Patents

Literature

39results about "Preparation rom asymmetrical anhydrides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing carboxylic esters

InactiveUS6916950B2Increased space-time yieldPreparation rom asymmetrical anhydridesOrganic compound preparationLiquid mediumAlcohol

Carboxylic esters are prepared by a process, which comprises reacting dicarboxylic or polycarboxylic acids or their anhydrides with alcohols in a liquid medium with the concomitant removal of water formed by the esterification reaction by azeotropic distillation together with the alcohol in the medium, wherein the amount of liquid removed from the reaction medium by azeotropic distillation is replaced in whole or in part with the alcohol.

Owner:OXENO OLEFINCHEMIE GMBH

Ester plasticizers based on ethylhexanol and propylheptanol

The present invention relates to an ester obtainable by reacting (a) an alcohol mixture comprising 20-50 wt% ethylhexanol, 40-64 wt% propylheptanol and 0-20 wt% of other alcohols with (b) a polycarboxylic acid. Further aspects of the invention relate to a thermoplastic polymer comprising the ester according to the invention and uses of said ester.

Owner:EMERY OLEOCHEMICALS GMBH

Fragrance mixture

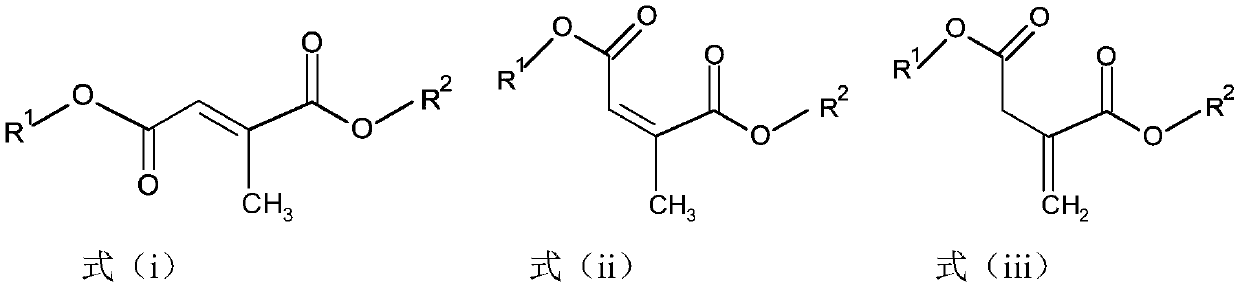

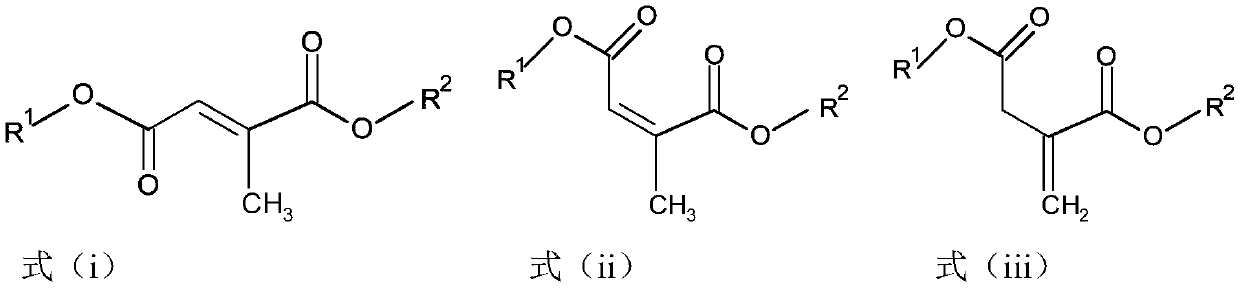

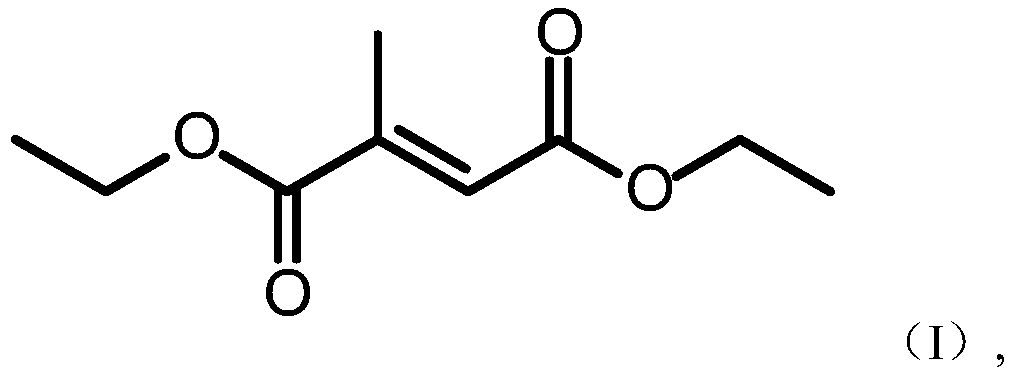

The invention relates to a fragrance mixture and the applications of same, particularly perfume oils, cosmetic agents, agents for application or detergents and cleaning agents, containing a sensorially effective amount of (i) (E)-2-methyl-but-2-ene dicarboxylic acid-diethyl ester, (ii) (Z)-2-methyl-but-2-ene dicarboxylic acid-diethyl ester, or (iii) 2-methylene butane dicarboxylic acid diethyl ester, and mixtures of same, as well as analogous esters derived from these compounds and mixtures.

Owner:SYMRISE GMBH & CO KG

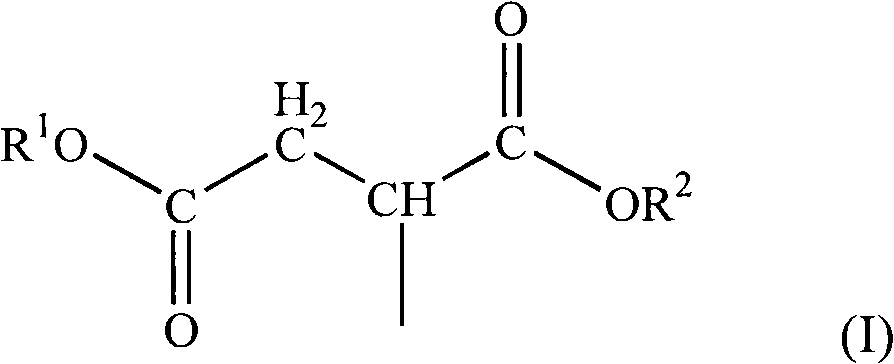

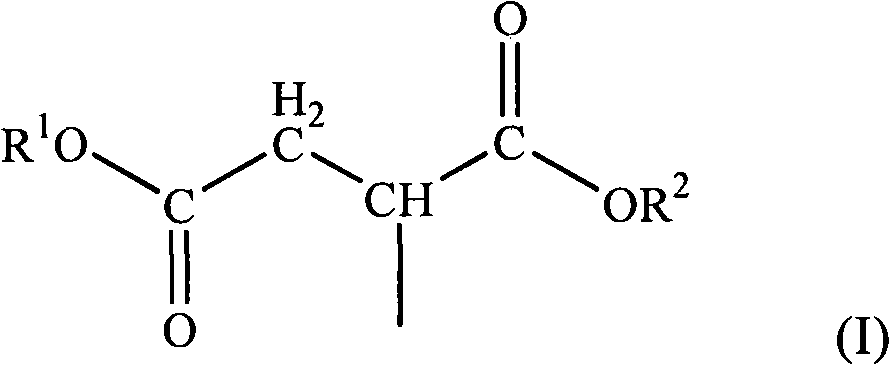

Bio-based polyol

ActiveUS20100222541A1Preparation rom asymmetrical anhydridesPolyureas/polyurethane adhesivesPolyolDiol

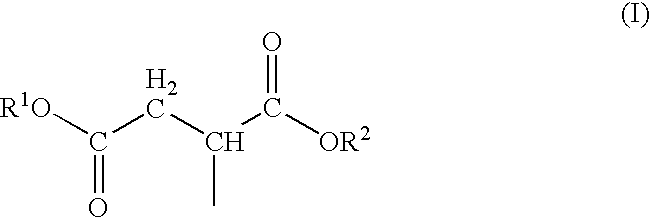

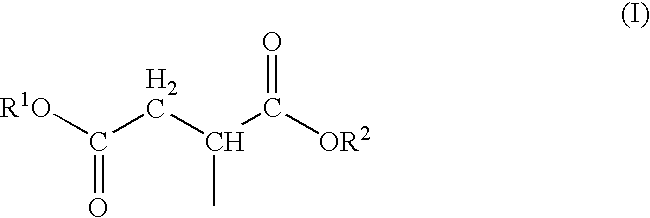

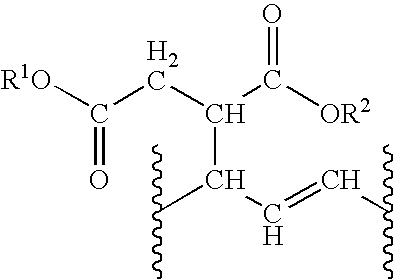

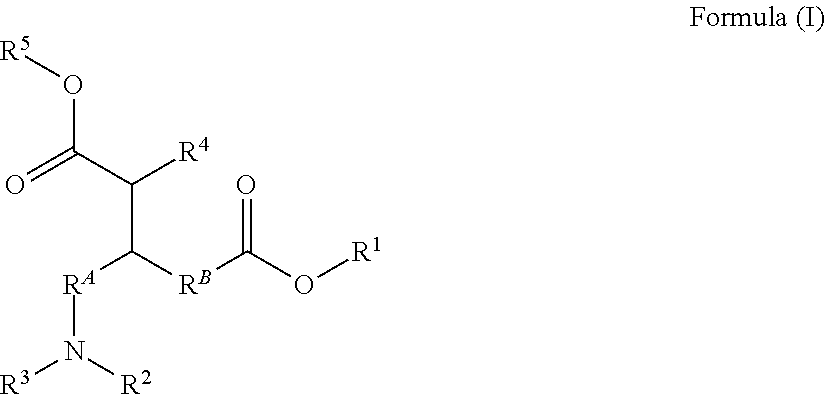

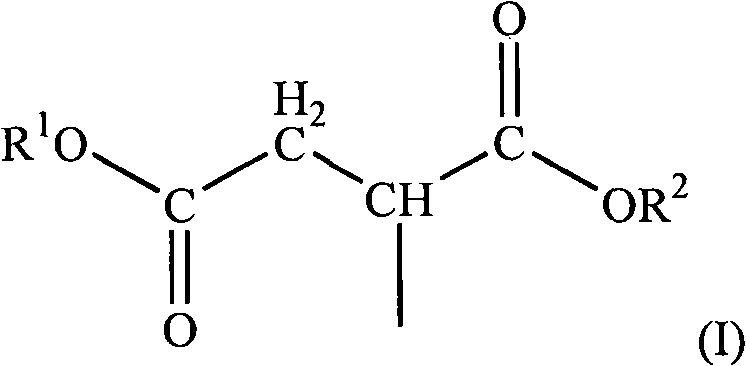

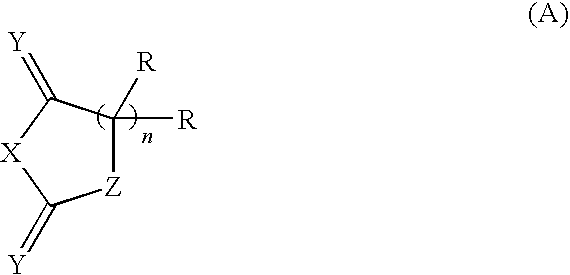

A polyol having a substituent of formula (I)attached via a carbon-carbon single bond to a saturated carbon atom in a fatty acid hydrocarbyl group; wherein R1 and R2 are esterified residues of aliphatic or cycloaliphatic diols; and from 0 to 15 wt % of esterified residues of at least one C4-C12 anhydride, C4-C12 diacid or C4-C12 lactone, not including units of formula (I) attached to a fatty acid hydrocarbyl group.

Owner:ROHM & HAAS CO

Cage-shaped cyclobutanoic dianhydrides and process for production thereof

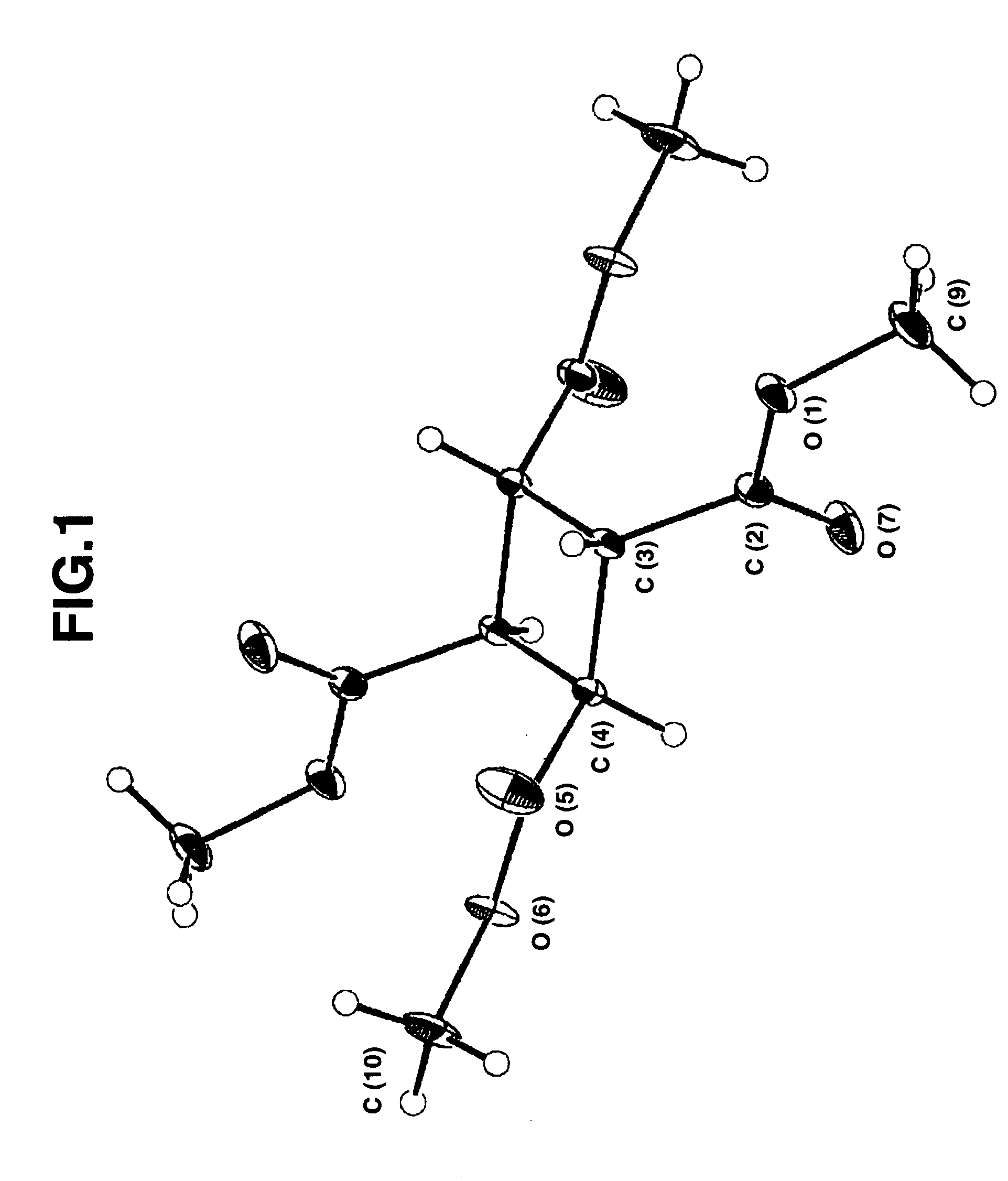

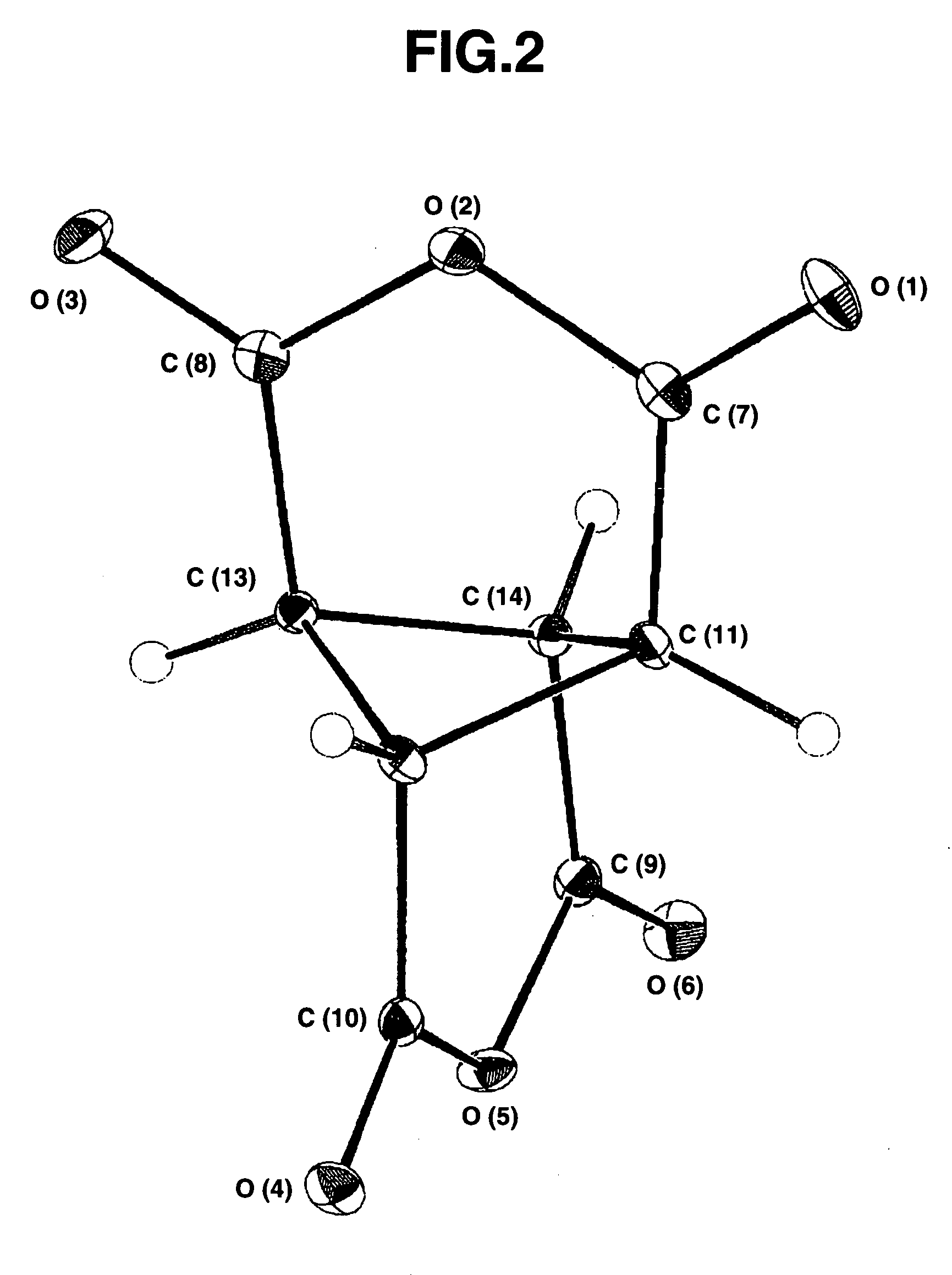

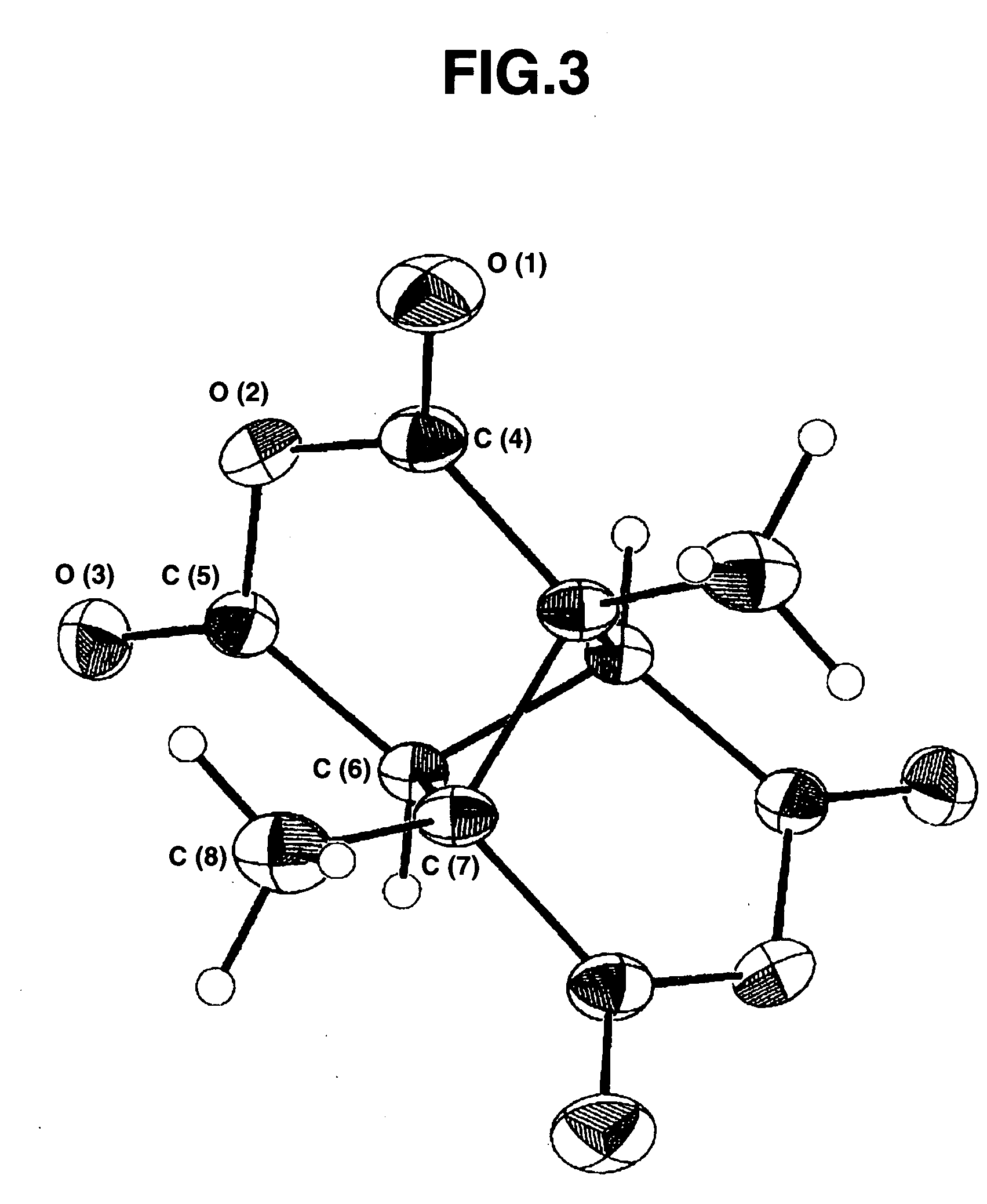

ActiveUS20090012318A1Good light transmissionImprove heat resistancePreparation rom asymmetrical anhydridesOrganic compound preparationOrganic acidHydrogen

A process which comprises reacting a 1,2,3,4-cyclobutanetetracarboxylic-1,2:3,4-dianhydride [1] with an alcohol [2] in the presence of an acid catalyst to obtain a compound [3], isomerizing the compound [3] with a base catalyst into a compound [4], reacting the compound [4] with an organic acid to obtain a compound [5], and reacting the compound [5] with a dehydrating agent to obtain a 1,2,3,4-cyclobutanetetracarboxylic-1,3:2,4-dianhydride: wherein R1 and R2 are each independently hydrogen, halogeno, alkyl of 1 to 10 carbon atoms, halogenated alkyl of 1 to 10 carbon atoms, cycloalkyl of 3 to 8 carbon atoms, phenyl, or cyano; and R3 is alkyl of 1 to 10 carbon atoms.

