Patents

Literature

78results about How to "Uninterrupted production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

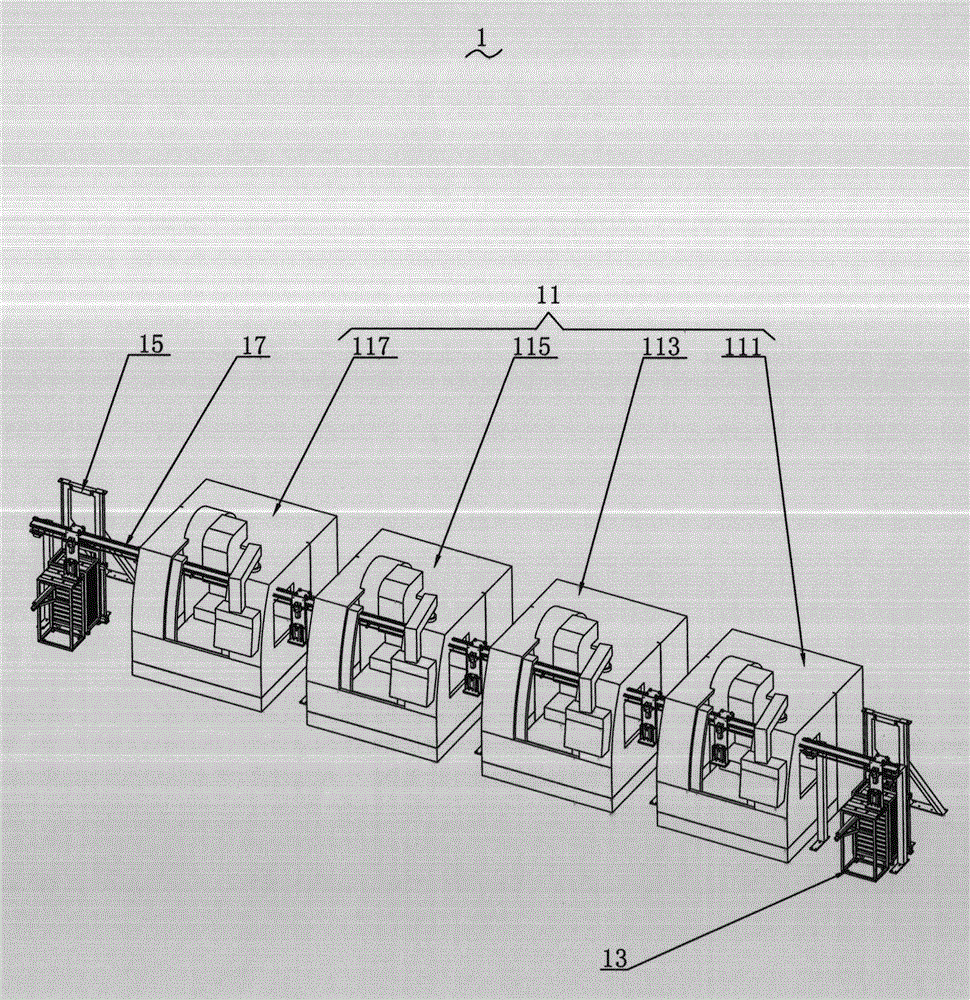

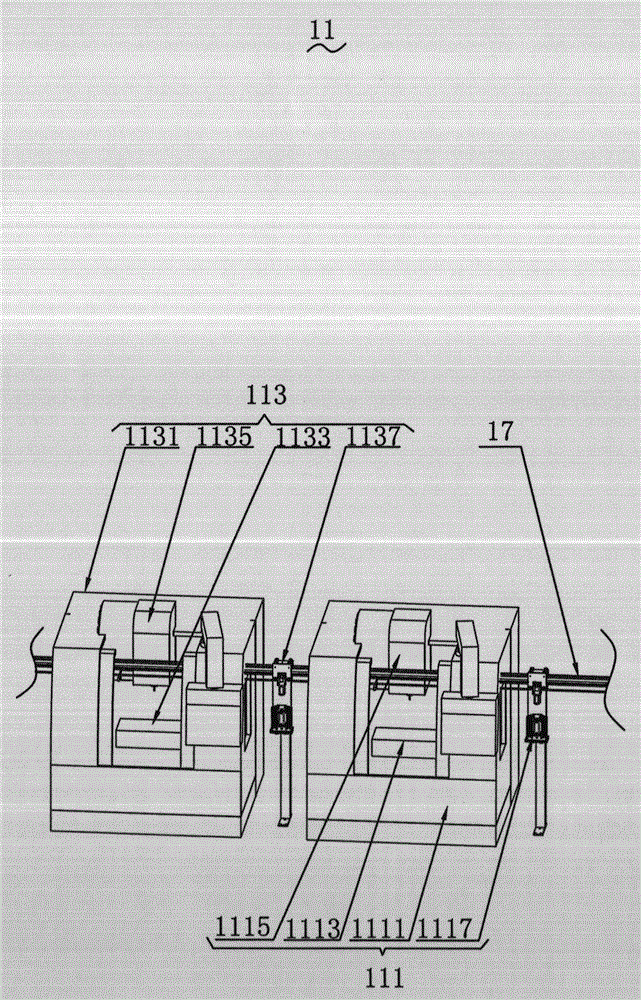

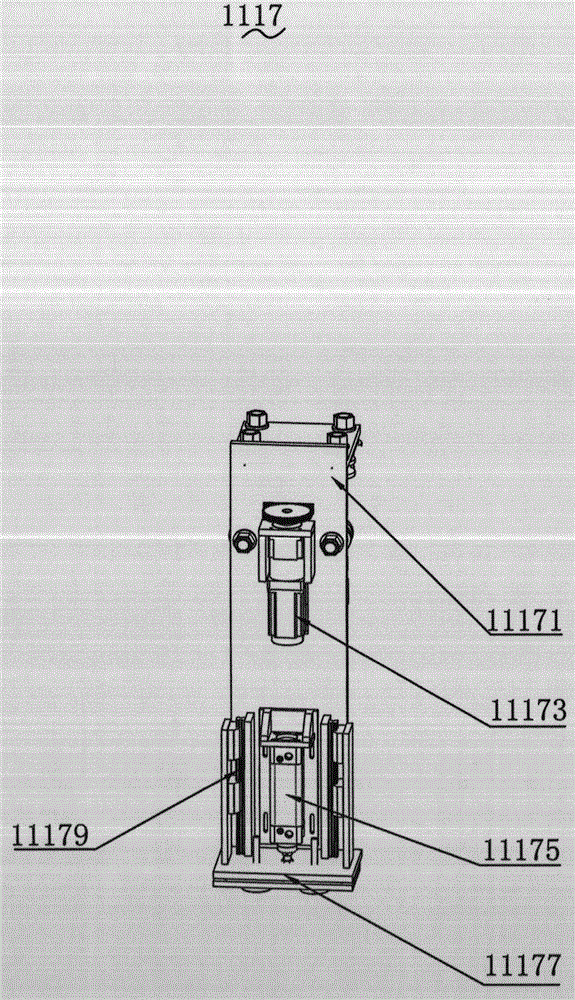

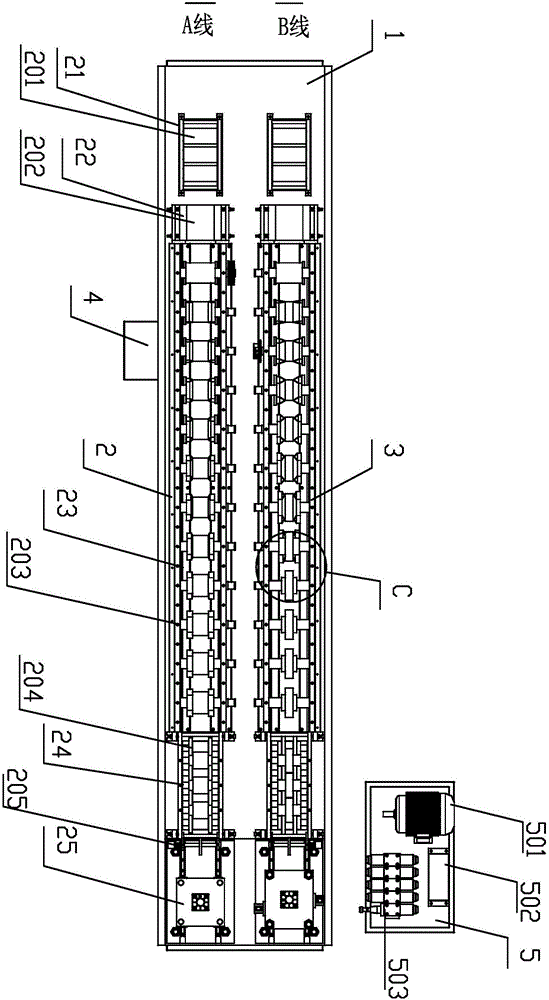

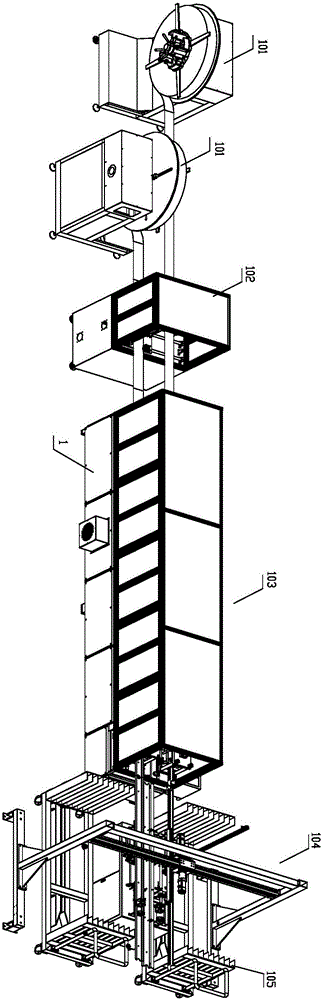

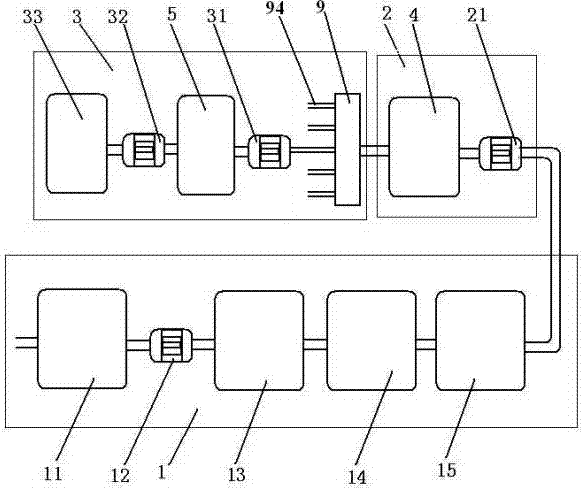

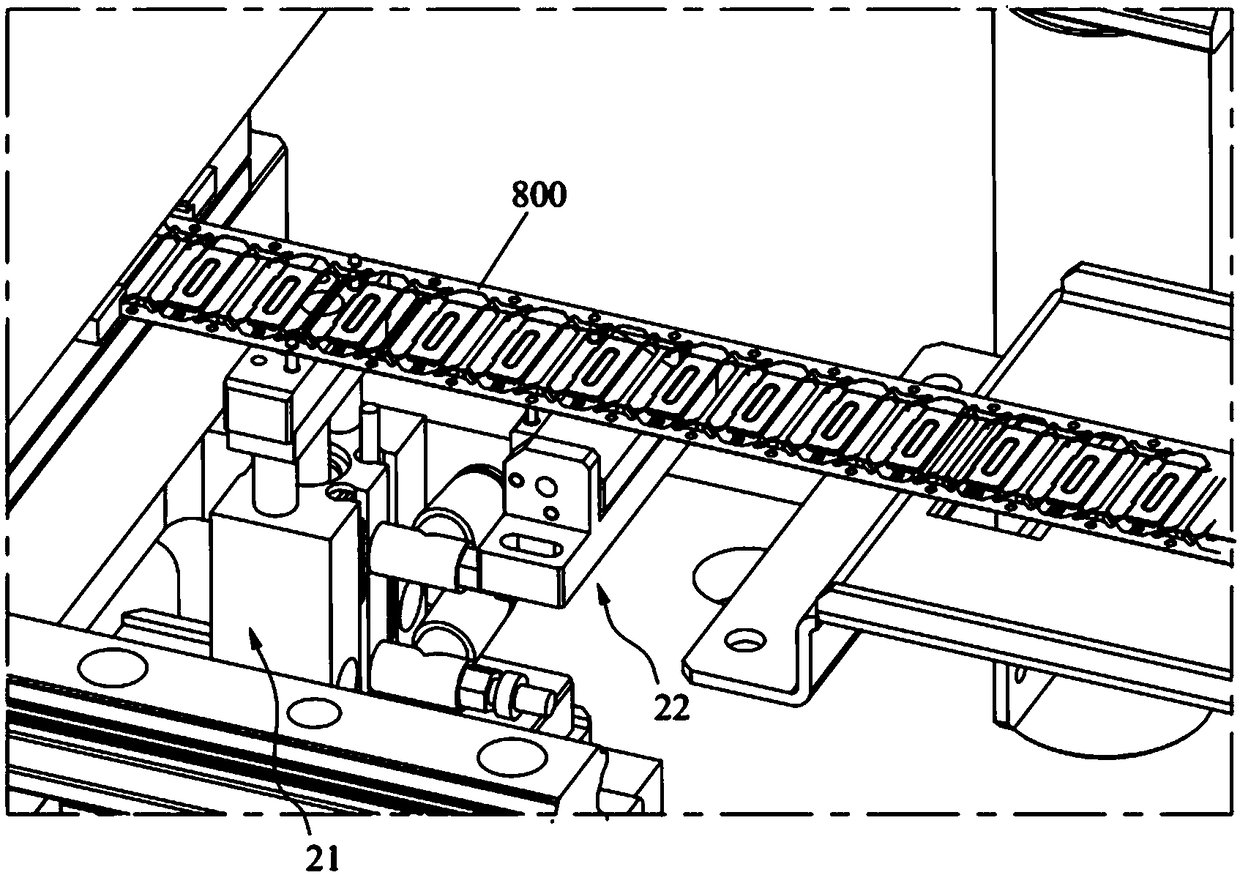

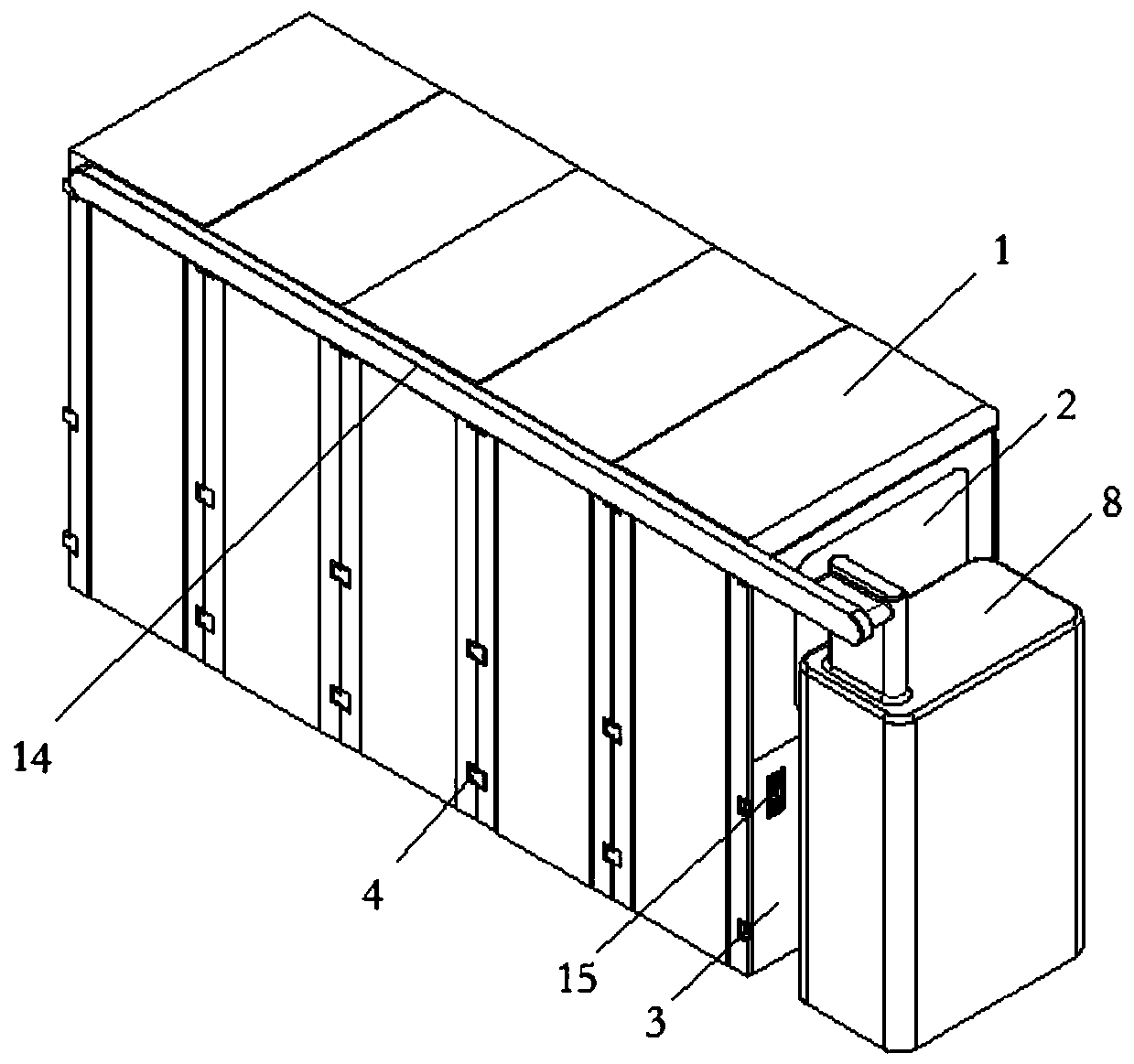

CNC linkage integrated equipment

InactiveCN105058173AReduce manual operationsLow costMetal working apparatusProduction lineReciprocating motion

The invention relates to CNC linkage integrated equipment. The CNC linkage integrated equipment comprises a supply device, a receiving device, a manipulator rail and a machine tool system, wherein the two ends of the manipulator rail are respectively connected with the supply device and the receiving device, and penetrate through the whole machine tool system; the machine tool system comprises multiple general machine tools; all the general machine tools are serially connected; the material transportation among the machine tools is realized through the manipulator rail; all the general machine tools in the machine tool system transfer materials through manipulators; the multiple manipulators on the manipulator rail perform a reciprocating motion to finish the transfer of the materials on a whole production line; the materials linearly flow on the whole production line without shifting outside the CNC linkage integrated equipment; and the design enables the CNC linkage integrated equipment to realize unmanned factory management to a certain extent.

Owner:SHENZHEN MATHENTECH INTELLIGENT TECH

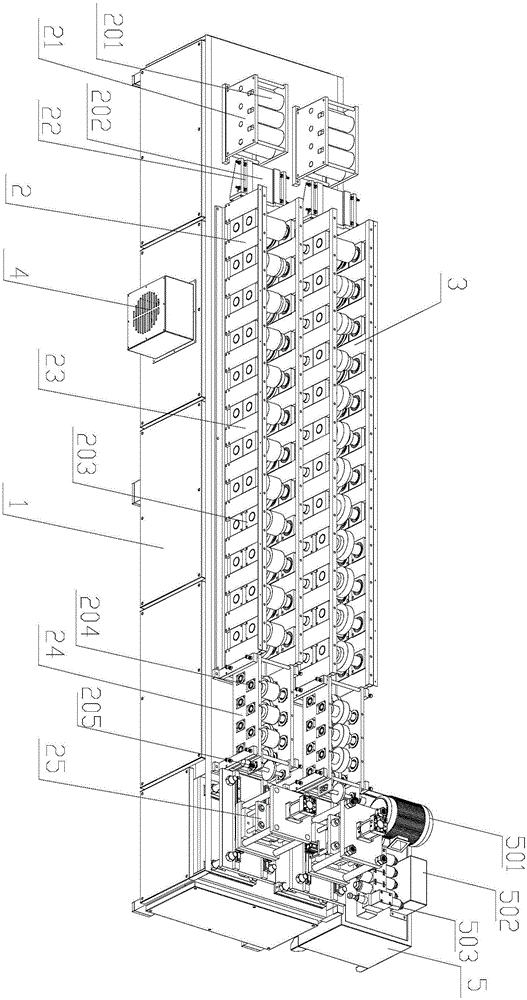

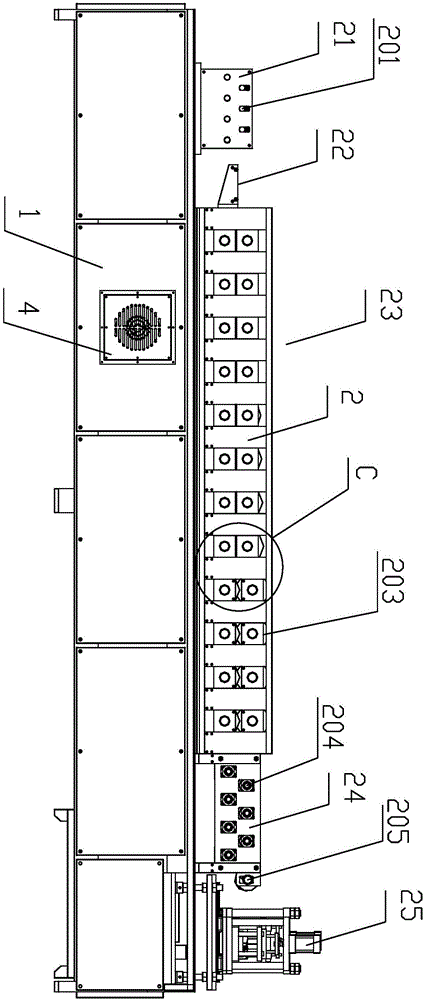

Novel full-automatic roll forming equipment

The invention discloses novel full-automatic roll forming equipment. The novel full-automatic roll forming equipment is provided with a plurality of production lines. Each production line comprises a leveling roller wheel set, a left-right correcting mechanism, a forming roller wheel set, a correcting roller wheel set and a cutting off mechanism; a metal plate enters the leveling roller wheel set from a material frame, is leveled by the leveling roller wheel set, then enters the left-right correcting mechanism, is adjusted by the left-right correcting mechanism, is made to always stay in the middle positions of roller wheels and then enters the forming roller wheel set, and after the metal plate is subjected to roll forming through the multiple sets of gradually varied roller wheels, a required section shape is obtained. The novel full-automatic roll forming equipment has the beneficial effects that a part with two different sections can be produced through the equipment, the shape and size of the sections and material thickness are all the same, but the materials can be different; the size of the sections formed through rolling is accurate and stable, and the consistency is good; the roll forming equipment can produce the parts continuously and is high in efficiency; and cutting off and punching positions are controlled by a computer, and the parts with different lengths and different hole positions can be obtained.

