Strong alkaline electrolyzed water production system

A production system and water electrolysis technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of pure water, can only be shut down to cool down, affect production efficiency, etc. Production quality and efficiency, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

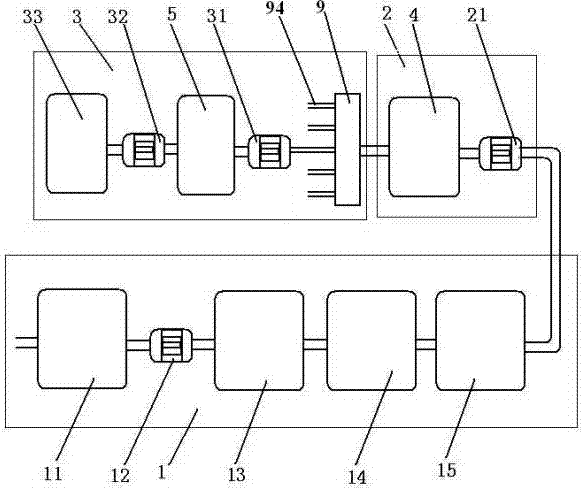

[0036] Such as figure 1 As shown, a strong alkaline electrolyzed water production system is installed. The production system is composed of a raw water purification device 1, an electrolyzed water generating device 2, and an electrolyzed water storage and packaging device 3.

[0037] The raw water purification device 1 is sequentially connected and connected by a raw water container 11 , a first booster pump 12 , a water softener 13 , a pure water machine 14 and a pure water storage container 15 through pipelines.

[0038] The electrolyzed water generating device 2 is connected and connected with the second booster pump 21 and the strong alkaline electrolyzed water machine 4 through pipelines, and the pure water storage container 15 is connected with the second booster pump 21 through pipelines.

[0039] The electrolyzed water storage and dispensing device 3 is connected and connected by the electrolyzed water automatic sub-reservoir 9, the third booster pump 31, the electroly...

Embodiment 2

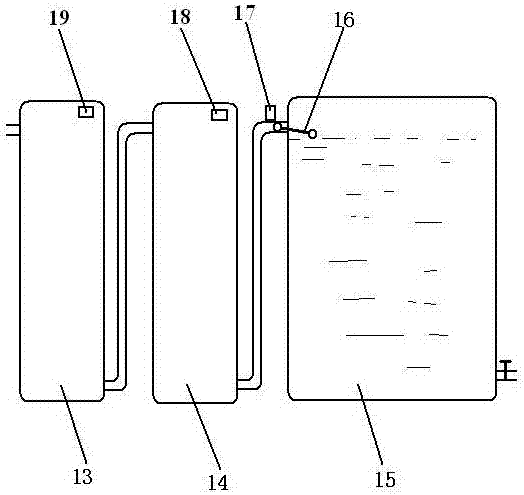

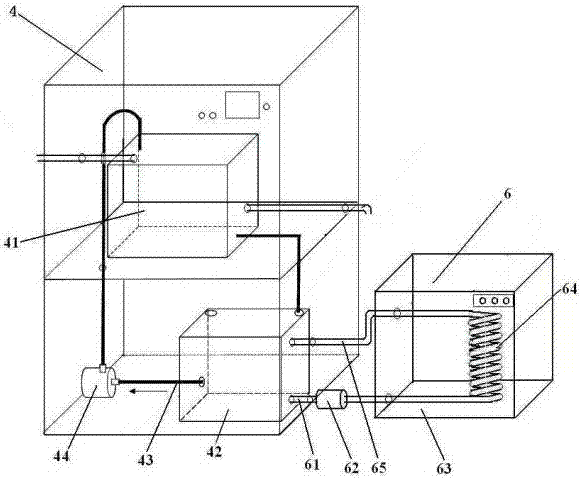

[0041] Such as figure 2 , 3 , 4, and 5, in the strongly alkaline electrolyzed water production system of the present invention, the specific structure of each component is as follows.

[0042] The raw water container 11 is a raw water tank for storing tap water; the tank is provided with a water level control valve, which automatically stops water injection when the tap water injection reaches the set water level, and automatically performs water injection when the water level is lower than the set water level.

[0043] The water softener 13 is sequentially equipped with a primary element filter, a multi-media filter, an activated carbon filter and a resin filter for removing impurities and calcium and magnesium ions in the raw water.

[0044] The pure water machine 14 is provided with an RO membrane filter for further preparation of pure water.

[0045] Described pure water storage 15 is pure water tank, is used for storing the pure water that pure water machine 14 prepare...

Embodiment 3

[0053] As shown in the figure, the specific production steps of the strong alkaline electrolyzed water production method of the present invention are as follows.

[0054] S1: inject raw water into the raw water container 11 in the raw water purification device 1, the raw water container 11 is provided with a water level control valve, when the tap water injection reaches the set water level, the water injection is automatically stopped, and when the water level is lower than the set water level, the water injection is automatically performed.

[0055] S2: The first booster pump 12 starts, and supplies water to the water softener 13 through the pipeline. Impurities and calcium and magnesium ions; then flow through the pure water machine 14, and carry out reverse osmosis through the RO membrane filter in the pure water machine 14 to obtain pure water; then inject the pure water into the pure water storage container 15 for storage; this implementation Pure water storage container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com