Method for the uninterrupted operation of a gas liquefaction system

A technology of operation method and equipment, applied in the field of gas liquefaction equipment, to achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

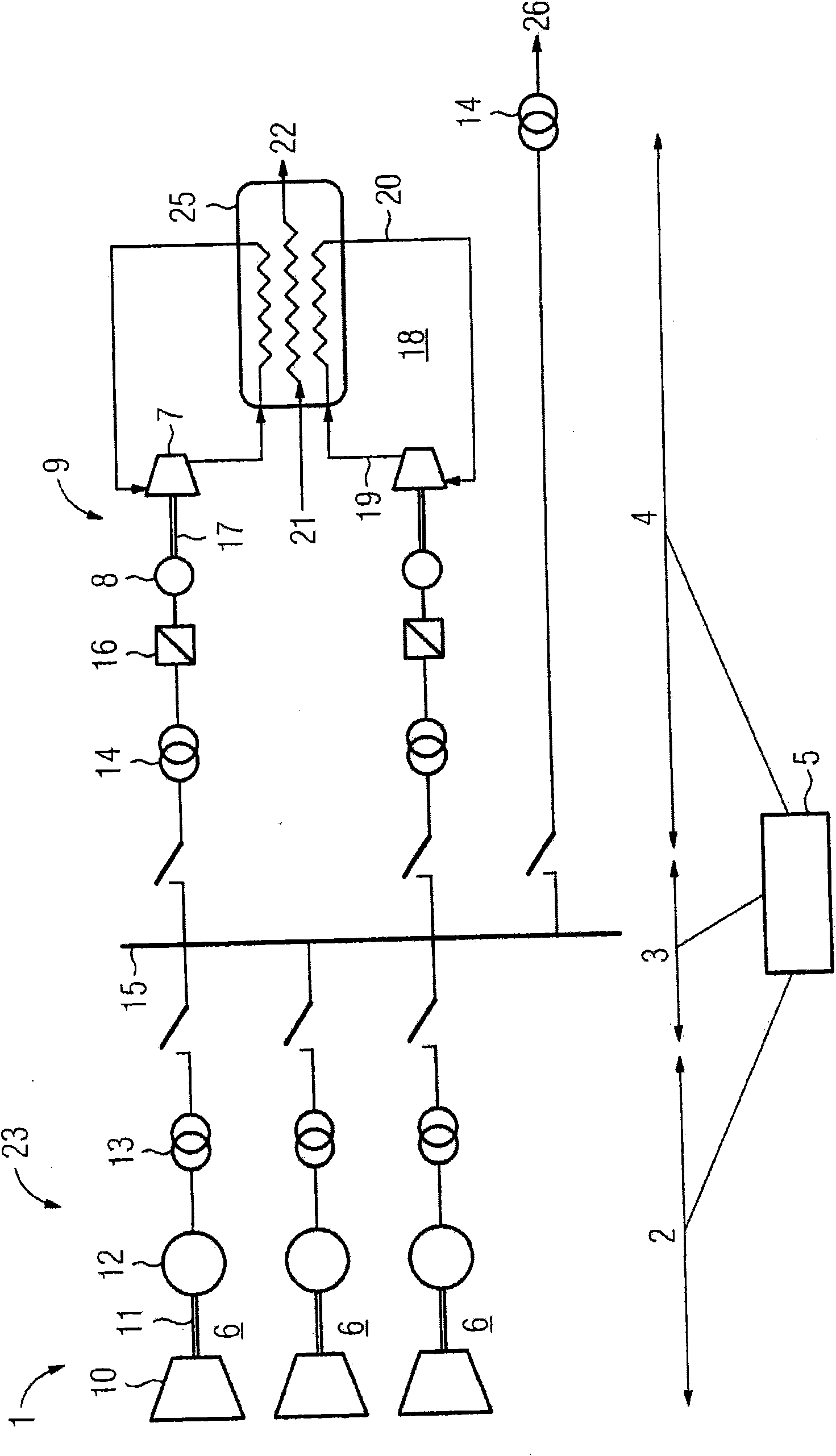

[0034] figure 1 An integrated scheme of the gas liquefaction plant 1 is shown, including an independent power plant 23 as the power generation part 2 , a power transmission part 3 for distributing electric energy, and a coolant compressor part 4 . The regulator 5 is connected to the power generation part 2 , the power transmission part 3 and the coolant compressor part 4 .

[0035]The power generation part 2 comprises three turbine units 6 , each having a turbine 10 and a generator 12 , which are connected via a shaft 11 . However, the power generation section 2 can also comprise fewer than three or more than three turbine sets 6 .

[0036] The turbine units 6 are each connected via a power transformer 13 to a power plant busbar 15 of the power transmission part 3 , which supplies electrical energy to the electric motors in the coolant compressor part 4 and / or other consumers 26 .

[0037] In the coolant compressor section 4 , the rotational speed variable motor 8 of the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com