Patents

Literature

54results about How to "Improve input-output ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

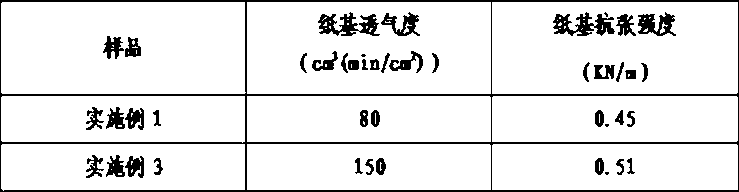

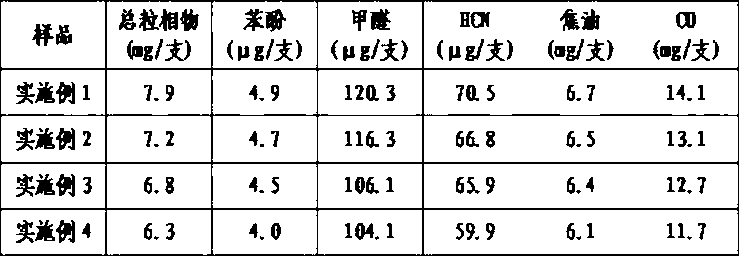

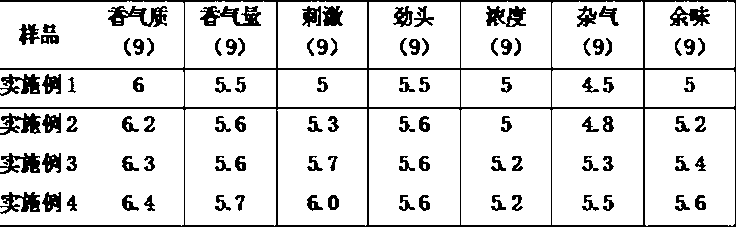

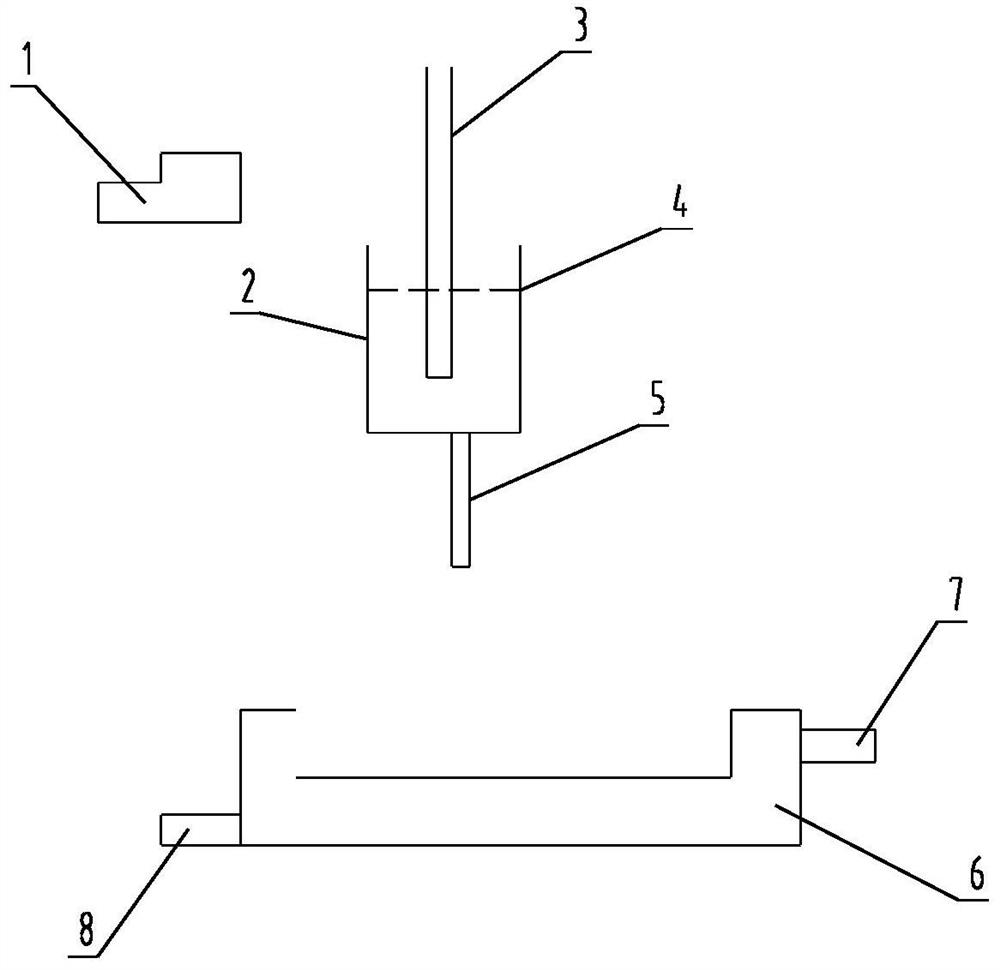

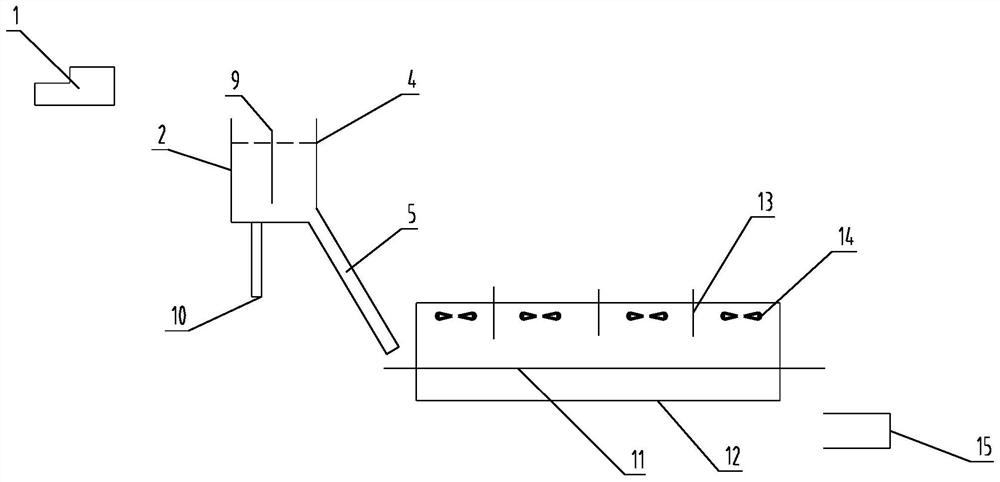

Method of manufacturing reconstituted tobacco through high-quality functional paper-making process

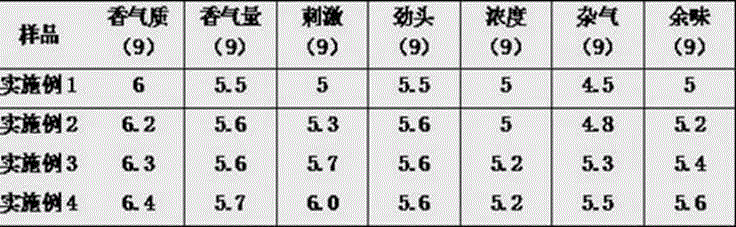

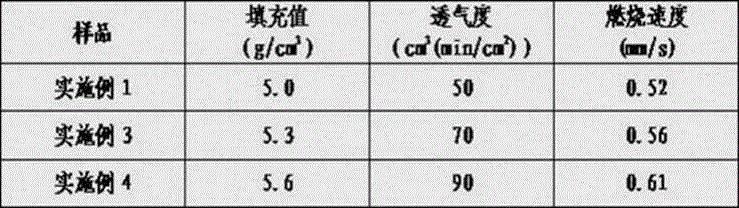

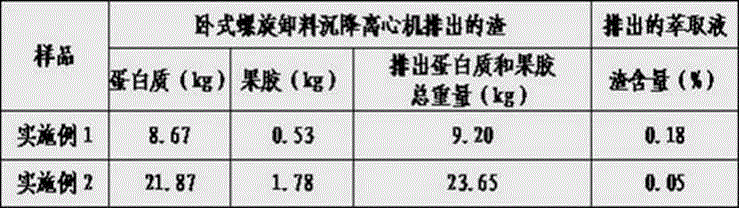

The invention relates to a method of manufacturing reconstituted tobacco through a high-quality functional paper-making process. The method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process is characterized by comprising the following steps: a. waste tobacco materials are extracted after being fully infiltrated in hot water, the mixture of each waste tobacco material and water enters a slurry-squeezing machine to be squeezed into slurry, and solid and liquid are separated; b. crude extract liquid enters a concentrating system and is concentrated after passing through a straight-line vibration screen and a horizontal screw decanter centrifuge, and solid-liquid separation is conducted on the crude extract liquid; c. after the slurry is squeezed through the slurry-squeezing machine, the mixture of waste tobacco materials and water enters a crude extract tobacco slurry pool, and biological enzyme processing is conducted on the tobacco slurry after compound proteases and lignin enzymes are added to the crude extract slurry pool or follow-up slurry pools. According to the method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process, the content of injurious components in raw tobacco materials such as proteins, amino acids, pectins, lignin and cellulose in the reconstituted tobacco can be selectively reduced so as to reduce the number of injurious components released when the reconstituted tobacco is combusted, a large amount of zymoprotein is not left in a finished reconstituted tobacco product, and meanwhile tobacco macromolecule substances are degraded through enzymes or are separated through flocculating agents.

Owner:杭州利群环保纸业有限公司

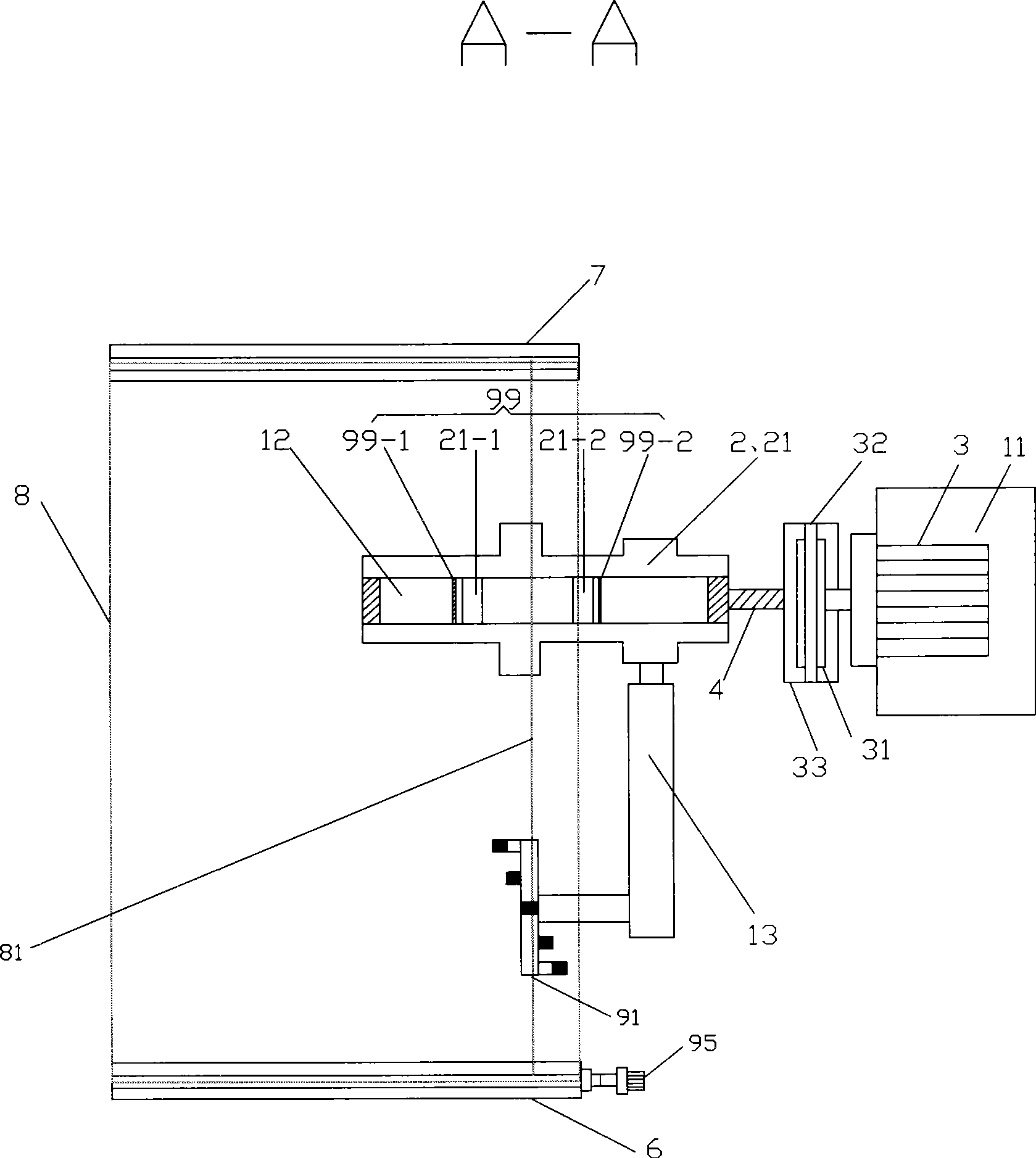

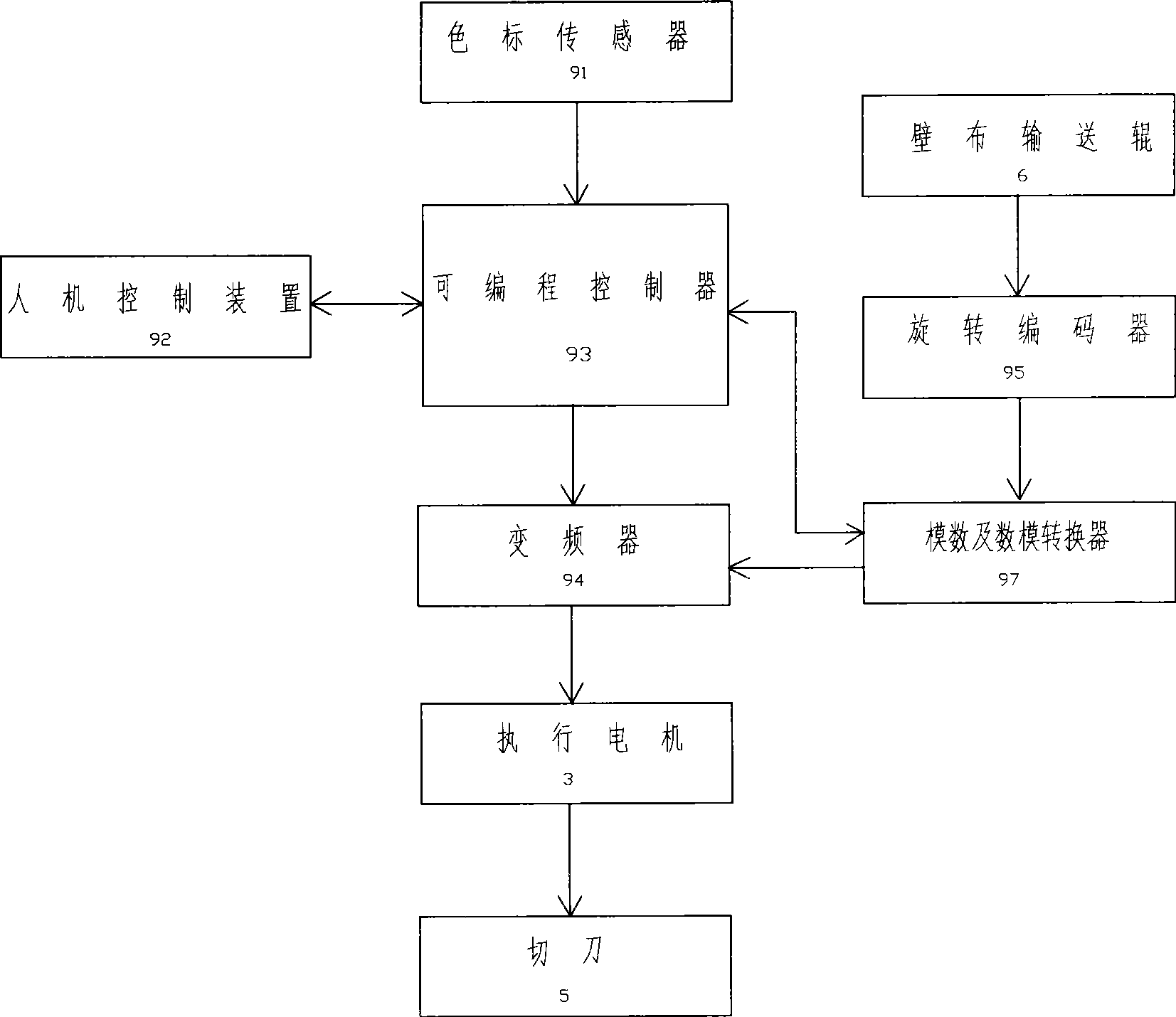

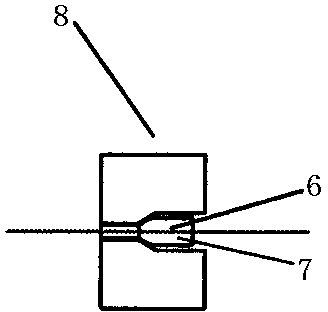

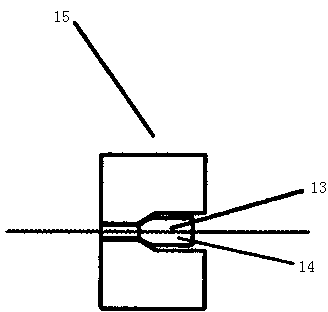

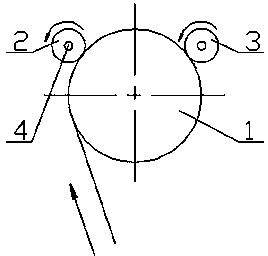

Glass fiber wall cloth edge-cutting electronic error-correcting apparatus

InactiveCN101368327AHigh degree of automationImprove quality and efficiencySevering textilesControl using feedbackColor ScaleGlass fiber

The invention discloses an electronic deviation rectifying device used in glass fiber wallhanging cut trimming, consisting of a control system and an execution system. The control system comprises at least two colour mark sensors, a programmable controller, a transducer, and a revolving coder, and the execution system is composed of an execution motor frame, a slide bar frame, a sensor frame, a cutter saddle, an execution motor, a screw mandrel and a cutter. After any of the colour mark sensors detects color streak which serves as a colour mark inlayed along the edge on the upper surface at one side of the edge to be cut of the wallhanging, the colour mark sensor sends the location information to the programmable controller to control the movement of the cutter so as to rectify deviation. The signals of the colour mark sensors can be used in high speed deviation rectification and low speed deviation rectification. The revolving coder feeds back the detected speed of the threads of the wallhanging to the programmable controller to control the movement speed of the cutter so as to ensure constant ratio of deviation rectification to the speed of the threads of the wallhanging. The electronic deviation rectifying device realizes automated control to deviation rectification and is high in rectification precision, stable in performance, simple in operation and installation and low in making cost.

