Material transferring device, drilling mechanism and processing center

A material and processing station technology, applied in the field of workpiece processing and manufacturing, can solve the problems of inability to continuous production, low efficiency, and stalled conveying devices, and achieve the effect of ensuring uninterrupted production, saving costs, and reducing space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

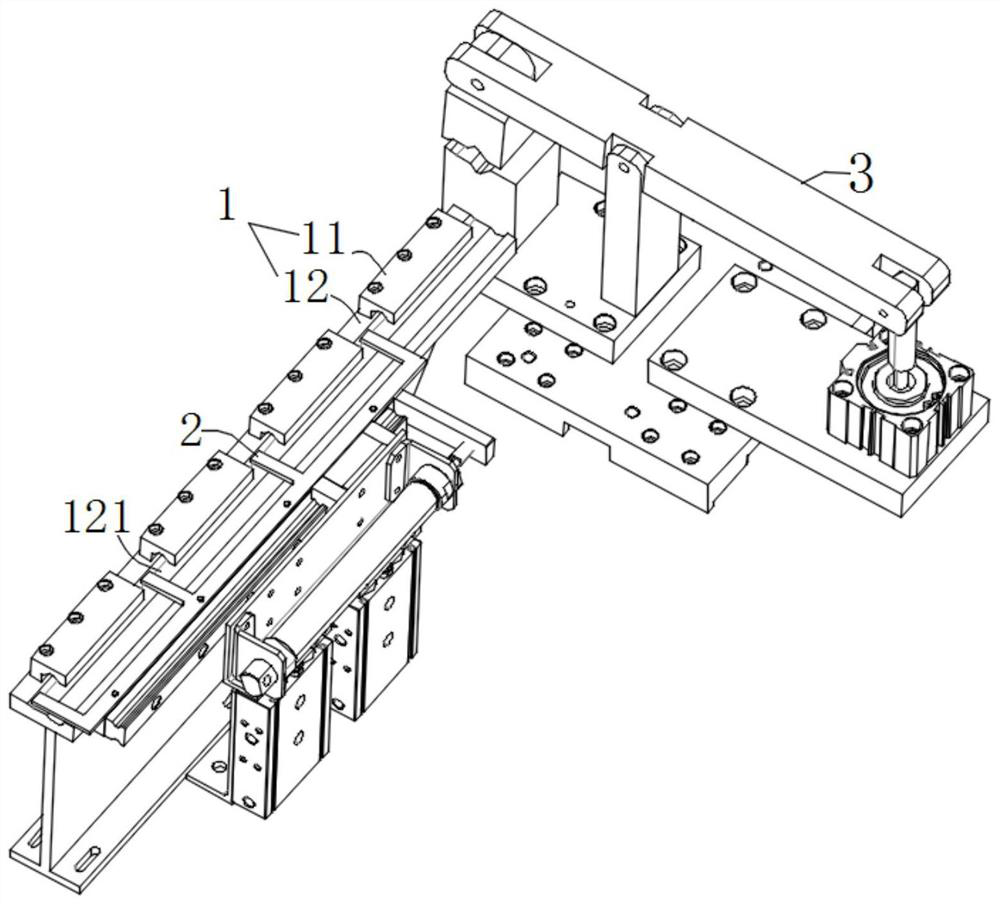

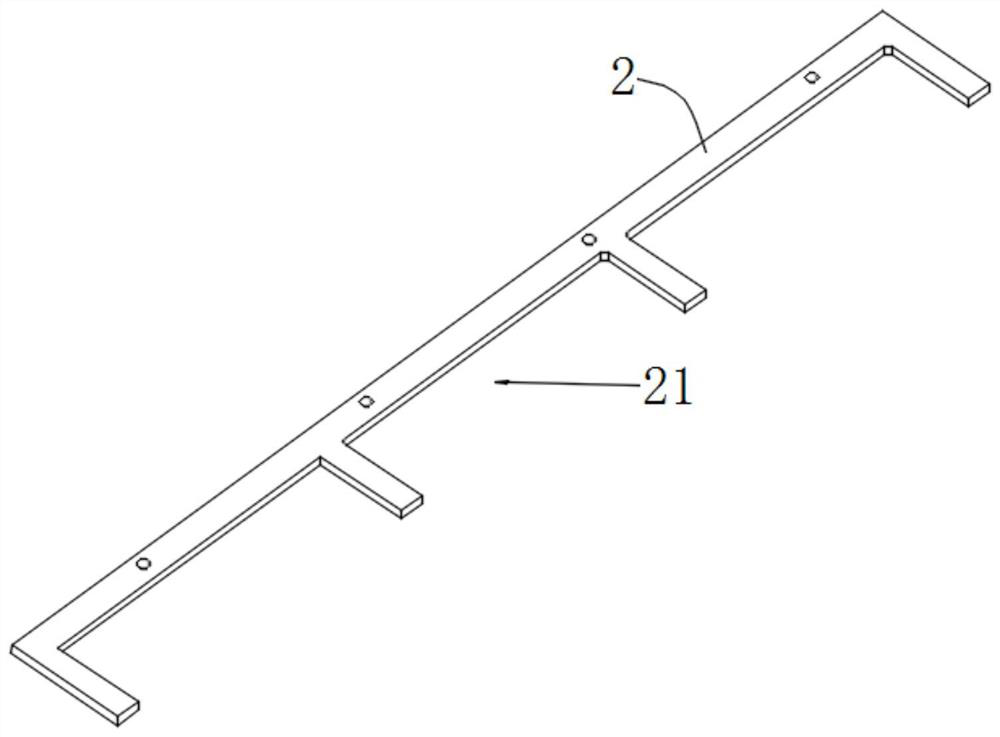

[0044] Such as Figure 1-9 As shown, the present embodiment provides a material circulation device, including a carrier body 1, a driving part 2 and a transfer module 3, wherein the carrier body 1 extends along the feeding direction, and a transfer area is arranged at the end of the feeding direction, and the driving part 2 Drive the workpiece to move along the carrier 1 to the transfer area, and then the transfer module 3 grabs the workpiece, and the transfer module 3 moves back and forth in a straight line between the transfer area and the processing station 4 to realize continuous and uninterrupted loading.

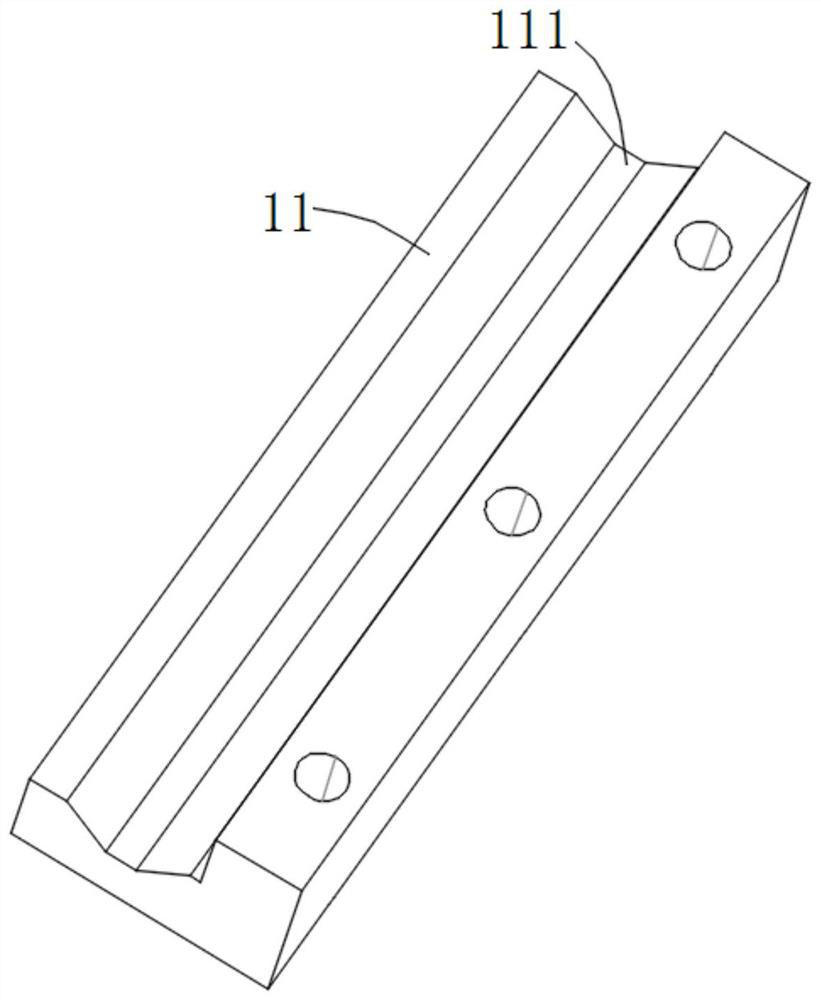

[0045] Preferably, the carrier 1 of this embodiment includes a guide plate 12 with a guide groove 121 on the guide plate 12, the workpiece is placed in the guide groove 121, and the workpiece will not deflect when the guide groove 121 is driven to move. The carrier 1 also includes a limiting block 11, which is fixedly mounted on the guide plate 12. The limiting block 1...

Embodiment 2

[0057] The present embodiment provides a drilling mechanism for processing lock cylinder holes, the drilling structure includes the above-mentioned material circulation device, the above-mentioned processing station 5 is configured as a drilling station, and the drilling station includes two opposite Arranged drilling machine, the drilling machine can drill holes on the lock core from both sides to form the gall hole of the lock core. In order to realize the continuous processing of the lock core bore, the drilling station in this embodiment is two and The layout is on both sides of the feeding direction. Each drilling station is equipped with a transfer module 3 correspondingly. The transfer module 3 is located between two opposite drilling machines. Further, the upstream and downstream directions of the transfer area are equipped with carriers. 1 and driving member 2, thereby realizing a drilling mechanism that can work continuously.

[0058] The previous station of the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com