Patents

Literature

38results about How to "Improve shipment rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

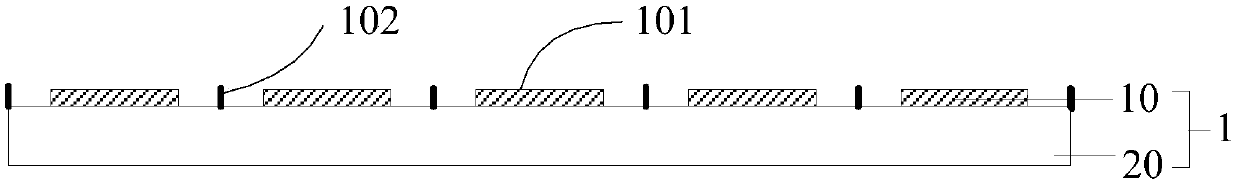

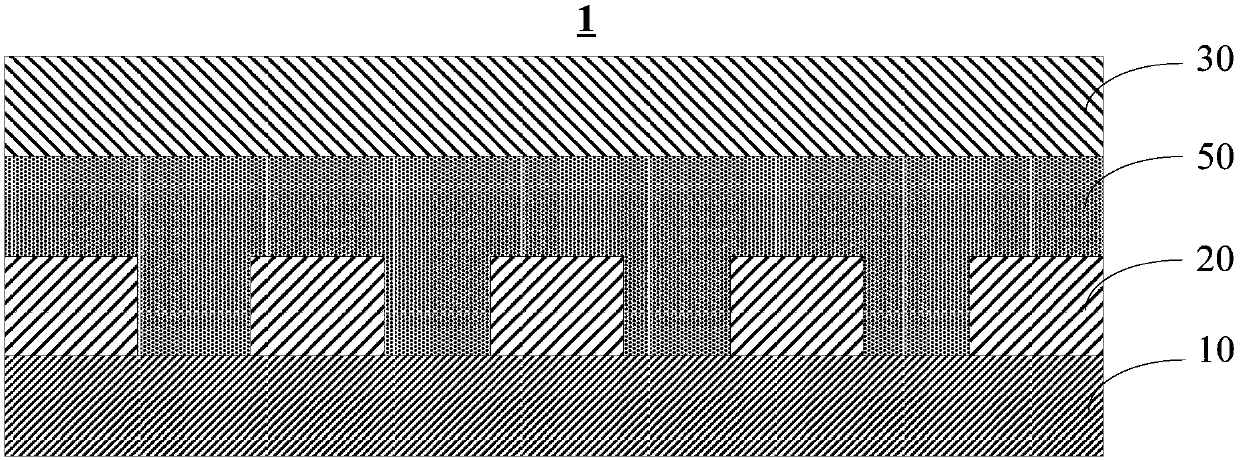

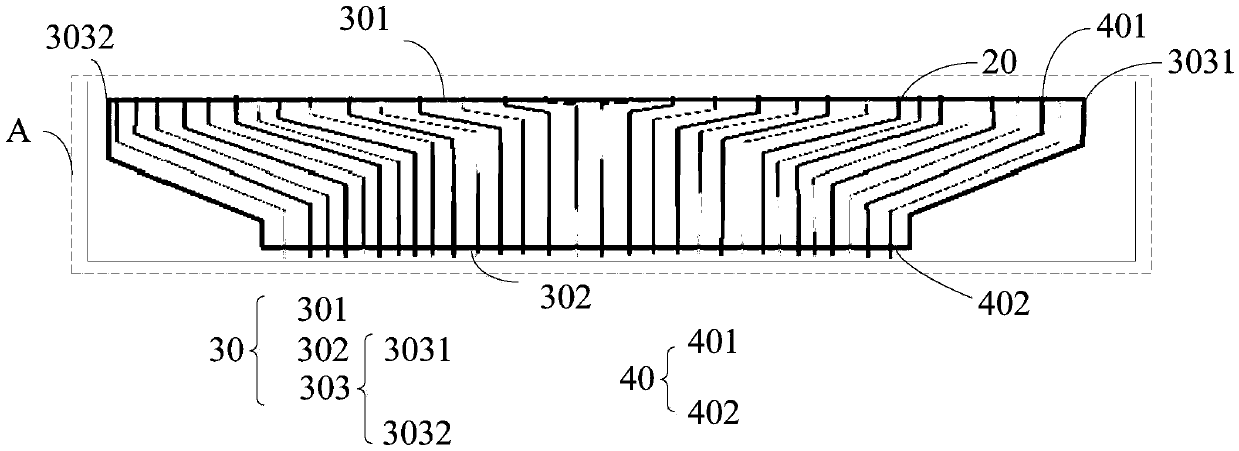

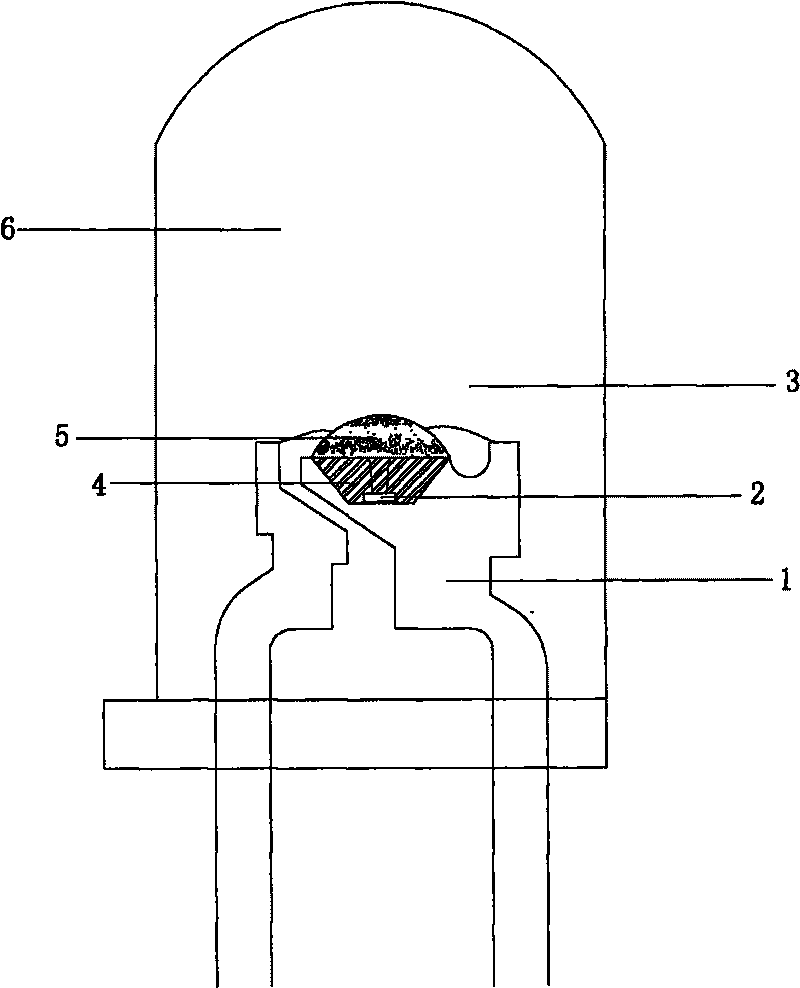

Optical source assembly structure of flip LED chip integrated package and manufacturing method thereof

ActiveCN105895785AImprove qualityHigh optical densitySolid-state devicesSemiconductor devicesElectricitySurface mounting

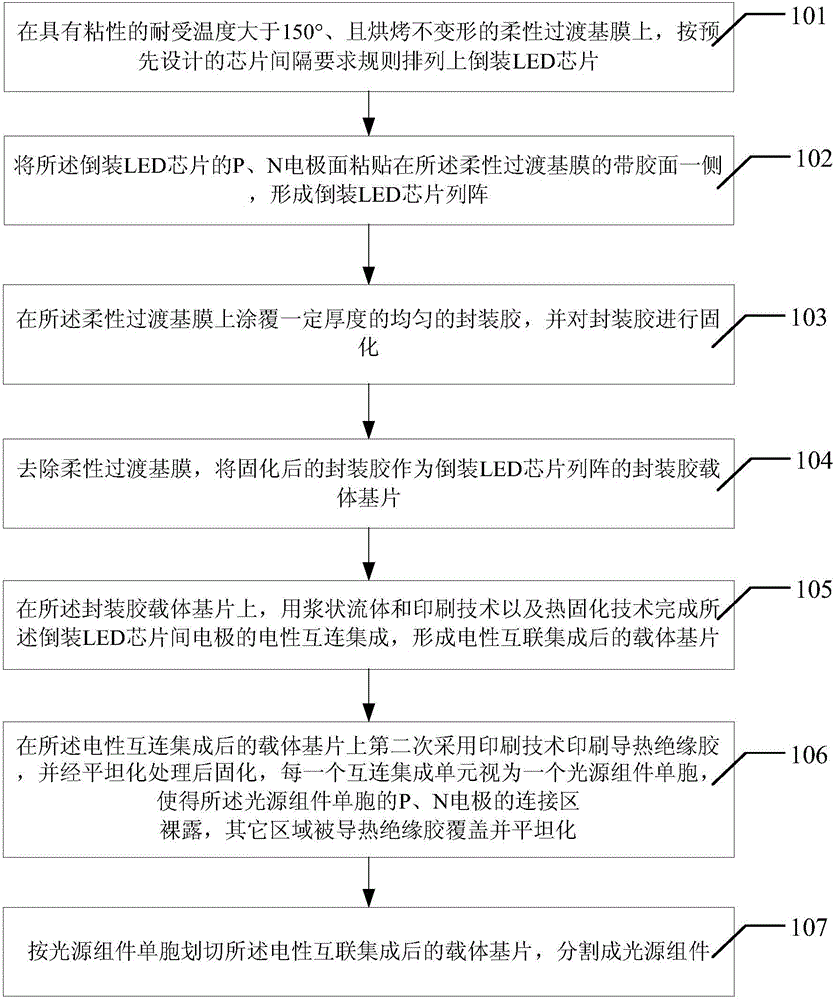

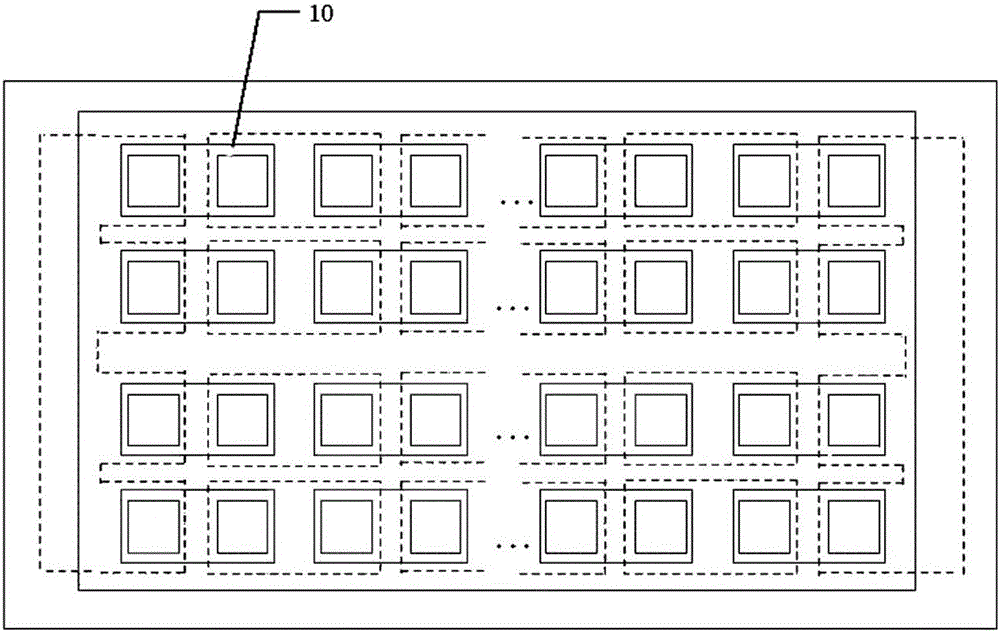

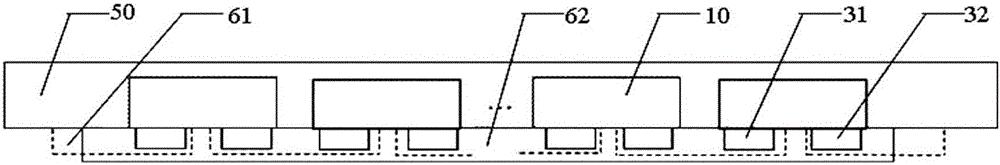

The invention discloses an optical source assembly structure of flip LED chip integrated package and a manufacturing method thereof. The method comprises the steps of arranging flip LED chips on a flexible transition base film to form a chip array; coating the base film uniformly with packaging glue to a certain thickness, and curing the packaging glue; removing the flexible transition base film, and using the cured packaging glue as a carrier substrate of the chip array; completing the electrical interconnect integration of electrodes among the chips on the packaging glue carrier substrate; printing and curing thermally conductive and insulation glue on the carrier substrate after electrical interconnect integration, to form various optical source assembly unit cells; and obtaining a separated optical source assembly in accordance with the various optical source assembly unit cells. The optical source assembly is bonded and assembled with a thermally conductive substrate to achieve electrical connection with an external circuit to be combined into an optical source. The method is free from the form of isolated chip interconnect integrated package on a COB board in the current packaging industry, eliminates the process steps of surface mounting and crystal curing and the like on the COB board, and simplifies the manufacturing process.