Owner:常州华碧宝特种新材料有限公司

Concentrated feed for over-sized fattening pigs and preparation method thereof

InactiveCN104489370AUniform growthReduce drug residuesAnimal feeding stuffBiotechnologyAnimal science

The invention relates to concentrated feed for over-sized fattening pigs and a preparation method thereof, belonging to the technical field of pig feed. The feed is prepared from the following raw materials in parts by weight: bean pulp, corn DDGS (distillers dried grains with soluble), soybean oil, mountain flour, calcium hydrogen phosphate, salt, organic selenium, 50% vitamin E, choline, 35% vitamin C, 75% glycine betaine, 98.5% lysine, threonine, an antioxidant, a mildew preventive, a composite enzyme preparation, a feed microecological preparation, phytase, a sweetening agent, a vitamin premix, a trace element premix and middlings bran. The later-stage physiological development characteristics of the over-sized fattening pigs are combined, the composite enzyme preparation and the microecological preparation are used for regulating the intestinal health of the pigs, no antibiotics are utilized, the normal feeding mode is changed, and after the concentrated feed is used for feeding the over-sized fattening pigs with weight of 125kg for 90-100 days before marketing, drug residues in meat are remarkably reduced, and the meat is relatively safe and excellent.

Owner:TONGWEI

Simplified cultivating method for dry-cure pepper

ActiveCN103493664AEnsure constant temperature and humidityGrowth inhibitionHorticultureFertilizer mixturesSoil temperatureTillage

The invention discloses a simplified cultivating method for dry-cure pepper. The method improves the emergence rate, the planting percent and the strong seedling rate of direct-seeded seeds of pepper by covering and using direct-seeding nutrition balls and direct-seeding nutrition matrix. The method furhter solves the problems that surface layers in field direct seeding is prone to hardening due to the fact that soil temperature and humidity are affected by environment to be large in change to be unfavorable for seed emergence of pepper seeds and growth of seedlings. In addition, the method achieves practicability of pepper direct-seeding techniques and widens popularization and application ranges. By means of black film covering and direct seeding cultivation, the problems of weed growth in fields and serious pepper lodging are effectively solved, minimal tillage or zero tillage in fields are achieved, the use of weed killers is reduced, specific fertilizers are screened through tests to solve the problem of one-time fertilization in pepper production, additional fertilizers are avoided in pepper production on the premise of avoiding output reduction of peppers, and the problem of harvesting dry-cure scatter and fresh peppers at one time in a concentrated mode is solved. Thus, the purposes of achieving low cost production of peppers and improving pepper quality are achieved.

Owner:贵州省辣椒研究所

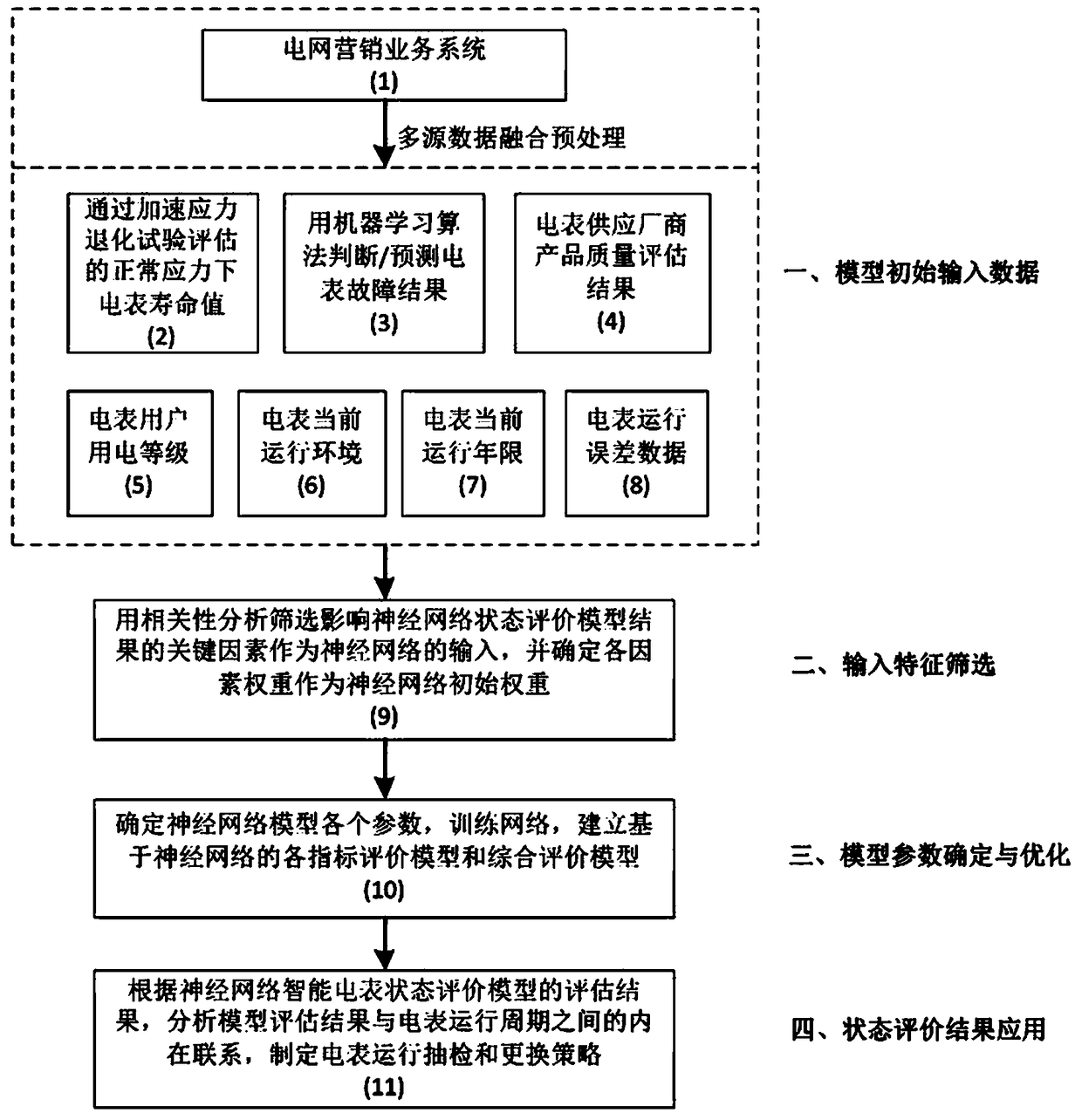

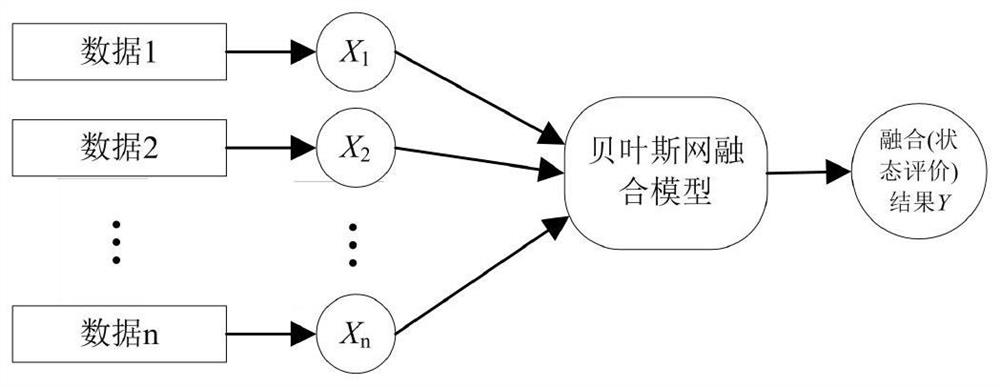

An intelligent electric meter state evaluation method based on neural network health degree evaluation

InactiveCN109447531AGood effectReduce human interferenceResourcesInformation technology support systemEvaluation resultAlgorithm

The invention provides an intelligent electric meter state evaluation method based on neural network health degree evaluation, which is a method for establishing and applying a model based on a neuralnetwork, and comprises the steps of A1 a model initial data acquisition method of acquiring network-accessed intelligent electric meter operation related data as initial input data of a neural network model through a power grid marketing business system; A2 screening model input data; A3 model parameter optimization of determining each parameter of the neural network model, and performing parameter training on the neural network model to establish an evaluation model based on the neural network, wherein the evaluation model comprises an electric meter index evaluation model and an electric meter state comprehensive evaluation model; A4 in the application of the state evaluation structure, according to the evaluation result of the evaluation model and the operation cycle of the electric meter participating in evaluation, analyzing the internal relation between the evaluation model and the operation cycle, and predicting the operation sampling inspection time and replacing selection parameters of the electric meter. According to the invention, the electric meter big data accumulated in power grid operation can be utilized to evaluate the on-grid electric meter.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

