A method of processing mold rolls with electrode microgrid using narrow pulse width laser direct writing

A technology of laser direct writing and processing molds, which is applied in the direction of producing decorative surface effects, manufacturing tools, laser welding equipment, etc., can solve the problems of low production efficiency, complicated process, low input-output rate, etc. High output rate, improved production efficiency, clear and consistent graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

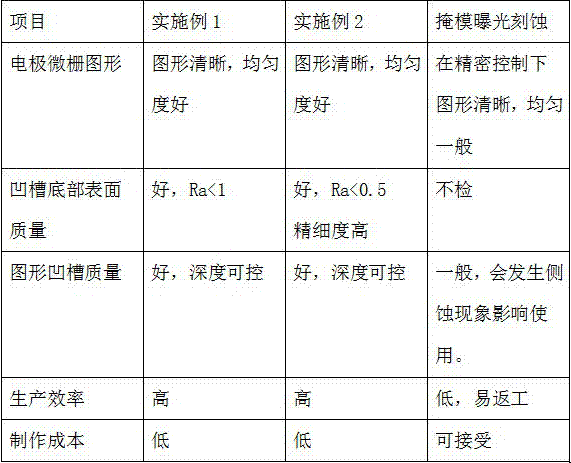

Embodiment 1

[0016] The present embodiment adopts the method for processing mold rolls with electrode micro-grid direct writing with narrow pulse width laser, and the specific steps of the method are as follows:

[0017] (1) Select the laser device: choose a laser with a pulse width of nanoseconds as the energy source for the direct writing device, the laser wavelength is 266 nm, and the energy density is greater than 20uJ@100KHz;

[0018] (2) Laser photoetching: The laser beam is converged to the surface of the roller material of the mold roller through beam expansion, collimation and spot shaping, and then finely photoetched to form the required concave electrode micro-grid pattern; the wavelength of the laser is 266nm, The average power is 20W, the laser scanning speed is 20-200mm / s, and the micro-grid pattern of the photo-etching vector electrode is scanned, and the depth of the concave groove is 2-3um;

[0019] (3) Post-processing: After laser photoetching, ultrasonic treatment, chemi...

Embodiment 2

[0021] The present embodiment adopts the method for processing mold rolls with electrode micro-grid direct writing with narrow pulse width laser, and the specific steps of the method are as follows:

[0022] (1) Select the laser device: Select the laser device: select the laser with a pulse width of picosecond level as the energy source of the direct writing device, the laser wavelength is 26 nanometers, and the energy density is greater than 20uJ@100KHz;

[0023] (2) Laser photoetching: The laser beam is converged to the surface of the roller material of the mold roller through speed expansion, collimation and spot shaping, and then finely photoetched to form the required concave electrode micro-grid pattern; the wavelength of the laser is 266nm, The average power is 3W, the laser scanning speed is 20-200mm / sec, and the micro-grid pattern of the photo-etching vector electrode is scanned, and the depth of the concave groove is 2-3um;

[0024] (3) Post-processing: After laser p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com