Owner:湖南省日晶照明科技有限责任公司

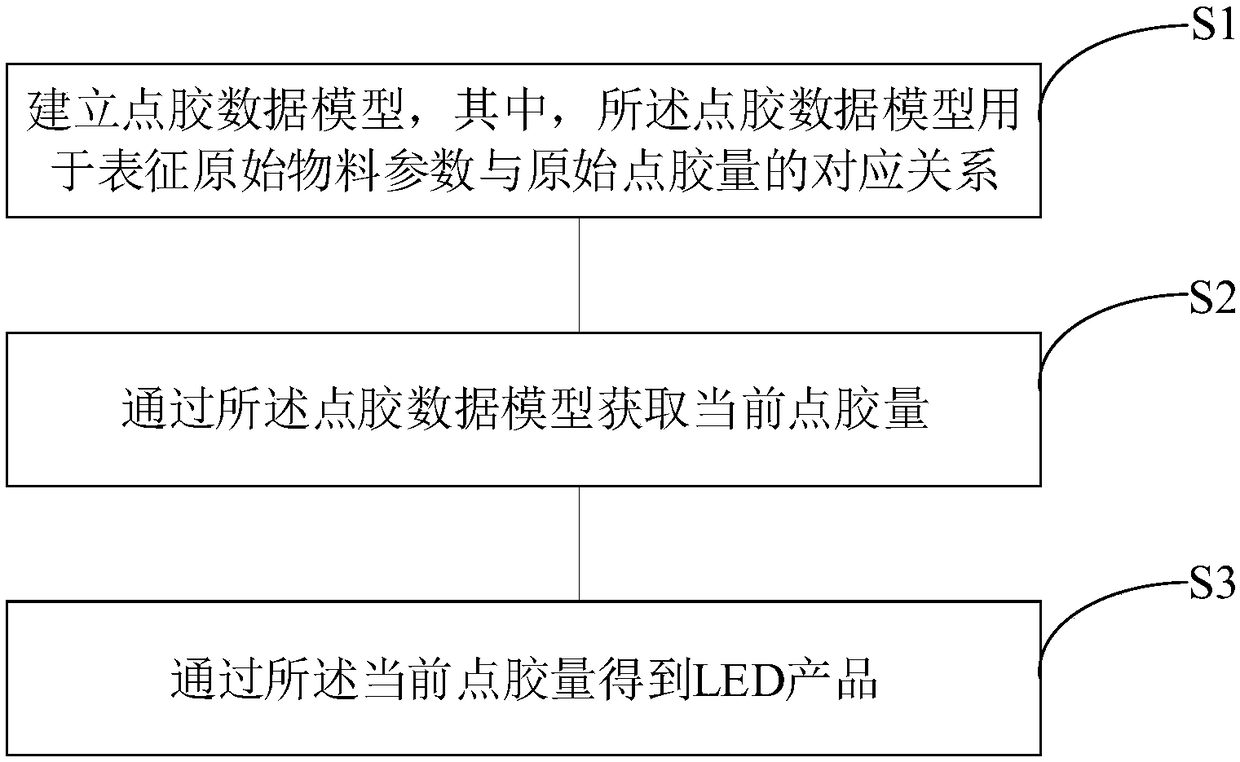

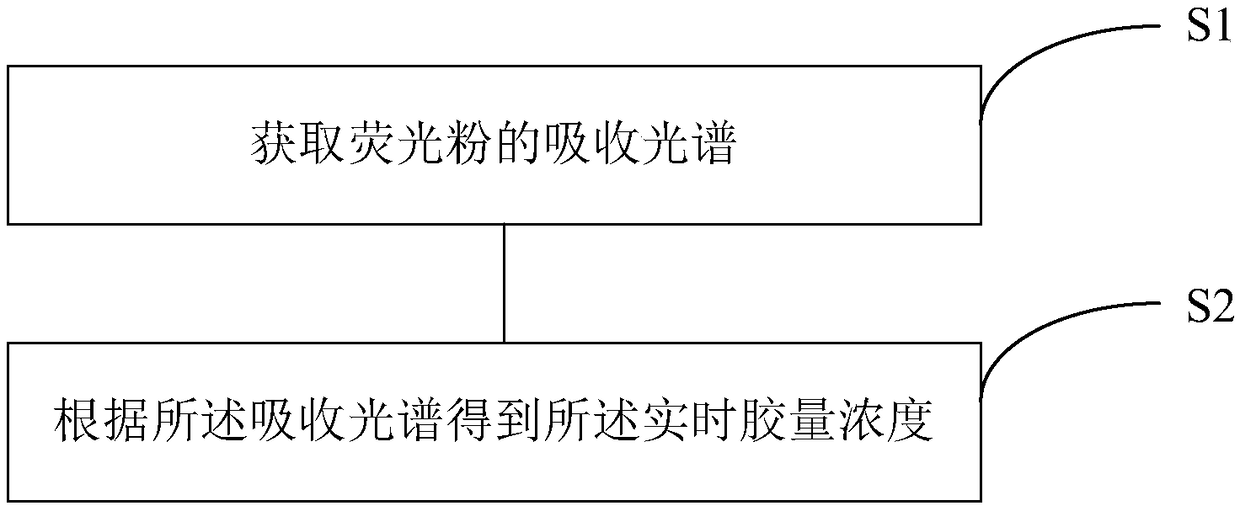

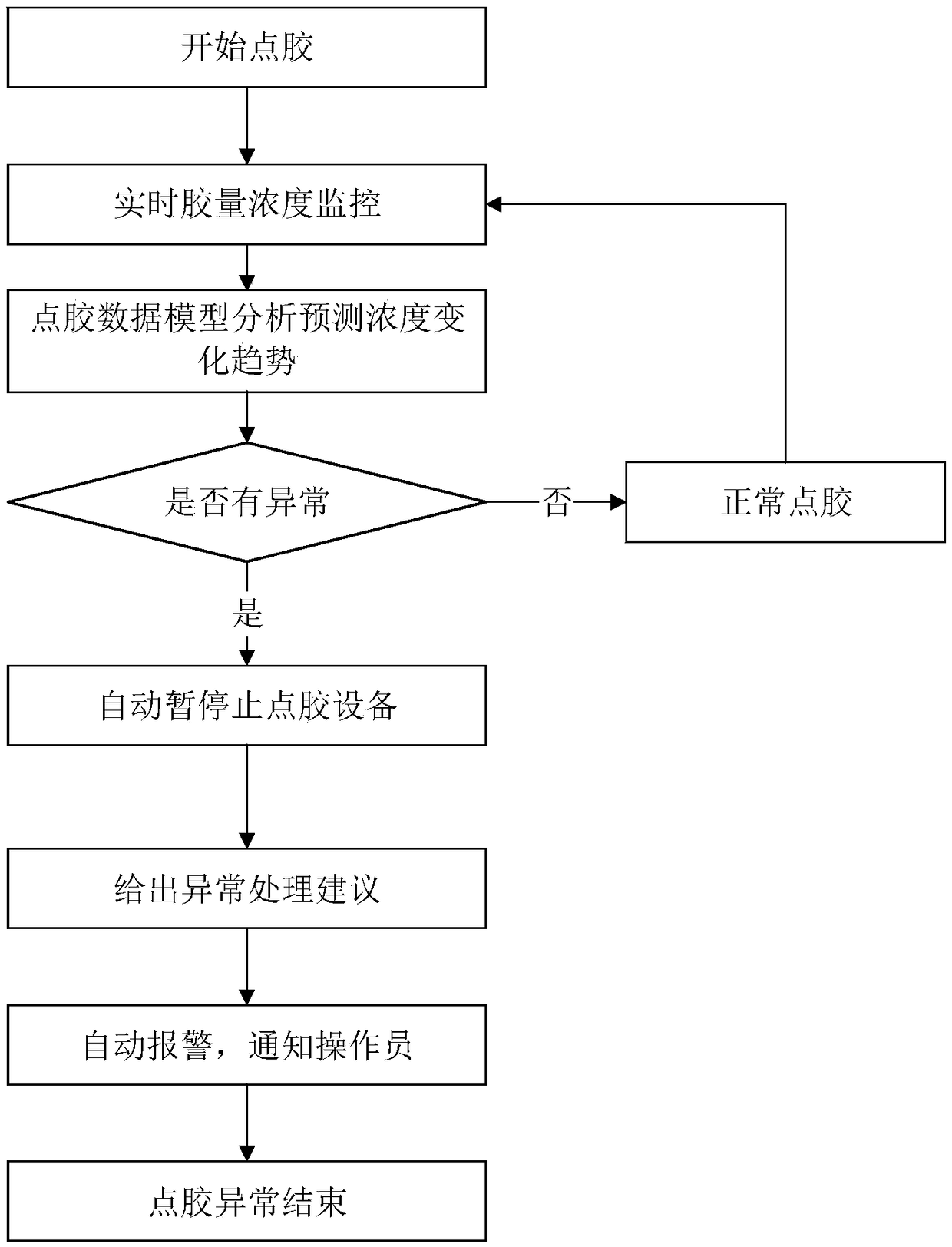

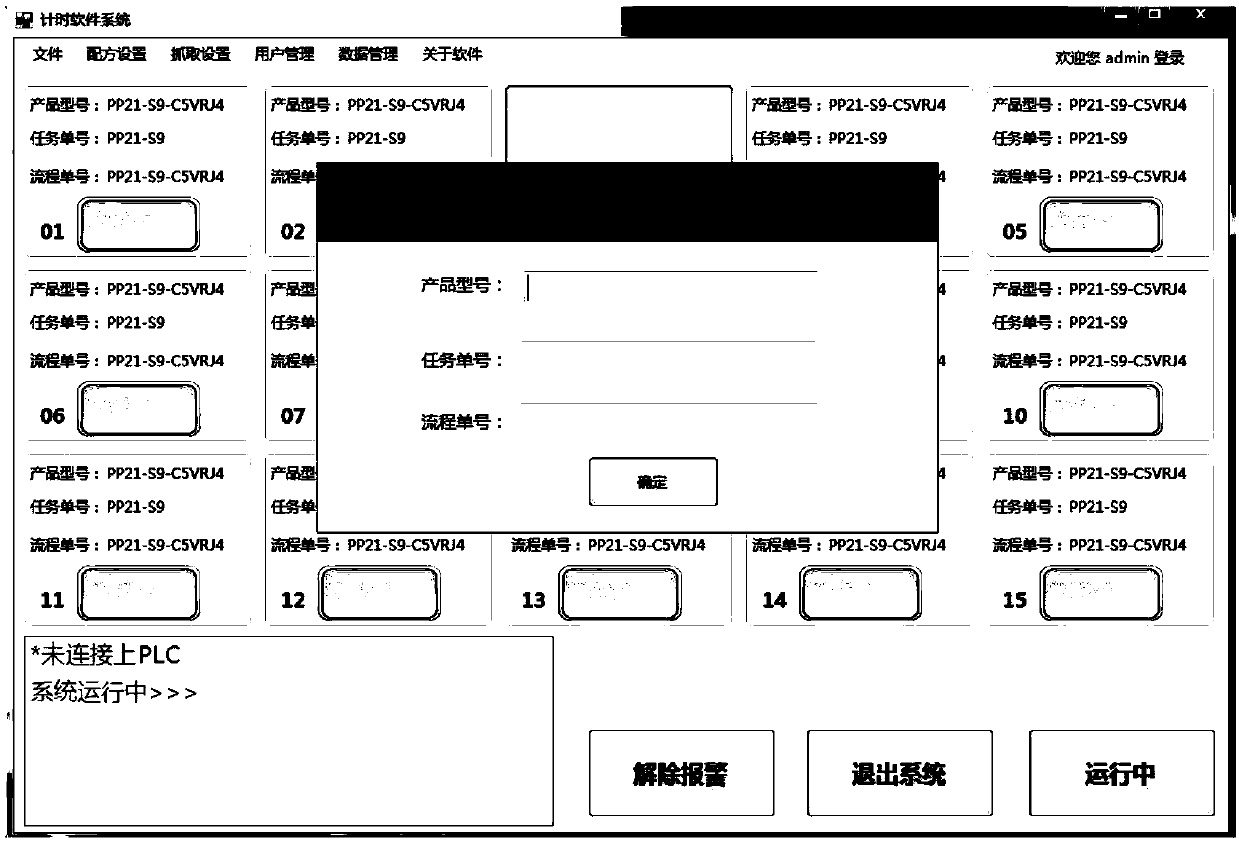

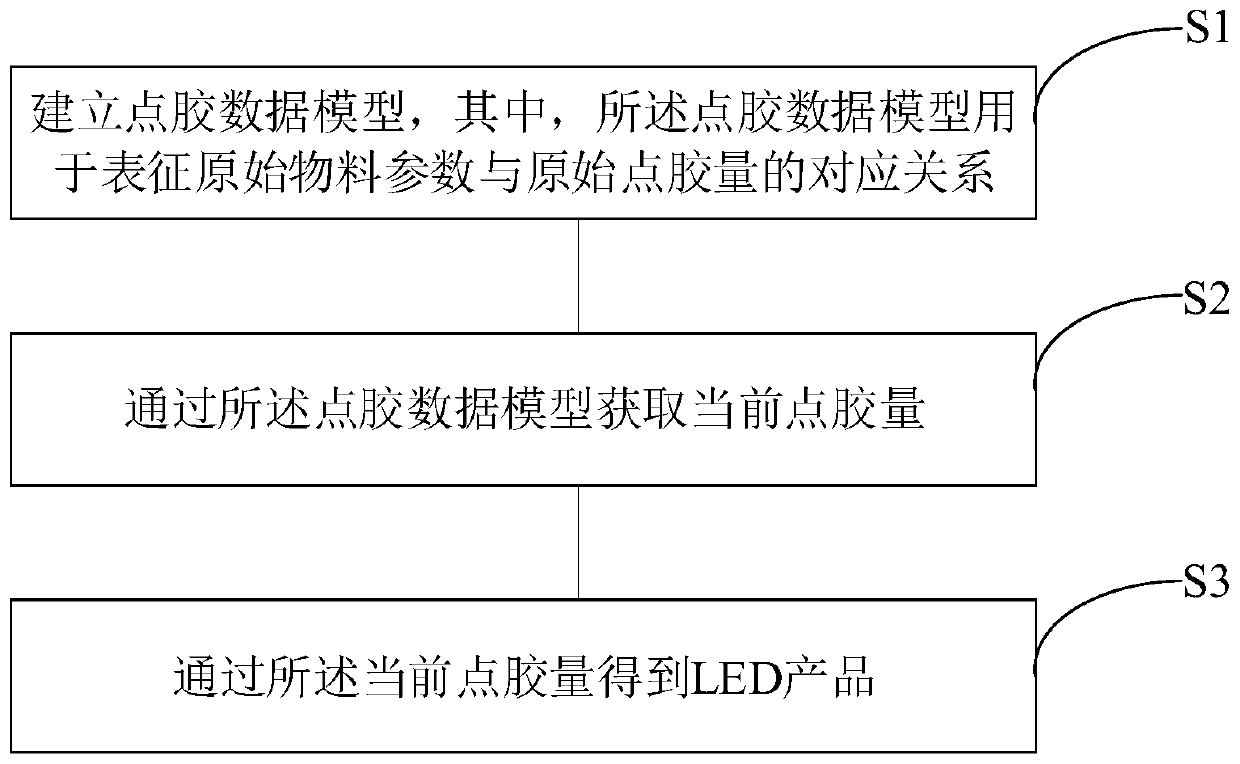

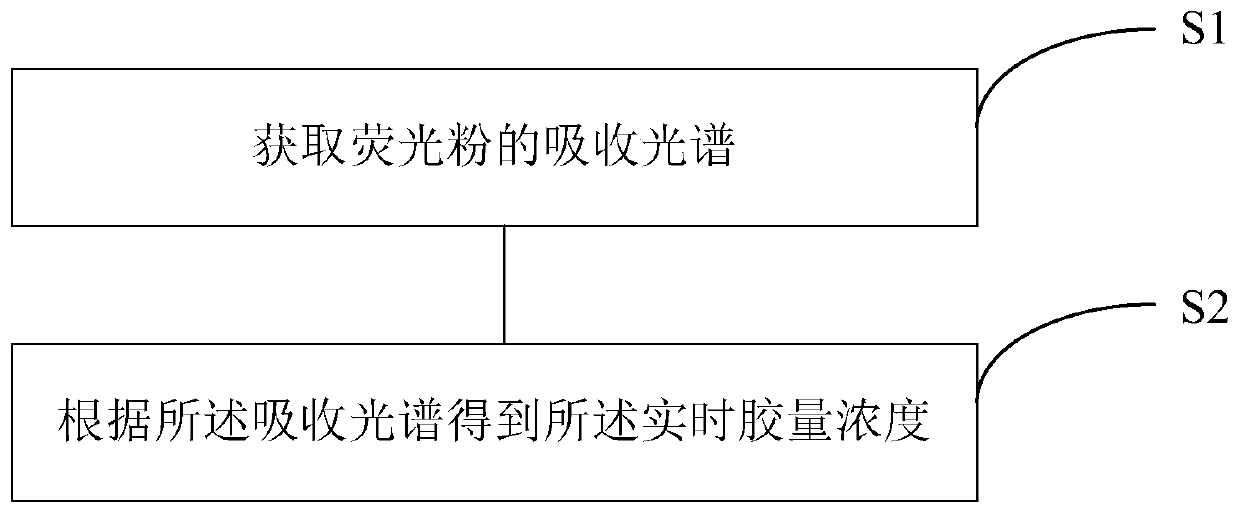

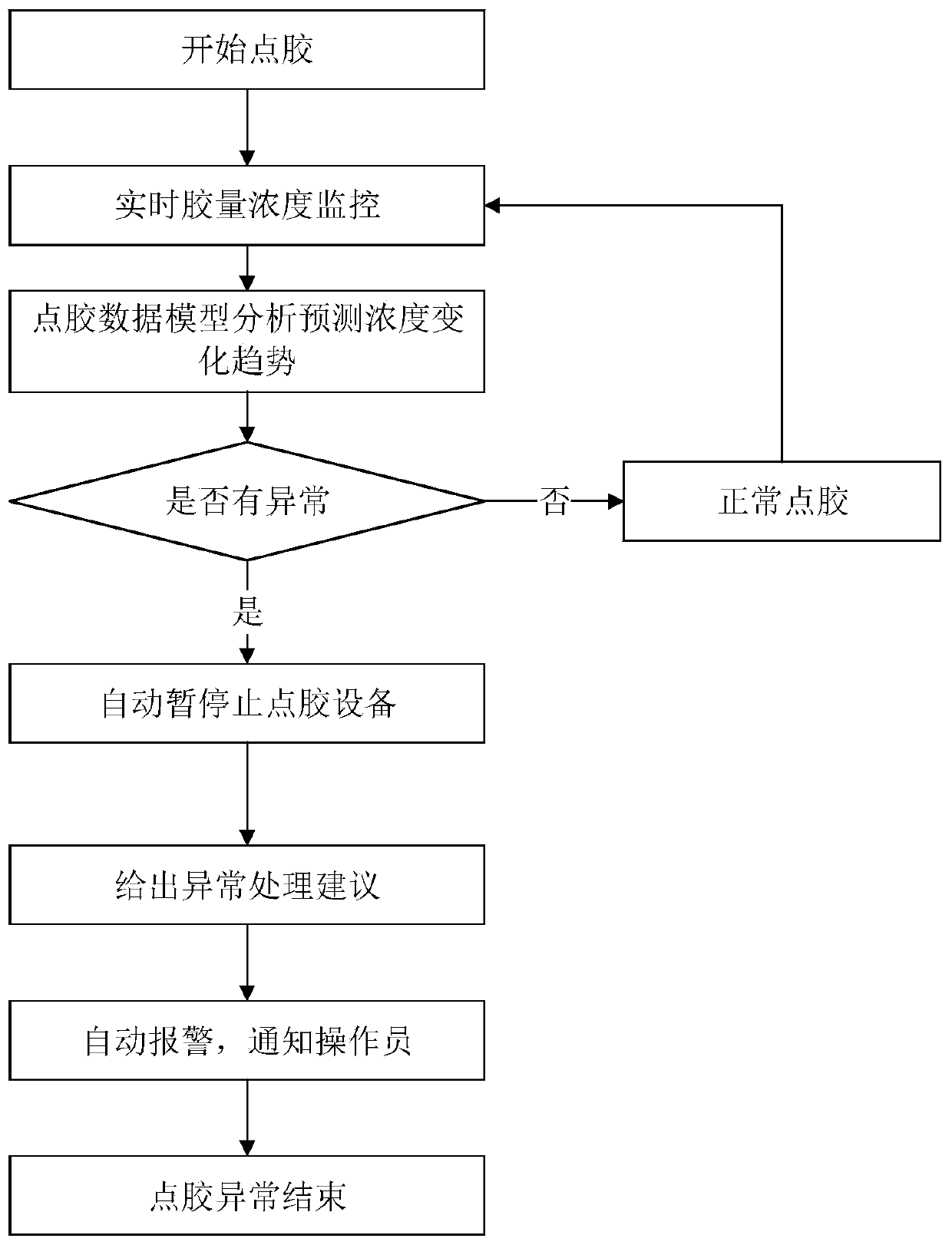

LED production process optimization method based on big data technology

ActiveCN108649106AReduce the influence of luminescence characteristicsConsistent level of luminescenceSemiconductor devicesProcess optimizationEngineering

The invention relates to an LED production process optimization method based on a big data technology, comprising the following steps: S1, establishing a dispensing data model, wherein, the dispensingdata model is used for representing the corresponding relationship between the original material parameters and the original dispensing amount; S2, obtaining the current dispensing amount through thedispensing data model; S3, obtaining the LED product by the current dispensing amount. The influence of fluorescent powder settling on LED products can be effectively reduced by the dispensing data model, and the luminous characteristics of the LED products can be kept consistent. The method can effectively improve the concentration degree of LED color coordinates and the falling Bin rate of themain color area in the mass production stage, improve the input-output ratio and productivity, increase the delivery rate and reduce the production cost. Through real-time monitoring the glue contentconcentration in the dispensing process, if the glue content concentration exceeds the threshold range or the on-line time exceeds the threshold range, timely detection and alarm increase the yield ofproducts and reduce abnormal losses.

Owner:浙江云科智造科技有限公司

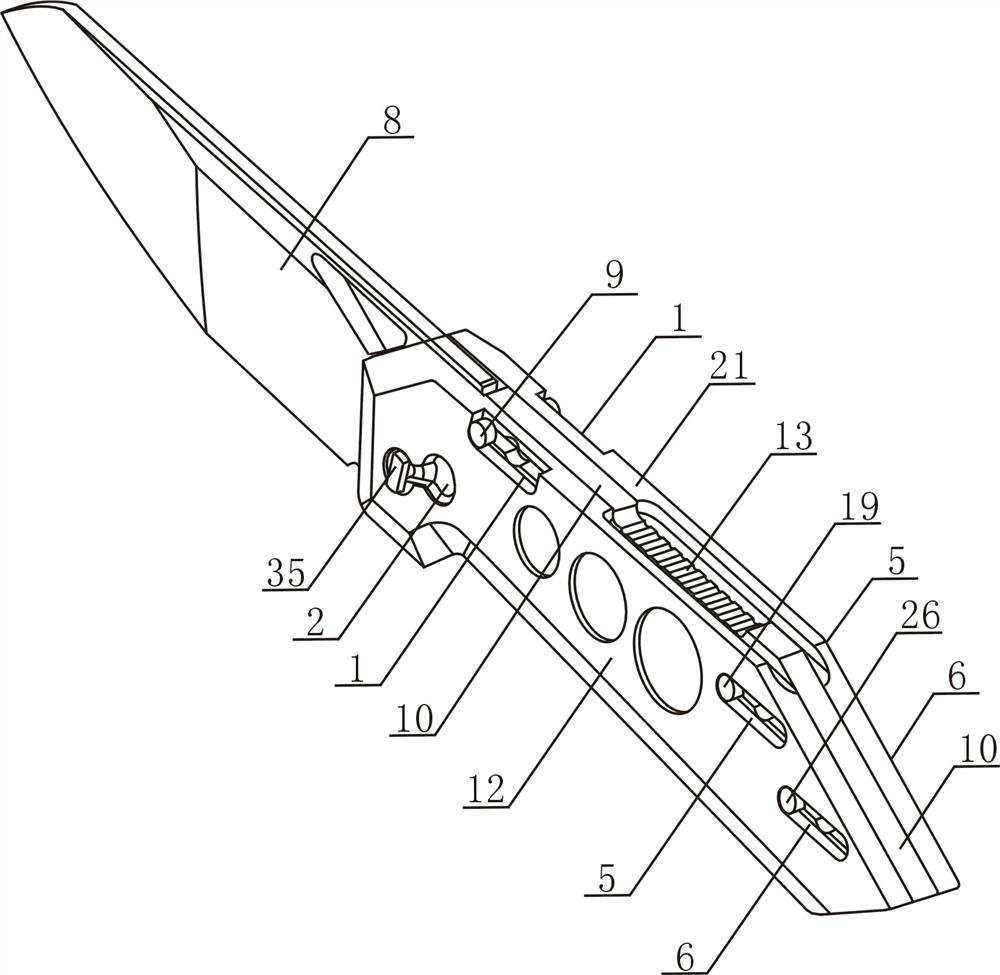

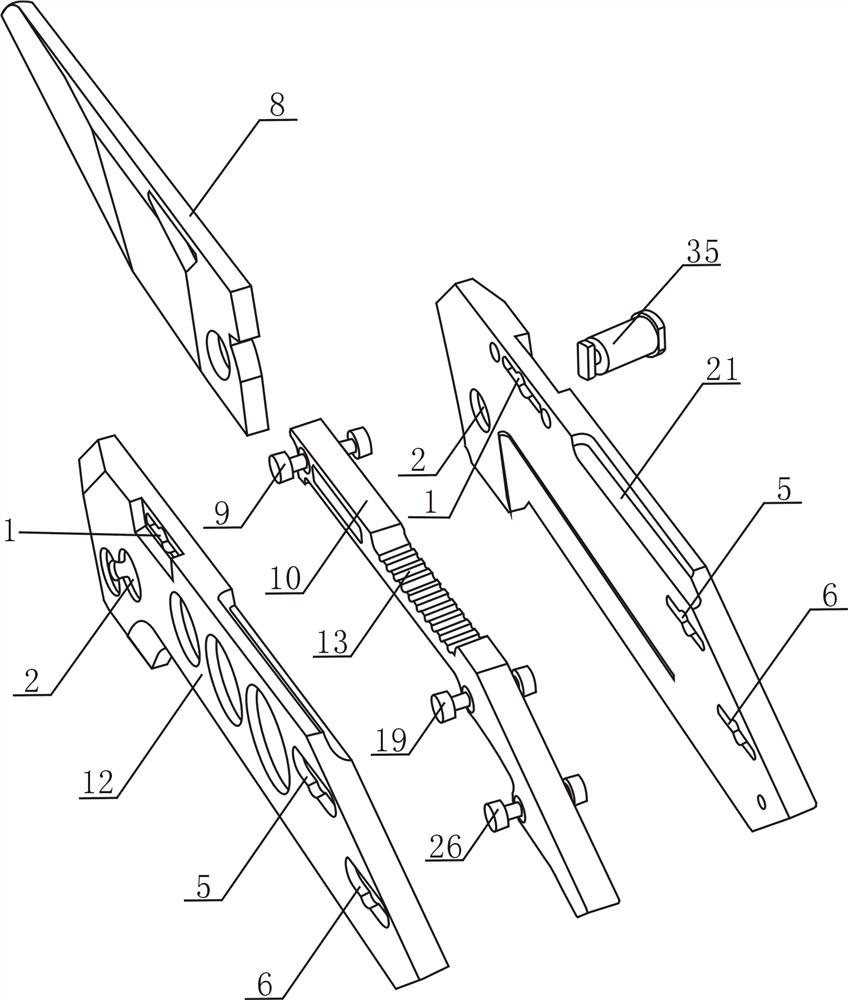

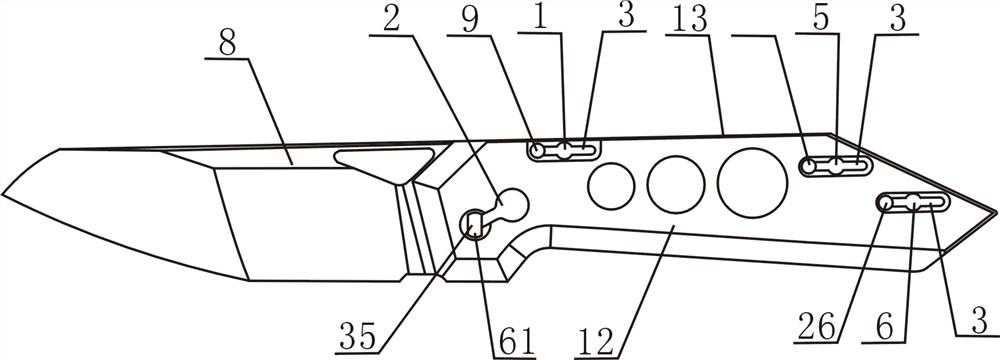

Folding knife fastened without thread or screw

PendingCN112265018ASimple structureEasy to operateMetal working apparatusStructural engineeringKnife blades

The invention provides a folding knife fastened without a thread or screw. The folding knife comprises a blade, a bottom rib, a left handle piece and a right handle piece, the left handle piece and the right handle piece are arranged at the two sides of the bottom rib, first lock catch holes, second lock catch holes, third lock catch holes and main shaft holes are correspondingly formed in the left handle piece and the right handle piece, and a first lock piece, a second lock piece and a third lock piece are fixedly arranged on the bottom rib. The first lock piece, the second lock piece and the third lock piece are each provided with a second convex shaft, a third convex shaft and a second concave shaft, the second convex shafts are fixedly connected with the bottom rib, and the third convex shafts and the second concave shafts protrude out of the two sides of the bottom rib and are buckled in the first lock catch holes, the second lock catch holes and the third lock catch holes to move front and back, and the aim of assembling or disassembling the folding knife is achieved. By the adoption of the structure, the first lock piece, the second lock piece and the third lock piece are effectively used for replacing the inconvenience that a folding knife is fixed through screws and threads in the prior art, all parts of the folding knife can be detached by hands to be cleaned, detaching and assembling are easy, a beginner and an experienced man both can operate the folding knife, the delivery rate is effectively increased, machining cost is reduced, and practicability is high.