Owner:SHANGHAI WESTHOUSE SWITCHGEAR

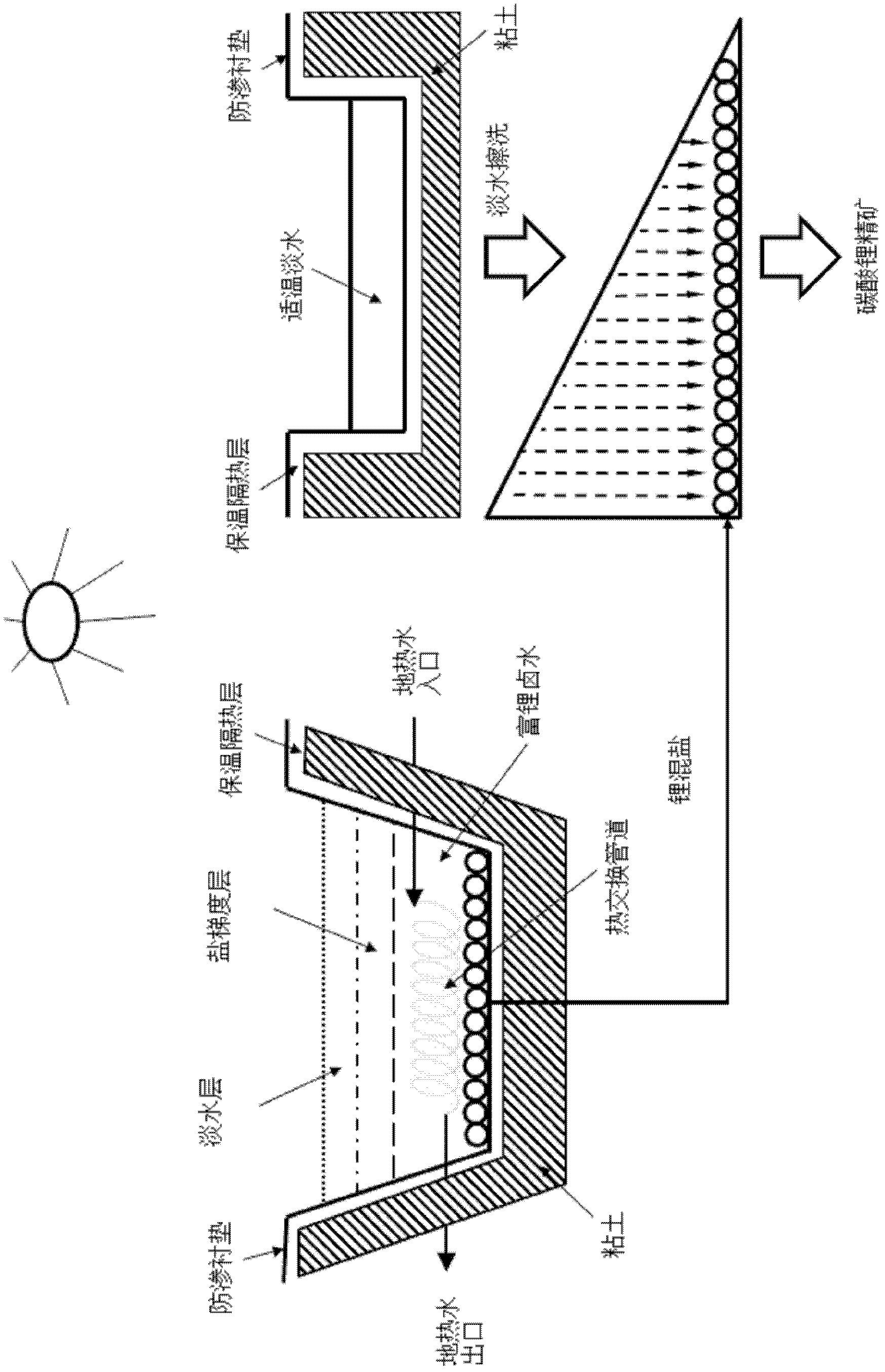

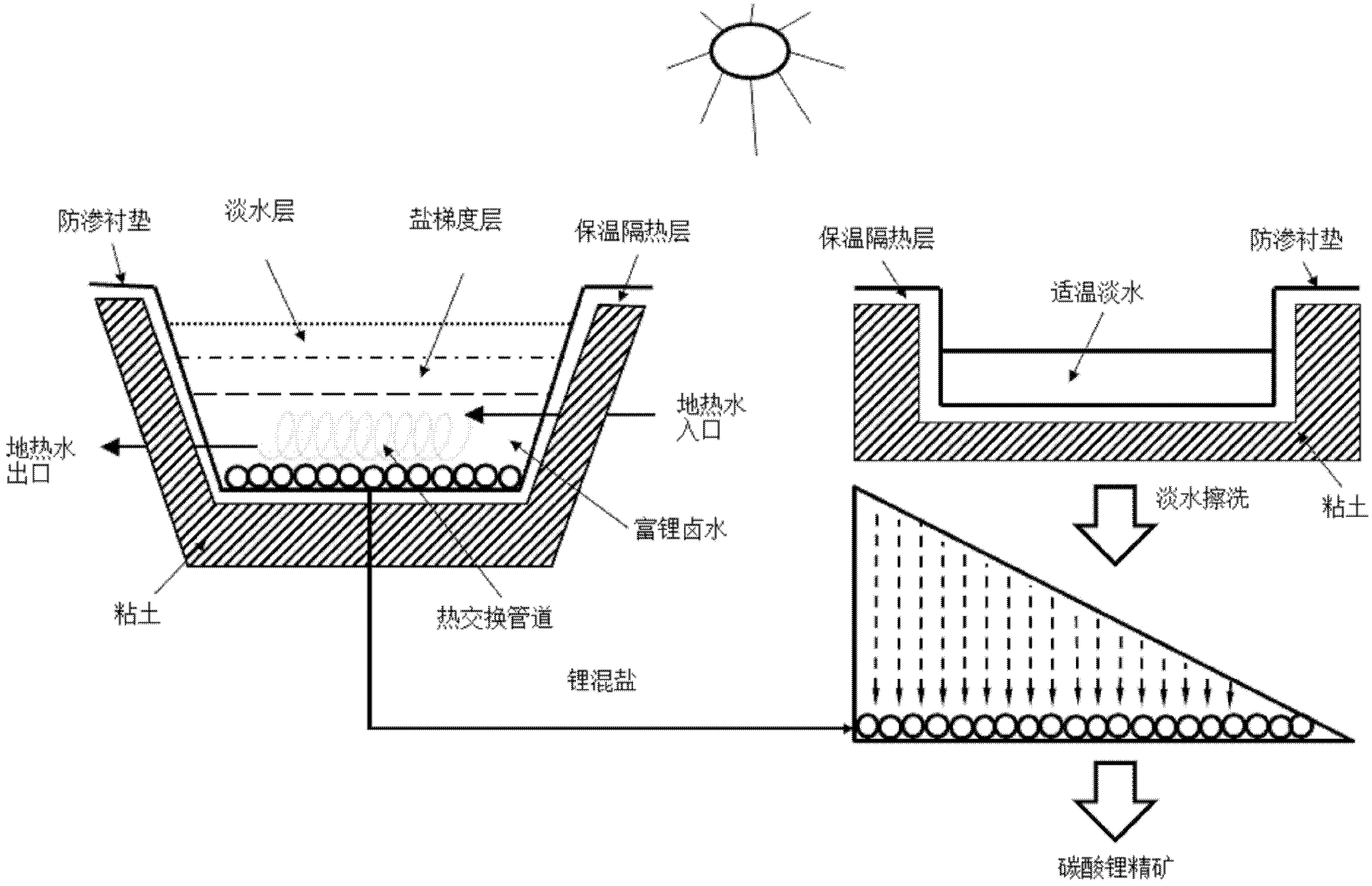

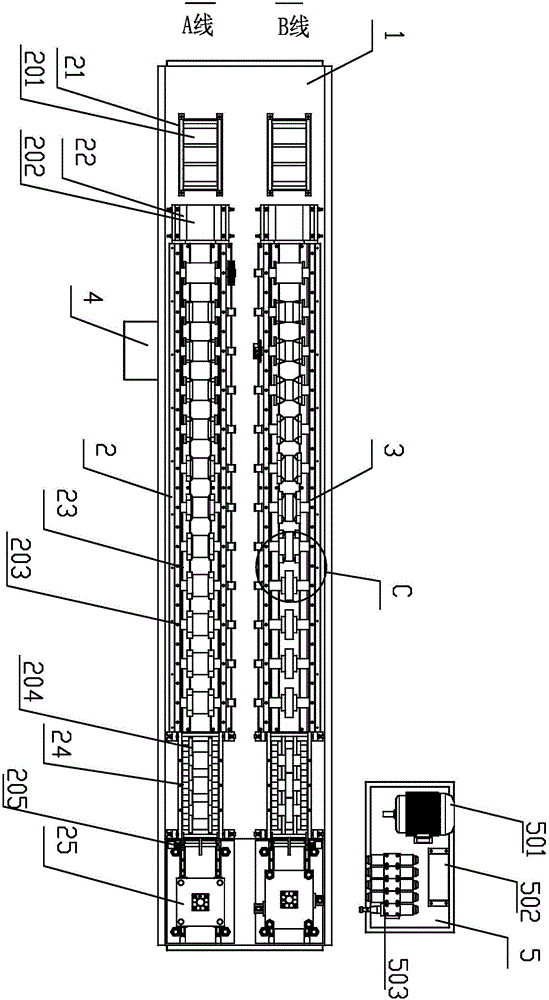

Method for extracting lithium carbonate from carbonate brine

InactiveCN102583454AImprove production efficiency and product yieldShorten the production cycleSolar heating energySolar heat collectors with working fluidsChemistryDual function

The invention discloses a method for extracting lithium carbonate from carbonate brine. A salt-gradient thermal-insulation solar pond is made of clay, a black ethylene-propylene-diene monomer (EPDM) waterproof roll, a geomembrane or high-density polyethylene plastic spraying canvas and the like are paved on the surface of the bottom of the pond to serve as liners, and a heat exchange pipeline is paved at the position 0.5-1m higher than the pond bottom. Lithium-rich brine prepared by freezing and solarization is directly injected into the salt-gradient thermal-insulation solar pond, a layer of fresh water is paved on the surface layer of the brine, the brine is warmed under the dual functions of solar radiation and geothermal water-heat exchange, lithium carbonate is separated out in a concentrated mode, and finally lithium-mixed salt obtained in the salt-gradient thermal-insulation solar pond is scrubbed through appropriate-temperature fresh water. The methods of the salt-gradient thermal-insulation solar pond, the geothermal water-heat exchange, scrubbing of the appropriate-temperature fresh water and the like are combined and applied to extraction of lithium carbonate from carbonate brine, the production efficiency and product quality are greatly improved, the production cycle is shortened, the production cost is reduced, and lithium carbonate ore concentrate can be obtained directly locally.

Owner:SALT LAKE & HOT WATER RESOURCE RES DEV CENT CHINESE ACAD OF GEOLOGICAL SCI

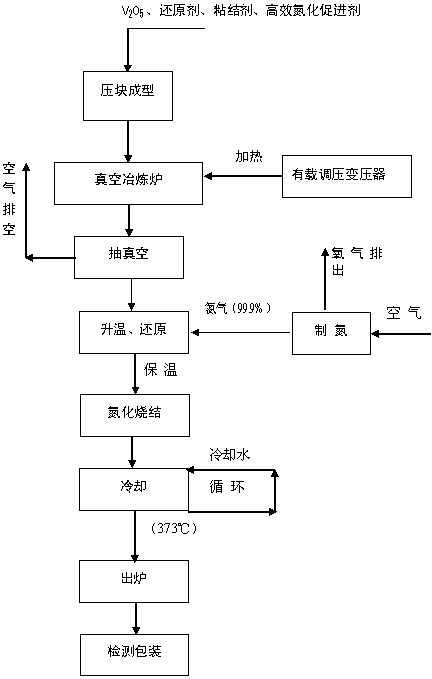

Production process for preparing high-nitrogen vanadium nitride by using vacuum furnace method

InactiveCN103303880AReduce energy consumptionPrecise process controlNitrogen-metal/silicon/boron binary compoundsVacuum furnaceVanadium pentoxide dust

The invention discloses a production process for preparing high-nitrogen vanadium nitride by using a vacuum furnace method, and relates to a production process for producing a high-nitrogen vanadium nitride product in a vacuum resistance furnace by taking high-purity vanadium pentoxide powder as the raw material through a nitridation sintering method. According to the production process, the process procedures of reduction, nitridation and sintering are carried out in a vacuum furnace, so that the energy consumption is low, the process control is accurate, the production efficiency of the product is high and stable, and the environment is not polluted.

Owner:湘西自治州丰达合金科技有限公司

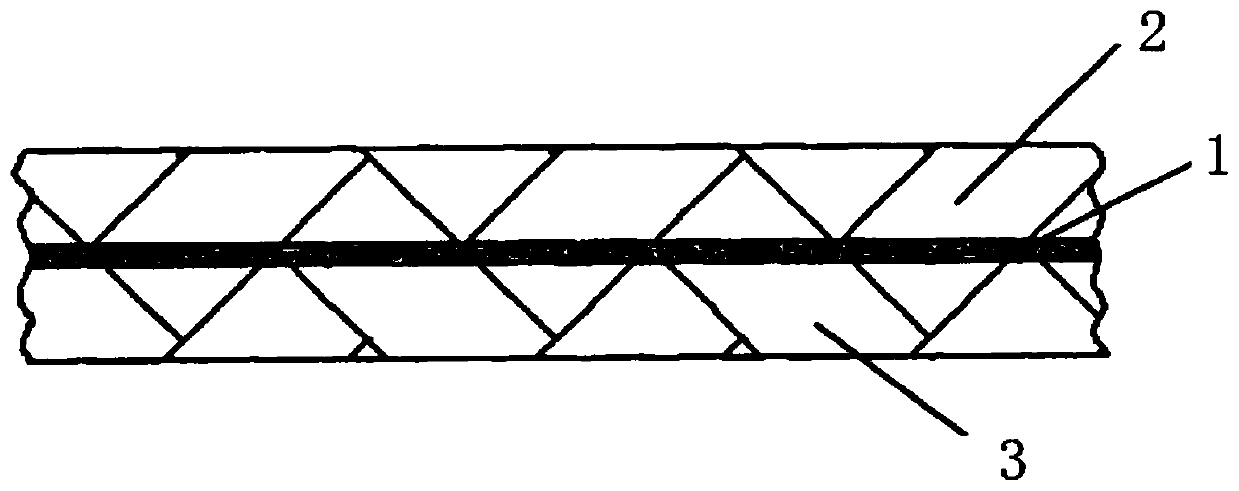

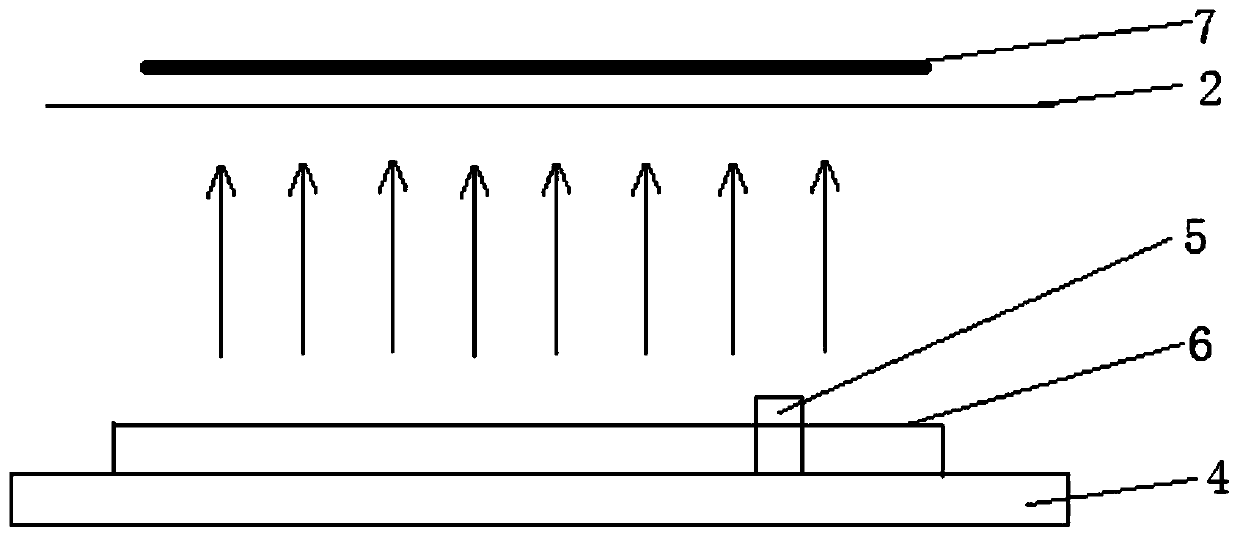

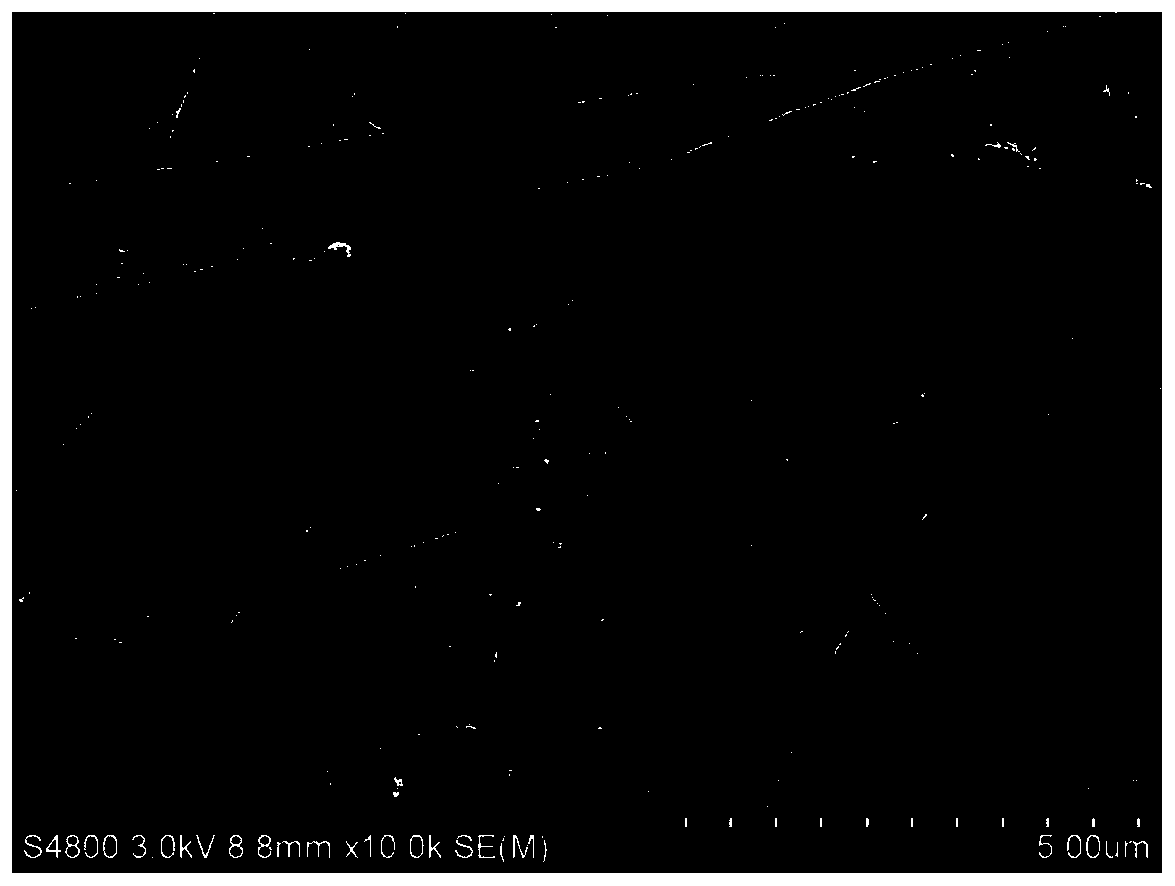

Nanofiber filtering material and preparation method thereof

InactiveCN110478980AImprove filtration efficiencySmall filter resistanceDispersed particle filtrationSynthetic resin layered productsElectrospinningNanofiber

The invention provides a nanofiber filtering material and a preparation method thereof. The nanofiber filtering material comprises a first spun-bonded filter material layer, a nanofiber filtering material layer and a second spun-bonded filtering material layer which are sequentially arranged from top to bottom, wherein the nanofiber filtering material layer is directly spun on the first spun-bonded filtering material layer through a needleless reciprocating type electrostatic spinning method, and the second spun-bonded filtering material layer is connected with the nanofiber filtering materiallayer in a press fit mode. The nanofiber filtering material prepared by the method is high in filtering efficiency and low in filtering resistance.

Owner:KUNSHAN TUNGRAY IND AUTOMATION

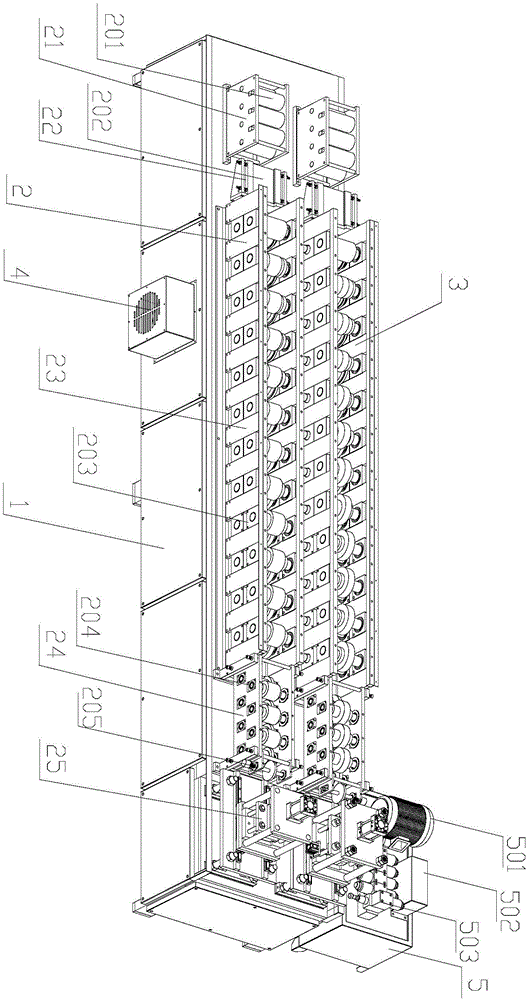

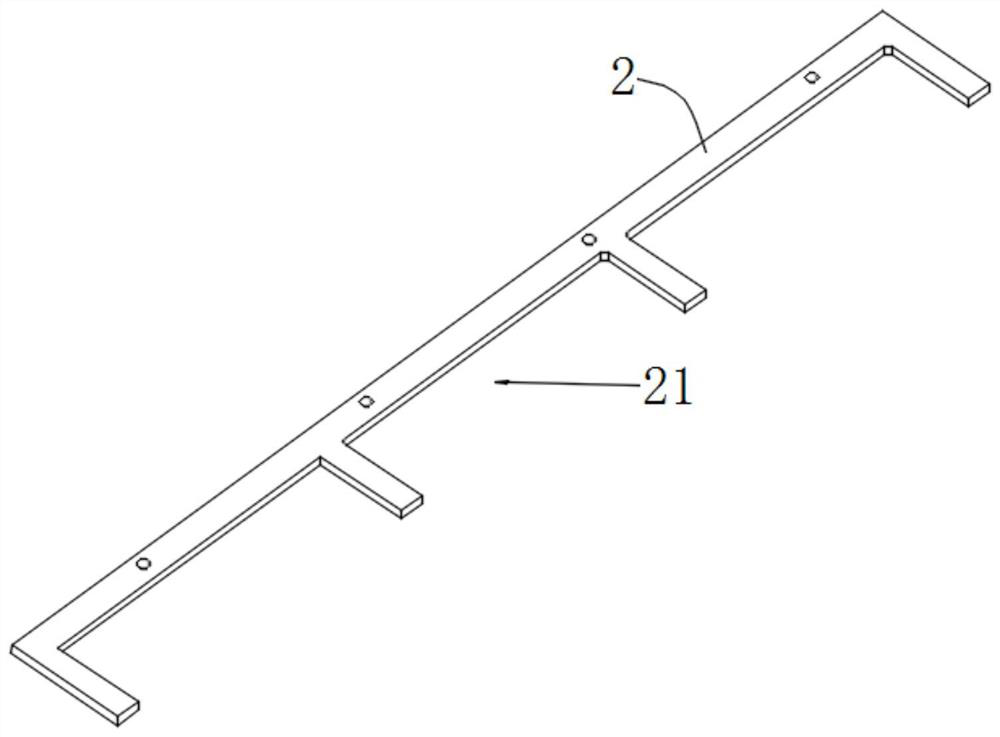

Novel full-automatic rolling forming production line

ActiveCN106695331AAccurate and stable section sizeImprove consistencyOther manufacturing equipments/toolsStacking articlesProduction linePunching

The invention discloses a novel full-automatic rolling forming production line comprising a material frame, an automatic welding machine, a rolling forming machine and an automatic stacking machine. The material frame is used for winding of a raw material coiled material. The automatic welding machine is used for butt welding of a new roll of a material with a last roll of an unspent material when a roll of material is used up and another roll of material needs to be put on. The rolling forming machine is used for enabling the raw material coiled material to be rolled into a required shape. The automatic stacking machine comprises an overturning mechanism used for overturning a workpiece, a conveying mechanism used for conveying the overturned workpiece and a stacking trolley used for workpiece placing. The novel full-automatic rolling forming production line has the advantages that equipment can manufacture parts with two kinds of sections, the shape, size of the sections and the thickness of the materials are all the same, but different materials are acceptable; the sizes of the rolled and formed sections are accurate, stable and good in consistency; the rolling forming equipment can manufacture continuously, and efficiency is high; and the positions of cut-off and punching are controlled by a computer, so that parts with different lengths and hole sites can be obtained.