Owner:NISSAN CHEM IND LTD

Method for producing fluorine-containing alkyl (meth)acrylate

InactiveUS7700800B2Efficient productionInhibition formationPreparation rom asymmetrical anhydridesOrganic compound preparationHydrogen atomAlcohol

Owner:TOKUYAMA CORP +1

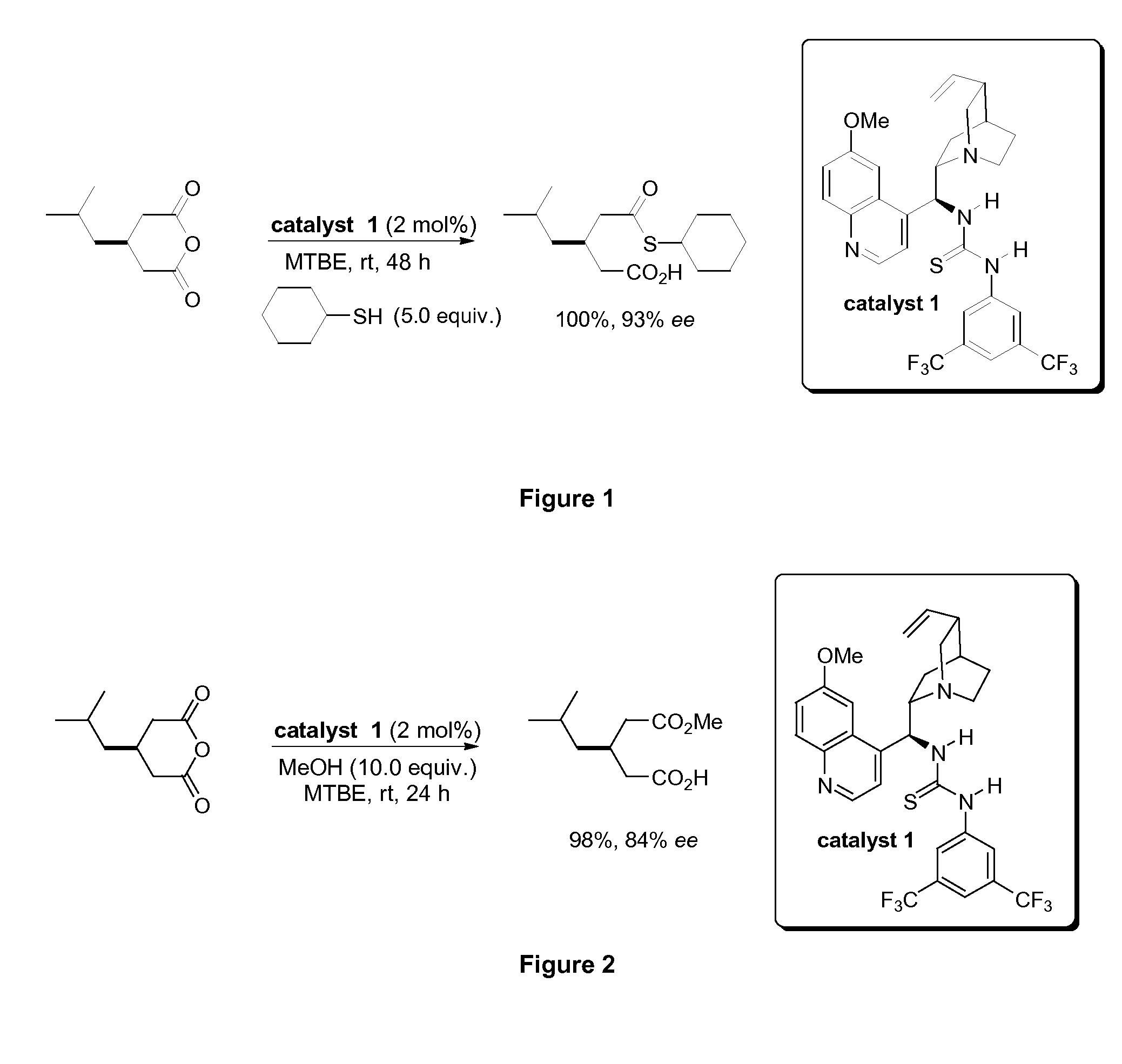

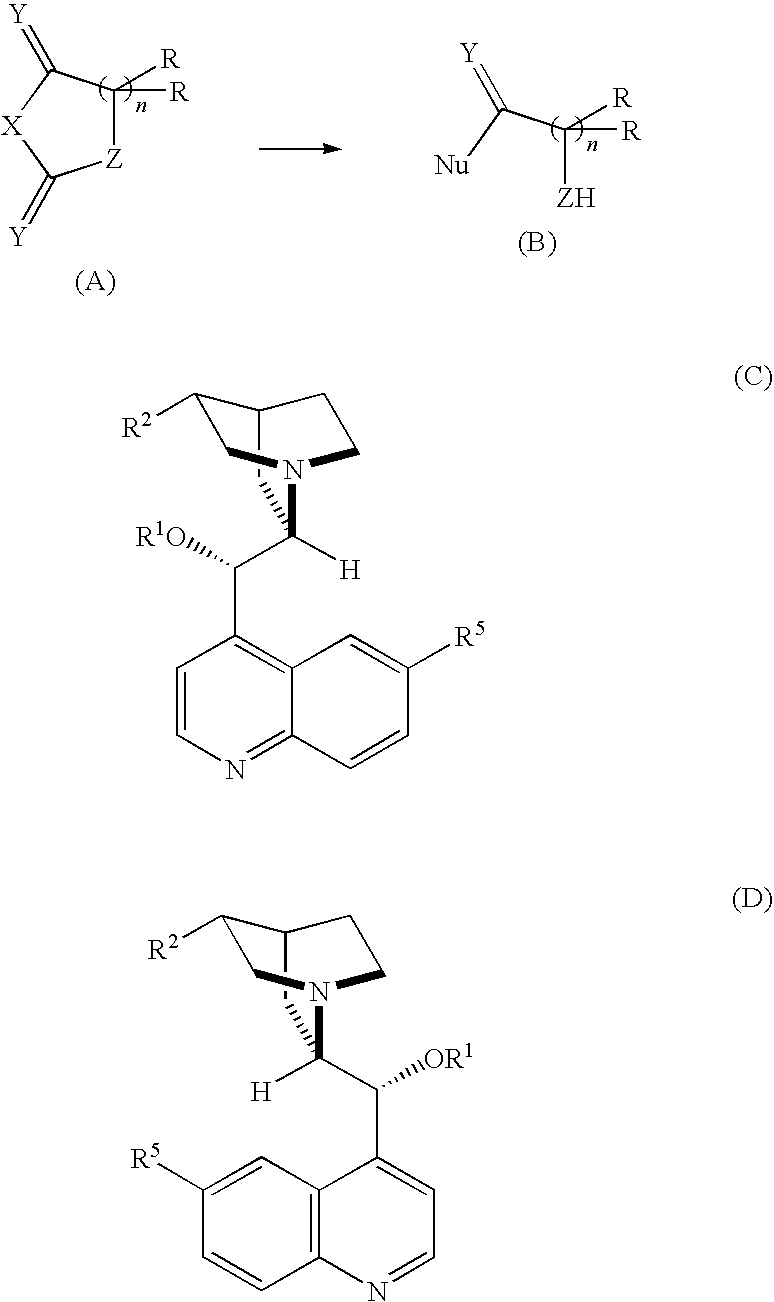

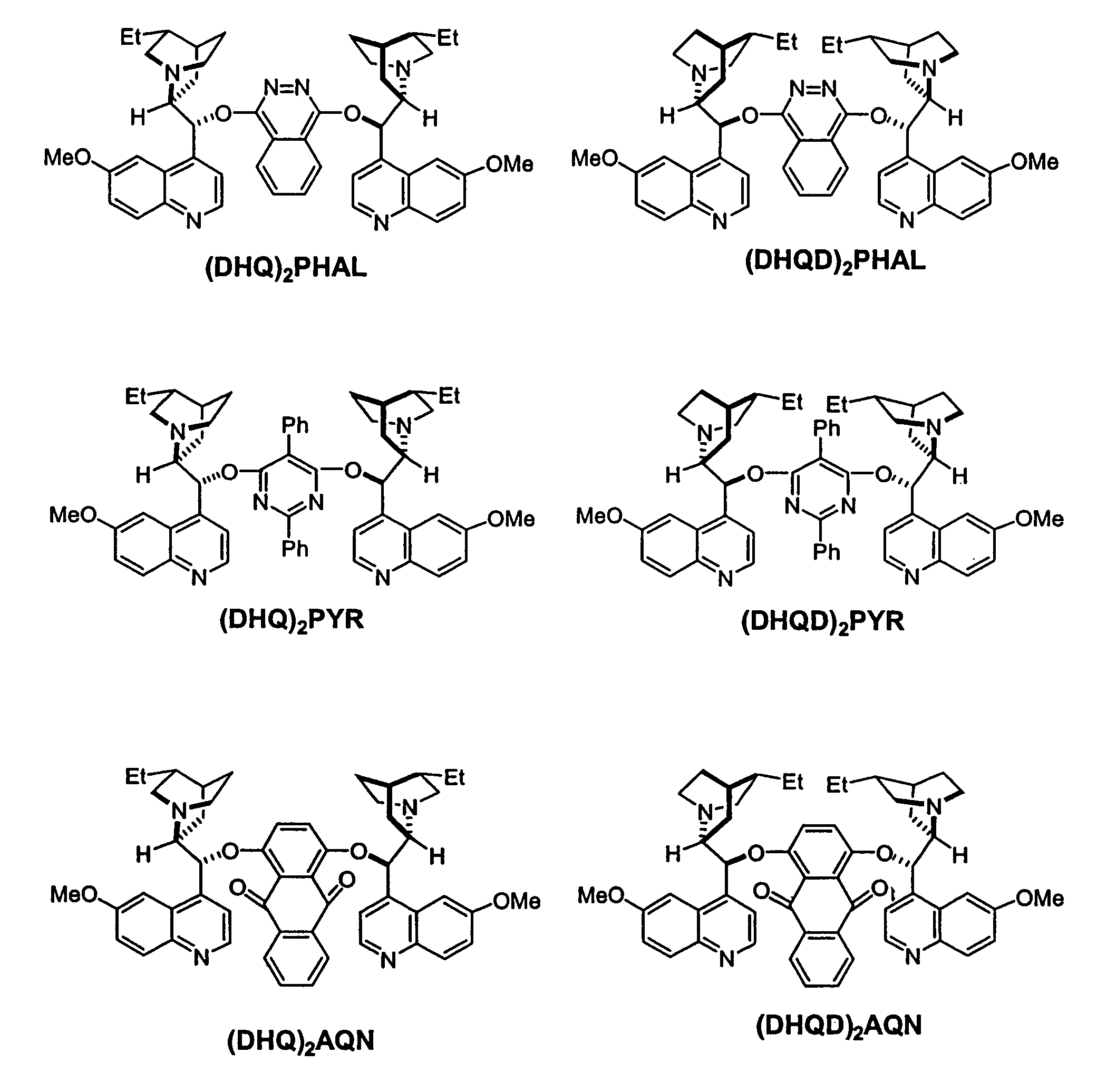

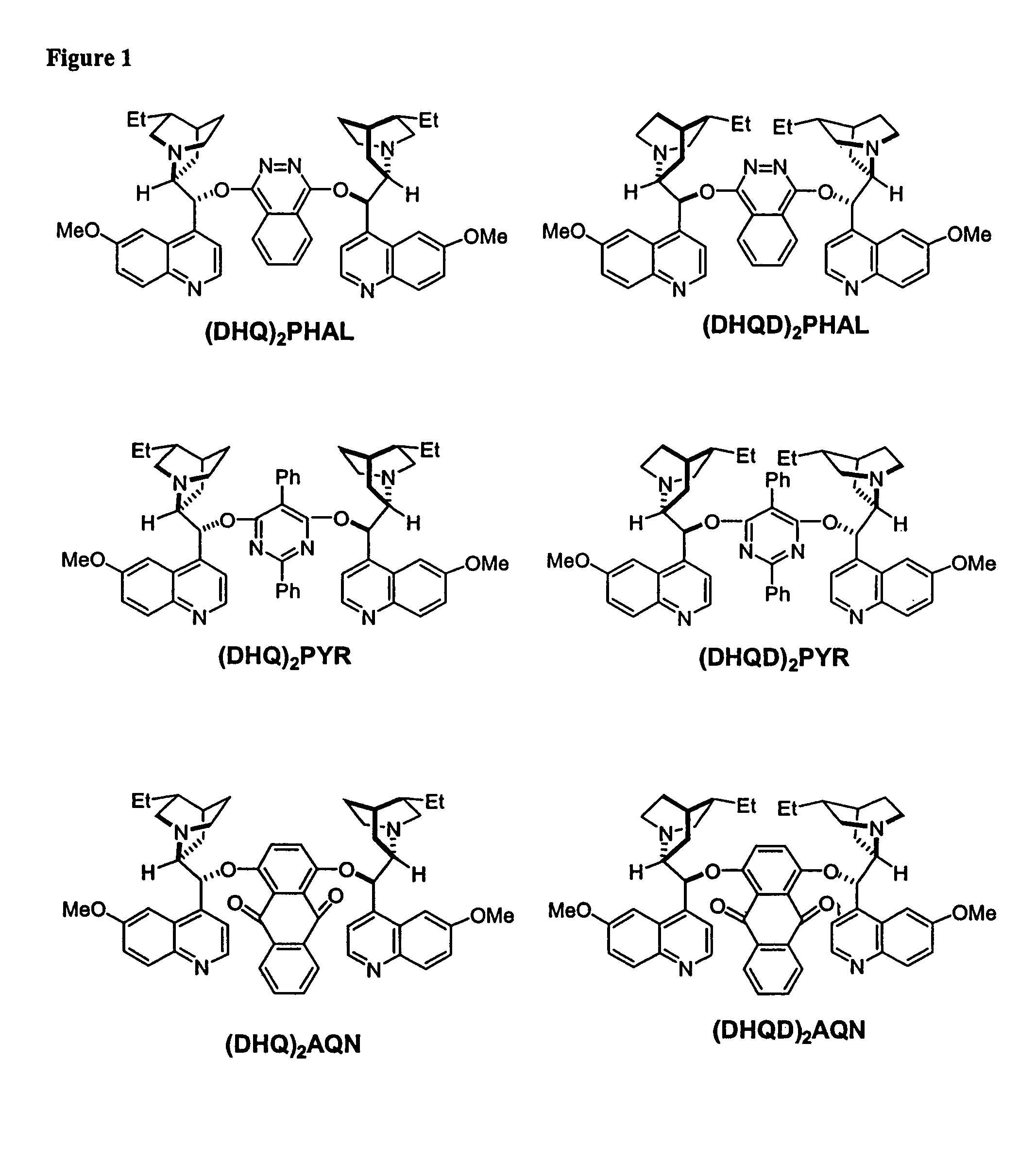

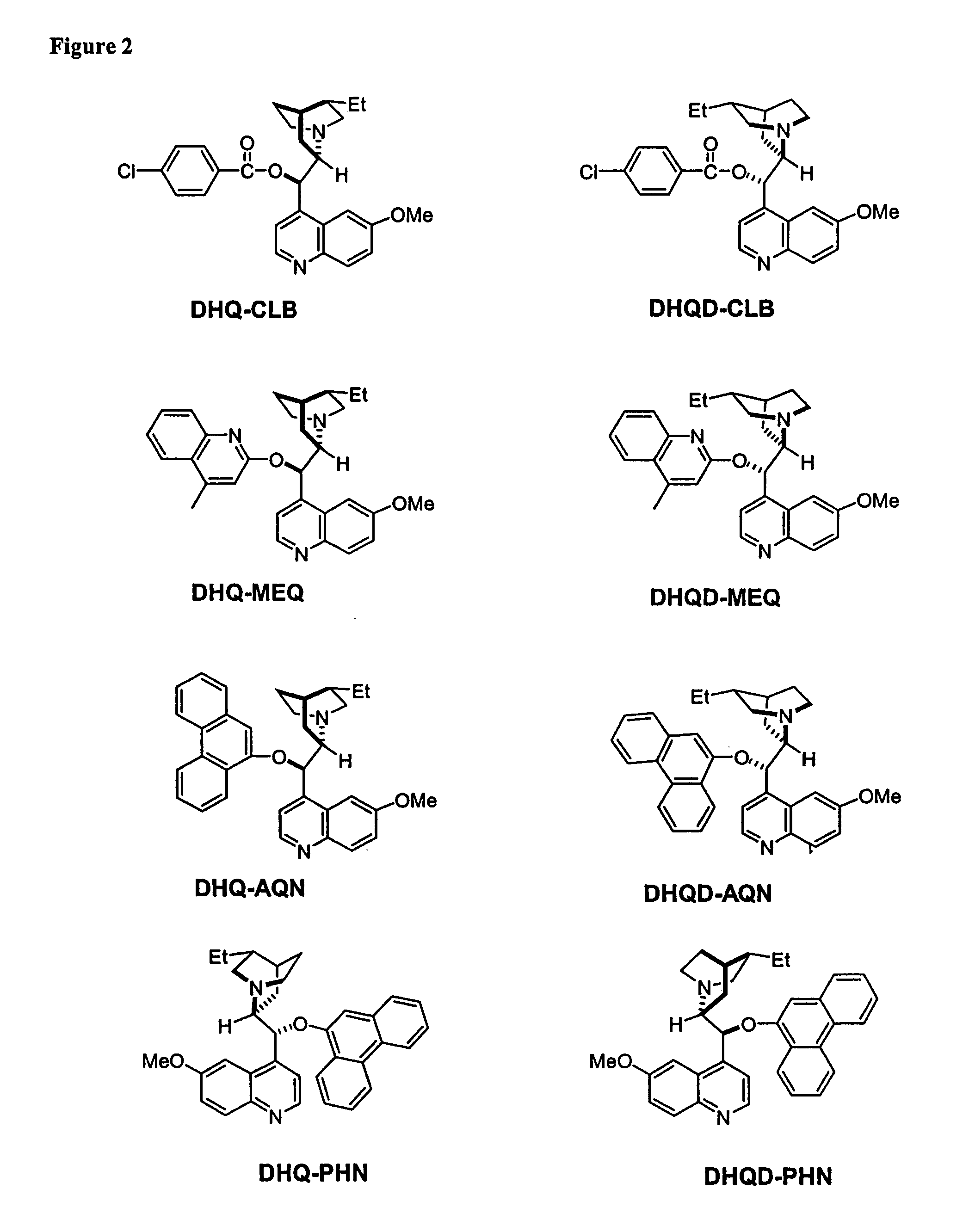

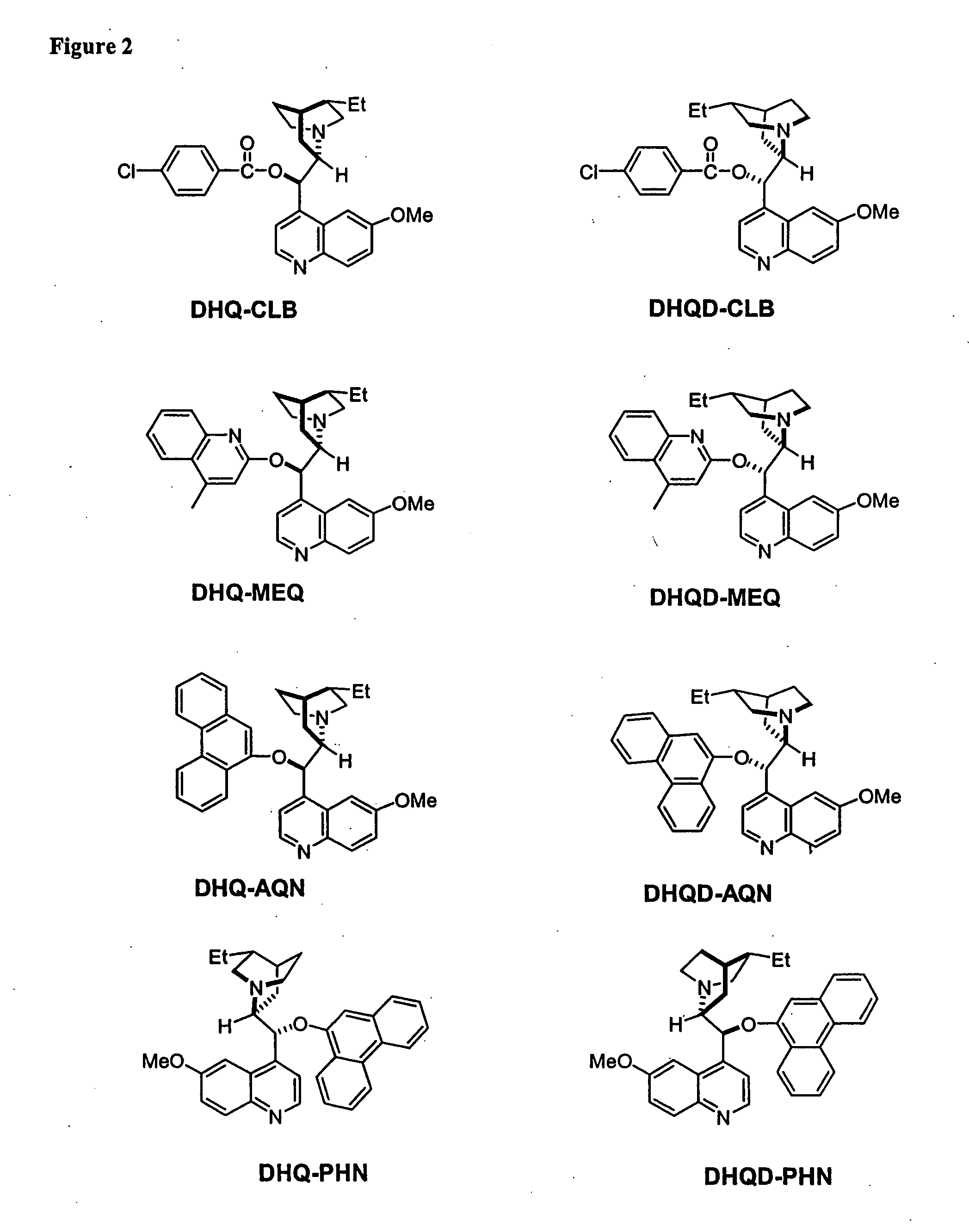

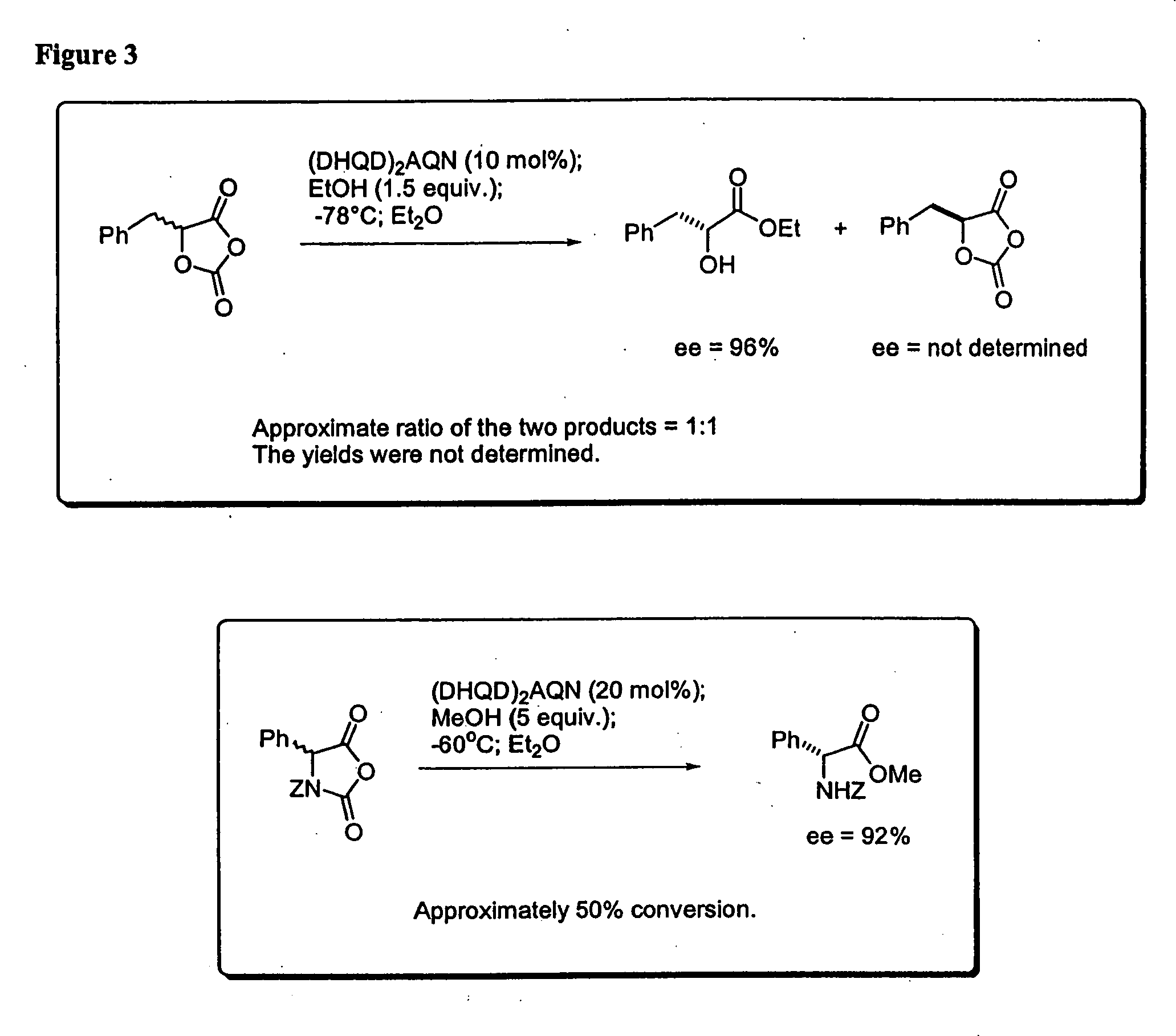

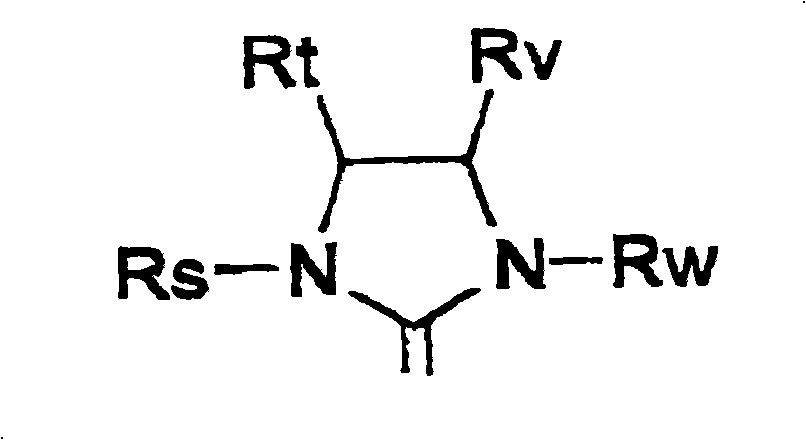

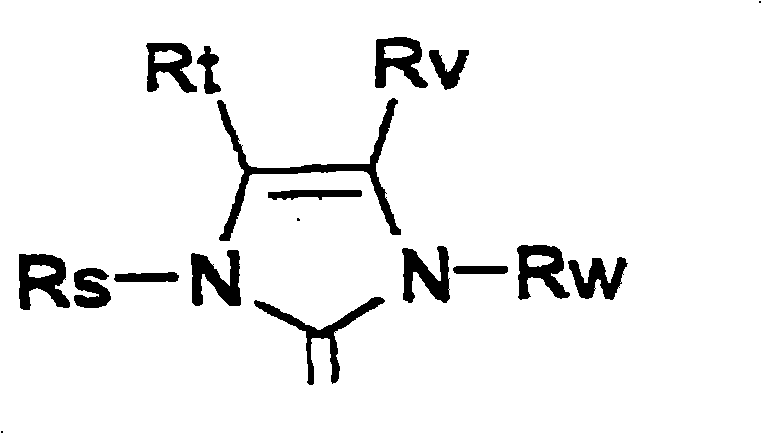

Novel optically active compounds, method for kinetic optical resolution of carboxylic acid derivatives and catalysts therefor

InactiveUS20050154209A1Efficient solutionPromote recoveryPreparation rom asymmetrical anhydridesOrganic compound preparationHydrogenHeteroatom

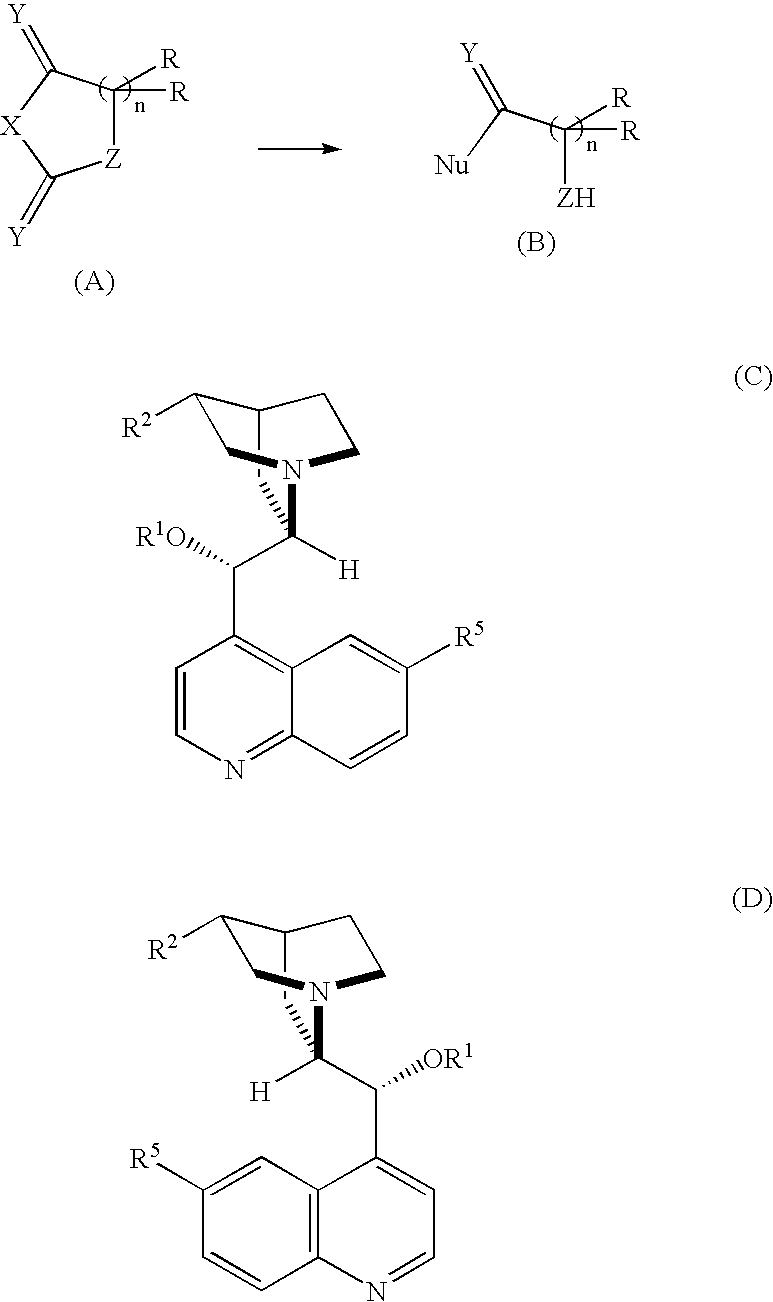

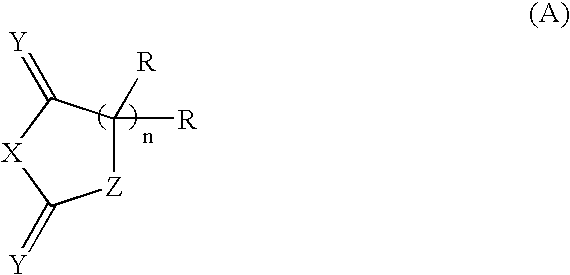

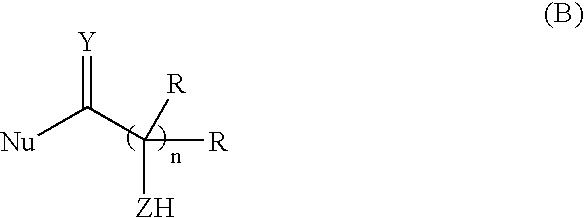

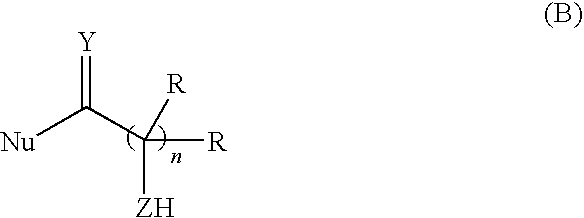

The present invention provides a method of kinetic optical resolution of carboxylic acid derivatives using specific optically active catalysts. A racemic or diastereomeric mixture of carboxylic acid derivatives of the formula (A) is reacted with a nucleophile in the presence of an optically active catalyst to form an optically active nucleophile derivative of the formula (B). The catalyst is an optically active compound represented by the formula (C) or (D) [wherein R1 is a substituted or unsubstituted, saturated or unsaturated, straight-chain, branched or alicyclic aliphatic hydrocarbon group which can have a heteroatom, R2 is ethyl or vinyl, and R5 is hydrogen or methoxy respectively].

Owner:OSAKA SODA CO LTD

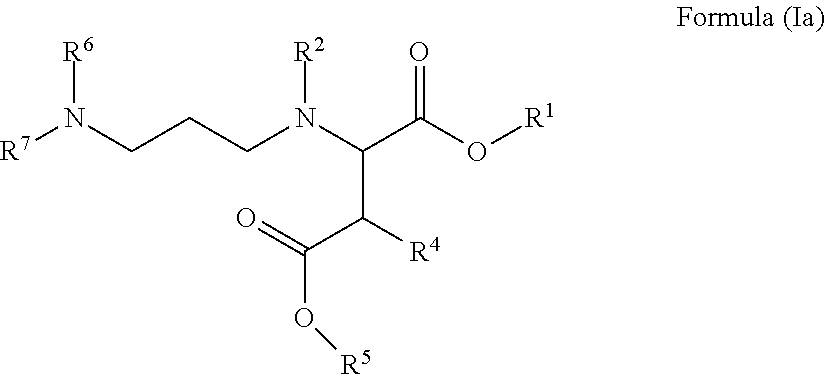

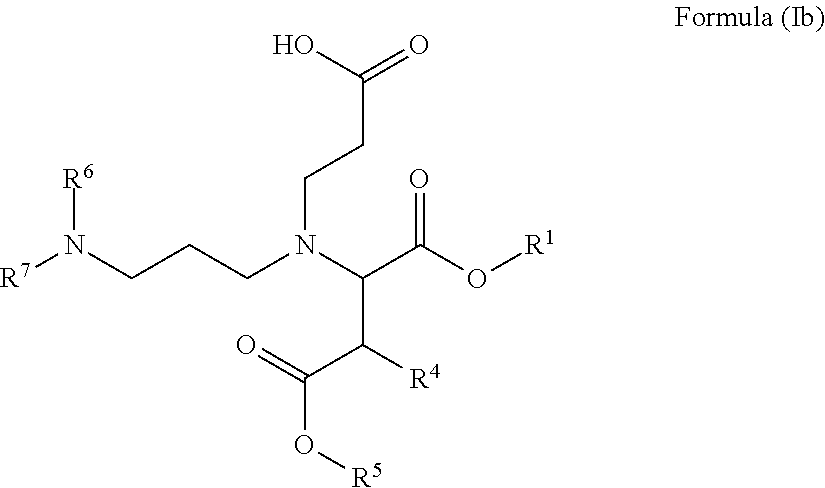

Carboxy alkyl-ester Anti-agglomerants for the control of natural gas hydrates

ActiveUS20190382360A1Inhibition formationPreparation rom asymmetrical anhydridesOrganic compound preparationLiquid hydrocarbonsLow dose

This disclosure relates to anti-agglomerant low dosage hydrate inhibitors that can inhibit the formation of hydrate agglomerants and / or plugs. Thus, provided herein are carboxy alkyl ester compounds that can be used in hydrate inhibitor compositions and methods of inhibiting formation of hydrate agglomerants in a fluid comprising water, a gas, and optionally a liquid hydrocarbon. Also provided herein are methods of making the carboxy alkyl ester compound.

