Natural oil polyols derived from post-consumer recycle oils

A technology of natural oil polyols and polyols, applied in the field of natural oil polyols derived from post-consumer recycled oils, which can solve problems affecting the overall performance of polyurethane foams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

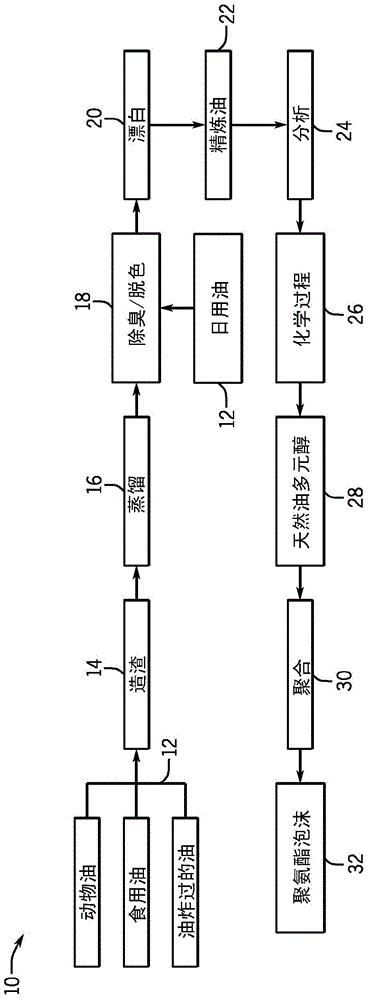

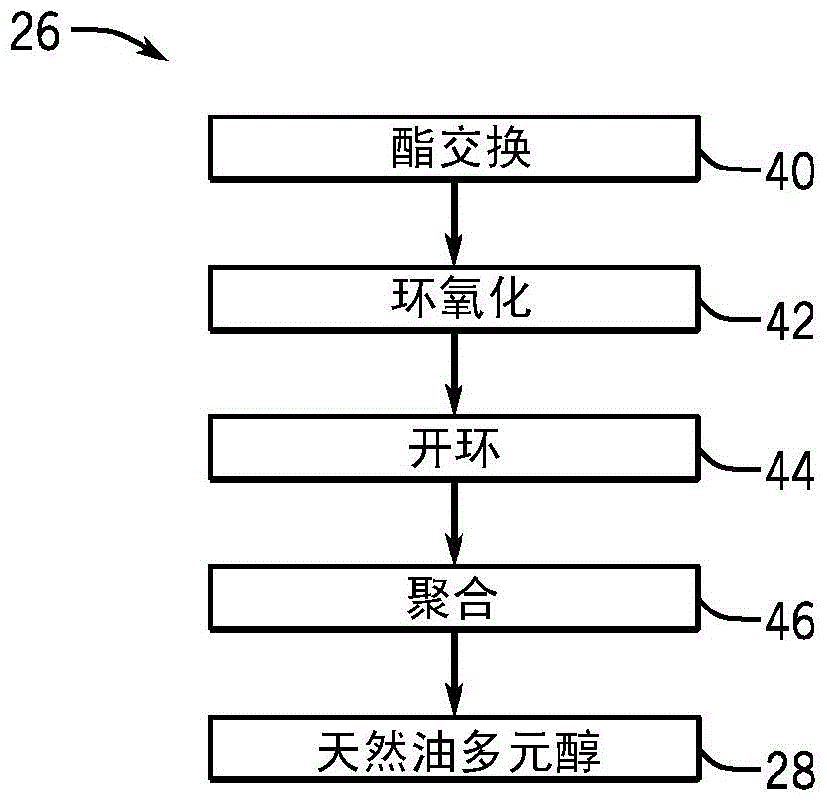

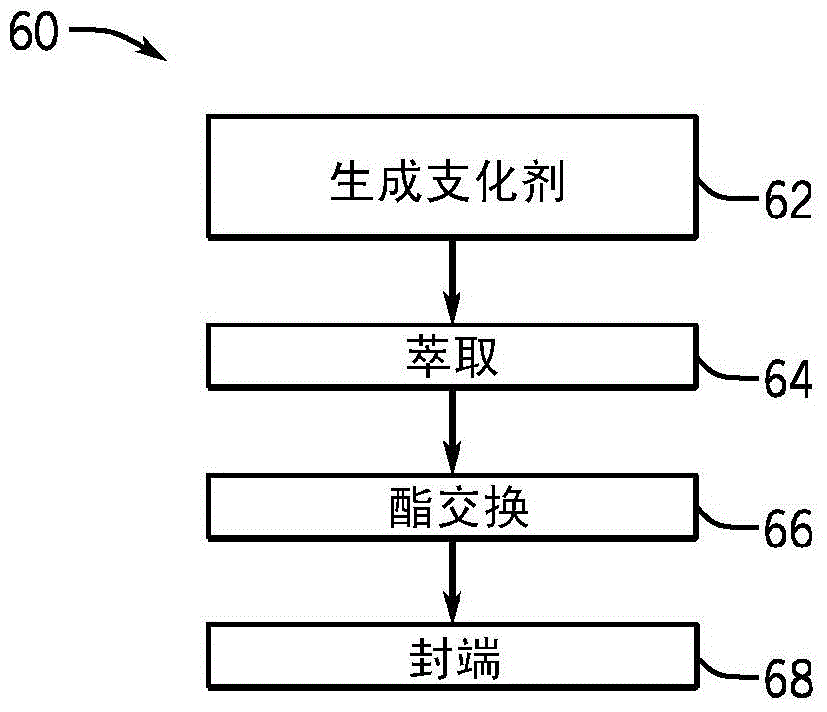

[0018] Many of the polyols used in the synthesis of polyurethanes are synthetic. Accordingly, there is a growing interest in generating natural oil polyols from bio-based sources to minimize dependence on petroleum products and reduce carbon footprint. Typically, natural oil polyols (NOPs) are derived from vegetable oils such as soybean oil, rapeseed oil, and palm oil, among others. These vegetable oils are derived down to their respective C 12 to C 22 organic saturated and unsaturated acids, which are used as initiators to generate NOP. However, the chemistry used to synthesize NOPs produces species with low molecular weight and / or secondary hydroxyl groups. Furthermore, sources of the required vegetable oils can be limited and / or expensive. Therefore, it may be desirable to use feedstock derived from recycled materials. According to the present disclosure, such recovered materials may include used oils, such as animal oils, cooking oils, frying oils, and waste oils. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com