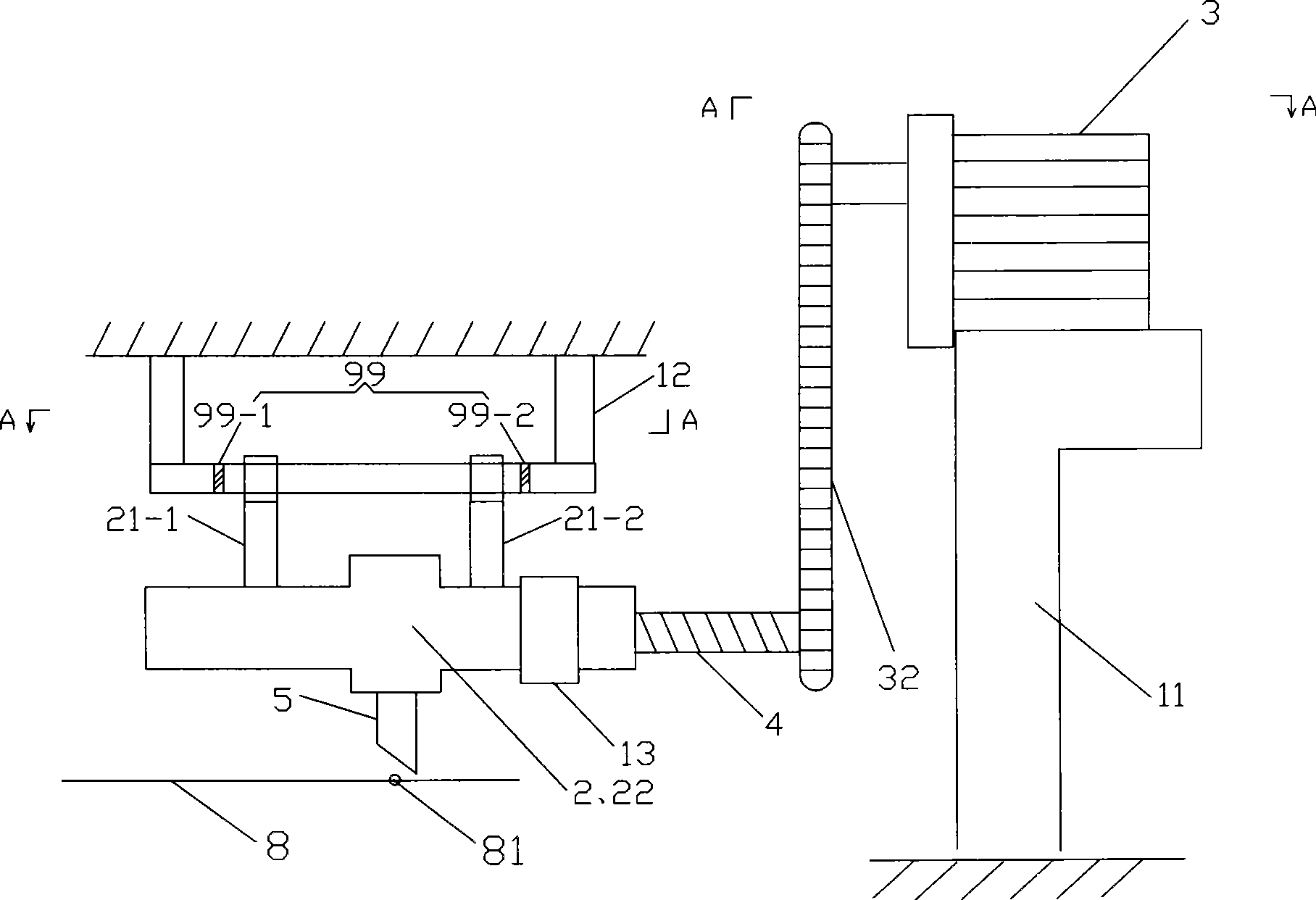

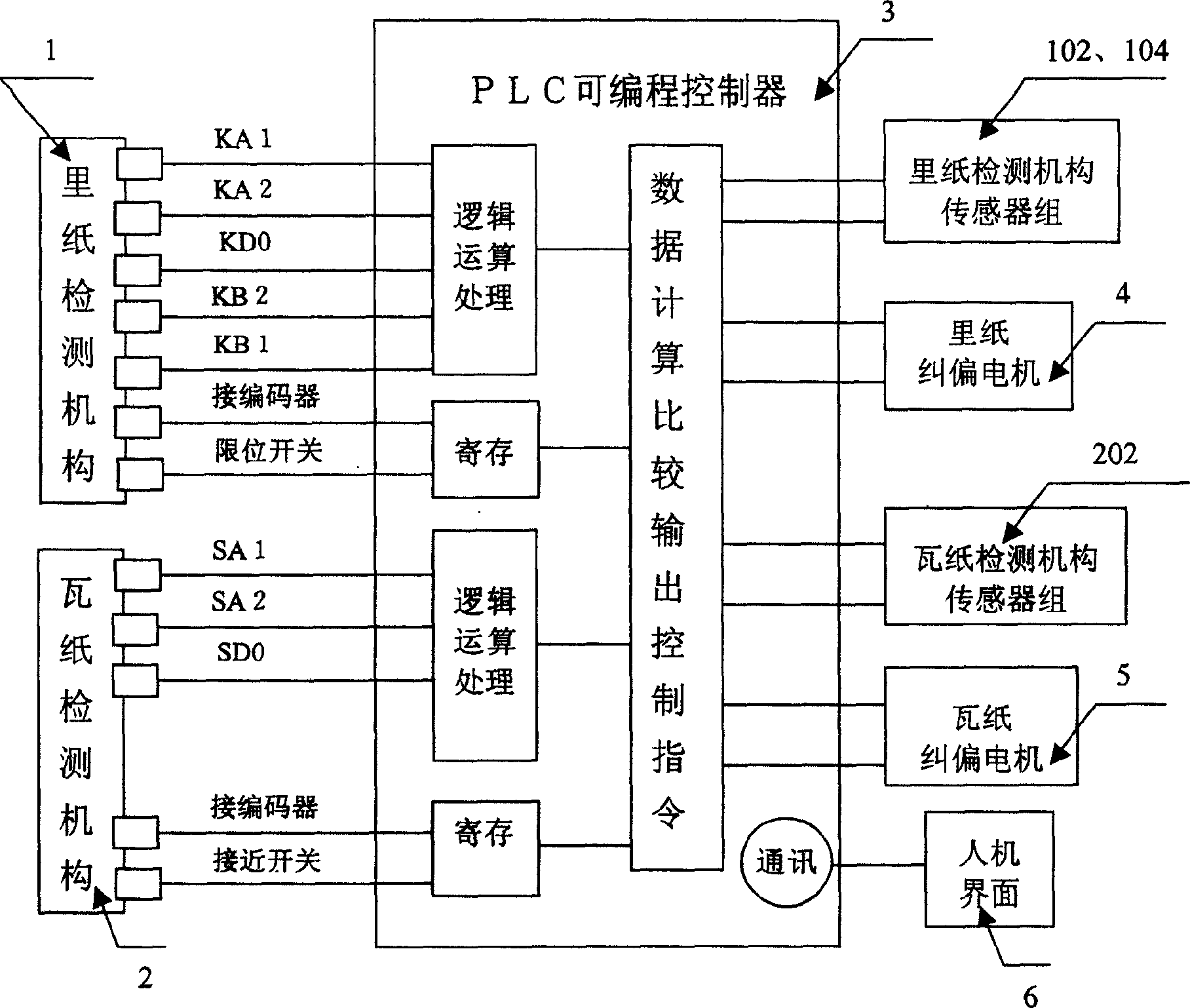

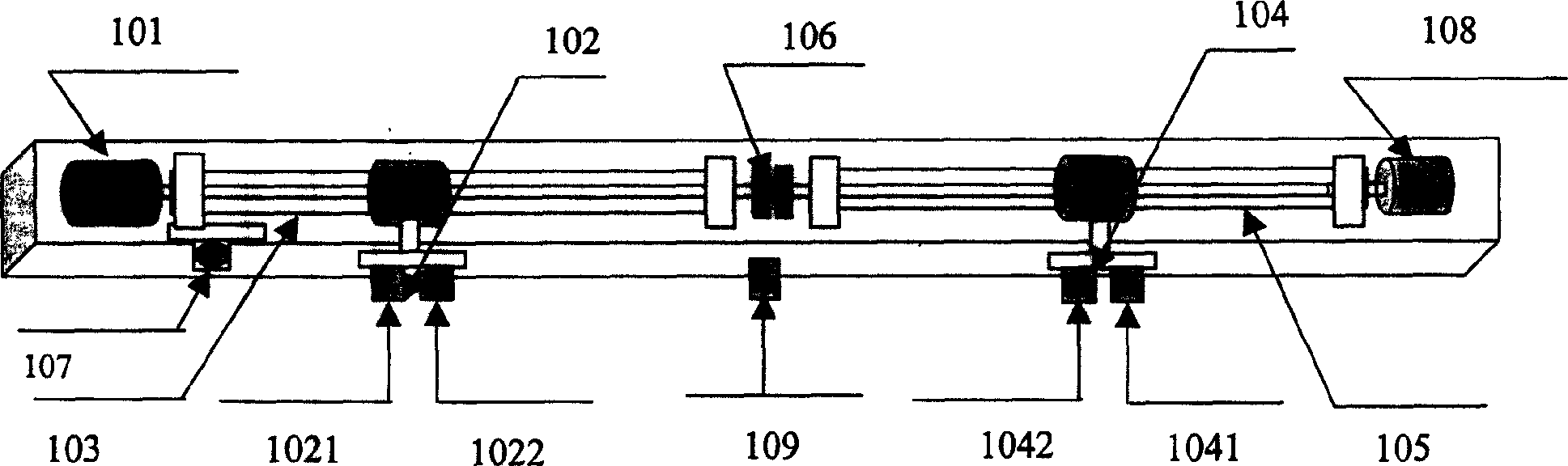

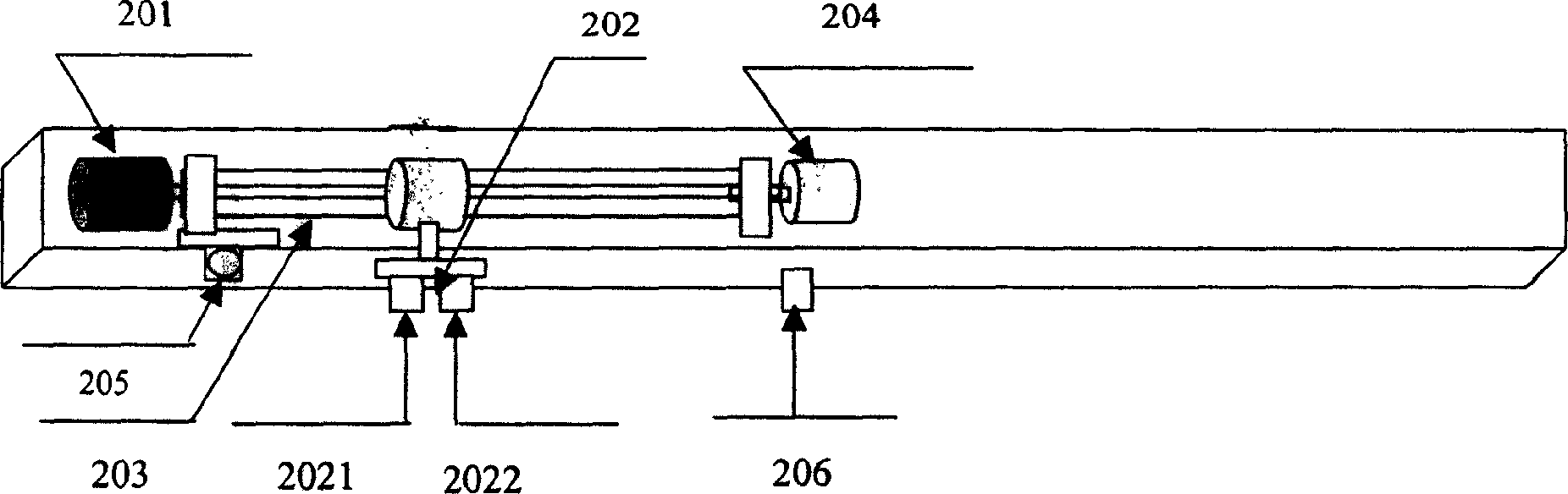

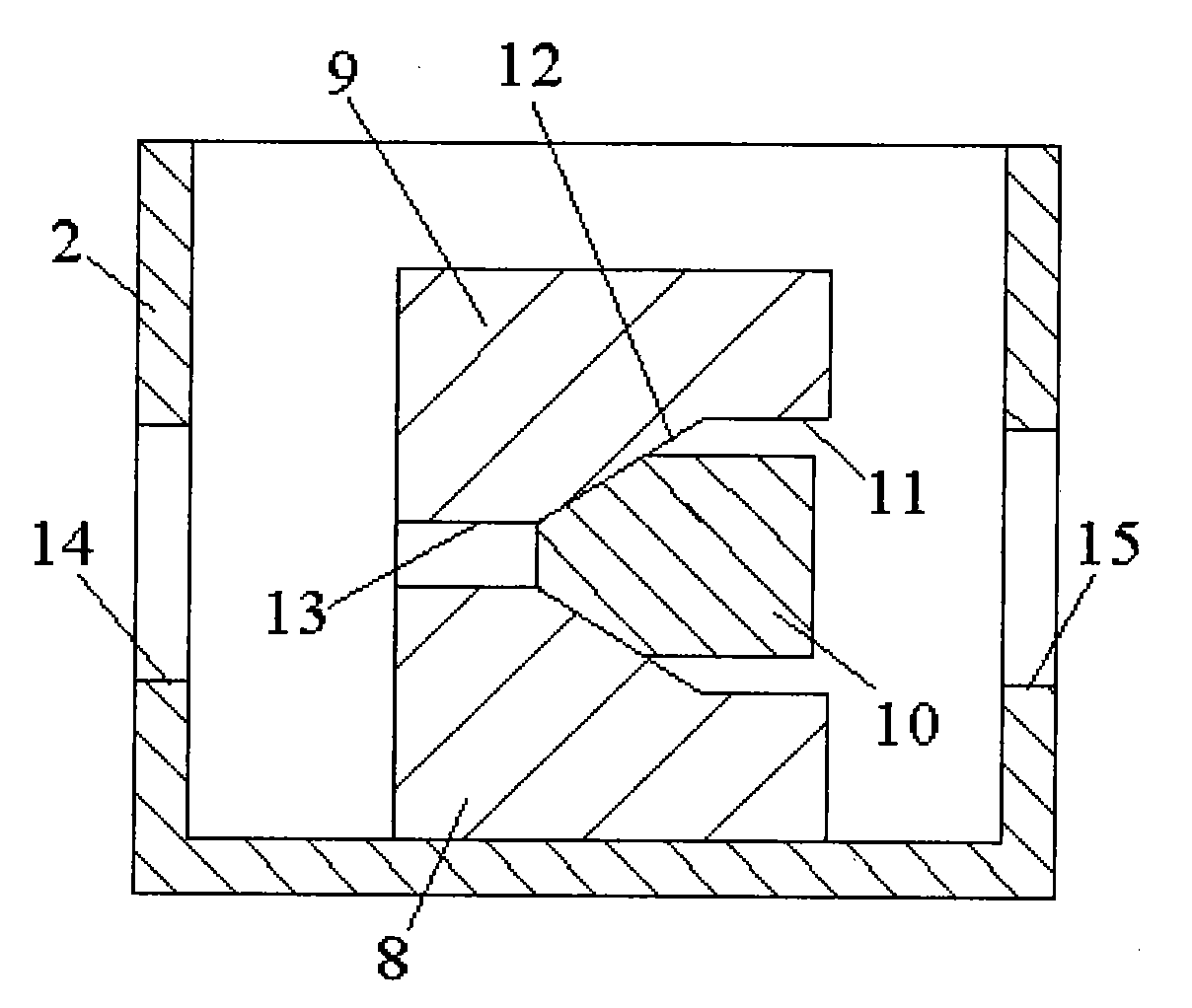

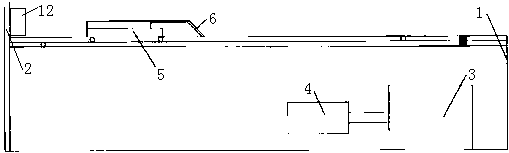

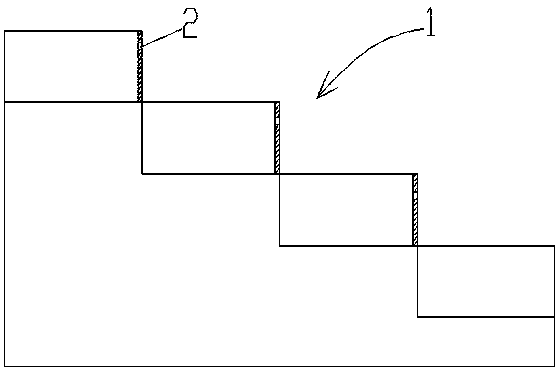

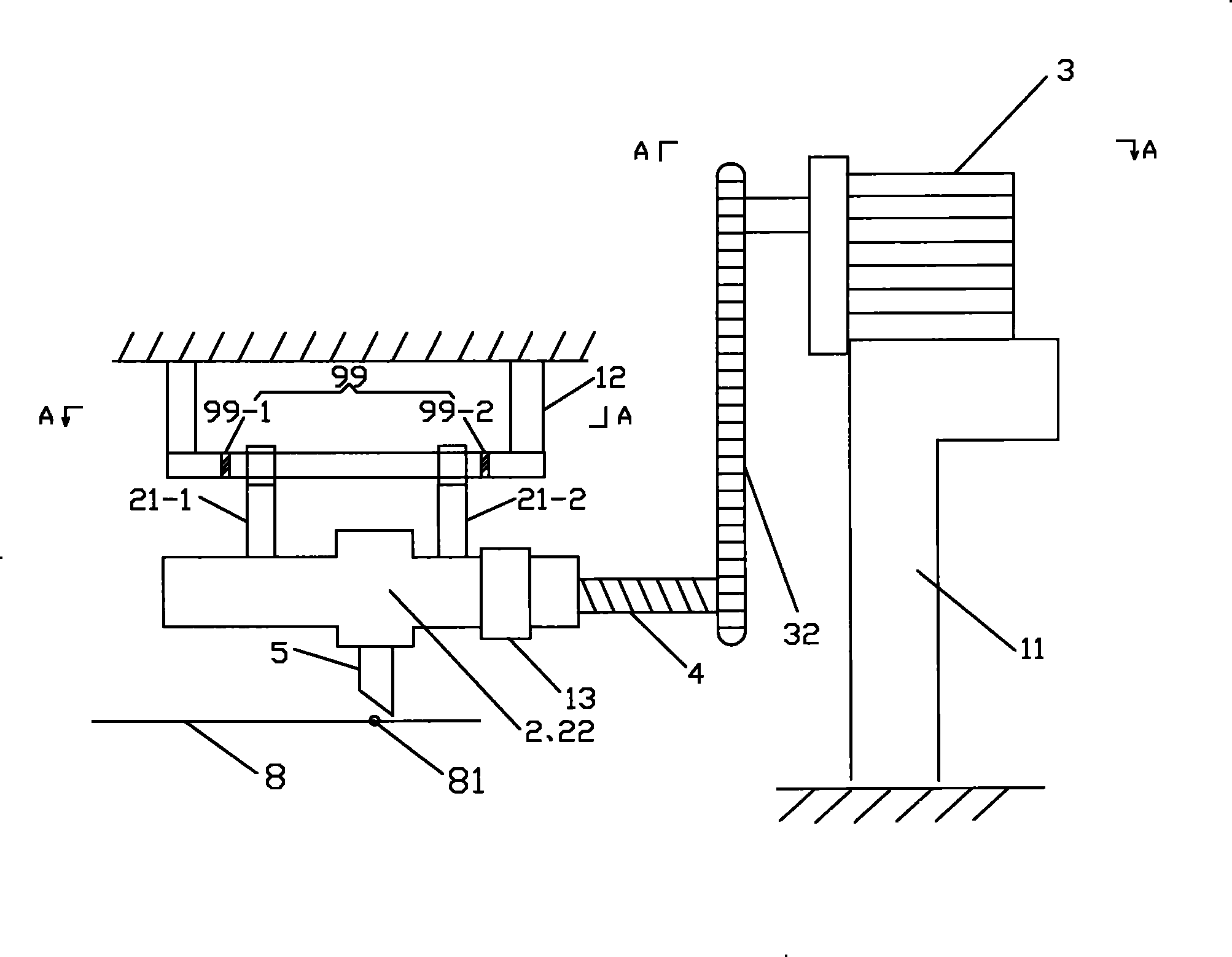

Full-automatic error correcting control device and method for paperboard production line

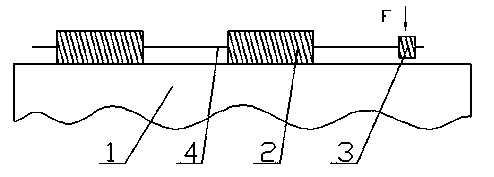

InactiveCN1603103AImprove input-output ratioReduce trimming allowanceMechanical working/deformationProduction linePaperboard

The invention discloses a corrugated board production line full automatic deviation rectifying control device and its method. It includes no less than two sets device which is installed the detection mechanism respectively detected the horizontal position and the offset of the paper material, programmable controller, deviation rectifying electric machine on the base paper rack. The detection mechanism is set between the base paper rack and the forming machine, and it is under the control of the programmable controller, and detects horizontal position and the offset of the paper sheet material. The detected data is transmitted to the programmable controller to do comparison and operation. After this, the programmable controller is transmitted the control deviation rectifying command to the deviation rectifying electric machine to moving the horizontal position of the paper material, make the paper material aligned vertically. The improvement of the control precision is greatly reduced the trimming allowance, increased the input-output rate of the paper material.