Owner:CHAMPIONX USA INC

Synthesis method of C10 mixed ester plasticizer

InactiveCN105175258AIncrease profitEmission reductionPreparation rom asymmetrical anhydridesOrganic compound preparationIsooctyl alcoholAlcohol

The invention discloses a synthesis method of a C10 mixed ester plasticizer, which comprises the following steps: (1) mixing mixed anhydride and isooctyl alcohol in a certain proportion, and then carrying out catalytic reaction; (2) after the catalytic reaction, filtering the catalyst out of the reaction product; (3) carrying out dealcoholization and dehydration treatment on the reaction product in which the catalyst is removed; and (4) carrying out decoloration treatment on the reaction product to obtain a finished product of the C10 mixed ester plasticizer, wherein the mixed anhydride and isooctyl alcohol used in the step (1) are byproducts obtained after oxidation of durene. In the invention, the synthesis raw material used for the synthesis method of the C10 mixed ester plasticizer is a C10 mixed anhydride byproduct, and byproducts obtained in actual production, such as phthalic anhydride and trimellitic anhydride, can be comprehensively utilized, so that the utilization ratio of C10 aromatic hydrocarbon is greatly increased, the waste discharge is reduced and the environment is protected.

Owner:NANJING POLYTECHNIC INSITUTE

Method for Producing Fluorine-Containing Alkyl (Meth)Acrylate

InactiveUS20090023948A1Low costHigh selectivityPreparation rom asymmetrical anhydridesOrganic compound preparationHydrogen atomAlcohol

The present invention discloses a method for producing a fluorine-containing alkyl (meth)acrylate represented by the following general formula (2):Rf—(CH2)k-[-A-(CH2)l—]m—OCOCR═CH2 (2)(wherein R is a hydrogen atom or a methyl group), characterized by reactinga fluorine-containing alcohol represented by the following general formula (1):Rf—(CH2)k-[-A-(CH2)l—]m—OH (1)(wherein Rf is a perfluoroalkyl group having 1 to 21 carbon atoms; A is S, SO or SO2; k is 0, 1 or 2; 1 is k, 2 or 3; m is 0 or 1; however, a case of k=0 and m=0 is excluded),(meth)acrylic acid, anda sulfonic acid halidein the presence of a base containing at least one kind of tertiary amine.