Owner:广东科赛普科技有限公司

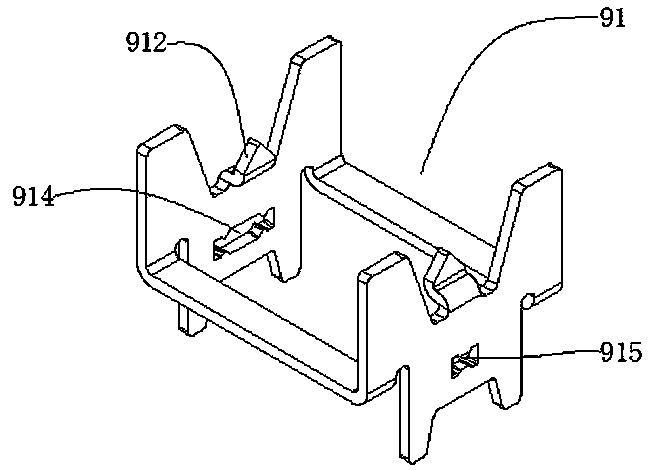

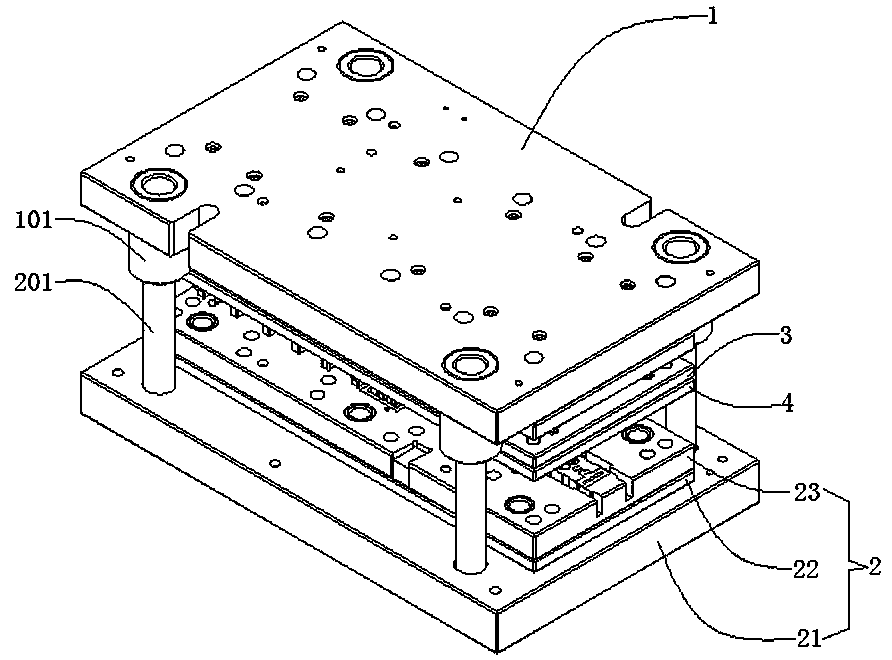

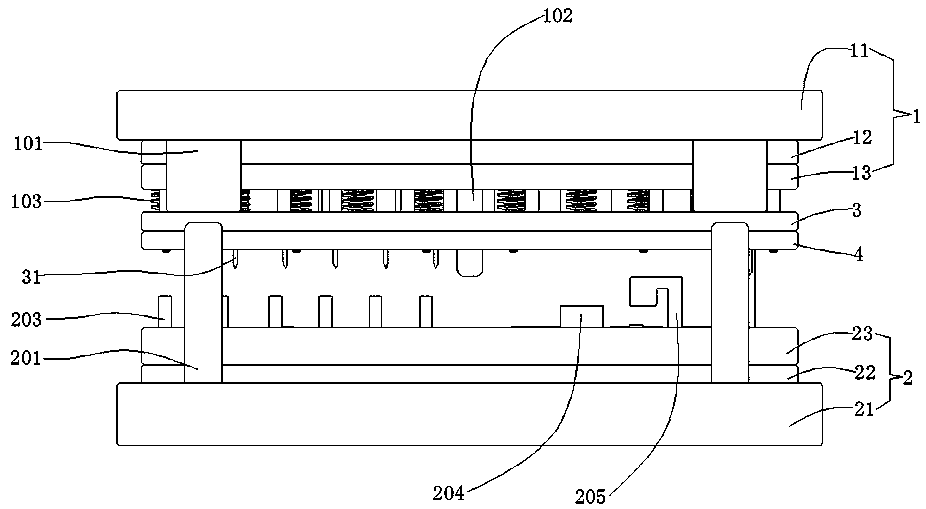

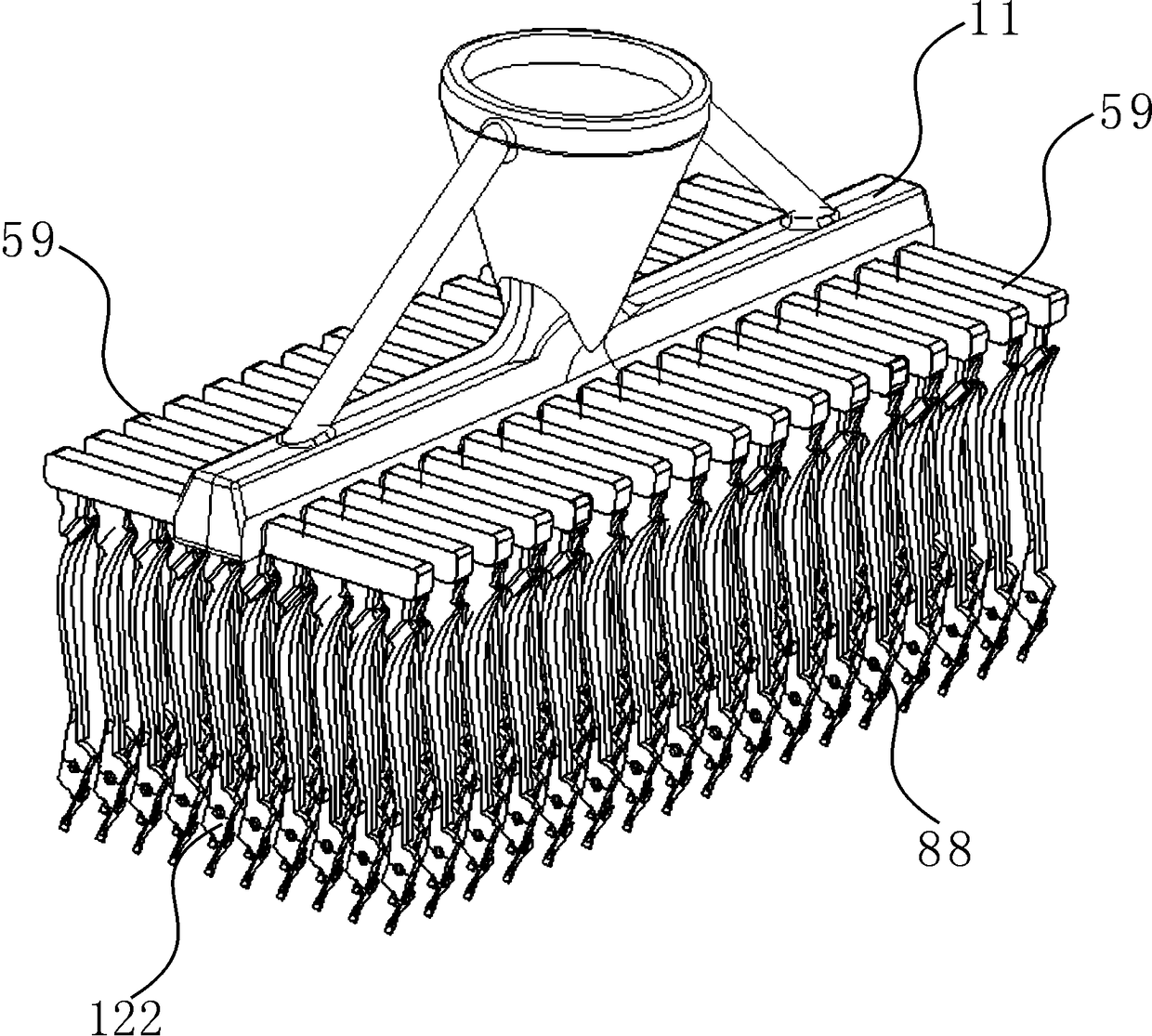

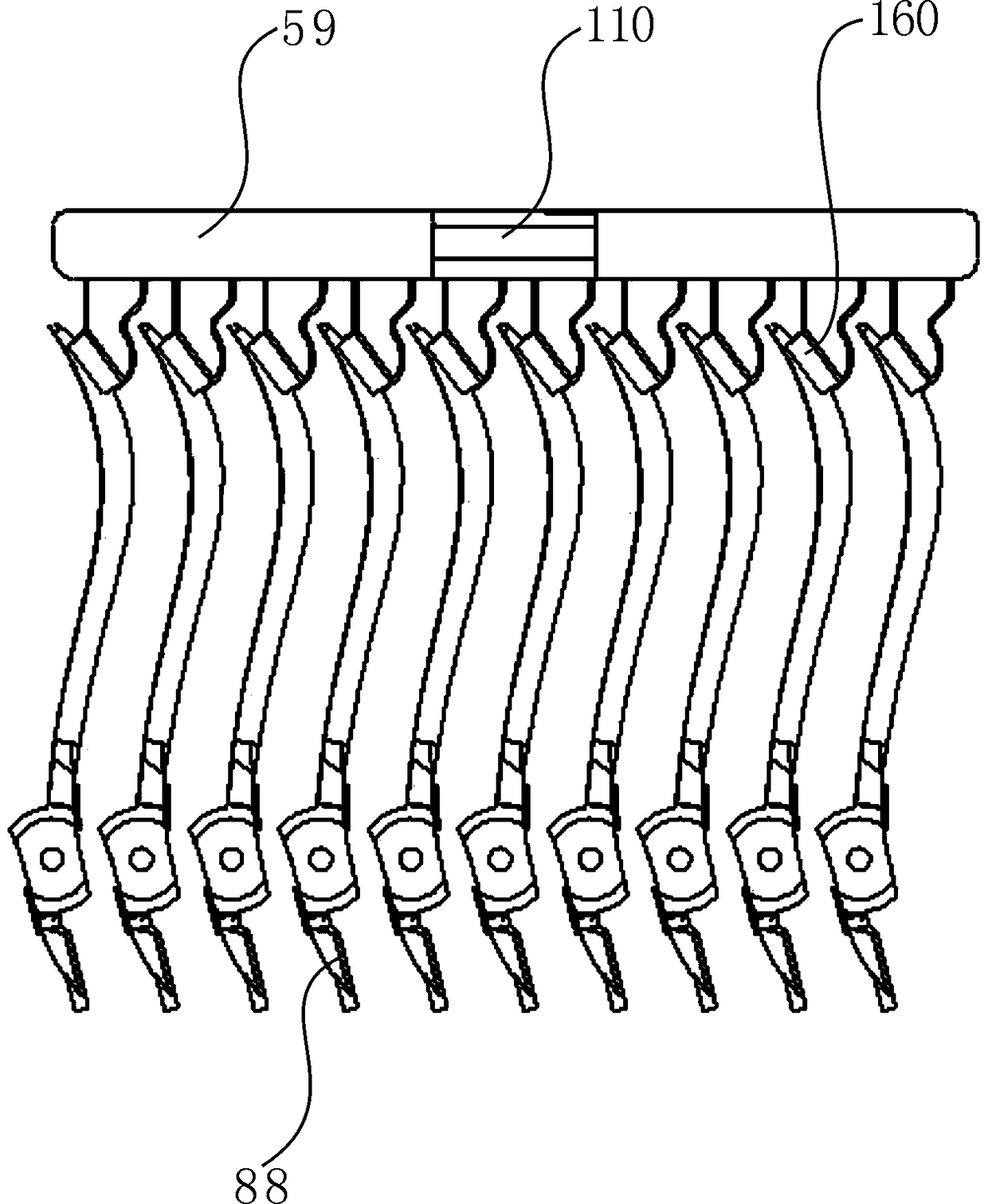

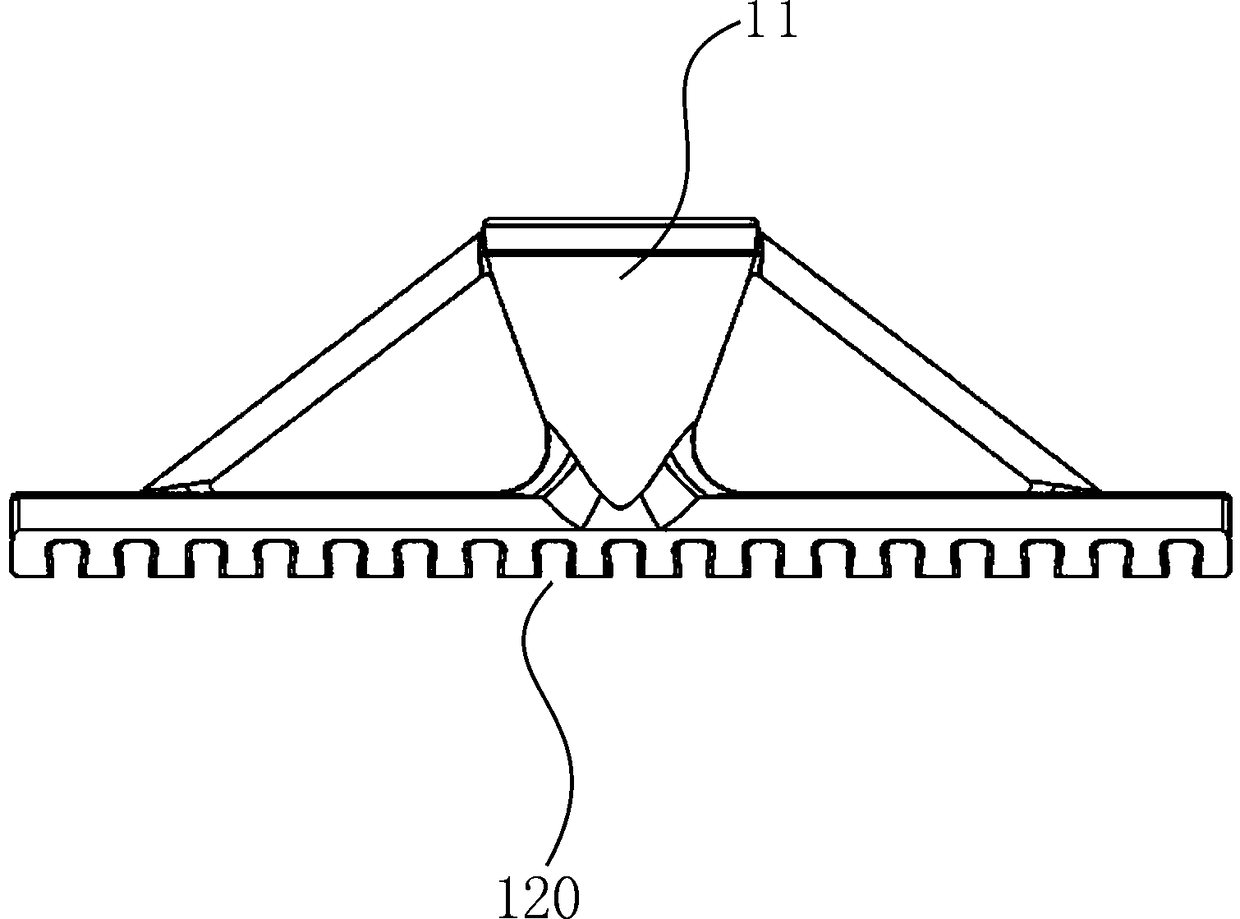

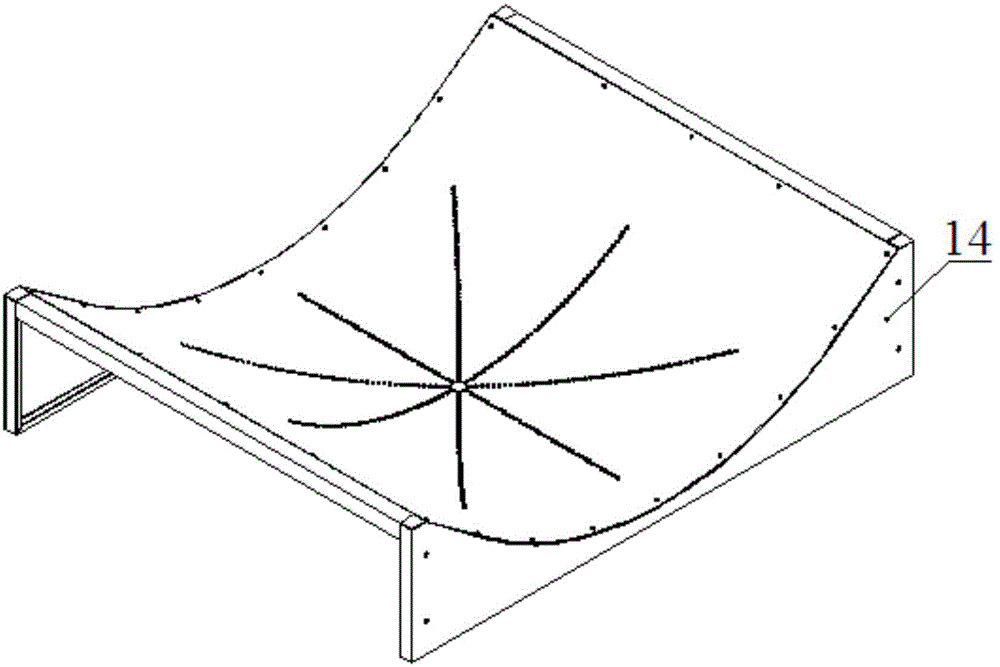

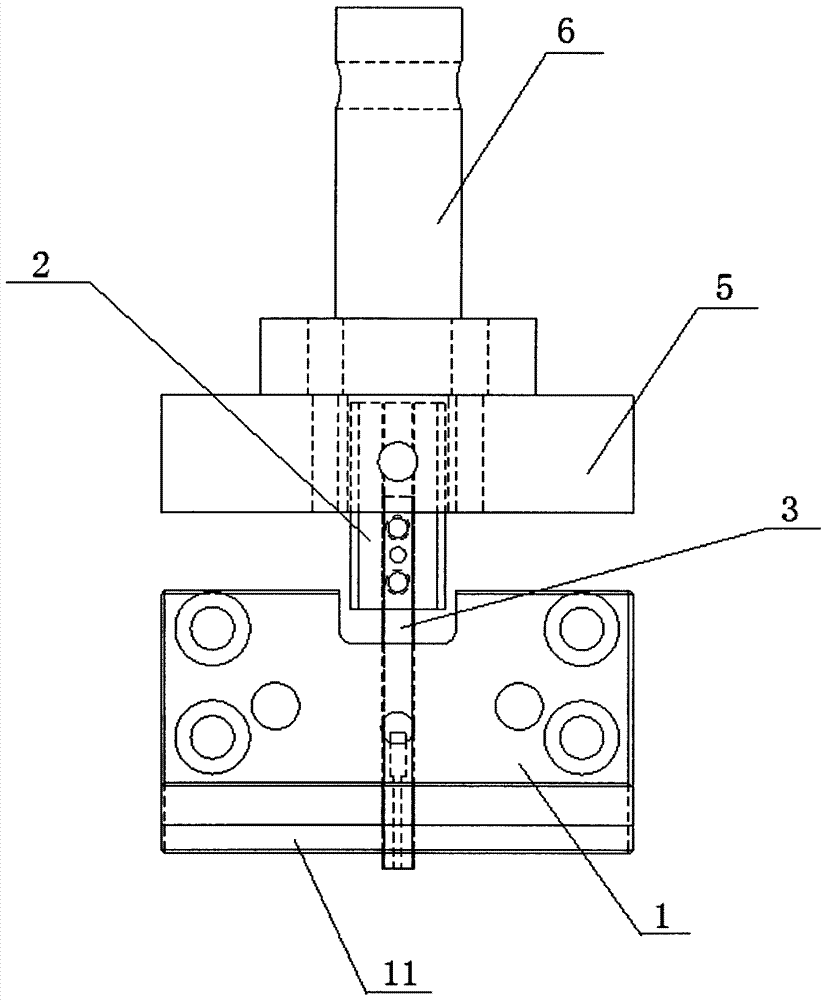

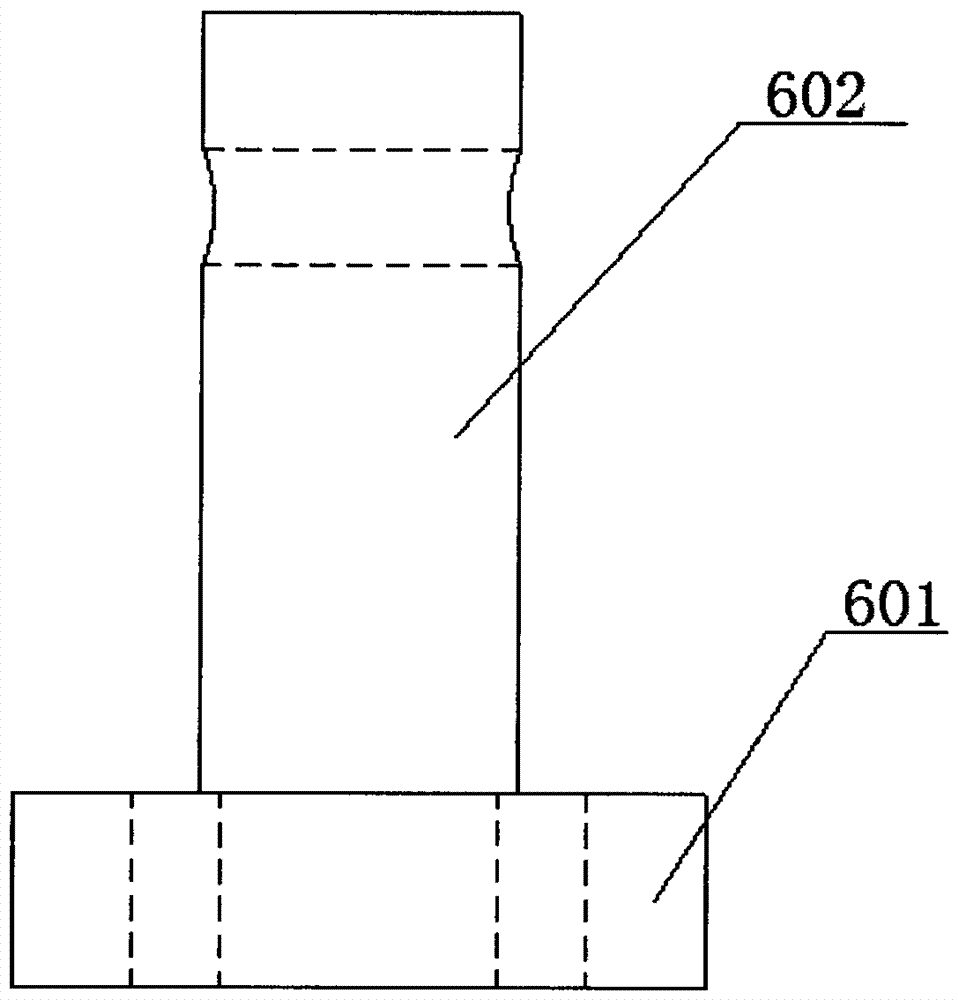

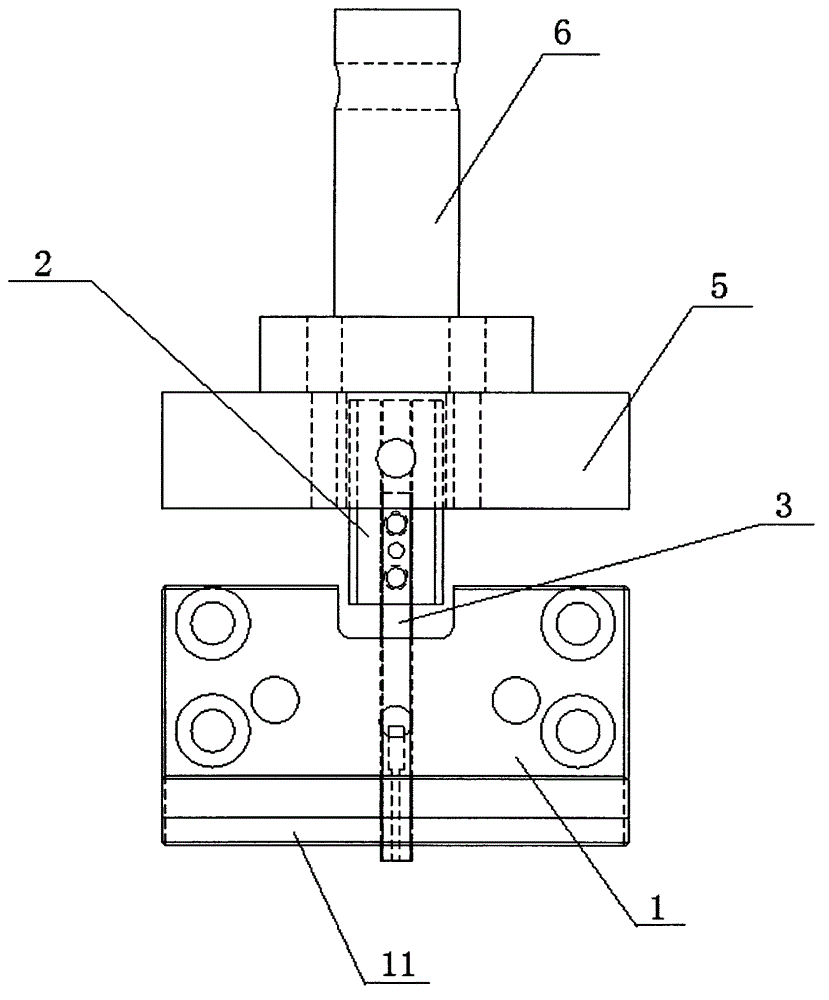

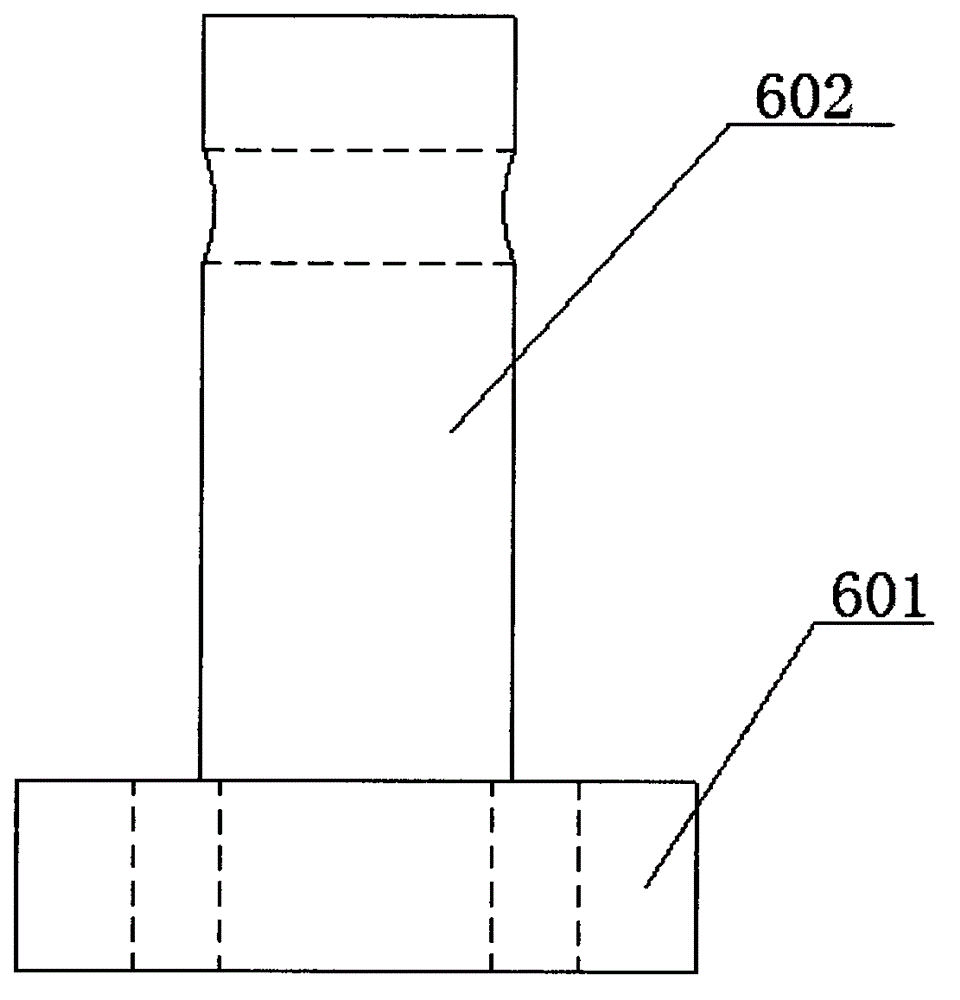

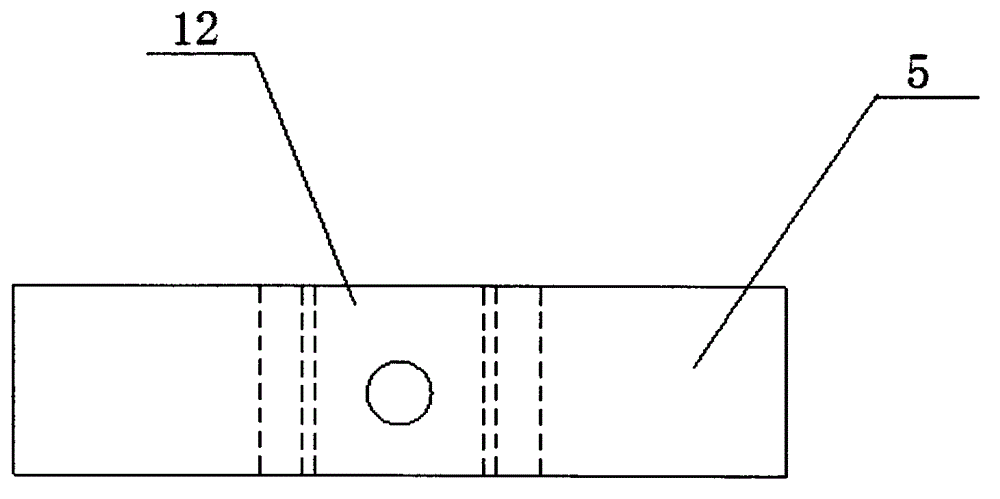

Contact supporting base forming tool

PendingCN107685107AIncrease productivityImprove shipment rateShaping toolsMetal-working feeding devicesPunch pressStructural engineering

The invention discloses a contact supporting base forming tool. The forming tool comprises an upper die holder, a stop plate, a stripper plate and a lower die holder, wherein the upper die holder is arranged on a punch press, a plurality of outer guide columns are fixed to the periphery of the upper surface of the lower die holder, and a plurality of outer guide column sleeves are fixedly arrangedon the relative positions of the upper die holder; the outer guide columns are in sliding fit with the outer guide column sleeves. A plurality of inner guide columns are fixedly arranged on the lowerportion of the upper die holder, and inner guide column holes matched with the inner guide columns are formed in the relative positions of the lower die holder; through holes allowing the inner guidecolumns to penetrate through are formed in the stop plate and the stripper plate respectively, and a plurality of sets of springs are vertically arranged between the stop plate and the upper die holder. A plurality of sets of punches are arranged below the upper die holder, and a plurality of sets of female dies matched with the sets of punches are arranged on the relative positions of the lowerdie holder. The forming tool has the advantages that the contact supporting base forming tool capable of achieving continuous discharging is provided, the production efficiency is high, the delivery rate is greatly increased, and the production cost is also reduced.

Owner:XIAMEN RONGXINDA IND

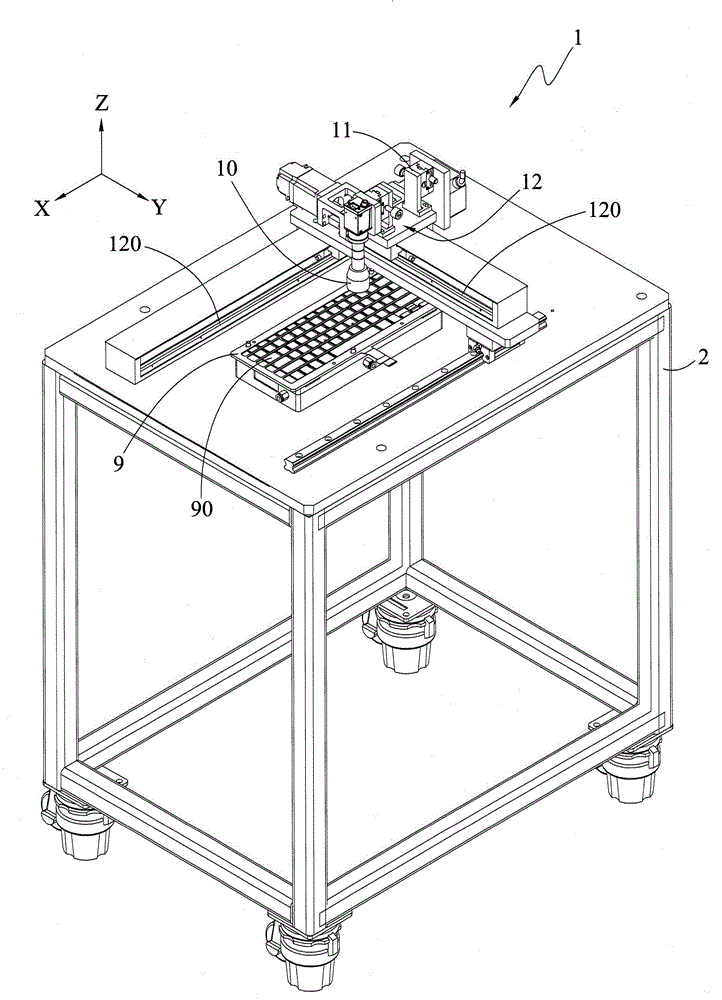

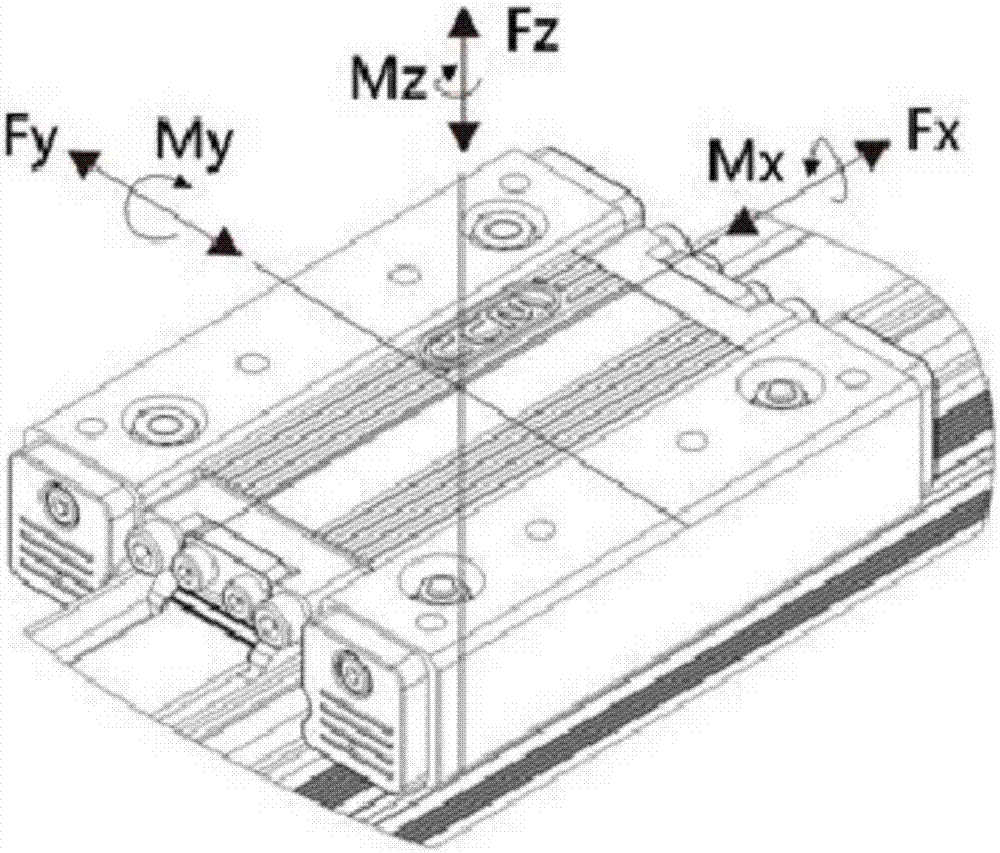

Keyboard detection equipment and detection method thereof

InactiveCN104792266ASave measurement time and labor costsImprove efficiencyUsing optical meansIncline measurementTesting equipmentEngineering

A piece of keyboard detection equipment and a detection method thereof are provided. The keyboard detection equipment comprises a laser device and a displacement control device. According to the detection method, a keyboard with a plurality of keys is provided first, then, the laser device is moved by the displacement control device to make the laser device in a moving state, and the height and inclination of the keys are detected at the same time. Thus, the measurement time is saved, and the overall efficiency of keyboard detection is effectively enhanced.

