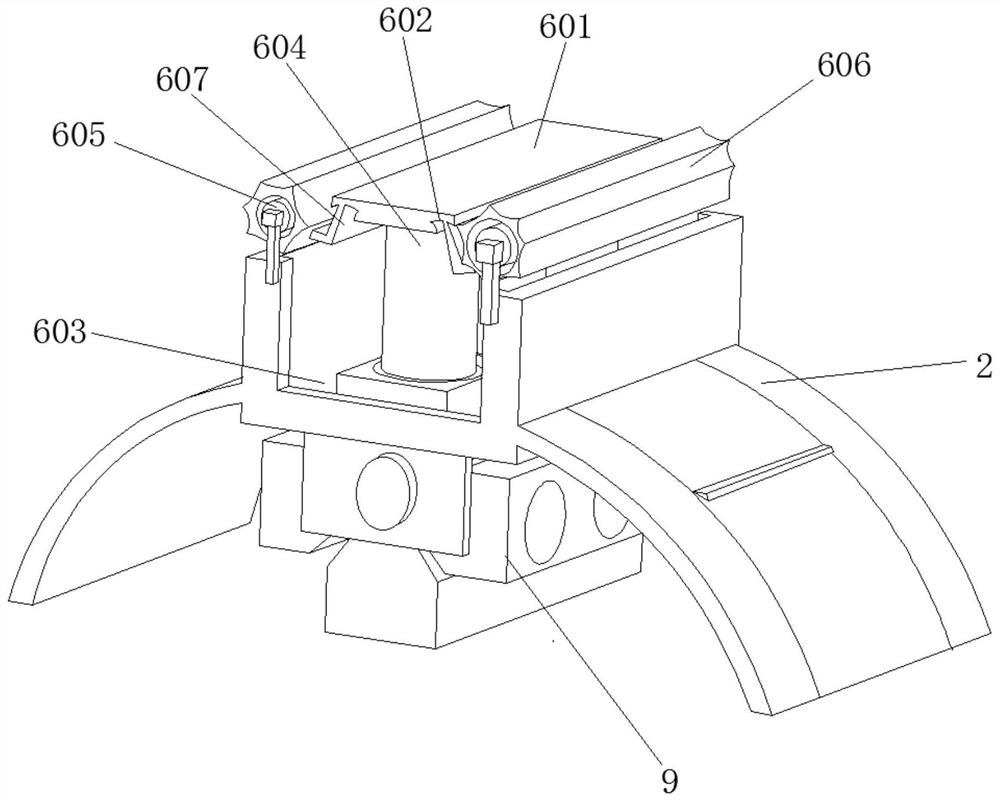

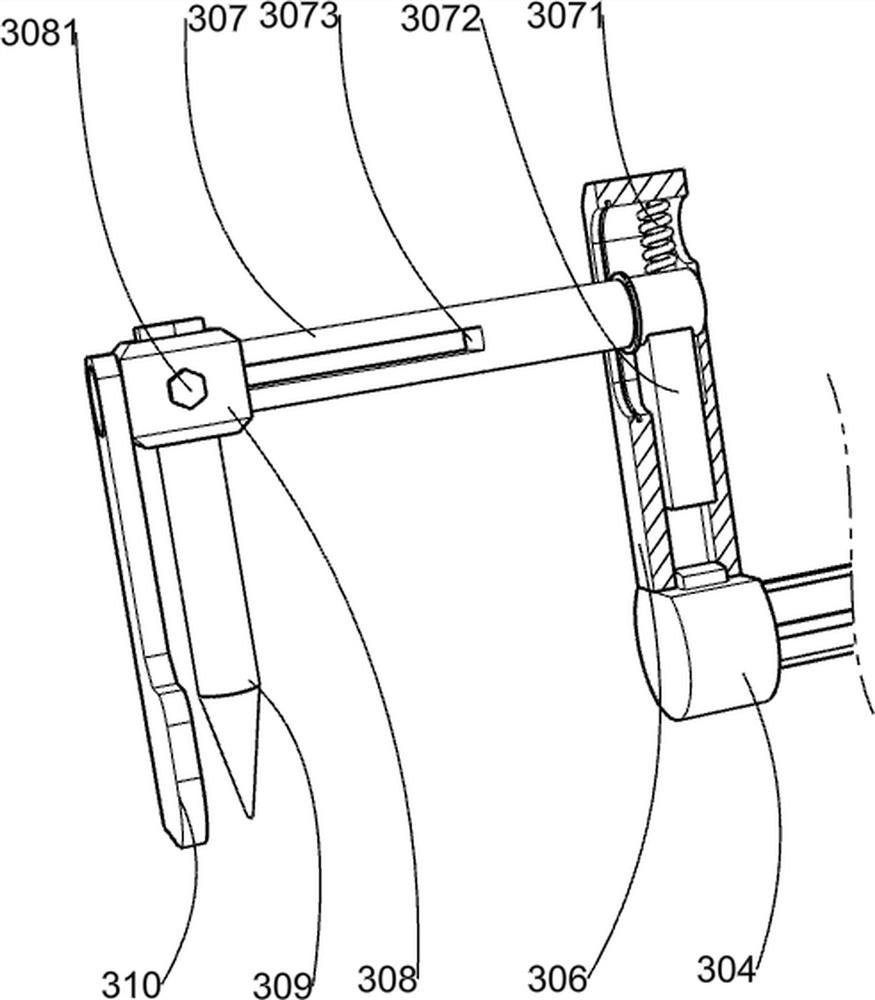

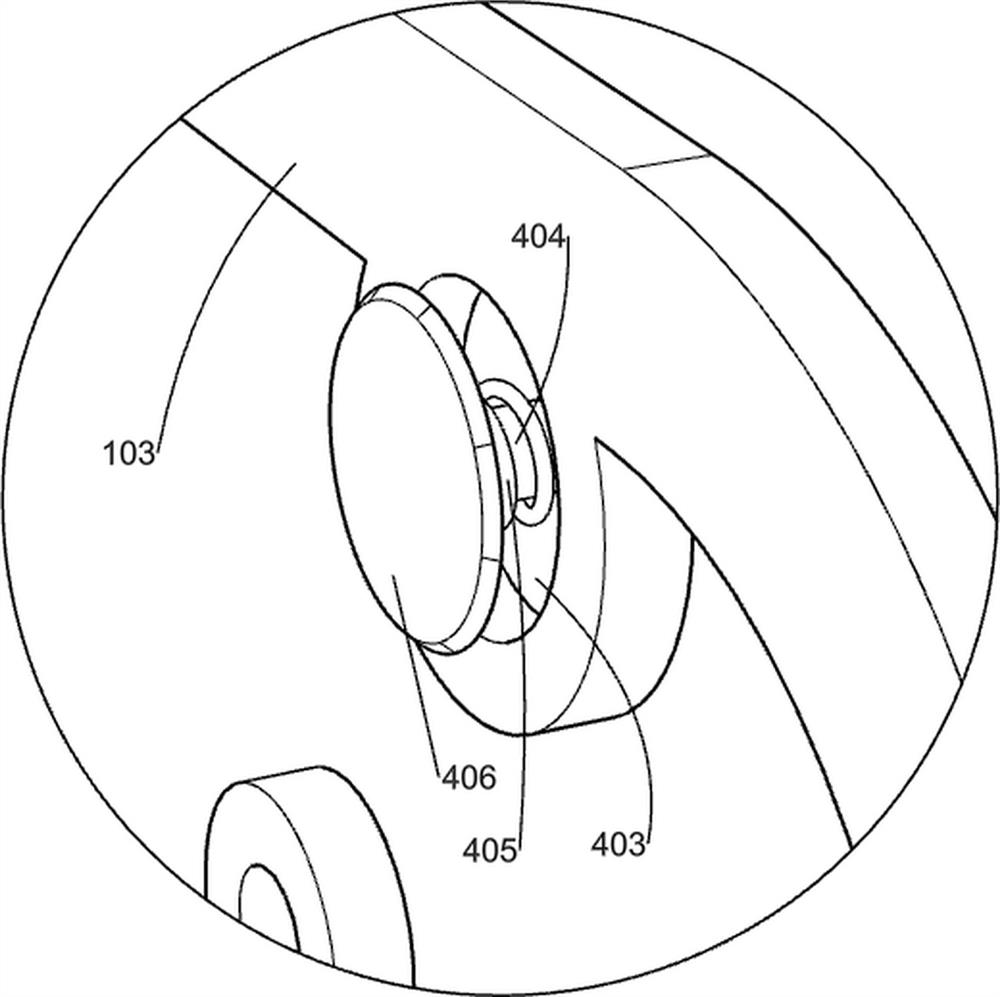

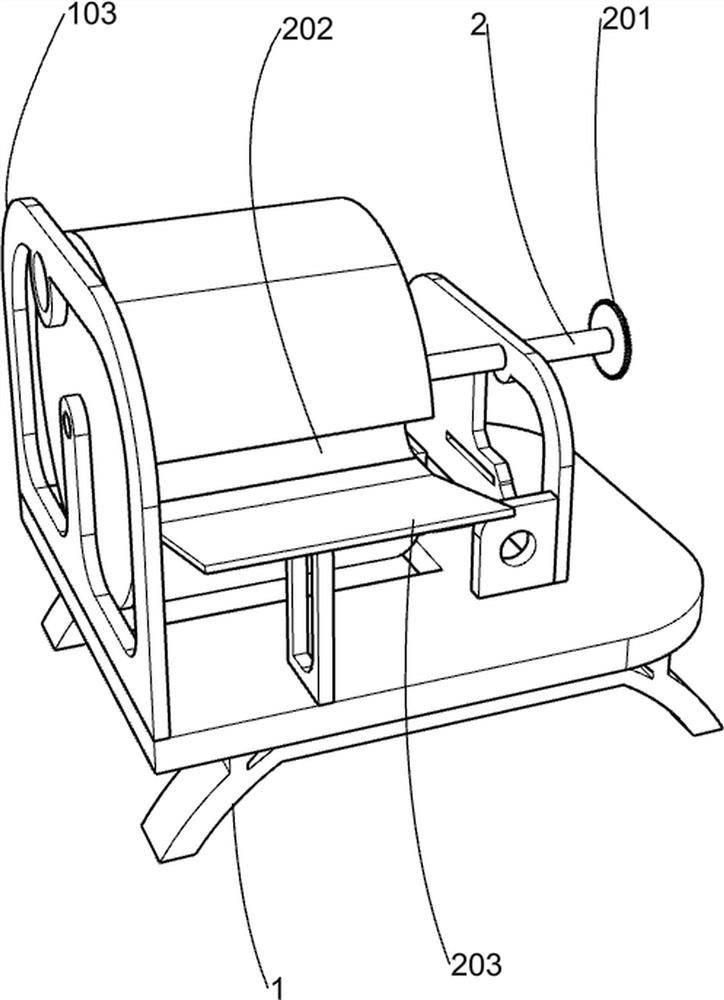

Hemming notch cutting device and method

ActiveCN103639702AFully automatedUninterrupted processingFeeding apparatusOther manufacturing equipments/toolsDrive motorCam