Owner:SHANGHAI WESTHOUSE SWITCHGEAR

Method for extracting lithium carbonate from carbonate brine

InactiveCN102815727AUninterrupted productionIncrease productivitySolar heating energySolar heat collectors with working fluidsGeomembraneLithium carbonate

The invention discloses a method for extracting lithium carbonate from carbonate brine. A salt gradient heat-preserving solar pond is built by clay; black ethylene-propylene-diene monomer waterproof coiled material, geomembrane or high density polyethylene spraying canvas and the like are laid at the bottom surface of the pond as the mat; a heat exchanging pipeline or an electric heating device is arranged 0.5-1m above the bottom of the pond; lithium-rich brine which is prepared by freezing and solarization is directly poured into the salt gradient heat-preserving solar pond, a layer of fresh water is laid at the surface of the brine, the brine is heated by the double action of solar irradiation and heat exchanging or electric heating and lithium carbonate is separated out concentratedly; and finally, lithium mixed salt obtained in the salt gradient heat-preserving solar pond is scrubbed with fresh water at proper temperature. The combination of the salt gradient heat-preserving solar pond, the heat exchanging or electric heating device and scrubbing by fresh water at proper temperature is applied to the extraction of lithium carbonate from carbonate brine, therefore, the production efficiency and the product quality are greatly improved, the production cycle is shortened, the production cost is lowered and lithium carbonate concentrate is obtained directly.

Owner:SALT LAKE & HOT WATER RESOURCE RES DEV CENT CHINESE ACAD OF GEOLOGICAL SCI

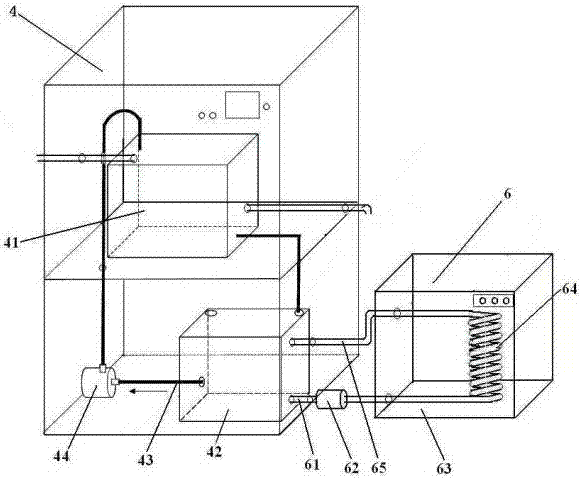

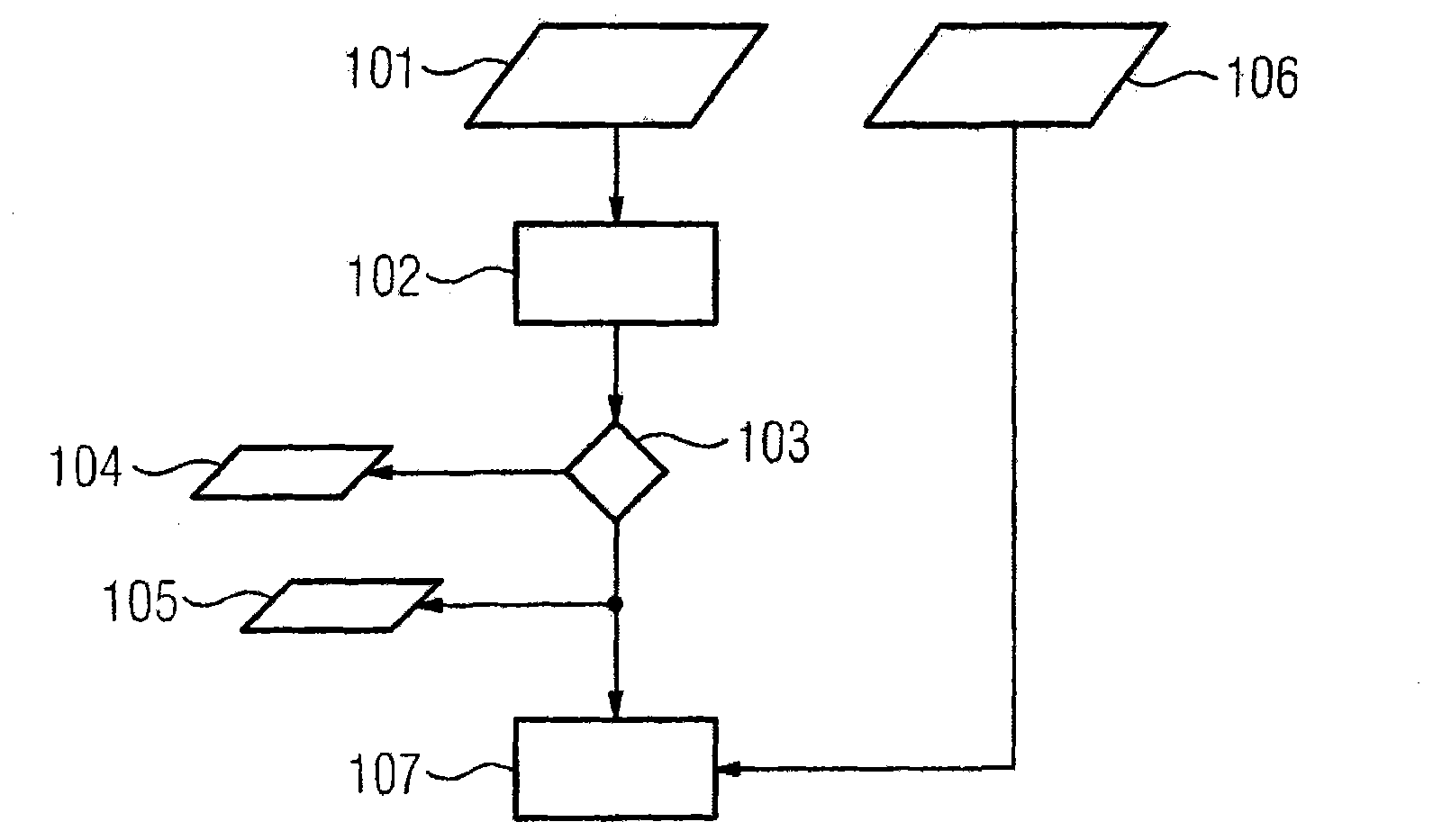

Strong alkaline electrolyzed water production system

InactiveCN106977022AUninterrupted productionImprove product qualityTreatment involving filtrationMultistage water/sewage treatmentElectrolysed waterWater production

The invention provides a strong alkaline electrolyzed water production system, belonging to the technical field of electrolyzed water production devices. The system is formed by sequentially connecting a raw water purification device, an electrolyzed water generation device, and an electrolyzed water split storage device. The raw water purification device is formed by sequentially communicating a raw water container, a first booster pump, a water softener, a water purifier, and a pure water storage container. The electrolyzed water generation device is formed by communicating a second booster pump and a strong alkaline electrolyzed water machine. The electrolyzed water split storage device is formed by sequentially communicating an electrolyzed water auto split storage device, a third booster pump, an electrolyzed water storage container, a fourth booster pump and a split charging machine. The strong alkaline electrolyzed water production system has the beneficial effects that the electrolyzed water generation device is provided with an electrolyte solution temperature stabilization device and an electrolyte solution concentration stabilization device, so that halt for cooling is prevented, manual filling for adjusting concentration of an electrolyte solution is avoided, a strong alkaline electrolyzed water machine can work continuously and efficiently, and the electrolyzed water production quality and efficiency are improved.

Owner:重庆七口泉生物医药科技有限公司

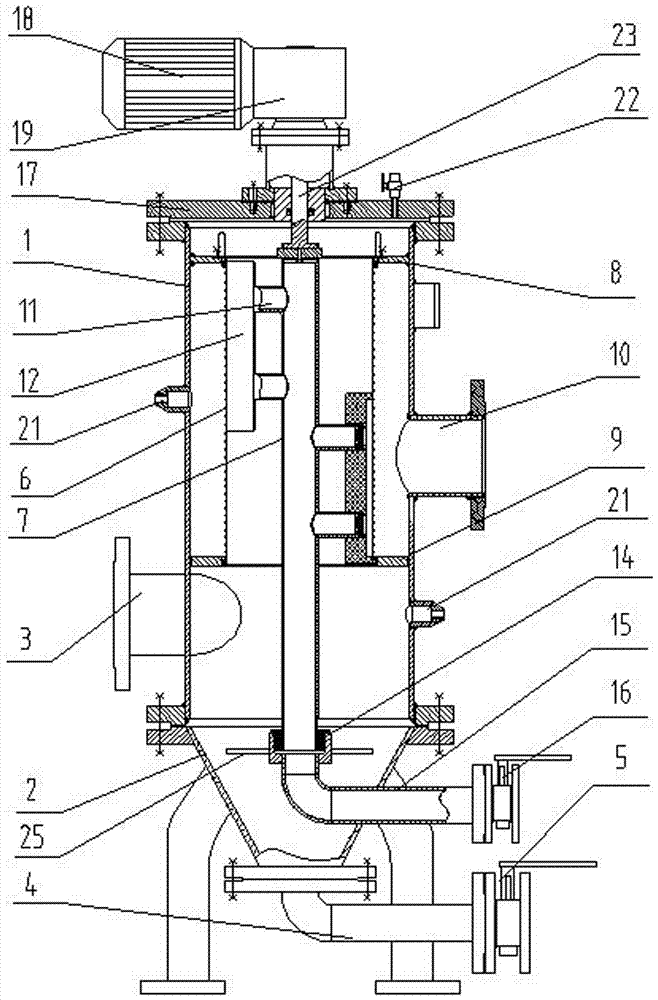

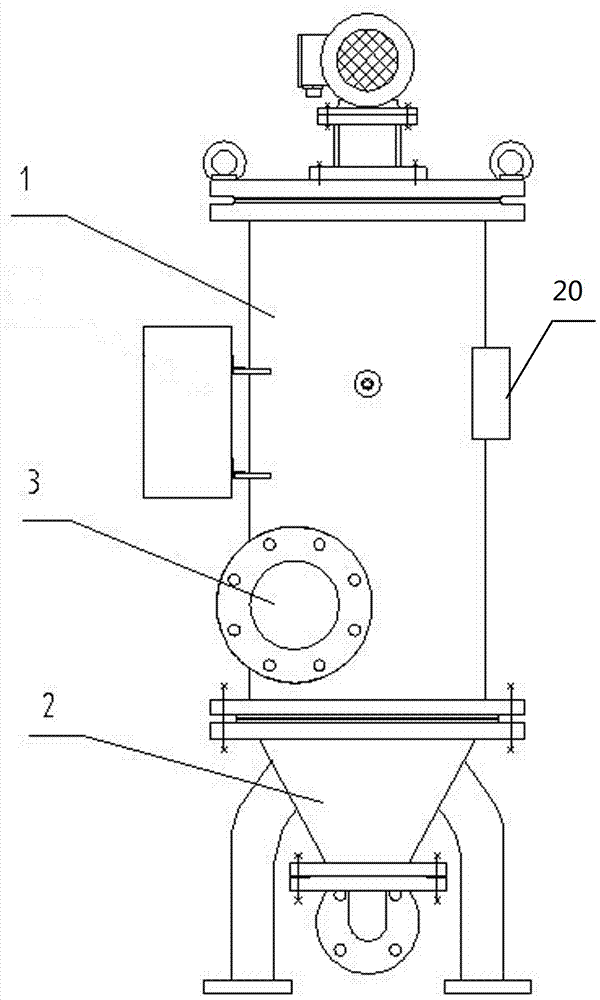

Swirling self-cleaning filter

InactiveCN107398114AAchieve pre-separationReduce filter pressureFiltration circuitsSewage treatmentFilter effect

The invention relates to the field of sewage treatment equipment, in particular to a swirling self-cleaning filter. The filter comprises a straight cylinder and a conical cylinder, wherein a swirling sewage discharge system is formed between the lower part of the straight cylinder and the conical cylinder and comprises a sewage inlet pipe arranged at the lower part of the straight cylinder in the tangential direction and a swirling sewage outlet pipe arranged at the lower end of the conical cylinder; a self-cleaning adsorption drainage system is arranged at the upper part of the straight cylinder and comprises a cylindrical filter element fixed in the straight cylinder and a hollow rotating shaft, a clean water outlet tube is arranged on the wall of the straight cylinder, and a plurality of sewage suction pipes are arranged on the hollow rotating shaft at intervals in the axial direction; a sewage suction head and an elastic element for tightly pressing the sewage suction head on the inner wall of the cylindrical filter element are arranged at one end, away from the hollow rotating shaft, of each sewage suction pipe; an adsorption sewage discharge pipe is connected to the lower end of the hollow rotating shaft through a rotary joint, one end, away from the hollow rotating shaft, of the adsorption sewage discharge pipe extends out of the wall of the conical cylinder, and a pressure control valve is arranged at the end. The filter is good in filtering effect and easy to maintain, and has a self-cleaning function.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

