Manufacturing device and manufacturing method of optical glass clinker

A technology for optical glass and manufacturing devices, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve problems such as low production efficiency, and achieve the effects of improving production efficiency, increasing input-output ratio, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Adopt the manufacturing method of the present invention to manufacture fluorophosphate optical glass clinker, the composition of fluorophosphate optical glass contains SiO in mass percent 2 : 30%, BaO: 20%, F: 15%, P 2 o 5 : 20%, La 2 o 3 : 5%, Na 2 O: 5%, B 2 o 3 : 5%, the manufacturing process is as follows:

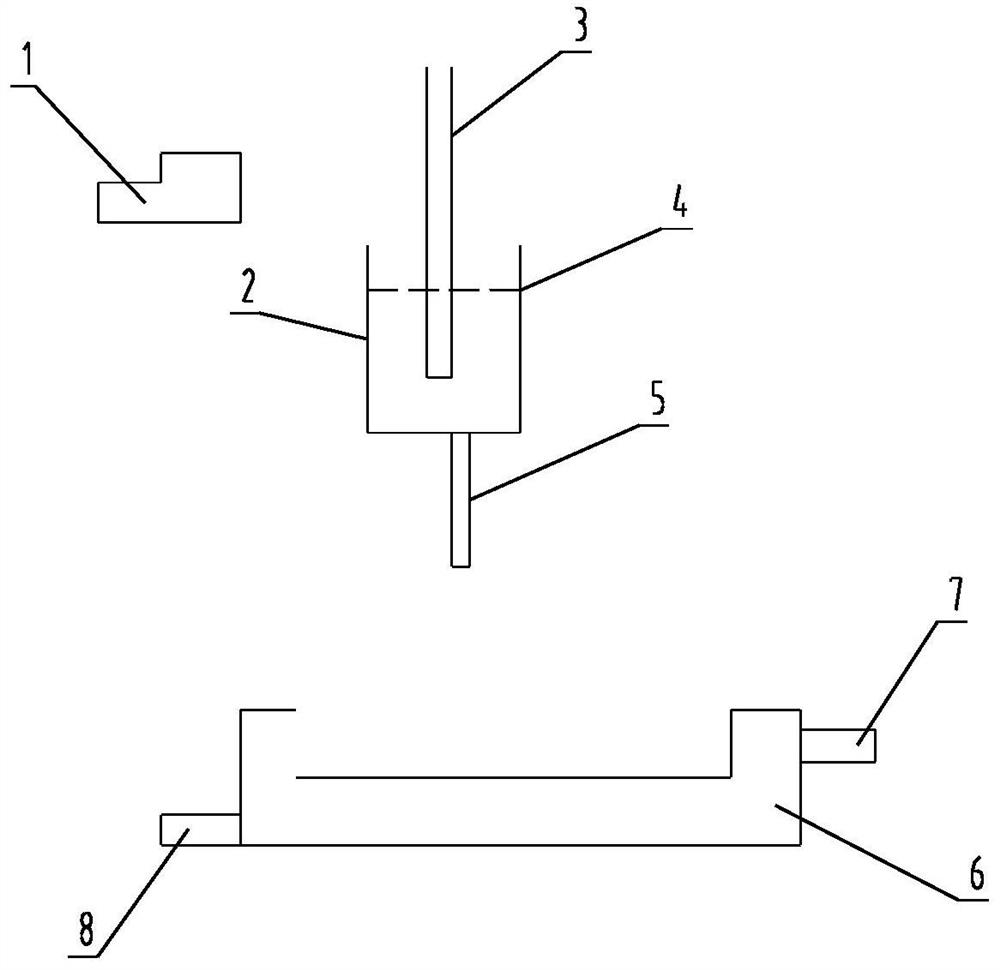

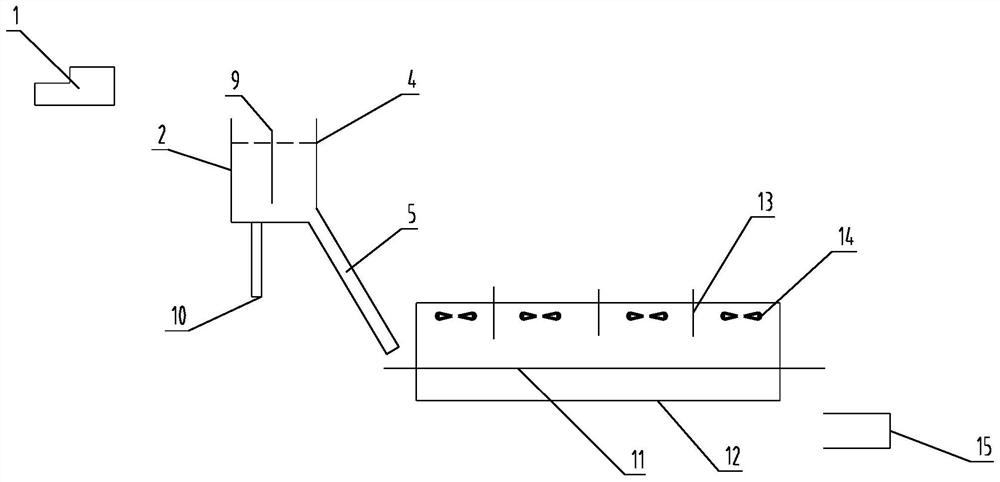

[0057] S1. Add the glass raw material into the smelting zone of the inner cavity of the smelting container 2 through the feeder 1, and then heat the glass raw material added to the smelting zone through the heating device to melt it into molten glass, continue to heat the molten glass and pass it through the lower drum Bubble tube 10 blows gas to the molten glass in the smelting zone to homogenize it;

[0058] S2, the homogenized molten glass flows into the discharge area through the glass liquid hole at the bottom of the vertical partition 9, and then discharges the glass liquid in the discharge area to the feeding front end of the conveyor belt 11 throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com