Owner:香港斯讬克股份有限公司

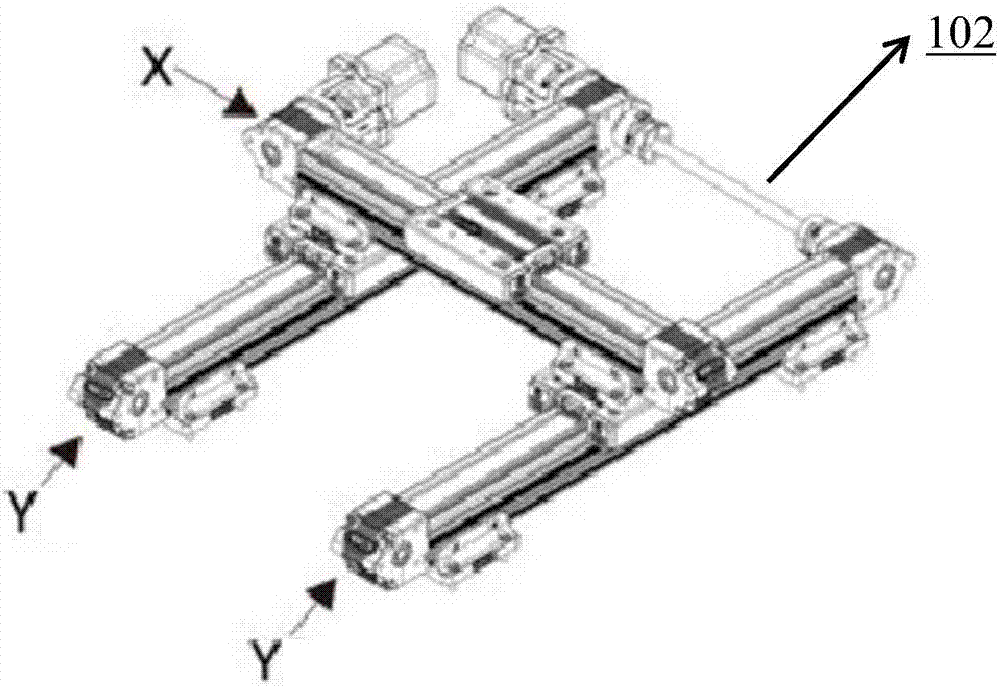

Novel vending machine based on manipulator

ActiveCN107393157AImprove performanceQuick responseCoin-freed apparatus detailsApparatus for dispensing discrete articlesRobotic armMiniaturization

The invention discloses a novel vending machine based on a manipulator. The novel vending machine comprises a goods storage container, a manipulator assembly and a transversely and longitudinally synchronous sliding table assembly; the goods storage container is of a matrix structure and comprises goods channels for storing goods, and each goods channel is in the vertical direction; a goods outlet for conveying the goods out is formed in the goods storage container; the manipulator assembly is located above the goods storage container and comprises a mechanical arm and a mechanical hand; the mechanical hand is connected to the lower portion of the mechanical arm; the transversely and longitudinally synchronous sliding table assembly is connected with the mechanical arm and moves to make the mechanical hand positioned above any one of the goods channels of the goods storage container, and the mechanical arm drives the mechanical hand to grab the goods in the goods channel. The novel vending machine based on the manipulator has the function of automatically identifying the goods, all physical parameters can be adjusted, and the usage range is widened; the purposes of miniaturization, multi-function and low power consumption can be achieved; meanwhile, vertical storage is achieved, goods feeding is conducted conveniently, the plot ratio is increased, and the goods discharging rate can be increased.

Owner:SHANGHAI MARITIME UNIVERSITY

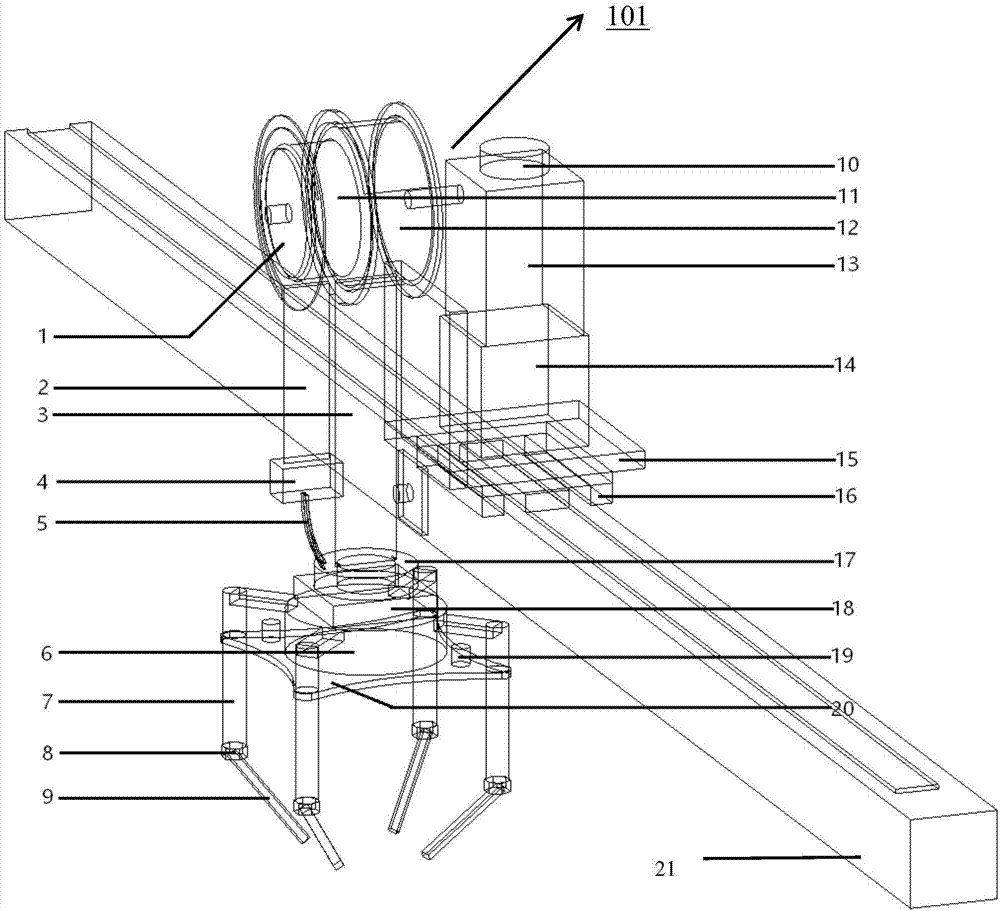

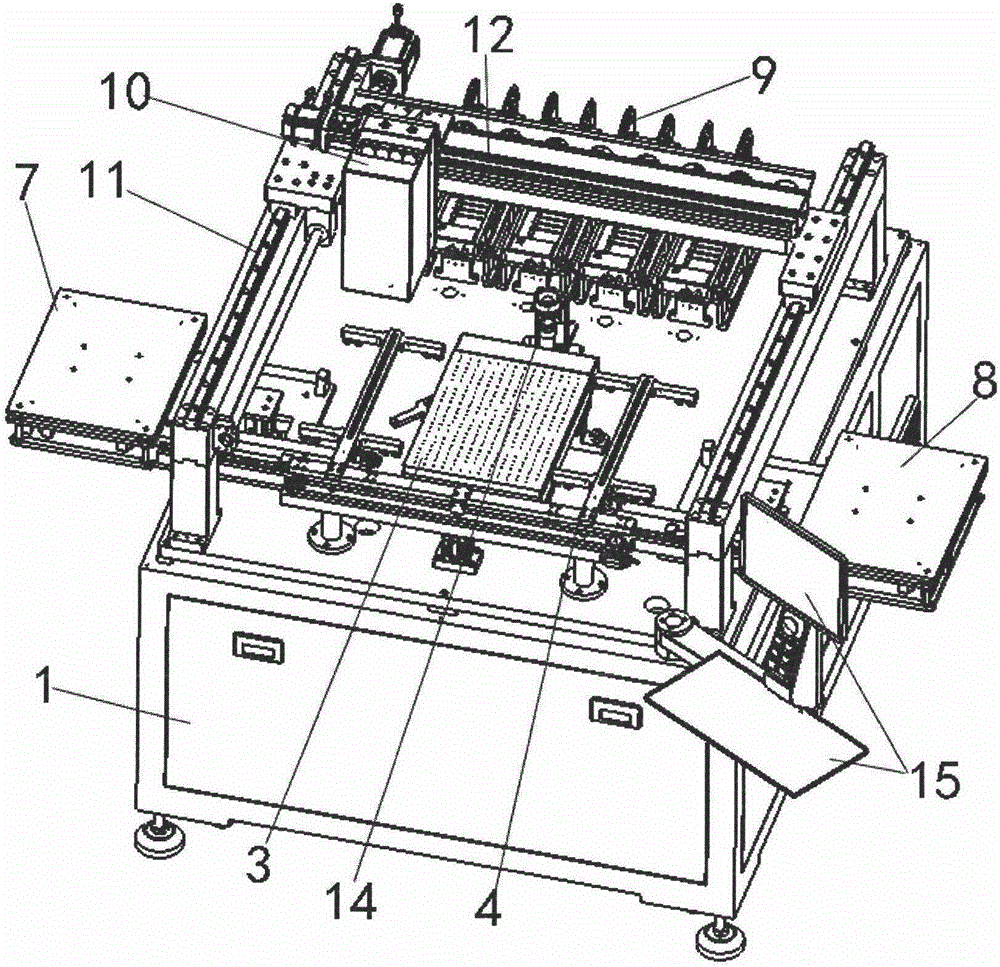

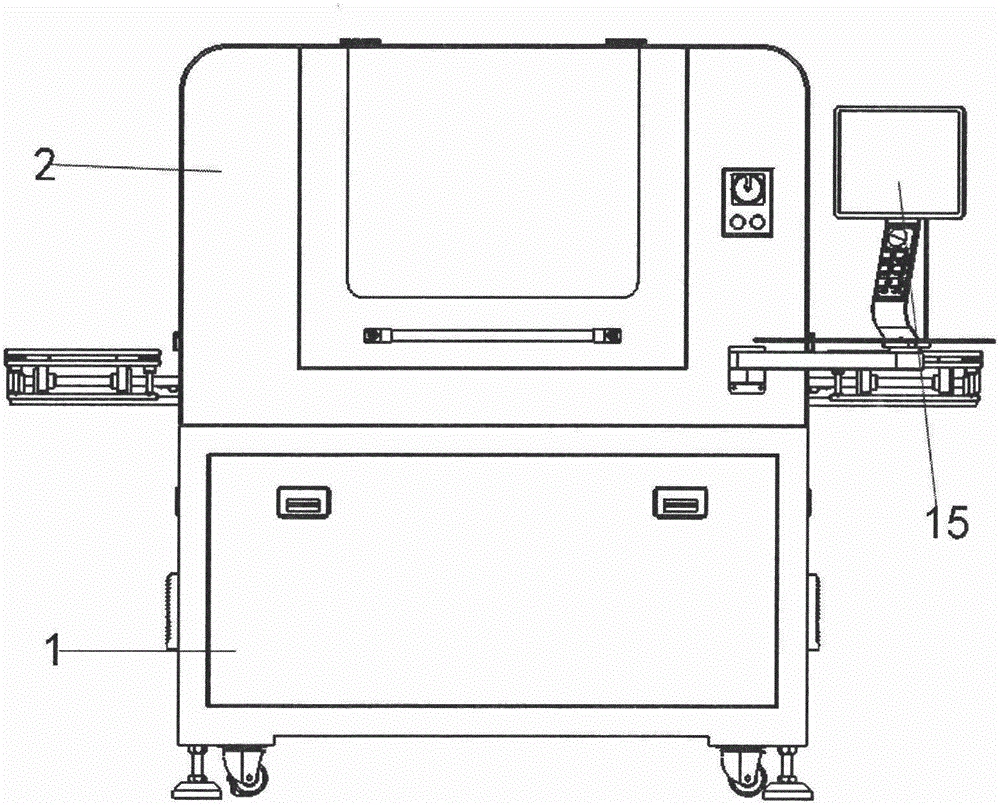

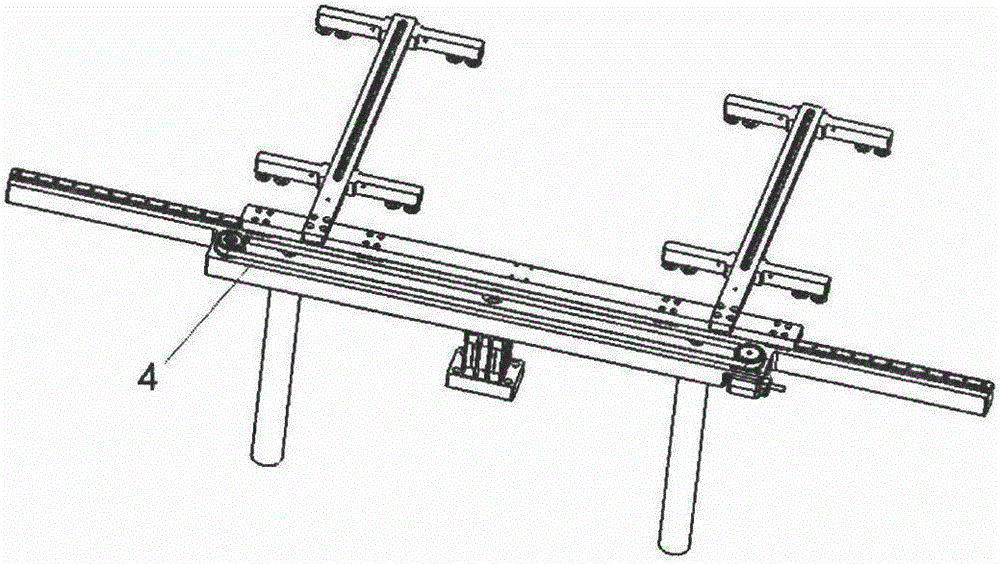

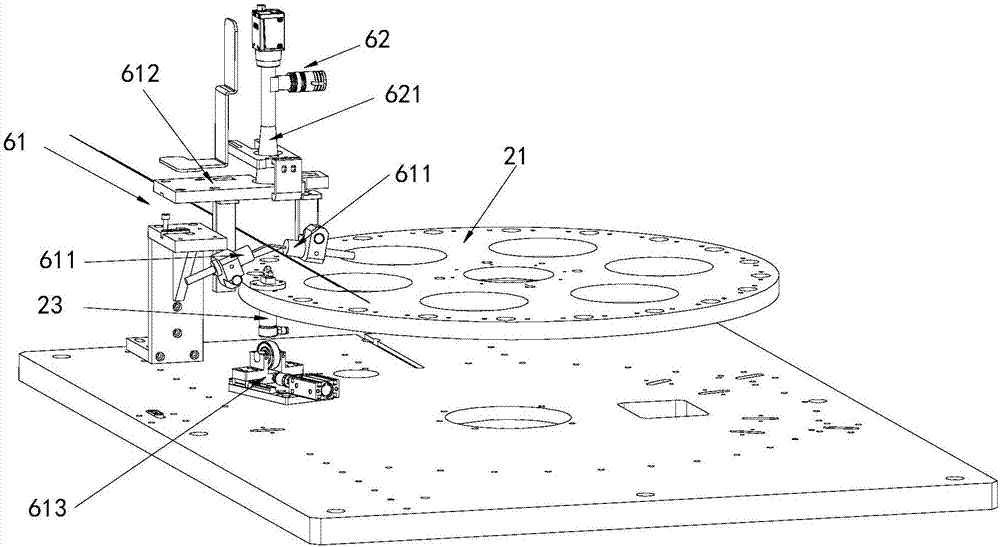

Automatic reinforcing machine

PendingCN106358368ARealize automated productionAccurate positioningPrinted circuit manufactureEngineeringWorkbench

The invention discloses an automatic reinforcing machine. The automatic reinforcing machine comprises a lower engine base; an upper engine shell; a workbench; a first horizontal traversing mechanism; at least one absorbing mechanism; a second horizontal traversing mechanism; a feeding tray; a third horizontal traversing mechanism; a discharging tray; at least one reinforcing material stripping mechanism; the reinforcing material installing mechanism comprises a moving mechanism, a reinforcing material pasting mechanism and a first image vision module; the automatic reinforcing machine further comprises a second image vision module. According to the automatic reinforcing machine, the automatic production can be combined with manual monitoring into one, and the reinforcing material can be accurately positioned and pasted on the reinforcing object; thus the automatic reinforcing machine effectively avoids the offset of the reinforcing material; the discharge and feeding are carried out at the same time, thus the processing time is saved and processing efficiency is improved; the floor area is greatly reduced and space is saved.

Owner:LENSEND AUTOMATION TECH SUZHOU

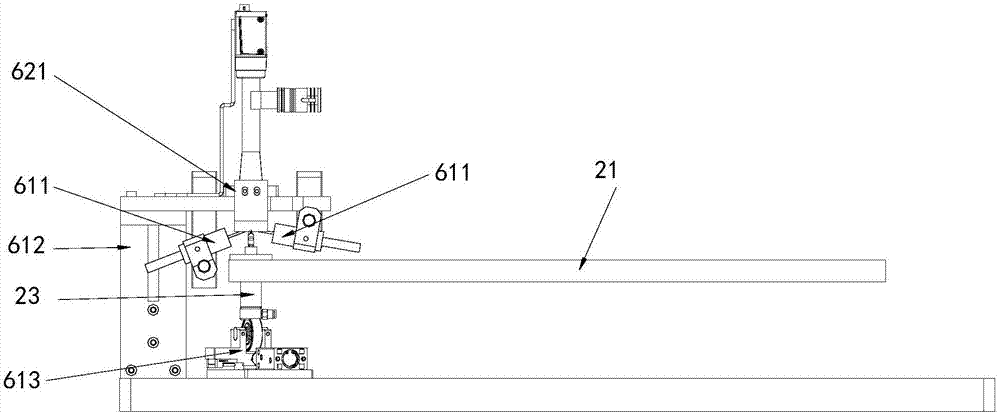

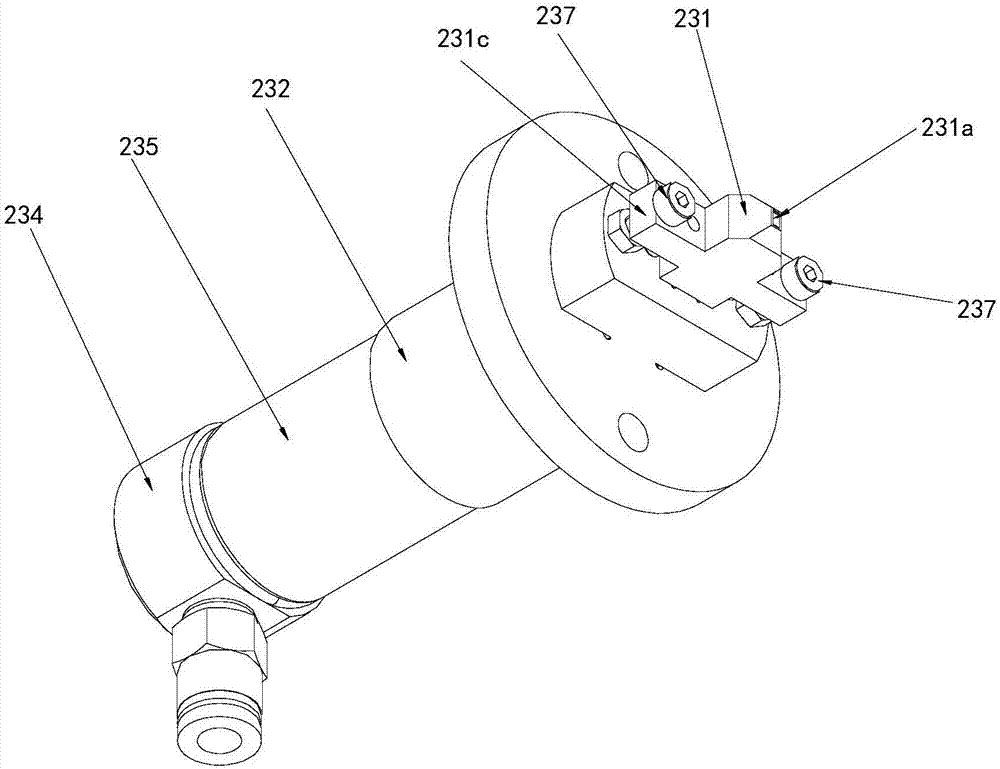

Full-automatic assembly device of LED string lights and welding and detection mechanism thereof

ActiveCN107378243AAvoid defective rateImprove shipment rateLaser beam welding apparatusEngineeringFully automated

The invention discloses a full-automatic assembly device of LED string lights and a welding and detection mechanism thereof. The welding and detection mechanism includes a welding assembly, a power supply assembly and a welding detection assembly, wherein the welding assembly is arranged on a welding position; the welding assembly includes a laser welding head, a welding head bracket and a welding head jacking assembly; the laser welding head is positioned above an LED fixing fixture on the welding position, and the welding head bracket is used for supporting the laser welding head; the welding head jacking assembly is used for driving the LED fixing fixture on the welding position to move upward to be close to wires; the power supply assembly is used for supplying power for the wires, and the welding detection assembly is used for detecting whether or not a patch LED can give out light. The welding and detection mechanism solves the problem that in the manufacture process, welding failure of light beads and wires leads to a defective product rate, and therefore the welding and detection mechanism greatly improves the non-defective product yield of string light production.