Owner:刘杰

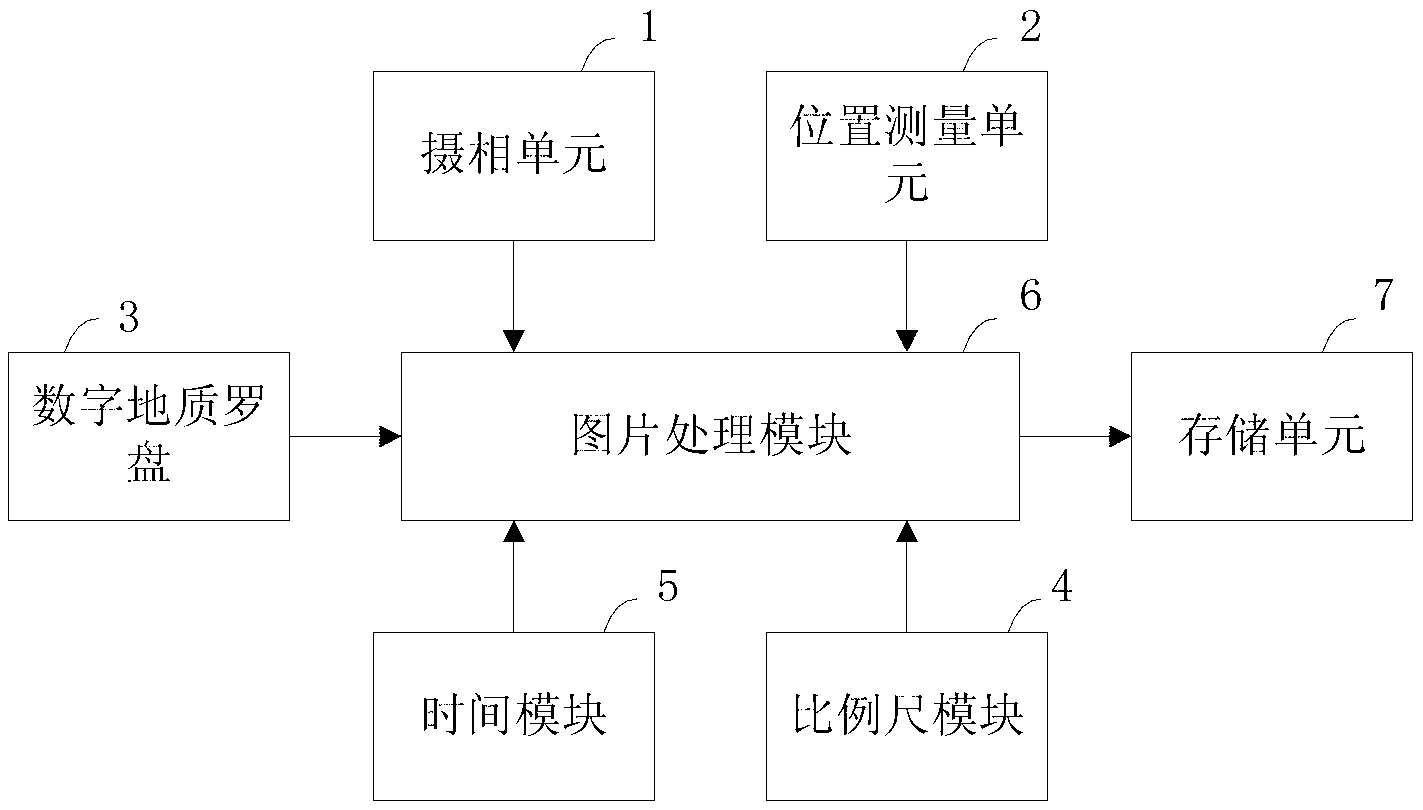

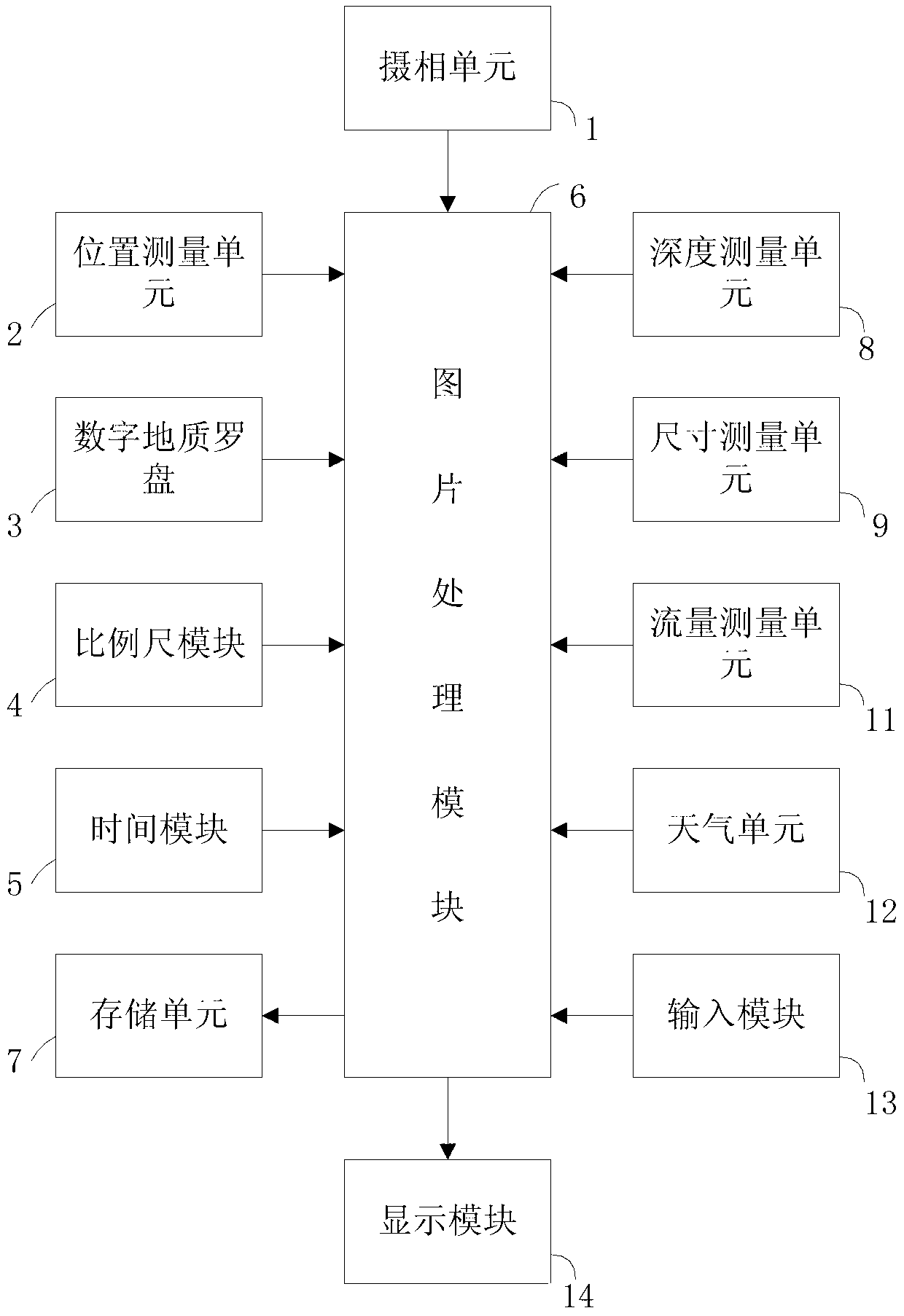

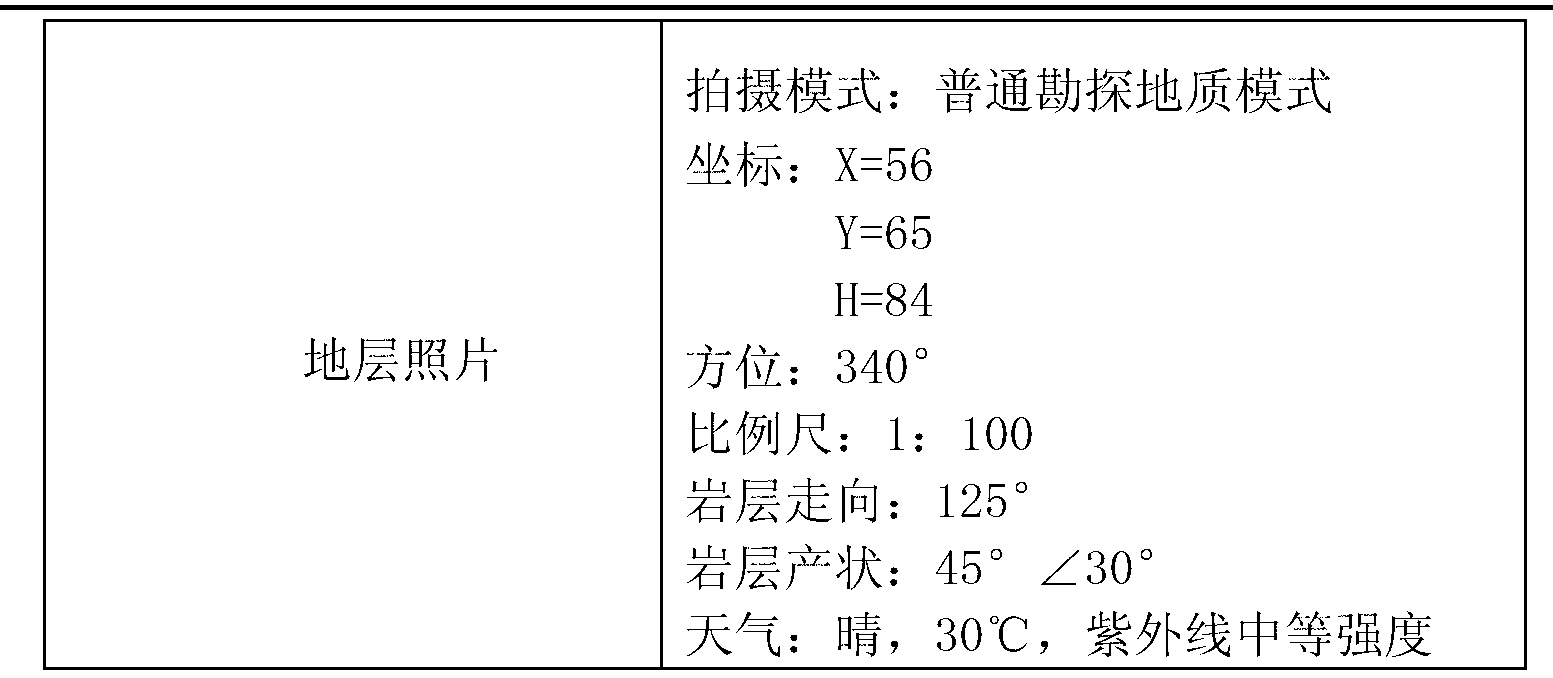

Geology shooting instrument

InactiveCN103234525AReduce workloadAvoid logging errorsPhotogrammetry/videogrammetryField dataWorkload

The invention discloses a geology shooting instrument, which comprises a shooting unit, a position measuring unit, a digital geology compass, a scale module, a time module, a picture processing module and a memory cell; the picture processing module combines or superimposes parameters obtained by the position measuring unit, the digital geology compass, the scale module and the time module and geology photographs obtained by the shooting unit for forming a geology picture, and sends the geology pictures to the memory cell. The geology shooting instrument can obtain geology pictures containing related parameters at one time, and real and high accuracy geology information can be obtained by the geology picture, and simultaneously workloads for geology personnel to record field data are minimized, and human errors of data are avoided; moreover, the geology shooting instrument can integrate the functions of compass, camera and field record book, thereby minimizing the carrying amount of field geology apparatuses.

Owner:王德文 +1

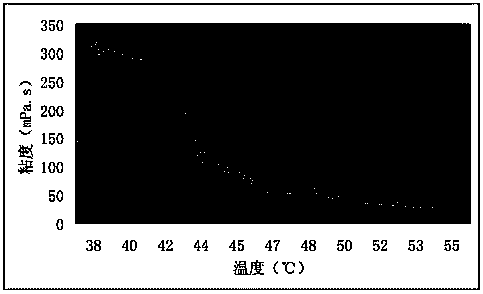

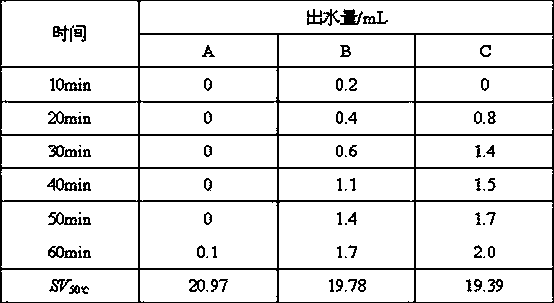

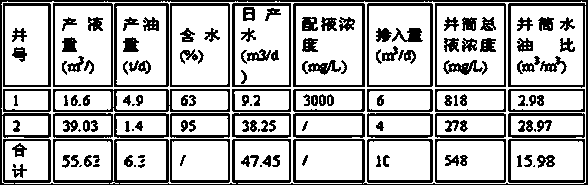

Thickened oil emulsification viscosity reduction-demulsification compound and preparation method thereof

InactiveCN103992784AGood viscosity reduction effectImprove input-output ratioDewatering/demulsification with chemical meansDrilling compositionWater contentChemistry

The invention relates to the technical field of thickened oil emulsification viscosity reduction and demulsification dehydration mining and discloses a thickened oil emulsification viscosity reduction-demulsification compound and a preparation method thereof. The thickened oil emulsification viscosity reduction-demulsification compound is prepared from 86.5-69 parts of water, 5-15 parts of an emulsifier, 5-10 parts of an emulsion stabilizing agent, 0.5-1 part of a de-emulsifier and 3-5 parts of an inorganic base. The thickened oil emulsification viscosity reduction-demulsification compound has the advantages that a thickened oil emulsification viscosity reduction ratio is in a range of 95-100%; a film is formed on the surface of a metal pipe wall so that the friction between thickened oil flowing in a shaft and a gathering and transportation pipe and the pipe wall is reduced; a static settling demulsification rate is in a range of 90-99% at a temperature of 80-90 DEG C; and processes are simple so that integration of reduction of viscosity of thickened oil in the shaft and demulsification dehydration before refining is realized. The thickened oil emulsification viscosity reduction-demulsification compound is mainly suitable for viscosity reduction of thickened oil having water content greater than or equal to 30% and viscosity less than 50000mPa.s at a temperature of room temperature to 100 DEG C in a shaft, and gathering and transportation of the thickened oil in a pipe.

Owner:KARAMAY XINRONG TECH

LED production process optimization method based on big data technology

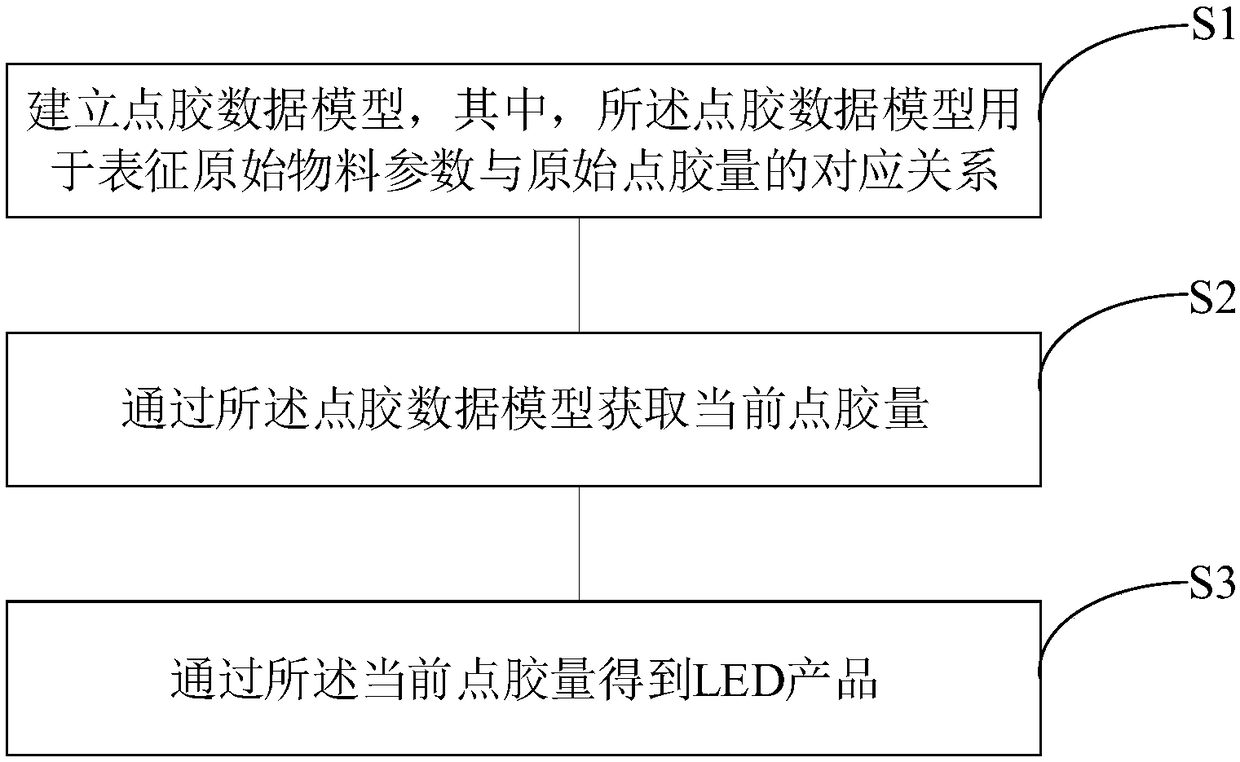

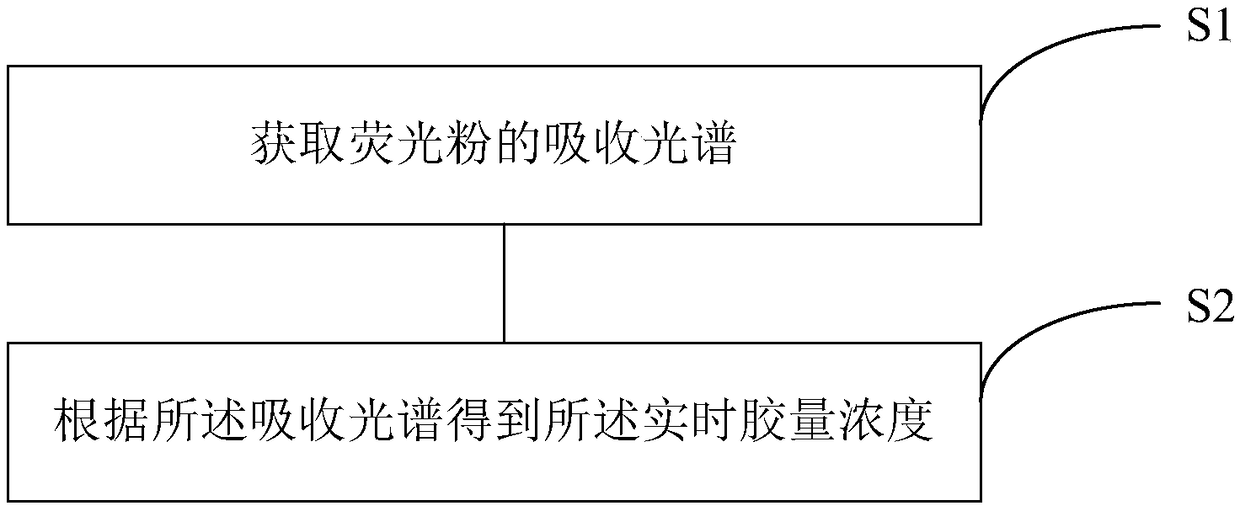

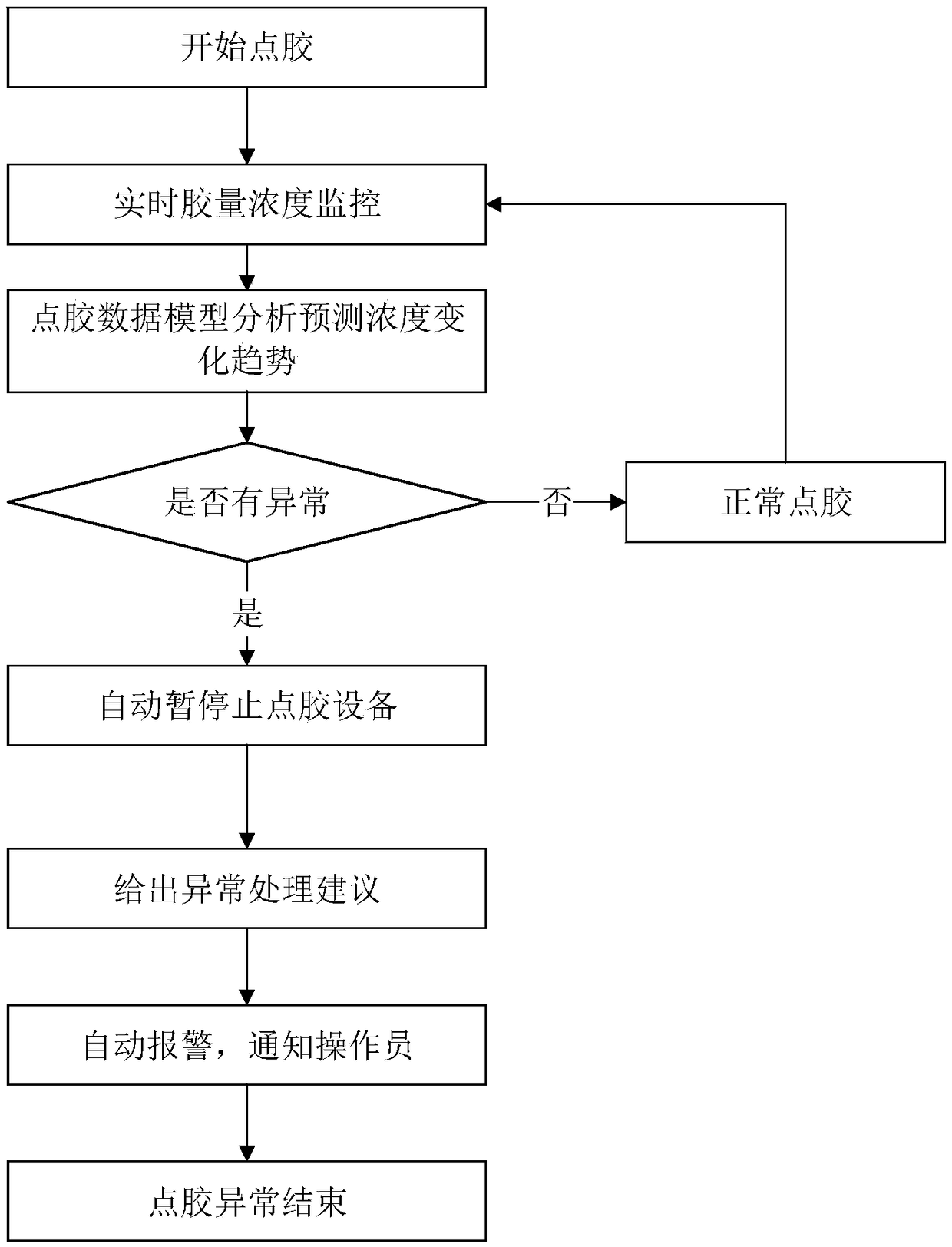

ActiveCN108649106AReduce the influence of luminescence characteristicsConsistent level of luminescenceSemiconductor devicesProcess optimizationEngineering

The invention relates to an LED production process optimization method based on a big data technology, comprising the following steps: S1, establishing a dispensing data model, wherein, the dispensingdata model is used for representing the corresponding relationship between the original material parameters and the original dispensing amount; S2, obtaining the current dispensing amount through thedispensing data model; S3, obtaining the LED product by the current dispensing amount. The influence of fluorescent powder settling on LED products can be effectively reduced by the dispensing data model, and the luminous characteristics of the LED products can be kept consistent. The method can effectively improve the concentration degree of LED color coordinates and the falling Bin rate of themain color area in the mass production stage, improve the input-output ratio and productivity, increase the delivery rate and reduce the production cost. Through real-time monitoring the glue contentconcentration in the dispensing process, if the glue content concentration exceeds the threshold range or the on-line time exceeds the threshold range, timely detection and alarm increase the yield ofproducts and reduce abnormal losses.

Owner:浙江云科智造科技有限公司

Manufacturing method of metal tube

The invention relates to a manufacturing method of a metal tube. The method comprises the following steps of manufacturing a tube blank, stretching the tube blank, finely stretching the tube blank, and cutting the tube blank to form a tube stock. The tube blank is manufactured in a way of welding a tube and is machined into a form of a seamless beam tube, the machined tube blank is brightly annealed in a closed space, and the annealed tube blank is slowly cooled in the closed space to reach the temperature of at least 500 DEG C below and then is naturally cooled, so that brilliance appears on the surface of the tube blank, and carbon removal can be avoided; through the coarse stretching, the tube blank can meet the same quality requirement of a stretched straight tube; the machining situation does not need to be frequently monitored after the tube blank is fed, and equipment can automatically stop running and give a prompt after manufacturing is finished; a fine stretching device is simple and convenient, the energy consumption is greatly reduced, and the working efficiency is also improved; in addition, a cutting device for cutting the metal tube is driven by a motor and an air cylinder, and multiple groups of metal tubes can be machined in one step, so that the efficiency is high, the cost is low, and convenience in maintenance can be achieved.

