Recycling method of meta-position aramid fiber waste and recycled material

A technology of aramid fiber and recycling method, which is applied in the field of polymer chemistry, can solve the problems of waste and pollution of meta-aramid fiber, and achieve the effects of being convenient for manual operation, solving environmental pollution, and having good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

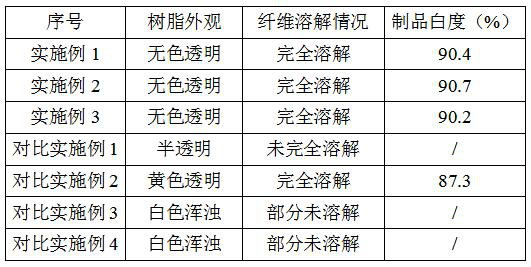

Embodiment 1

[0030] Place the 6mm meta-aramid chopped fiber waste in a vacuum oven at 80°C for 1.5h, after cooling, accurately weigh 17.0g chopped fiber and add it to 100ml DMPU, soak at room temperature for 2h, add 1.0g to the slurry Lithium chloride, the slurry was poured into a 250ml single-necked flask, and stirred at 90° C. with a mechanical seal for 1 hour to obtain a colorless and transparent aramid resin solution.

Embodiment 2

[0032] Place meta-aramid fibrous waste in a vacuum oven at 90°C for 2 hours, and after cooling, process it with a crusher to make it smaller than 1cm 2 Then accurately weigh 10.0g of the broken precipitated fiber waste and add it to 100ml DMPU, soak at room temperature for 1h, add 1.5g of magnesium chloride to the slurry, pour the slurry into a 250ml single-necked flask, and place at 85°C Stir with a mechanical seal for 1.5 hours to obtain a colorless and transparent aramid resin solution.

Embodiment 3

[0034] Place the meta-aramid filament waste in a vacuum drying oven at 80°C for 1 hour, and after cooling, process it into 6mm chopped fibers by a fiber cutter, then accurately weigh 12.0g of chopped fibers and add them to 100ml DMPU, soak at room temperature for 1.5 h, add 1.0 g of lithium chloride to the slurry, pour the slurry into a 250 ml one-necked flask, and stir for 1.5 h with a mechanical seal at 80° C. to obtain a colorless and transparent aramid resin solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com