Owner:TOKUYAMA CORP +1

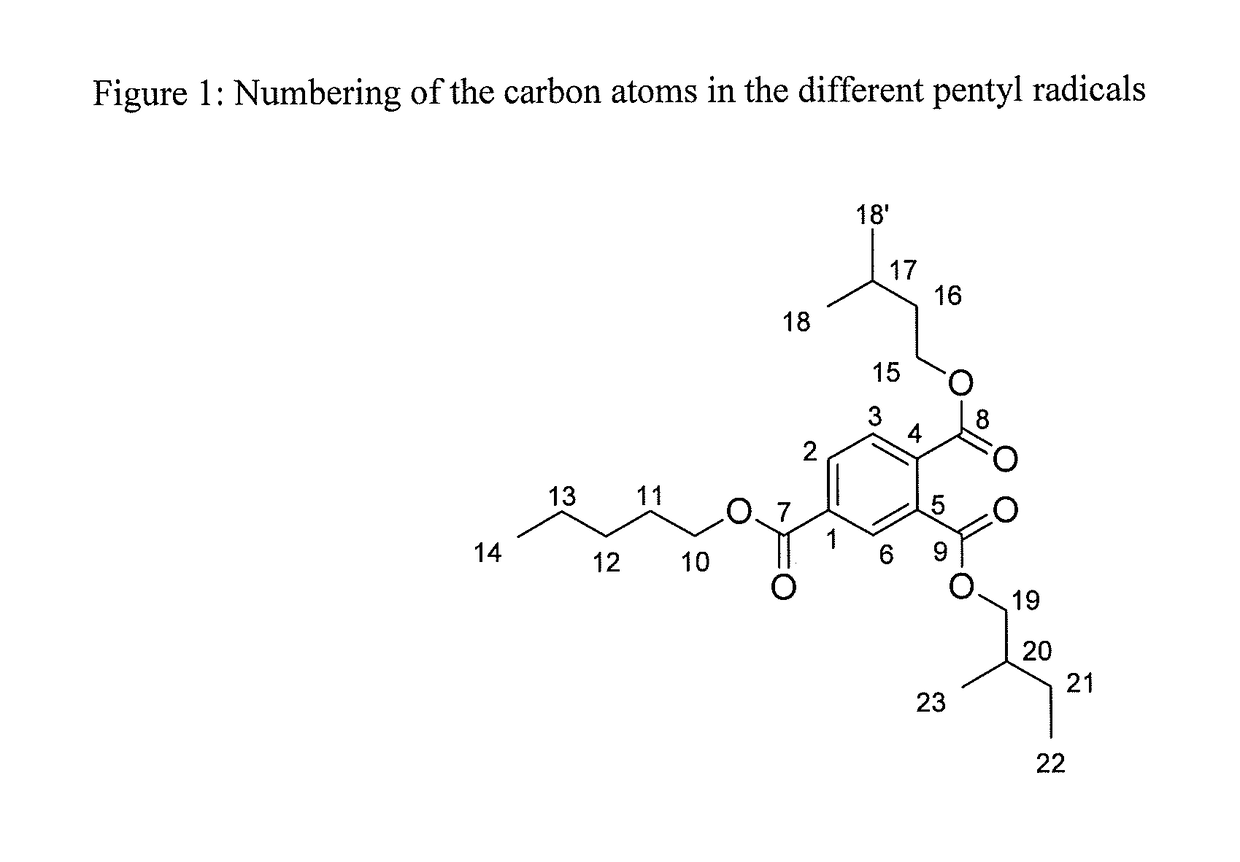

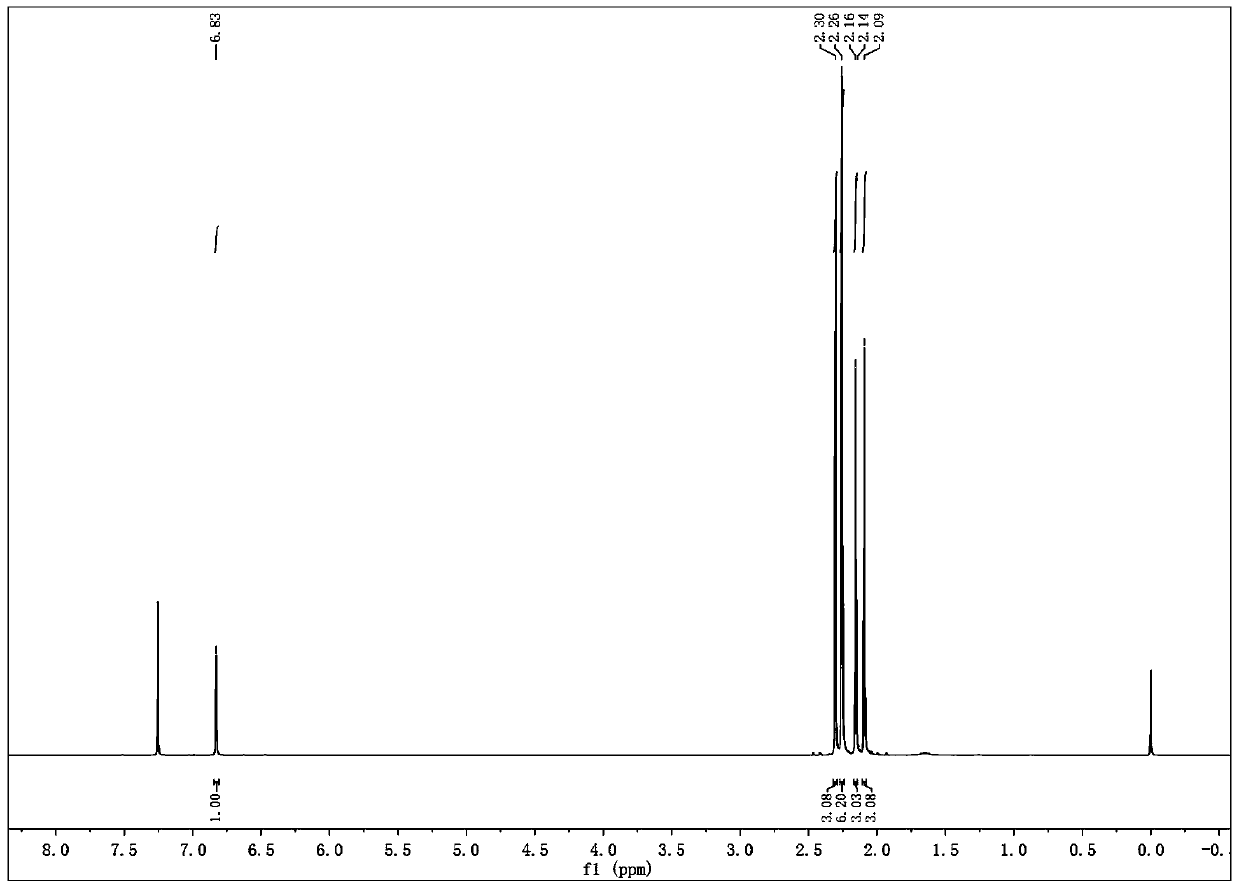

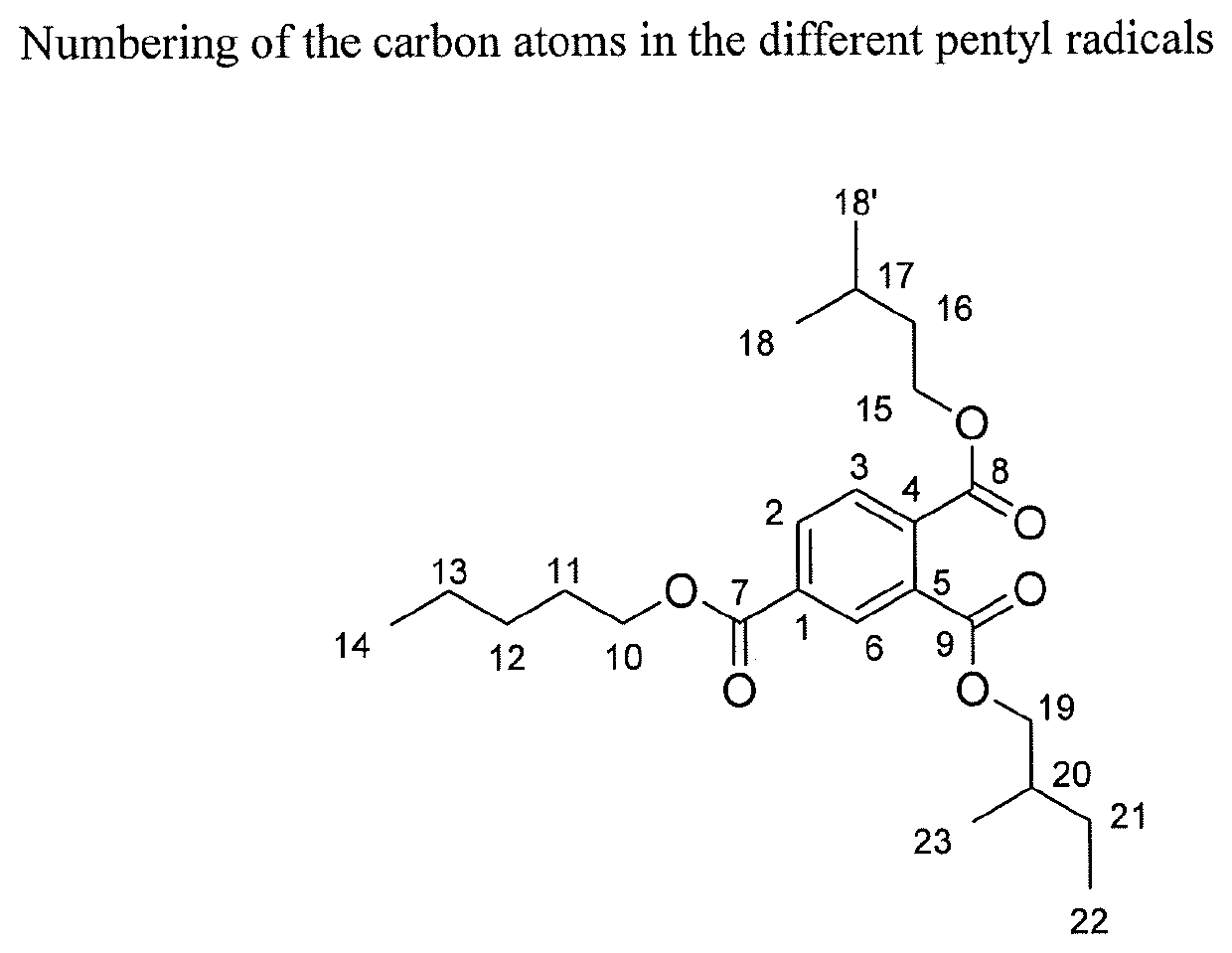

Tripentyl esters of trimellitic acid

ActiveUS20170088691A1Low tendency to migratePreparation rom asymmetrical anhydridesOrganic compound preparationTrimellitic acidMedicinal chemistry

Tripentyl esters of trimellitic acid, especially mixtures of triisopentyl esters of trimellitic acid comprising isomeric pentyl radicals in which more than 5 mol % of the isomeric pentyl radicals incorporated in the ester mixture are branched, have good compatibility with PVC and PVC-containing polymers and simultaneously exhibit a lesser tendency to migrate.

Owner:EVONIK OPERATIONS GMBH

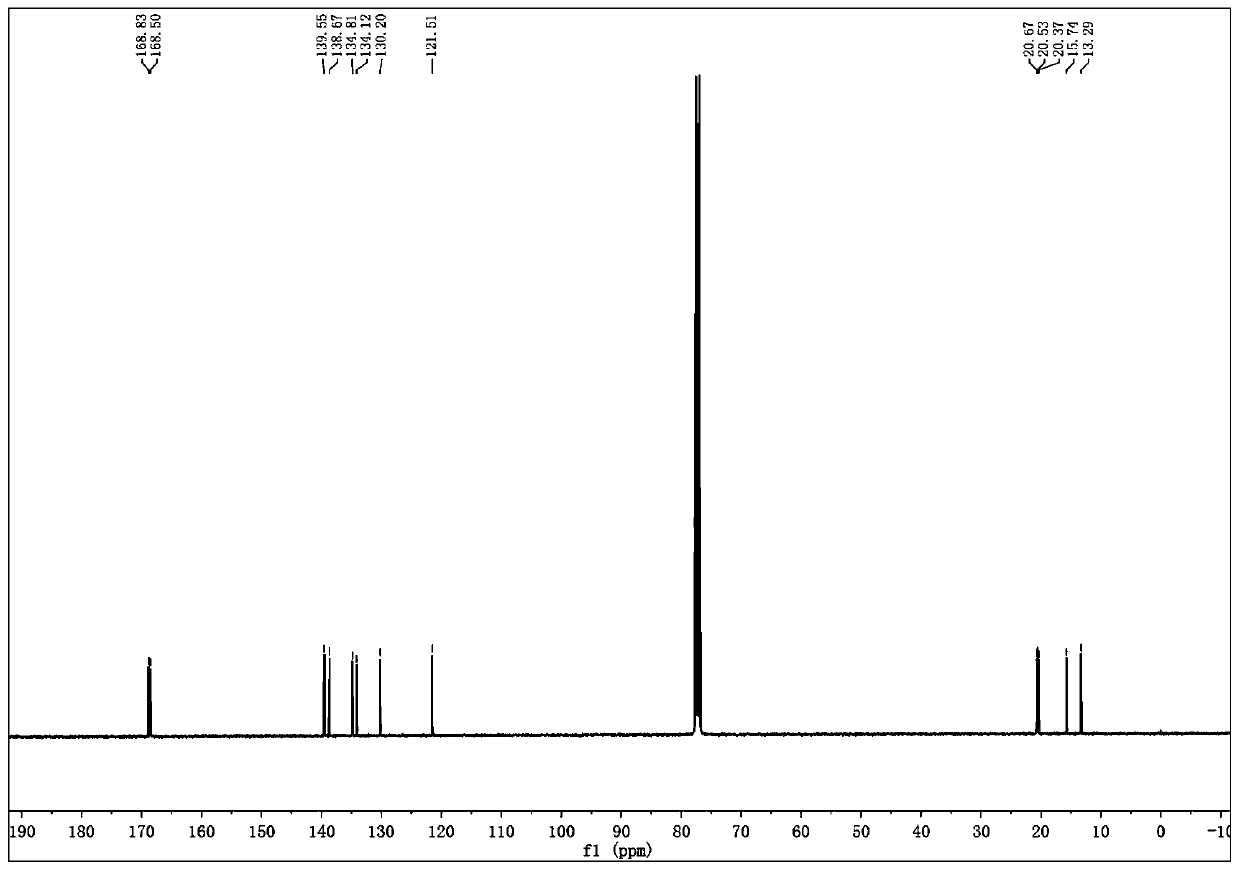

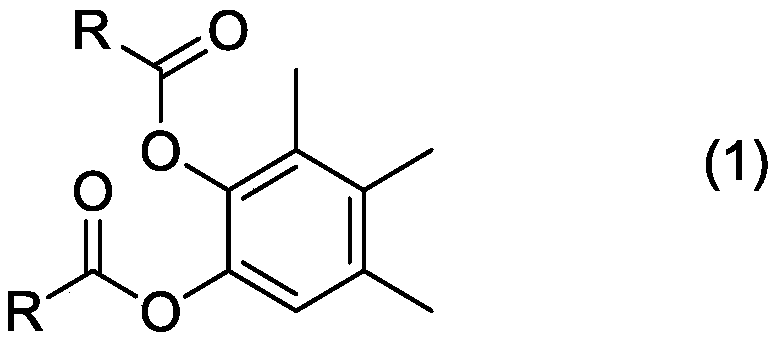

Preparation method of 3, 4, 5-trimethylhydroquinone dialkanoate

ActiveCN111393290AHigh selectivityHigh yieldPreparation rom asymmetrical anhydridesPreparation from carboxylic acid halidesO-Phosphoric AcidPtru catalyst

The invention provides a preparation method of 3, 4, 5-trimethylhydroquinone dialkanoate. The preparation method comprises the following steps: reacting in the presence of a catalyst and a cocatalystand carrying out esterification and rearrangement reaction on 2, 6, 6-trimethylcyclohexyl-2-ene-1, 4-diketone and an acylating agent to obtain the product, wherein the catalyst is selected from sulfuric acid, hydrochloric acid, phosphoric acid, fluoroboric acid, p-toluenesulfonic acid, benzenesulfonic acid, methanesulfonic acid, chloroacetic acid, BF3, BF3.OEt2, AlCl3, FeCl3, ZnCl2, TiCl4, SnCl2 and the like, and the cocatalyst is selected from nicotinic acid, 3-pyridylaldehyde, phenyl nicotinate, furoate nicotinate, 5-hydroxy-6-methyl nicotinic acid and 5-hydroxy-6-methyl ethyl nicotinate. The process has the advantages of easiness in industrialization, good selectivity, high product yield and the like.

Owner:WANHUA CHEM GRP CO LTD

Bio-based polyol

A polyol having a substituent of formula (I) attached via a carbon-carbon single bond to a saturated carbon atom in a fatty acid hydrocarbyl group; wherein R 1 and R 2 are esterified residues of aliphatic or cycloaliphatic diols; and from 0 to 15 wt % of esterified residues of at least one C 4 -C 12 anhydride, C 4 -C 12 diacid or C 4 -C 12 lactone, not including units of formula (I) attached to a fatty acid hydrocarbyl group.

Owner:ROHM & HAAS CO

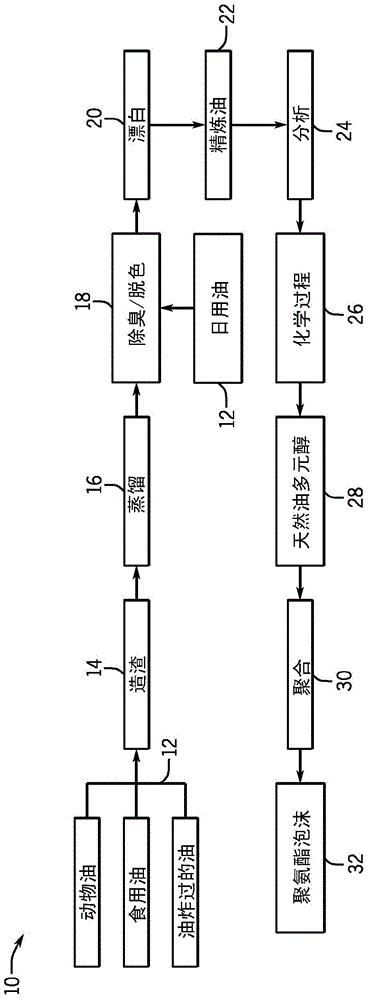

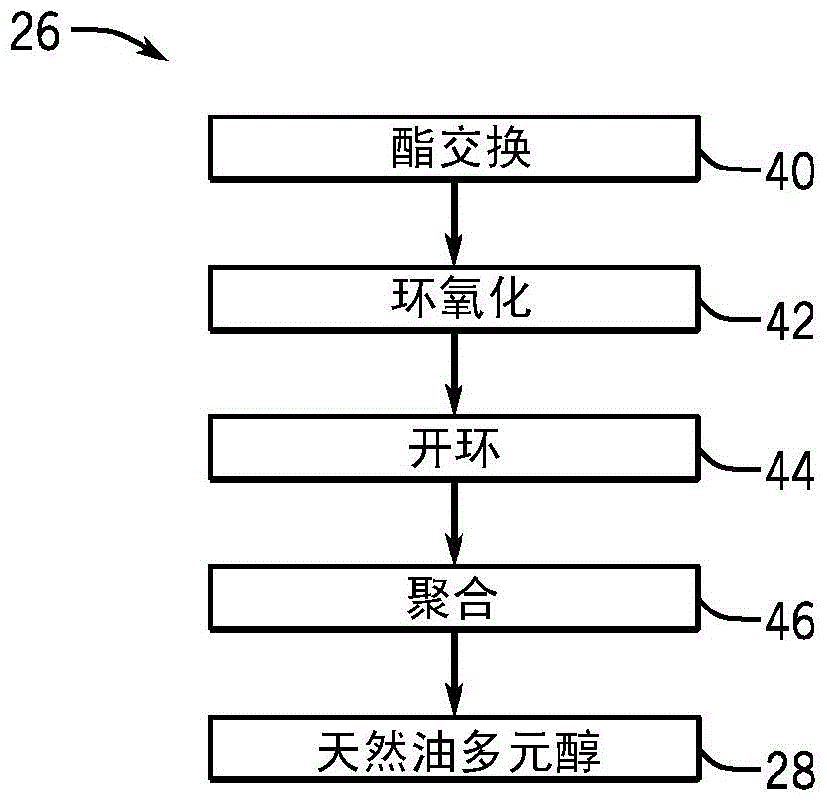

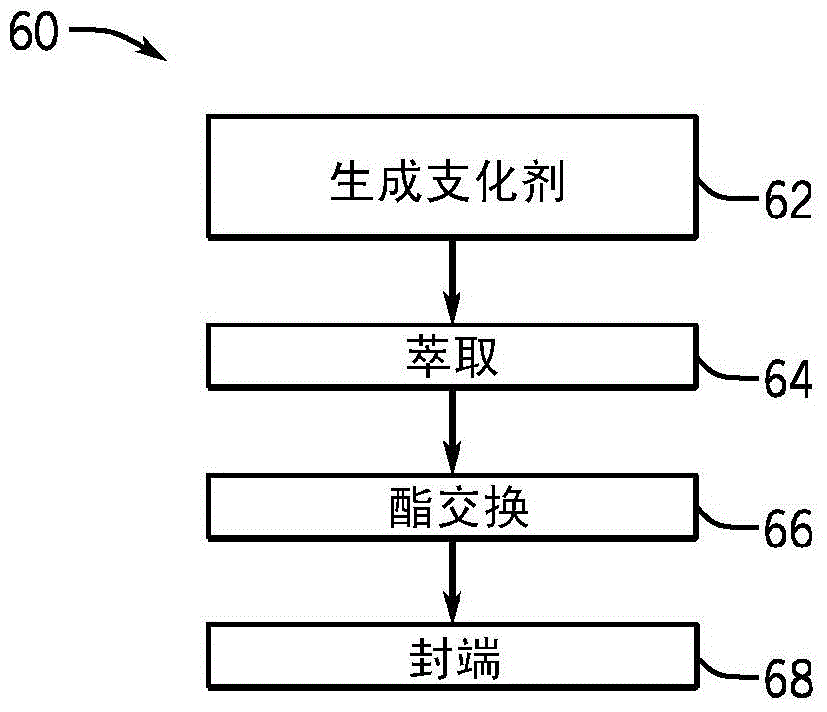

Natural oil polyols derived from post-consumer recycle oils

InactiveCN105764947APreparation rom asymmetrical anhydridesOrganic compound preparationGlycerolDolichol

Disclosed embodiments include an open cell, molded polyurethane foam comprising the reaction product of a reaction mixture comprising: an isocyanate mixture; and a polyol formulation, comprising a glycerin-initiated, alkylene-oxide capped natural oil polyol having a molecular weight of between 3,000 and 8,000 and a polydispersity index (PDI) of between approximately 1.5 and 2.5, wherein the PDI is defined as the ratio of the weight-average molecular weight, Mw, to the number-average molecular weight, Mn.