Owner:DONGQING TECH

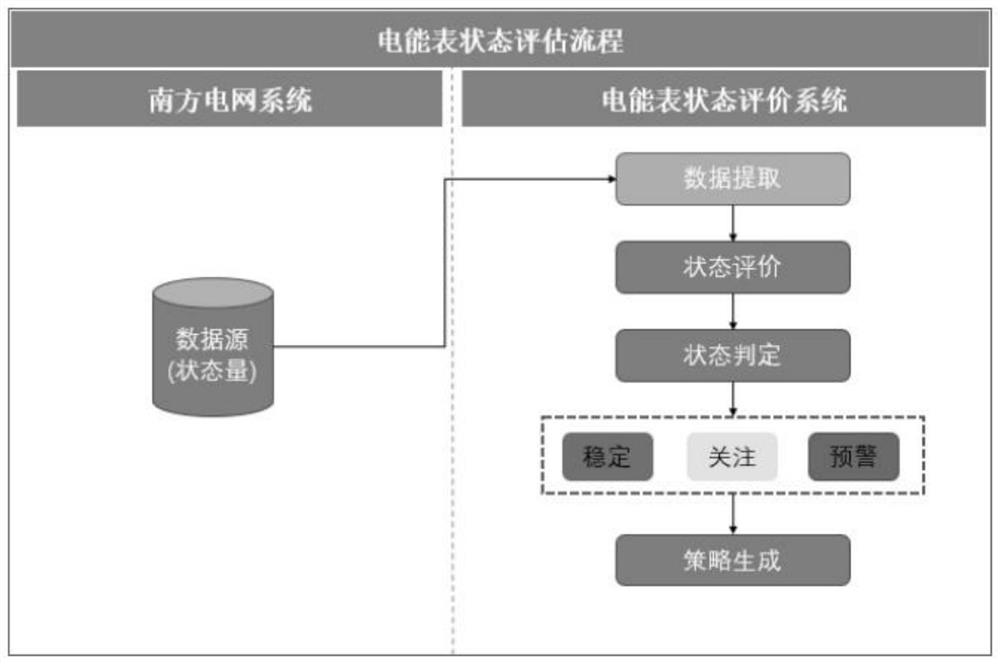

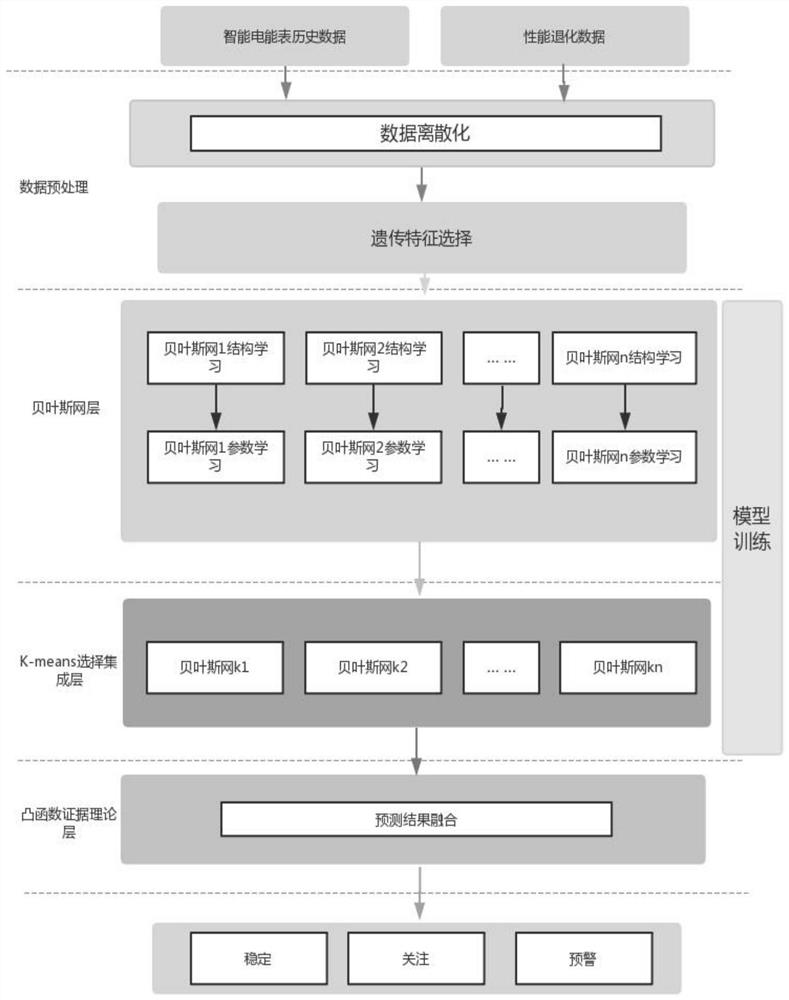

System and method for detecting and evaluating running state of intelligent electric energy meter

PendingCN114065605AReduce investmentGood delayed inspectionForecastingCharacter and pattern recognitionEvaluation resultEngineering

The invention provides a system and method for detecting and evaluating the running state of an intelligent electric energy meter, wherein the method comprises the steps: S1, obtaining a plurality of error state data of the intelligent electric energy meter, and recording the data as the historical data of the intelligent electric energy meter; S2, performing quantization processing and normalization processing on the multiple pieces of error state data in sequence; S3, performing normalization evaluation weighting on the normalized data, performing state evaluation according to a preset threshold value, and recording an evaluation result as performance degradation data; S4, performing data preprocessing on the performance degradation data and the historical data of the intelligent electric energy meter to obtain training data; S5, establishing a detection and evaluation model, and performing model training by using the training data to obtain an optimal detection and evaluation model; and S6, substituting the error state data of the to-be-detected intelligent electric energy meter into the optimal detection and evaluation model, and thus obtaining an operation state detection and evaluation result of the to-be-detected intelligent electric energy meter. According to the method, the running state and performance degradation failure prediction of the intelligent electric energy meter can be scientifically evaluated.

Owner:QUJING POWER SUPPLY BUREAU YUNNAN POWER GRID CO LTD

Method for recovering aromatic hydrocarbon in tail gas of oxydol production apparatus

InactiveCN1483503AHigh adsorption and removal activityHigh recovery rateOther chemical processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesRecovery methodDesorption

The method for purifying and recovering aromatic hydrocarbon in the tail gas of oxydol production equipment adopts the pretreated active carbon catalyst as adsorption agent to remove aromatic hydrocarbon and recover and reuse it. Its adsorption condition is as follows: tail gas pressure is 0.2-2 MPa, temp. is 0-40 deg.C, space velocity is 100-2000 h(-1), and the inlet aromatic hydrocarbon content is less han or equal to 1000 ppm generally; then it uses the superheated stream or N2 to heat at 120 deg.C-400 deg.C to make desorption, and make cooling treatment so as to recover aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP

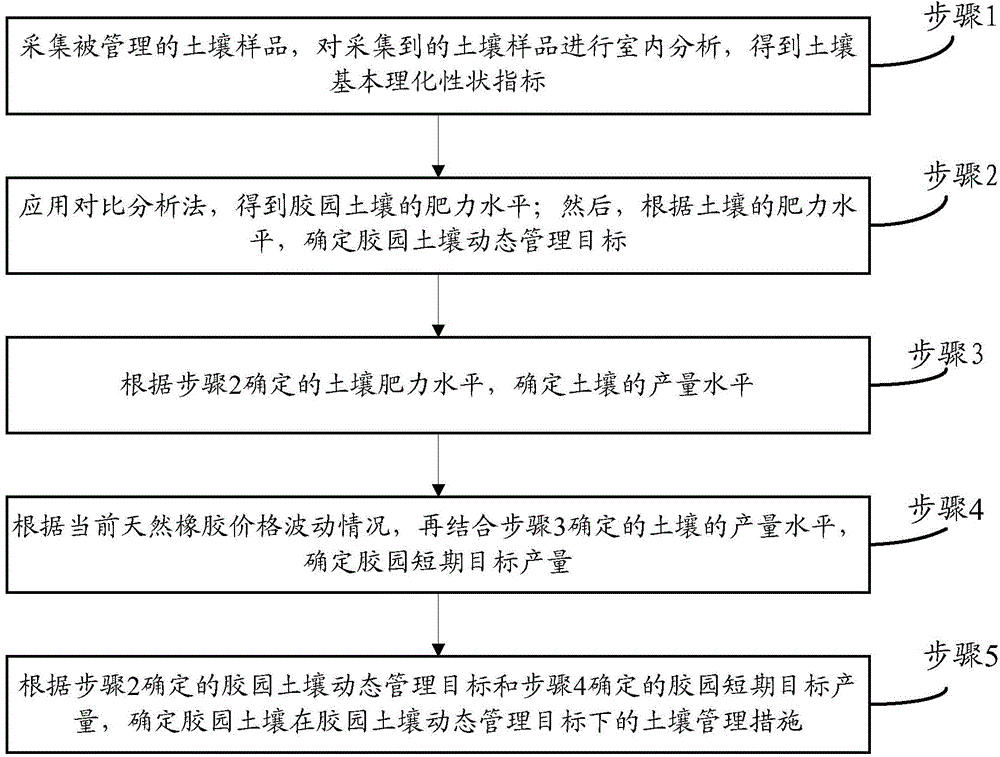

Dynamic management method for soil nutrients in rubber plantation

ActiveCN104885671AEnsure sustainable developmentImprove input/output ratioFertilising methodsInorganic fertilizerNatural rubber

The present invention provides a dynamic management method for soil nutrients in a rubber plantation, comprising the following steps: dynamic managing target for the soil in the rubber plantation is determined according to the soil fertility level; the short-term target yield in the rubber plantation is determined in accordance with the current natural rubber price fluctuation and combined with the soil yield level; soil managing measures of soil in the rubber plantation under the dynamic management target for the soil of the rubber plantation is determined according to the dynamic management target for the soil of the rubber plantation and the short-term target yield in the rubber plantation; the soil management measures comprise: the application amount of organic fertilizers, the application amount of inorganic fertilizers and a dynamic fertilizer application method. Through the dynamic management method for the soil nutrients in the rubber plantation, on the one hand, rubber planters / rubber planting enterprises can use the minimum investment to obtain the maximum economic benefit so as to improve the input-output ratio; on the other hand, through the method, the goal of utilizing and nourishing rubber trees and utilizing and nourishing the land can be achieved; therefore, the stability of china's natural rubber total output and the sustainable development of natural rubber industry can be ensured.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Manufacturing method of optical glass

InactiveCN111204955AReduce manufacturing costImprove securityCharging furnaceGlass furnace apparatusMelting tankOptical glass

The invention belongs to the technical field of glass manufacturing, and particularly discloses a manufacturing method of optical glass capable of improving the input-output rate of products. According to the manufacturing method of the optical glass, a glass raw material is effectively smelted by reasonably controlling the heating temperature; a melting tank is used for melting the glass raw material; the bottom surface of a melting cavity is an inclined surface; the lower edge of a melting discharge port is not higher than the inclined lower end of the bottom surface of the melting cavity; therefore, almost all high-temperature molten glass in the melting cavity can flow out of the melting discharge port to enter the next procedure in the later period of product production, and finally aqualified product is formed, so that the input-output rate of the product reaches 95% or above, the input-output rate of the product is greatly increased, and the manufacturing cost of the optical glass is reduced; besides, compared with an existing manufacturing method of the optical glass, the step of removing scrapped products is omitted, and meanwhile the step of manually beating and burningcondensed glass at the discharge hole through a burning gun is omitted.

Owner:CDGM OPTICAL GLASS

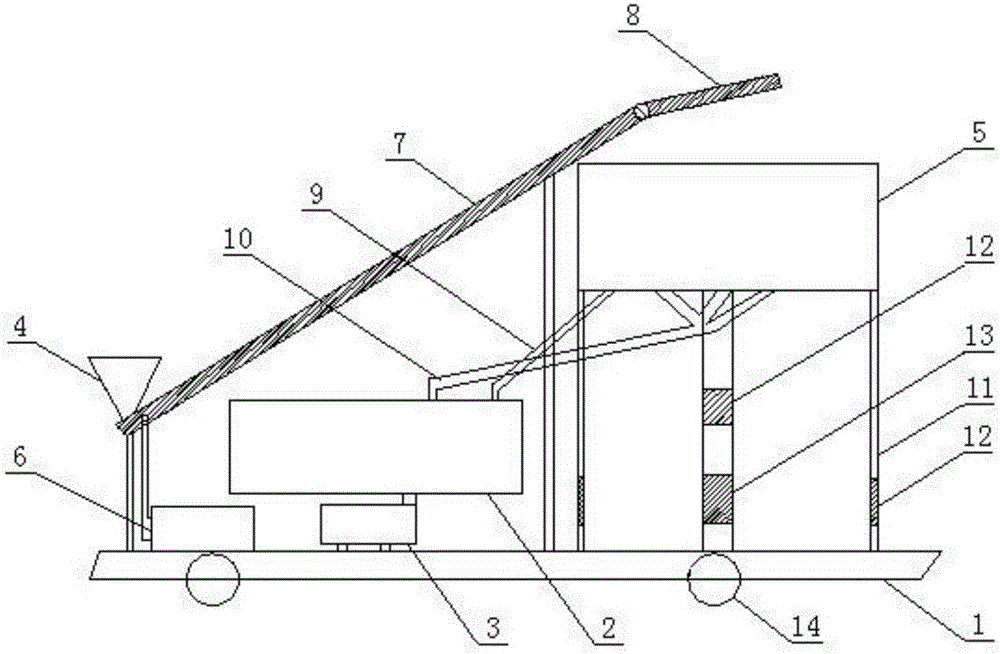

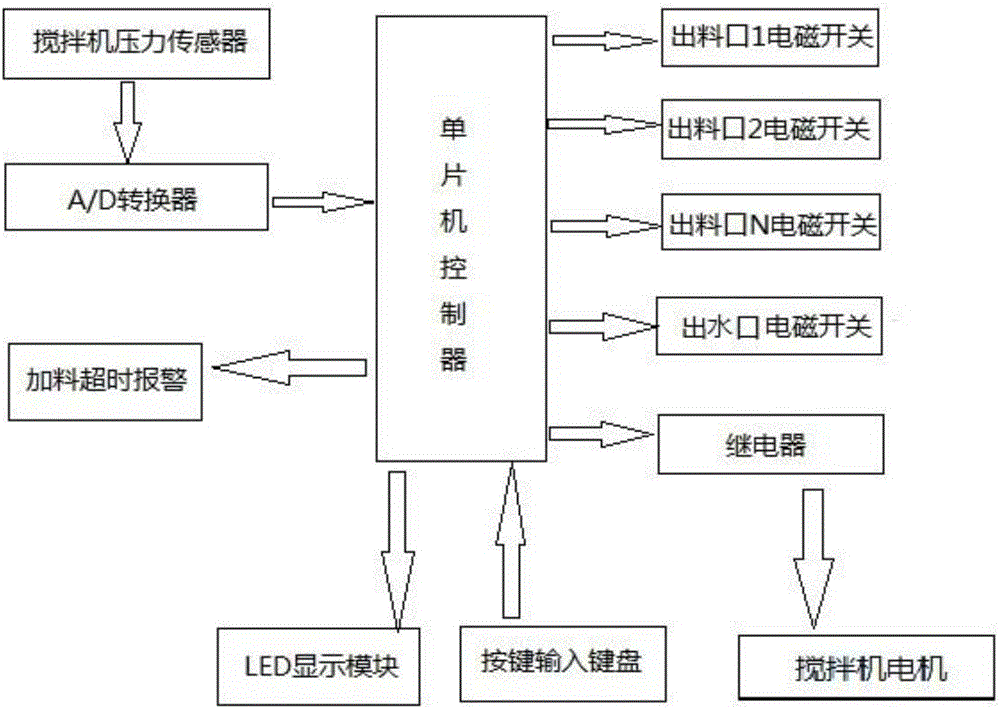

Intelligent mortar stirrer

InactiveCN105835229AImprove reliabilityPrecisionMixing operation control apparatusIngredients proportioning apparatusSingle chipMaterials science

The invention discloses an intelligent mortar stirrer. The intelligent mortar stirrer comprises a base, a mortar stirring groove and a stirrer motor and further comprises a material storage partition groove and a feeding port which are formed in the base; the feeding port conveys raw materials to the material storage partition groove through a motor and a conveying device; the material storage partition groove comprises at least one material trough and a water trough which are connected with the mortar stirrer; a water outlet of the water trough and a material outlet of the material trough are each provided with an electromagnetic switch; a support of the material storage partition groove is provided with a pressure sensor and an intelligent module which comprises a single-chip microcomputer controller; the signal input end of the single-chip microcomputer controller is connected with the pressure sensor; and the signal output end of the single-chip microcomputer controller is connected with the stirrer motor and connected with the electromagnetic switches arranged on the material outlet of the material trough and the water outlet of the water trough. The intelligent mortar stirrer can automatically perform material throwing and stirring according to the set mortar matching ratio and the consistence, and the mortar reliability is improved.

