Production method for cold bending products

A production method and product technology, applied in printing devices, printing and other directions, can solve the problems of low pass rate, large deviation of cold bending angle and dimension, low input-output rate, etc., so as to improve the qualified rate and input-output rate, Cold bending for precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical means, creative features, goals and effects of the device easy to understand, the following will be described in detail in combination with specific diagrams.

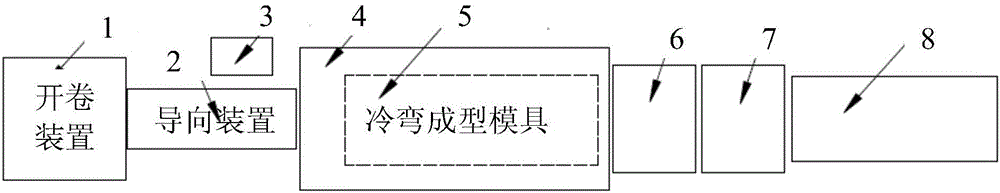

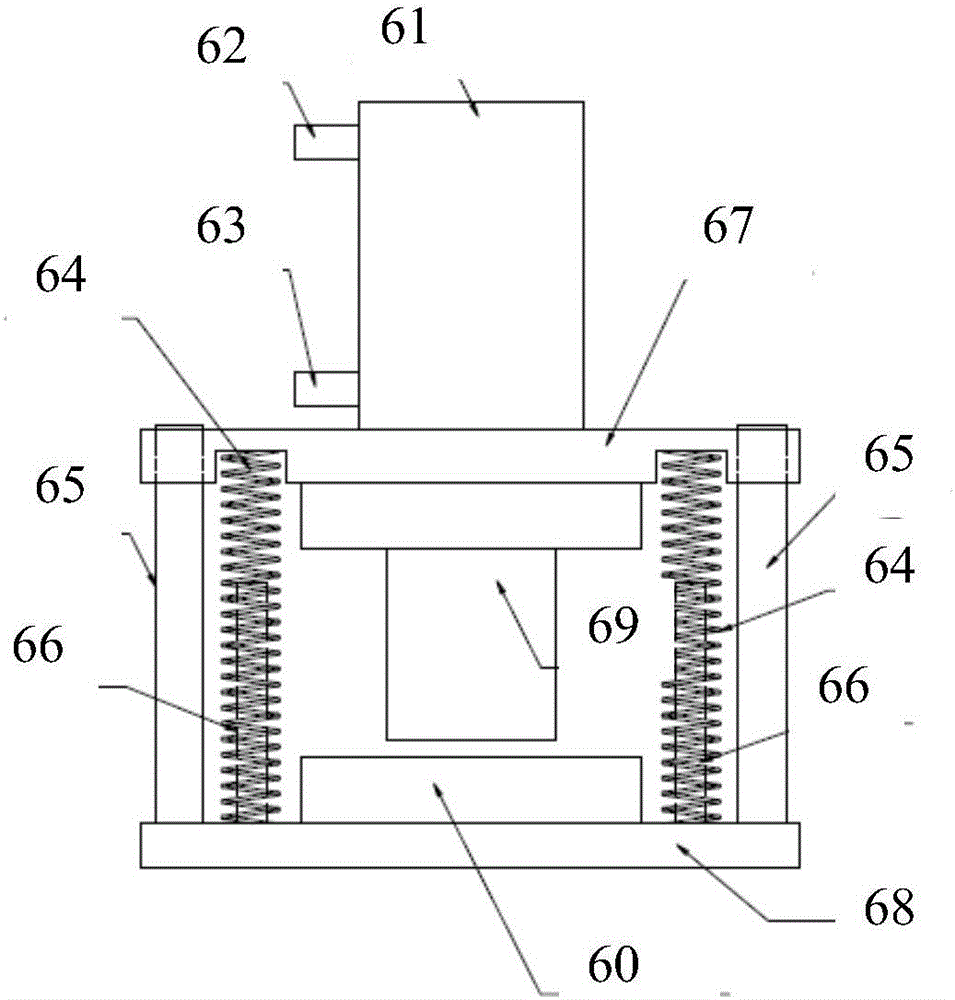

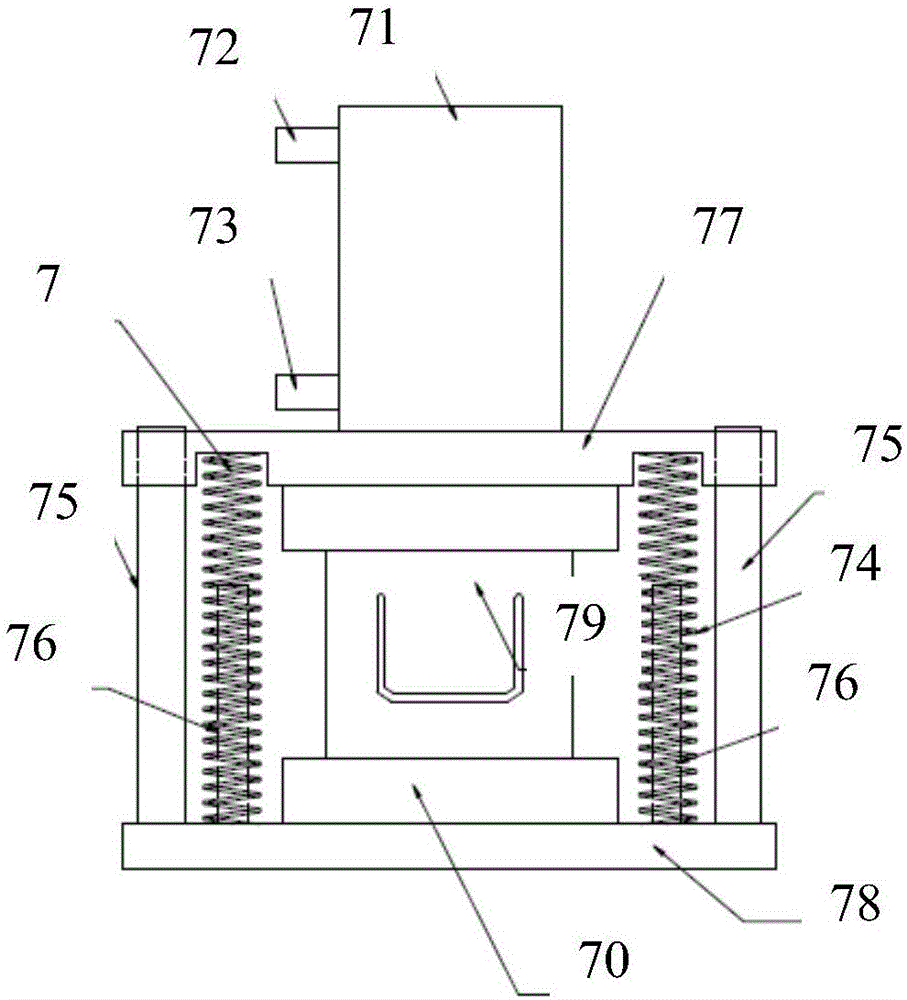

[0046] Realize the device of the present invention as attached figure 1 A production device for cold-bending products is shown, including: uncoiling device 1, guiding device 2, inkjet printer 3, cold-bending forming device 4, cold-bending forming mold 5, stamping device 6, cutting device 7 and finished product collecting device 8. Using this device to complete material cold bending includes the following steps:

[0047] A. Uncoiling method: the PLC programmable controller issues an opening command, and the uncoiling device detects whether there is raw material on the uncoiling device, and if there is, the uncoiling device is automatically activated to fix the raw material to the specified position and tension, and the uncoiling is successful;

[0048] B. Guide method: The guide d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com