Owner:ZHUHAI BOJAY ELECTRONICS

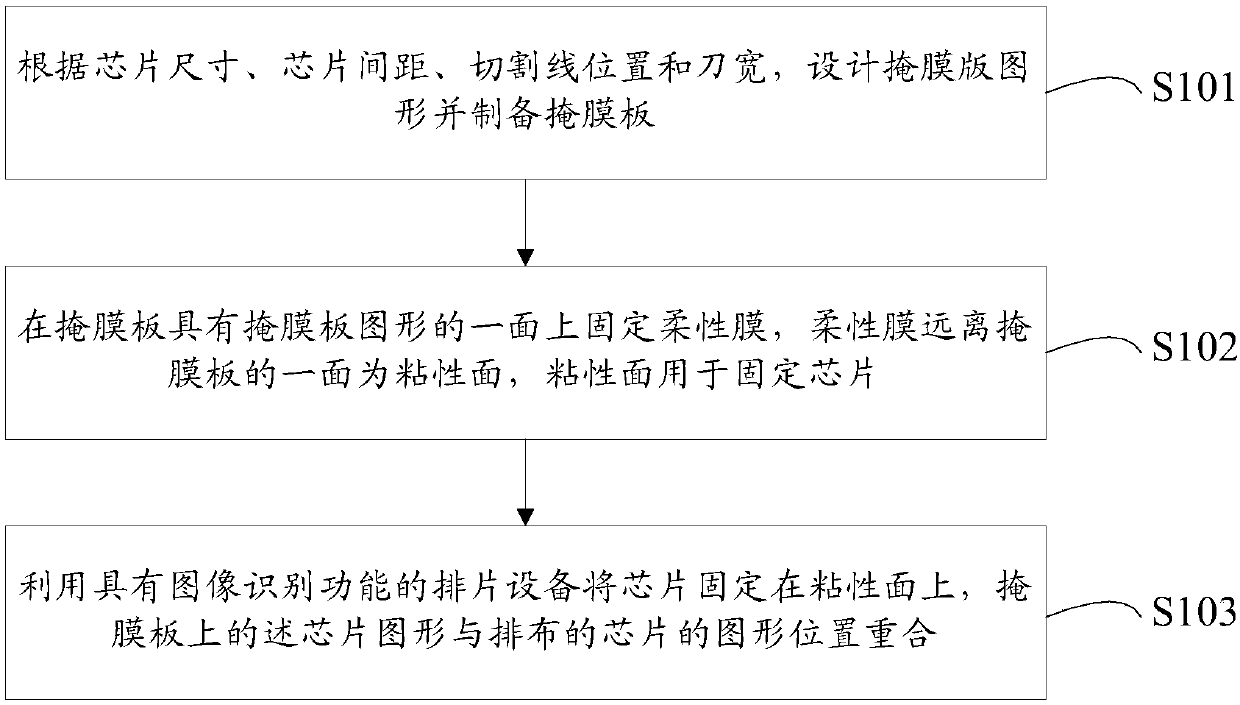

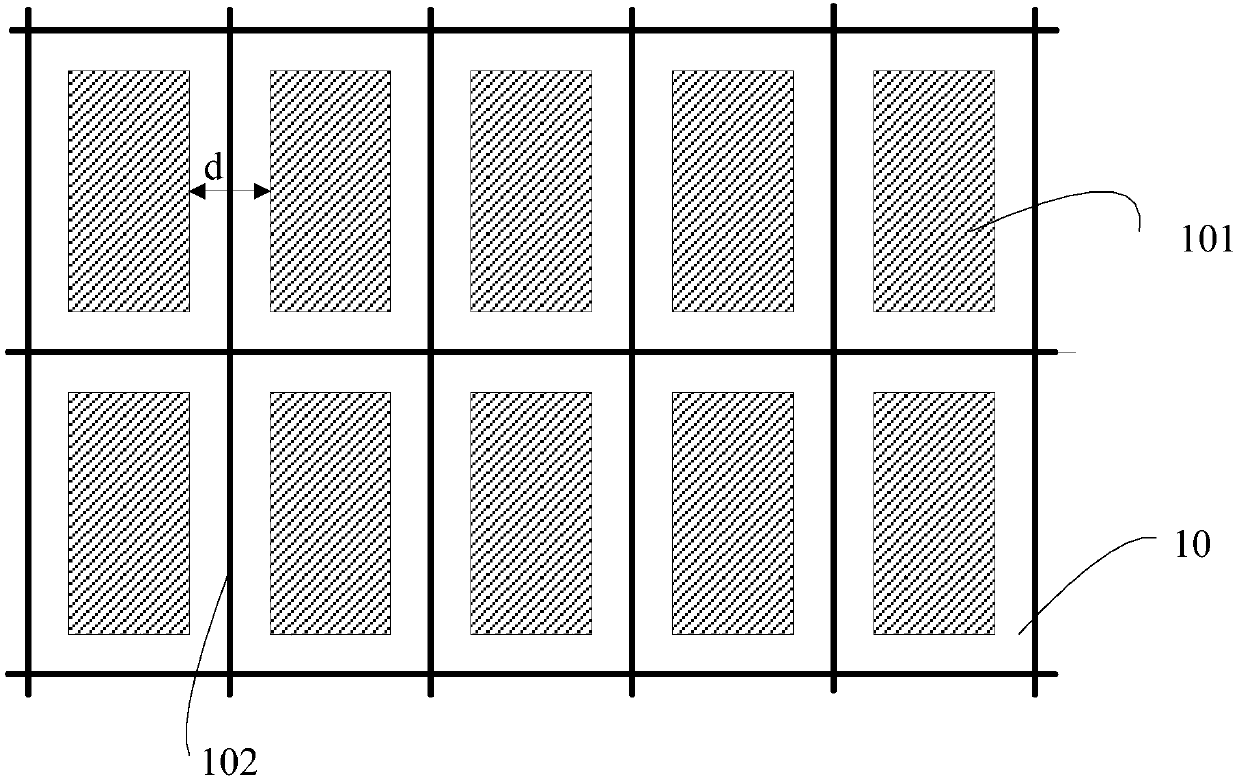

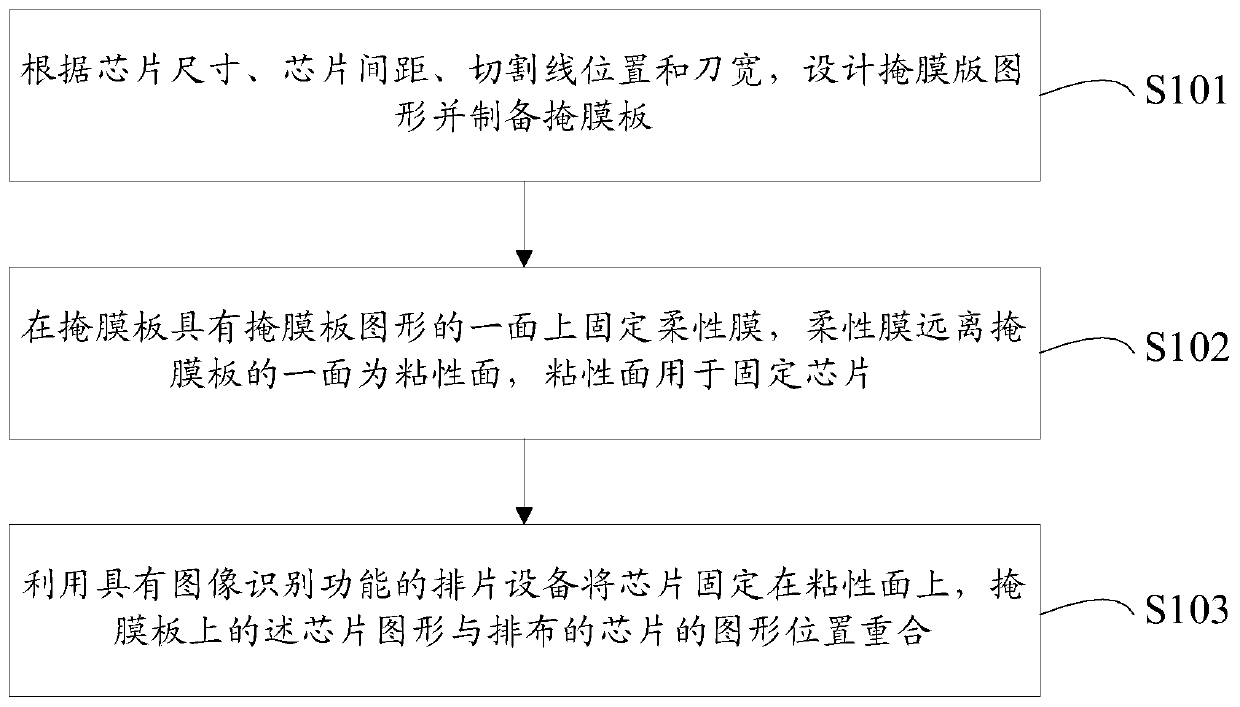

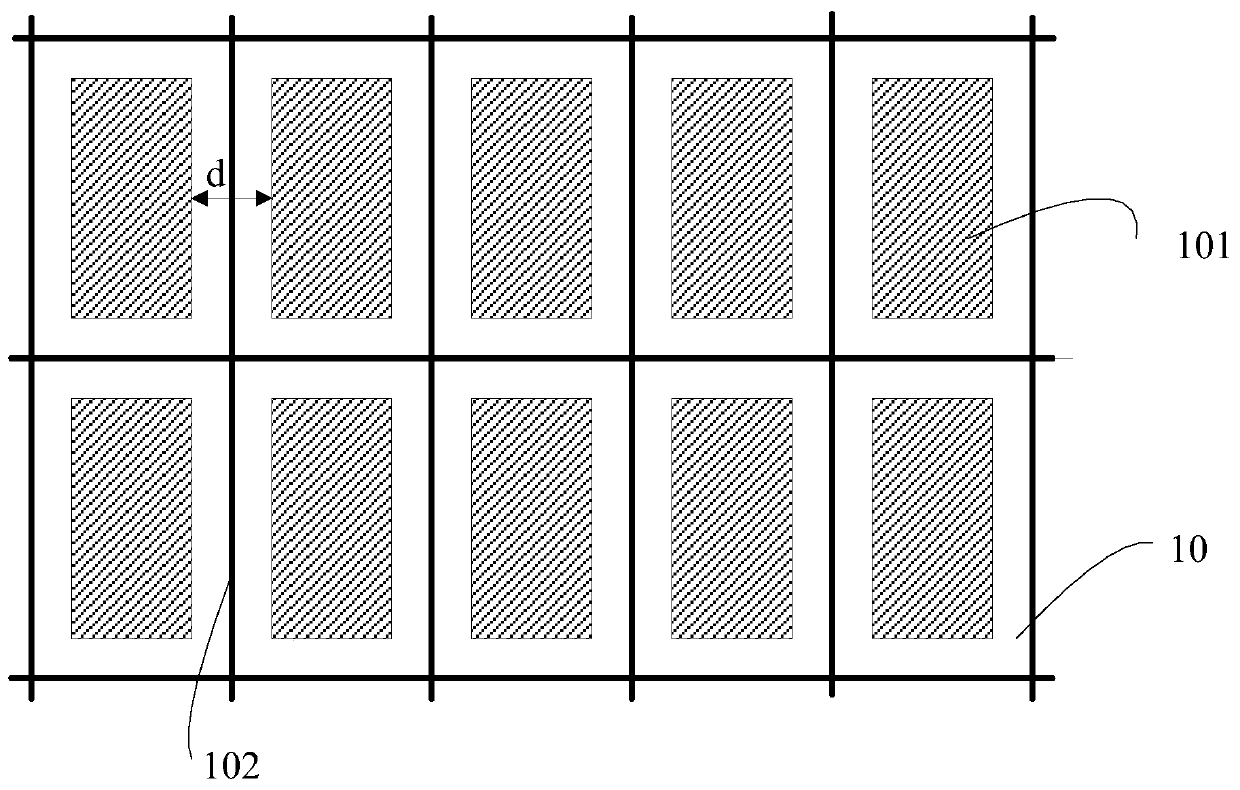

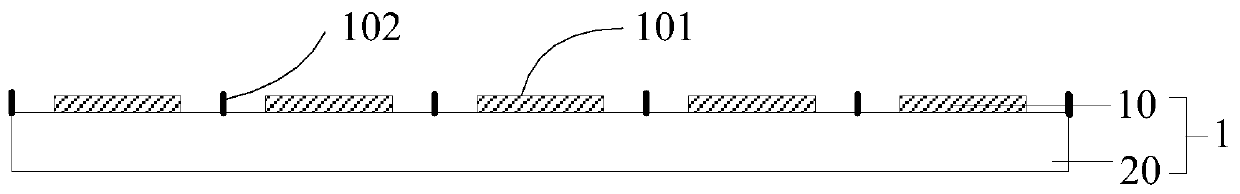

High-precision positioning method for LED chip array arrangement

ActiveCN107731985AHigh precisionEnsure consistencySemiconductor/solid-state device manufacturingSemiconductor devicesChip sizeEngineering

The present application provides a high-precision positioning method for LED chip array arrangement. The method includes the following steps that: a mask layout is designed according to chip size, a chip spacing, a cutting line position and knife width, and a mask plate is manufactured, wherein the mask layout contains a plurality of arrayed chip patterns; a flexible film is fixed onto one side ofthe mask plate, wherein the one side of the mask plate is provided with the mask layout, the flexible film is a transparent thin film resistant to temperatures greater than 150 DEG C, and a surface of the flexible film, which is far away from the mask plate, is an adhesive surface, the adhesive surface is used for fixing the chips; and a chip arrangement device with an image identification function is utilized to fix the chips on the adhesive surface, and the chip patterns on the mask plate are overlapped with the patterns of the arranged chips. With the method adopted, the accuracy of the arrangement spacing of the chips can be improved, the uniformity of the thickness of the encapsulant of the CSP (Chip Scale Package) chips and the uniformity of the color temperature of the CSP chips can be improved, and the yield of LED chip package can be improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

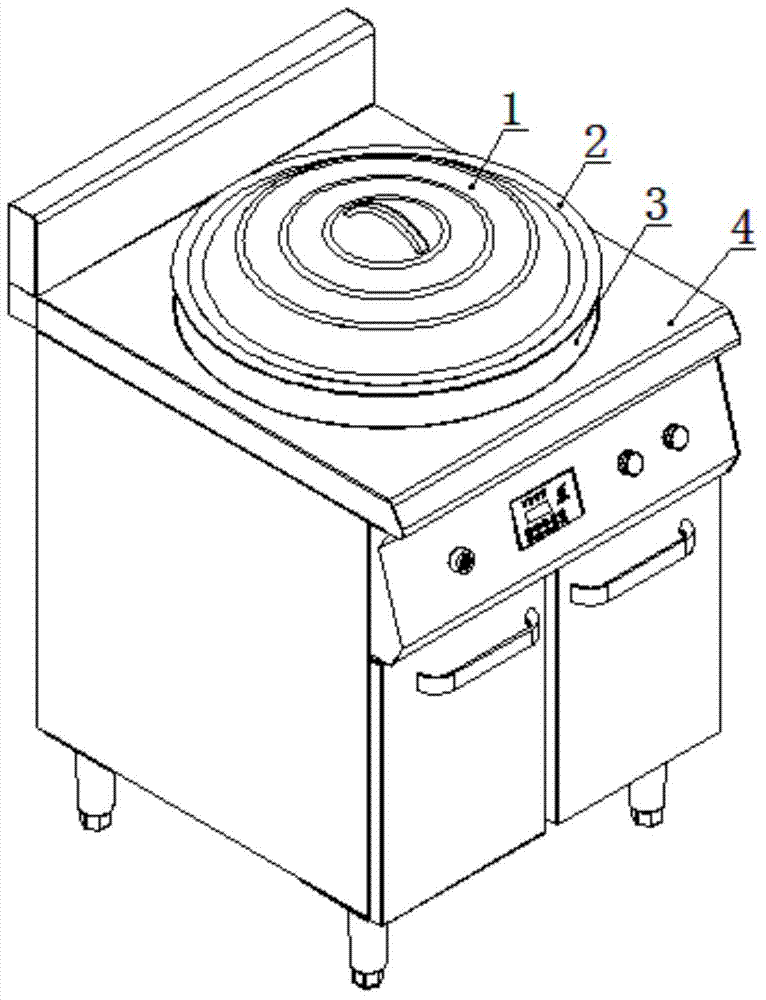

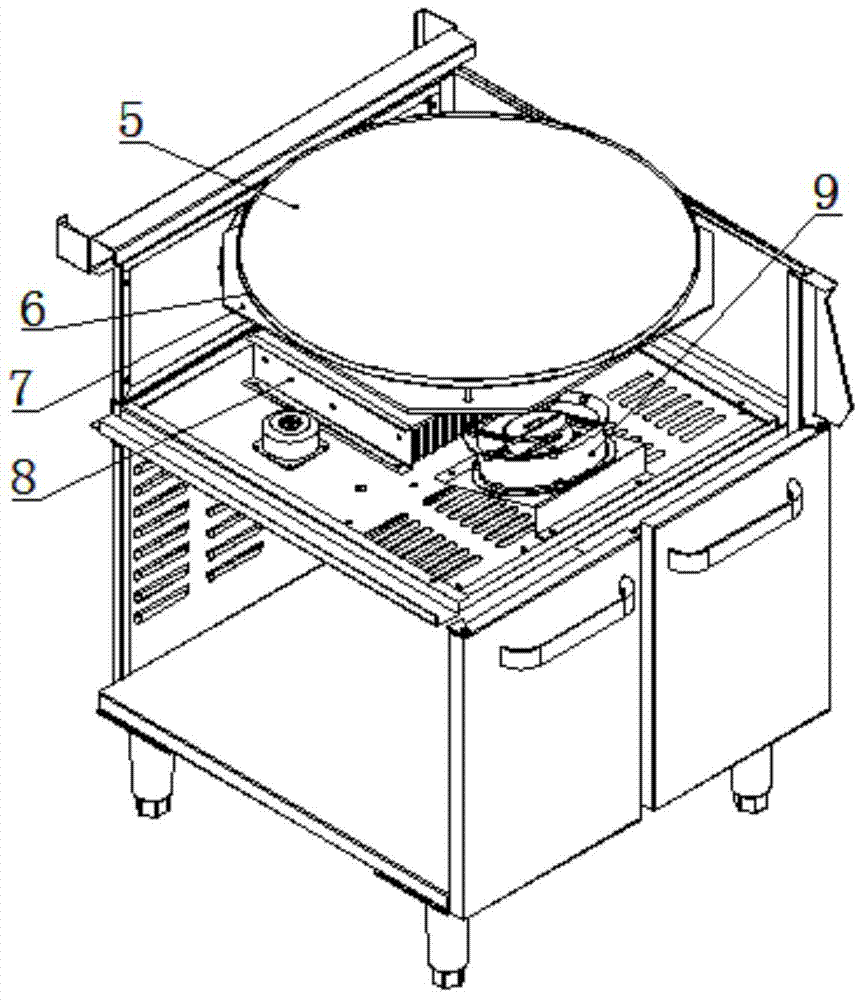

Electromagnetic induction frying-stove energy-saving device

InactiveCN104771090AHigh heating efficiencyImprove energy savingDomestic stoves or rangesLighting and heating apparatusElectromagnetic shieldingElectromagnetic heating

The invention discloses an electromagnetic induction frying-stove energy-saving drive. The electromagnetic induction frying-stove energy-saving device comprises a shell, a pot cover, a frying pan, a pot frame and a microcrystal glass, wherein a mica plate is arranged under the bottom of the microcrystal glass in a lining manner, an electromagnetic coil disc is installed on the bottom of the mica plate, a separation plate is installed inside the shell, an electromagnetic heating core is installed on the separation plate, and the electromagnetic heating core is connected with the electromagnetic coil disc by virtue a high-temperature conducting wire; the pot frame is installed on the shell and arranged above the microcrystal glass, and the frying pot is arranged on the pot frame. The electromagnetic heating way is used for heating the frying pot, so that the electromagnetic induction frying-stove energy-saving device has advantages of safety in use, environmental protection, energy conservation and time conservation.

Owner:HEFEI SHUNCHANG ELECTROMAGNETIC INDUCTION TECH

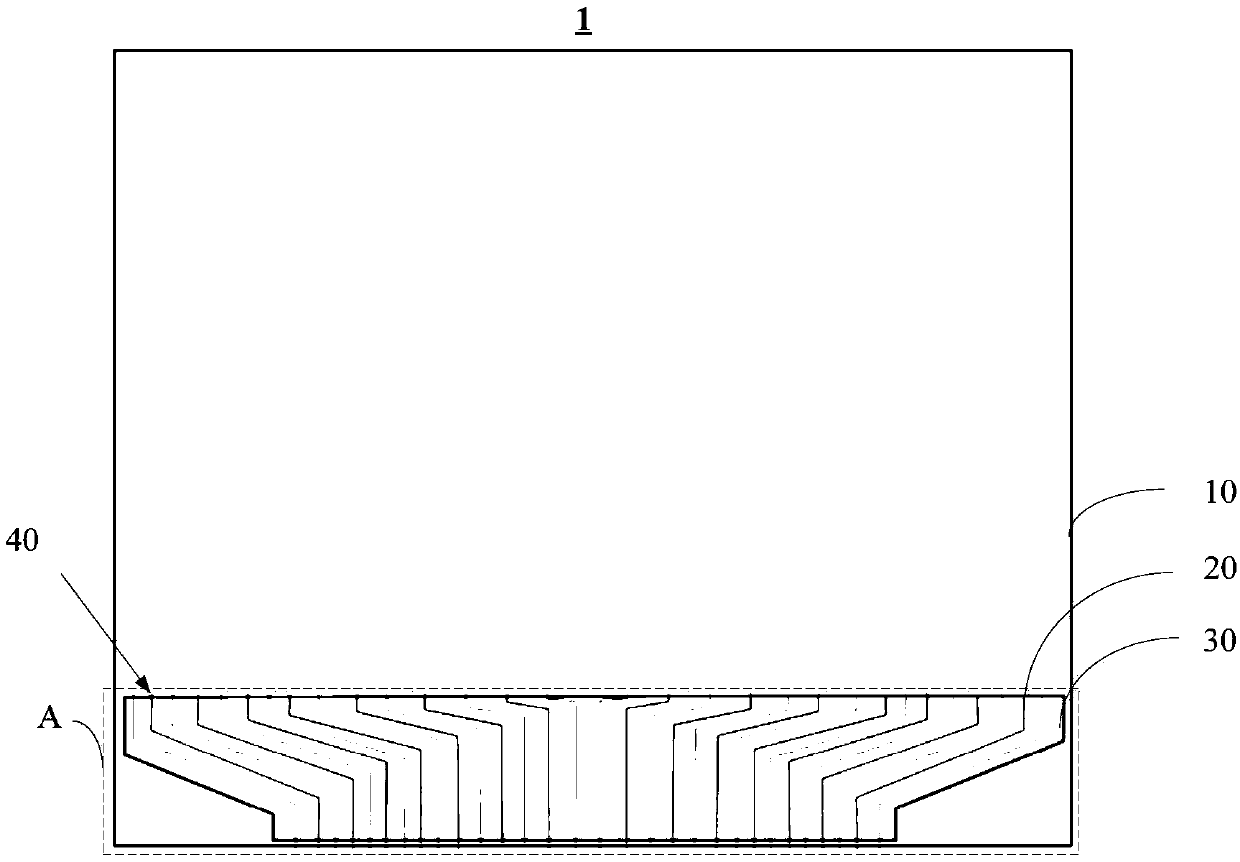

OLED display panel

ActiveCN109637996AImprove display qualityImprove production yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringSignal lines

An OLED panel provided by the present application includes a substrate, and a plurality of signal lines and at least one spare line which are disposed on the substrate, wherein the signal lines and the spare line are located in different layers; the spare line is equipped with a plurality of preset connection points; the projection of any of the signal lines on the substrate coincides with the projection of two preset connection points on the substrate; and when any of the signal lines is in an open circuit, the signal line in the open circuit is electrically connected to the spare line through the preset connection point in order that the signal line in the open circuit works normally through the spare line. The at least one spare line is disposed on the substrate. When any signal line isin the open circuit, the signal line in the open circuit can work normally through the spare line, thereby achieving a purpose of improving the display quality of the OLED display panel, improving the product yield of the OLED display panel, and also increasing the shipment rate of the OLED display panels.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

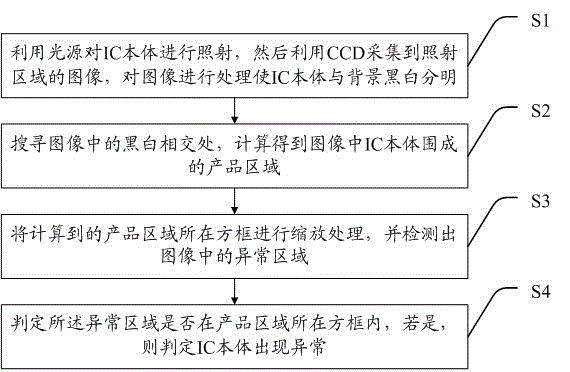

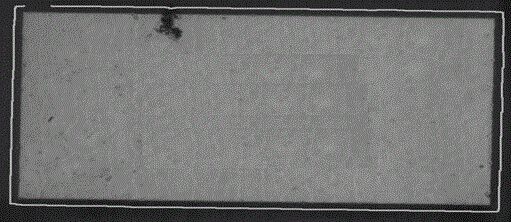

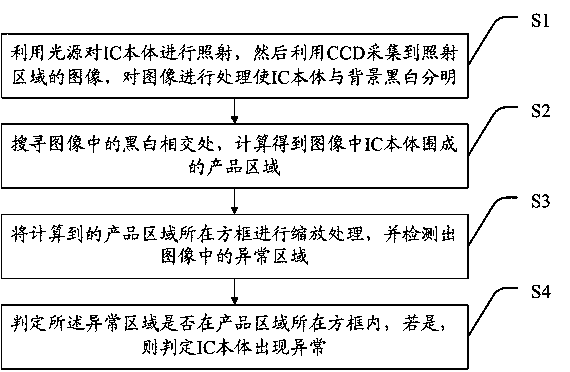

Method and system for testing glass integrated circuit (IC)

ActiveCN105261019AReduce exception costsImprove yield rateImage enhancementImage analysisLight reflectionComputer science

The invention discloses a method and a system for testing a glass IC. The method comprises the steps of A, irradiating an IC body by means of a light source, then acquiring an image of an irradiating area by means of a CCD, processing the image for distinguishing the IC body from a background in a black-and-white manner; B, searching for crossing parts between black parts and white parts in the image, and obtaining a product area which is surrounded by the IC body in the image through calculation; C, performing zooming processing on a square frame in which the calculated product area exists, and detecting an abnormal area in the image; and D, determining whether the abnormal area exists in the square frame in which the product area exists, and if yes, determining a fact that the abnormity of the IC body occurs. According to the method and the system, through adjusting the light source and processing through a corresponding software algorithm, a problem of light reflection on glass is settled. Image identification technology is used for detecting abnormal products, and a product yield rate is improved. The method for testing according to the invention has functions of reducing number-of-times of inferior mounting on a template, reducing abnormal cost for an enterprise, and improving output amount and quality of products.