Owner:TIANJIN 20 CONSTR

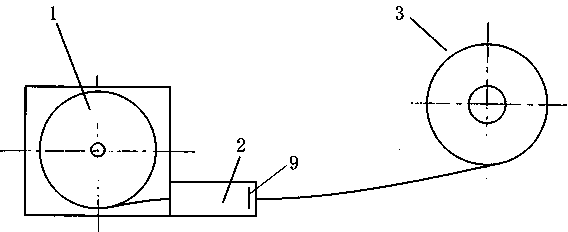

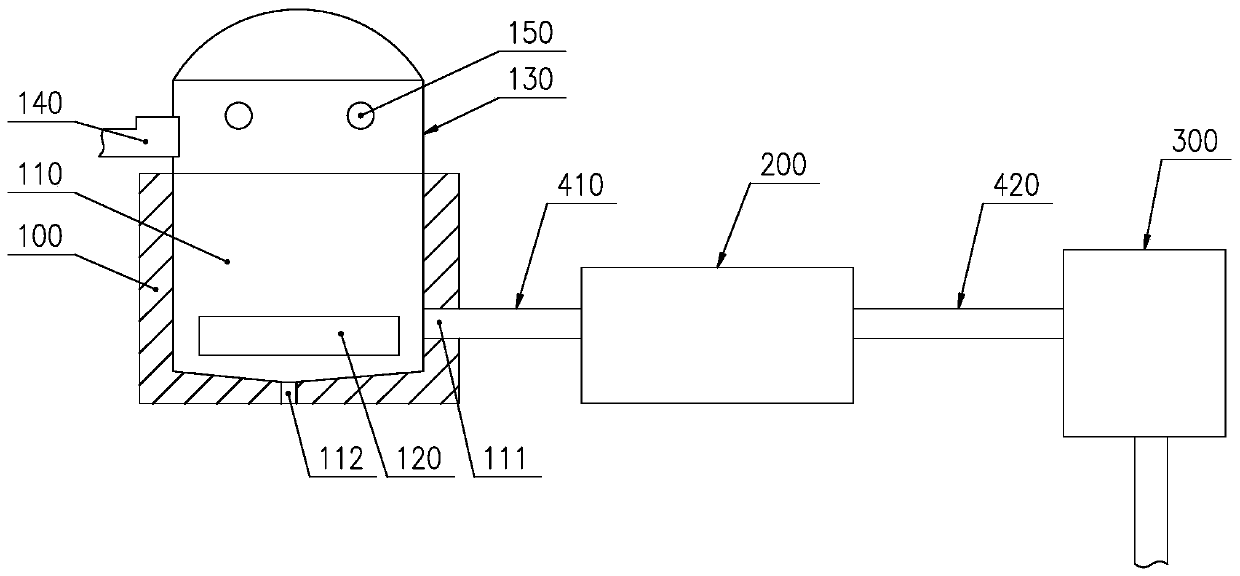

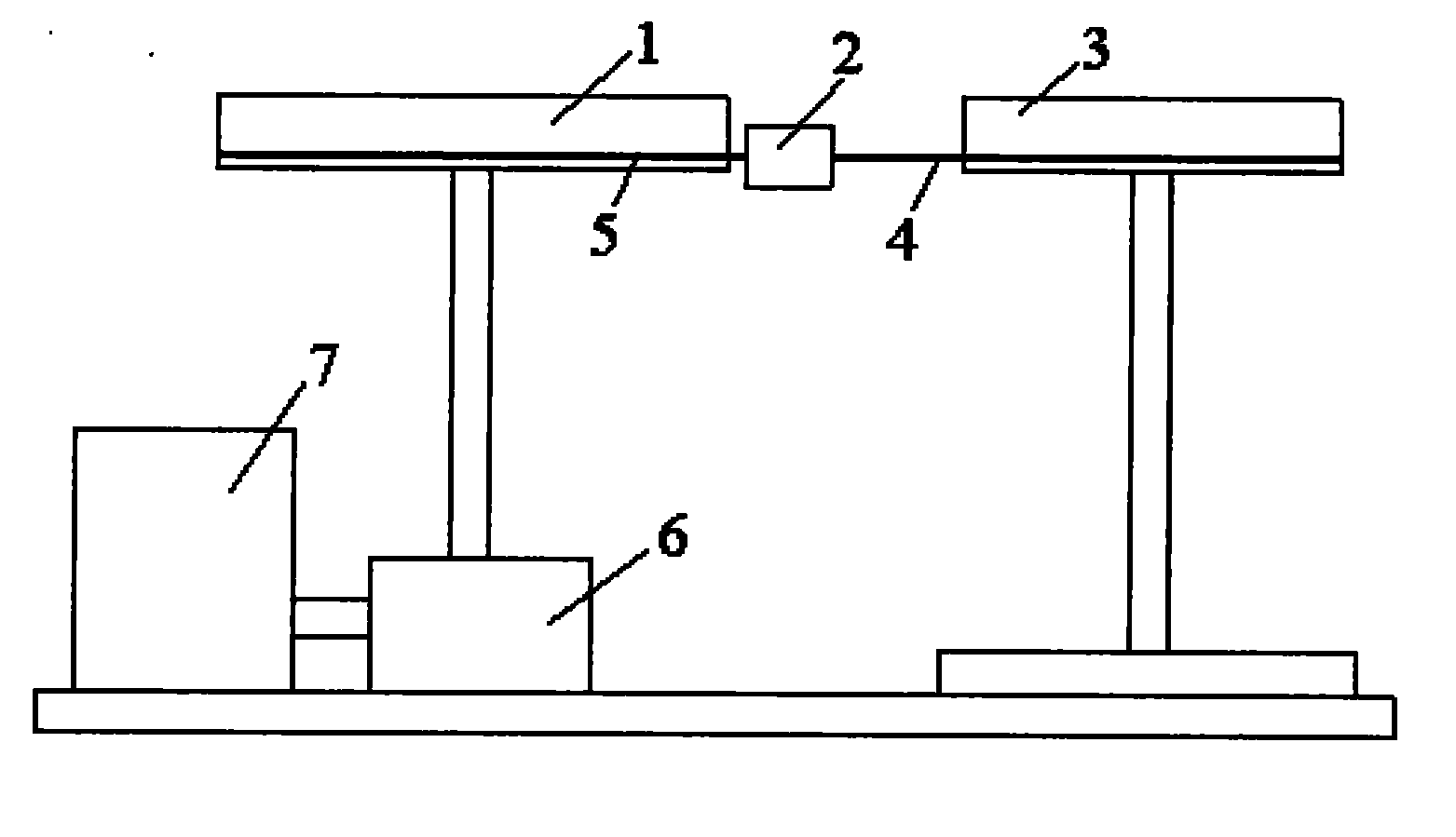

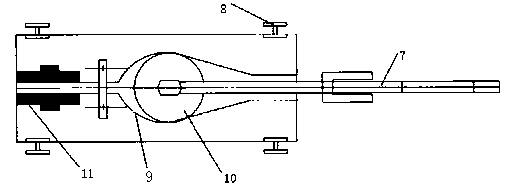

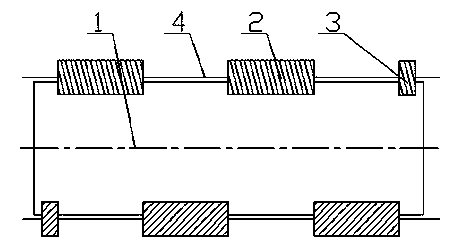

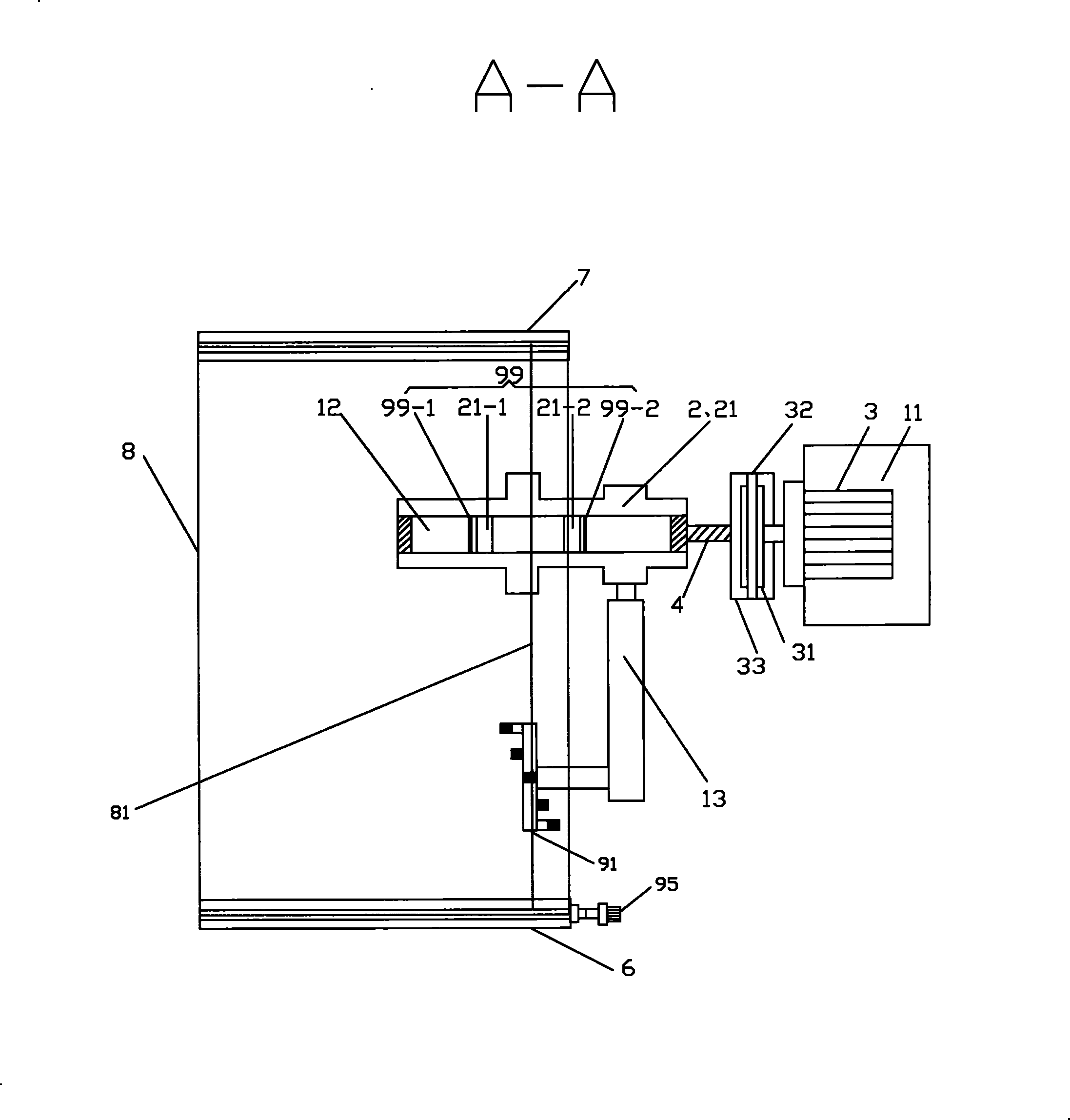

Automatic coil wall-thickness reduction and drawing device and drawing method of small-diameter capillary tube

InactiveCN101804423AImprove quality controllabilityImprove input-output ratioDrawing diesLubricationEngineering

The invention relates to an automatic coil wall-thickness reduction drawing device and drawing method of a small-diameter capillary tube. The drawing device comprises a feeding tray, an electric motor and a gear box controlled by the electric motor, wherein the power take-off shaft of the gear box is fixed connected with a drawing mechanism; the drawing device also comprises a mould box, wherein moulds are arranged in the mould box, a raw material tube inlet and a finished tube outlet are separately processed on the opposite side walls of the mould box, a start-stop sensor is arranged at the finished tube outlet, and the start-stop sensor is connected with a control system. The drawing method of the invention adopts oil bath type lubrication, the auxiliary materials can be recycled, the small-diameter capillary tube meeting the drawing quality requirements of the straight pipe can be drawn, the quality controllability is high, the machining condition is not needed to monitor frequently, the work efficiency is greatly increased, the input-output ratio are improved, and the consumption of auxiliary materials is reduced.

Owner:CAIHONG GRP ELECTRONICS CO LTD

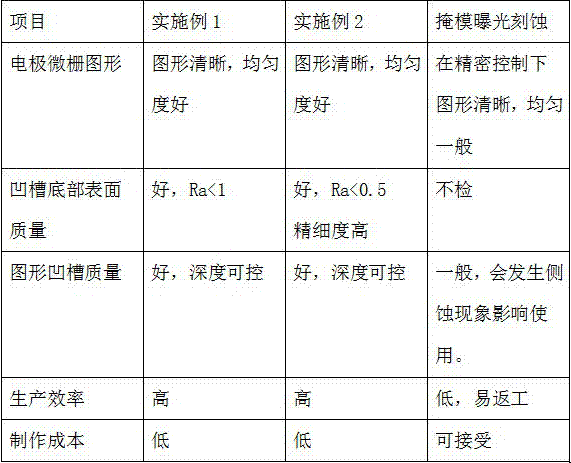

Manufacture method of die roller used for impressing electrode micro-grid films

ActiveCN105666848AImprove input-output ratioReduce manufacturing costCleaning using liquidsLaser beam welding apparatusAdhesiveThin membrane

The invention relates to a manufacture method of a die roller used for impressing electrode micro-grid films. The die roller is manufactured by the manufacture method by the following steps: coating a masking adhesive, carrying out laser direct writing photoetching on the masking adhesive, ultrasonically washing and electrodepositing. The manufacture method has the advantages that through controlling special technical conditions and parameters about laser photoetching, ultrasonic washing and electro-deposition in the manufacture process, electrode micro-grid patterns on the surface of the die roller manufactured are kept clear and consistent; and through the manufacture method, the die roller manufactured is high in input-output ratio but low in manufacture cost.

Owner:NANTONG VEEYEE NEW MATERIAL TECH CO LTD

A method for manufacturing high-quality functional paper-making reconstituted tobacco leaves

ActiveCN103251125BLow lignin contentReduce releaseTobacco preparationPapermakingMacromolecular Substances

The invention relates to a method of manufacturing reconstituted tobacco through a high-quality functional paper-making process. The method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process is characterized by comprising the following steps: a. waste tobacco materials are extracted after being fully infiltrated in hot water, the mixture of each waste tobacco material and water enters a slurry-squeezing machine to be squeezed into slurry, and solid and liquid are separated; b. crude extract liquid enters a concentrating system and is concentrated after passing through a straight-line vibration screen and a horizontal screw decanter centrifuge, and solid-liquid separation is conducted on the crude extract liquid; c. after the slurry is squeezed through the slurry-squeezing machine, the mixture of waste tobacco materials and water enters a crude extract tobacco slurry pool, and biological enzyme processing is conducted on the tobacco slurry after compound proteases and lignin enzymes are added to the crude extract slurry pool or follow-up slurry pools. According to the method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process, the content of injurious components in raw tobacco materials such as proteins, amino acids, pectins, lignin and cellulose in the reconstituted tobacco can be selectively reduced so as to reduce the number of injurious components released when the reconstituted tobacco is combusted, a large amount of zymoprotein is not left in a finished reconstituted tobacco product, and meanwhile tobacco macromolecule substances are degraded through enzymes or are separated through flocculating agents.

Owner:杭州利群环保纸业有限公司

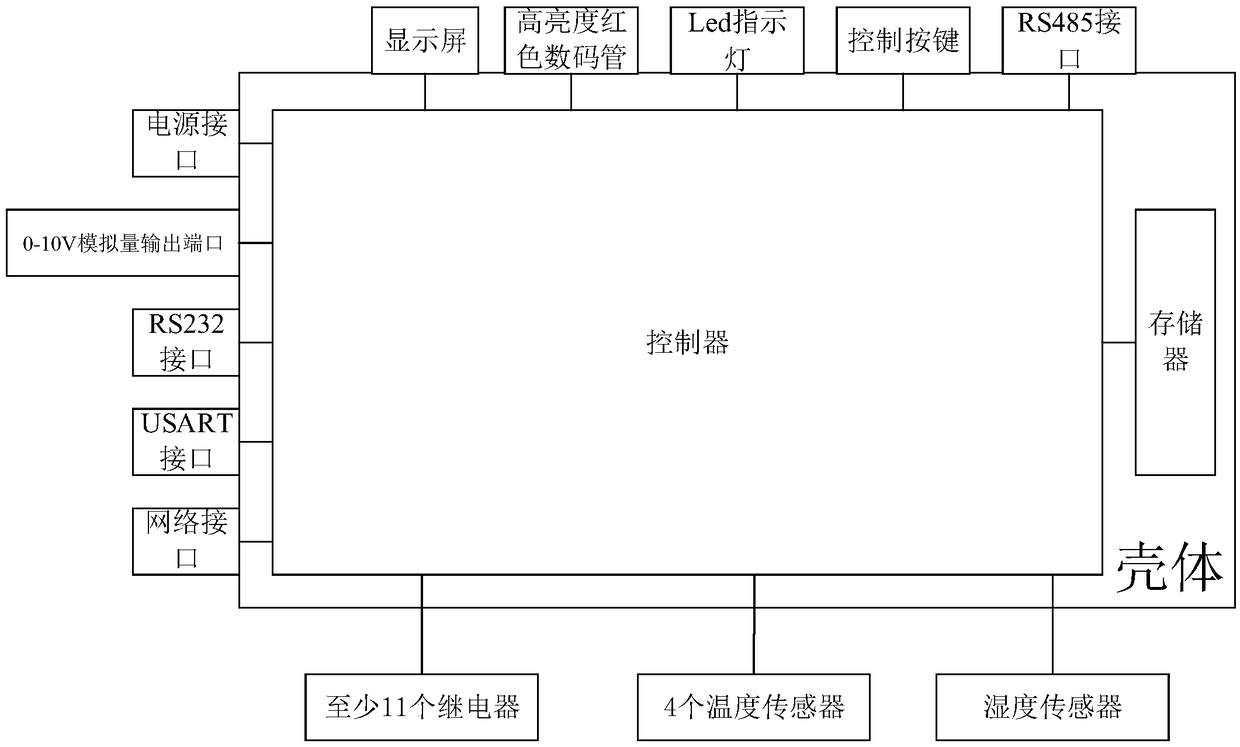

Advanced environment controller and control method thereof

PendingCN109407734AProduct Quality Safety GuaranteePromote healthy developmentSimultaneous control of multiple variablesThe InternetEngineering

The invention discloses an advanced environment controller and a control method thereof. The environment controller comprises a housing, and a controller and a memory electrically connected with the controller are installed in the housing. The surface of the housing is provided with a display screen, a high-brightness red digital tube, an Led indicator, a control key, an RS485 interface, an RS232interface, a USART interface, a network interface, a power interface and a 0-10V analog output port, which are electrically connected with the controller. The exterior of the housing is provided withrelays, a temperature sensor and a humidity sensor, which are all electrically connected with the controller, wherein the number of relays is greater than 11, and each of the relays is electrically connected with a fan and a small window switch driver. The advanced environment controller and the control method thereof disclosed by the invention rely on the Internet of Things technology to controlthe temperature of the livestock and poultry culture within a set range according to the signals monitored by the temperature and humidity sensors through ventilation, heat dissipation, humidification, heating, water curtains and small windows, so as to meet the requirements for livestock growth.

Owner:OCEAN UNIV OF CHINA

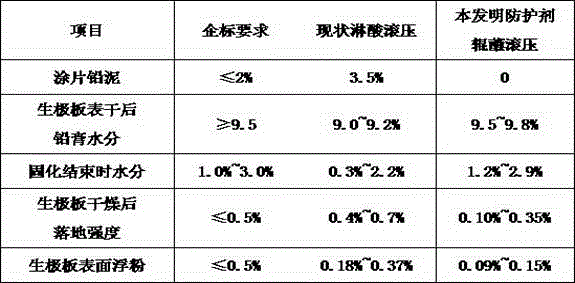

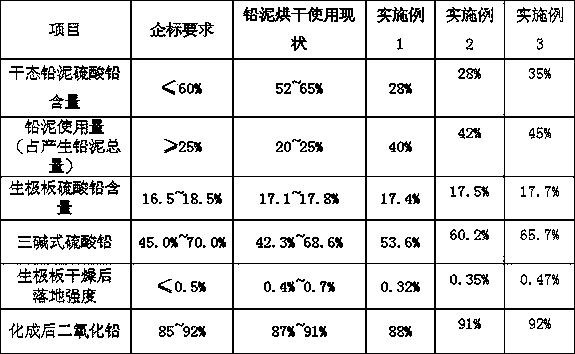

Environment-friendly and energy-saving protective agent for coating surface of positive unformed plate and coating production method employing environment-friendly and energy-saving protective agent

The invention discloses an environment-friendly and energy-saving protective agent for coating the surface of a positive unformed plate. The environment-friendly and energy-saving protective agent comprises nano fumed silica, a 60% polytetrafluoroethylene emulsion, carboxymethylcellulose, carboxyl cellulose, a polyester fiber, a sulfuric acid and distilled water. The invention further discloses a coating production method employing the protective agent in a roller-dipping rolling manner. The advantages of acid leaching rolling are reserved; the adverse consequences generated by an acid leaching hydraulic mode are avoided; and the protective agent has important significance in the economic benefit aspect of reducing the production cost and the social benefit aspect of reducing the lead slag and waste acid effluents.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

Precise tube drawing machine

The invention designs a precise tube drawing machine. The precise tube drawing machine comprises a cam trolley, wherein wheels of the trolley are arranged on guide rails at the two sides of a transmission chain; a cam groove is formed in the center of the trolley; the cam groove is internally provided with a cam; the front side of the cam is connected with a pull rod; the head of the pull rod is bent downwards to form a downward hook; the back side of the cam is provided with clamping blocks for clamping a material to be processed; when the cam moves frontwards, the clamping blocks are at a clamped state; when the cam moves backwards, the clamping blocks are at a loosened state; the trolley coordinates the pull rod and the clamping blocks by using the cam; in an operation process, the hook at the front end of the trolley slightly hooks the transmission chain; the transmission chain drives the trolley to move frontwards; the cam moves frontwards and the clamping blocks are used for clamping a tubular product; after the tubular product completely passes though a positioning device, the tubular product is not subjected to a backward pull force; the cam moves frontwards and the hook is raised upwards; then the cam moves backwards and the tubular product is released by the clamping blocks; only does a motor button on the positioning device need to be pressed and the trolley can be pulled back to a normal position to carry out next time of tube drawing; the precise tube drawing machine is simple and convenient.