The invention discloses a hemming notch cutting device which comprises a driving motor, a hemming wheel, a cutter, a driving structure A for driving the hemming wheel to move in the radial direction of the output shaft of the driving motor to drive the cutter to move in the axial direction of the output shaft of the driving motor, a workpiece locating disc, a cam divider with an output shaft connected with the workpiece locating disc, a mandril right opposite to the output shaft of the driving motor, a driving structure B for sucking workpieces and driving the mandril to move in the axis direction and a cam control device for controlling the driving structure A and the driving structure B to work, wherein the hemming wheel and the cutter are arranged on two sides of an output shaft of the driving motor. The invention further discloses a hemming notch cutting method. The device and method has the advantages of being high in efficiency, stable in product quality and low in rejection rate compared with traditional manual operation.

Owner:SICHUAN XINGDA PACKAGING EQUIP MFG

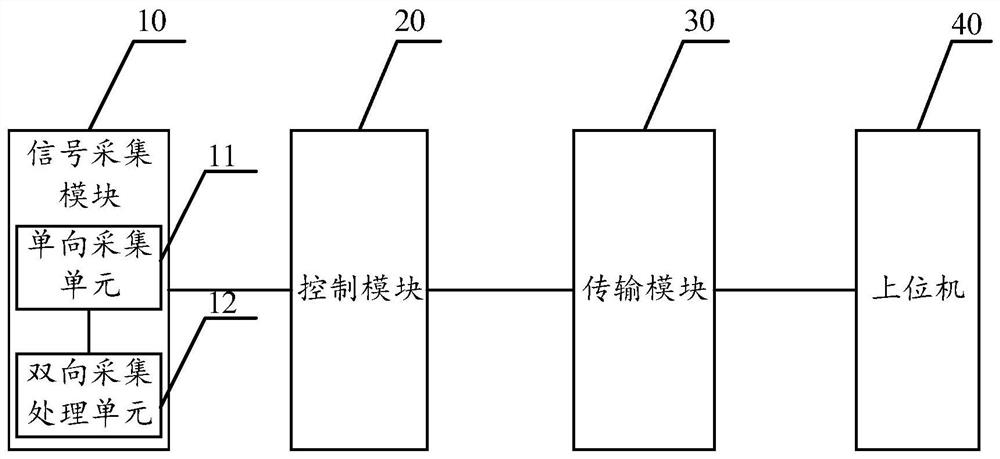

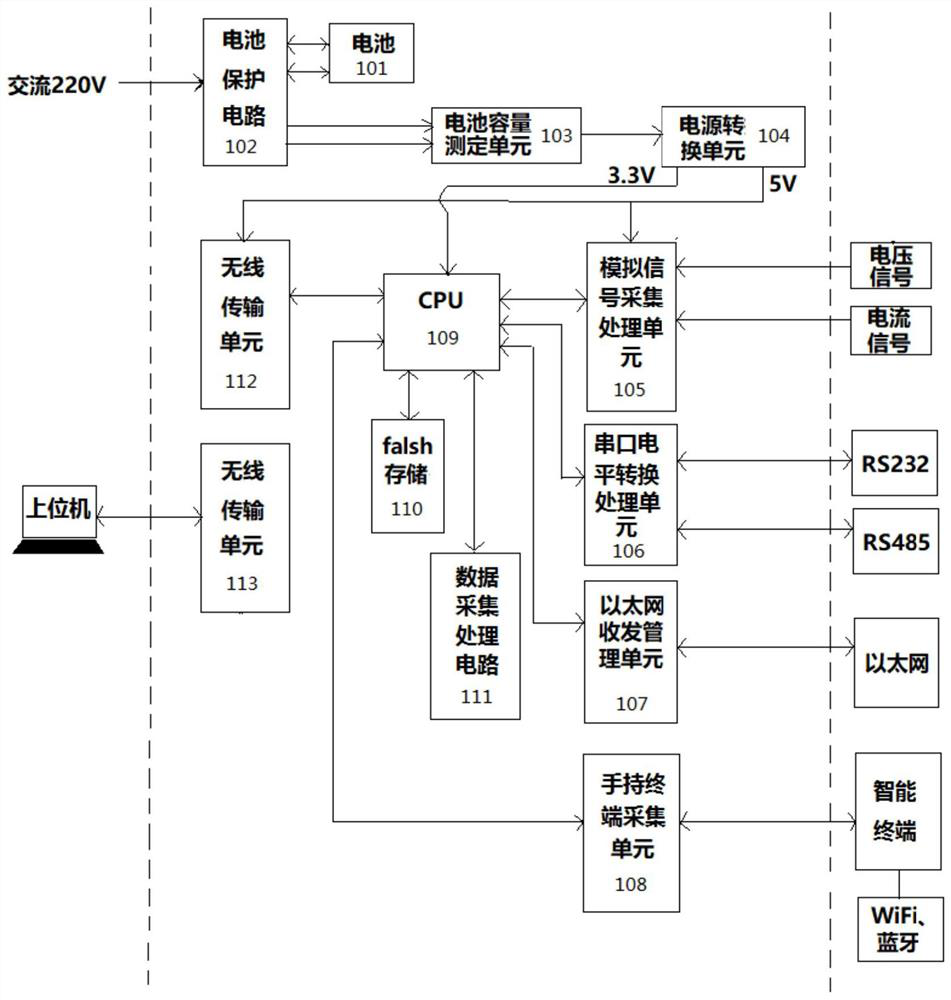

Wireless multifunctional data collector for energy-saving monitoring

ActiveCN113949947AIncrease credibilityIncrease the burdenMain station arrangementsCentralised architecture usageProcessing elementEthernet

The invention relates to a wireless multifunctional data collector for energy-saving monitoring, and the collector comprises a signal collection module which is used for receiving various collected signals, the signal collection module comprising a one-way collection unit and a two-way collection processing unit, the one-way collection unit being used for collecting current, voltage, active power and power factors, two-way collection processing unit comprising a serial port level conversion processing unit, an Ethernet transmit-receive management unit and a hand-held terminal acquisition unit; acontrol module, used for processing the signal received by the signal acquisition module; a transmission module, used for transmitting the signal processed by the control module; and an upper computer, used for receiving the transmitted signal and adjusting the acquisition frequency of the bidirectional acquisition processing unit in the signal acquisition module according to the data volume of the transmitted signal. By effectively adjusting the data volume, the matching between the data processing speed and the accuracy of the evaluation result is realized, so that the energy-saving monitoring process is more efficient actually.

Owner:PETROCHINA CO LTD

Continuous ultrasonic cleaning device

InactiveCN109647794AReduce churnContinuous processingFlexible article cleaningCleaning using liquidsMegasonic cleaningEngineering

The invention relates to a continuous ultrasonic cleaning device. The continuous ultrasonic cleaning device comprises a water box, an upper ultrasonic generator, a lower ultrasonic generator, a plurality of conveying rollers, an inlet gate and an outlet gate; the two ends of the conveying rollers are rotatably installed on the left side wall and the right side wall of the water box, and the conveying rollers are used for conveying glass; the upper ultrasonic generator and the lower ultrasonic generator are arranged in the water box and located above and below the conveying rollers correspondingly; the front side wall of the water box is provided with an inlet for allowing the glass to enter, and the rear side wall of the water box is provided with an outlet for discharging the glass; and the inlet gate is used for closing and opening the inlet, and the outlet gate is used for closing and opening the outlet. The continuous ultrasonic cleaning device can conduct ultrasonic cleaning on the glass under the continuous glass conveying situation and can be compatible and be combined with glass continuous conveying or glass roller brushing of other glass processing procedures, so that themachining process is continuous and ceaseless, additional clamping, moving and other operation are not needed, and the working efficiency is improved.