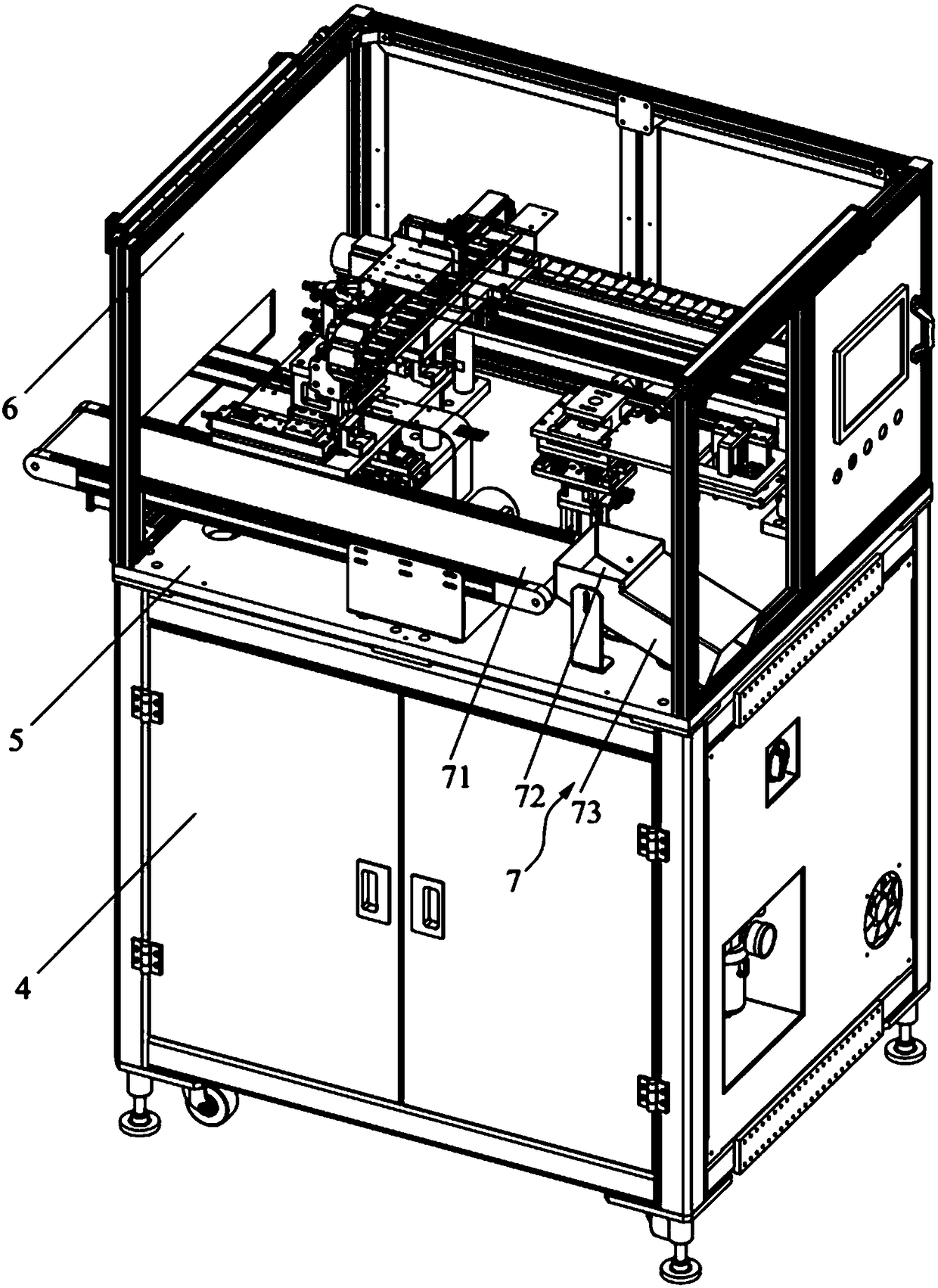

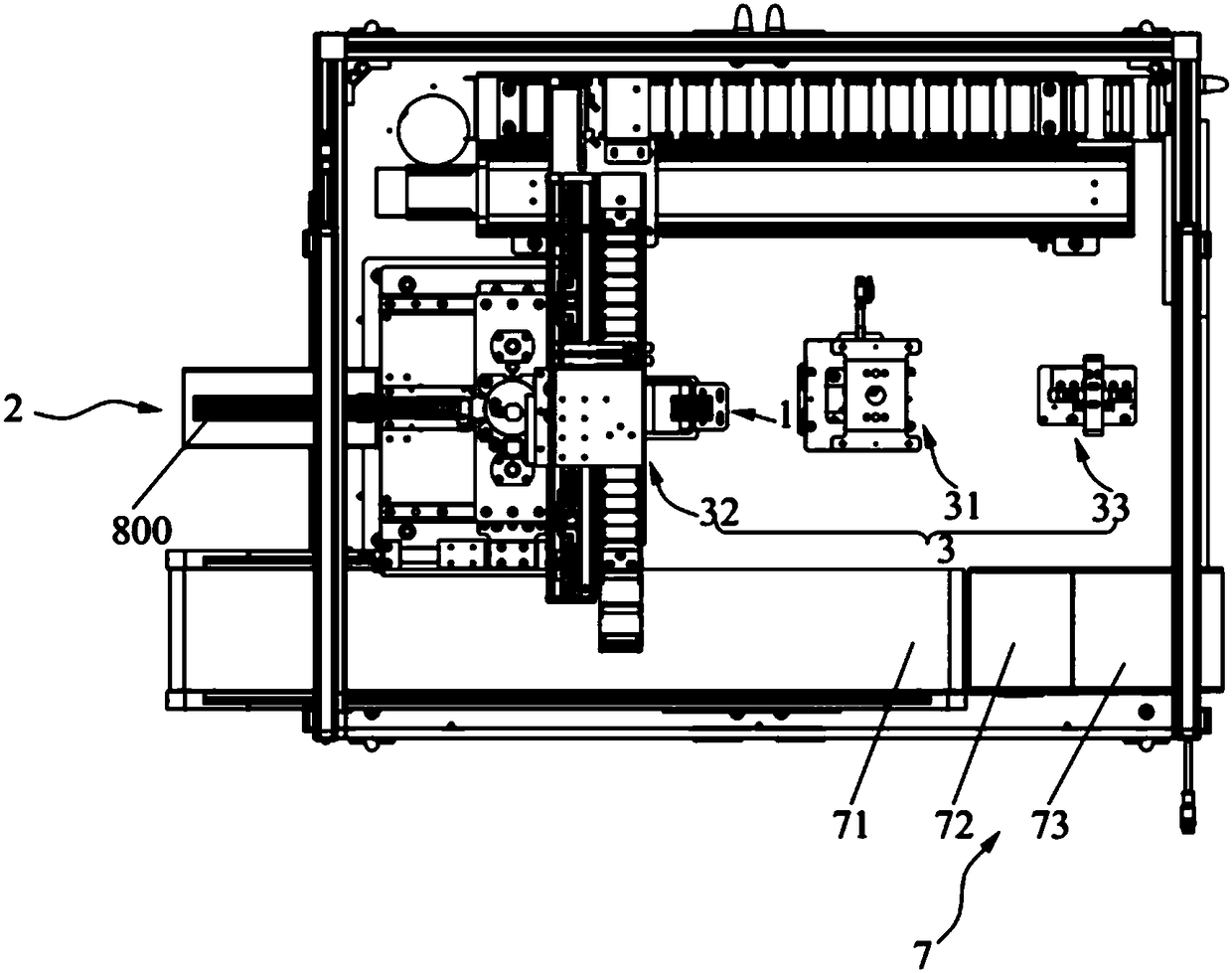

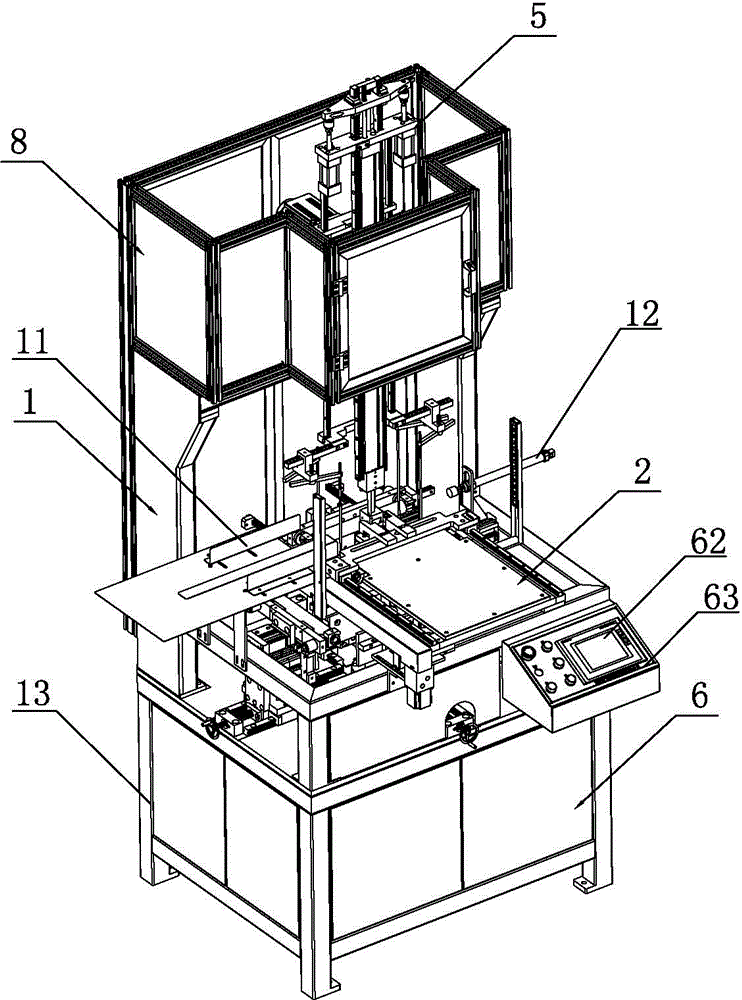

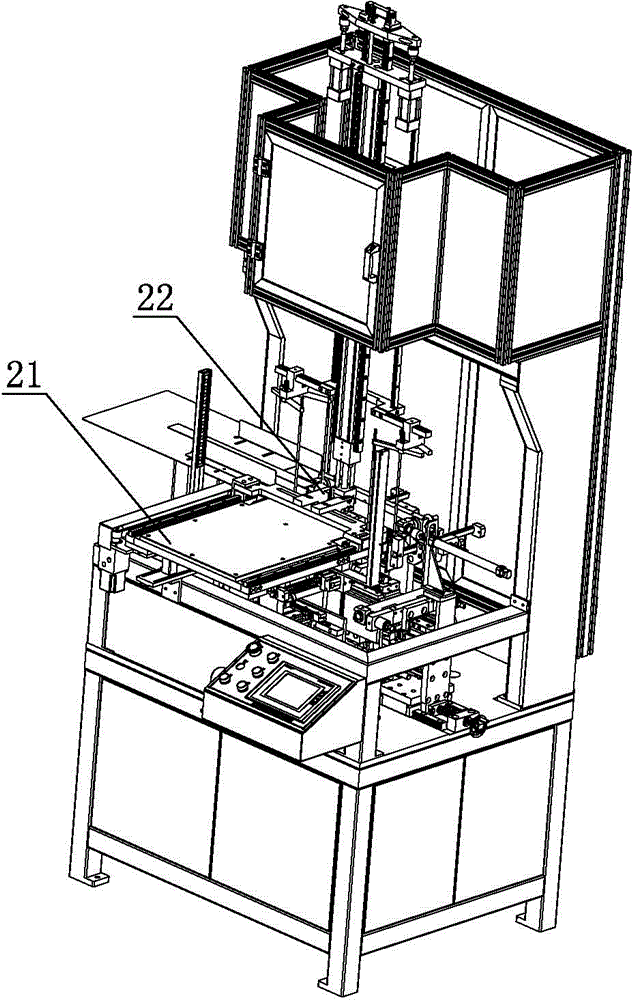

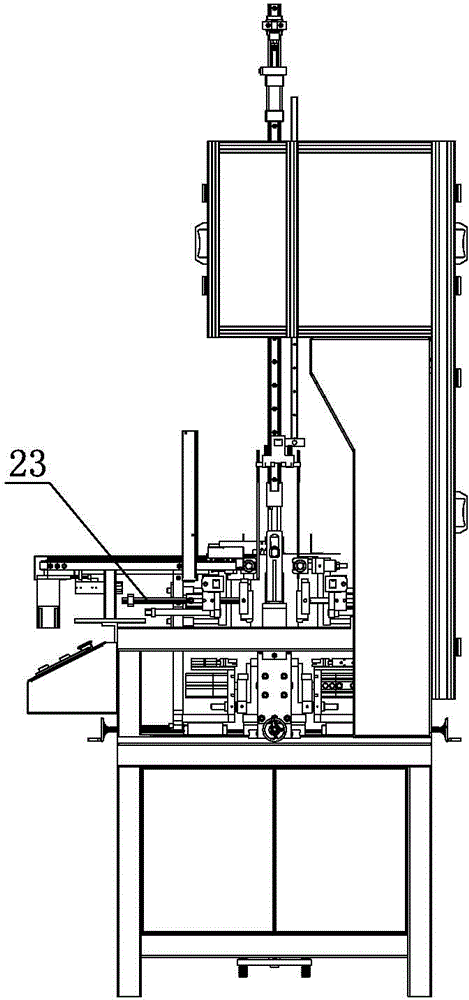

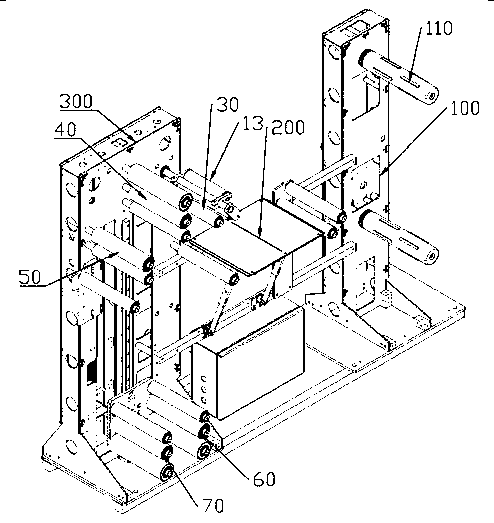

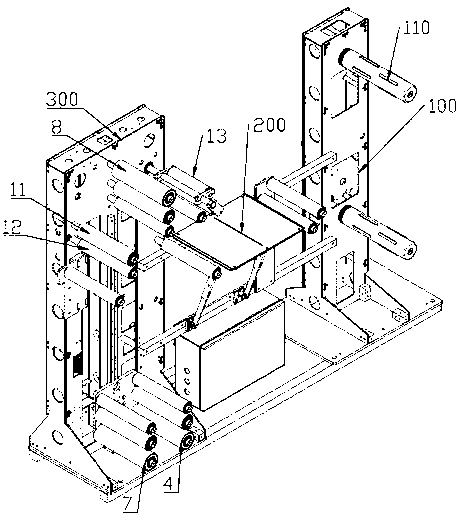

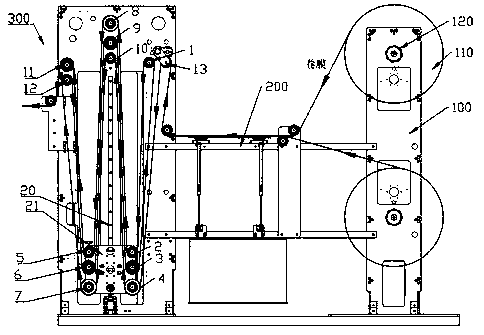

Feeding and blanking device with cutting function

PendingCN109159363AImprove pass rateSmall amount of deformationCoatingsEngineeringInjection molding machine

The invention belongs to the technical field of feeding and blanking equipment, and discloses a feeding and blanking device with a cutting function. The feeding and blanking device comprises a cuttingmechanism, a feeding mechanism and a conveying mechanism; the cutting mechanism can cut a tape feeder to form mutually separated workpieces; the feeding mechanism can move the tape feeder onto the cutting mechanism; the conveying mechanism and the feeding mechanism are respectively arranged at an upstream and a downstream of the cutting mechanism; and the conveying mechanism can pick up and convey the workpieces to an injection molding machine, and take out finished products and wastes after accomplishing injection molding from the injection molding machine. Compared with a manual operation way in the prior art, the feeding and blanking device disclosed by the invention is continuous and uninterrupted in production, the production time is saved, and the production efficiency is effectively improved.

Owner:KUSN MAIZHI FIXTURE TECH

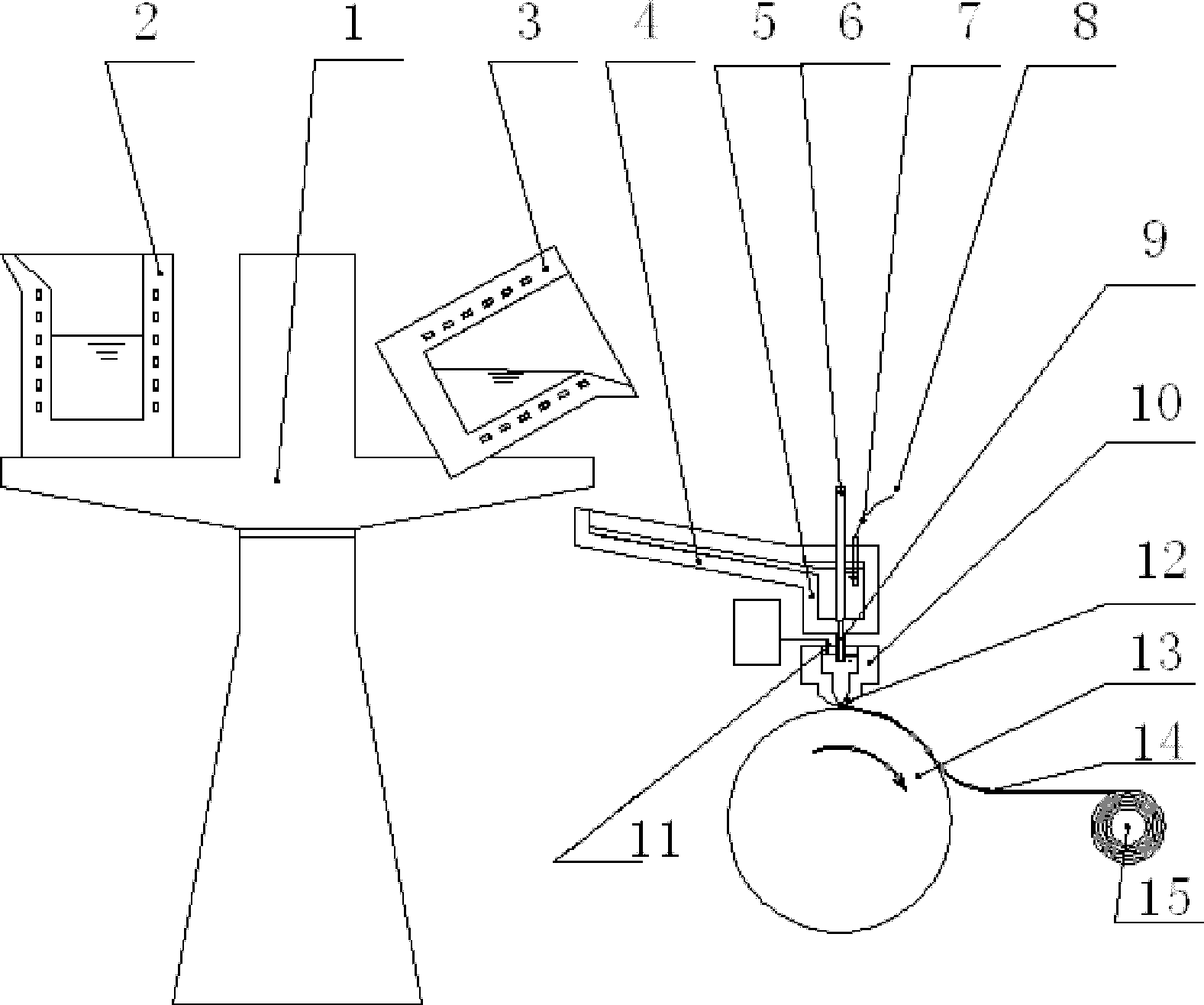

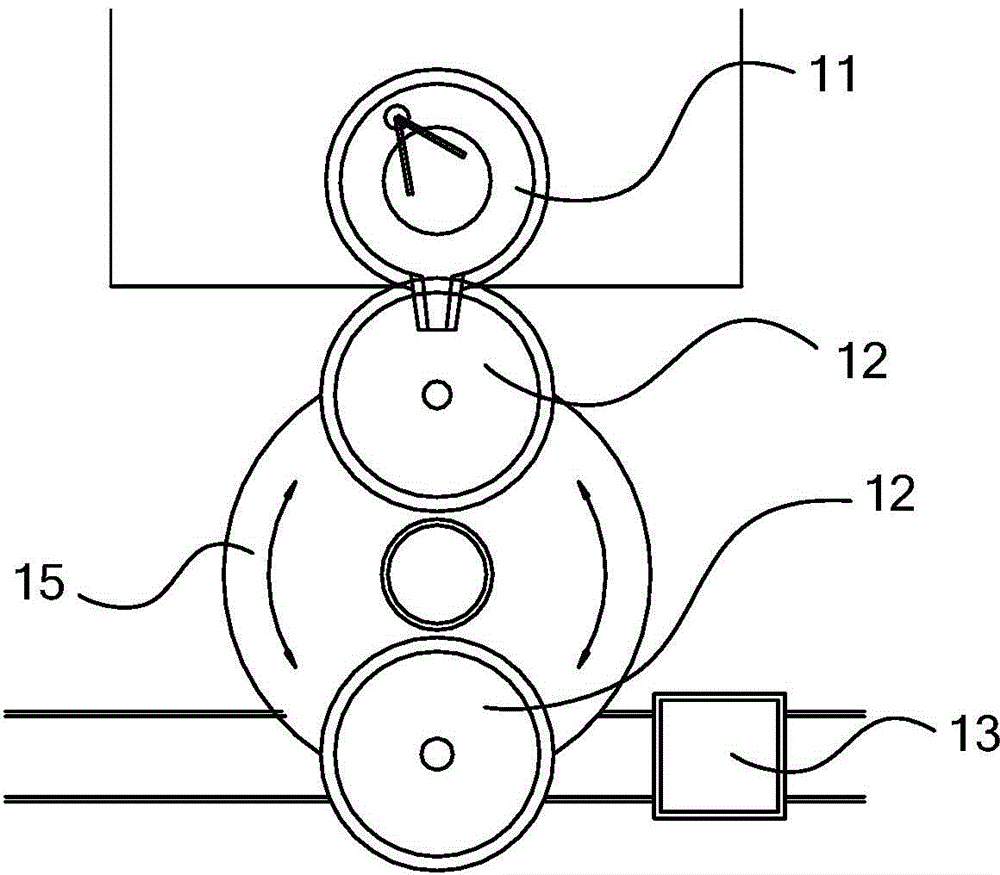

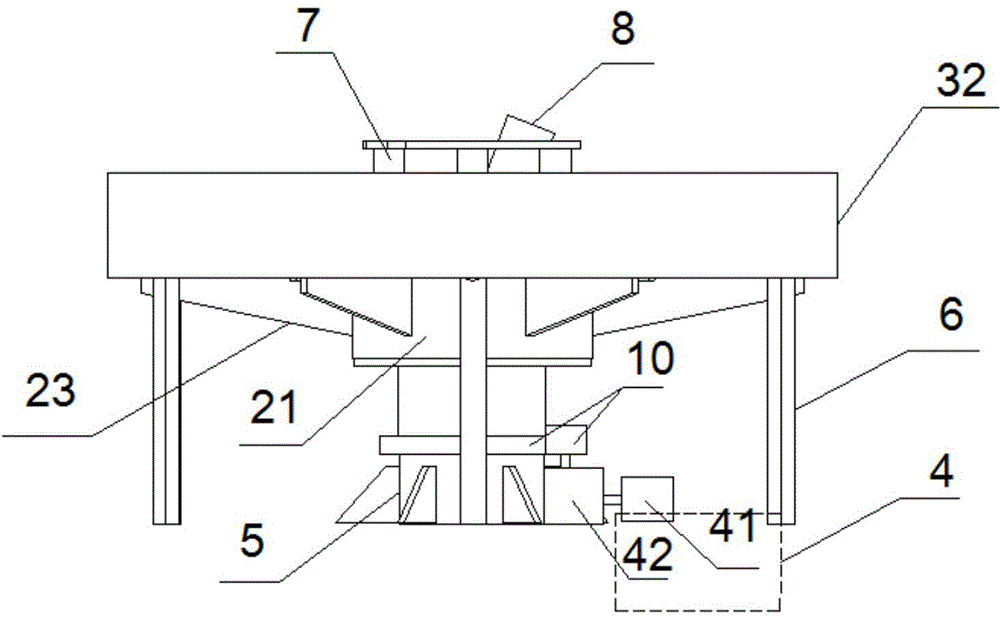

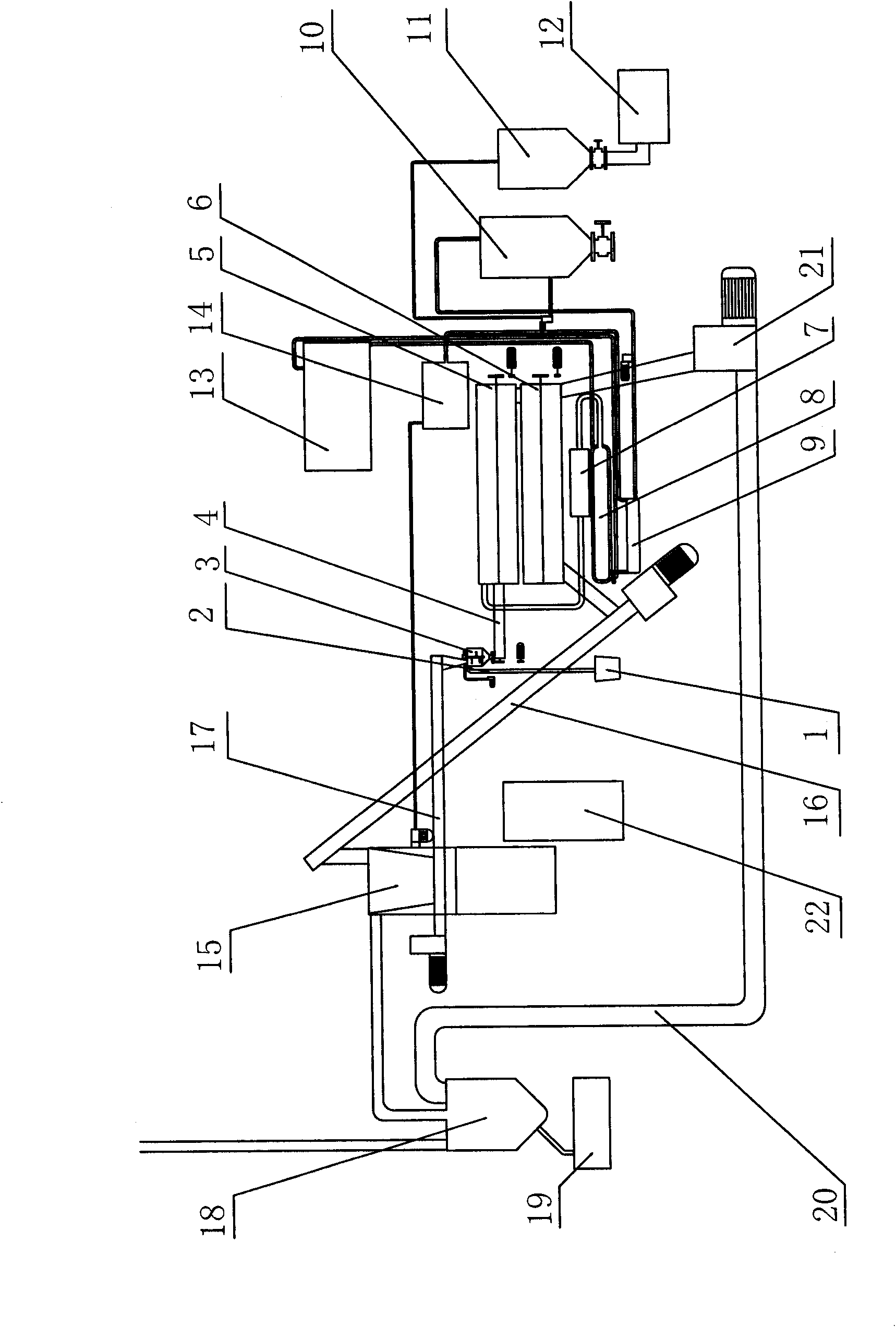

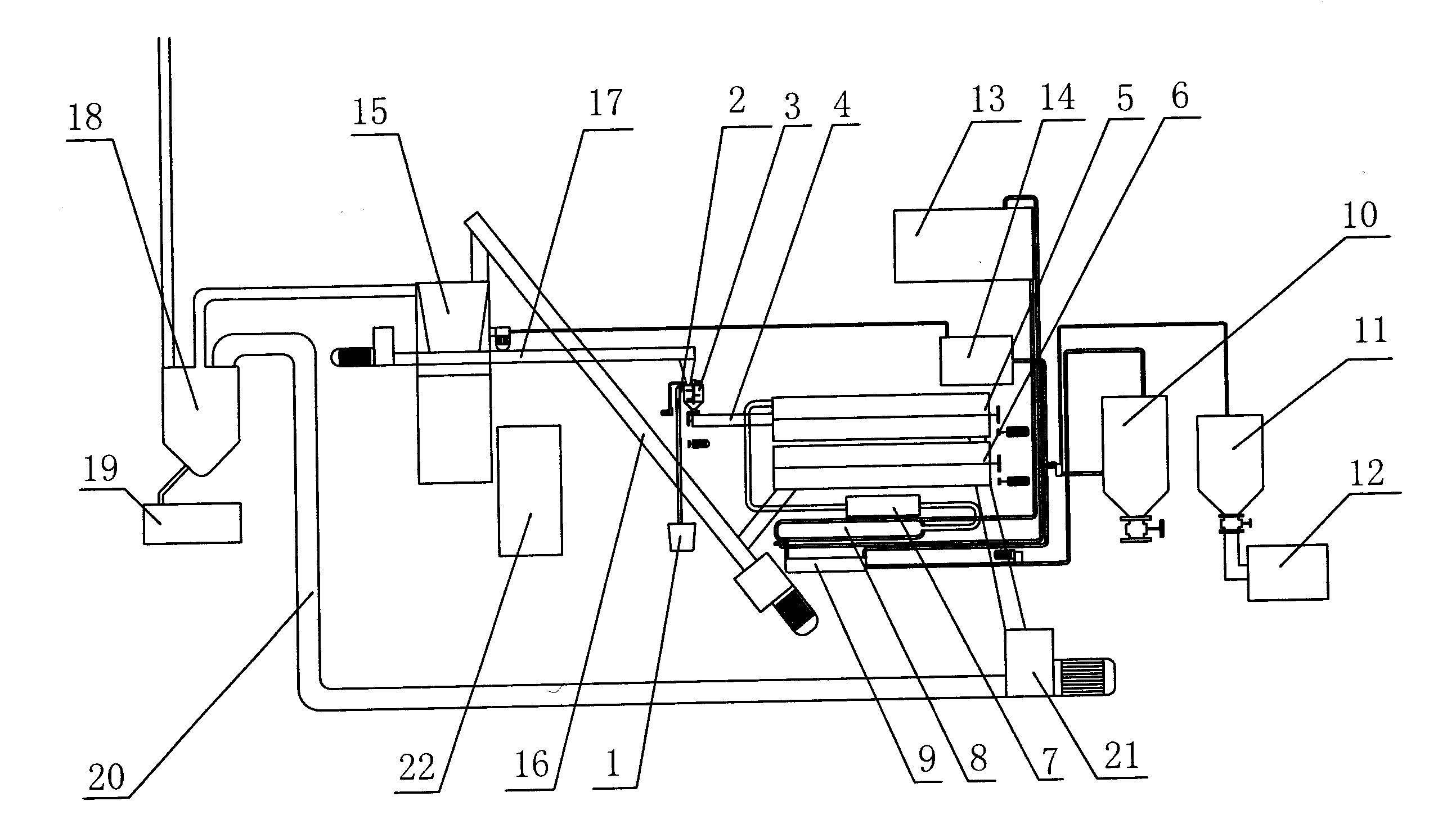

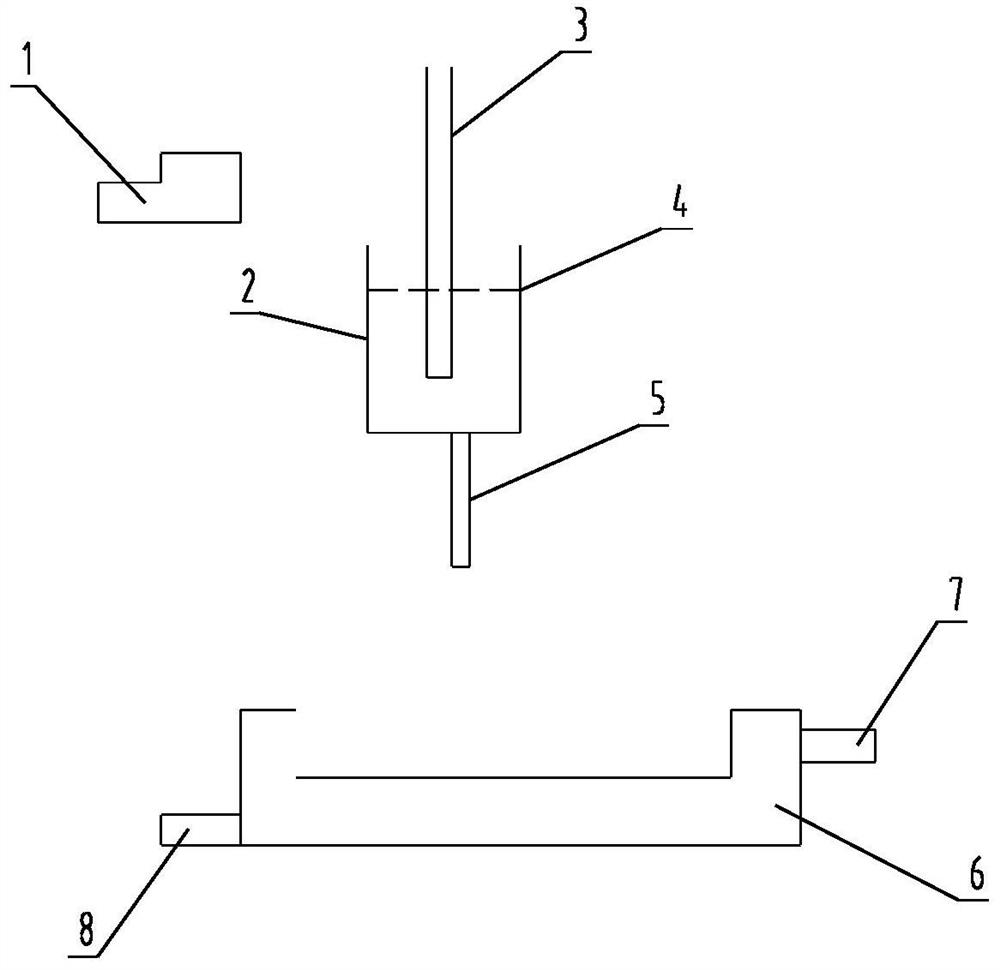

Continuous production device for amorphous belt

ActiveCN102211182BContinuous productionUninterrupted productionCasting safety devicesTemperature controlControl system