Owner:DONGQING TECH

A method for reusing lead sludge produced by smear leaching acid

ActiveCN105846008BReduce wasteEasy to recycleLead-acid accumulator electrodesWaste accumulators reclaimingApparent densityRed mud

The invention discloses a recycling method of lead slime produced by acid leaching and rolling of a smear. The recycling method sequentially comprises the following steps: (1) fishing out the lead slime which is precipitated for 1-3 hours from a precipitation tank of a smear machine; (2) placing the fished lead slime into a grinding mixer for mixing for 30-60 minutes and then taking out the lead slime; (3) adding pure water to the mixed lead slime until the apparent density is 2.0-3.0g / cm<3> to prepare pasty lead slime; (4) weighing the pasty lead slime which is 2.5%-4.5% of formula amount of positive lead paste for later use; and (5) adding weighed pasty lead slime to a paste mixing machine within 3-5 minutes after beginning of wet mixing in the paste mixing technology to prepare the positive lead paste. Crushing after drying is not needed, so that secondary pollution of dust is not caused; environmental protection equipment does not need to input when energy consumption is reduced; the lead slime is directly adjusted for use; the fed materials are fully utilized; waste is reduced; the input-output ratio is improved; and the production cost is directly reduced.

Owner:TIANNENG GRP JIANGSU TECH

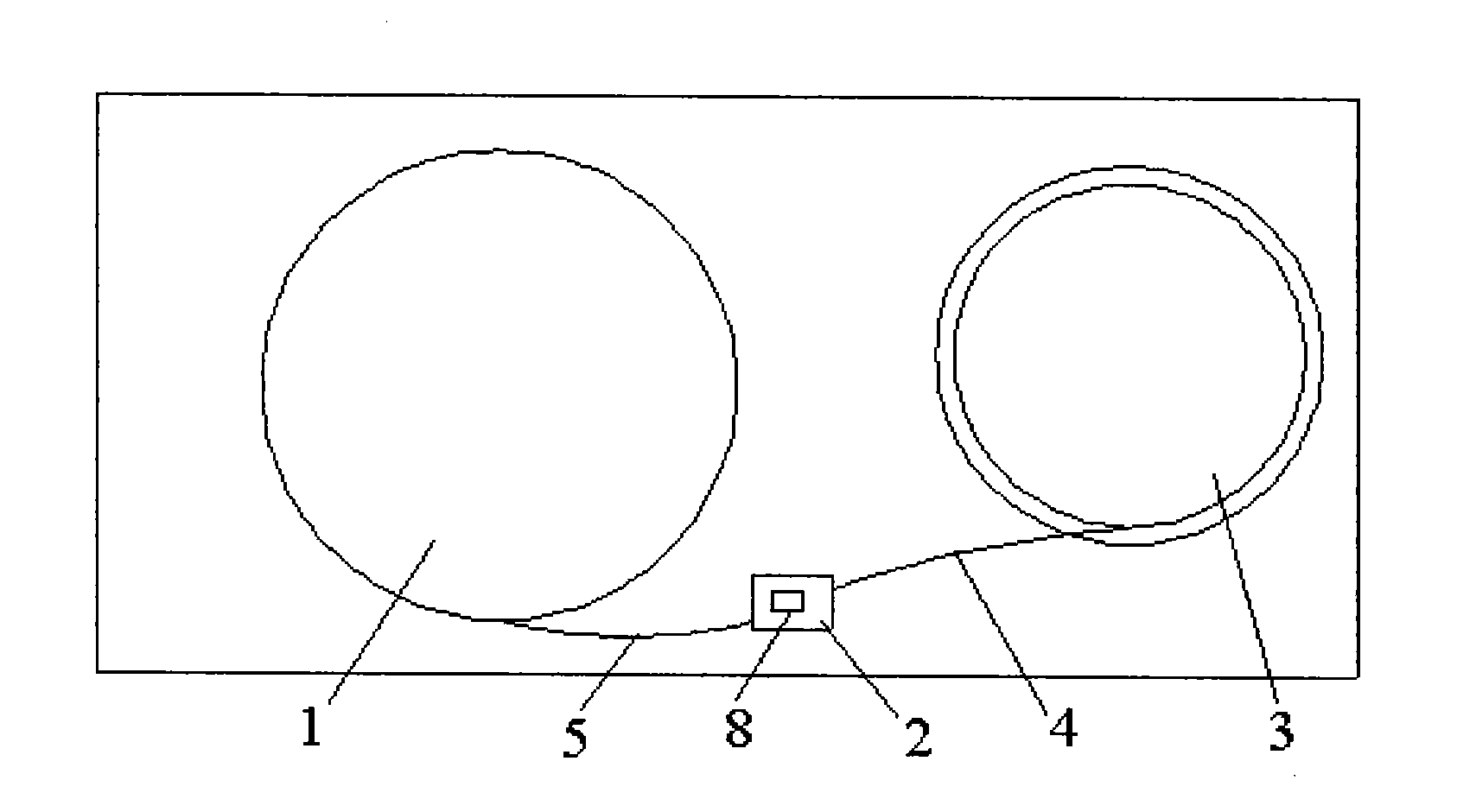

Film slitting machine with finished film take-up shafts and edge film take-up shafts separate from each other

ActiveCN103482387AWork will not affectAvoiding Quality Problem SituationsWebs handlingEngineeringMechanical engineering

The invention discloses a film slitting machine with finished film take-up shafts and edge film take-up shafts separate from each other. The film slitting machine comprises a take-up contact roller, a plurality of finished film rolls, two edge film rolls, two finished film take-up shafts, and two edge film take-up shafts. The finished film take-up shafts are disposed on two sides of the take-up contact roller and axially parallel to the take-up contact roller. The finished film rolls alternately disposed on the two finished film take-up shafts at intervals. The edge film take-up shafts are disposed around the take-up contact roller and axially parallel to the take-up contact roller. The two edge film rolls are disposed on the edge film take-up shafts and arranged at two ends of the take-up contact roller respectively. The film slitting machine has the function that take-up defects of the edge film roll are prevented from causing quality problem in the finished film rolls.

Owner:ANHUI SAFE ELECTRONICS

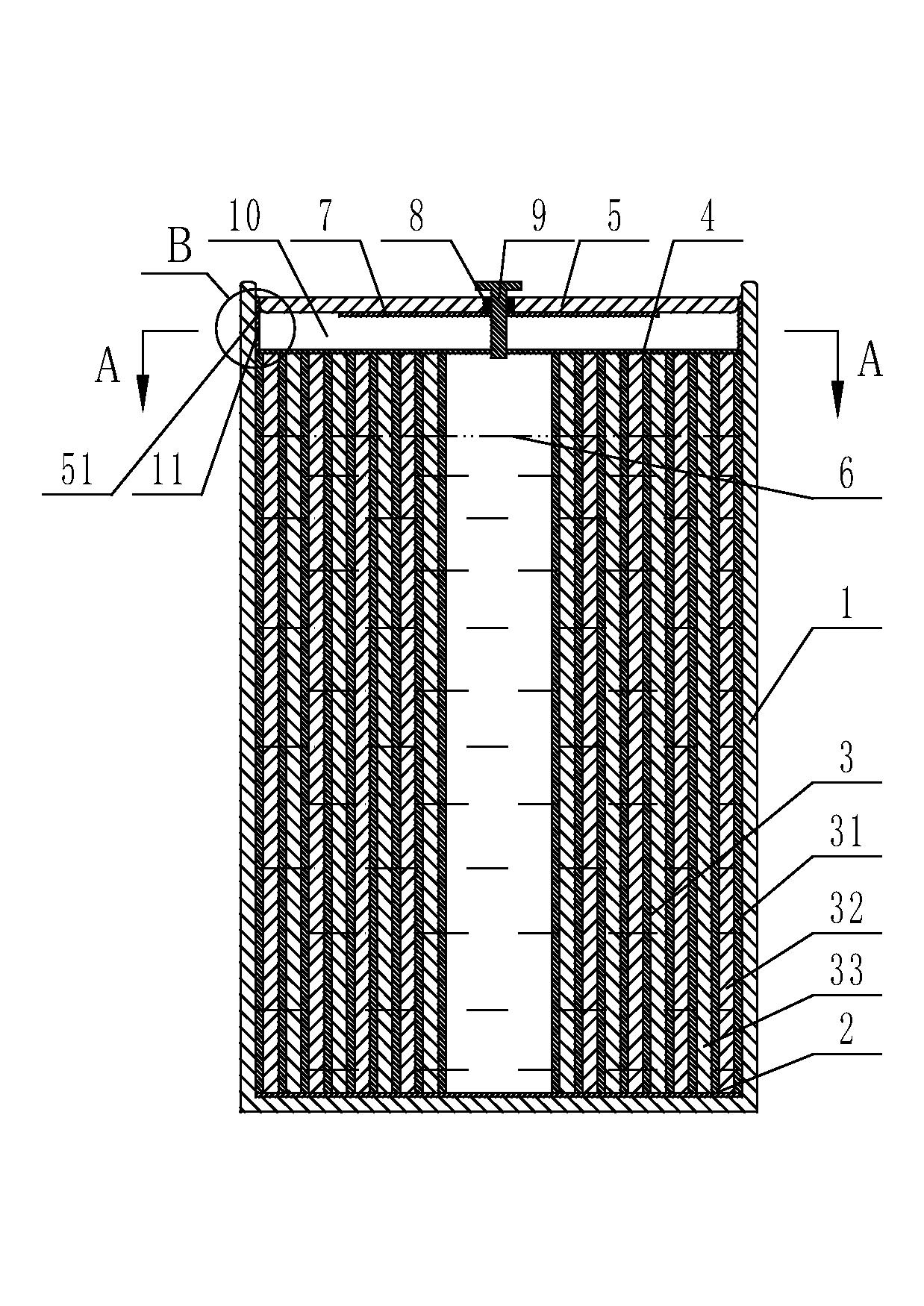

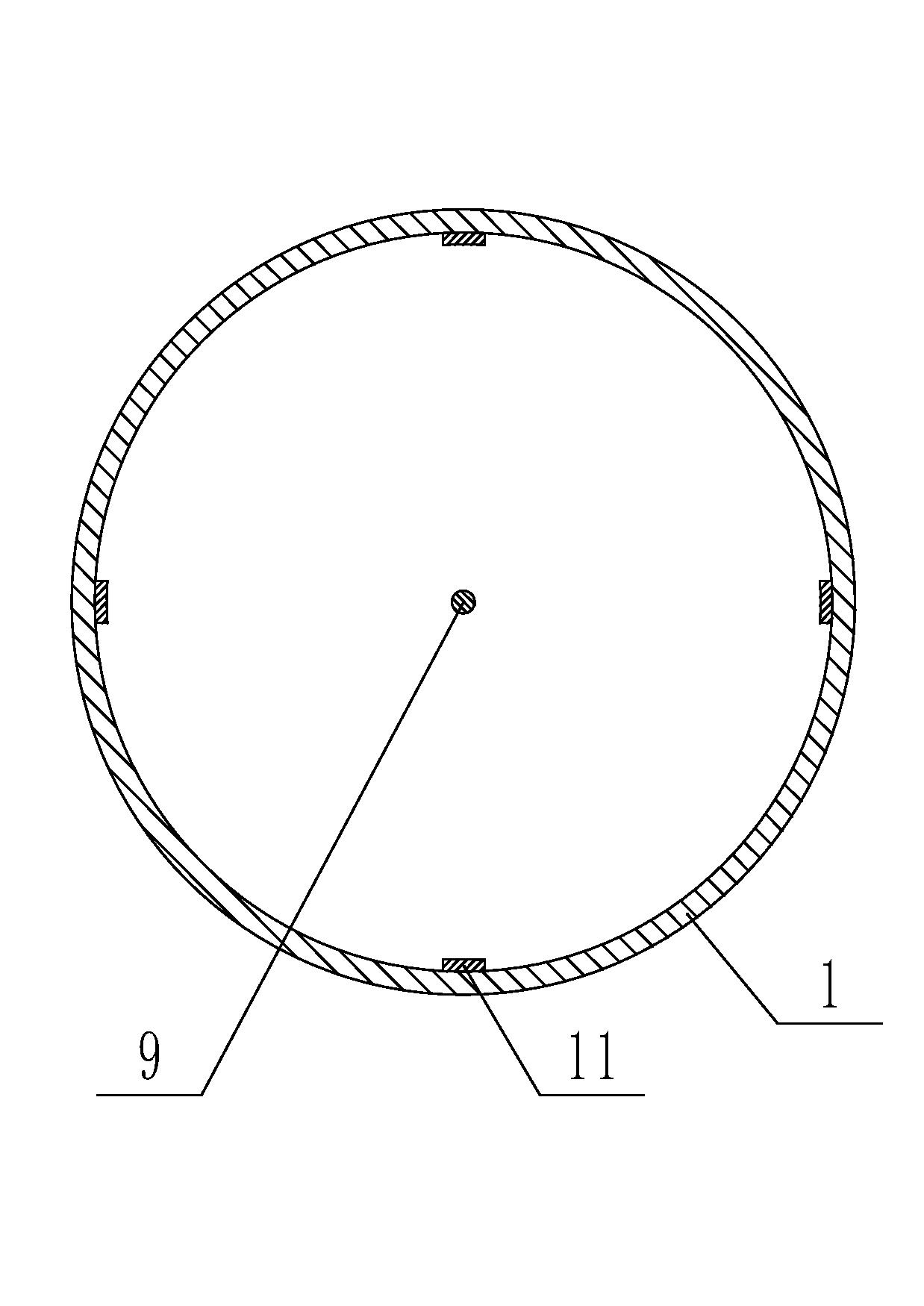

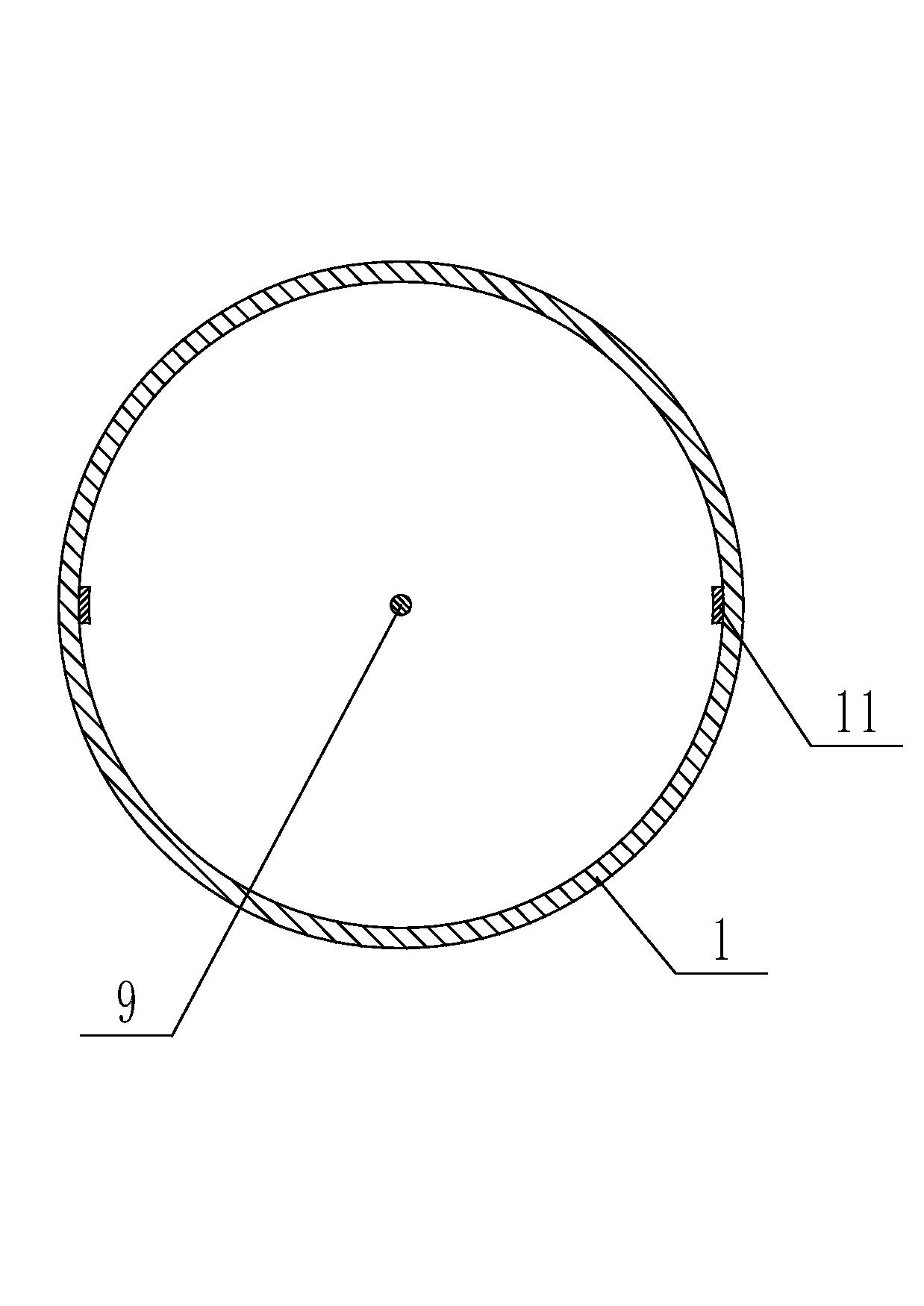

Impact resistant and vibration resistant lithium/thionyl chloride battery

ActiveCN102306826AImprove input-output ratioHigh concentricityLi-accumulatorsCell component detailsLithiumGeological exploration

The invention relates to an impact resistant and vibration resistant lithium / thionyl chloride battery. The battery comprises a housing. The following components are orderly arranged in the housing, from bottom to top: a bottom insulating sheet, a battery core, an upper insulating sheet, a top insulating sheet, and a metal-glass top cap. Electrolyte is filled in the battery core. The battery core is in a structure of rolled layers. The battery core comprises orderly arranged components of: a separating membrane, a cathode sheet, another separating membrane, and an anode sheet. The metal-glass top cap is provided with a central column in the center. A cathode lead is connected with the central column. An arc transition is arranged on the edge of the lower surface of the metal-glass top cap. Anode leads are clamped and welded between the metal-glass top cap and the housing. There are at least two anode leads. The anode leads are annularly and uniformly distributed along the inner wall of the battery housing. The battery is suitable to be applied in oil exploitation and geological exploration engineering. The battery resists environmental probations of high temperatures, and impacts and vibrations of drilling bits and drill pipes. With the battery, the battery core is prevented from loosening.