Owner:PROSYST ELECTRONICS TECH

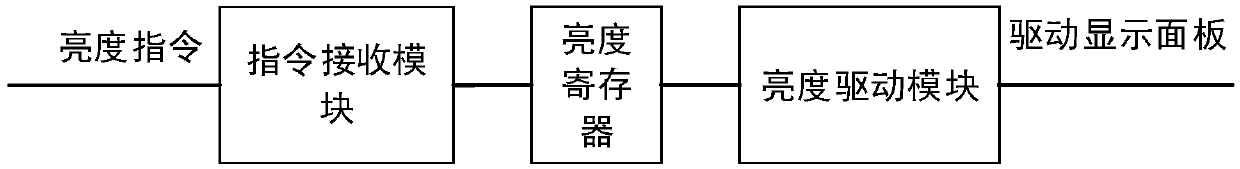

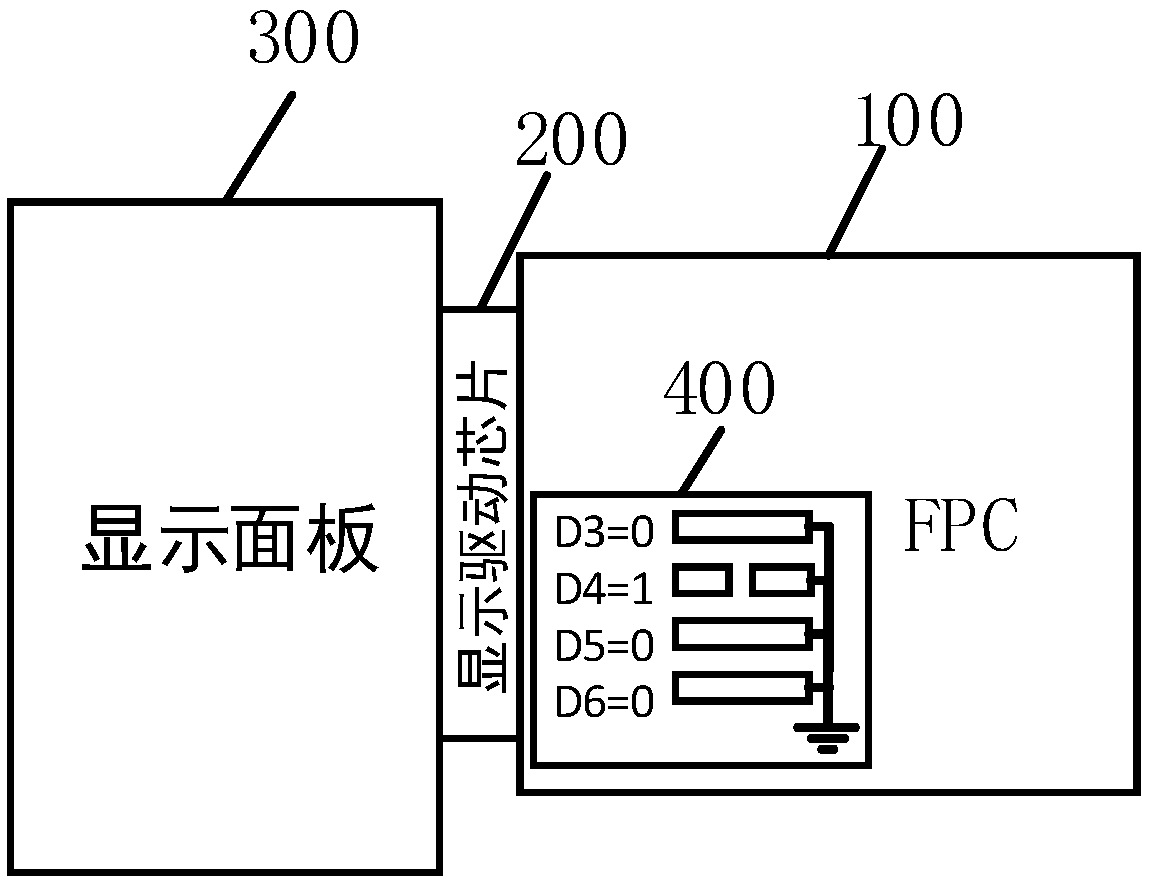

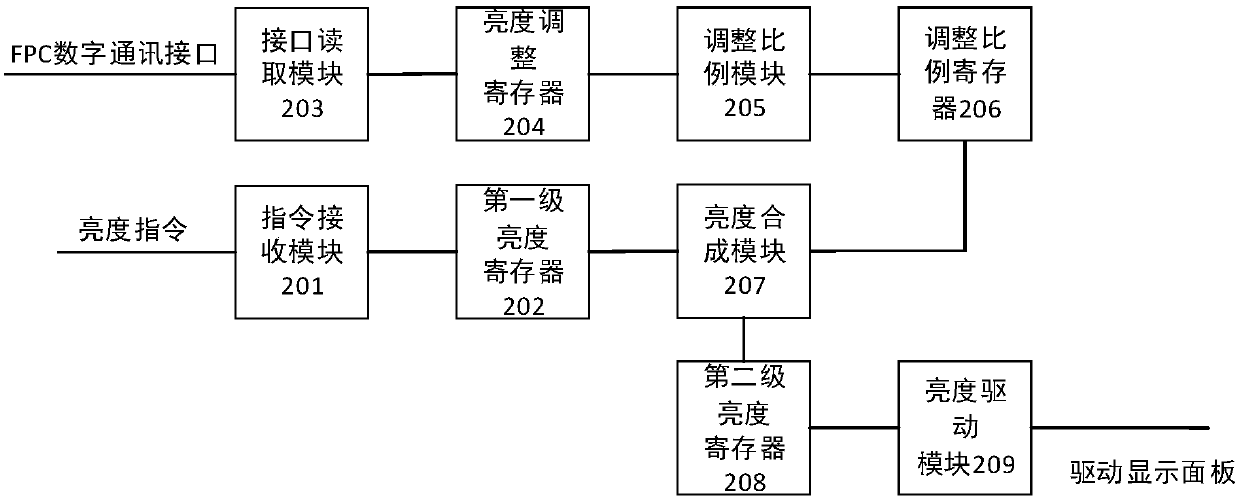

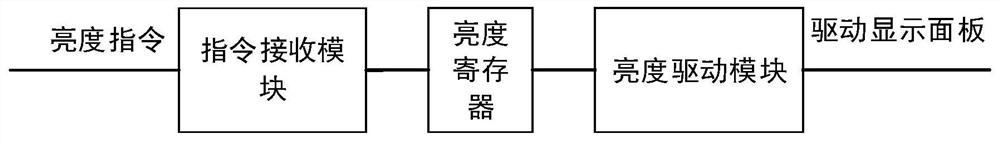

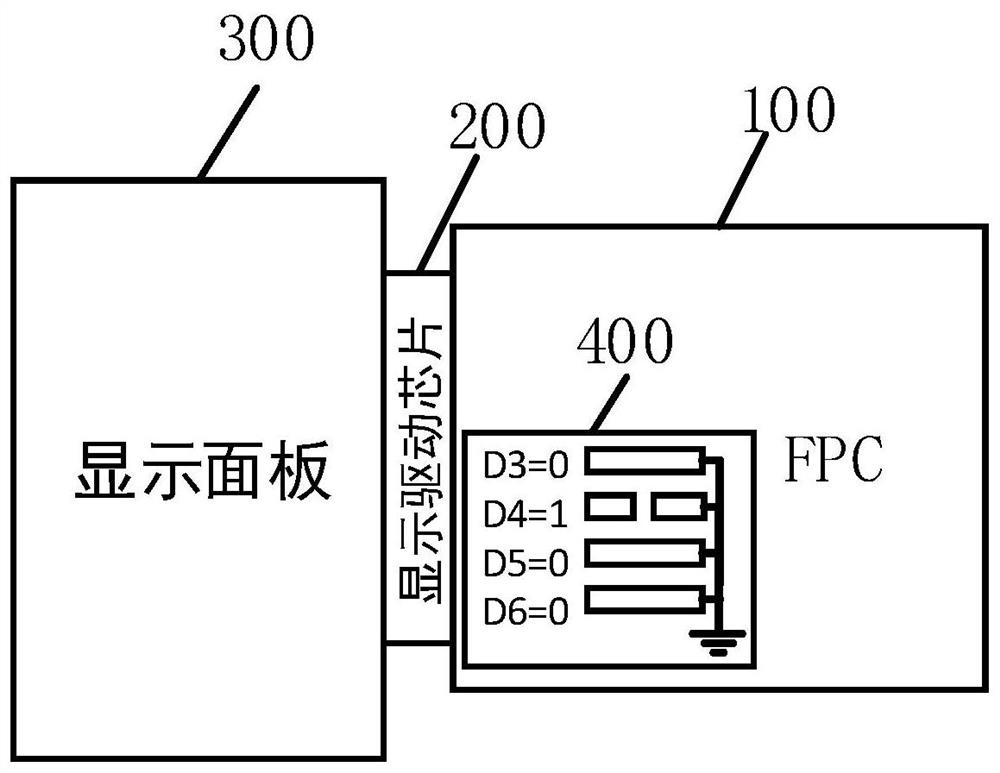

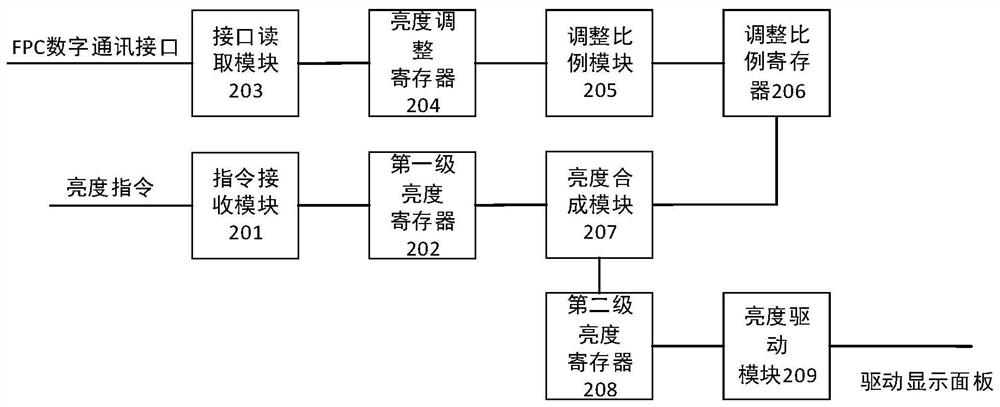

Brightness adjustment device, system and method of PMOLED display module

ActiveCN109637448AEase brightnessUniformity of responseStatic indicating devicesFlexible circuitsComputer module

The invention provides a brightness adjustment device, system and method of a PMOLED display module, and relates to the display field. The technical problem that the existing PMOLED display module haslarge brightness difference and poor uniformity can be alleviated. The device comprises a flexible circuit board, a display driving chip and a display panel, which are connected in sequence, whereinthe flexible circuit board is used for receiving a brightness instruction sent by an MCU and transmitting the brightness instruction to the display driving chip; a level adjustment module is arrangedon the flexible circuit board; the level adjustment module is used for generating a level value corresponding to brightness adjustment ratio data and outputting the level value to the display drivingchip; the brightness adjustment ratio data are determined by the factory brightness and the target brightness of the display module; and the display driving chip is used for generating a brightness driving signal based on the level value and the brightness instruction and outputting the brightness driving signal to the display panel. The device can improve the brightness difference of the PMOLED display module and improve the uniformity.