Owner:福州东旭光电科技有限公司 +2

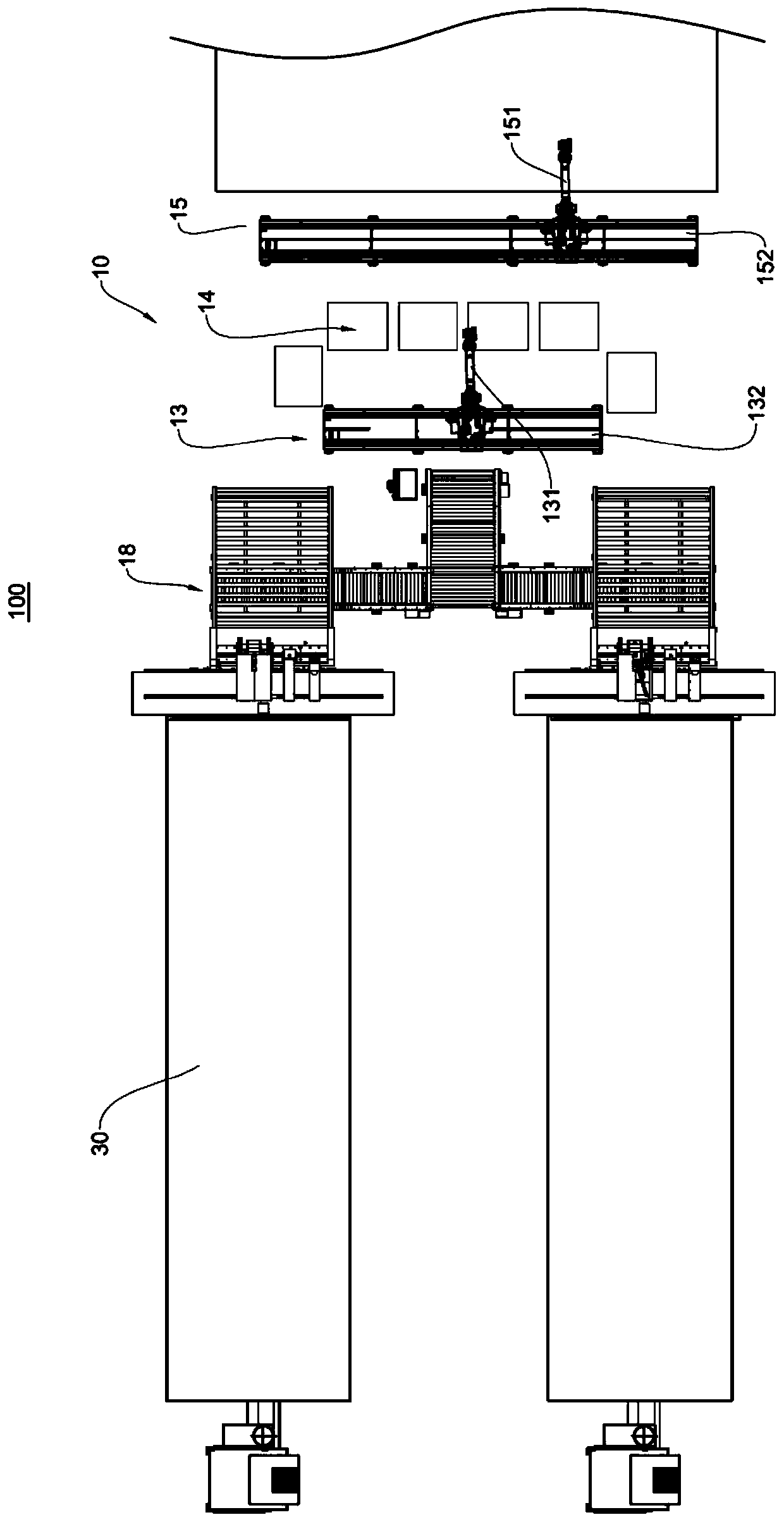

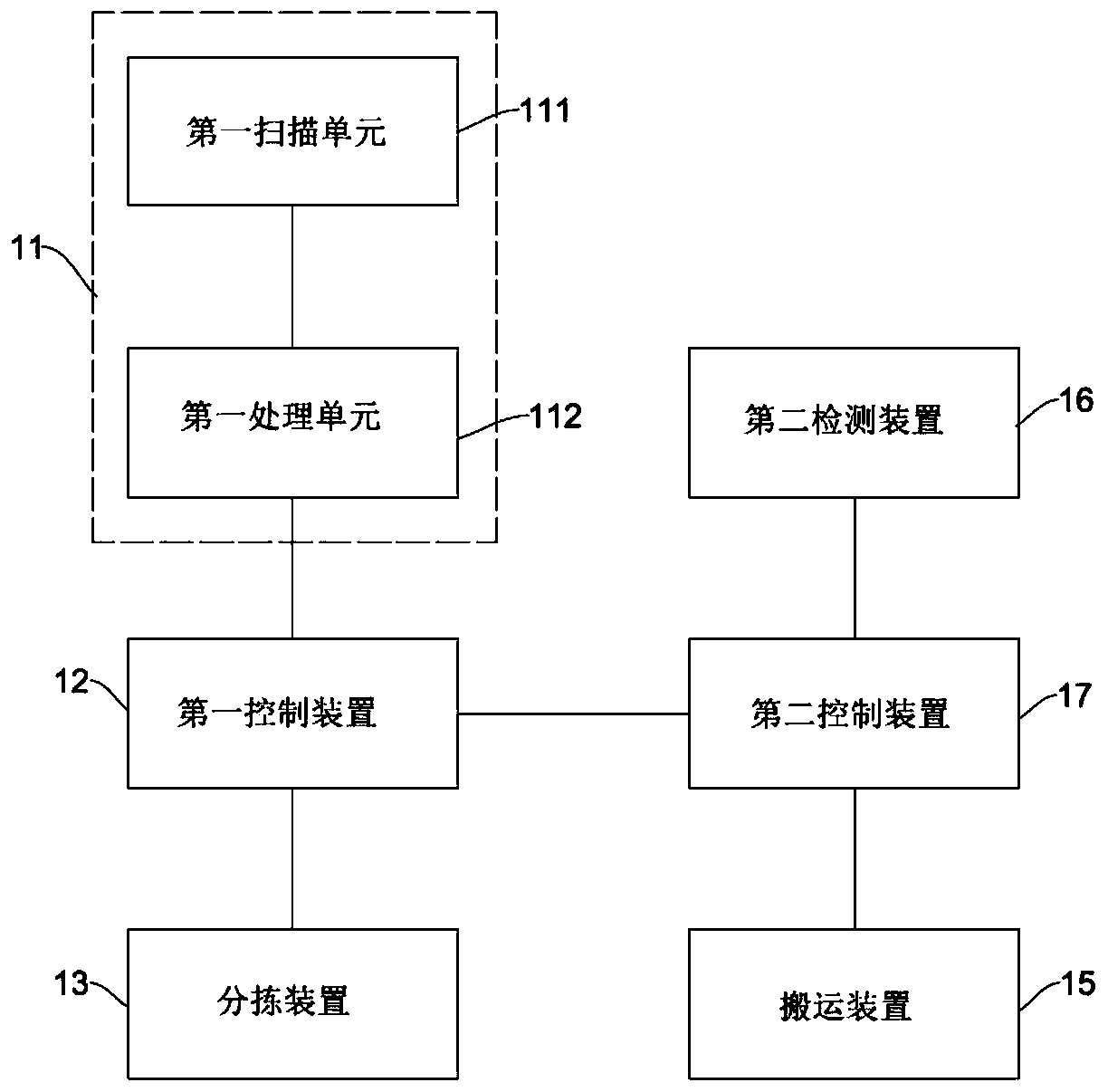

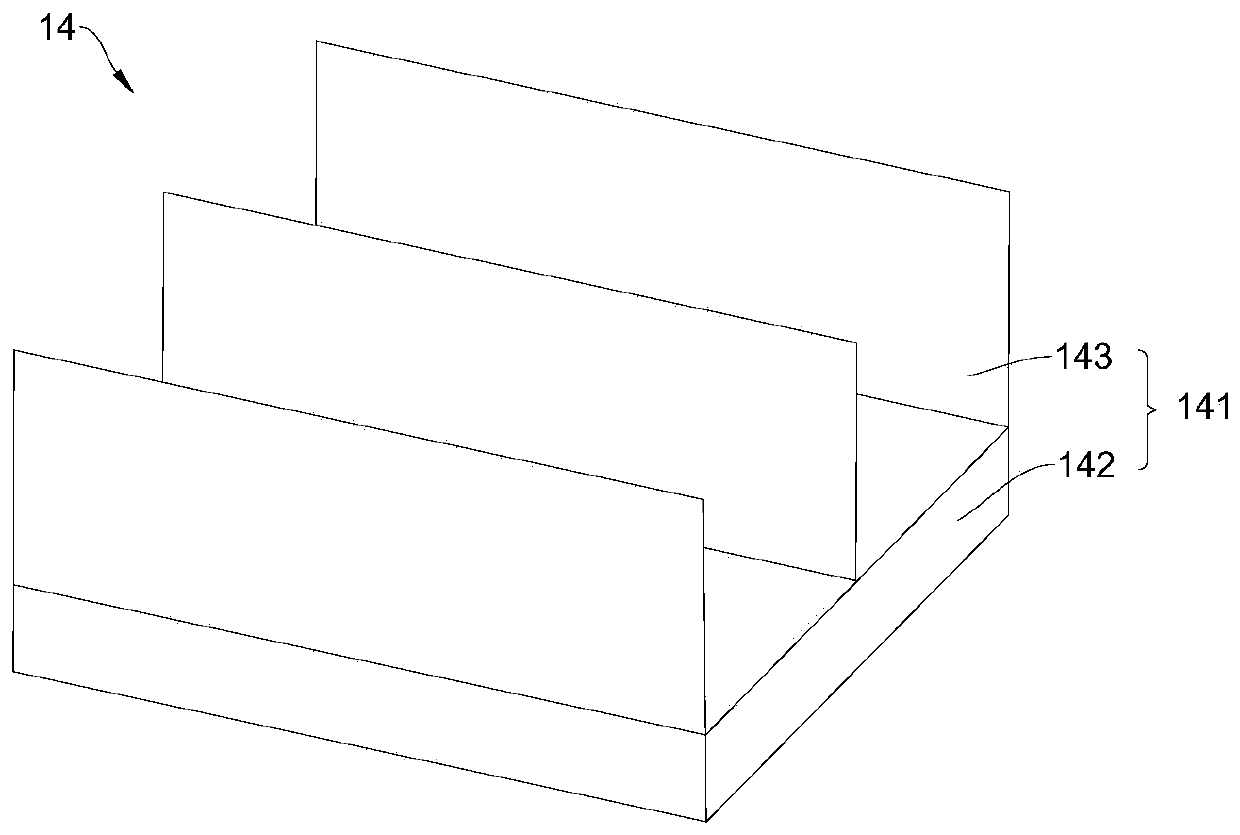

Sorting and conveying system and steel plate production line

The embodiment of the invention provides a sorting and conveying system and a steel plate production line, and belongs to the technical field of steel plate machining. The sorting and conveying systemis used for the steel plate production line; the steel plate production line comprises a machining center, wherein the machining center is used for machining and outputting steel plates; the sortingand conveying system comprises a first detection device, a first control device, a sorting device and a plurality of storage devices; the first detection device and the sorting device are correspondingly in communication with the first control device; the first detection device is used for scanning and identifying the shape of the steel plate output by the machining center and outputting a corresponding first signal; the first control device is used for controlling the sorting device according to the first signal; and the sorting device is used for transferring the steel plate into the corresponding storage device under the control of the first control device. The sorting and conveying system can automatically complete the sorting and conveying work of the special-shaped steel plates, thelabor intensity of workers can be reduced, and the quality control of manufacturing is enhanced.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