Owner:JOHNSON CONTROLS TECH CO +1

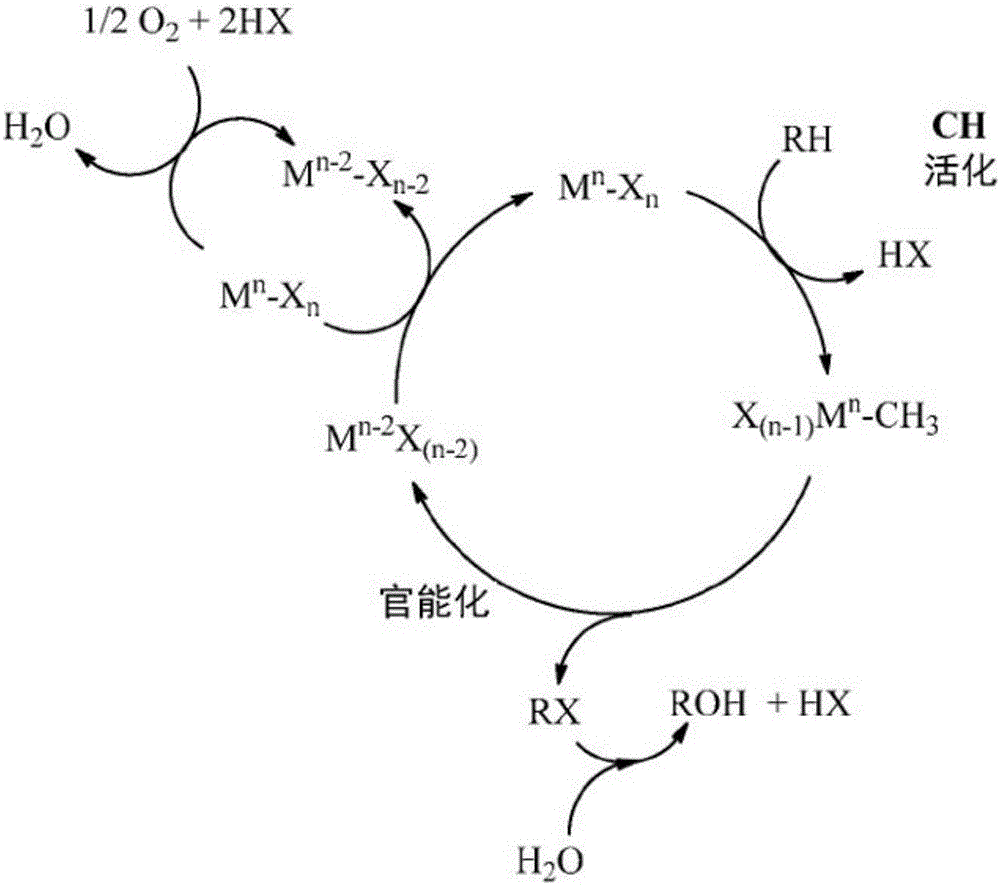

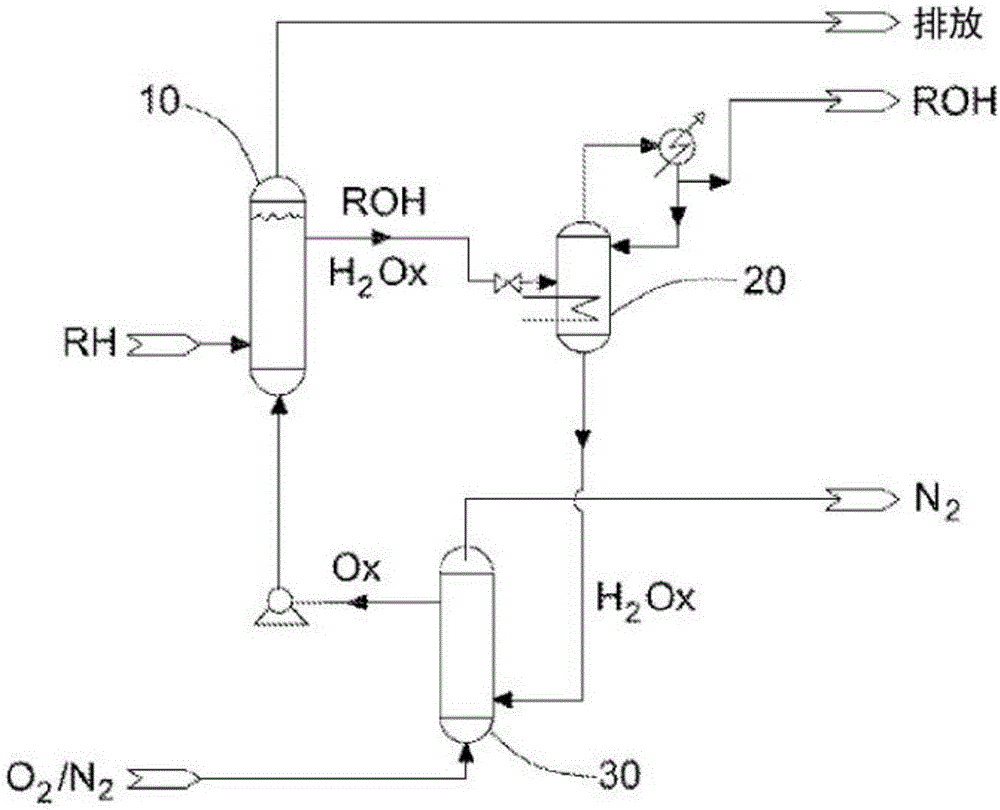

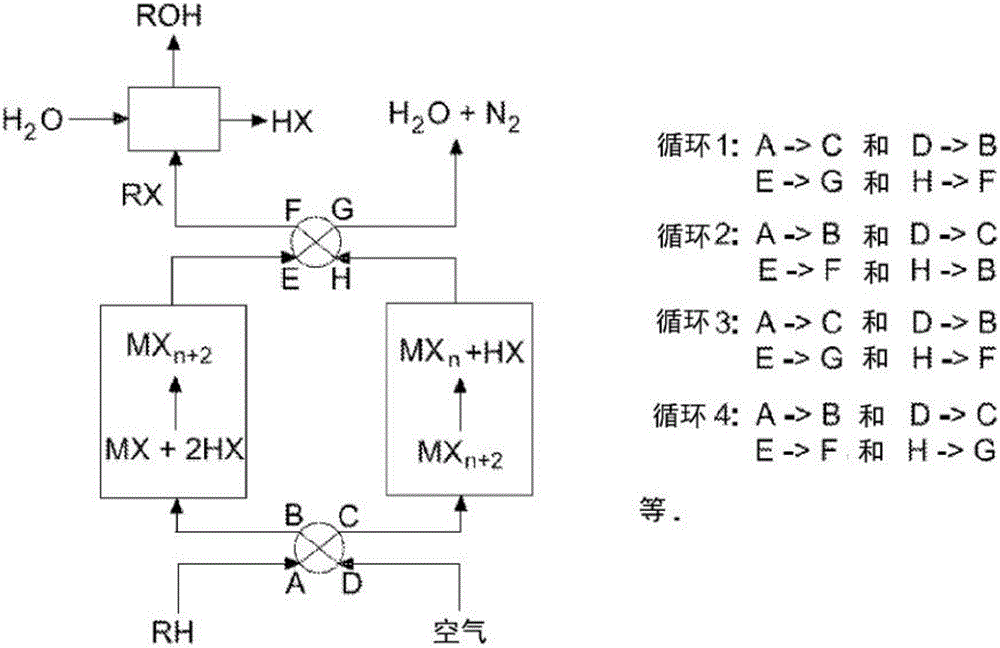

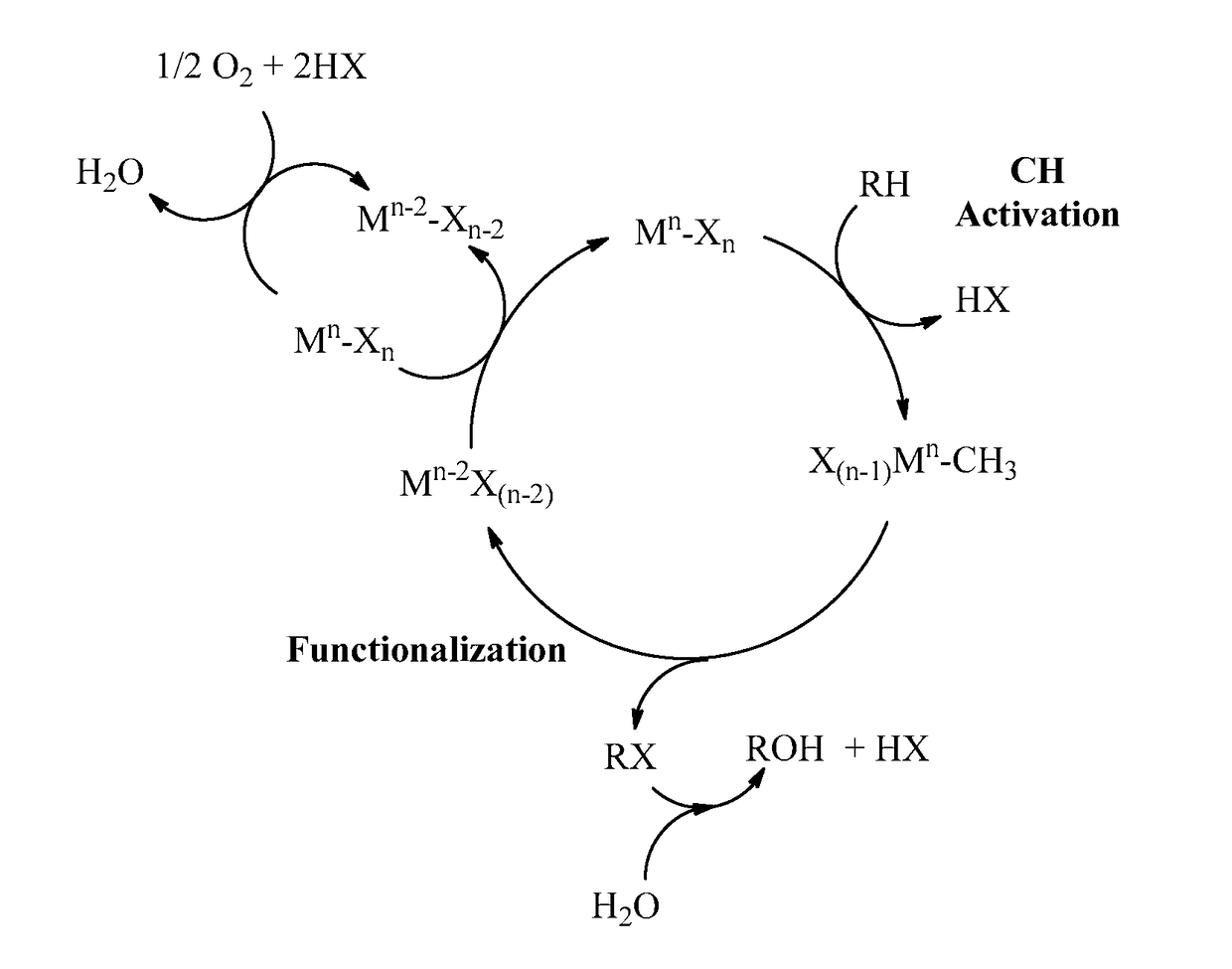

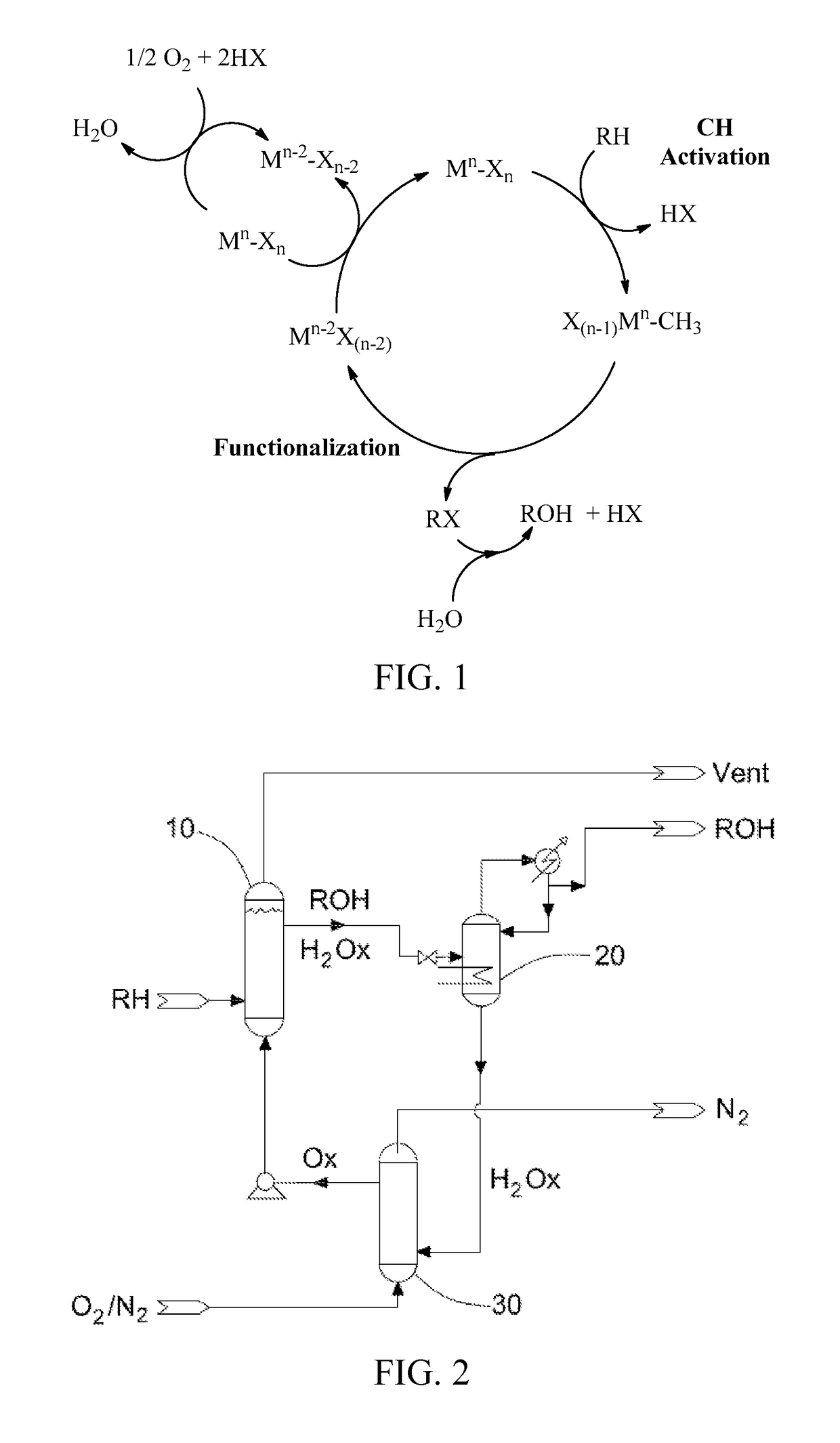

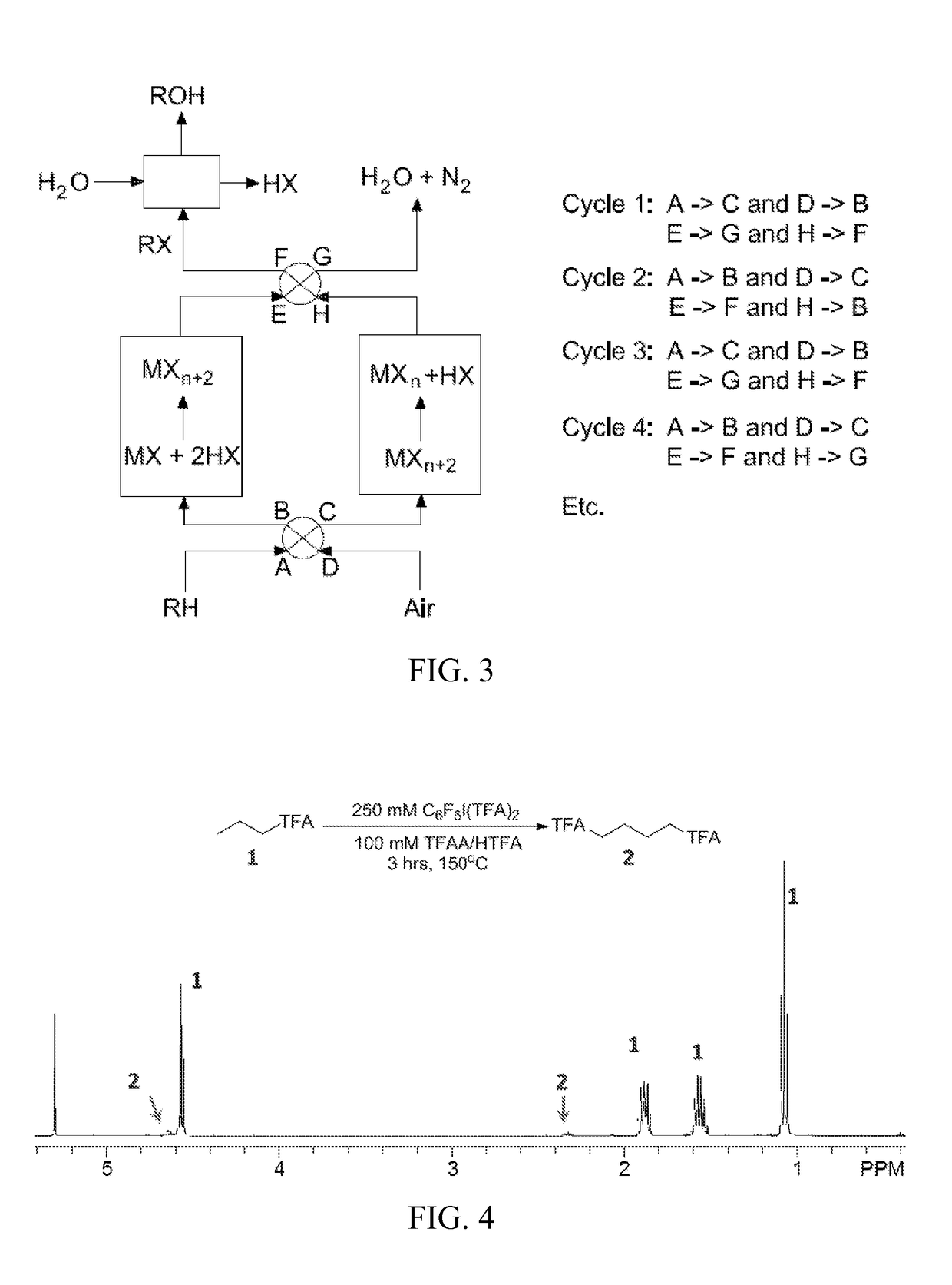

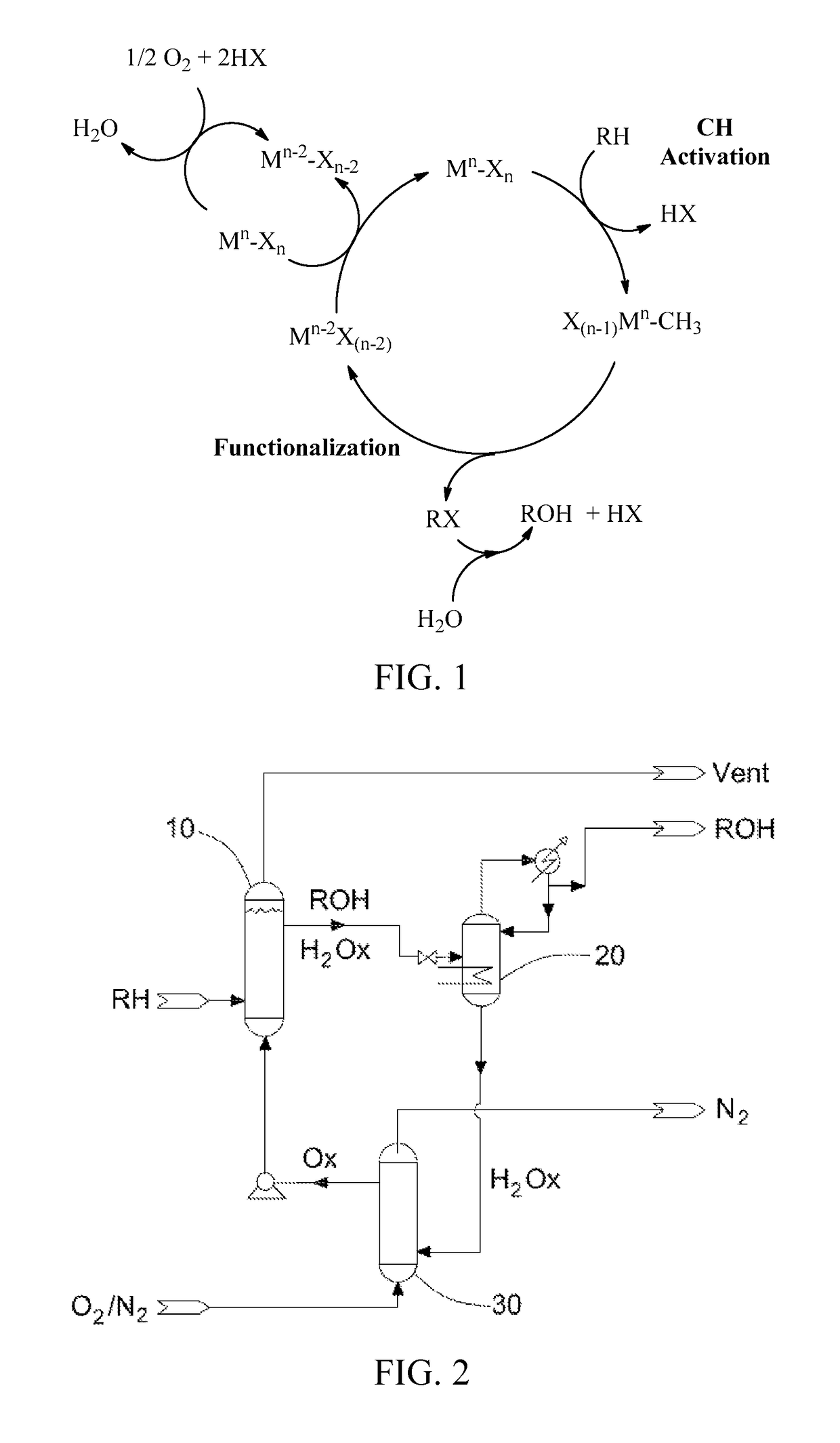

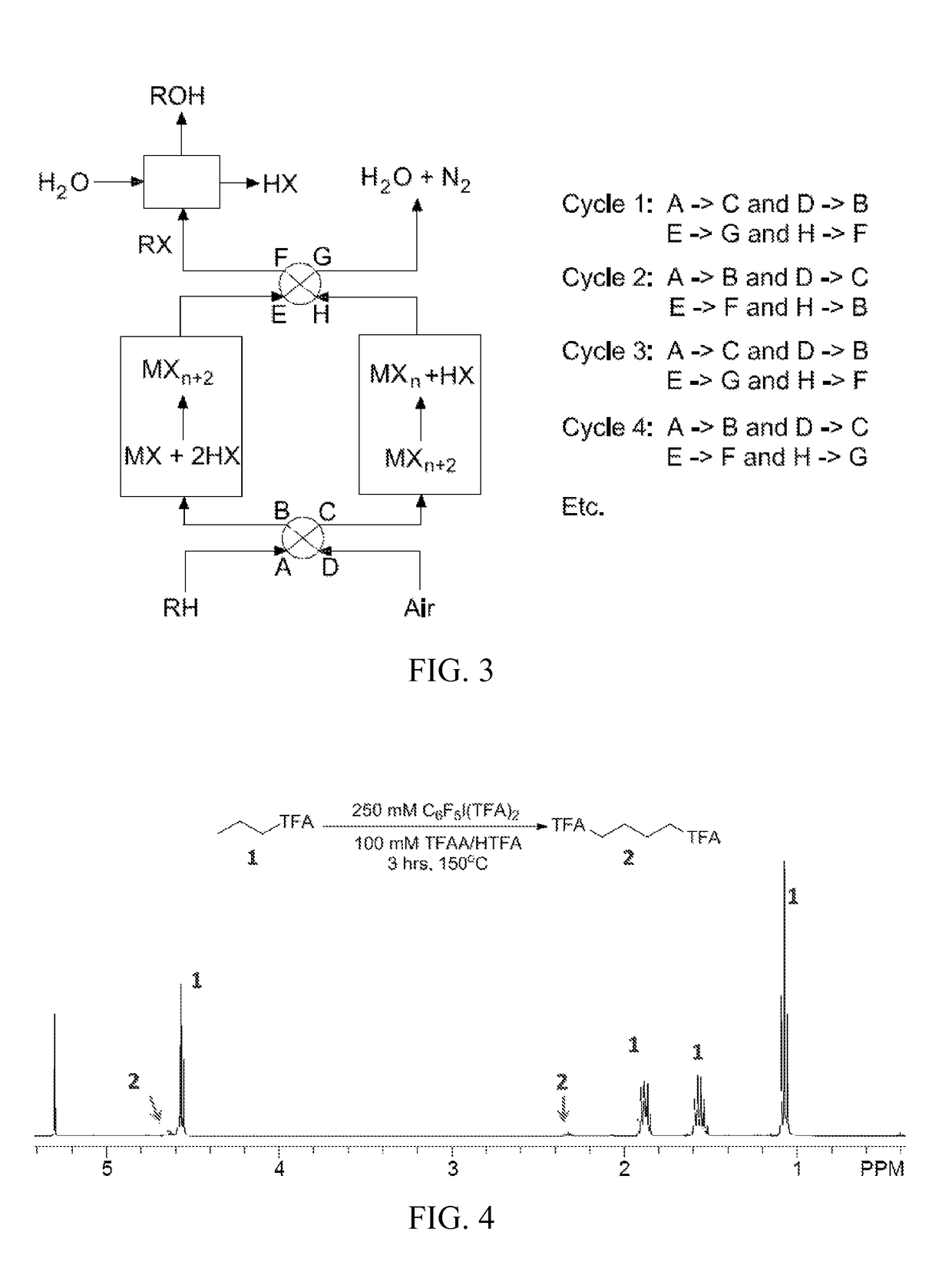

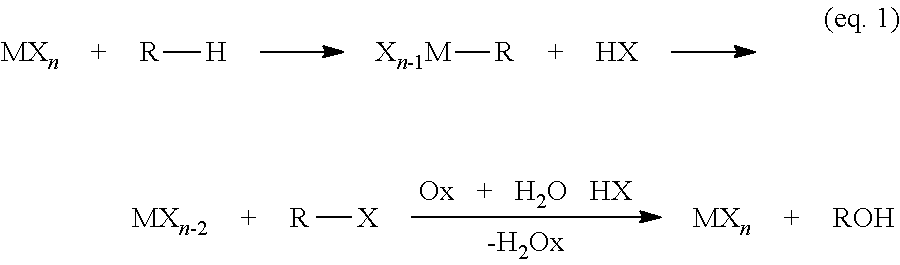

Process for the functionalization of heteroalkanes and arenes

InactiveCN106687439AHigh affinityIncreased affinity of products of higher alkanesPreparation rom asymmetrical anhydridesPreparation by oxidation reactionsMetalloleHydrogen atom

Provided are methods and materials for the functionalization of a heteroalkane or arene using an oxidizing electrophile as a stoichiometric agent or catalyst. The reaction involves the replacement of a hydrogen atom on an sp3-hybridized carbon atom of the heteroalkane or of a hydrogen atom on an sp2-hybridized carbon atom of the arene. A main group element organometallic intermediate is formed that undergoes further conversion to a functionalized heteroalkane or arene.

