Impact resistant and vibration resistant lithium/thionyl chloride battery

A thionyl chloride battery, impact-resistant technology, applied to the battery field, can solve the problems of battery core battery performance, battery safety performance hazards, drilling operation interruption, battery core loosening, etc., so as to increase input-output rate and improve economy. Benefit, the effect of enhancing concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

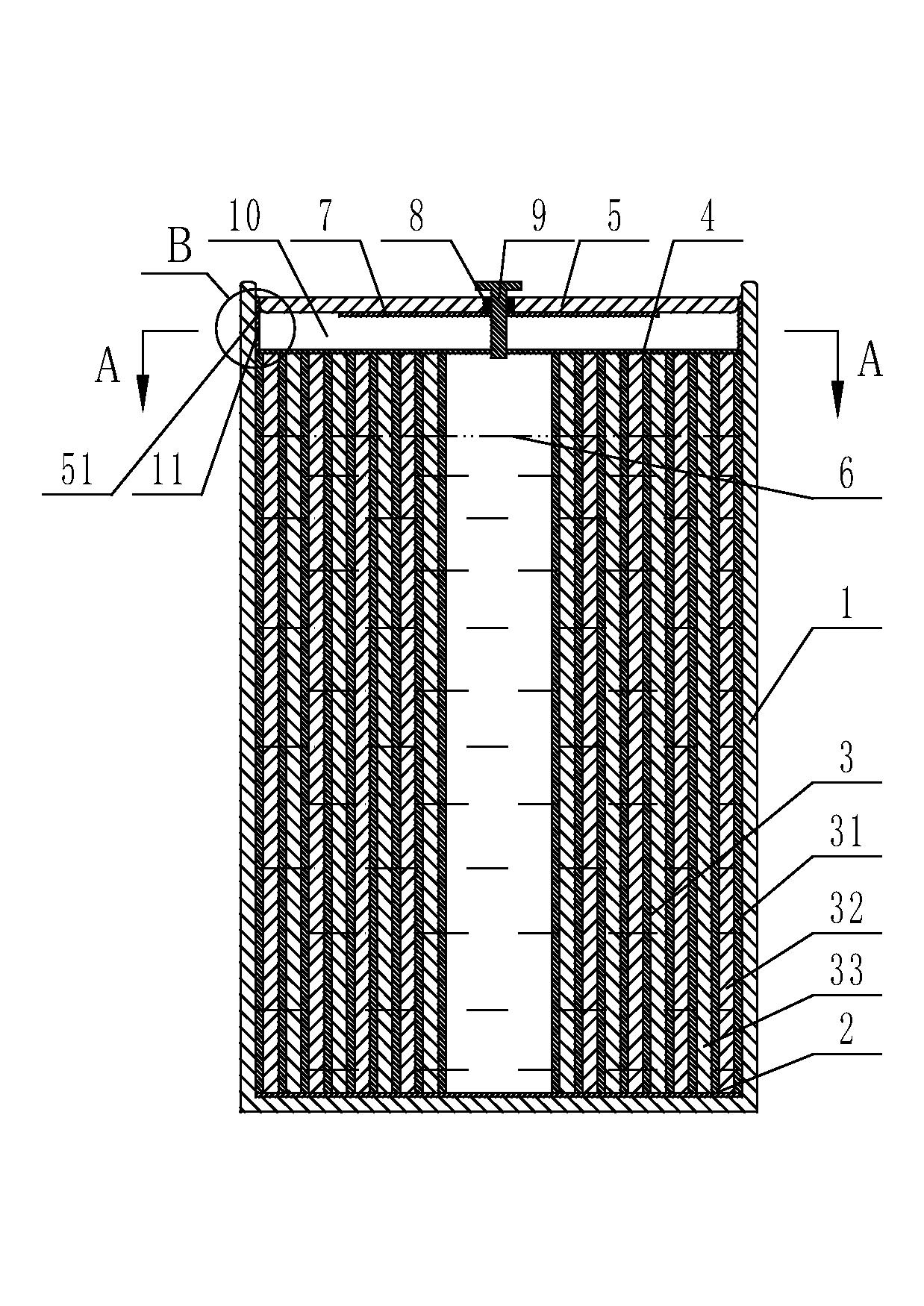

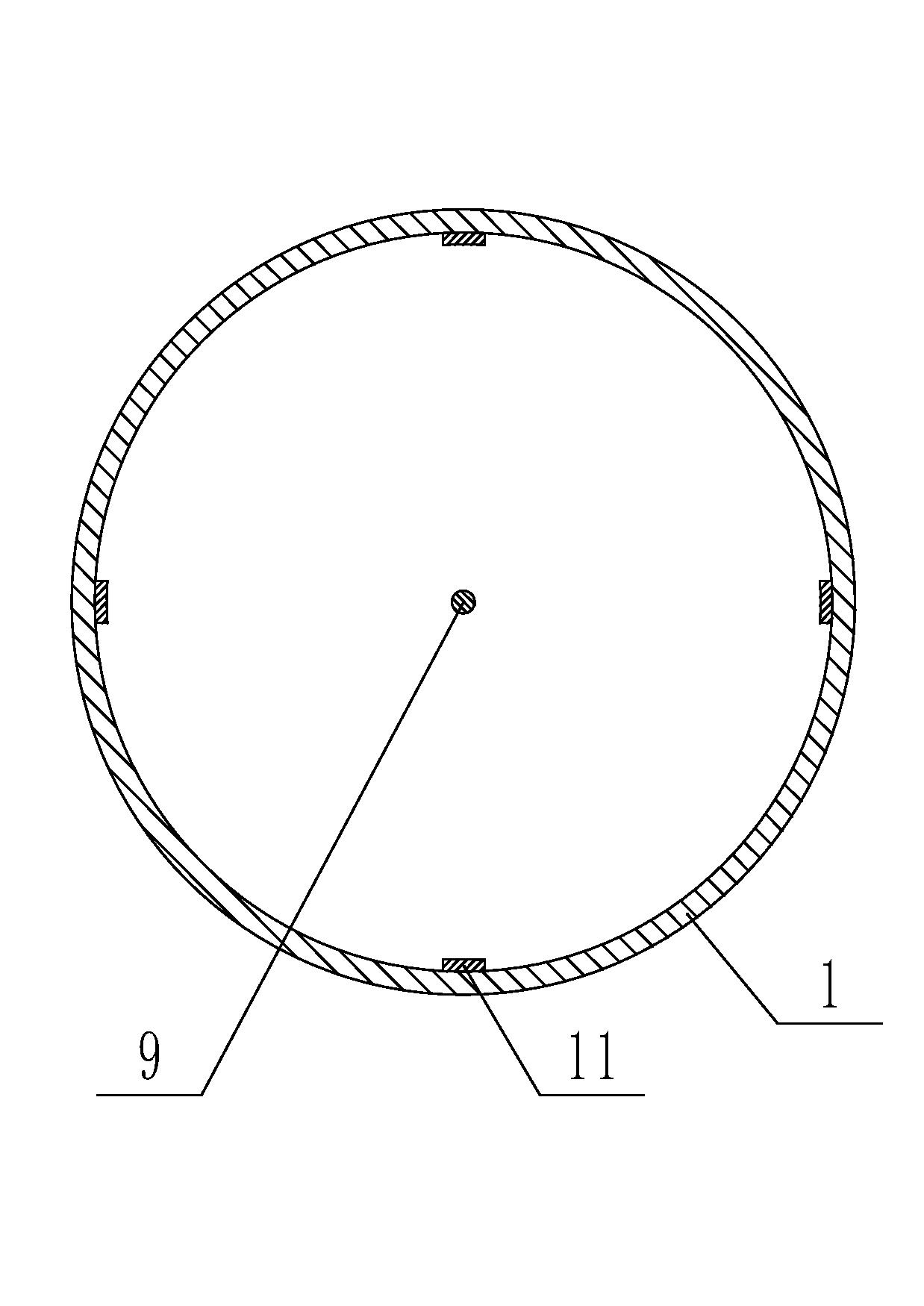

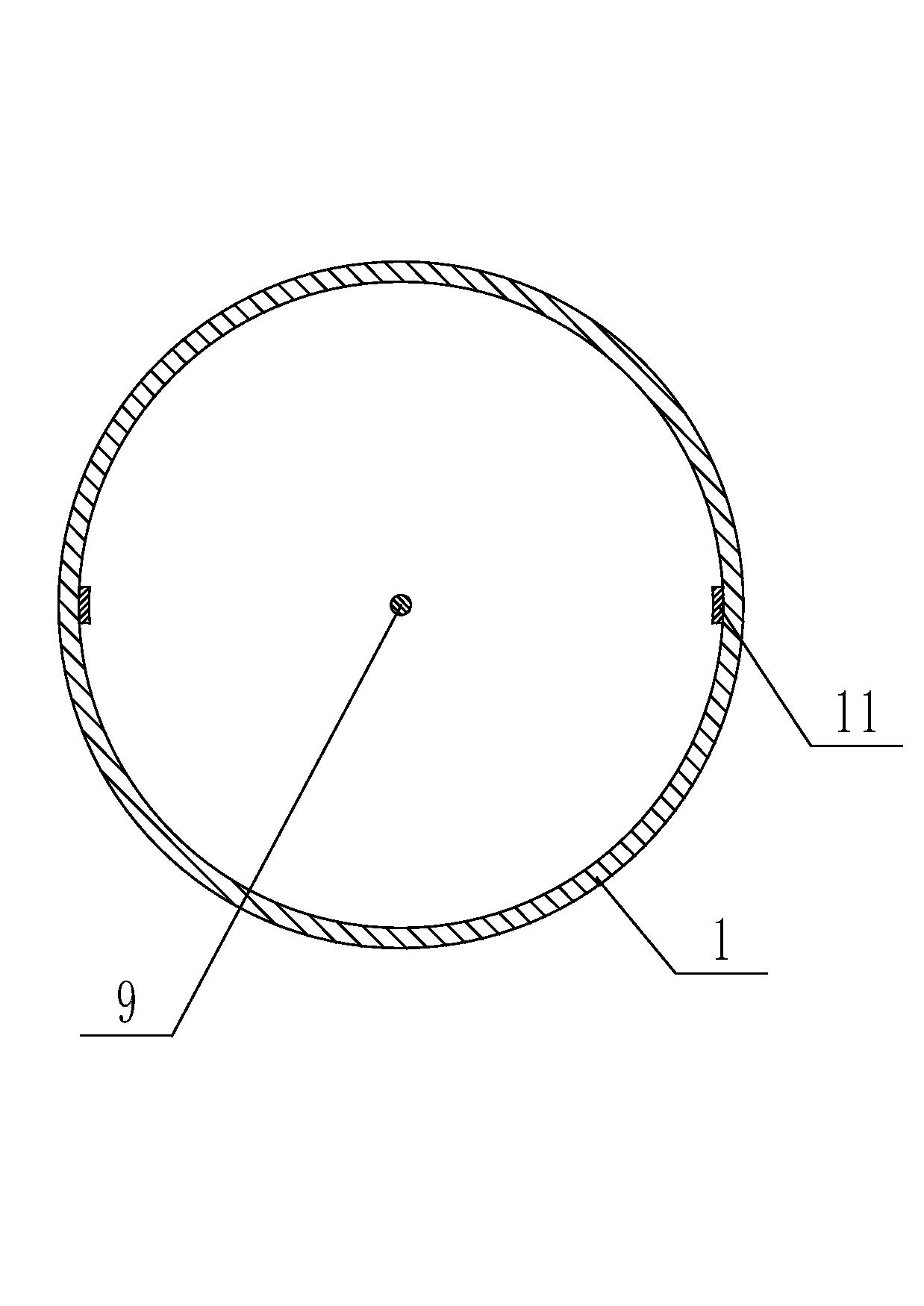

[0022] Such as figure 1 As shown, a shock-resistant and vibration-resistant lithium / thionyl chloride battery includes a shell 1, and the inside of the shell 1 is sequentially provided with a bottom insulating sheet 2, a battery core 3, an upper insulating sheet 4 and a metal - glass sealing cover 5, electrolyte 6 is arranged in the battery core body 3, the battery core body 3 is a multi-layer roll structure, including a diaphragm 31, a cathode pole piece 32 and an anode pole piece 33, and the diaphragm 31 is a non- Woven glass fiber, the cathode pole piece 32 is a composite film of carbon and polytetrafluoroethylene