The invention relates to a continuous production device for an amorphous belt, comprising a rotary table, a smelting induction furnace, a pouring induction furnace and a temperature measuring and liquid level control system. The smelting induction furnace and the pouring induction furnace alternately change positions by virtue of the rotary action of the rotary table, alloy solution is continuously supplied to a pouring ladle, and continuous amorphous belt preparation on multi-furnace alloy solution is realized; a temperature control system is used for measuring the temperature of alloy solution in the pouring ladle or belt spraying ladle, and closed-loop control is formed by the power supply power of the pouring induction furnace and the measured temperature to control the temperature ofthe alloy solution in the pouring ladle or the belt spraying ladle to be basically stable; and a liquid level detection system is used for measuring the liquid level of the alloy solution in the pouring ladle, the closed-loop control is formed by the tapping flow of the pouring induction furnace and the measured liquid level to control the liquid level of the alloy solution in the pouring ladle to be basically stable, and continuous and stable production on the amorphous belt is realized.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

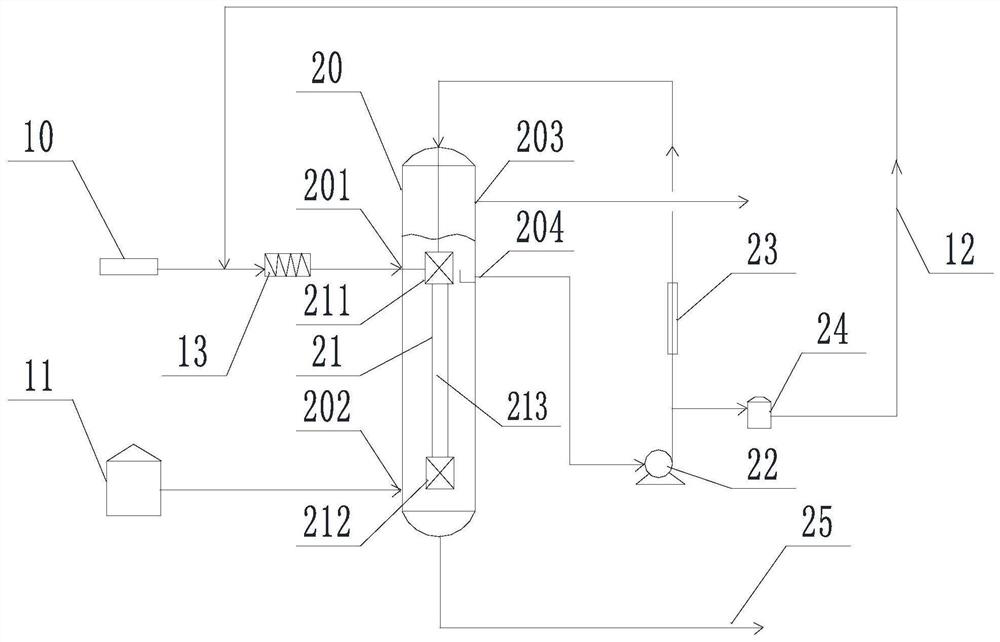

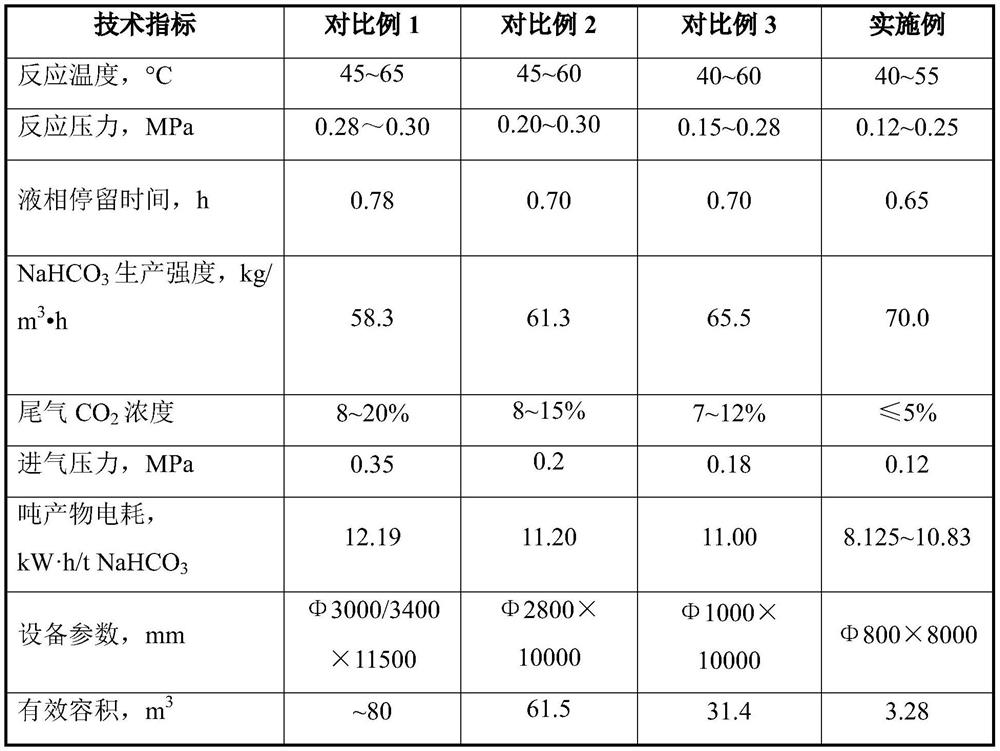

Micro-interface reinforced combined alkali production device and production method

The invention provides a micro-interface reinforced combined alkali production device. The production device comprises a carbonization tower, one side of the carbonization tower is provided with a gas inlet and a liquid inlet, the carbonization tower is internally provided with a composite micro-interface generator, the gas inlet is communicated with the composite micro-interface generator to crush and disperse incoming gas, the liquid inlet is communicated with an AII liquid storage tank for providing AII liquid for the carbonization tower, and the composite micro-interface generator is immersed below the liquid level in the carbonization tower so as to enable the AII liquid to serve as a liquid phase medium of the composite micro-interface generator. According to the device, the composite micro-interface generator is arranged in the carbonization tower, incoming gas is crushed and dispersed into micro-bubbles, the phase boundary mass transfer area of the gas and AII liquid is increased, gas with low CO2 concentration can be used, the occupied area of equipment is reduced, the reaction temperature and pressure are reduced, and the cost is saved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

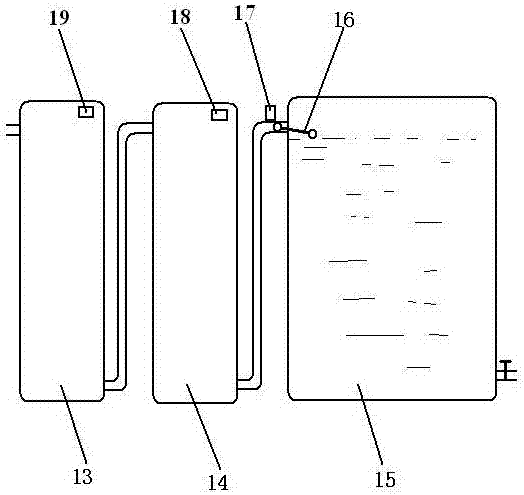

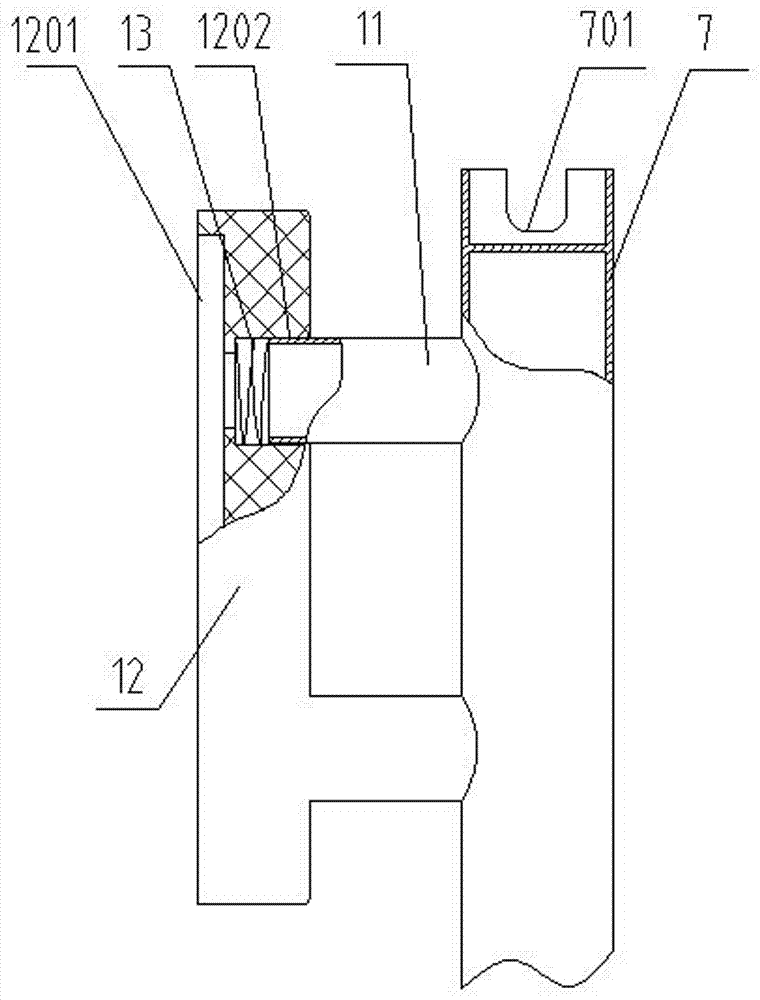

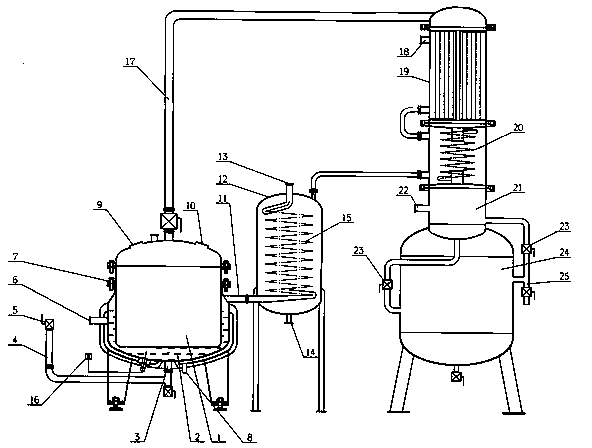

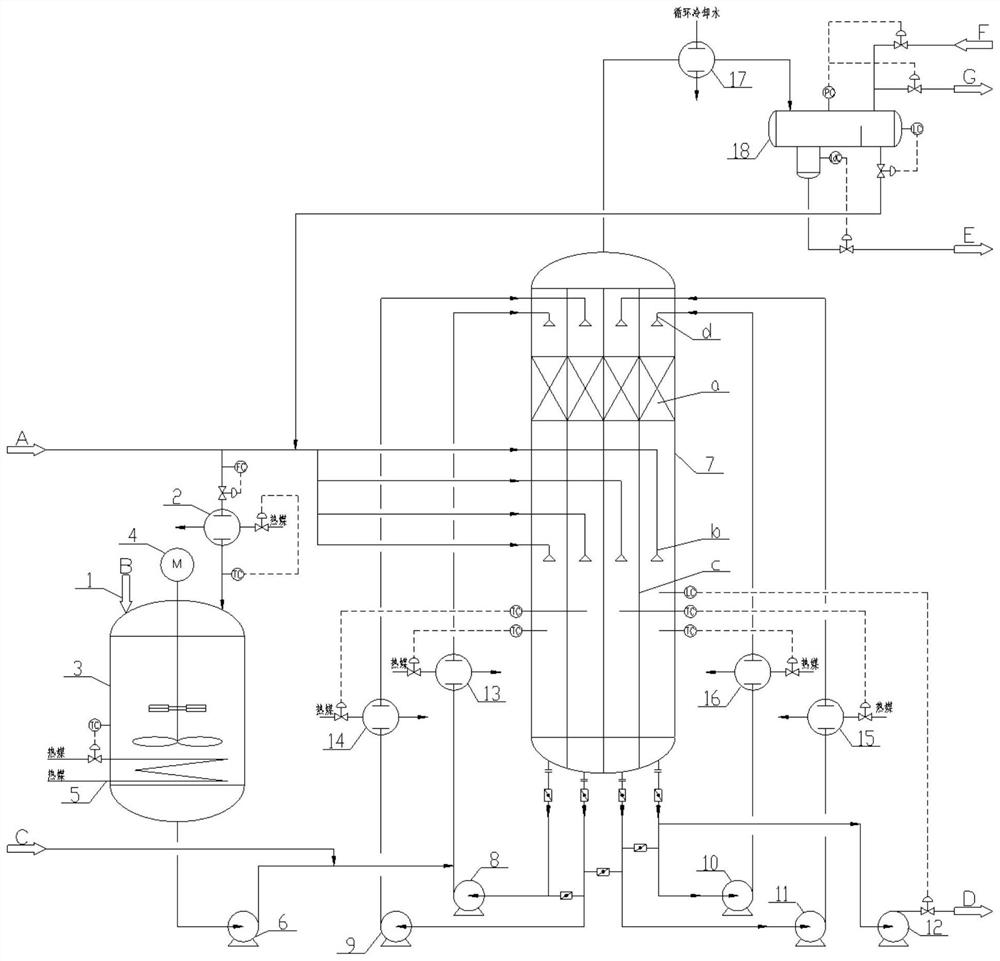

Special liquid medicine water bath heating and concentrating device used in clean area

InactiveCN104324509AMaintain humidityGuaranteed water levelEvaporator accessoriesWater bathsEngineering

The invention discloses a special liquid medicine water bath heating and concentrating device used in a clean area, belonging to the technical field of liquid medicine concentration. The device comprises a concentration tank (1), a water bath interlayer pot (2), a liquid receiving tank (24), two coil pipe condensers (12 and 20) and a pipe bundle condenser (19), wherein the concentration tank (1) is connected with the liquid receiving tank (24) by the pipe bundle condenser (19) and one coil pipe condenser (20). The special liquid medicine water bath heating and concentrating device is characterized in that the water bath interlayer pot (2) sleeves the concentration tank (1) by connecting flanges (7); a steam discharge pipe (11) of the water bath interlayer pot (2) is communicated with a condenser pipe (15) of the other coil pipe condenser (12); the two coil pipe condensers (12 and 20) are communicated with a condenser pipe of the pipe bundle condenser (19). The device is capable of preventing the temperature and the humidity of the clean area from being damaged and guaranteeing the production environment of the clean area, and has the beneficial effects of being high in cooling efficiency, less in energy consumption, etc.

Owner:DALI PHARMA

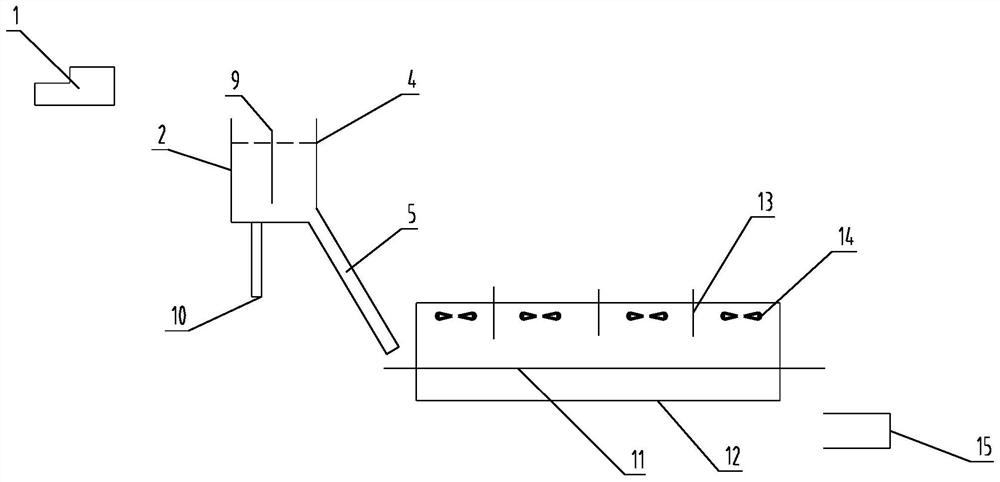

Continuous strip spraying device

The invention relates to a continuous strip spraying device which comprises a smelting furnace, a bottom pouring furnace, a spray ladle and a crystallizer, wherein the smelting furnace is located at the top of the device and used for smelting molten steel, the bottom pouring furnace is located below the smelting furnace and used for receiving molten steel flowing out of the smelting furnace and calming the molten steel, and the bottom pouring furnace is installed on a rotary table, the spray ladle is located below the bottom pouring furnace and used for receiving molten steel flowing out of the bottom pouring furnace, and the crystallizer is located below the spray ladle and used for quickly cooling molten steel flowing out of the spray ladle so as to form an amorphous alloy strip on the crystallizer. The continuous strip spraying device provided by the invention can continuously, ceaselessly and stably produce amorphous alloy strips. The continuous strip spraying device is simple in structure and occupies a small area. The design of the rotary table of the bottom pouring furnace is more beneficial to calming molten steel, thereby reducing impurities in molten steel flowing into the spray ladle and improving the magnetic performance of the amorphous alloy strip.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

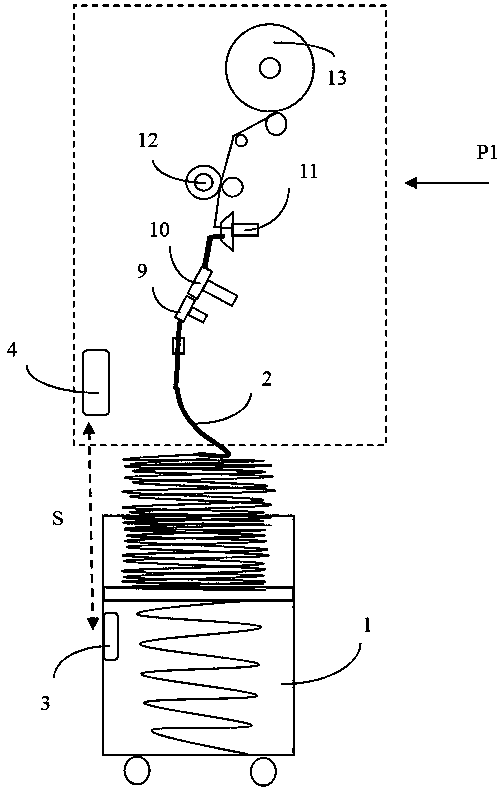

Can fiber ribbon reading device and recognition method

PendingCN111394842AReduce workloadUninterrupted productionTextiles and paperFiberMechanical engineering

The invention provides a can fiber ribbon reading device. The information of the length of a can fiber ribbon, broken end number and fiber ribbon length between broken ends is read through a fiber ribbon information storing component of a can in a non-contact manner, the can fiber ribbon exhausting time and end breaking time are calculated based on the fiber ribbon feeding speed, fiber ribbon feeding stopping time and other parameters, and therefore the state information of the fiber ribbon is recognized. Furthermore, the fiber ribbon reading device sends the fiber ribbon exhausting time and end breaking time information to machine equipment, and the next action is carried out. The machine equipment comprises but not limited to a drawing frame, a drawing and rolling combination machine, aroving frame, a revolving cup spinner, a vortex spinner (also called jet vortex spinner and air spinner), an AGV, a jointing machine, a doffer, a cleaning machine and the like. The next action comprises but not limited to new can replacing, fiber ribbon jointing, fibber ribbon feeding stopping, alarm signal sending and the like.