Owner:THE SCRIPPS RES INST

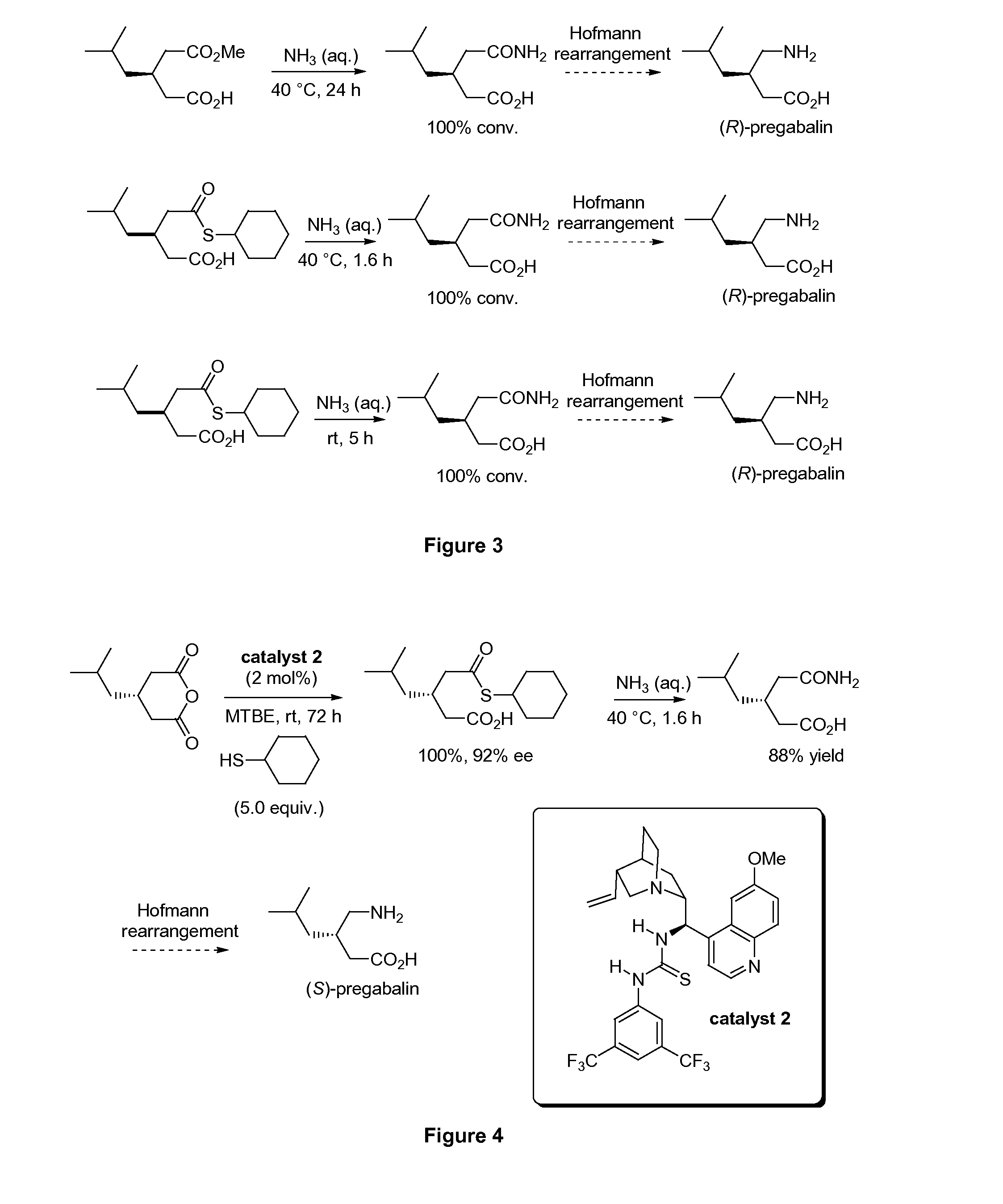

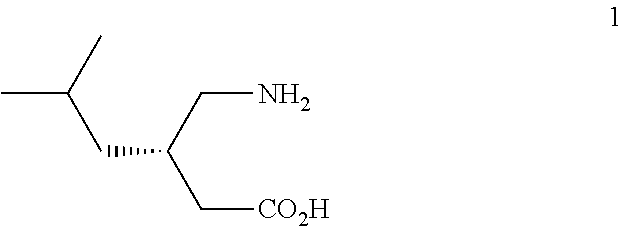

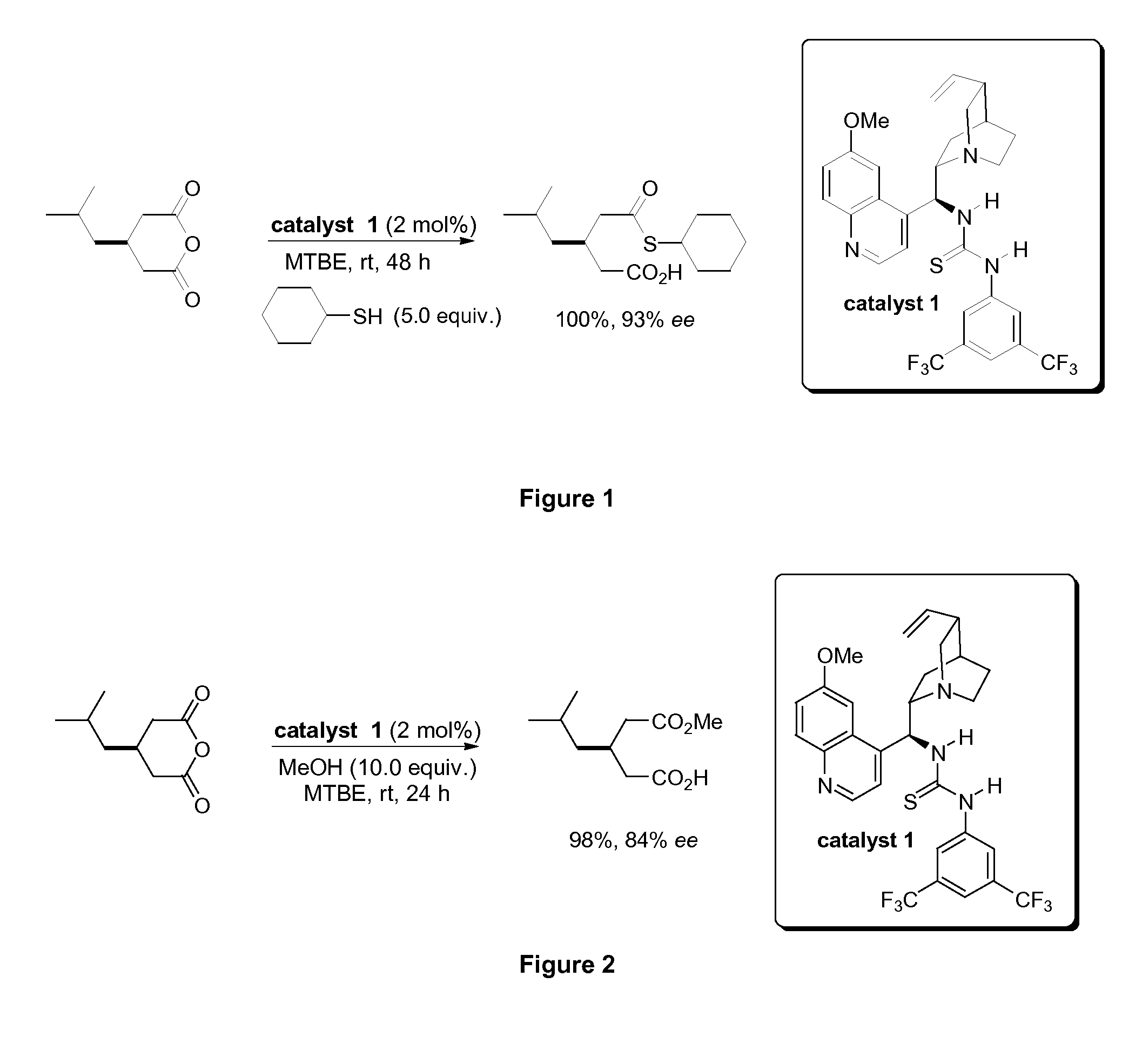

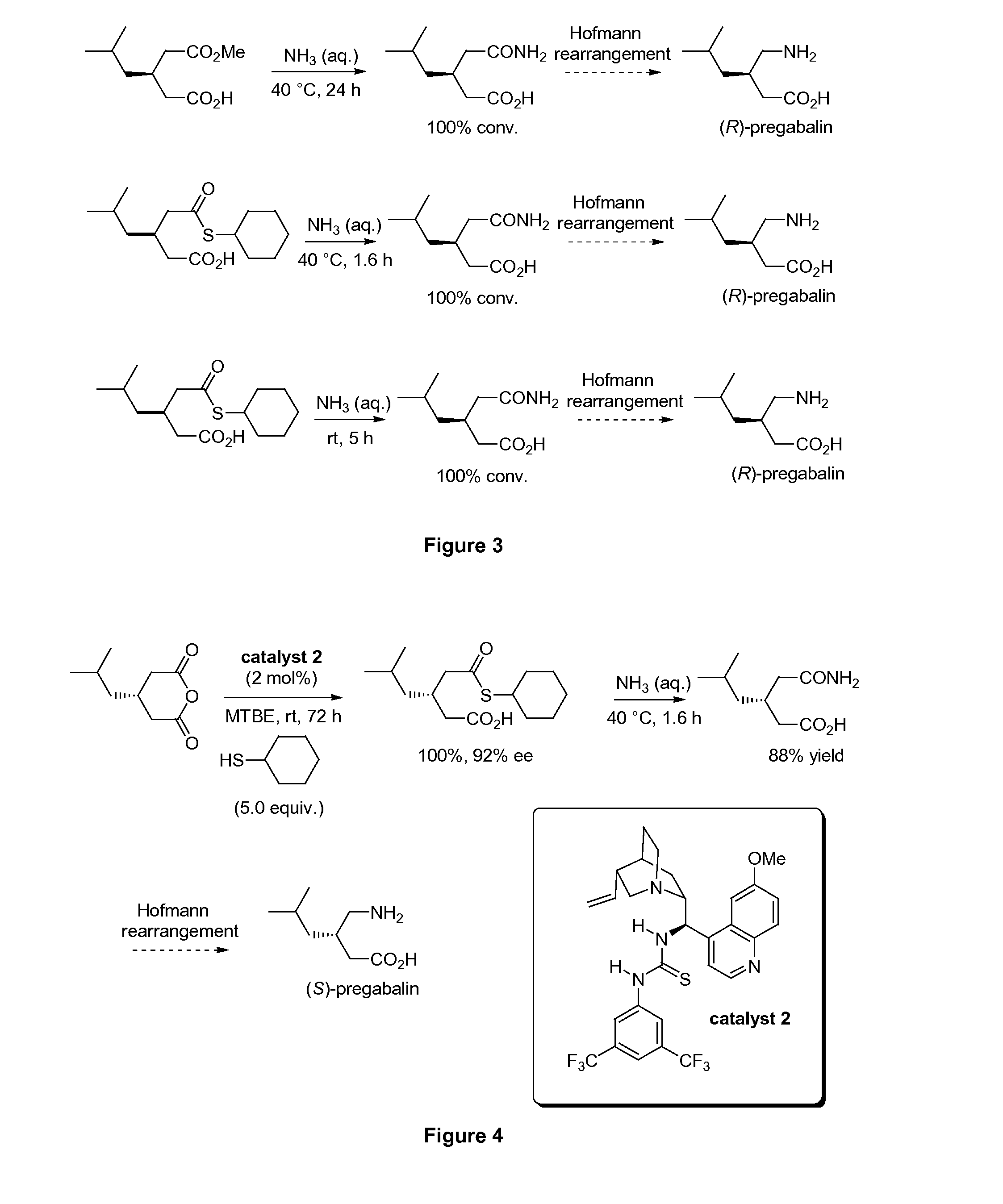

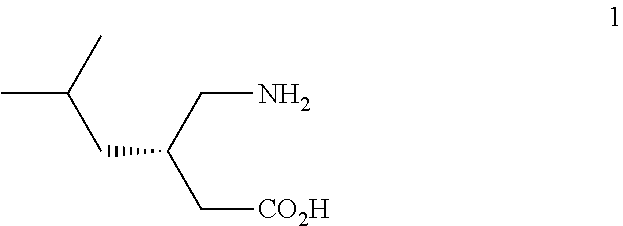

Intermediates in the enantioselective synthesis of 3-(aminomethyl)-5-methyl-hexanoic acid

InactiveUS20120046468A1Improve reaction speedHigh enantioselectivityPreparation rom asymmetrical anhydridesOrganic compound preparationChronic Widespread PainPregabalin

(S)-(+)-3-(aminomethyl)-5-methyl-hexanoic acid or (S)-pregabalin is an anticonvulsive drug. In addition to its use as an anticonvulsive agent, pregabalin has also been indicated as a medicament in the treatment of anxiety, neuropathic pain and pain in patients with fibromyalgia. Provided herein are thioester intermediates in the synthesis of and processes for the synthesis of 3-(aminomethyl)-5-methyl-hexanoic acid in the (R) or (S) configuration.