Owner:SUZHOU JINKEFA LITHIUM BATTERY

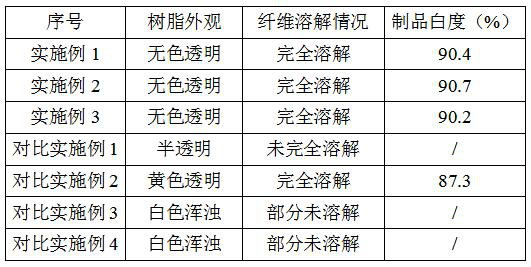

Recycling method of meta-position aramid fiber waste and recycled material

ActiveCN113802217ALow toxicityImprove solubilityArtificial filament recoveryPlastic recyclingSpinningOrganic solvent

The invention provides a recycling method of meta-position aramid fiber waste and a recycled material, and belongs to the technical field of high polymer chemistry. The recycling method comprises the following steps: (1) drying meta-position aramid fiber waste, and cutting or crushing the meta-position aramid fiber waste to prepare chopped fibers or precipitation fragments; (2) soaking the chopped fibers or the precipitation fragments in the step (1) with an organic solvent under normal pressure to obtain slurry; and (3) mixing the slurry with a cosolvent, and carrying out a stirring reaction under a closed condition to obtain a colorless and transparent meta-position aramid resin solution. According to the recycling method, adopted equipment is simple, the technological process is simple, the treatment cost is low, and industrial feasibility is achieved; solvent consumption is relatively low, and low toxicity and environmental protection are realized; and a high-temperature aerobic environment is avoided in the technological process, the apparent color of the prepared meta-position aramid resin solution does not turn yellow obviously, the performance of subsequent products is not affected, the meta-position aramid resin solution can be directly used for spinning or preparation of fibrid, the problem of environmental pollution caused by meta-position aramid fibers is solved, and the input-output rate of the meta-position aramid resin is increased.

Owner:ZHUZHOU TIMES FIBER PIONEER MATERIAL TECH CO LTD

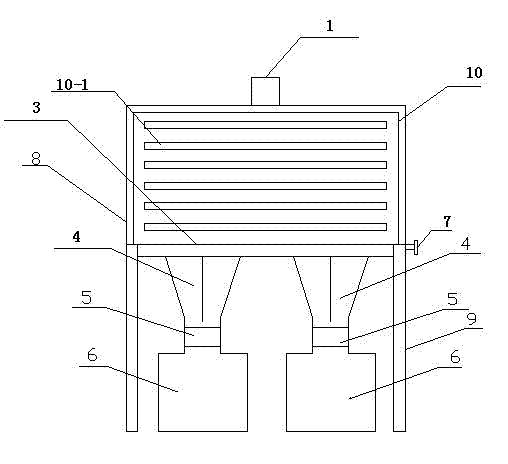

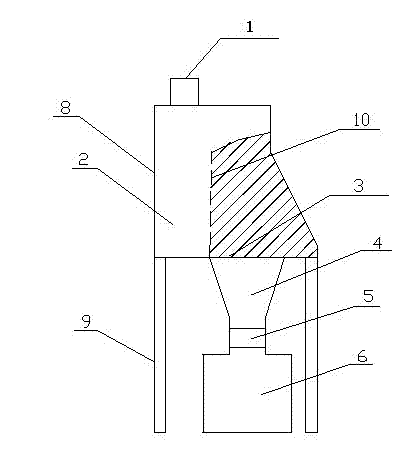

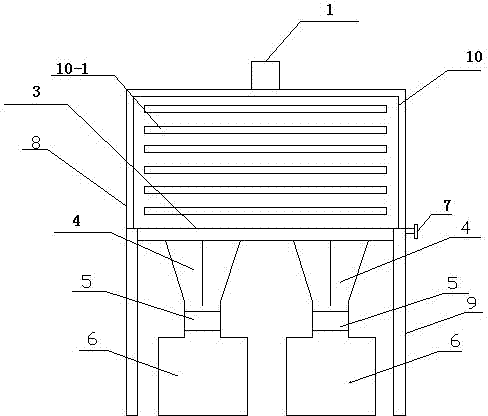

Powdered ink separating and recycling device for detecting

The invention relates to a powdered ink separating and recycling device for detecting. A metal hood is arranged on a frame; a negative-pressure extract opening is formed above the metal hood; an oblong-shaped baffle plate provided with a plurality of through holes is fixed in the metal hood; a cavity formed between the baffle plate and a back hood panel serves as a dust absorbing channel; the platform surface of the frame serves as a detection operation platform surface; the upper ports of a plurality of powdered ink recycling hoppers are formed on the detection operation platform surface; a powdered ink recycling tank is arranged in the frame; a connecting sleeve is used for connecting the lower ends of the powdered ink recycling hoppers with the powdered ink recycling tank; and a grounding contact is formed on one side of the metal hood. The invention has the advantages that: due to the adoption of the device, about 80 percent of powdered ink left after detection is successfully recycled, the detection cost is reduced, the input-output rate is increased, and carbon emission is reduced; meanwhile, flying dust produced by powdered ink for detection can be absorbed, so that the dust is prevented from harming a human body.

Owner:TIANJIN ZHONGHUAN TIANJIA ELECTRONICS

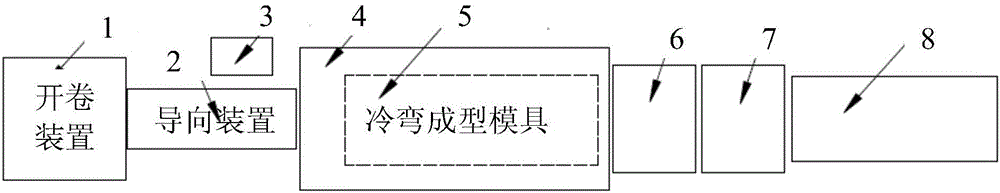

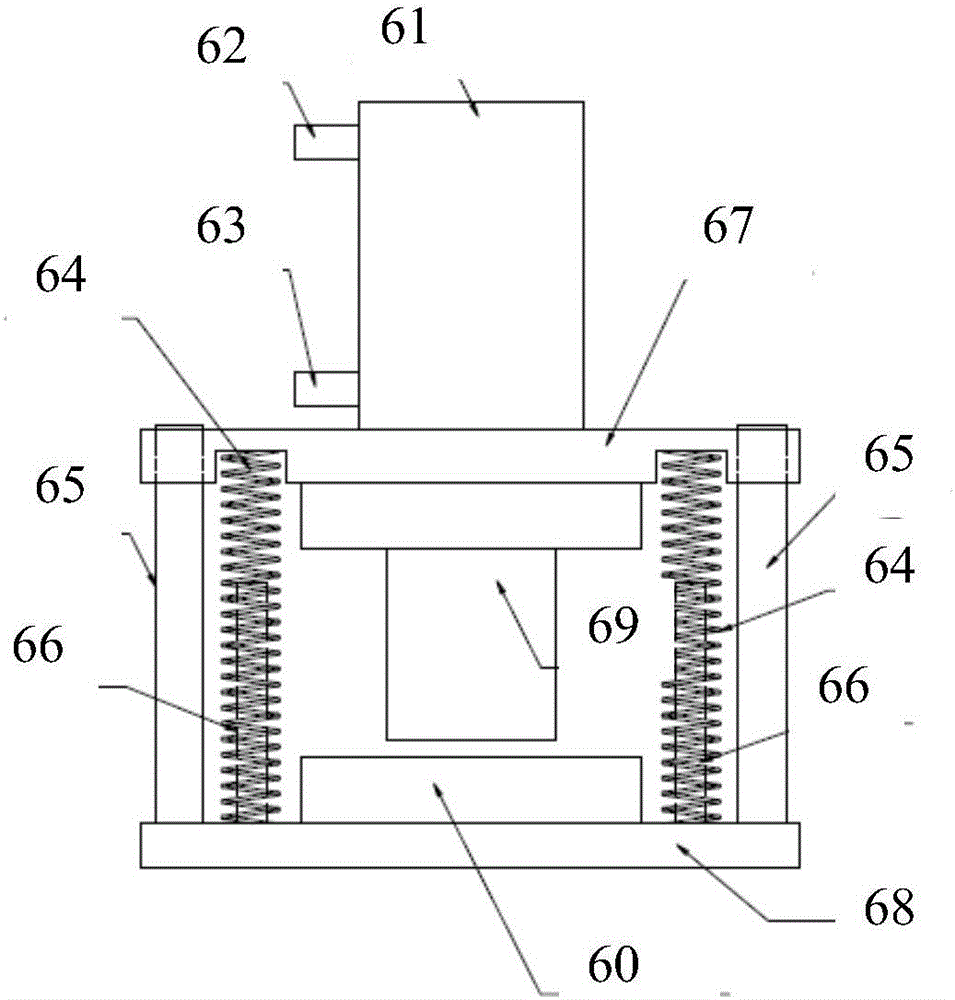

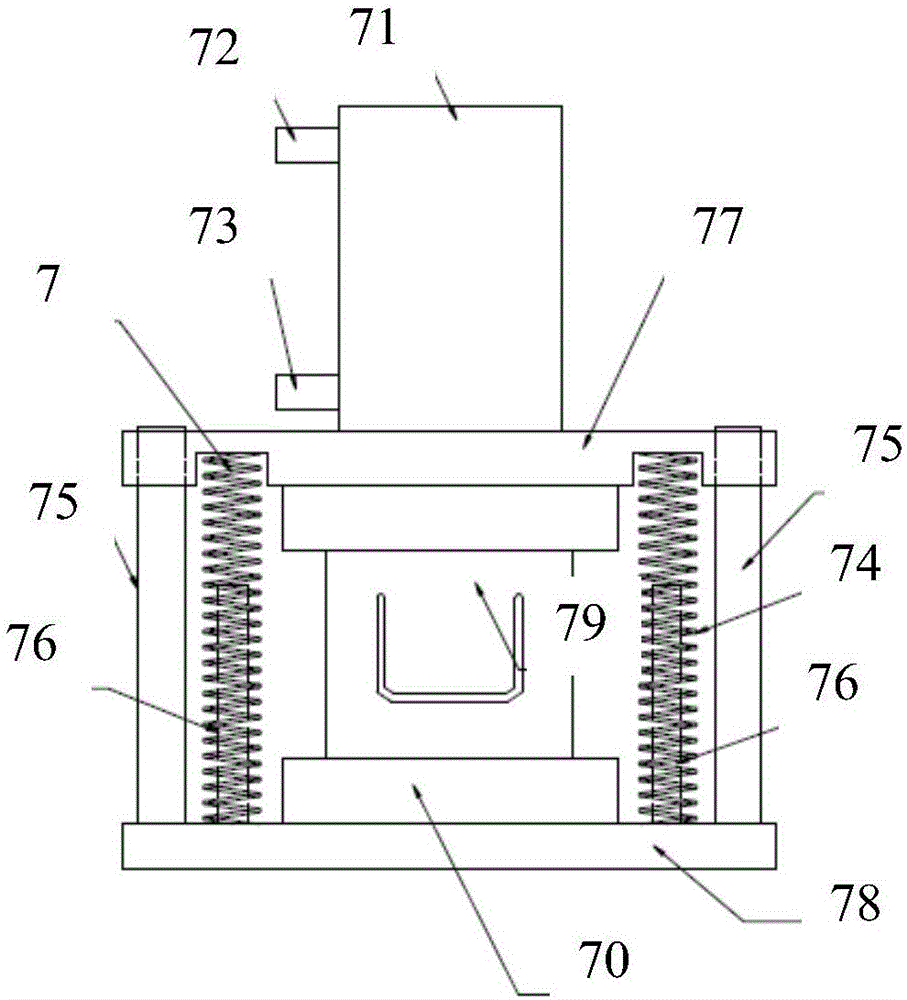

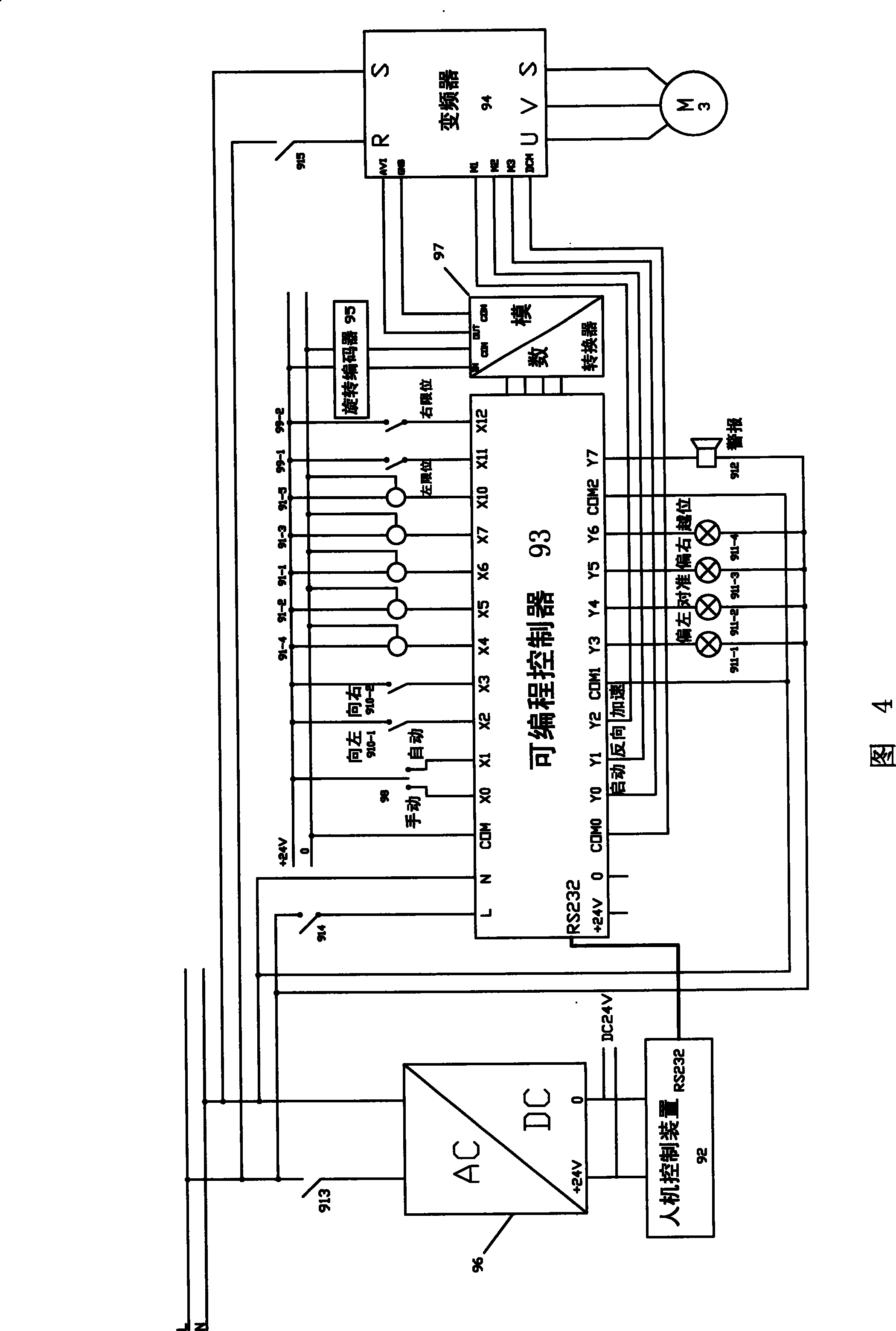

Production method for cold bending products

ActiveCN106734574APrecise cold bendingImprove pass rateOther printing apparatusAutomatic controlProgrammable logic controller

The invention relates to a production method for cold bending products. The production is automatically controlled by a programmable logic controller (PLC) in the production method. The method comprises the steps of uncoiling, guiding, cold bending, steel seal printing and cutting-off. The cold bending work of materials is completed fully automatically, and the problems that the deviation of the cold bending angle dimension of the materials is too large due to too much manual participation, the yield is low and the input-output ratio is much lower are effectively solved.

Owner:北新建材(陕西)有限公司

Glass fiber wall cloth edge-cutting electronic error-correcting apparatus

InactiveCN101368327BHigh degree of automationImprove quality and efficiencySevering textilesControl using feedbackGlass fiberControl system

The invention discloses an electronic deviation rectifying device used in glass fiber wallhanging cut trimming, consisting of a control system and an execution system. The control system comprises at least two color mark sensors, a programmable controller, a transducer, and a revolving coder; the execution system is composed of an execution motor frame, a slide bar frame, a sensor frame, a cuttersaddle, an execution motor, a screw mandrel and a cutter. After any of the color mark sensors detects color streak which serves as a color mark inlaid along the edge on the upper surface at one side of the edge to be cut of the wallhanging, the color mark sensor sends the location information to the programmable controller to control the movement of the cutter, so as to rectify deviation. The signals of the color mark sensors can be used in high speed deviation rectification and low speed deviation rectification. The revolving coder feeds back the detected speed of the threads of the wallhanging to the programmable controller to control the movement speed of the cutter, so as to ensure the constant ratio of deviation rectification to the speed of the threads of the wallhanging. The electronic deviation rectifying device realizes automated control to deviation rectification and is high in rectification precision, stable in performance, simple in operation and installation and low in making cost.

Owner:常州华碧宝特种新材料有限公司

Manufacturing device and manufacturing method of optical glass clinker

PendingCN113480140AAvoid damageUninterrupted productionCharging furnaceGlass furnace apparatusOptical glassCooling channel

The invention belongs to the technical field of glass production, particularly discloses a manufacturing device and a manufacturing method of optical glass clinker, and aims at solving the problem that an existing device for manufacturing fluorophosphate optical glass clinker is low in production efficiency. According to the manufacturing device, a vertical partition plate is arranged in the inner cavity of a smelting container to divide the inner cavity into a smelting area and a discharging area, and a molten glass passing hole for communicating the smelting area with the discharging area is formed in the lower portion of the vertical partition plate, so that molten glass can be smelted and homogenized in the smelting area, then flows into the discharging area through the molten glass passing hole, then is discharged through a discharging pipe for producing the glass clinker. Therefore, glass raw materials are fed into the smelting area in the production process, it is ensured that molten glass can be discharged outwards all the time in the discharging area, uninterrupted production of the glass clinker can be achieved, and the production efficiency is greatly improved. By arranging a traction annealing furnace with a cooling channel, the production efficiency can be further improved, meanwhile, the labor intensity of workers is greatly reduced, and the input-output rate can be increased.

Owner:CDGM OPTICAL GLASS

A method of processing mold rolls with electrode microgrid using narrow pulse width laser direct writing

ActiveCN105665937BImprove input-output ratioIncrease productivityDecorative surface effectsChemical vapor deposition coatingPicosecond pulsed laserPicosecond

The invention relates to a method for processing mold rolls with an electrode micro-grid using narrow pulse width laser direct writing. Straightening and light spot shaping converge on the surface of the roller material of the mold roller, and perform fine photoetching to form the required concave electrode micro-grid pattern; after laser photoetching, ultrasonic treatment, chemical or electroplating polishing is performed on the surface of the roller material, This in turn optimizes the roller surface. The present invention has the advantages of: inventing a method for processing mold rolls using electrode micro-grid direct writing with narrow pulse width laser, the traditional printing pattern is a laser photoetching pattern, thereby greatly improving production efficiency; at the same time, by controlling the specific conditions of the laser process parameters, so that the electrode micro-grid pattern on the surface of the mold roll is clear and consistent, and the input-output rate of the mold roll is high.

Owner:南通天鸿镭射科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com