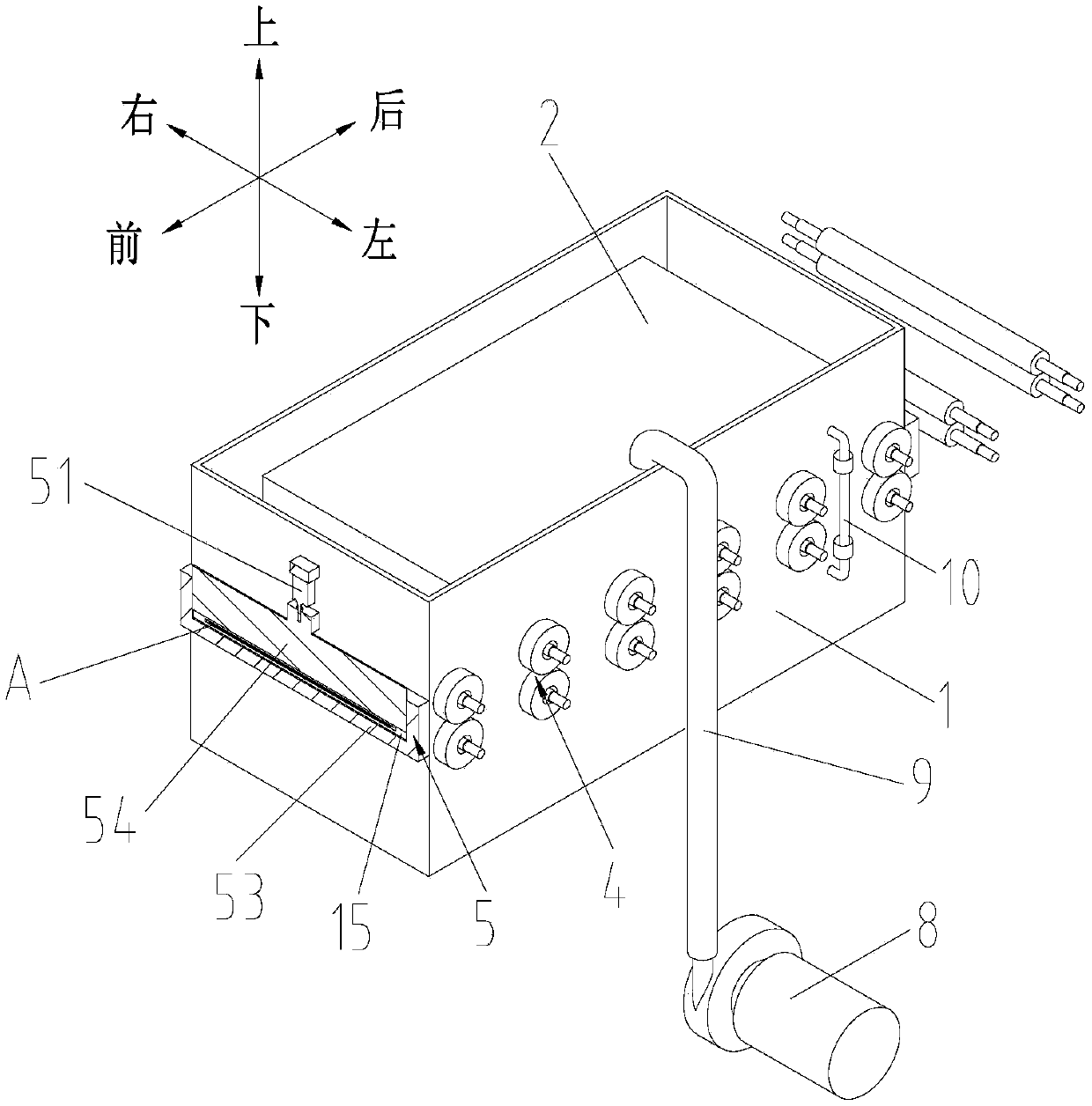

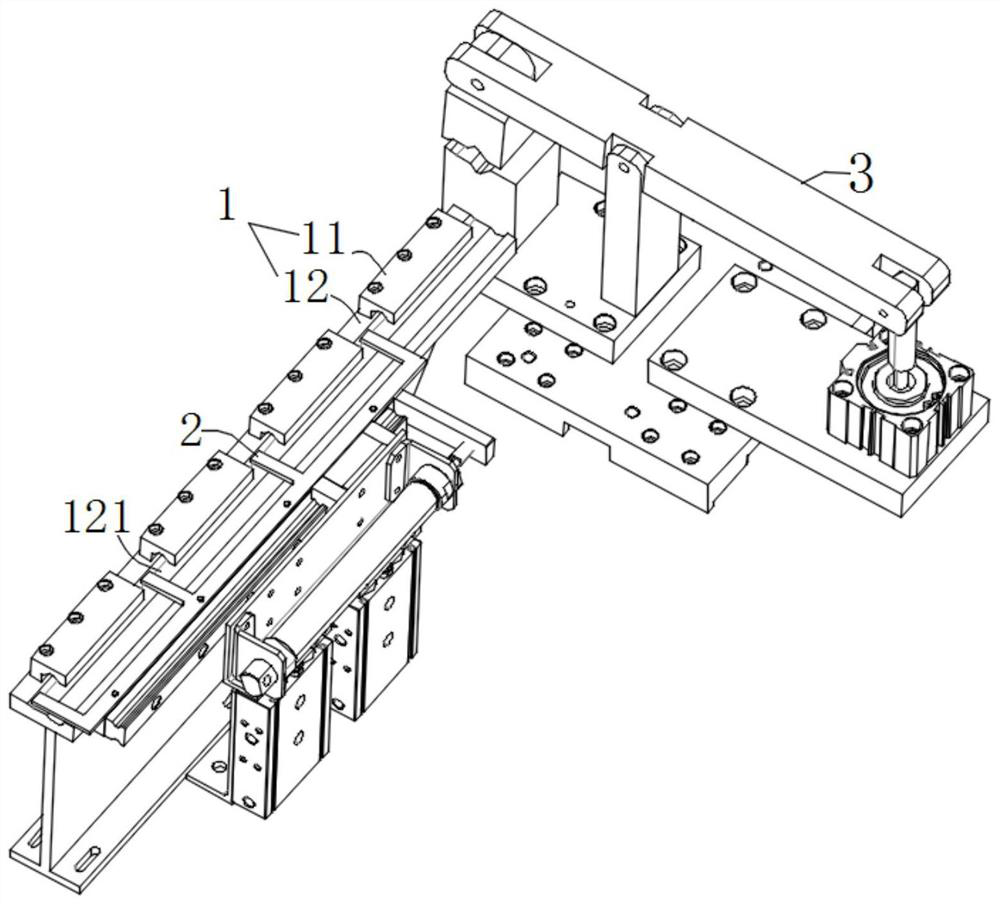

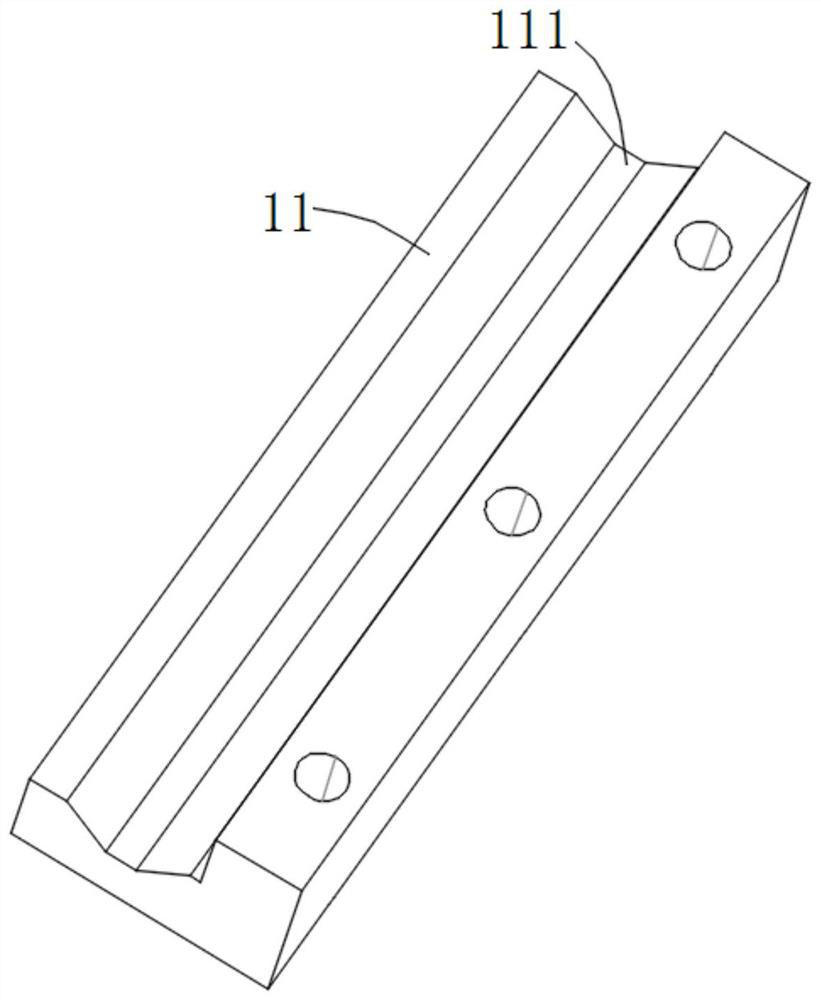

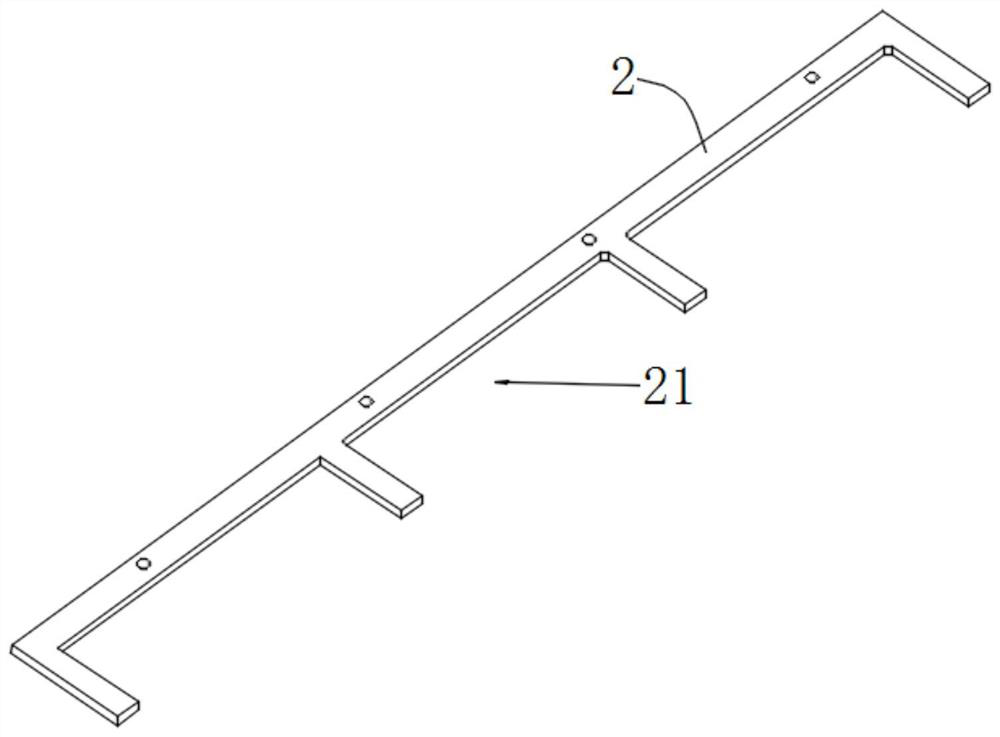

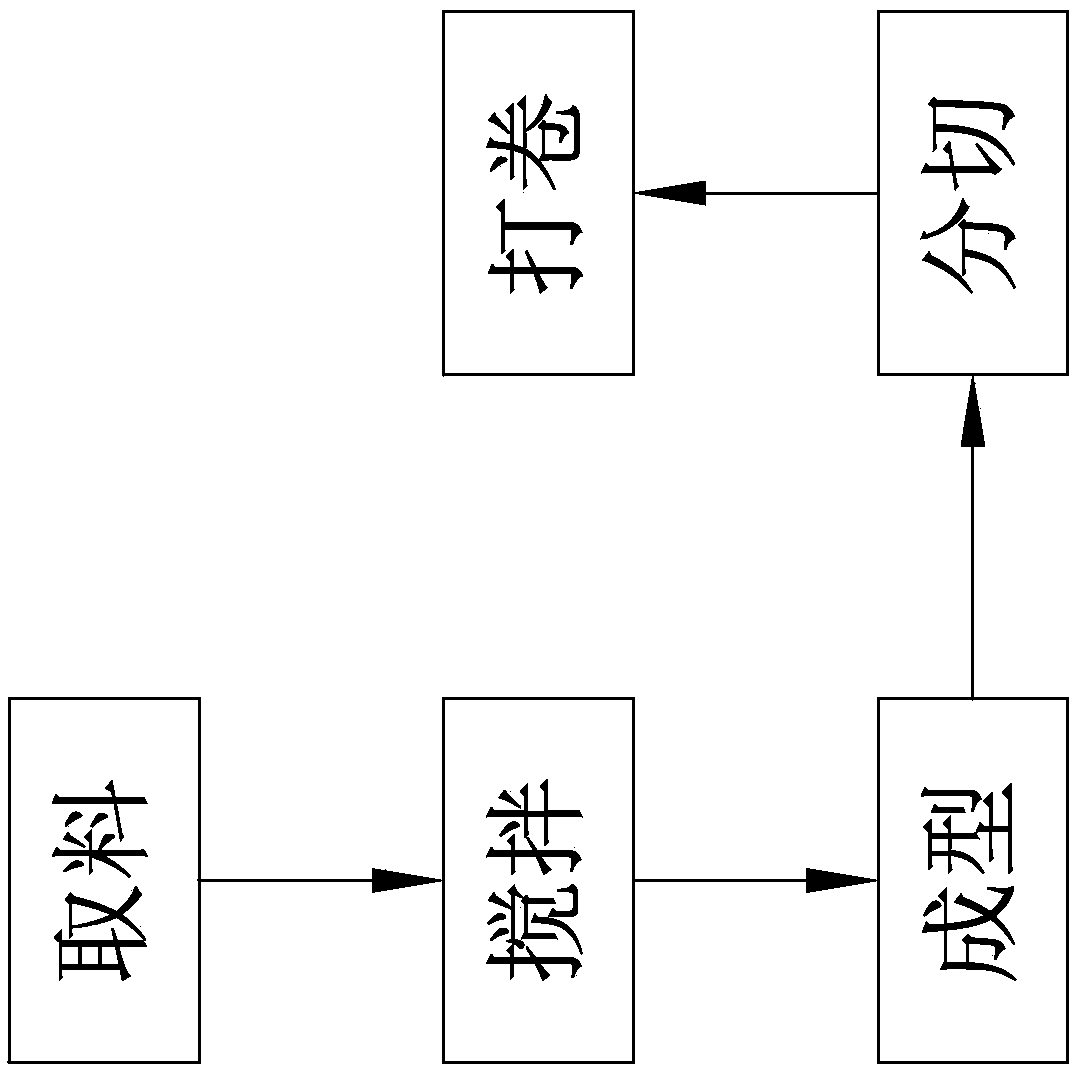

Material transferring device, drilling mechanism and processing center

PendingCN111673141AUninterrupted productionContinuous uninterrupted feedingMetal working apparatusBoring/drilling machinesThermodynamicsProcess engineering

The invention relates to the field of workpiece processing and manufacturing, in particular to a material transferring device, a drilling mechanism and a processing center. A material transferring device comprises a carrier, a drive member, a transferring module and a compressing part, wherein the carrier extends along a feeding direction, and the tail end of the carrier located in the feeding direction is provided with a transferring area; the drive member is used for driving a workpiece to move along the feeding direction; the transferring module is used for clamping the workpiece, the transferring module is configured to be installed linearly, and the transferring module moves between the transferring area and a processing station; the transferring module comprises a receiving part, andthe receiving part and a carrying surface of the carrier are on a same horizontal plane; and the compressing part is used for compressing and fixing the workpiece. According to the invention, the technical problems of impossible continuous production, low degree of automation and low efficiency when the workpiece is processed, a conveying device needs to be stopped in a lock workpiece productionline in the prior art.

Owner:JIANGSU UNIV OF TECH

Degradable bubble protective film and processing method thereof

InactiveCN109384987APromote degradationPromote environmental protectionLow-density polyethyleneTectorial membrane

The invention provides a degradable bubble protective film and a processing method thereof. The degradable bubble protective film of the invention solves the technical problems that conventional bubble protective films cannot be degraded, easily cause white pollution, has poor environmental protection performance and the like. The degradable bubble protective film of the invention is composed of the following components by weight: 60-80 parts of low-density polyethylene, 3-5 parts of an antioxidant, 1.5-2.5 parts of a plasticizer and 2.4-4.6 parts of a biodegradable additive. The degradable bubble protective film of the invention has the advantages of good environmental protection performance.