Owner:芯颖科技有限公司

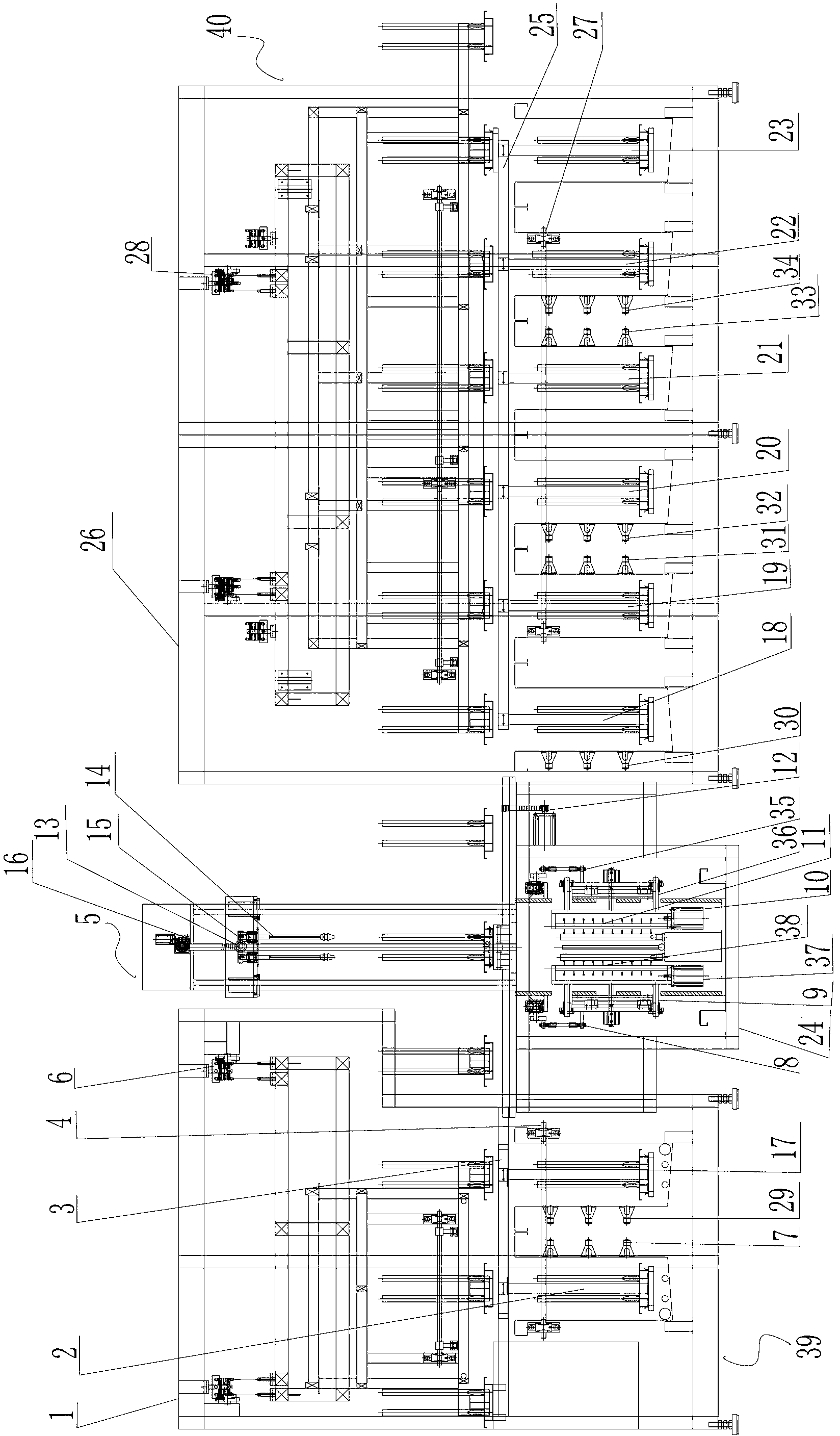

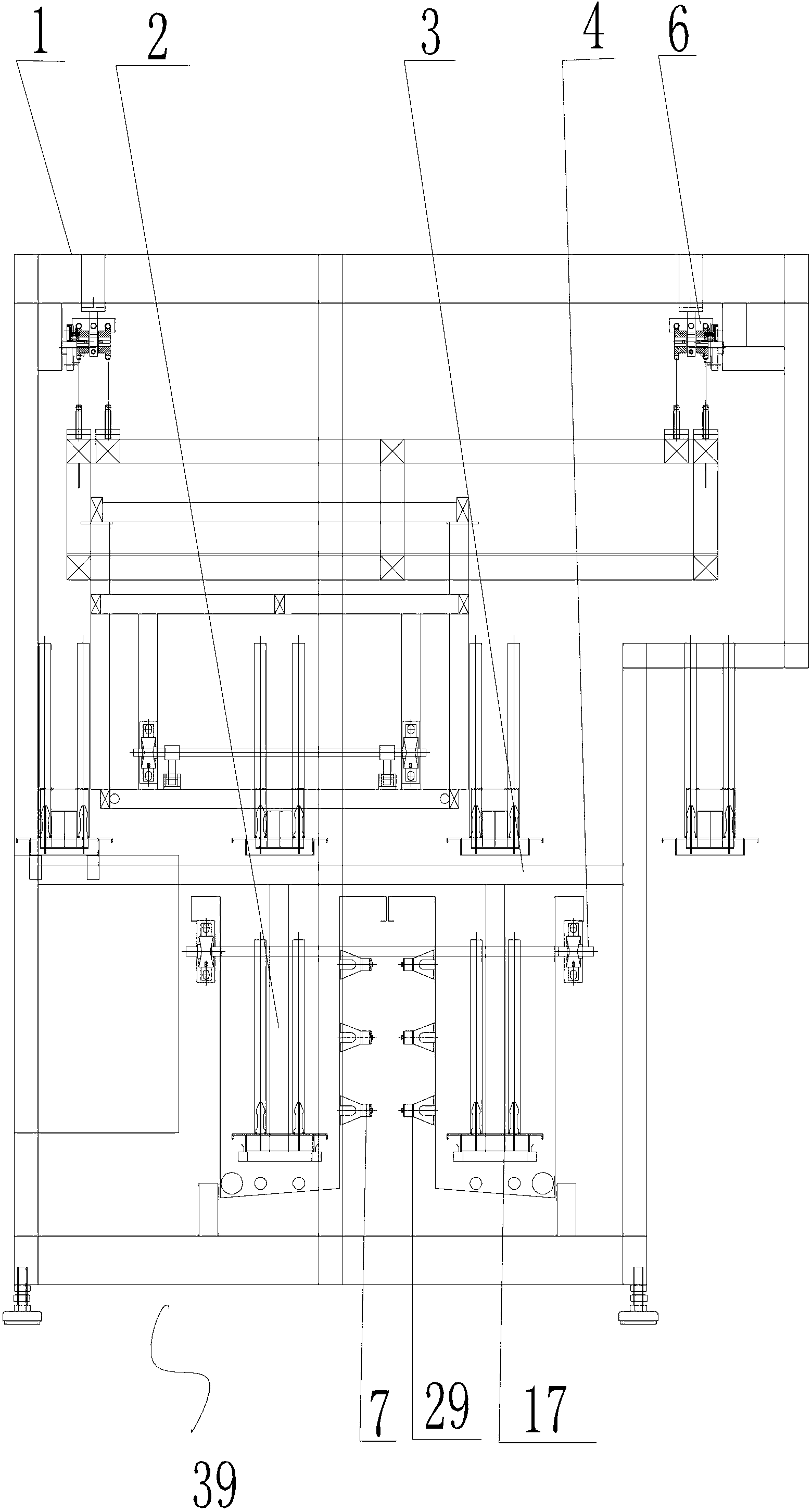

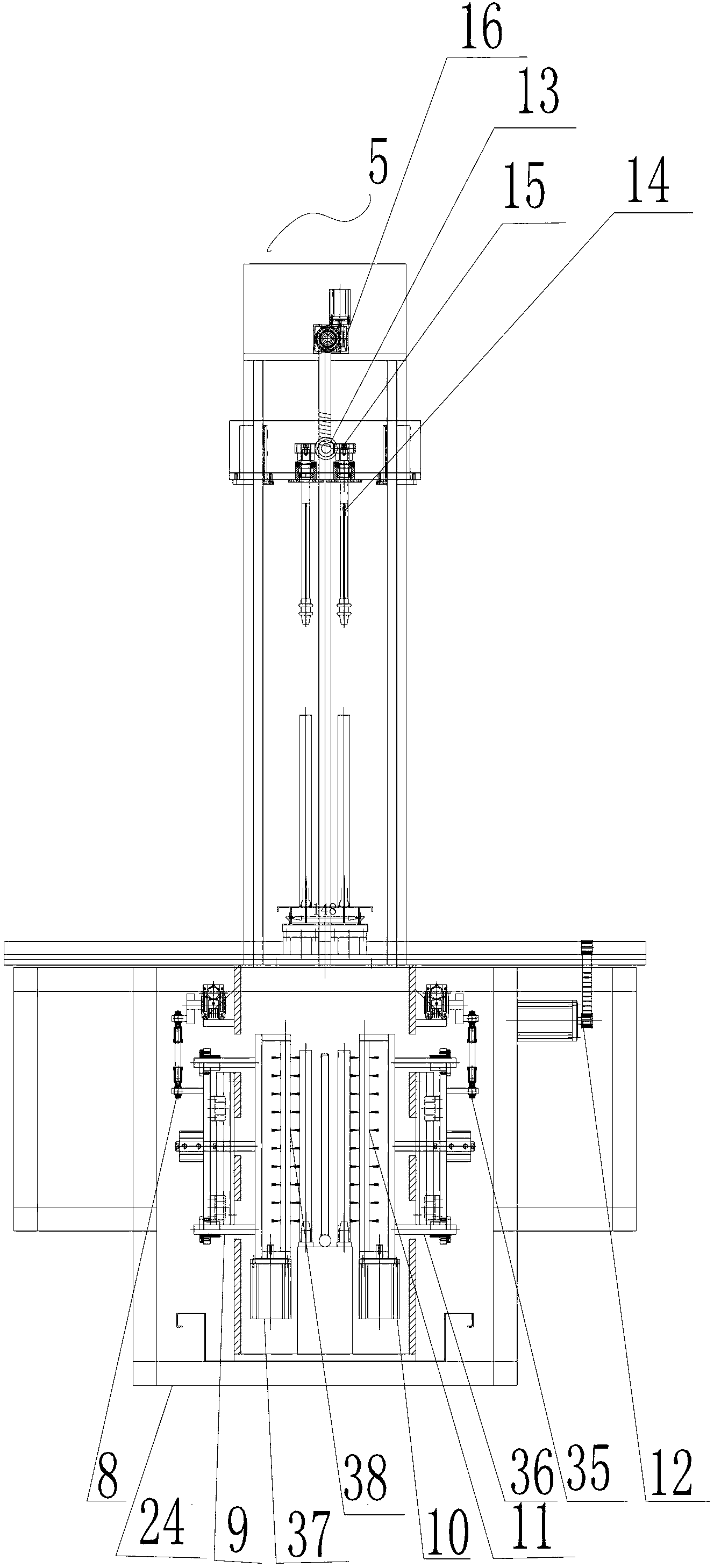

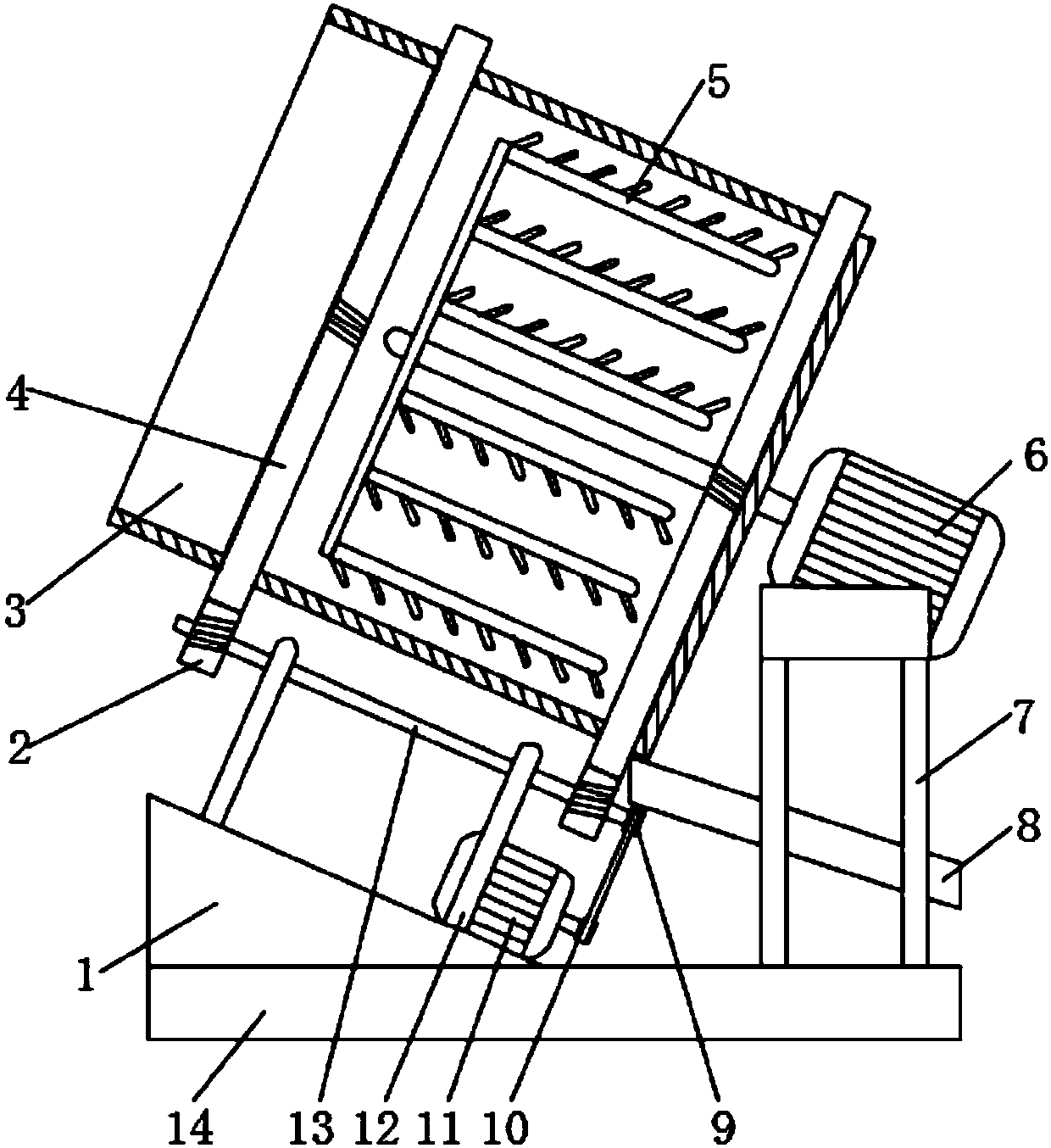

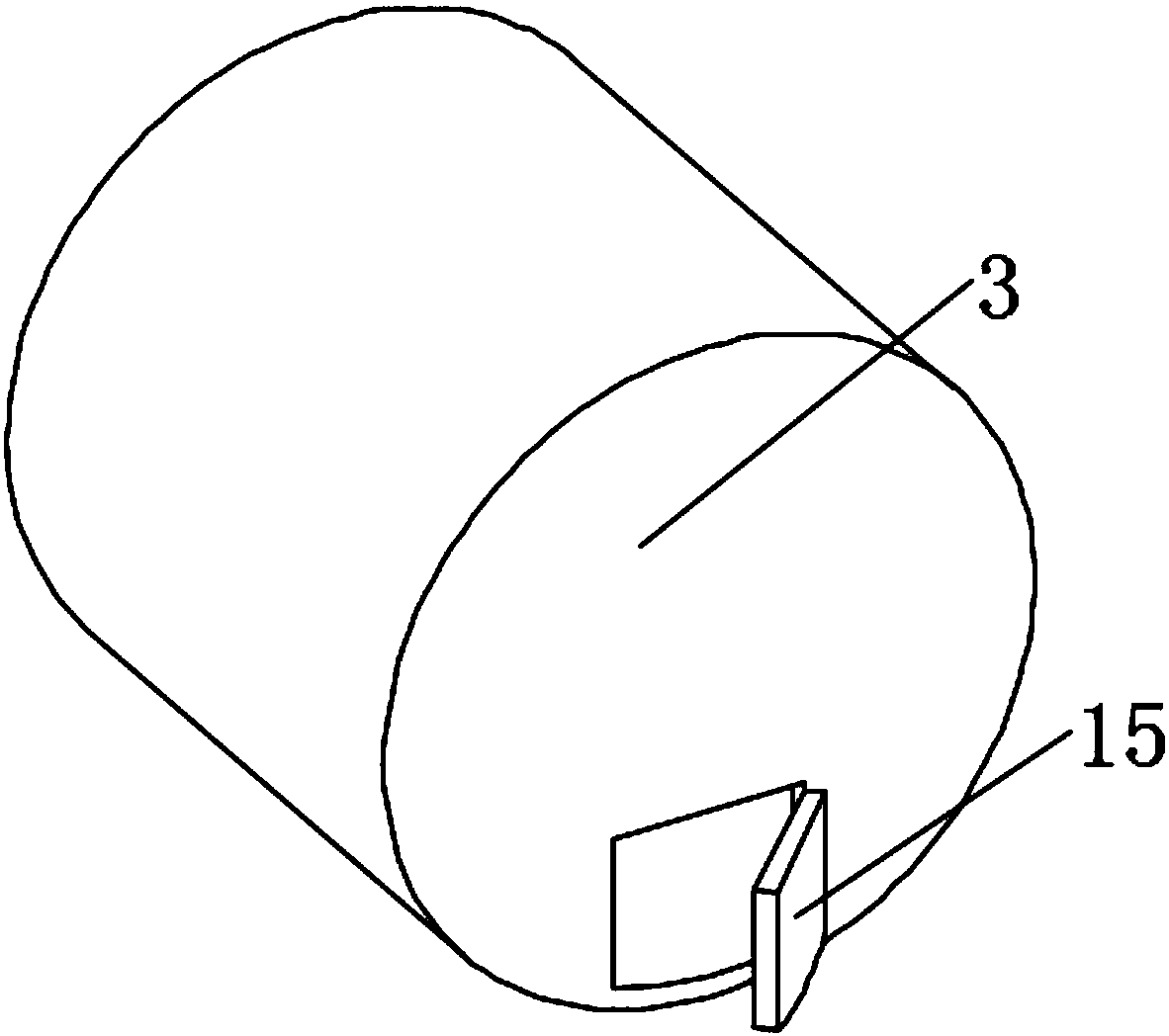

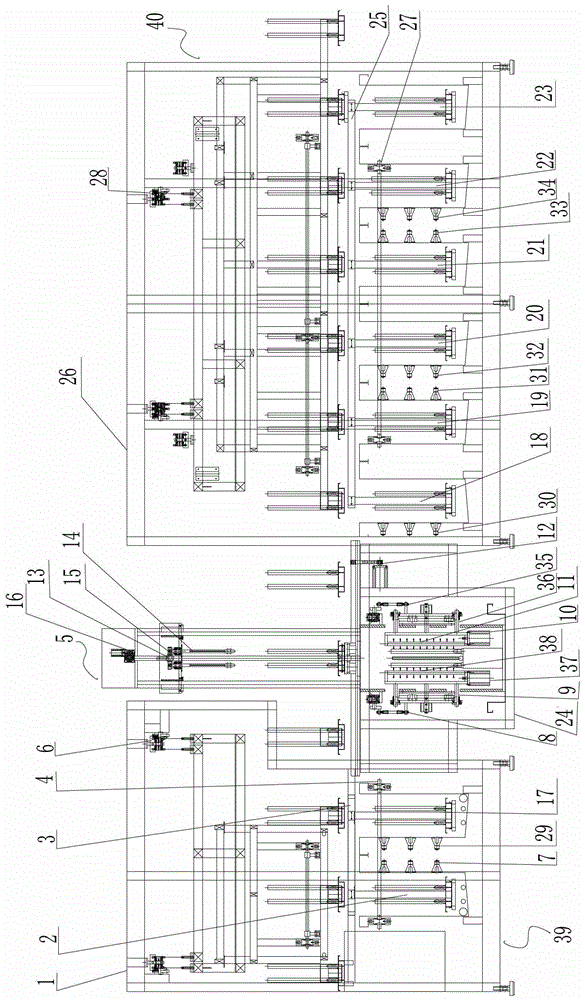

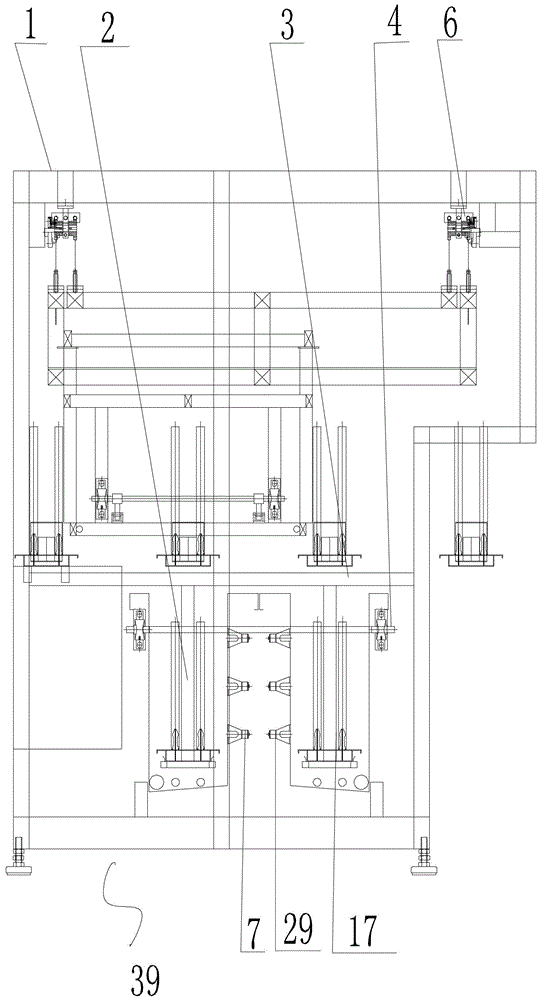

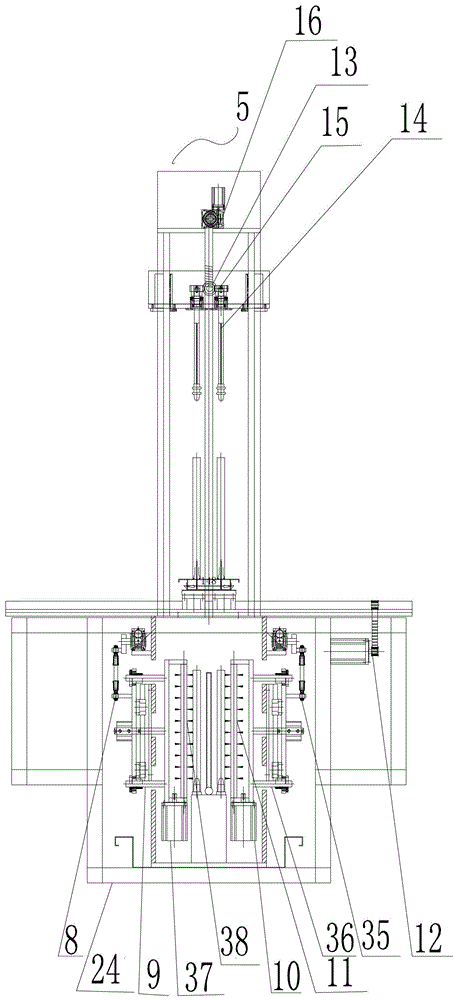

Cleaning device and cleaning method of selenium (Se) drum component of printer

The invention discloses a cleaning device and cleaning method of selenium (Se) drum component of a printer. The cleaning device of the Se drum component of the printer comprises a scrubbing device (5), an alkaline cleaning device (39) and a fine cleaning device (40), wherein the alkaline cleaning device (39) is connected with the scrubbing device (5) through a connecting piece, and the scrubbing device (5) is connected with the fine cleaning device (40) through a connecting piece. The cleaning method of the cleaning device of the Se drum component of the printer includes the following steps that the Se drum component of the printer sequentially passes through a first tank body (2) and a second tank body (17) which are located on the alkaline cleaning device (39) and enters a first scrubbing device (11) and a second scrubbing device (38) of the scrubbing device (5) after two times of alkaline cleaning, after the two times of scrubbing, the Se drum component enters a third tank body (18), a fourth tank body (19), a fifth tank body (20), a sixth tank body (21), a seventh tank body (22) and an eighth tank body (23) of the fine cleaning device (40) in sequence, and a product is obtained after rinsing and purifying are completed so that the product can be cleaned thoroughly.

Owner:SHANGHAI CHAOJING MACHINERY

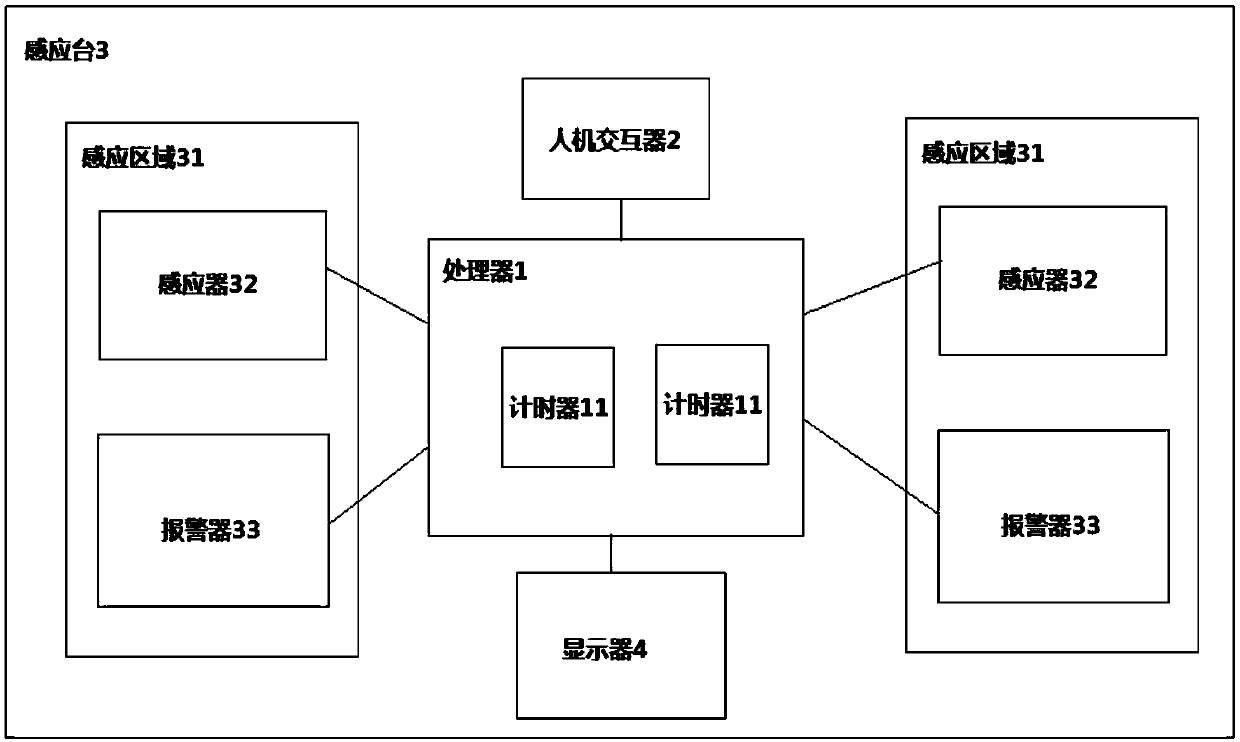

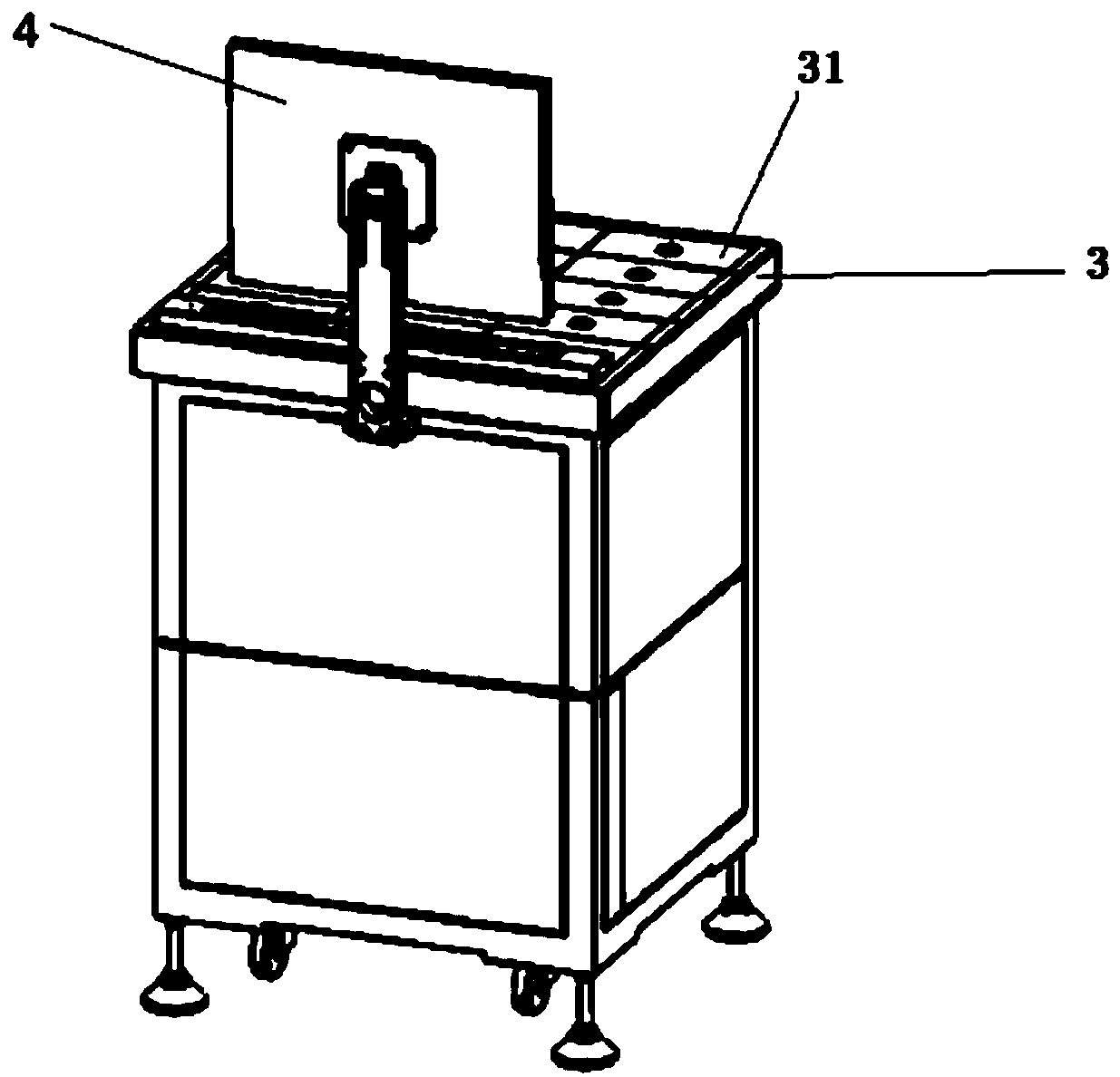

LED (Light Emitting Diode) fluorescent powder deposition control device and method

ActiveCN109671655AAvoid drifting situationsImprove accuracySemiconductor/solid-state device manufacturingEnergy saving control techniquesOn boardEngineering

The invention discloses an LED (Light Emitting Diode) fluorescent powder deposition control device and method. An operator only needs to input deposition time to a timer of a processor through a man-machine interaction device; when an inductor induces an LED substrate, an induction signal is sent to the processor to start the timer; after reaching the deposition time input through the timer, alarming is carried out through an alarm, so as to remind the operator that fluorescent powder of the LED substrate is settled and next-step operation including curing and baking can be carried out; a condition that the standing and deposition time is not accurate after a COB (Chip On Board) material is dispensed and packaged so that the settlement of the fluorescent powder is not consistent and a color zone of a product is drifted can be effectively avoided, the accuracy of the color zone is effectively improved and the shipment rate of the product is improved, and the stock pressure is reduced. Meanwhile, powerful guarantees are provided for standardized management and a manufacturing procedure; the quality of the product can be sufficiently ensured, and the accuracy and scientificity of a COB packaging manufacturing procedure technology and the quality reliability of the product are effectively ensured.

Owner:APT ELECTRONICS

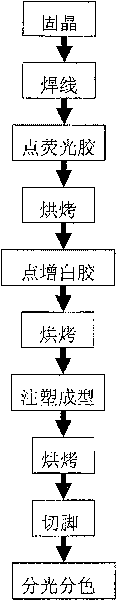

Encapsulation method of white light LED for improving facula

Owner:LEDMAN OPTOELECTRONICS CO LTD

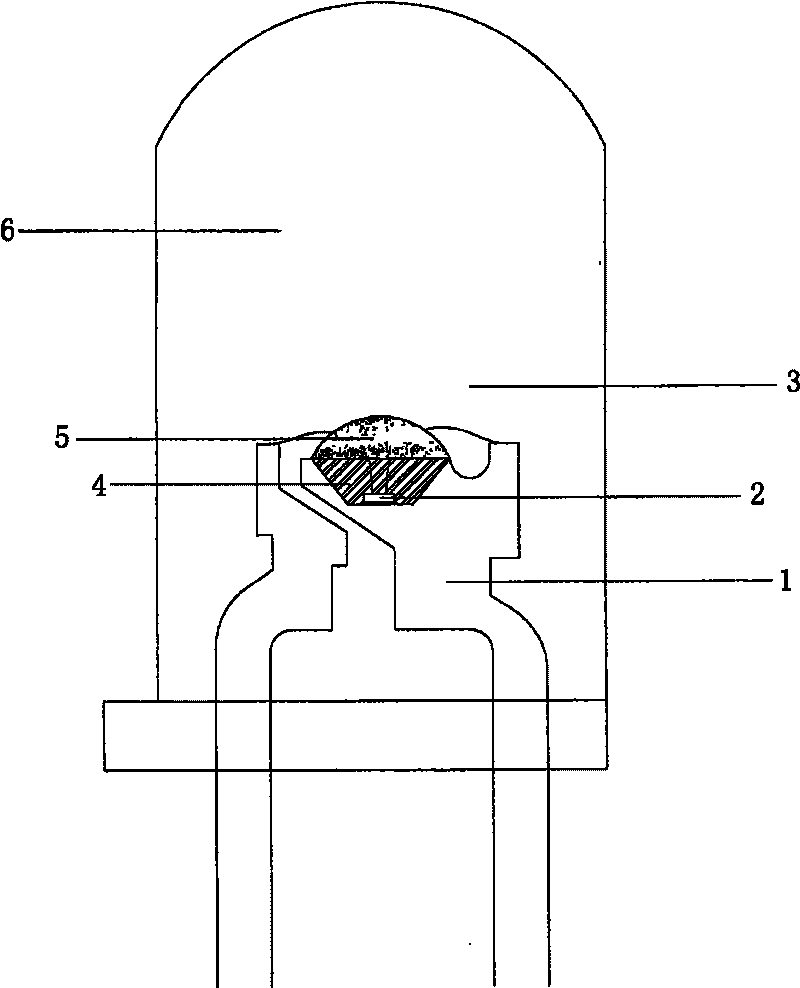

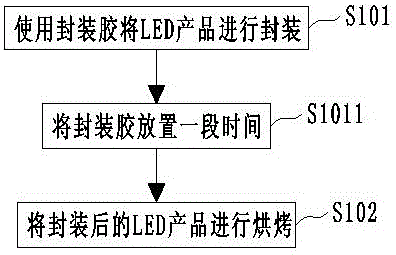

LED packaging method improving color zone in-BIN rate

InactiveCN105845811AIncrease in BIN rateFully uniform excitationSemiconductor devicesEngineeringLead field

The invention belongs to the technical field of LEDs, and specifically relates to an LED packaging method with a higher color zone entering BIN rate; the technical problem to be solved is: to provide a high color zone entering BIN rate that improves the shipment rate of LED white light products LED encapsulation method; the adopted technical scheme is: an LED encapsulation method with a higher color area into BIN rate, including the steps: S101: encapsulating the LED product with encapsulation glue; S102: baking the encapsulated LED product Baking; after the step S101, further include: S1011: leave the encapsulation glue for a period of time; the present invention is applicable to the LED field.

Owner:CHANGZHI HONGYUAN PHOTOELECTRIC TECH

Pmoled display module brightness adjustment device, system and method

ActiveCN109637448BImprove Brightness DifferenceImprove shipment rateStatic indicating devicesComputer hardwareFlexible circuits

The invention provides a brightness adjustment device, system and method of a PMOLED display module, and relates to the display field. The technical problem that the existing PMOLED display module haslarge brightness difference and poor uniformity can be alleviated. The device comprises a flexible circuit board, a display driving chip and a display panel, which are connected in sequence, whereinthe flexible circuit board is used for receiving a brightness instruction sent by an MCU and transmitting the brightness instruction to the display driving chip; a level adjustment module is arrangedon the flexible circuit board; the level adjustment module is used for generating a level value corresponding to brightness adjustment ratio data and outputting the level value to the display drivingchip; the brightness adjustment ratio data are determined by the factory brightness and the target brightness of the display module; and the display driving chip is used for generating a brightness driving signal based on the level value and the brightness instruction and outputting the brightness driving signal to the display panel. The device can improve the brightness difference of the PMOLED display module and improve the uniformity.

Owner:芯颖科技有限公司

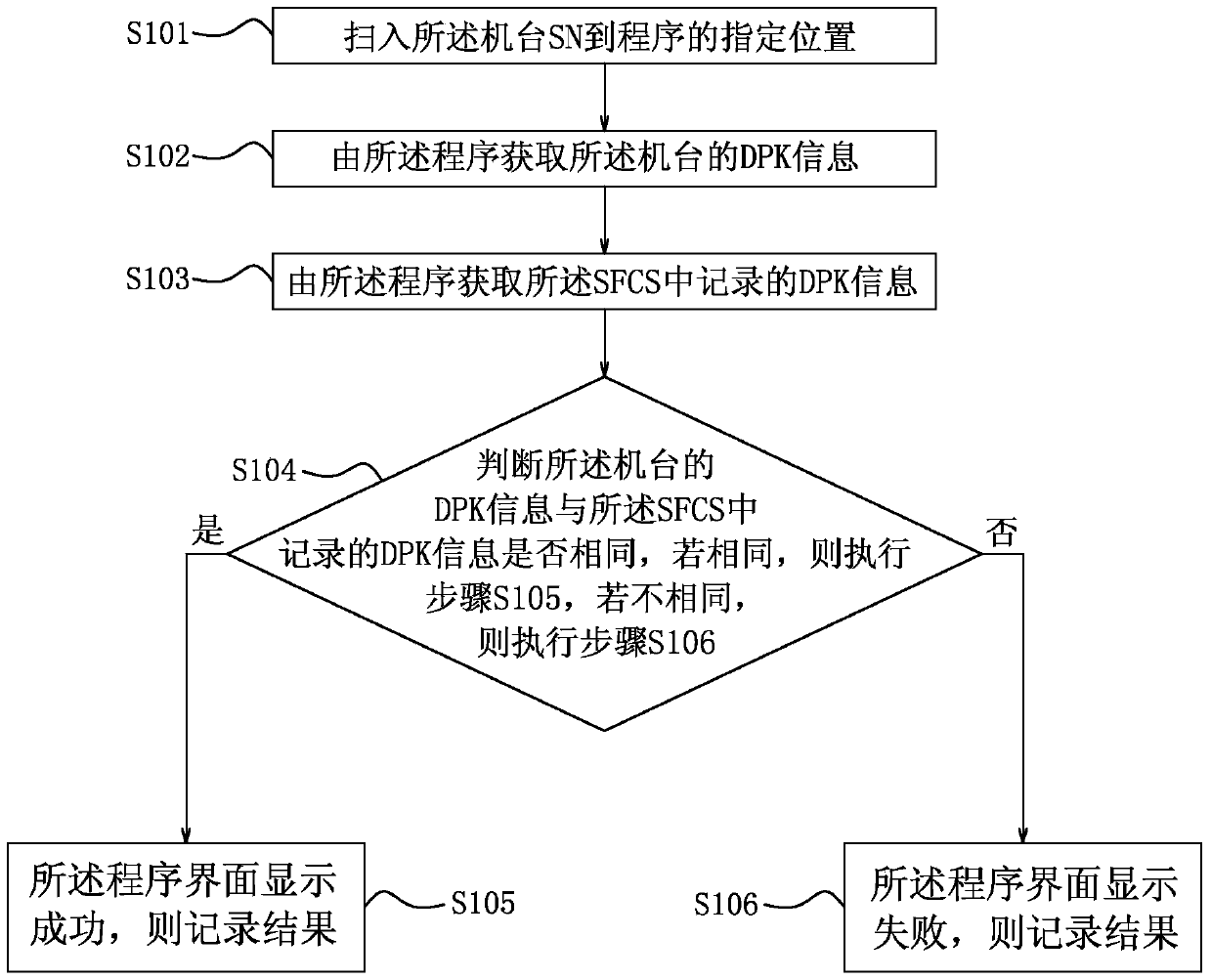

Windows8 key automatic detection method

ActiveCN104809412BImprove shipment rateGuarantee quality and efficiencyInternal/peripheral component protectionSoftware engineeringBiological activation

A Windows8 key automatic detection method, comprising the following steps: (1) scanning the SN of the machine to a designated position of the program; (2) obtaining the DPK information of the machine by the program; (3) by the The above program obtains the DPK information recorded in the SFCS; (4) judge whether the DPK information of the machine is the same as the DPK information recorded in the SFCS, if they are the same, perform step (5), if not, then Execute step (6); (5) if the program interface shows success, record the result; (6) if the program interface fails, record the result. The invention greatly improves the product shipment rate, and at the same time ensures the product quality and work efficiency, and the invention can solve the problems of inaccurate verification before shipment and unsuccessful system activation.