Owner:邱丽遐

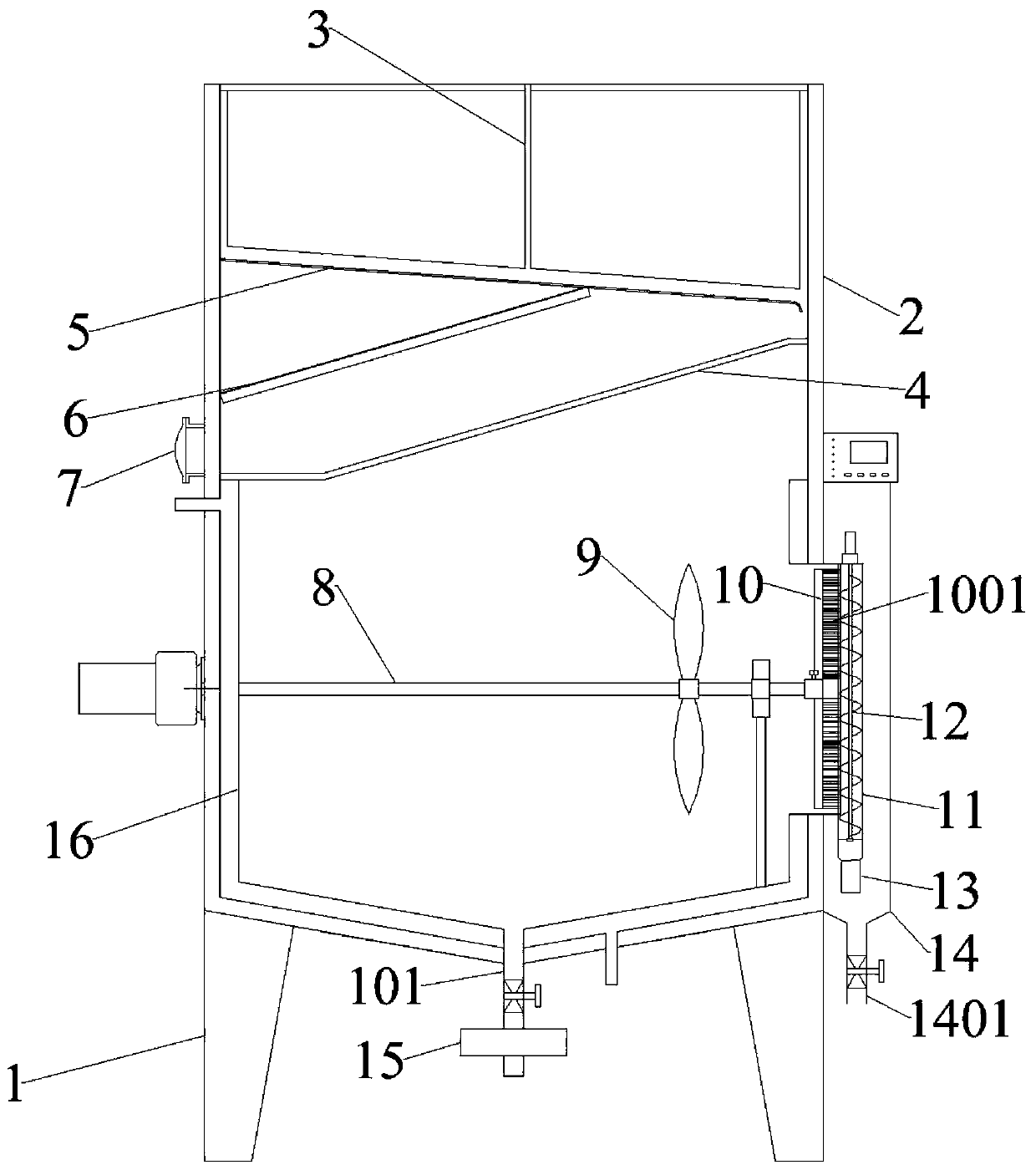

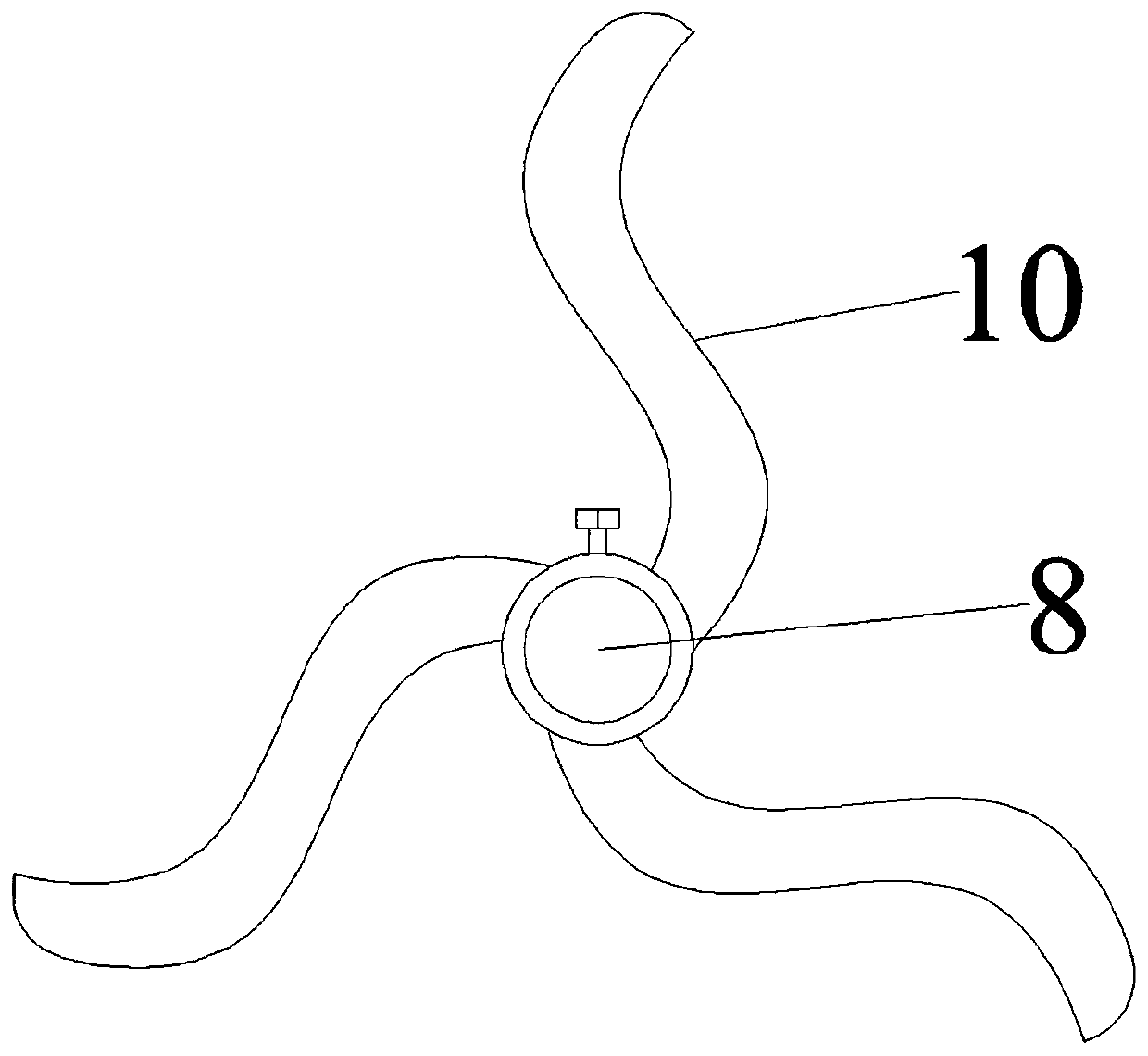

Honey impurity removing device and method

ActiveCN109701307AImprove the efficiency of impurity removalImprove stabilityClimate change adaptationStationary filtering element filtersBiochemical engineeringPropeller

The invention discloses a honey impurity removing device, comprising: a honey impurity removing device, which is characterized in that: a box body is provided with a feeding port at the top, a filtering port is arranged on the side wall of the box body, and a filter screen is arranged at the filtering port; a main shaft is arranged inside that box body, one end of the main shaft is provided with aimpurity scraping plate, the impurity scraping plate is in contact with the surface of the filter screen, and a propeller is arranged on the main shaft, and the acting force generated by the rotationof the propeller faces the filter screen. The invention also discloses a honey impurity removing method. The invention can automatically remove and convey the impurities on the filter screen, save time and labor, realize the continuous impurity removal operation, and improve the efficiency, stability and product quality of the impurity removal of honey.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

Box forming machine

InactiveCN104443547AQuality improvementUnified standardPaper-makingBox making operationsMolding machineEngineering

The invention relates to the technical field of packaging machine equipment and discloses a box forming machine. The box forming machine comprises a rack connected with an electric control cabinet. The rack is provided with a box feeding mechanism for feeding boxes into a drawing die position. A first combining device used for being attached to first opposite edges of the boxes and a second combining device used for being attached to second opposite edges of the boxes are arranged below the box feeding mechanism. The box forming machine further comprises a drawing die mechanism which is arranged above the rack and used for adsorbing the boxes to be conveyed downwards or upwards. Attaching and forming are finished through the machine in the whole process, the automation degree is high, the produced boxes are good in quality and uniform in standard, the continuous production of an enterprise can be ensured, and the labor cost of the enterprise can be saved to the maximum degree.

Owner:孙百军

Rooting method for un-rooted tissue culture seedlings of salix matsudana var.tortuosa

InactiveCN103535279AFew materialsExplant richPlant tissue cultureHorticulture methodsGramActivated carbon

The invention provides a rooting method for un-rooted tissue culture seedlings of salix matsudana var.tortuosa. A culture medium is used for the rooting culture of the un-rooted tissue culture seedlings of salix matsudana var.tortuosa, and every liter of culture medium comprises MS, 0.01 to 1 milligram of NAA (naphthylacetic acid), 0.01 to 1 milligram of 6-BA (6-benzylaminopurine), 30 grams of sucrose, 6.5 grams of agar powder and 0.5 to 3 grams of activated carbon. According to the method, the un-rooted tissue culture seedlings are high in rooting speed and rooting rate; a culture medium formula is not required to be replaced in a tissue culture process, so that tissue culture operation is simplified; the method has higher scientific value, economic value and practical value.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

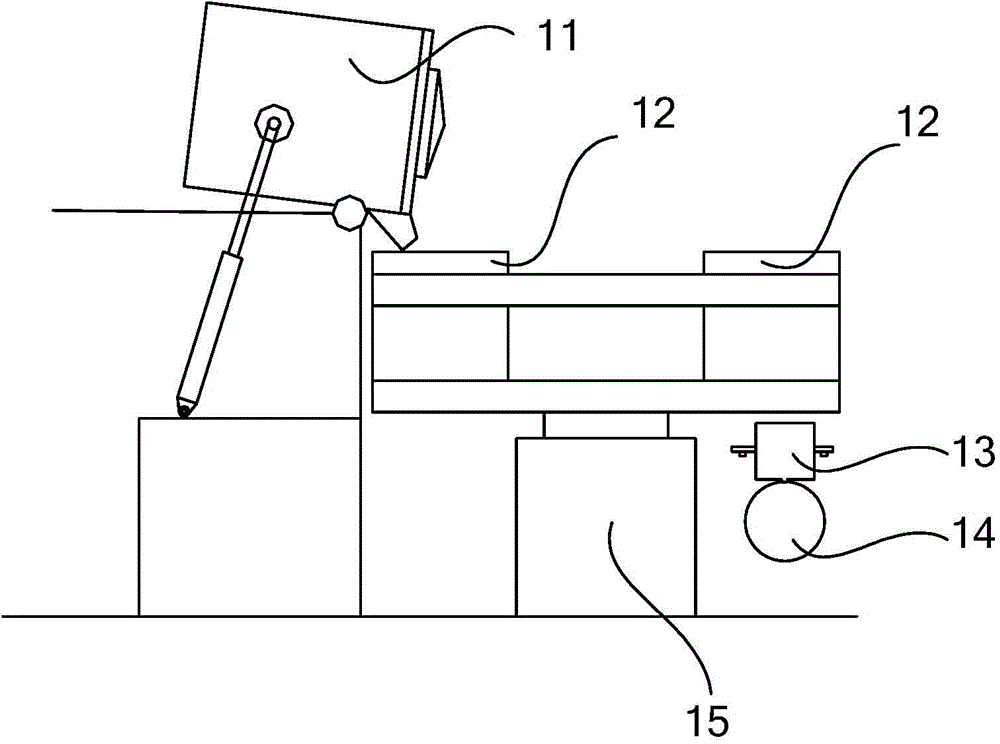

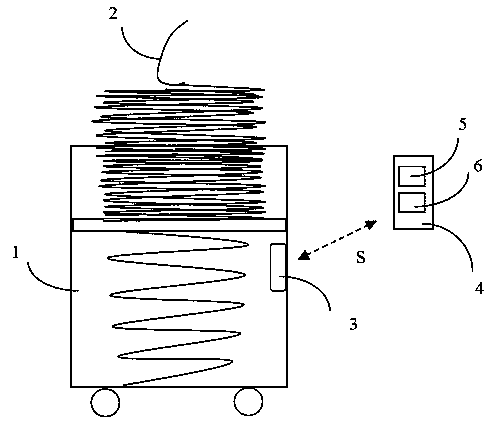

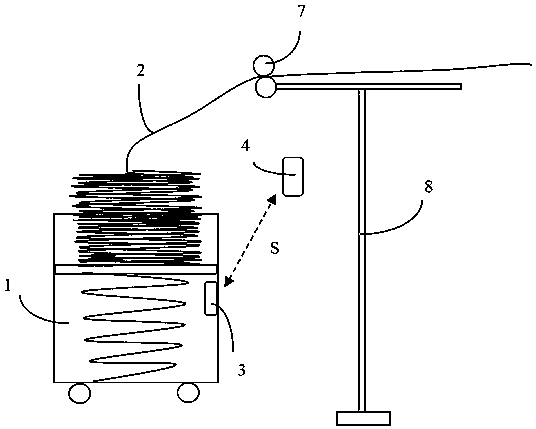

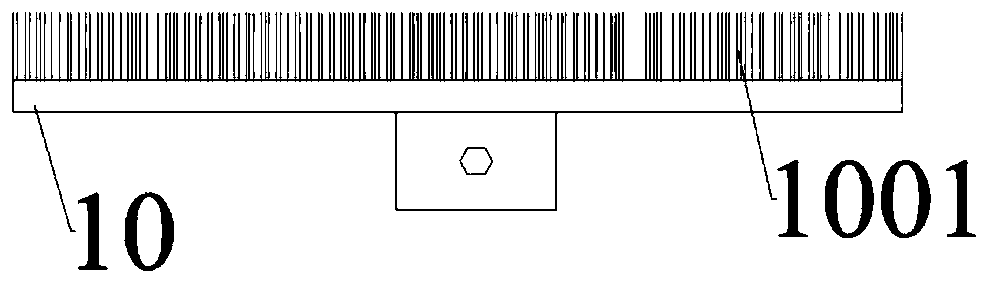

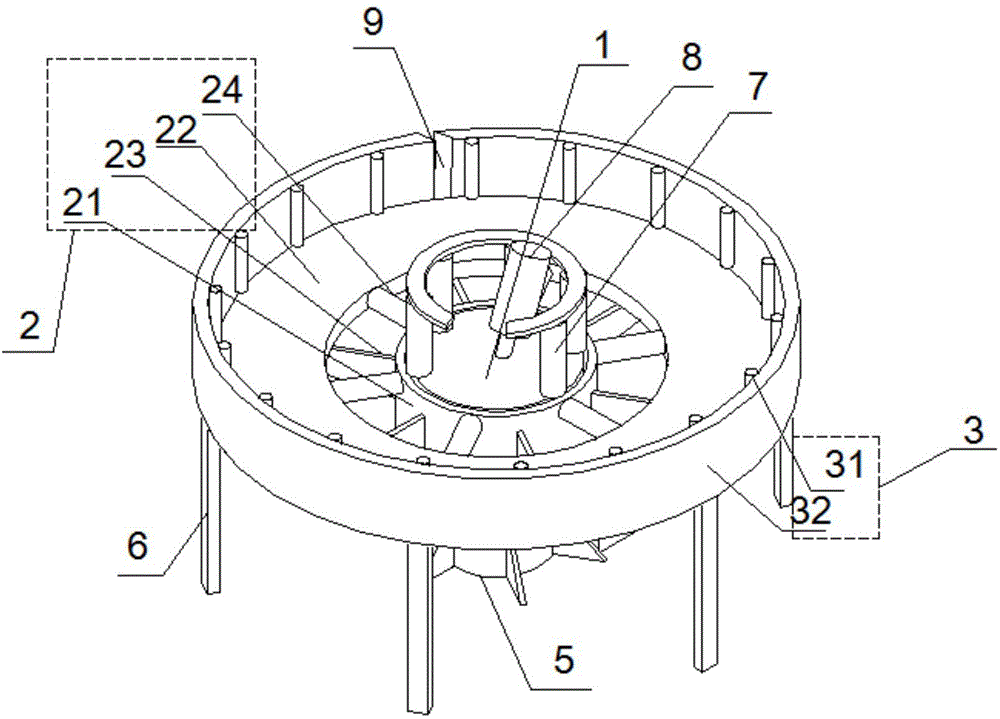

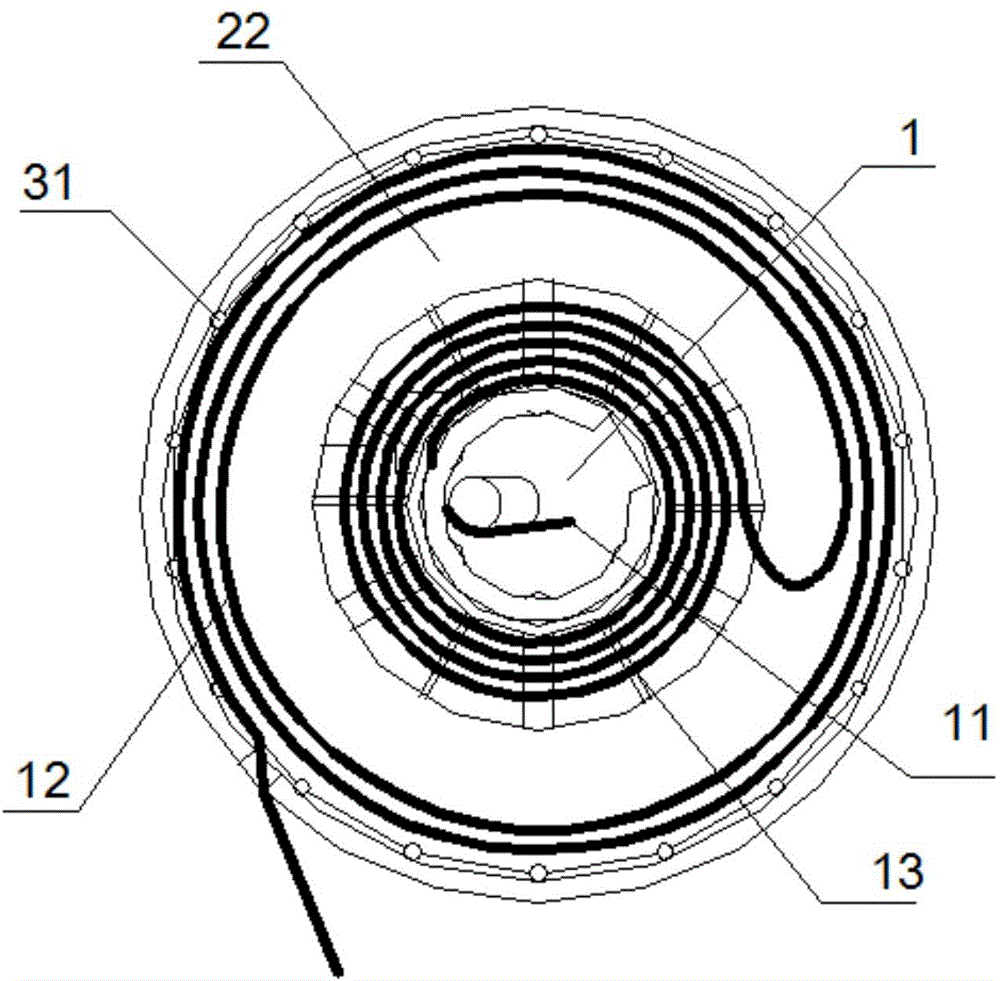

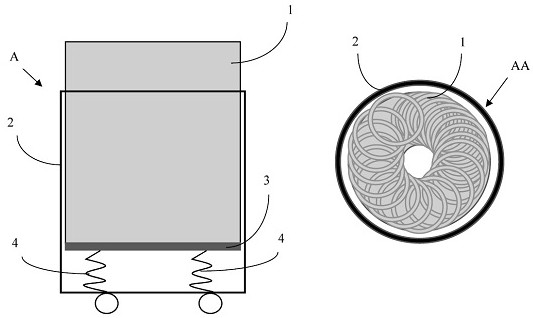

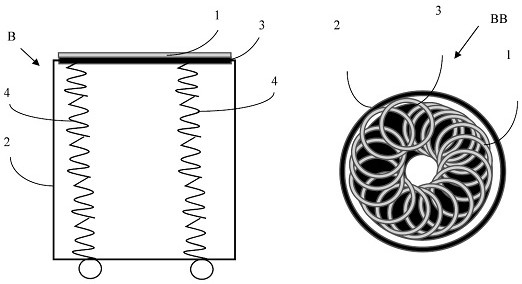

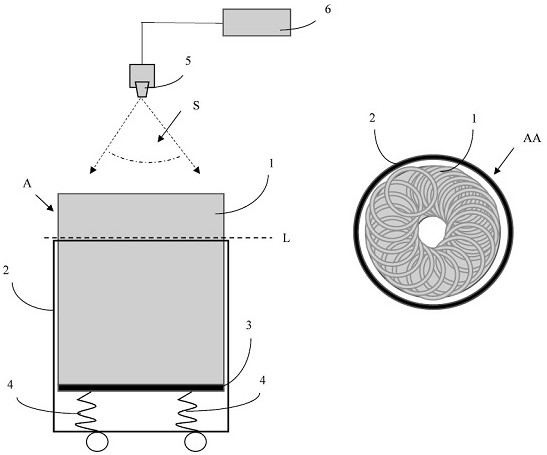

Practical storage device for steel belt

InactiveCN105583320AContinuous productionUninterrupted productionMetal-working feeding devicesPositioning devicesArchitectural engineeringSteel belt

The invention provides a practical storage device for a steel belt. The practical storage device comprises an inner fixed plate, an outer rotating plate, a driving device and a surrounding device. The inner fixed plate is fixed to the ground through a supporting column arranged in the center of the inner fixed plate. The outer rotating plate is arranged on the outer side of the inner fixed plate in a sleeving mode, connected with the supporting column through a bearing and connected with the driving device. The surrounding device is arranged at the outer edge of the outer rotating plate and fixed to the ground through supporting legs. A circle of first rolling shafts are arranged at the outer edge of the surface of the inner fixed plate. A second rolling shaft is arranged in the center of the surface of the inner fixed plate. The outer rotating plate can rotate around the inner fixed plate. The surrounding device is higher than the surface of the outer rotating plate. The surrounding device is provided with a steel belt inlet. The practical storage device for the steel belt has the beneficial effects that a steel pipe bending machine does not need to be stopped during replacing of the steel belt, and the production efficiency is improved.