Owner:TONGXIANG KAIRUI PACKAGING MATERIAL

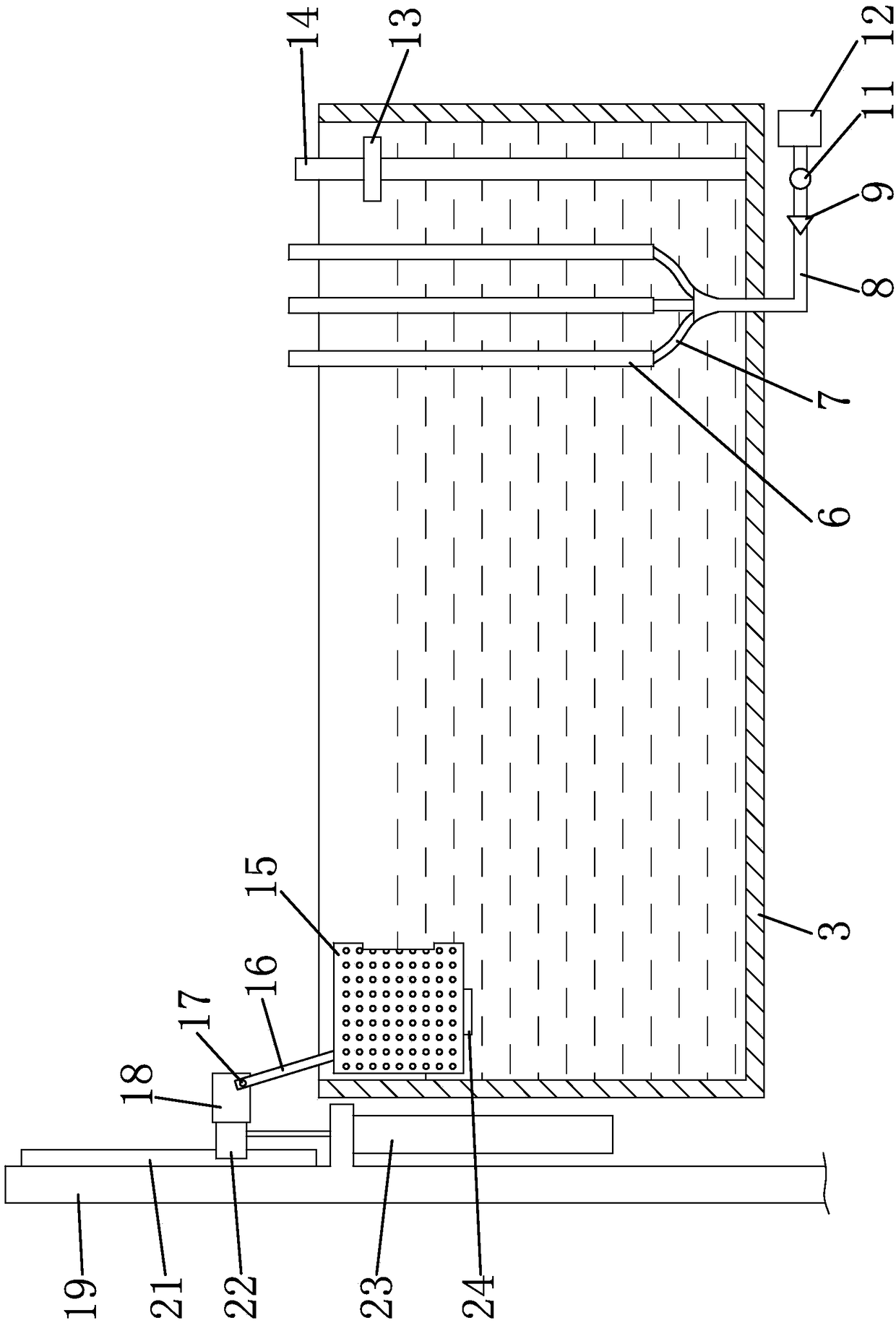

Low-temperature flue gas ozone denitration system

PendingCN110394044AImprove processing efficiencySmall footprintGas treatmentDispersed particle separationFlue gasNitrogen oxide

The invention discloses a low-temperature flue gas ozone denitration system, and belongs to the field of flue gas denitration. The low-temperature flue gas ozone denitration system comprises a spray purification tower; an ozone feeding and mixing device is connected to an inlet of the spray purification tower; an ozone device of which the output end is connected with the ozone feeding and mixing device; a waste gas inlet pipe connected with the ozone feeding and mixing device; an air outlet pipe connected to the upper end of the spray purification tower; a circulating water tank, of which thewater outlet end is connected with the spray pipe in the spray purification tower and the water inlet end is connected to the lower end of the spray purification tower. The waste gas inlet pipe is connected to a smoke outlet of the heat treatment furnace for cooling the flue gas to below 80 DEG C and feeding the flue gas into the ozone feeding and mixing device; meanwhile, ozone is generated through the ozone device, is conveyed into the ozone feeding and mixing device and is absorbed by an alkaline solution through the spraying purification tower, so that denitration is achieved. The system is small in occupied area, small in investment and high in low-concentration nitrogen oxide treatment efficiency.

Owner:广州格邦机械工程有限公司

Vacuum food processing device

InactiveCN112357214AReduce the number of times you add to the bagIncrease productivityPackaging by pressurising/gasifyingLoading/unloadingElectric machineryProcess engineering

The invention discloses a vacuum food processing device, and relates to the technical field of food processing. The vacuum food processing device comprises a fixed base, a feeding box, a material taking assembly, a conveying disc, a vacuum sealing machine and a finished product placing box. The top of the fixed base is fixedly provided with a first fixed rod, and the top of the first fixed rod isfixedly provided with a first motor. The feeding box is fixedly installed on an output shaft of the first motor, the first motor can drive the feeding box to rotate, containing grooves are formed in the feeding box and used for containing packaging bags, the positions of all the containing grooves can be switched through the rotating feeding box, and enough packaging bags can be contained in all the containing grooves at a time in actual use. The number of times of adding the packaging bags is reduced, the production efficiency is improved, the top of the fixed base is welded with a support frame, and one side of the top of the support frame is fixedly provided with a second motor. According to the device, the production efficiency is high, the occupied area is small, the integration degree is high, operation is easy, the finished product quality is higher, and the practical value is high.

Owner:丰城市子龙冻米糖厂

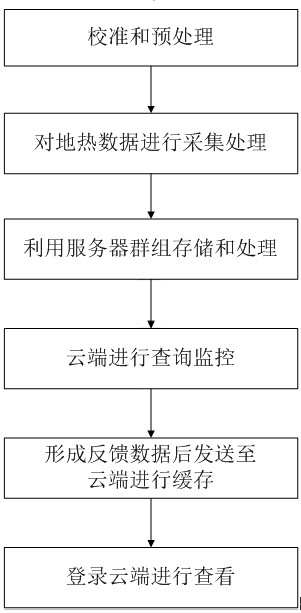

A geothermal monitoring system and method

ActiveCN114629890BAchieve no lossImplement updateError preventionGeothermal energy generationThermodynamicsMonitoring system

A geothermal monitoring system and method, the system includes a client terminal, a communication network, a cloud and a server group, and a plurality of monitoring terminals, wherein the server group is respectively connected to the cloud, a plurality of monitoring terminals through the communication network, and the cloud and the client terminal are connected. The connection can realize fast and accurate real-time monitoring of geothermal heat, and use cloud technology to achieve safe and reliable, fast and efficient continuous data processing, improve efficiency and save costs.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队 +3

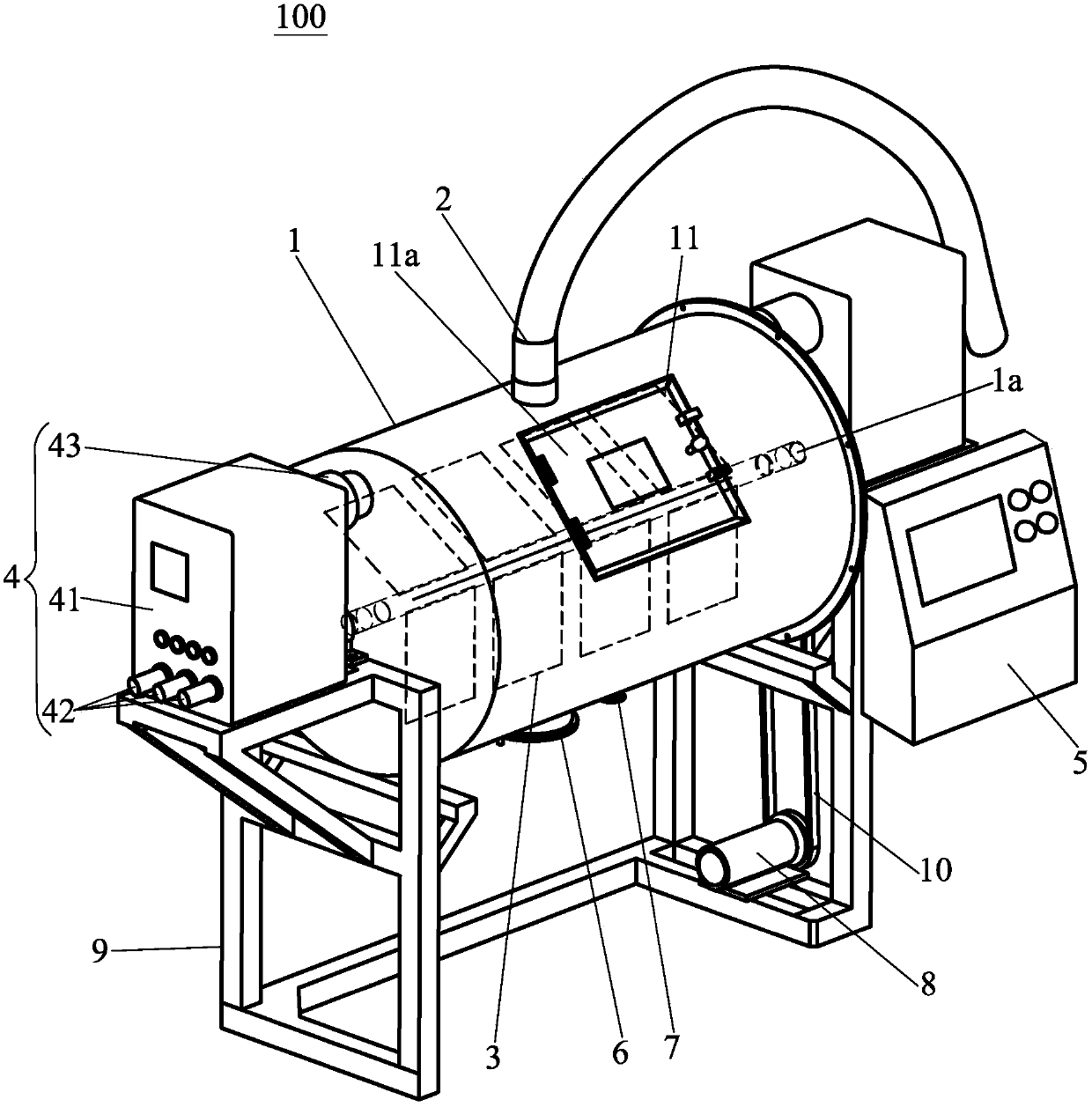

Atmospheric pressure plasma particle polymer material processing equipment

The invention discloses an atmospheric pressure plasma particle polymer treatment device. The device comprises a tank, wherein an argon inlet is connected to the tank and a stainless steel stirring paddle is installed in the tank, an atmospheric pressure jet processor, wherein the atmospheric pressure jet processor comprises a power supply, an inlet and a spray gun, the power supply provides powder for the atmospheric pressure jet processor, plasma, water and gas fed through the inlet are treated and then are sprayed through the spray gun and the spray gun is seal-connected to the tank, and an automatic control and induction system, wherein the system comprises a temperature sensing unit, a data acquisition unit and a control unit, the temperature sensing unit is arranged in the tank and can detect a temperature in the tank, the detected data is transmitted to the control unit through the data acquisition unit and the control unit determines if the atmospheric pressure jet processor needs to be started to carry out plasma water cooling injection in the tank. The invention provides an atmospheric pressure plasma treatment method and device for a particle polymer.