Owner:TRINITY COLLEGE DUBLIN

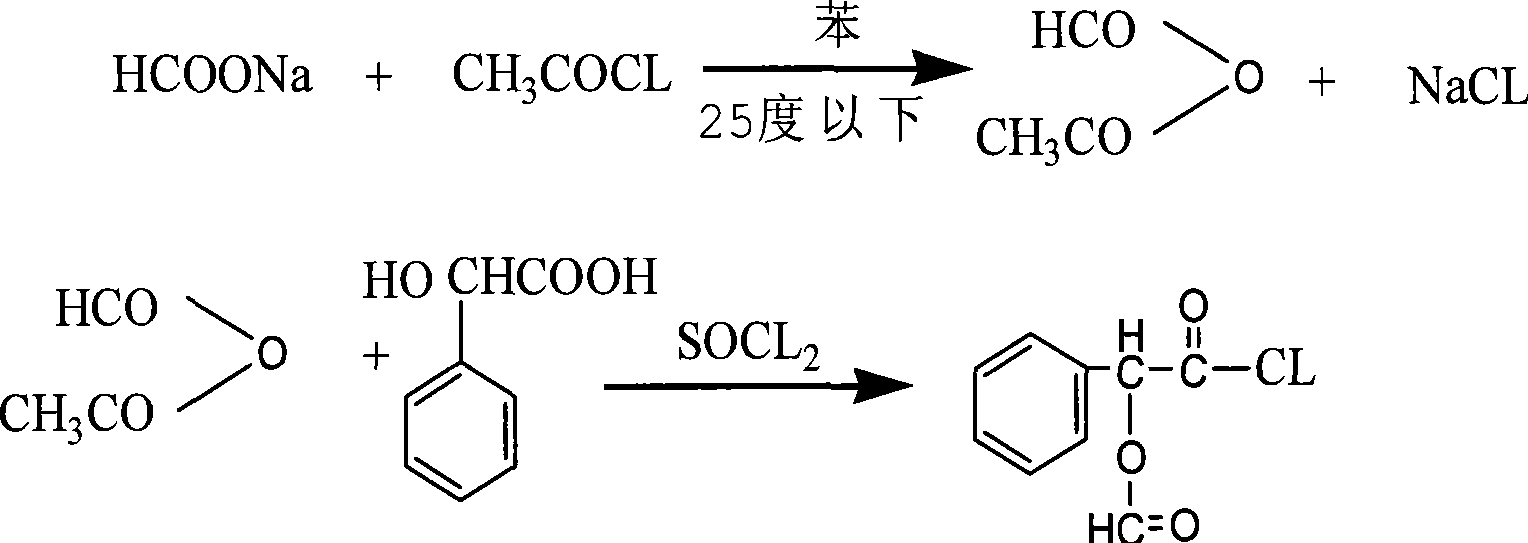

Method for preparing alpha-formyloxy phenylacetyl chloride

InactiveCN101362690AHigh yieldSimple processPreparation rom asymmetrical anhydridesBenzeneAcetyl chloride

The invention discloses a method for preparing a-formyloxy phenyl acetyl chloride, belonging to the chemical engineering field. The materials adopted comprise sodium formate, acetyl chloride, mandelic acid, thionyl chloride and benzene. The preparation process is as follows: 1. material feeding: sodium formate and benzene are added according to the weight ratio of two to one, and proper amount of thionyl chloride is slowly dropped into the solution below 25 DEG C; 2. heat insulation: the solution is insulated under 17 DEG C for 8 hours; 3. processing: suction filtering is carried out, a filter cake is cleaned by benzene and the solution is reserved; 4. material feeding: benzene and mandelic acid with the same weight as the benzene and mandelic acid in step 1 are added, the solution obtained in step 3 is dropped; 5. heat insulation: the solution is insulated under 16 DEG C for 7 hours; 6. distillation: the benzene is decompressed and dried by distillation; 7. material feeding: proper amount of thionyl chloride is added in the product obtained by decompression and drying by distillation, the thionyl chloride is heated, stirred and dried by distillation; 8. decompression and distillation: high vacuum distillation is carried out, finally, a-formyloxy phenyl acetyl chloride is obtained. The method of the invention has the advantages of high yield, simple process, being convenient for large production, less pollution and greening of the material used for synthesis, milder reaction condition and higher selectivity.

Owner:SHIJIAZHUANG GUODA INDAL

Optically active compounds, method for kinetic optical resolution of carboxylic acid derivatives and catalysts therefor

InactiveUS7649094B2Efficient solutionPromote recoveryPreparation rom asymmetrical anhydridesOrganic compound preparationEthyl groupCarboxylic acid

The present invention provides a method of kinetic optical resolution of carboxylic acid derivatives using specific optically active catalysts. A racemic or diastereomeric mixture of carboxylic acid derivatives of the formula (A) is reacted with a nucleophile in the presence of an optically active catalyst to form an optically active nucleophile derivative of the formula (B). The catalyst is an optically active compound represented by the formula (C) or (D) [wherein R1 is a substituted or unsubstituted, saturated or unsaturated, straight-chain, branched or alicyclic aliphatic hydrocarbon group which can have a heteroatom, R2 is ethyl or vinyl, and R5 is hydrogen or methoxy respectively].

Owner:OSAKA SODA CO LTD

Process for the functionalization of heteroalkanes and arenes

ActiveUS20170275222A1Improve stabilityLow costPreparation rom asymmetrical anhydridesPreparation by oxidation reactionsMain group elementHydrogen atom

Provided are methods and materials for the functionalization of a heteroalkane or arene using an oxidizing electrophile as a stoichiometric agent or catalyst. The reaction involves the replacement of a hydrogen atom on an sp3-hybridized carbon atom of the heteroalkane or of a hydrogen atom on an sp2-hybridized carbon atom of the arene. A main group element organometallic intermediate is formed that undergoes further conversion to a functionalized heteroalkane or arene.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

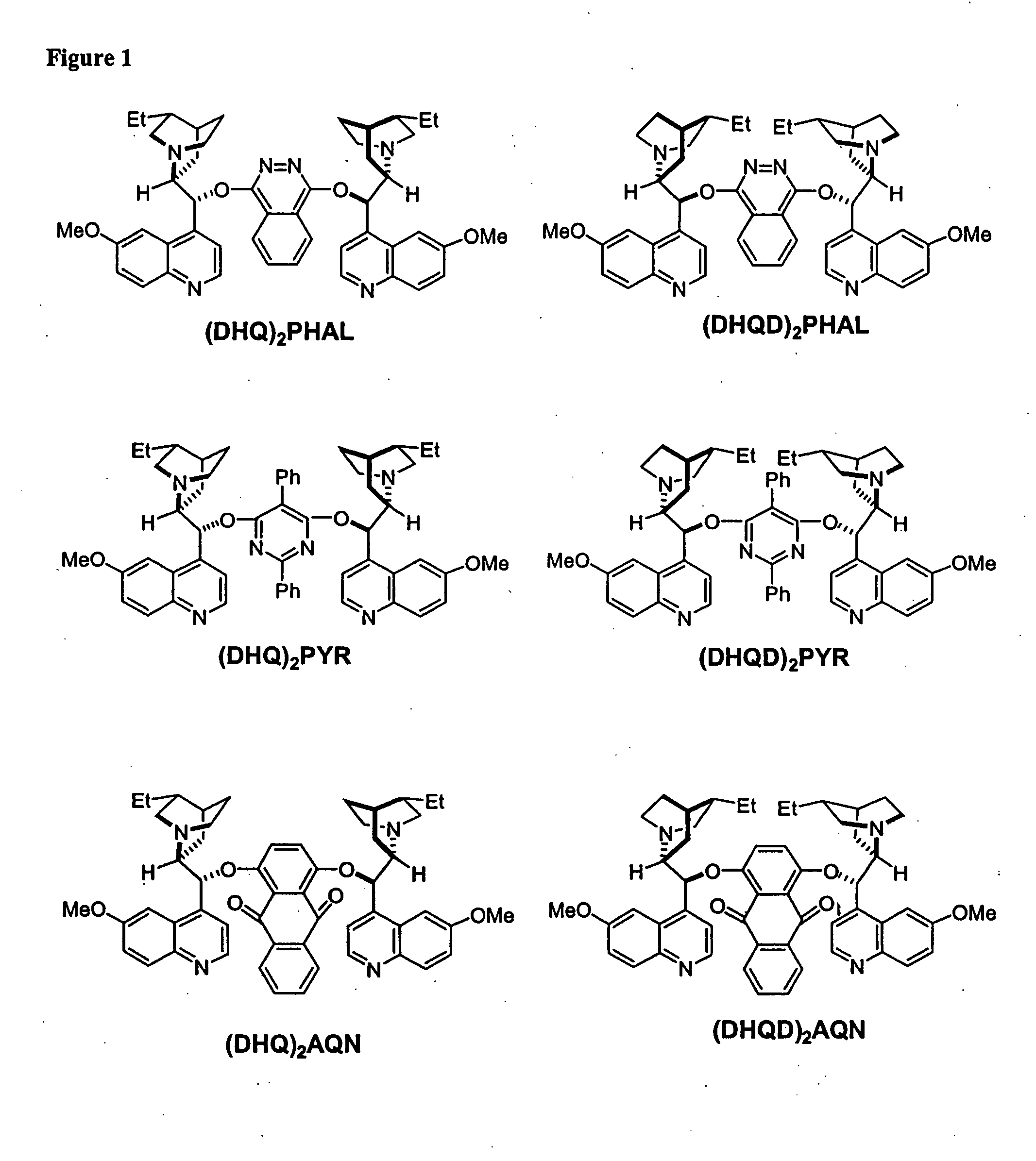

Kinetic resolutions of chiral 2- and 3-substituted carboxylic acids

InactiveUS7057038B2Preparation rom asymmetrical anhydridesCarbamic acid derivatives preparationCarbamateEnantiomer

One aspect of the present invention relates to a method for the kinetic resolution of racemic and diastereomeric mixtures of chiral compounds. The critical elements of the method are: a non-racemic chiral tertiary-amine-containing catalyst; a racemic or diastereomeric mixture of a chiral substrate, e.g., a cyclic carbonate or cyclic carbamate; and a nucleophile, e.g., an alcohol, amine or thiol. A preferred embodiment of the present invention relates to a method for achieving the kinetic resolution of racemic and diastereomeric mixtures of derivatives of α- and β-amino, hydroxy, and thio carboxylic acids. In certain embodiments, the methods of the present invention achieve dynamic kinetic resolution of a racemic or diastereomeric mixture of a substrate, i.e., a kinetic resolution wherein the yield of the resolved enantiomer or diastereomer, respectively, exceeds the amount present in the original mixture due to the in situ equilibration of the enantiomers or diastereomers under the reaction conditions prior to the resolution step.

Owner:BRANDEIS UNIV

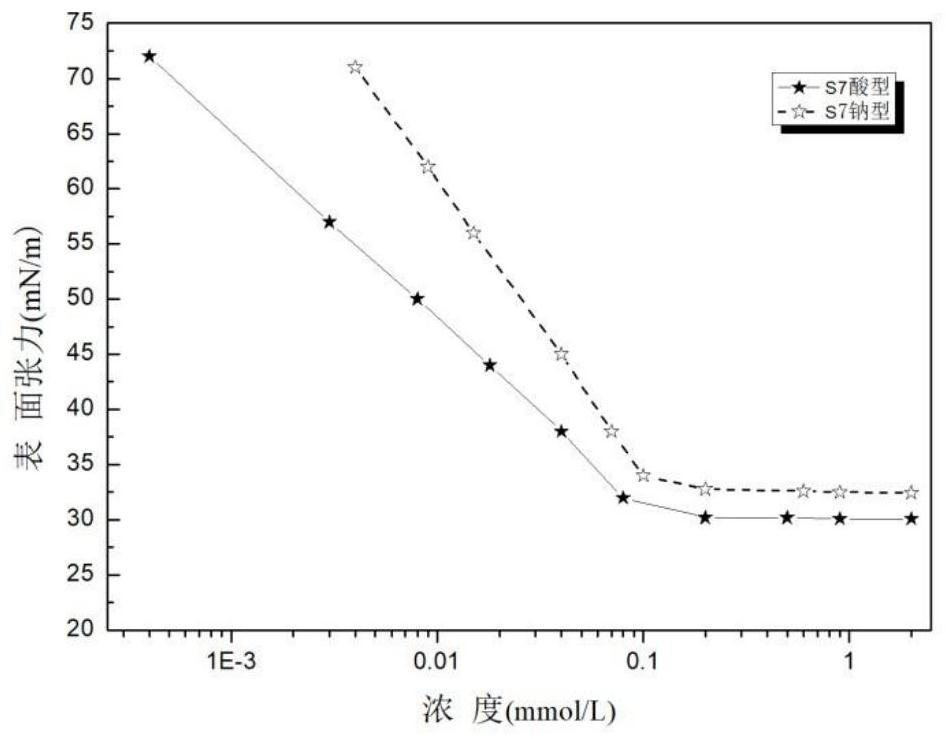

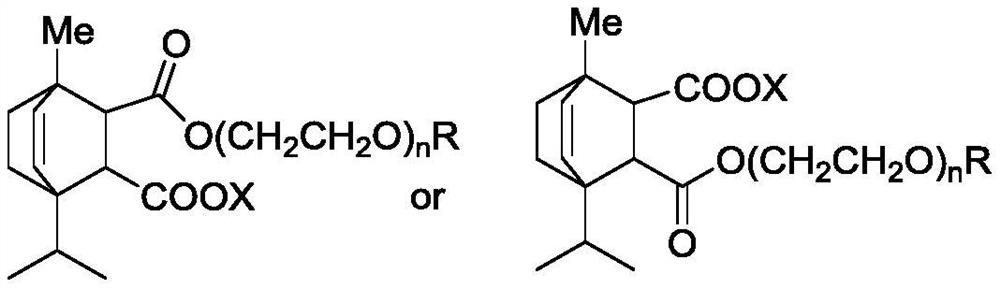

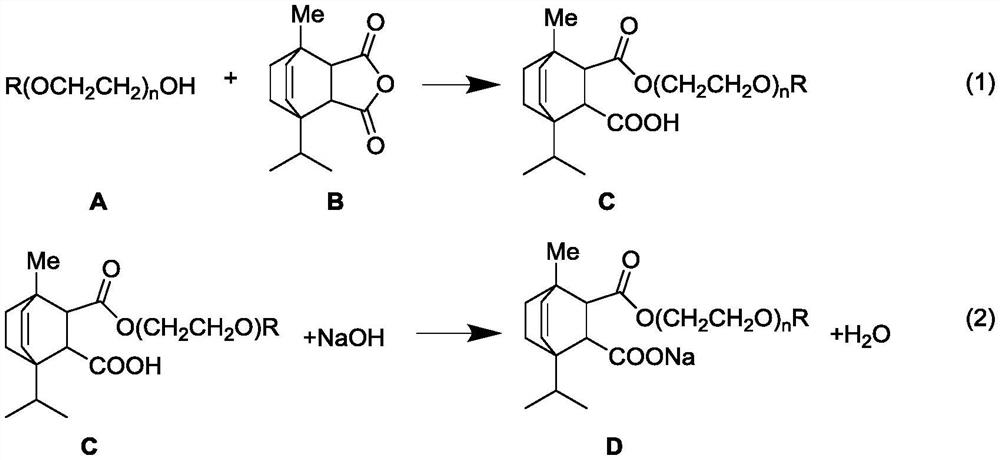

Fatty alcohol ether alpha-pinene-maleic anhydride addition acid surfactant and preparation method thereof

PendingCN114478258AEasy to synthesizeEasy to degradePreparation rom asymmetrical anhydridesOrganic compound preparationActive agentCarboxylic salt

The invention discloses a fatty alcohol ether alpha-pinene-maleic anhydride addition acid surfactant and a preparation method thereof, the surfactant is prepared by the following steps: carrying out acid anhydride alcoholysis reaction on fatty alcohol ether and alpha-pinene-maleic anhydride adduct, and salifying to obtain the corresponding novel fatty alcohol ether carboxylic acid (salt) surfactant. The surfactant is easy to synthesize, easy to degrade, green and pollution-free.

Owner:艾茵化学(深圳)有限公司

Tripentyl esters of trimellitic acid

ActiveUS10577479B2Low tendency to migratePreparation rom asymmetrical anhydridesOrganic compound preparationTrimellitic acidMedicinal chemistry

Tripentyl esters of trimellitic acid, especially mixtures of triisopentyl esters of trimellitic acid comprising isomeric pentyl radicals in which more than 5 mol % of the isomeric pentyl radicals incorporated in the ester mixture are branched, have good compatibility with PVC and PVC-containing polymers and simultaneously exhibit a lesser tendency to migrate.

Owner:EVONIK OXENO GMBH & CO KG

Method for producing fluorine-containing alkyl (meth)acrylate

InactiveCN101142165APreparation rom asymmetrical anhydridesOrganic compound preparationAlcoholHydrogen atom

Disclosed is a method for producing a fluorine-containing alkyl (meth)acrylate represented by the general formula (2) below. The method is characterized in that a fluorine-containing alcohol represented by the general formula (1) below, a (meth)acrylic acid and a sulfonic acid halide are reacted in the presence of a base containing at least one tertiary amine. Rf-(CH2)k-[-A-(CH2)l-]m-OH (1) (In the formula, Rf represents a perfluoroalkyl group having 1-21 carbon atoms; A represents S, SO or SO2; k represents 0, 1 or 2; l represents 1, 2 or 3; and m represents 0 or 1. In this connection, k = 0 and m = 0 do not occur at the same time. Rf-(CH2)k-[-A-(CH2)l-]m-OCOCR=CH2 (2) (In the formula, R represents a hydrogen atom or a methyl group.

Owner:TOKUYAMA CORP +1

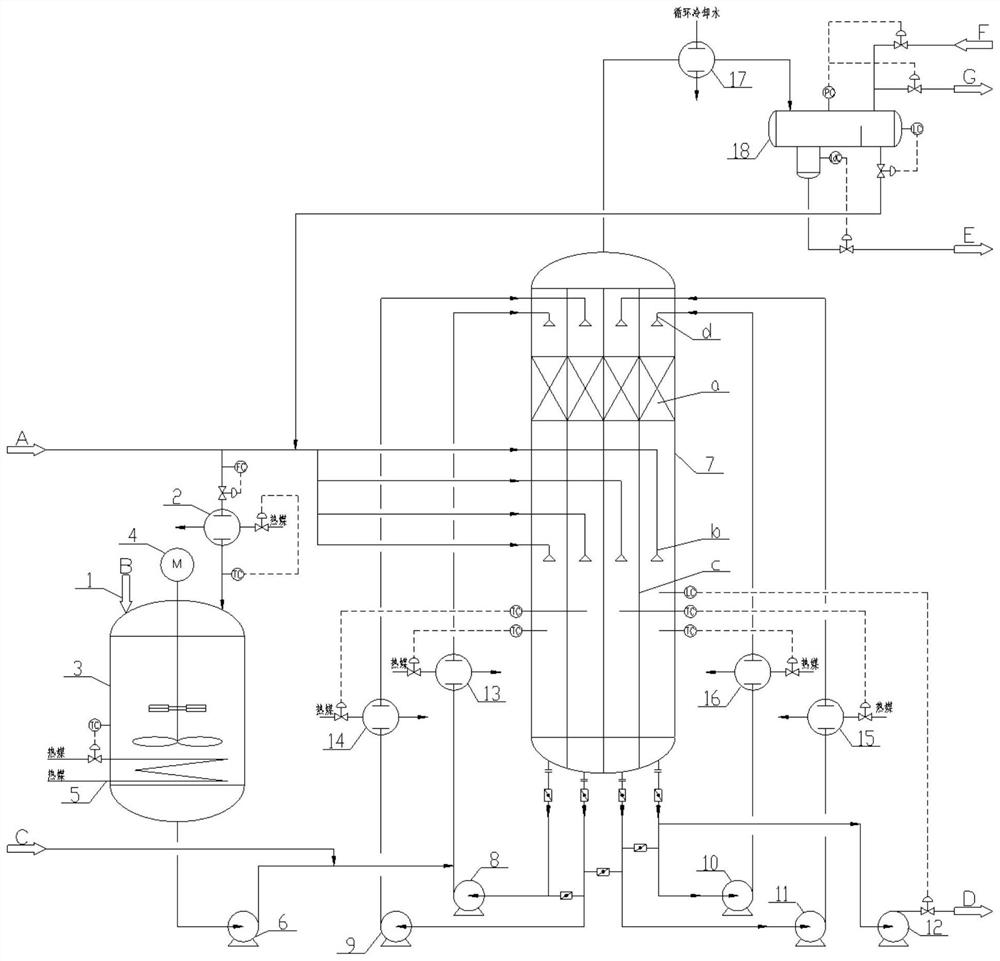

Production method for preparing environment-friendly plasticizer by adopting continuous method

PendingCN112679345AHigh automation purityImprove efficiencyPreparation rom asymmetrical anhydridesOrganic compound preparationBenzoic acidPtru catalyst

The invention relates to a production method for preparing an environment-friendly plasticizer by adopting a continuous method, which comprises the following steps: reacting benzoic acid with alcohol in the presence of a catalyst to obtain a benzoate plasticizer, and is characterized by comprising the following steps: mixing solid granular or blocky raw material benzoic acid with alcohol to obtain a raw material reaction solution; mixing and heating raw material reaction liquid, a catalyst and first-stage reaction liquid to 160-250 DEG C and allowing the raw material reaction liquid, a catalyst and first-stage reaction liquid to enter the top of a first-stage reaction cavity of a partition plate tower reactor, introducing alcohol from the middle of each stage of reaction cavity of the tower reactor to be subjected to esterification reaction with reaction mixed liquid, and externally and circularly heating each stage of reaction liquid to 160-250 DEG C to maintain the reaction temperature, wherein unreacted alcohol at each stage and water generated by reaction are vaporized, are collected and discharged at the top of the partition plate tower reactor, and are condensed, layered and separated; and enabling crude ester discharged from the bottom of the fourth-stage reaction chamber to be subjected to post-treatment to obtain a plasticizer product. According to the invention, continuous production of the environment-friendly plasticizer is realized in a manner of series connection of multiple stages of reaction cavities in the partition plate tower type reactor, and the method has the characteristics of safety, high efficiency, high automation degree, small occupied area and energy conservation.