Owner:TIANJIN XINZHIQIANG STEEL PIPE

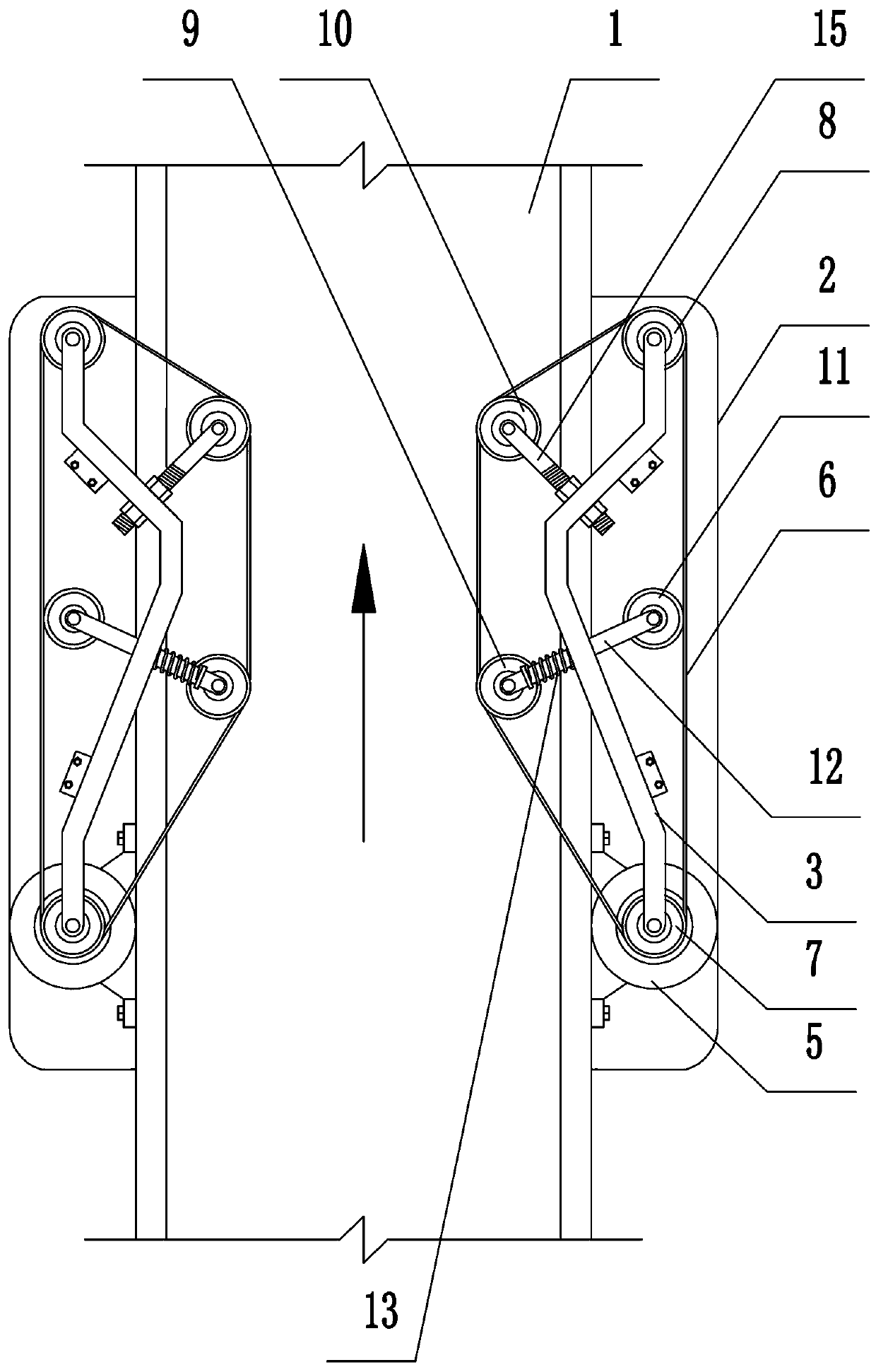

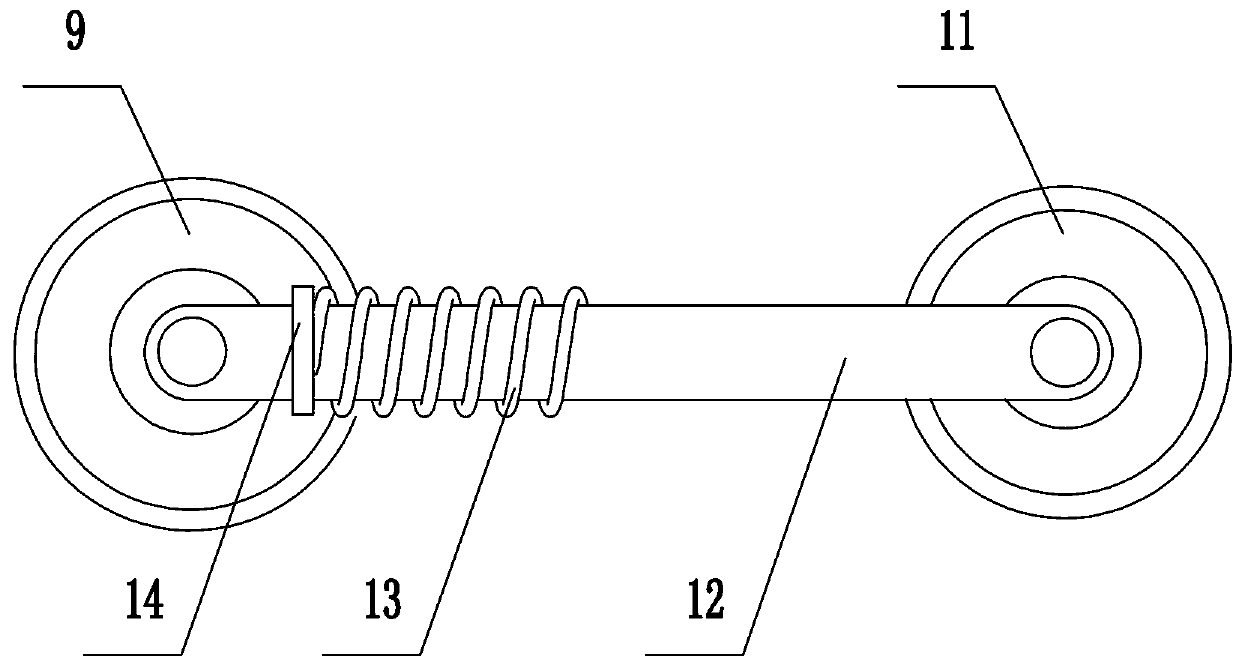

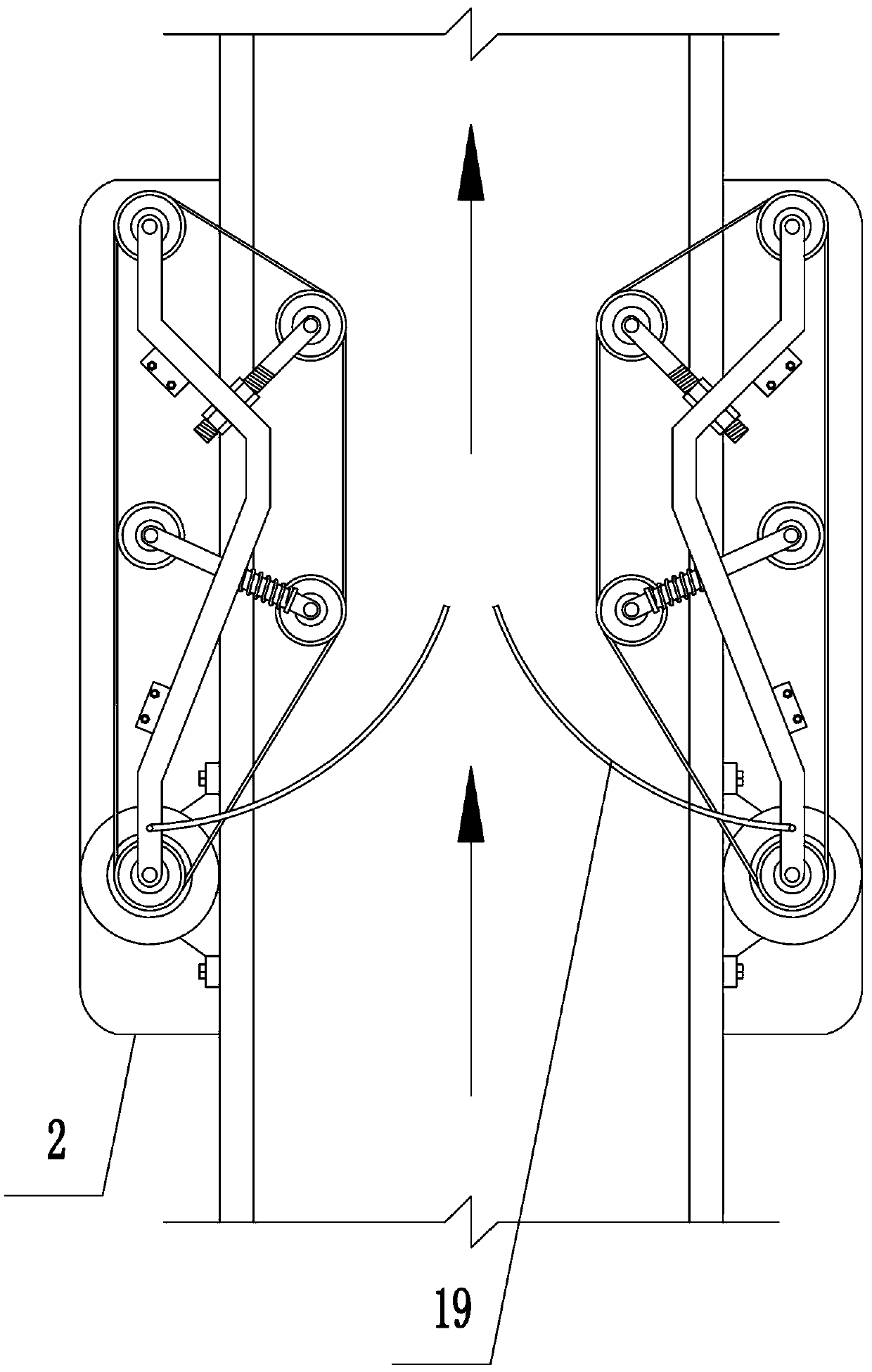

Correction device for winebottle posture

PendingCN110127296AConsistent positionReduce vibration amplitudeConveyorsConveyor partsDrive wheelFixed frame

The invention relates to the technical field of glass procession equipment, in particular to a correction device for winebottle posture. Two sides of a conveying mechanism are respectively provided with a correction device. Each correction mechanism comprises a fixed frame, a drive wheel, a driven wheel, a first correction wheel, a second correction wheel and a third correction wheel, wherein a sliding rod is arranged between the first correction wheel and the third correction wheel; the first correction wheel and the third correction wheel are respectively located on two sides of the slidingrod; the sliding rod and the fixed frame are in sliding connection; the extension direction of the sliding rod and the conveying direction of the conveying mechanism are formed in an obtuse angle; thesecond correction wheel is arranged on the fixed frame through a screw rod; and the extension direction of the screw rod and the conveying direction of the conveying mechanism are formed in an acuteangle. According to the correction device for winebottle posture, the correction mechanisms are arranged on the two sides of the conveying mechanism, the self-adjusting function of winebottle postureis achieved, and quality of decorating firing is guaranteed.

Owner:ANYANG COUNTY YONGSHENG GLASS PAINT&PRINTING CO LTD

State monitoring device and method for fiber strands in cans

PendingCN113201826AReduce workloadUninterrupted productionSafety devices for fibre treatmentFiberMachine

The invention relates to a state monitoring device and method for fiber strands in cans in the textile industry, and belongs to the technical field of textile machinery. The device comprises fiber strand sensors and a signal processing unit. The sensors are additionally arranged above the fiber strand cans or on the circular edges of can trays, so that the states of the fiber strands in the cans, especially the states when the fiber strands are nearly used up, can be monitored, and signals can be transmitted to a machine in time. Therefore, the machine can inform an operator or an AGV to replace the cans in time in real time, so that uninterrupted production is guaranteed, the production efficiency is improved, and the workload of the operator is reduced. Furthermore, the machine can know the fiber strand states of the cans in real time, especially the states that the fiber strands are about to be used up, the AGV and a fiber strand splicing robot are combined and can cooperate together to achieve unmanned automatic fiber strand splicing and can changing, and a foundation is laid for unmanned and intelligent operation of a drawing frame, a drawing and lapping combined machine, a roving frame, a rotor spinning machine and a vortex spinning machine.

Owner:邱丽遐

Fluidizing bed type waste plastic continuous oil refining device with environment protection and high efficiency

InactiveCN101805630APromote lysisAchieve energy saving effectTreatment with plural serial stages onlyLiquid hydrocarbon mixture productionCombustionSlag

The invention discloses a fluidizing bed type waste plastic continuous oil refining device with environment protection and high efficiency. The raw material is lifted from a material storing tank through a material supplying machine, passes through a feeding machine, and enters a first reaction kettle from an extruder. The first reaction kettle is connected to a catalyzing tank. An oil storing tank is connected to an impurity removing tank through a pipeline. The impurity removing tank is connected to a filtering tank. The filtering tank is connected to a finished oil tank. A converting agent and waste slag in a second reaction kettle are lifted into a combustion tower by a lifter. The combustion tower is connected to a dust removing tank, and the dust removing tank is connected to the second reaction kettle. The invention uses the waste plastic products or waste oil as raw materials, and integrates automatic material delivery, automatic slag discharge, cracking, catalyzing, cooling, liquefying, impurity removal, filtering and the like. The invention has the advantage that the miniature circular flash evaporation reaction kettle with continuous catalyzing reaction is developed, the converting agent using the self to continuously obtain high temperature is utilized to catalyze and crack the raw material in a full automatic circulation way, and then the high-efficiency closed continuous production is formed.

Owner:JIANGSU TAOISO ENVIRONMENT PROTECTION TECH

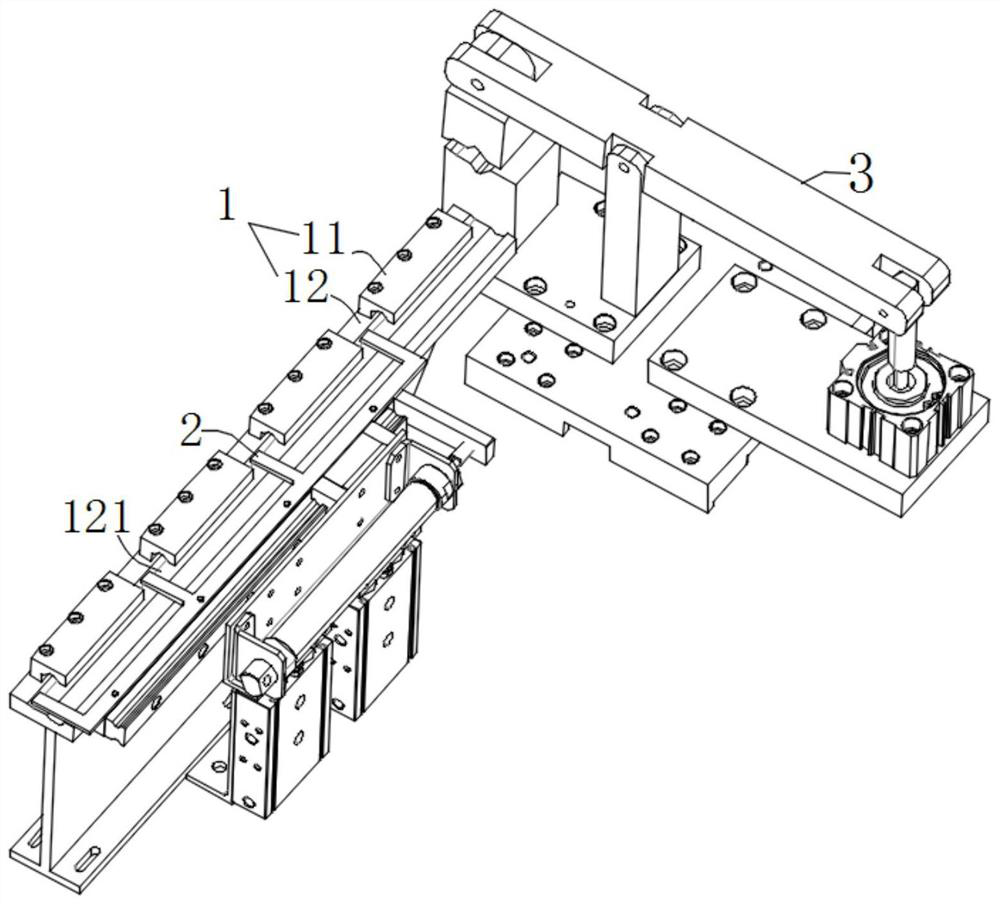

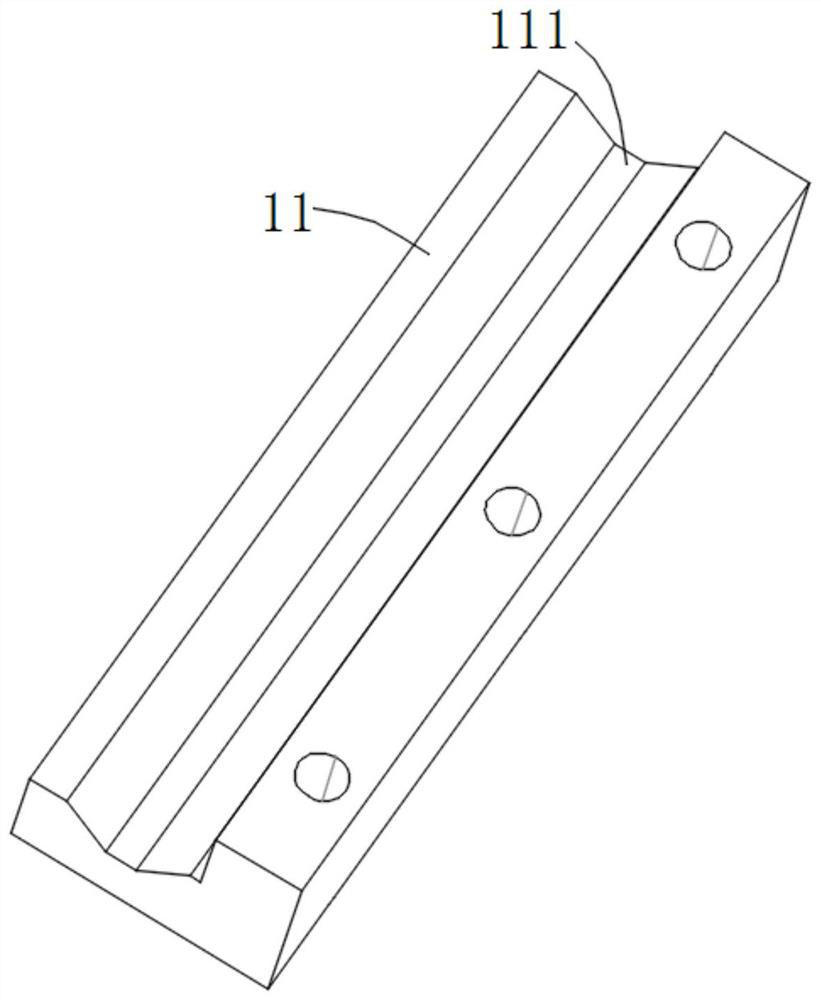

Material transferring device, drilling mechanism and processing center

PendingCN111673141AUninterrupted productionContinuous uninterrupted feedingMetal working apparatusBoring/drilling machinesThermodynamicsProcess engineering

The invention relates to the field of workpiece processing and manufacturing, in particular to a material transferring device, a drilling mechanism and a processing center. A material transferring device comprises a carrier, a drive member, a transferring module and a compressing part, wherein the carrier extends along a feeding direction, and the tail end of the carrier located in the feeding direction is provided with a transferring area; the drive member is used for driving a workpiece to move along the feeding direction; the transferring module is used for clamping the workpiece, the transferring module is configured to be installed linearly, and the transferring module moves between the transferring area and a processing station; the transferring module comprises a receiving part, andthe receiving part and a carrying surface of the carrier are on a same horizontal plane; and the compressing part is used for compressing and fixing the workpiece. According to the invention, the technical problems of impossible continuous production, low degree of automation and low efficiency when the workpiece is processed, a conveying device needs to be stopped in a lock workpiece productionline in the prior art.

Owner:JIANGSU UNIV OF TECH

Bag-making machine loading device

PendingCN109109383AIngenious structureIncrease productivityBag making operationsPaper-makingEngineeringPerpendicular direction

The invention discloses a bag-making machine loading device which is sequentially provided with a double-film-roll support frame, a first guiding roller, a material receiving platform and a film rolling storage rack, wherein a one-way bearing roll set and a plurality of rolling idler wheels are arranged on the film rolling storage rack; the one-way bearing roll set comprises a one-way bearing roller and a compression roller; the rolling idler wheels comprise fixed idler wheels and movable idler wheels; and the movable idler wheels are mounted and fixed on the sliding block of a rodless cylinder arranged in the perpendicular direction and can move along with up-down motion of the sliding block. The bag-making machine loading device can avoid halt when a film roll is changed to greatly improve the production efficiency and is extremely high in practicality.

Owner:江阴市汇通印刷包装机械有限公司

Method for continuously producing peach flowers and peaches with separated refrigeration houses and greenhouses through batch-to-batch cultivation

PendingCN109526519AUninterrupted productionShort fruiting periodClimate change adaptationGreenhouse cultivationGreenhousePollination

The invention discloses a method for continuously producing peach flowers and peaches with separated refrigeration houses and greenhouses through batch-to-batch cultivation. The method comprises the following steps: 1, carrying out low-temperature on-batch dormancy, namely moving an expected number of seedlings or grown peach trees growing in fixed planting containers into a low-temperature dormancy refrigeration house for dormancy at one time or in different batches, and moving the peach trees with sufficient refrigeration into dormancy breaking greenhouse in different batches at intervals ofblooming lasting time; 2, carrying out on-batch dormancy breaking blooming acceleration, namely using the peach trees which are moved into the dormancy breaking blooming acceleration greenhouse on batch as a flower admiring product at a flower stage, carrying out artificial pollination on plants for fruits at a blooming stage, and transferring into a fruiting greenhouse from the dormancy breakingblooming acceleration greenhouse; 3, carrying out on-batch fruiting, namely enabling the peach trees transferred into the fruiting greenhouse on batch to fruit, harvesting the fruits, carrying out chemical defoliation, and returning into the low-temperature dormancy refrigeration house. The method has the beneficial effects that as peach trees are cultivated in different refrigeration houses andgreenhouses in an on-batch joint cultivation manner, peach flowers and fresh peaches can be continuously produced in a whole year, in a region where the peach trees are cultivated with the method, social demands on peach flowers and fresh peaches can be met at any time, and the development of peach culture can be promoted.

