LED production process optimization method based on big data technology

A technology of big data technology and optimization method, which is applied in the field of LED production process optimization based on big data technology, can solve the problems such as the difficulty of keeping the light emission level of the chip consistent, the change of the number of phosphor particles, and the attenuation of the concentration of phosphor powder, so as to increase the production efficiency. rate, improve the input-output ratio and production capacity, and increase the effect of the shipment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

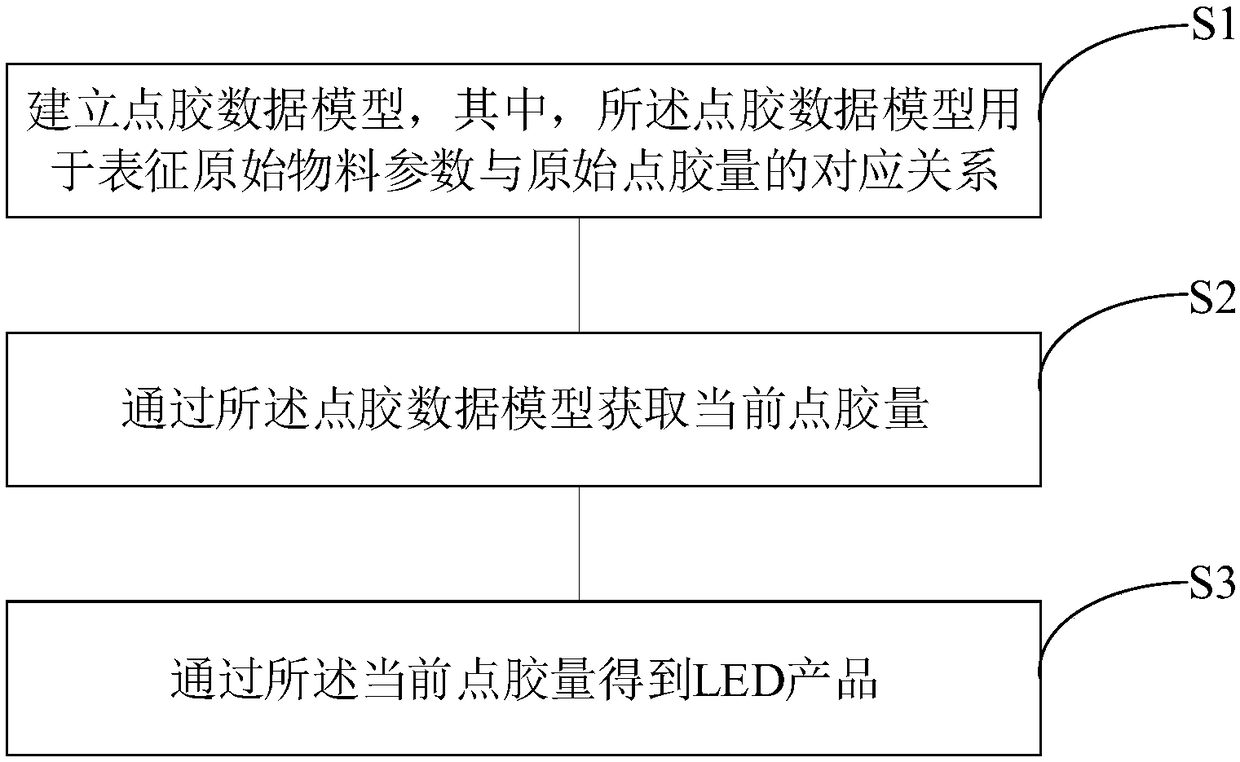

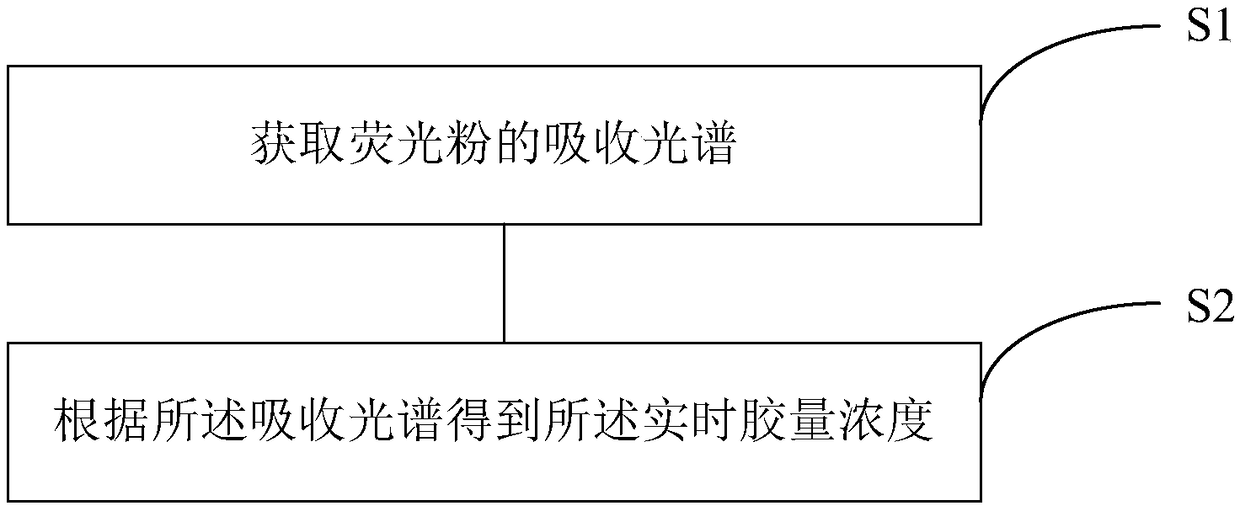

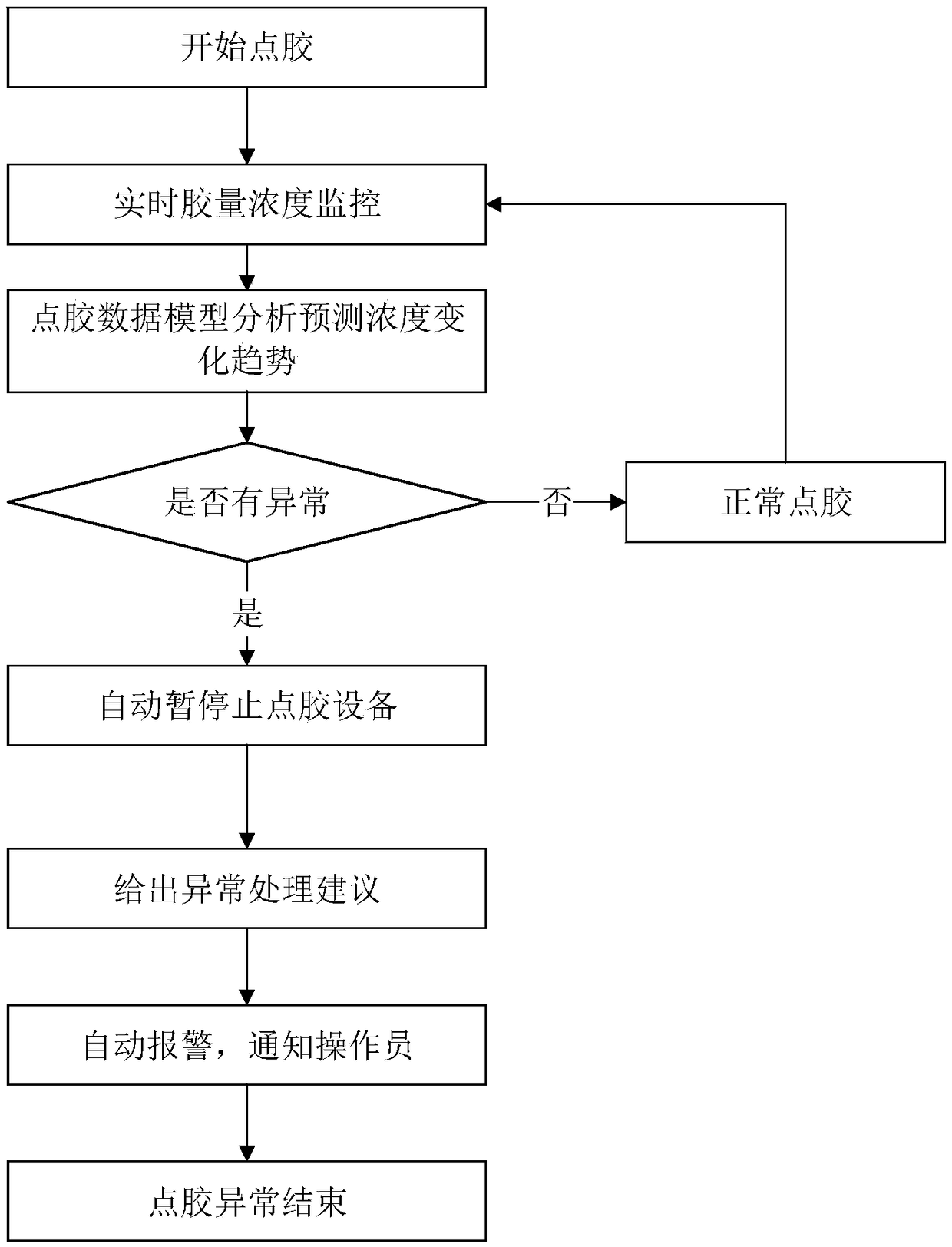

[0048] See figure 1 , figure 1 A schematic flow diagram of an LED production process optimization method based on big data technology provided by an embodiment of the present invention; figure 2 It is a schematic flow diagram of obtaining real-time glue concentration in an LED production process optimization method based on big data technology provided by the embodiment of the present invention; image 3 It is a schematic flow diagram of dispensing abnormality alarm processing flow of a LED production process optimization method based on big data technology provided by an embodiment of the present invention. The three primary colors of RGB refer to the three basic colors that cannot be further decomposed in the color, namely red (R), green (G), and blue (B). Mixing these three colors in different proportions can make up most of the colors in nature. . According to the principle of RGB three primary colors mentioned above, any light can use red R (λ) , Green G (λ) , Blue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com