Owner:长沙立兴环保科技有限公司

An underground space environment monitoring system and method

ActiveCN114689129BAchieve no lossImplement updateMeasurement devicesTotal factory controlTelecommunications linkDynamic monitoring

An underground space environment monitoring system and method relate to the field of underground environment monitoring and are applied to underground space environment monitoring, wherein the system setting is applied to a server, and the server is connected to a terminal device through a network, wherein the network is used to connect between the terminal device and the server Provide a communication link; the system includes a monitoring center, a monitoring terminal, a multi-channel transmission interface, a standard sensing device and a plurality of monitoring and sensing devices, the monitoring center, the monitoring terminal and the multiple monitoring and sensing devices are respectively connected with the multi-channel transmission interface, the The system can solve the problem of fast and accurate real-time monitoring of the underground space environment, realize uninterrupted and continuous data processing quickly and efficiently, improve efficiency while saving costs, and solve the problem that the previous single function could not achieve fast and accurate dynamic monitoring.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队 +2

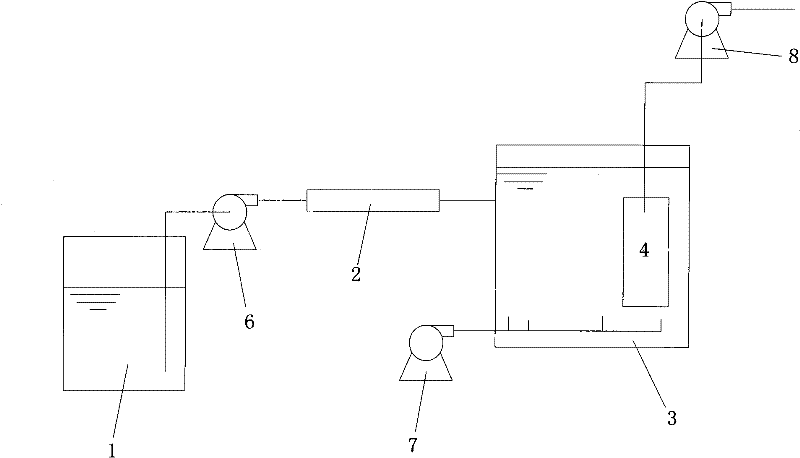

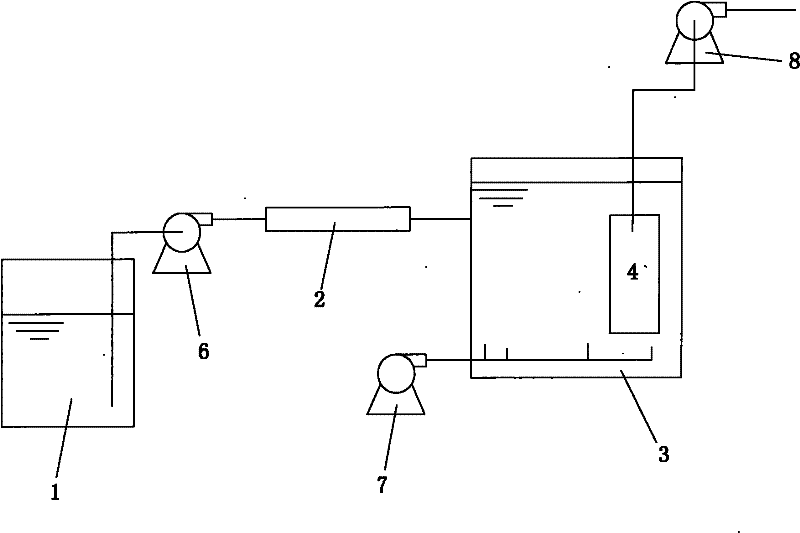

Method for treating paper-making wastewater by utilizing photocatalytic oxidation film coagulation reactor

InactiveCN101863571BUninterrupted processingImprove water chemical reactivityEnergy based wastewater treatmentMultistage water/sewage treatmentChemical reactorCatalytic oxidation

The invention provides a method for treating paper-making wastewater by utilizing a photocatalytic oxidation film coagulation reactor, which relates to a wastewater treating method, and provides a method for treating paper-making wastewater by utilizing a photocatalytic oxidation film coagulation reactor and a device thereof. The device is provided with a photocatalytic oxidation reactor and a film coagulation reactor; and the water outlet end of the photocatalytic oxidation reactor is communicated with the water inlet end of the film coagulation reactor. The paper-making wastewater is conveyed into the water inlet end of the oxidation reactor of the photocatalytic oxidation film coagulation reactor wastewater treating device by a water inlet system, and the water outlet end of the photocatalytic oxidation reactor is communicated with the water inlet end of the film coagulation reactor; after a water inlet pump of the water inlet end of the photocatalytic oxidation reactor is started, the photocatalytic oxidation reactor is started; a water treatment agent is thrown into a chemical reactor of the film coagulation reactor, an air pump is started for aeration so as to form suspended solids in the paper-making wastewater to form floc under the function of the water treatment agent, and then the floc is removed; and the normal working state of the photocatalytic oxidation film coagulation reactor wastewater treating device is maintained.

Owner:厦门凯瑞尔数字环保科技有限公司

Electrostatic composite intelligent cleaning type waste gas purification device

PendingCN111437995AReduce the burden onExtended service lifeExternal electric electrostatic seperatorElectrode constructionsProcess engineeringStructural engineering

The invention provides an electrostatic composite intelligent cleaning type waste gas purification device. A bracket is provided with a front pattern plate and a rear pattern plate which are arrangedin parallel, and a plurality of anode cylinders are arranged between the two. A cathode frame and a plurality of cathode rods are arranged on the rear side of the rear pattern plate; the cathode rodsforwards extend into the corresponding anode cylinders; a cylinder pushing frame is arranged in front of the front pattern plate; a plurality of push cylinders are fixed behind the push cylinder frame, extend backwards into the corresponding anode cylinders and are arranged on the outer sides of the corresponding cathode rods in a sleeving manner; a pushing device is arranged between the cylinderpushing frame and the bracket; piston rings are arranged on the rear outer sides of the push cylinders; annular wipers are arranged on the outer side of piston rings; each push cylinder comprises an insulating outer-layer cylinder body and a lining metal layer; and the annular wipers outside the piston rings can clean the inner walls of the anode cylinders. Plasma and an electrostatic field act together to purify waste gas, the purification capacity is higher, the purification efficiency is higher, the service life is longer, and equipment operation is more stable.

Owner:辽宁国泰众欣环保科技有限公司

Curling incision device and method

ActiveCN103639702BFully automatedUninterrupted processingFeeding apparatusOther manufacturing equipments/toolsDrive motorCam

The invention discloses a hemming notch cutting device which comprises a driving motor, a hemming wheel, a cutter, a driving structure A for driving the hemming wheel to move in the radial direction of the output shaft of the driving motor to drive the cutter to move in the axial direction of the output shaft of the driving motor, a workpiece locating disc, a cam divider with an output shaft connected with the workpiece locating disc, a mandril right opposite to the output shaft of the driving motor, a driving structure B for sucking workpieces and driving the mandril to move in the axis direction and a cam control device for controlling the driving structure A and the driving structure B to work, wherein the hemming wheel and the cutter are arranged on two sides of an output shaft of the driving motor. The invention further discloses a hemming notch cutting method. The device and method has the advantages of being high in efficiency, stable in product quality and low in rejection rate compared with traditional manual operation.