Owner:SHENXUN COMP KUNSHAN

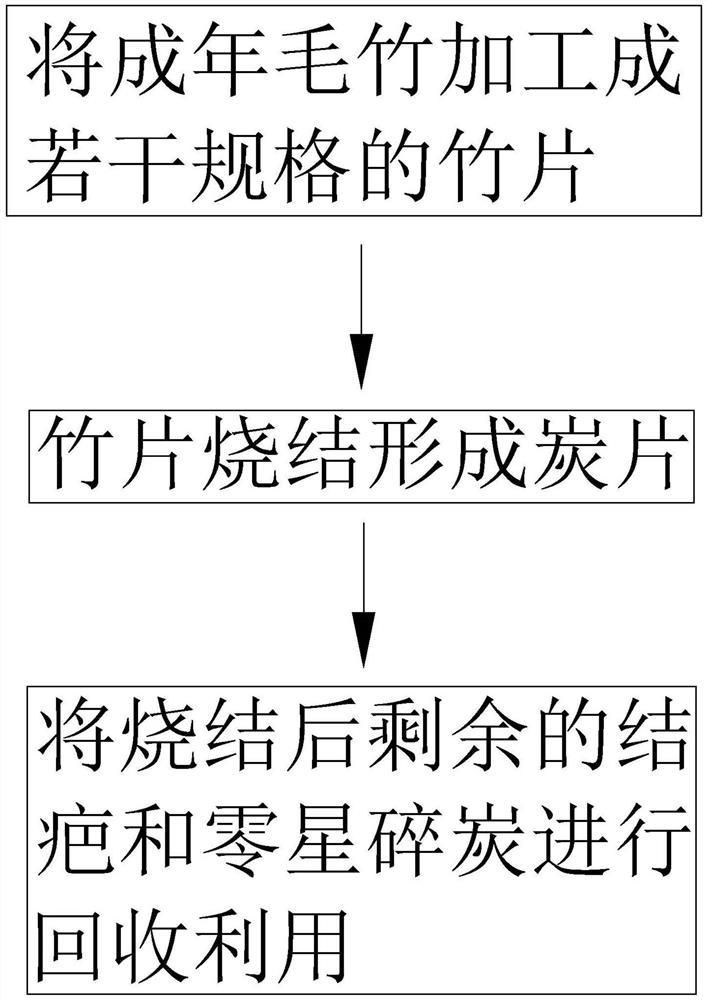

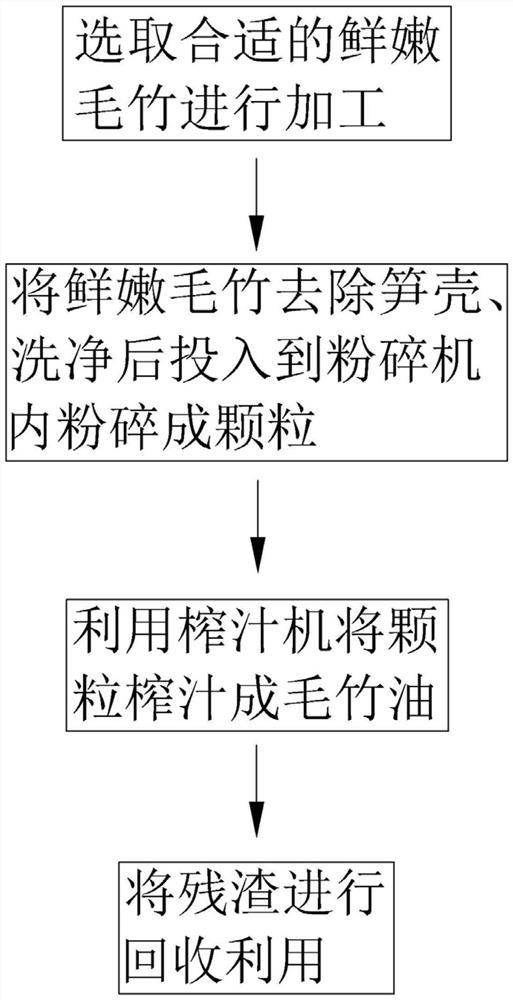

Processing technology of moso bamboos

PendingCN113287759AHigh economic valueRaise the ratioDough treatmentMetabolism disorderBiotechnologyEngineering

The invention discloses a moso bamboo processing technology, and the technology comprises an adult moso bamboo processing technology and a fresh and tender moso bamboo processing technology, and the adult moso bamboo processing technology comprises the following steps: 1, processing adult moso bamboo into bamboo chips of a plurality of specifications; 2, sintering the bamboo chips to form carbon sheets; 3, recycling residual scabs and sporadic broken carbon after sintering. The processing technology of the fresh and tender moso bamboos comprises the following steps: A, selecting proper fresh and tender moso bamboos for processing; B, removing bamboo shoot shells from fresh and tender moso bamboos, cleaning, and crushing into particles in a crusher; C, juicing the particles into moso bamboo oil by using a juicer; D, recycling the residues. The invention has the beneficial effect that the purpose of improving the economic value of the moso bamboo is achieved.

Owner:黄达模

Casting and support connecting structure device

The invention discloses a casting and support connecting structure device comprising a support and at least one shaft pin. The shaft pins are detachably connected with the support, at least one to-be-machined casting is arranged on each shaft pin, and the castings are horizontally arranged and formed with the shaft pins in a one-time casting mode to form a main body. At least one shaft pin grooveis formed in the bottom of the support and is of a swallow tail buckle type with the wider upper portion, the shaft pins with the castings are inserted into the shaft pin grooves and fixedly connectedwith the support to constitute a combined tree body, and protrusion lock positions are integrally arranged on the surfaces of the two edges of the middle sections of the shaft pins. When the shaft pins with the castings are inserted into the shaft pin grooves, through buckled locking of the protrusion lock positions and the shaft pin grooves, the castings and the support form the combined tree body, so that the phenomena of uneven arrangement and irregularity due to the fact that the castings need to be welded to a support one by one in the prior art is effectively avoided, the casting machining efficiency is effectively improved, the casting shipping rate is effectively increased, meanwhile the machining cost is effectively reduced, and the effects of manpower and money saving are achieved.

Owner:苏德政

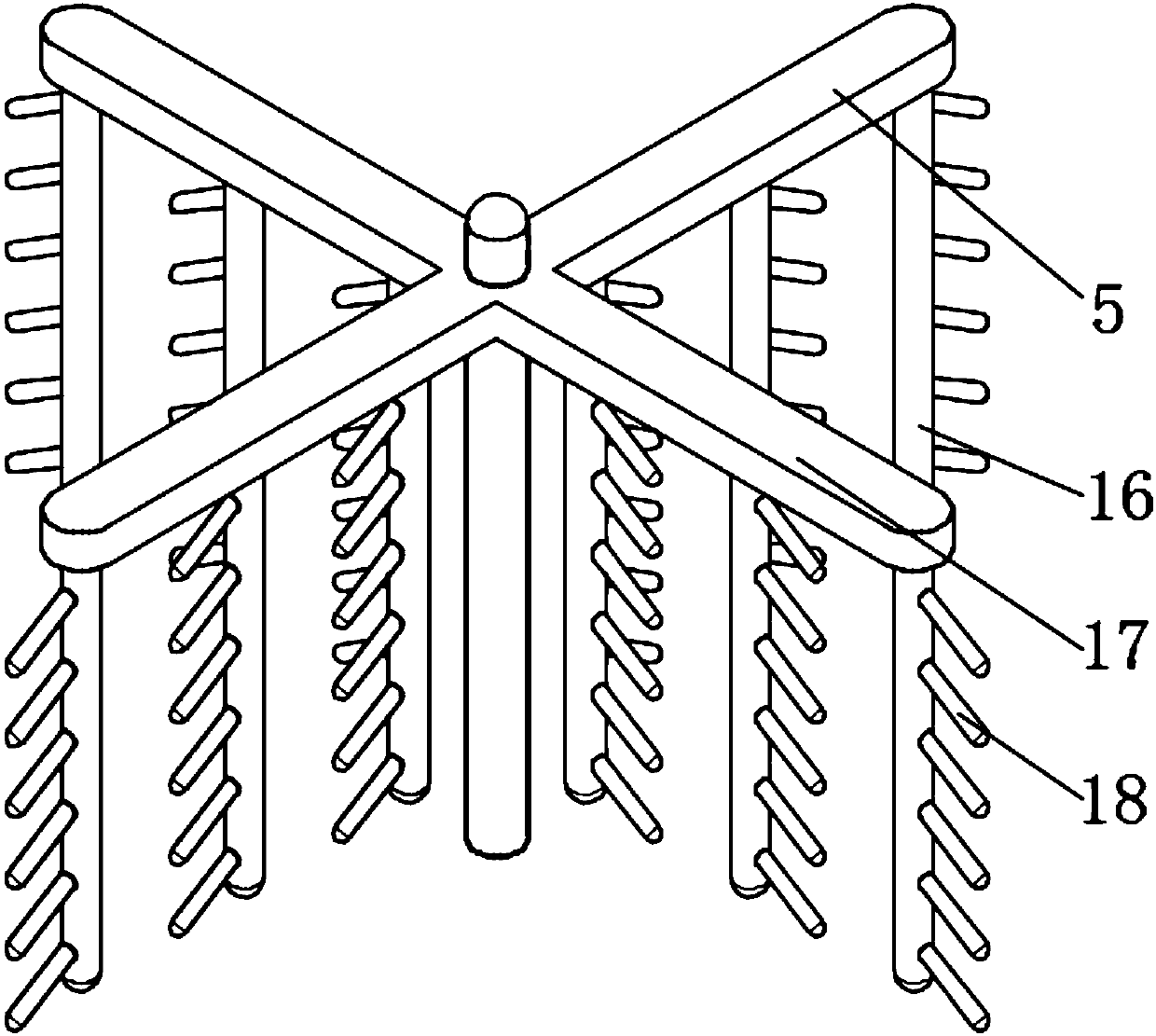

Biomass fertilizer material mixing device

PendingCN107744758AReduce spillageImprove shipment rateRotating receptacle mixersTransportation and packagingFertilizerBiomass

The invention relates to a biomass fertilizer material mixing device, which comprises a stirring tube, a stirrer and a base, wherein one side of the upper end surface of the base is connected with aninclined block; the upper end surface of the inclined block is connected with two pairs of second support frames; a rotating shaft is rotationally connected between each pair of second support frames;each of the two ends of the rotating shaft is connected with a gear; a second motor is arranged on the upper end surface of the inclined block; the second motor is in transmission connection with a driving belt wheel through a motor shaft. A stirring tube is in inclined placement through the inclined block, and the bottom of the stirring tube is rotationally connected a turning door, so that a user can easily feed the biomass fertilizer from the open end of the stirring tube; then, the biomass fertilizer can be discharged out from the turning door arranged at the bottom of the stirring tube under the gravity effect; the scattering quantity of the biomass fertilizer in the feeding process can be reduced; meanwhile, the yield of the stirring tube is improved.

Owner:咸丰隆态生物科技有限公司

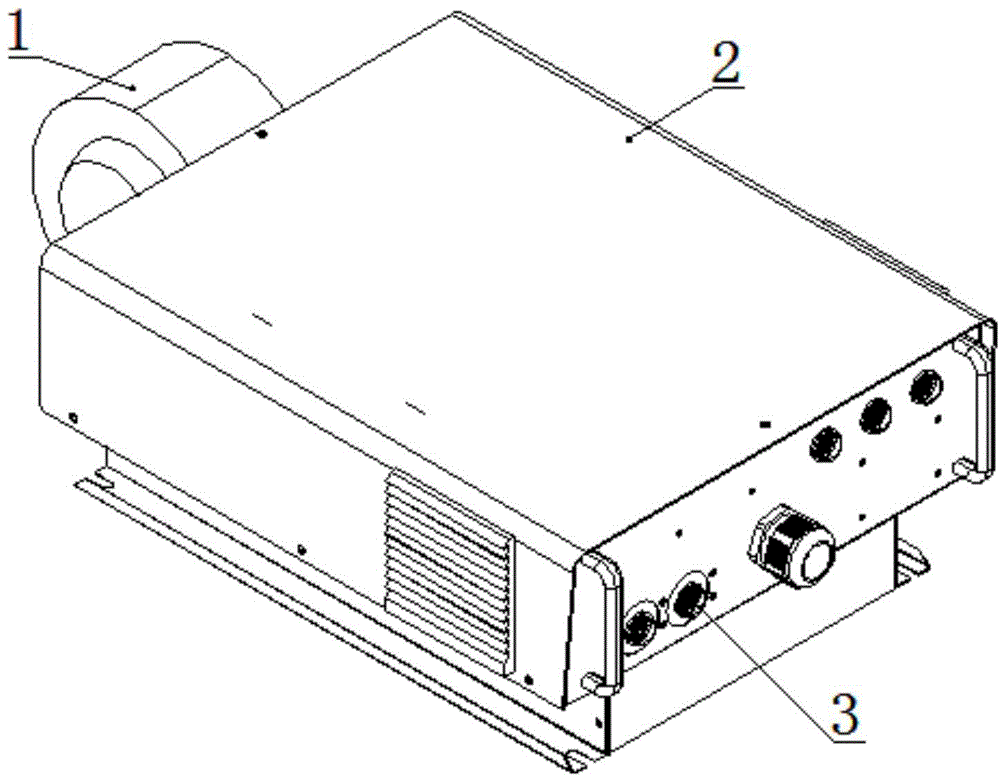

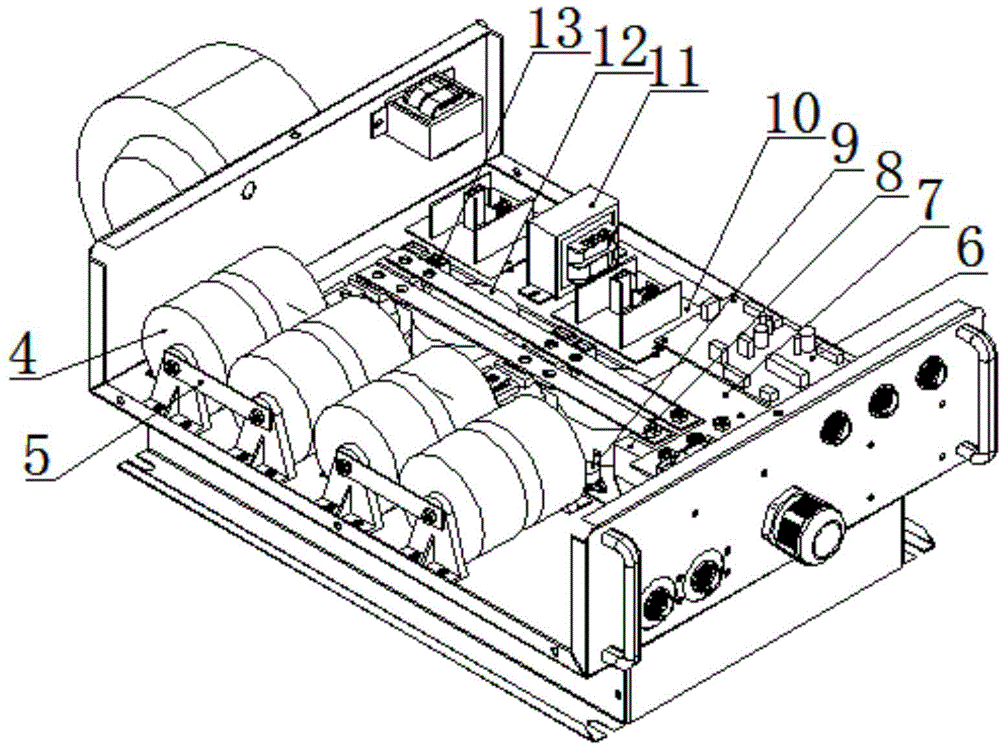

Electromagnetic induction type heating device for roasted nuts and seeds

InactiveCN104886720AImprove heating efficiencyImprove energy savingFood processingFood preservationResonant capacitorElectromagnetic induction

The invention discloses an electromagnetic induction type heating device for roasted nuts and seeds. The heating device comprises a core and a heating coil tray, wherein the core is connected with the heating coil tray through high-temperature wires; the core comprises a cooling centrifugal blower, a radiator, a casing, resonant capacitors, a high-frequency inverter circuit, a rectifying board, a driving board, a control board, a transformer and aerial sockets. The heating device disclosed by the invention performs heating by electromagnetic induction, so that a rolling drum of a machine for roasted nuts and seeds is heated, and the heating device has the advantages of being safe in usage, being environment-friendly, and being energy-saving and time-saving.

Owner:HEFEI SHUNCHANG ELECTROMAGNETIC INDUCTION TECH

Cleaning Equipment and Cleaning Method for Printer Toner Cartridge Parts

The invention discloses a cleaning device and cleaning method of selenium (Se) drum component of a printer. The cleaning device of the Se drum component of the printer comprises a scrubbing device (5), an alkaline cleaning device (39) and a fine cleaning device (40), wherein the alkaline cleaning device (39) is connected with the scrubbing device (5) through a connecting piece, and the scrubbing device (5) is connected with the fine cleaning device (40) through a connecting piece. The cleaning method of the cleaning device of the Se drum component of the printer includes the following steps that the Se drum component of the printer sequentially passes through a first tank body (2) and a second tank body (17) which are located on the alkaline cleaning device (39) and enters a first scrubbing device (11) and a second scrubbing device (38) of the scrubbing device (5) after two times of alkaline cleaning, after the two times of scrubbing, the Se drum component enters a third tank body (18), a fourth tank body (19), a fifth tank body (20), a sixth tank body (21), a seventh tank body (22) and an eighth tank body (23) of the fine cleaning device (40) in sequence, and a product is obtained after rinsing and purifying are completed so that the product can be cleaned thoroughly.

Owner:SHANGHAI CHAOJING MACHINERY

A kind of glass IC detection method and system

ActiveCN105261019BReduce exception costsImprove yield rateImage enhancementImage analysisLight reflectionComputer science

The invention discloses a method and a system for testing a glass IC. The method comprises the steps of A, irradiating an IC body by means of a light source, then acquiring an image of an irradiating area by means of a CCD, processing the image for distinguishing the IC body from a background in a black-and-white manner; B, searching for crossing parts between black parts and white parts in the image, and obtaining a product area which is surrounded by the IC body in the image through calculation; C, performing zooming processing on a square frame in which the calculated product area exists, and detecting an abnormal area in the image; and D, determining whether the abnormal area exists in the square frame in which the product area exists, and if yes, determining a fact that the abnormity of the IC body occurs. According to the method and the system, through adjusting the light source and processing through a corresponding software algorithm, a problem of light reflection on glass is settled. Image identification technology is used for detecting abnormal products, and a product yield rate is improved. The method for testing according to the invention has functions of reducing number-of-times of inferior mounting on a template, reducing abnormal cost for an enterprise, and improving output amount and quality of products.

Owner:PROSYST ELECTRONICS TECH

A Knife Die for Automatic Punching Machine with Adsorption Function

The invention discloses an automatic blanking machine cutting die with an adsorption function. The automatic blanking machine cutting die comprises a female blanking knife die, a blanking knife hole allowing a blanking knife head to pass is formed in the female blanking knife die, and the blanking knife head and the blanking knife hole are in tight fit. The blanking knife head is fixed to a flange transfer block through a blanking knife sleeve, and a flange is fixedly arranged on the flange transfer block. A vacuum nozzle opening is formed in the female blanking knife die and communicates with the blanking knife hole. A vacuum pipeline is arranged in the blanking knife head, and a vacuumizing opening is formed in the side wall of the blanking knife head and communicates with the vacuum pipeline. Blanking holes are formed in the bottom of the blanking knife head and communicate with the vacuum pipeline. A storing groove for storing a material is formed in the position, below the vacuum nozzle opening, of the female blanking knife die, and the blanking knife hole penetrates through the storing groove. The automatic blanking machine cutting die can conduct blanking completely in a vacuum state, so that products are not prone to falling freely when the products in any shape and with any thickness are blanked, and the precision is high; and the blanking knife head and the blanking knife hole can be designed in any shape, so that the automatic blanking machine cutting die is convenient to use.

Owner:LENSEND AUTOMATION TECH SUZHOU

A LED production process optimization method based on big data technology

ActiveCN108649106BReduce the influence of luminescence characteristicsConsistent level of luminescenceSemiconductor devicesProcess optimizationProcess engineering

The invention relates to an LED production process optimization method based on a big data technology, comprising the following steps: S1, establishing a dispensing data model, wherein, the dispensingdata model is used for representing the corresponding relationship between the original material parameters and the original dispensing amount; S2, obtaining the current dispensing amount through thedispensing data model; S3, obtaining the LED product by the current dispensing amount. The influence of fluorescent powder settling on LED products can be effectively reduced by the dispensing data model, and the luminous characteristics of the LED products can be kept consistent. The method can effectively improve the concentration degree of LED color coordinates and the falling Bin rate of themain color area in the mass production stage, improve the input-output ratio and productivity, increase the delivery rate and reduce the production cost. Through real-time monitoring the glue contentconcentration in the dispensing process, if the glue content concentration exceeds the threshold range or the on-line time exceeds the threshold range, timely detection and alarm increase the yield ofproducts and reduce abnormal losses.

Owner:浙江云科智造科技有限公司

A high-precision positioning method for LED chip array arrangement

ActiveCN107731985BHigh precisionEnsure consistencySemiconductor/solid-state device manufacturingSemiconductor devicesChip sizeChip-scale package

The present application provides a high-precision positioning method for LED chip array arrangement. The method includes the following steps that: a mask layout is designed according to chip size, a chip spacing, a cutting line position and knife width, and a mask plate is manufactured, wherein the mask layout contains a plurality of arrayed chip patterns; a flexible film is fixed onto one side ofthe mask plate, wherein the one side of the mask plate is provided with the mask layout, the flexible film is a transparent thin film resistant to temperatures greater than 150 DEG C, and a surface of the flexible film, which is far away from the mask plate, is an adhesive surface, the adhesive surface is used for fixing the chips; and a chip arrangement device with an image identification function is utilized to fix the chips on the adhesive surface, and the chip patterns on the mask plate are overlapped with the patterns of the arranged chips. With the method adopted, the accuracy of the arrangement spacing of the chips can be improved, the uniformity of the thickness of the encapsulant of the CSP (Chip Scale Package) chips and the uniformity of the color temperature of the CSP chips can be improved, and the yield of LED chip package can be improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

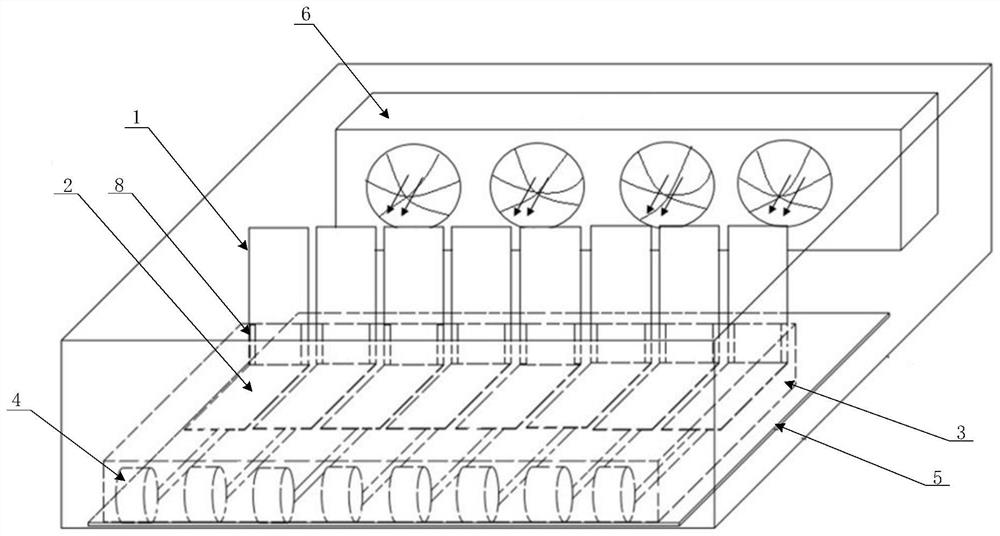

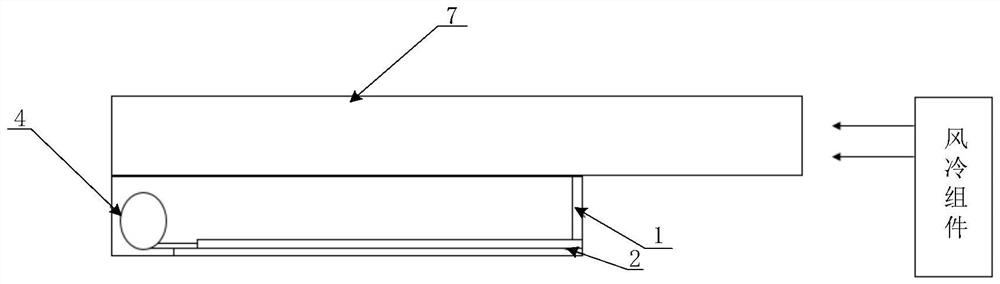

Card holder and server

ActiveCN113490377AVersatilityReduce developmentCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsCold airEngineering

The invention discloses a card holder which comprises a card holder body and further comprises blocking pieces, the blocking pieces are arranged on the side, close to an air cooling assembly, of the card holder body, the blocking pieces are used for blocking cold air, the blocking pieces are elastic pieces, the blocking pieces are arranged side by side, after a board card is installed, the corresponding blocking pieces are shrunk under extrusion of the board card, and after pressure is relieved, the corresponding blocking piece can be reset. According to the invention, the sizes of all the blocking pieces are the same. The board cards of different sizes can extrude the blocking pieces of different numbers. The blocking piece has universality and is suitable for board cards of different sizes, so that development of parts is reduced, the mold opening cost is reduced, and meanwhile the production rate and the shipment rate are improved. The blocking pieces are not disassembled, after the board card is installed, the corresponding blocking pieces automatically contract to form the air channels, and after the board card is disassembled, the corresponding blocking pieces can automatically reset. The invention further discloses a server.

Owner:NANCHANG HUAQIN ELECTRONIC TECH CO LTD

Automatic blanking machine cutting die with adsorption function

ActiveCN106142217AReduce wasteSave intermediate costsMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic blanking machine cutting die with an adsorption function. The automatic blanking machine cutting die comprises a female blanking knife die, a blanking knife hole allowing a blanking knife head to pass is formed in the female blanking knife die, and the blanking knife head and the blanking knife hole are in tight fit. The blanking knife head is fixed to a flange transfer block through a blanking knife sleeve, and a flange is fixedly arranged on the flange transfer block. A vacuum nozzle opening is formed in the female blanking knife die and communicates with the blanking knife hole. A vacuum pipeline is arranged in the blanking knife head, and a vacuumizing opening is formed in the side wall of the blanking knife head and communicates with the vacuum pipeline. Blanking holes are formed in the bottom of the blanking knife head and communicate with the vacuum pipeline. A storing groove for storing a material is formed in the position, below the vacuum nozzle opening, of the female blanking knife die, and the blanking knife hole penetrates through the storing groove. The automatic blanking machine cutting die can conduct blanking completely in a vacuum state, so that products are not prone to falling freely when the products in any shape and with any thickness are blanked, and the precision is high; and the blanking knife head and the blanking knife hole can be designed in any shape, so that the automatic blanking machine cutting die is convenient to use.

Owner:LENSEND AUTOMATION TECH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com