Owner:南京中设石化工程有限公司

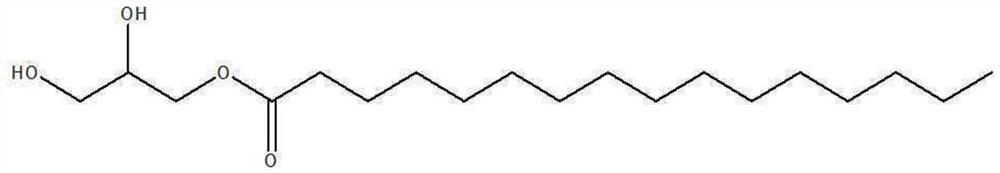

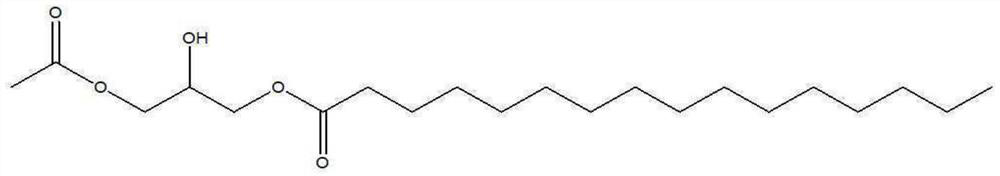

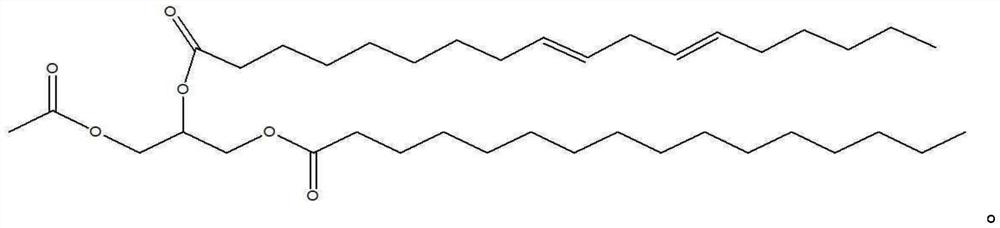

Method for producing 1-palmitoyl-2-linoleoyl-3-acetyl glycerol

PendingCN112661634AHigh purityInhibition formationPreparation rom asymmetrical anhydridesPreparation from carboxylic acid halidesAcetyl chlorideAcetic anhydride

Disclosed is a method for producing 1-palmitoyl-2-linoleoyl-3-acetyl glycerol of high purity with high yield by carrying out acetylation of 1-palmitoyl glycerol with acetic anhydride or a mixture of acetic anhydride and acetyl chloride. The method for producing 1-palmitoyl-2-linoleoyl-3-acetyl glycerol comprises the steps of: preparing 1-palmitoyl-3-acetyl glycerol intermediate of Chemical formula 2 in the specification by reacting 1-palm itoyl glycerol of Chemical formula 1 in the specification and an acetylating agent selected from the group consisting of (i) acetic anhydride and (ii) a mixture of acetic anhydride and acetyl chloride; and reacting the 1-palmitoyl-3-acetyl glycerol intermediate and linoleic acid. The method suppresses the formation of impurities or degradation products and does not need an additional purification step.

Owner:ENZYCHEM LIFESCI CORP

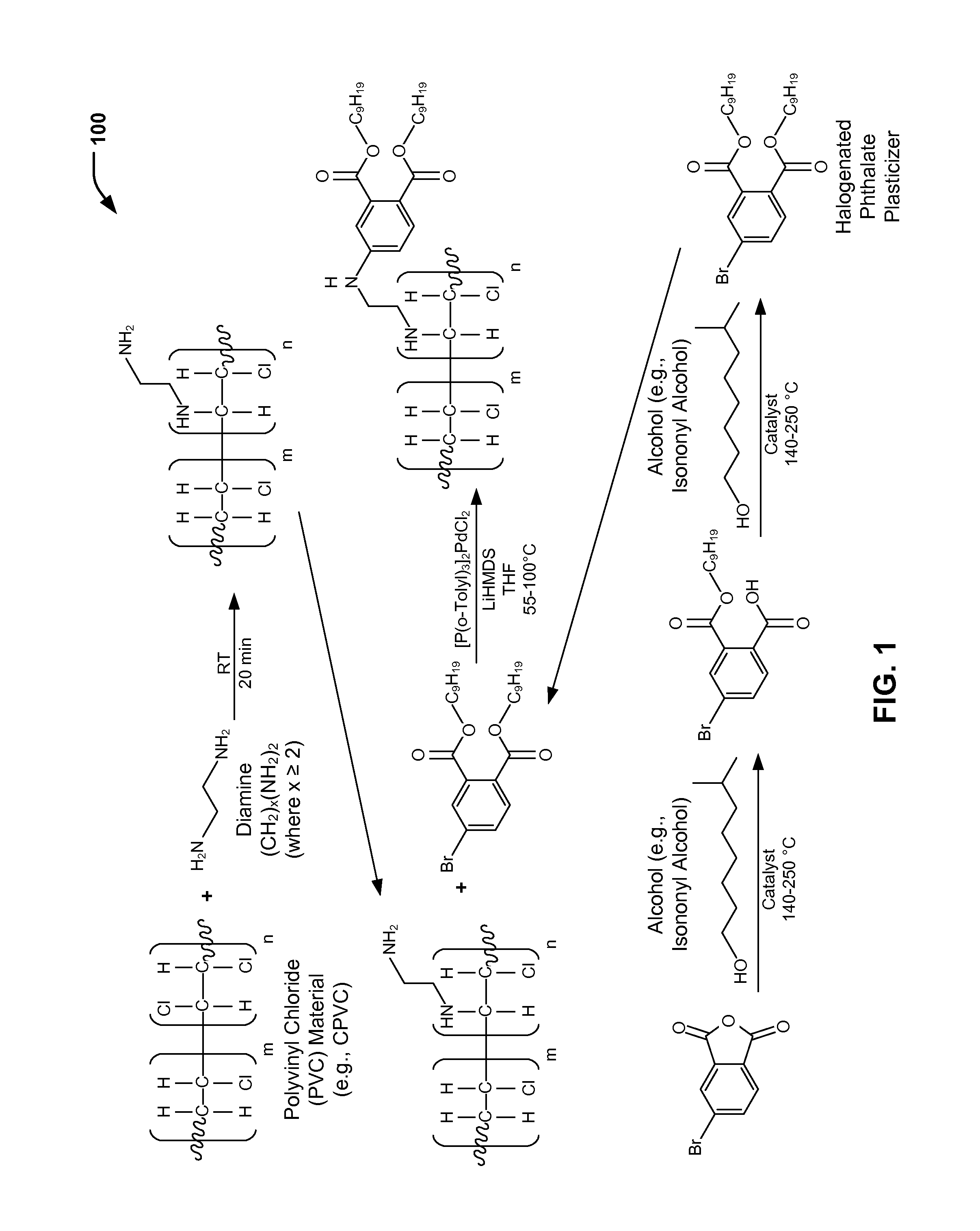

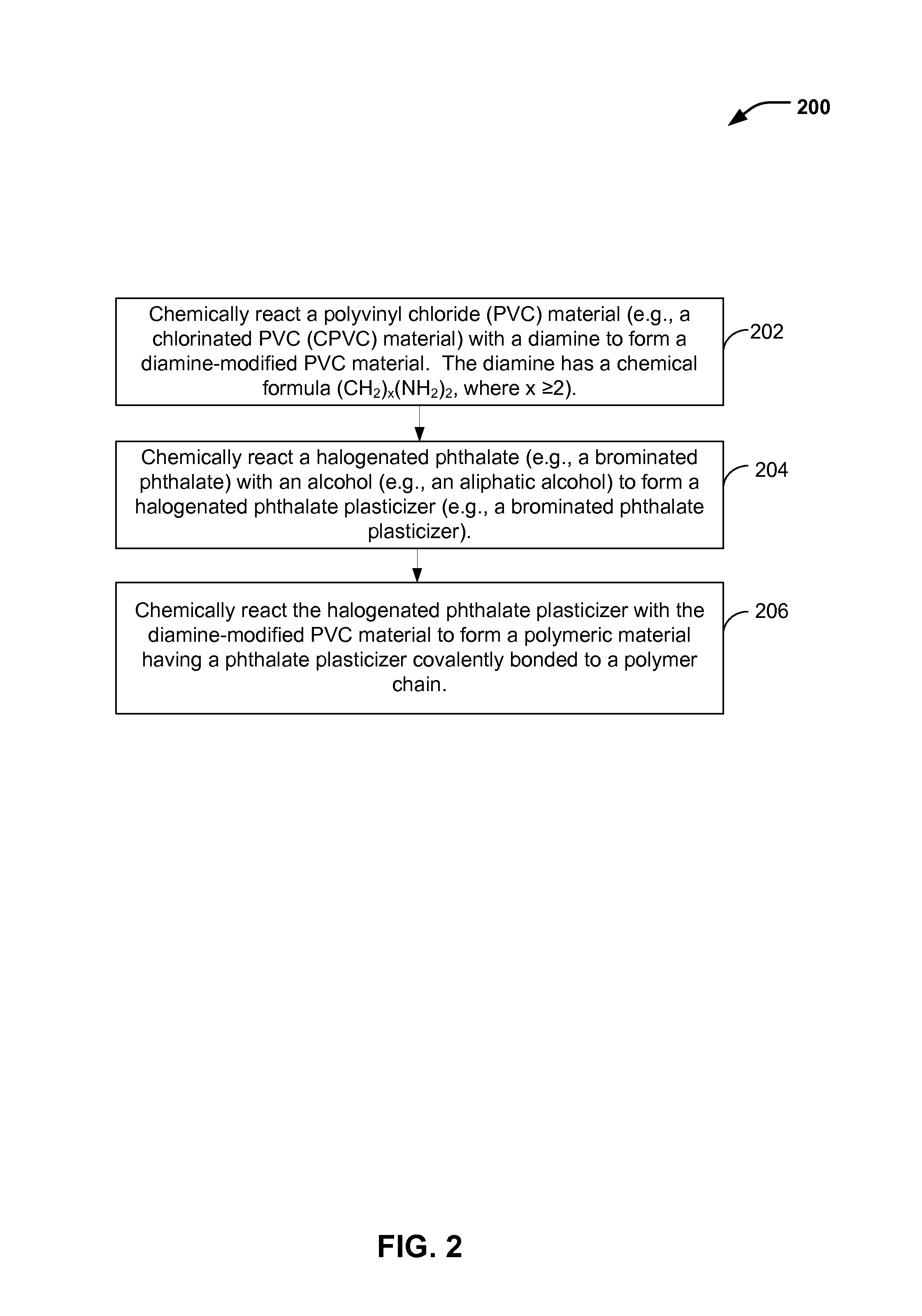

Polymeric materials having phthalate plasticizers covalently bonded to a polymer chain

InactiveUS9567417B1Reduce/prevent leach-outImprove freedom of movementPreparation rom asymmetrical anhydridesPolymer sciencePlasticizer

In an example, a process of forming a polymeric material is disclosed. The process may include chemically reacting a polyvinyl chloride (PVC) material with a diamine to form a diamine-modified PVC material. The diamine has a chemical formula (CH2)x(NH2)2, where x is not less than 2. The process may also include chemically reacting a halogenated phthalate plasticizer with the diamine-modified PVC material to form a polymeric material having a phthalate plasticizer covalently bonded to a polymer chain.

Owner:IBM CORP

Intermediates in the enantioselective synthesis of 3-(aminomethyl)-5-methyl-hexanoic acid

InactiveUS8476441B2Improve reaction speedHigh enantioselectivityPreparation rom asymmetrical anhydridesOrganic compound preparationChronic Widespread PainMedicine

(S)-(+)-3-(aminomethyl)-5-methyl-hexanoic acid or (S)-pregabalin is an anticonvulsive drug. In addition to its use as an anticonvulsive agent, pregabalin has also been indicated as a medicament in the treatment of anxiety, neuropathic pain and pain in patients with fibromyalgia. Provided herein are thioester intermediates in the synthesis of and processes for the synthesis of 3-(aminomethyl)-5-methyl-hexanoic acid in the (R) or (S) configuration.

Owner:TRINITY COLLEGE DUBLIN

Kinetic resolutions of chiral 2- and 3-substituted carboxylic acids

InactiveUS20050020849A1Preparation rom asymmetrical anhydridesCarbamic acid derivatives preparationCarbamateEnantiomer

One aspect of the present invention relates to a method for the kinetic resolution of racemic and diastereomeric mixtures of chiral compounds. The critical elements of the method are: a non-racemic chiral tertiary-amine-containing catalyst; a racemic or diastereomeric mixture of a chiral substrate, e.g., a cyclic carbonate or cyclic carbamate; and a nucleophile, e.g., an alcohol, amine or thiol. A preferred embodiment of the present invention relates to a method for achieving the kinetic resolution of racemic and diastereomeric mixtures of derivatives of α- and β-amino, hydroxy, and thio carboxylic acids. In certain embodiments, the methods of the present invention achieve dynamic kinetic resolution of a racemic or diastereomeric mixture of a substrate, i.e., a kinetic resolution wherein the yield of the resolved enantiomer or diastereomer, respectively, exceeds the amount present in the original mixture due to the in situ equilibration of the enantiomers or diastereomers under the reaction conditions prior to the resolution step.

Owner:BRANDEIS UNIV

Process for the functionalization of heteroalkanes and arenes

ActiveUS10011547B2Improve stabilityLow costPreparation rom asymmetrical anhydridesPreparation by oxidation reactionsMain group elementHydrogen atom

Provided are methods and materials for the functionalization of a heteroalkane or arene using an oxidizing electrophile as a stoichiometric agent or catalyst. The reaction involves the replacement of a hydrogen atom on an sp3-hybridized carbon atom of the heteroalkane or of a hydrogen atom on an sp2-hybridized carbon atom of the arene. A main group element organometallic intermediate is formed that undergoes further conversion to a functionalized heteroalkane or arene.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

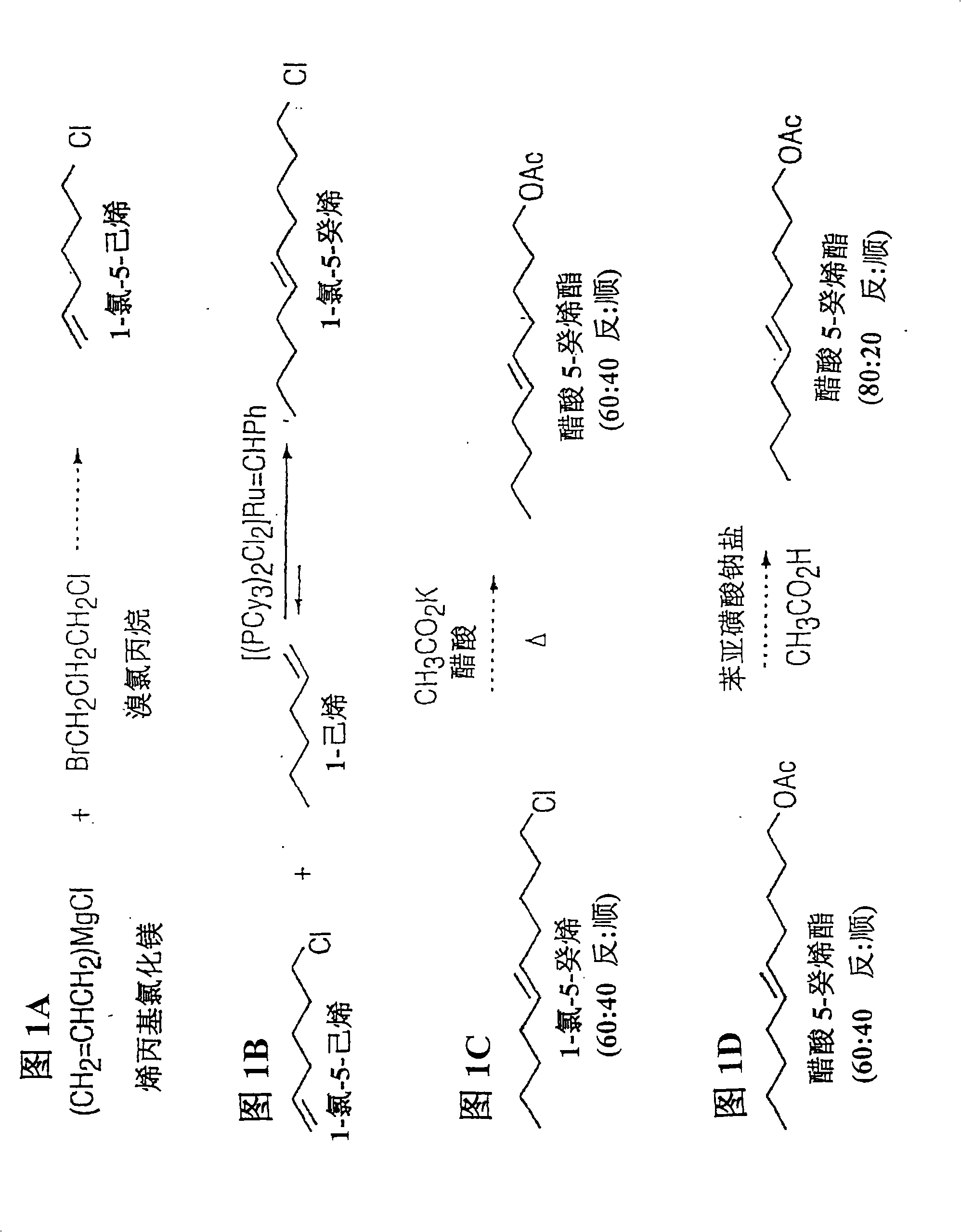

Metathesis synthesis of pheromones or their components

InactiveCN100528829CPreparation rom asymmetrical anhydridesOrganic compound preparationDiamondback mothMicrobiology

The present invention relates to metathesis syntheses for insect sex-attractant pheromones or their components, such as E-5-decenyl acetate, the major component of the Peach Twig Borer pheromone; (5R, 6S)-6-acetoxy-5-hexadecanolide, the mosquito oviposition attractant pheromone; E9, Z11-hexadecadienal, the pecan nut casebearer moth pheromone; 9-tetradecenyl formate, an analog of the Diamondback Moth (DBM) pheromone; 11-tetradecenyl acetate, the Omnivorous Leafroller (OLR) pheromone; E-4-tridecenyl acetate, the major component of the Tomato Pinworm (TPW) pheromone; E,E-8,10-dodecadienol, the Codling Moth (CM) pheromone. The syntheses preferably employ a Class I-IV metathesis catalyst, entail few reaction steps, use generally commercially available starting materials, and have relatively short process times. These syntheses produce good yields without the need for expensive or sophisticated equipment. The invention also provides an inexpensive route for producing omega-haloalkenols by cross-metathesizing alpha-omega-diacetoxy alkenes and alpha-omega-dihalides to yield omega-haloalkenols, which are easily converted into omega-haloalkanols under traditional hydrogenation methods.

Owner:R·L·佩德森 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com