Owner:SICHUAN XINGDA PACKAGING EQUIP MFG

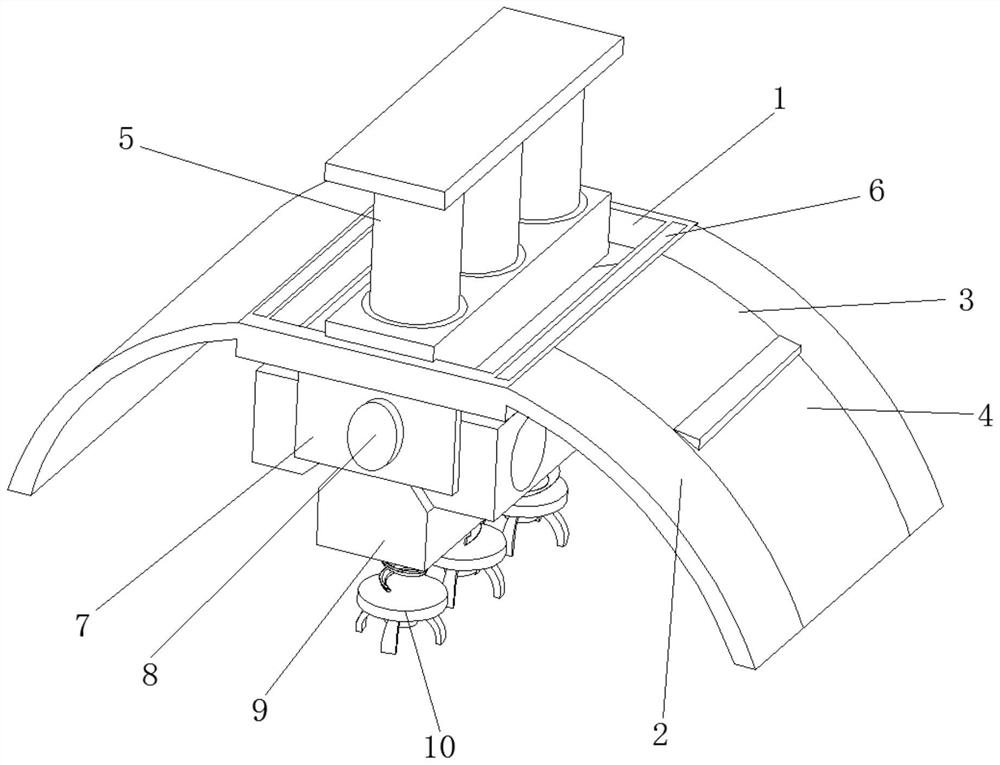

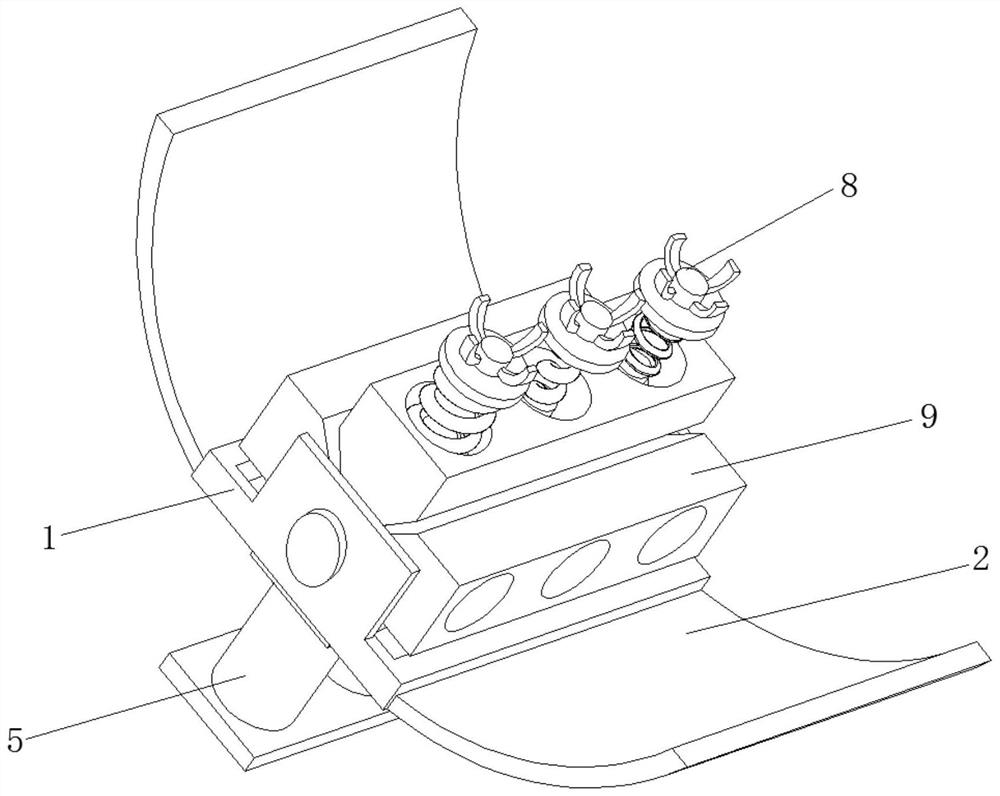

Treatment equipment for solid waste pollution

ActiveCN113732012AReduce moisture contentReduce processing stepsSpecific water treatment objectivesSolid waste disposalWater storageSewage

The invention discloses treatment equipment for solid waste pollution, and relates to the technical field of solid waste pollution. The treatment equipment for solid waste pollution comprises a fixing frame, arc-shaped supporting plates are fixedly connected to the left side and the right side of the fixing frame, fixing grooves are formed in the outer surfaces of the arc-shaped supporting plates, a water storage mechanism is fixedly connected to the inner surfaces of the fixing grooves, a compaction column is slidably connected to the inner surface of the fixing frame, and a stabilizing mechanism is movably connected to the fixing frame. A plurality of compaction bins are arranged in the equipment, a large-volume machining mode is changed into a one-by-one small-volume machining mode, when liquid in solid waste is separated, the interior of the solid waste can be compacted and formed at the same time, and in the process that the equipment extrudes the solid waste, internal water can directly enter the water storage mechanism and can be mixed with a solvent arranged in the water storage mechanism by utilizing water pressure, so that the sewage is diluted, deodorized and the like, and meanwhile, the water content in the solid waste is reduced.

Owner:厦门易富通科技有限公司

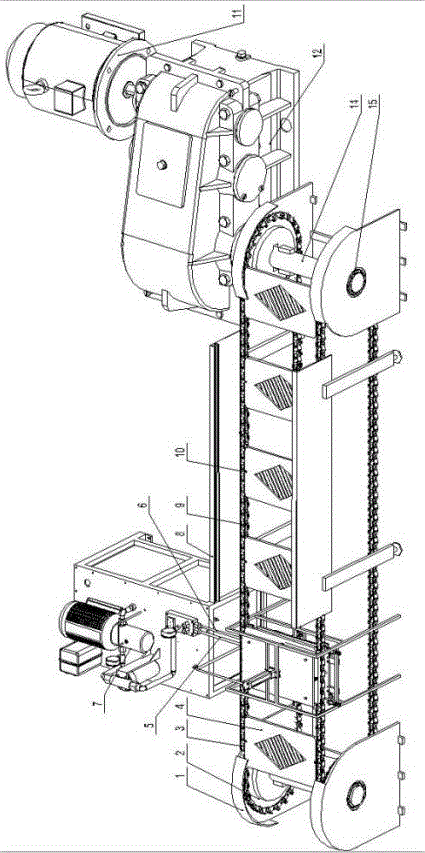

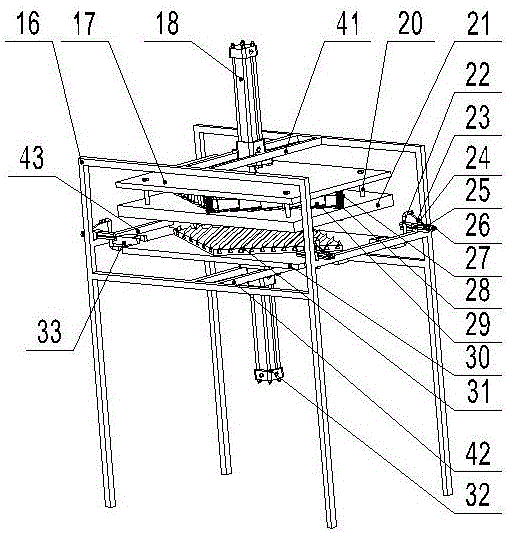

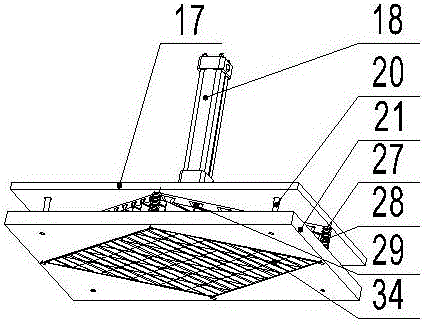

An automatic forming machine for tofu string

The invention discloses an automatic forming machine of a bean curd string. The machine comprises a chain plate conveying mechanism, a flower cutting mechanism and a power mechanism, and is reasonable in structure, low in equipment manufacturing cost and simple in operation; the cutting of a whole board of bean curds and the double-surface flower cutting process can be realized in one station; the automation degree is high; the bean curds have no need to be overturned; automatic unloading can be realized after the flower cutting is finished, so that the processing time is saved, the processing efficiency can be greatly improved, and the operation is safe and reliable; and a chain plate is used for conveying, so that the conveying is reliable, and continuous processing operation can be realized. Edge beams positioned at two sides of a chain are arranged on a cutter rack; and pressing mechanisms are respectively arranged at the two ends of the edge beams for positioning bean curd trays, so that the positioning is precise and reliable, and the flower cutting quality is guaranteed.

Owner:HENAN POLYTECHNIC UNIV

Angle-adjustable laser cutting device

ActiveCN112605539AEasy to adjust cutting lengthGood stitchingLaser beam welding apparatusTool bitElectric machinery

The invention relates to pipeline production and processing equipment, in particular to an angle-adjustable laser cutting device. According to the angle-adjustable laser cutting device, a pipeline notch is smooth, a tool bit is not prone to being damaged, the notch cutting angle can be adjusted conveniently, and the angle-adjustable laser cutting device can adapt to pipelines of different types. The angle-adjustable laser cutting device comprises a base, a rack, a motor, a first support, a supporting plate and the like. The rack, the first support and the supporting plate are fixedly installed on the base; the rack and the supporting plate are located on the two sides of the base; and the motor is fixedly connected to the end, away from the base, of the rack. According to the angle-adjustable laser cutting device, pipeline cutting is completed through mutual cooperation of a first regulation and control assembly and a second regulation and control assembly in a cutting assembly, the first regulation and control assembly facilitates adjustment of the angle of a pipeline notch, the second regulation and control assembly facilitates adjustment of the cutting length of a pipeline, the pipeline notch can be smooth through laser cutting, and splicing of pipelines with different notches is facilitated.

Owner:深圳科锐尔精工技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com