Bio-based polyol

一种多元醇、烃基的技术,应用在多元醇领域,能够解决材料粘稠等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

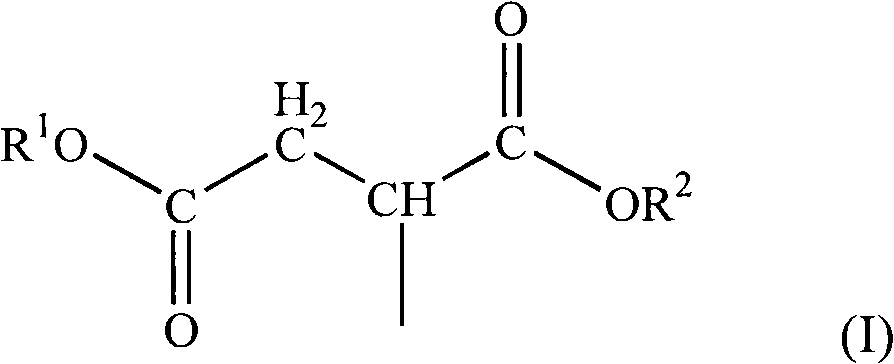

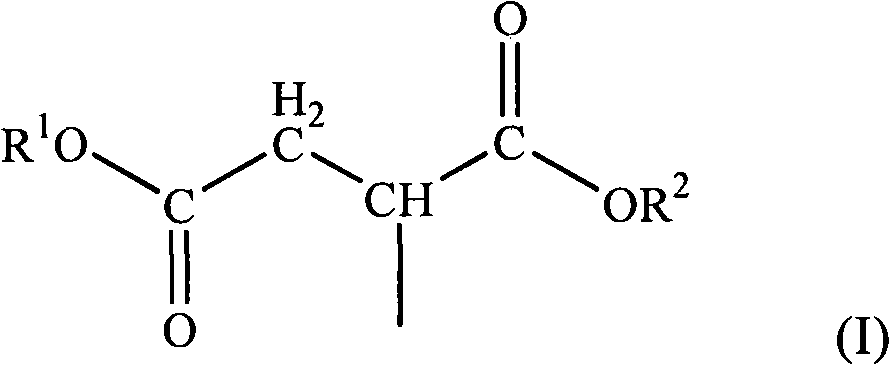

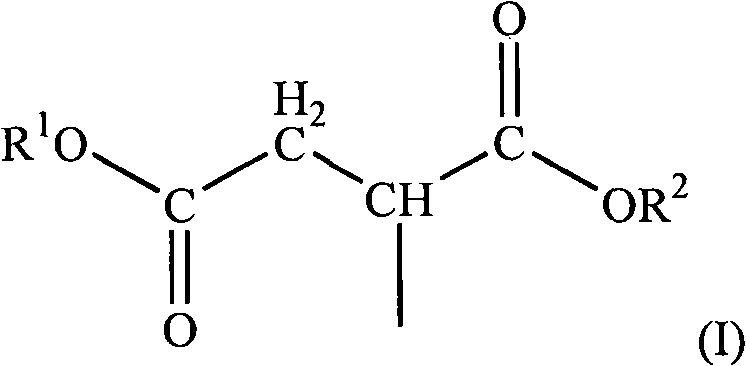

Method used

Image

Examples

Embodiment 1

[0034]Embodiment 1: prepare bio-based polyester resin (polyol) (comparison)

[0035] project

Monomer / Intermediate

Amount added (g)

1

1000.90

2

222.27

3

Ethylene glycol

304.77

4

glycerin

0.34

5

Butyltin tris(2-ethylhexanoate)

1.23

[0036] 1. Add items 1 and 2 to the reactor at ambient temperature (approximately 25°C).

[0037] 2. Heat the resin to 200°C while stirring under nitrogen.

[0038] 3. Resin is held at 200°C for 2 hours, viscosity is monitored at 1 hour intervals.

[0039] 4. Cool the resin to about 50°C.

[0040] 5. Add items 3, 4 and 5 to resin over 10 minutes; hold at 50°C for 30 minutes.

[0041] 6. Heat the resin to 100°C and hold at 100°C for 30 minutes.

[0042] 7. Heat resin to 225°C and hold at 225°C until AV < 5 (monitor AV and viscosity at 1 hour intervals).

[0043] 8. When AV≤5, the resin is cooled ...

Embodiment 2

[0045] Embodiment 2: preparation bio-based polyester resin (comparison)

[0046] project

Monomer / Intermediate

Amount added (g)

1

1004.85

2

maleic anhydride

222.92

3

Ethylene glycol

284.10

4

glycerin

0.38

5

Butyltin tris(2-ethylhexanoate)

0.58

[0047] 1. Add items 1-2 to container at ambient temperature (25-30°C).

[0048] 2. Heat the resin to 200°C while stirring under nitrogen.

[0049] 3. The resin is maintained at 200°C for 2 hours, and the viscosity is monitored every hour.

[0050] 4. Cool the resin to about 50°C.

[0051] 5. Add item 5 to the reactor.

[0052] 6. Add items 3 and 4 to the resin over a period of 10 minutes; hold at 50°C for 30 minutes.

[0053] 7. Heat slowly to 100°C and hold for 30 minutes.

[0054] 8. Resin was heated to 210°C and maintained at 210°C for 1 hour, monitoring AV and viscosity every hour.

[0055] 9....

Embodiment 3

[0058] Embodiment 3: preparation bio-based polyester resin (comparison)

[0059] project

Monomer / Intermediate

Amount added

(gram)

1

1006.80

2

maleic anhydride

223.20

3

Ethylene glycol

283.58

[0060] project

Monomer / Intermediate

Amount added

(gram)

4

glycerin

0.36

5

Butyltin tris(2-ethylhexanoate)

0.51

[0061] 1. Add items 1-2 to container at ambient temperature (25-30°C).

[0062] 2. Heat the resin to 200°C while stirring under nitrogen.

[0063] 3. The resin is maintained at 200°C for 2 hours, and the viscosity is monitored every hour.

[0064] 4. Cool the resin to about 60°C.

[0065] 5. Add item 5 to the reactor.

[0066] 6. Add items 3 and 4 to resin over ten minutes; hold at 50-60°C for 30 minutes.

[0067] 7. Heat slowly to 100°C and hold for 30 minutes.

[0068] 8. Heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com