Owner:高秀民

Low temperature continuous cracking system for rubber

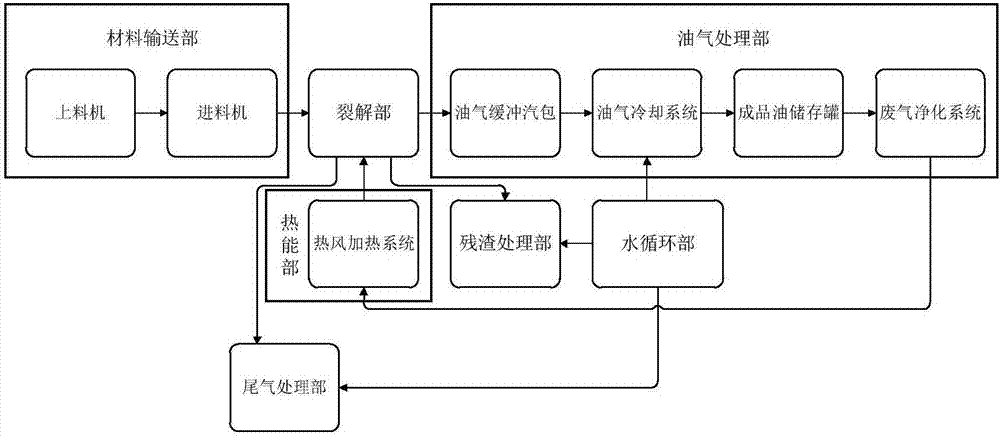

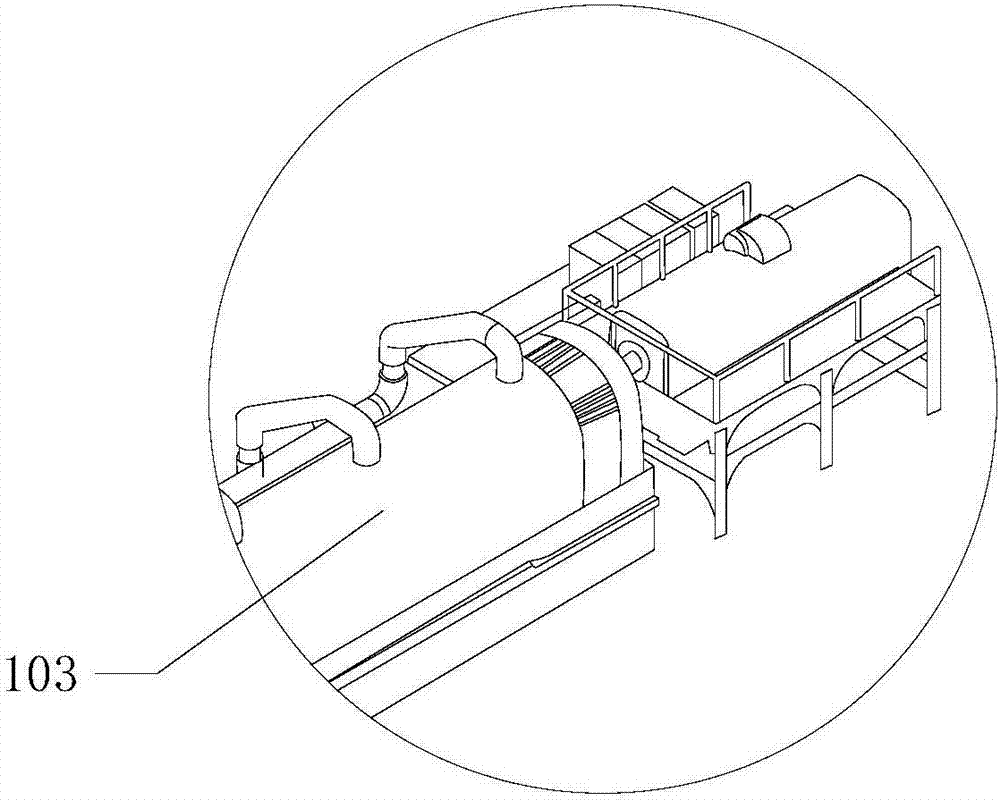

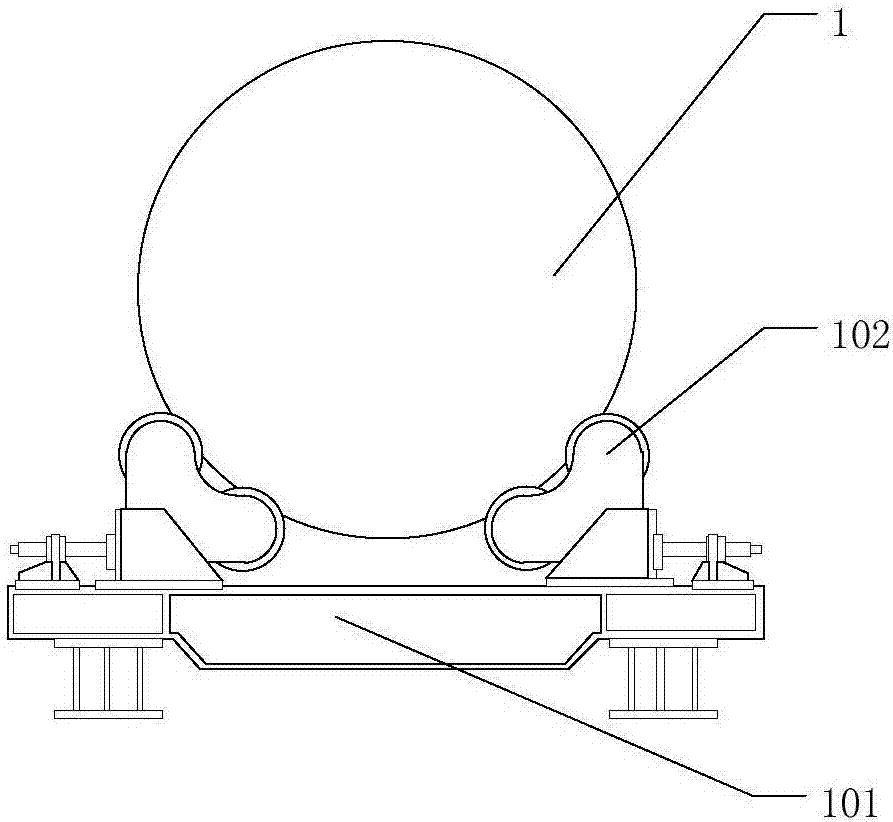

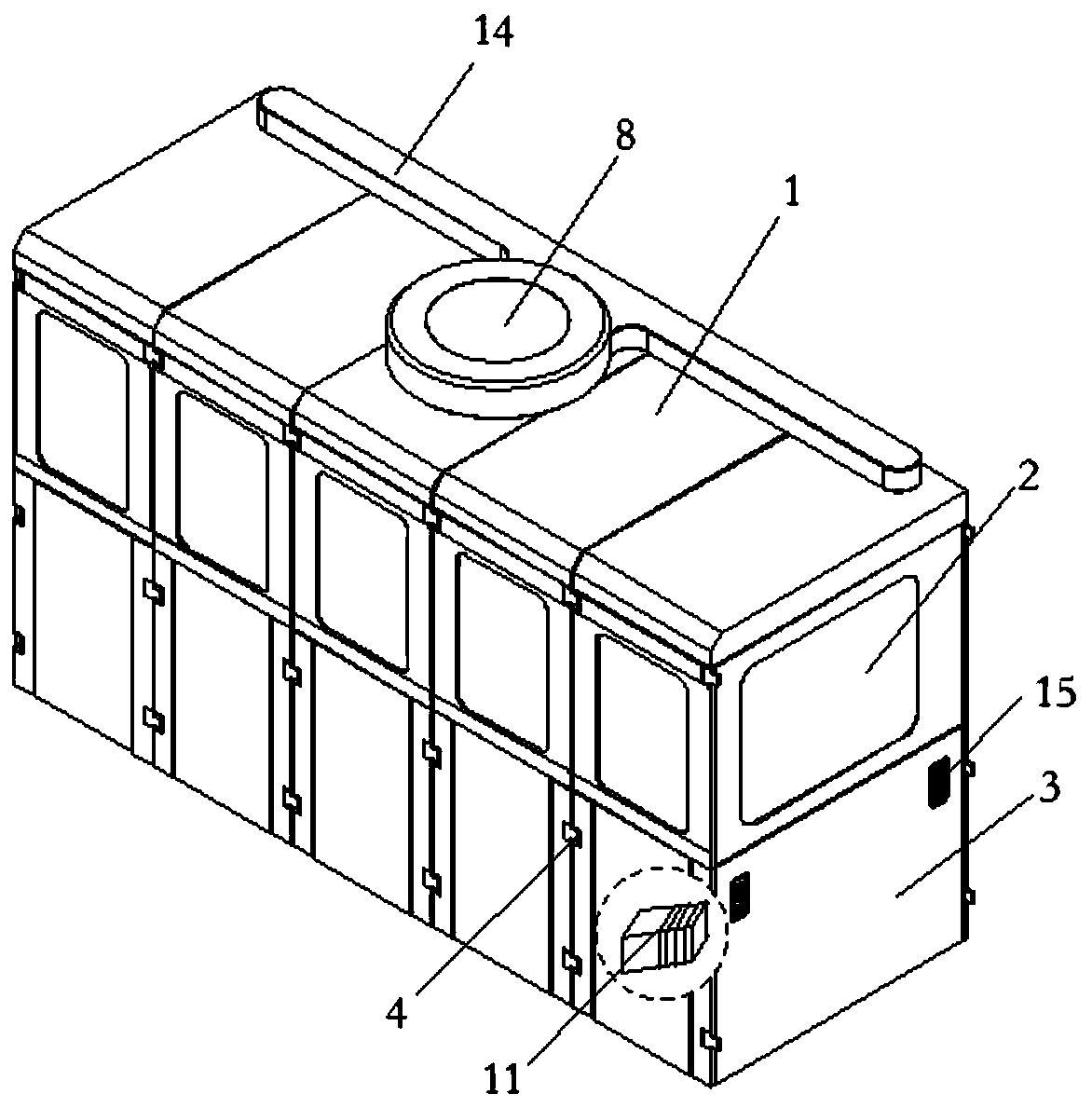

InactiveCN107057745AImprove securityReduce consumptionCombination devicesProductsThermal energyEngineering

The invention discloses a low temperature continuous cracking system for rubber. The system is characterized in that the system comprises a material conveying portion, a cracking portion, an oil-gas processing portion, a residue treatment portion, a thermal energy portion, a tail gas treatment portion, a water circulation portion and a control host computer which is connected with the other portions; the material conveying portion is connected with the feeding port of the cracking portion; the cracking portion is provided with at least one oil-gas outlet which is connected to the oil-gas processing portion, at least one residue outlet which is connected to the residue treatment portion, at least two hot wind pipelines which are connected to the thermal energy portion and at least two tail gas pipelines which are connected to the tail gas treatment portion; the water circulation portion is provided with a circulation water pipeline which is connected to the oil-gas processing portion, the tail gas treatment portion and the residue treatment portion respectively. The system achieves low temperature cracking for rubber and other recyclable materials, reduces the dependence on human in the cracking process, and improves the cracking efficiency; meanwhile, the system improves the stripping and removing degree of the harmful ingredients of the petroleum gas, and improves the recycling rate of the available ingredients of the cracking petroleum gas. Therefore, the low temperature continuous cracking system is worth of being popularized.

Owner:重庆市聚洪环保科技有限公司

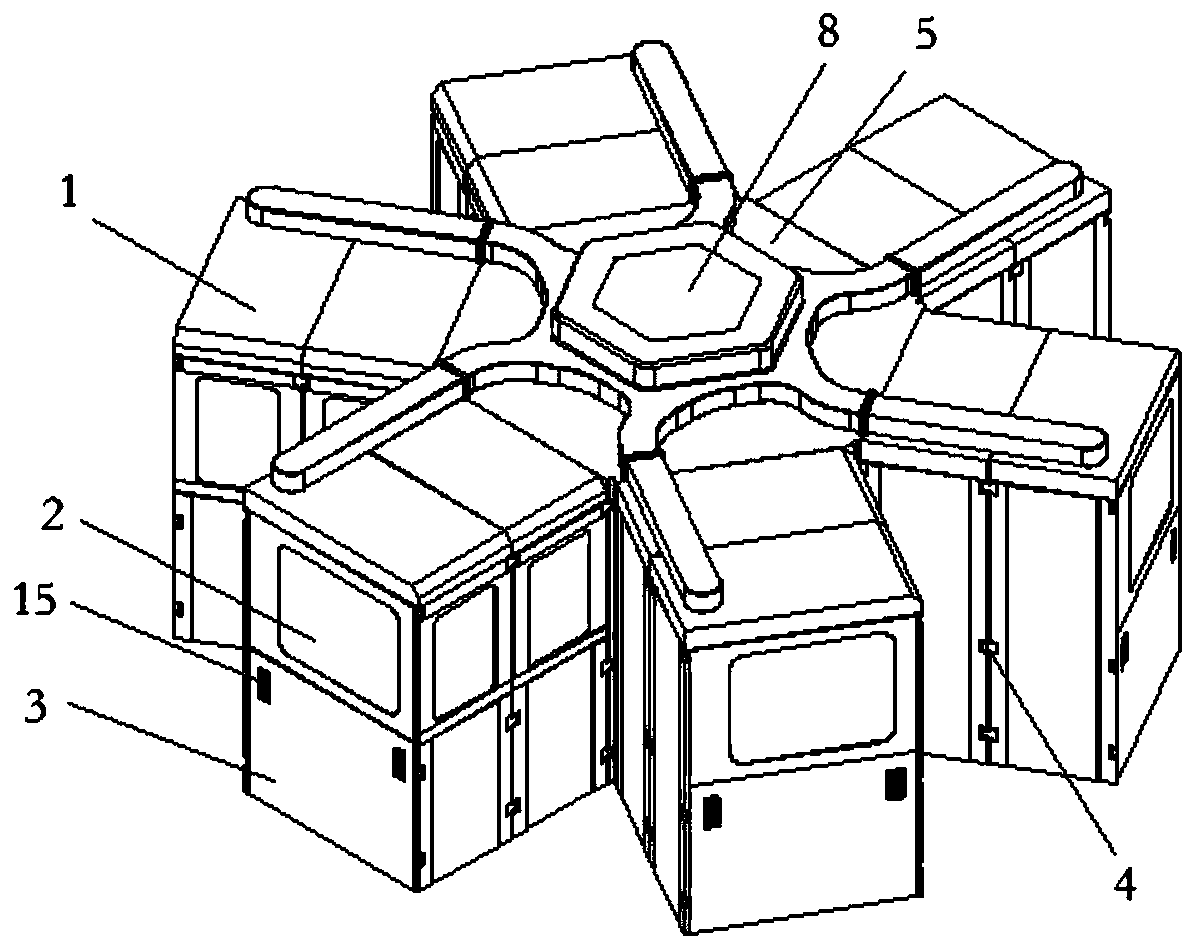

Biological tissue production device

InactiveCN110484448AStable deliveryUninterrupted productionBioreactor/fermenter combinationsBiological substance pretreatmentsCryopreservationEngineering

The invention provides a biological tissue production device, and relates to the technical field of biological tissue production. The biological tissue production device includes multiple functional modules and a material conveying mechanism; each functional module is provided with a material conveying opening; the material conveying mechanism is used for inputting or outputting materials for thefunctional modules through the material conveying openings of the functional modules; the functional modules comprise a cell expansion module, a biological culture module, a printing module, a detection module, a cryopreservation warehouse module and a consumable item supply module. The arrangement of the material conveying mechanism can avoid the impact of manual operation experience on the product, the product consistency is good, and the problems of low yield and high unit price are avoided; contamination caused by manual operation is eliminated, and the cleanliness of a processing environment is easier to maintain; moreover, the productivity is improved.

Owner:REGENOVO BIOTECH

Production method for preparing environment-friendly plasticizer by adopting continuous method

PendingCN112679345AHigh automation purityImprove efficiencyPreparation rom asymmetrical anhydridesOrganic compound preparationBenzoic acidPtru catalyst

The invention relates to a production method for preparing an environment-friendly plasticizer by adopting a continuous method, which comprises the following steps: reacting benzoic acid with alcohol in the presence of a catalyst to obtain a benzoate plasticizer, and is characterized by comprising the following steps: mixing solid granular or blocky raw material benzoic acid with alcohol to obtain a raw material reaction solution; mixing and heating raw material reaction liquid, a catalyst and first-stage reaction liquid to 160-250 DEG C and allowing the raw material reaction liquid, a catalyst and first-stage reaction liquid to enter the top of a first-stage reaction cavity of a partition plate tower reactor, introducing alcohol from the middle of each stage of reaction cavity of the tower reactor to be subjected to esterification reaction with reaction mixed liquid, and externally and circularly heating each stage of reaction liquid to 160-250 DEG C to maintain the reaction temperature, wherein unreacted alcohol at each stage and water generated by reaction are vaporized, are collected and discharged at the top of the partition plate tower reactor, and are condensed, layered and separated; and enabling crude ester discharged from the bottom of the fourth-stage reaction chamber to be subjected to post-treatment to obtain a plasticizer product. According to the invention, continuous production of the environment-friendly plasticizer is realized in a manner of series connection of multiple stages of reaction cavities in the partition plate tower type reactor, and the method has the characteristics of safety, high efficiency, high automation degree, small occupied area and energy conservation.

Owner:南京中设石化工程有限公司

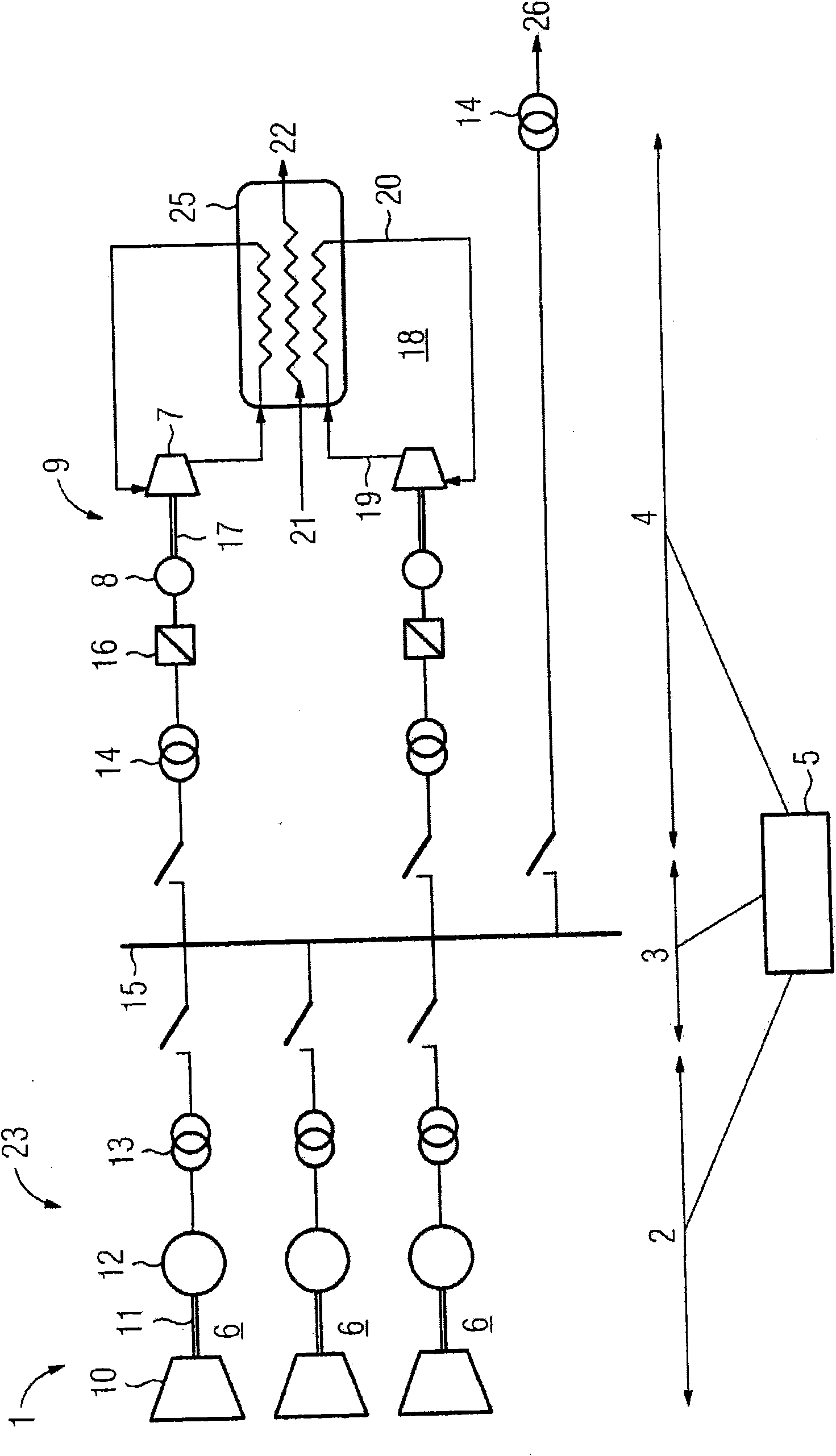

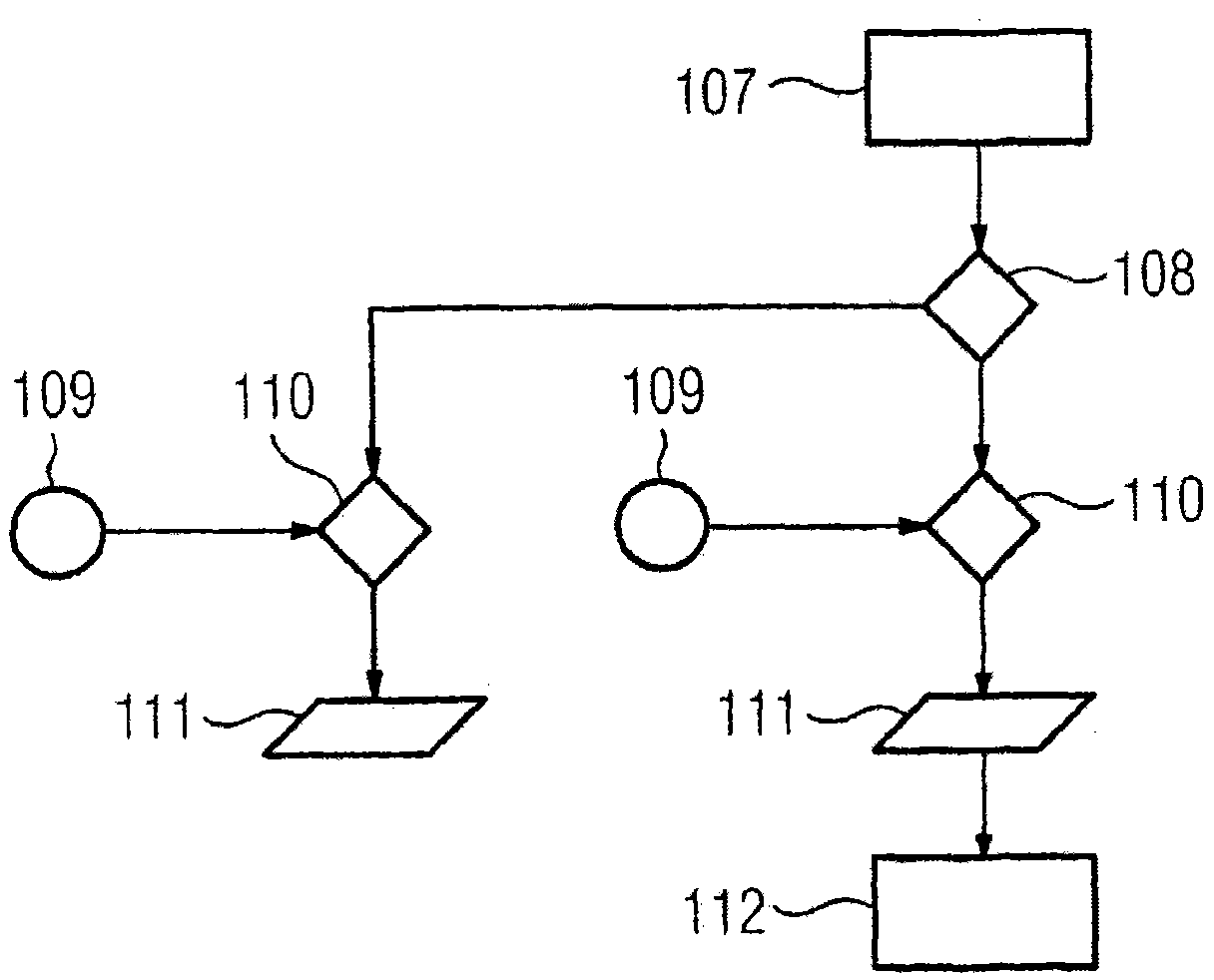

Method for the uninterrupted operation of a gas liquefaction system

InactiveCN101784857AUninterrupted productionSustain production without interruptionSolidificationLiquefactionEngineeringProduct gas

The invention relates to a method for the uninterrupted operation of a gas liquefaction system (1), wherein the operation is continuously monitored for at least those users of the refrigerant compressor component (4) which represent a two-digit percentage of the total load on the refrigerant compressor component (4). A total instantaneously available negative load reserve is calculated, and at least one predetermined turbine (10) is switched off when the load reserve reachable via a frequency regulation of the one or more refrigerant compressors (7) is lower than the energy demand of the largest of the refrigerant compressors (7) and either a refrigerant compressor (7) fails or a speed of frequency change (df / dt) for the power supply network for the gas liquefaction system (1) exceeds a preset threshold (121).

Owner:SIEMENS AG

Manufacturing device and manufacturing method of optical glass clinker

PendingCN113480140AAvoid damageUninterrupted productionCharging furnaceGlass furnace apparatusOptical glassCooling channel

The invention belongs to the technical field of glass production, particularly discloses a manufacturing device and a manufacturing method of optical glass clinker, and aims at solving the problem that an existing device for manufacturing fluorophosphate optical glass clinker is low in production efficiency. According to the manufacturing device, a vertical partition plate is arranged in the inner cavity of a smelting container to divide the inner cavity into a smelting area and a discharging area, and a molten glass passing hole for communicating the smelting area with the discharging area is formed in the lower portion of the vertical partition plate, so that molten glass can be smelted and homogenized in the smelting area, then flows into the discharging area through the molten glass passing hole, then is discharged through a discharging pipe for producing the glass clinker. Therefore, glass raw materials are fed into the smelting area in the production process, it is ensured that molten glass can be discharged outwards all the time in the discharging area, uninterrupted production of the glass clinker can be achieved, and the production efficiency is greatly improved. By arranging a traction annealing furnace with a cooling channel, the production efficiency can be further improved, meanwhile, the labor intensity of workers is greatly reduced, and the input-output rate can be increased.

Owner:CDGM OPTICAL GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com