binder and nickel expansion, the anode pole piece 33 is a composite film of lithium and nickel expansion, and the bottom of the metal-glass sealing cover 5 is provided with The top insulating sheet 7, the center of the metal-glass sealing cover 5 is provided with a central column 9 through a glass body 8, and the cathode tab is connected with the central column 9, ...

Embodiment 2

[0025] Such as figure 1 As shown, a shock-resistant and vibration-resistant lithium / thionyl chloride battery includes a shell 1, and the inside of the shell 1 is sequentially provided with a bottom insulating sheet 2, a battery core 3, an upper insulating sheet 4 and a metal - glass sealing cover 5, electrolyte 6 is arranged in the battery core body 3, the battery core body 3 is a multi-layer roll structure, including a diaphragm 31, a cathode pole piece 32 and an anode pole piece 33, and the diaphragm 31 is a non- Woven glass fiber, the cathode pole piece 32 is a composite film of carbon and polytetrafluoroethylene binder and nickel expansion, the anode pole piece 33 is a composite film of lithium and nickel expansion, and the bottom of the metal-glass sealing cover 5 is provided with The top insulating sheet 7, the center of the metal-glass sealing cover 5 is provided with a central column 9 through a glass body 8, and the cathode tab is connected with the central column 9, ...

Embodiment 3

[0028] Such as figure 1 As shown, a shock-resistant and vibration-resistant lithium / thionyl chloride battery includes a shell 1, and the inside of the shell 1 is sequentially provided with a bottom insulating sheet 2, a battery core 3, an upper insulating sheet 4 and a metal - glass sealing cover 5, electrolyte 6 is arranged in the battery core body 3, the battery core body 3 is a multi-layer roll structure, including a diaphragm 31, a cathode pole piece 32 and an anode pole piece 33, and the diaphragm 31 is a non- Woven glass fiber, the cathode pole piece 32 is a composite film of carbon and polytetrafluoroethylene binder and nickel expansion, the anode pole piece 33 is a composite film of lithium and nickel expansion, and the bottom of the metal-glass sealing cover 5 is provided with The top insulating sheet 7, the center of the metal-glass sealing cover 5 is provided with a central column 9 through a glass body 8, and the cathode tab is connected with the central column 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com