Patents

Literature

69 results about "Lead field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special flame-retardant light diffuser grade polycarbonate composition for LED (light-emitting diode) and preparation method thereof

The invention relates to a special flame-retardant light diffuser grade polycarbonate composition for an LED (light-emitting diode), which comprises the following components in parts by weight: 100 parts of polycarbonate, 0.05-10 parts of light diffuser, 0.1-3 parts of heat stabilizer, 0.1-3 parts of light stabilizer and 5-30 parts of flame retardant. According to the technical scheme, the prepared polycarbonate composition achieves the effect of high-efficiency flame retardant; and the haze and light transmittance of the material are well balanced, thereby greatly widening the application range of the polycarbonate composition in the LED field. The product prepared from the special flame-retardant light diffuser grade polycarbonate composition for an LED has the excellent properties of high environment-friendly flame retardancy and balanced haze and light transmittance, and meets the requirements for use safety of the material under the condition of a severe environment.

Owner:大河宝利材料科技(苏州)有限公司

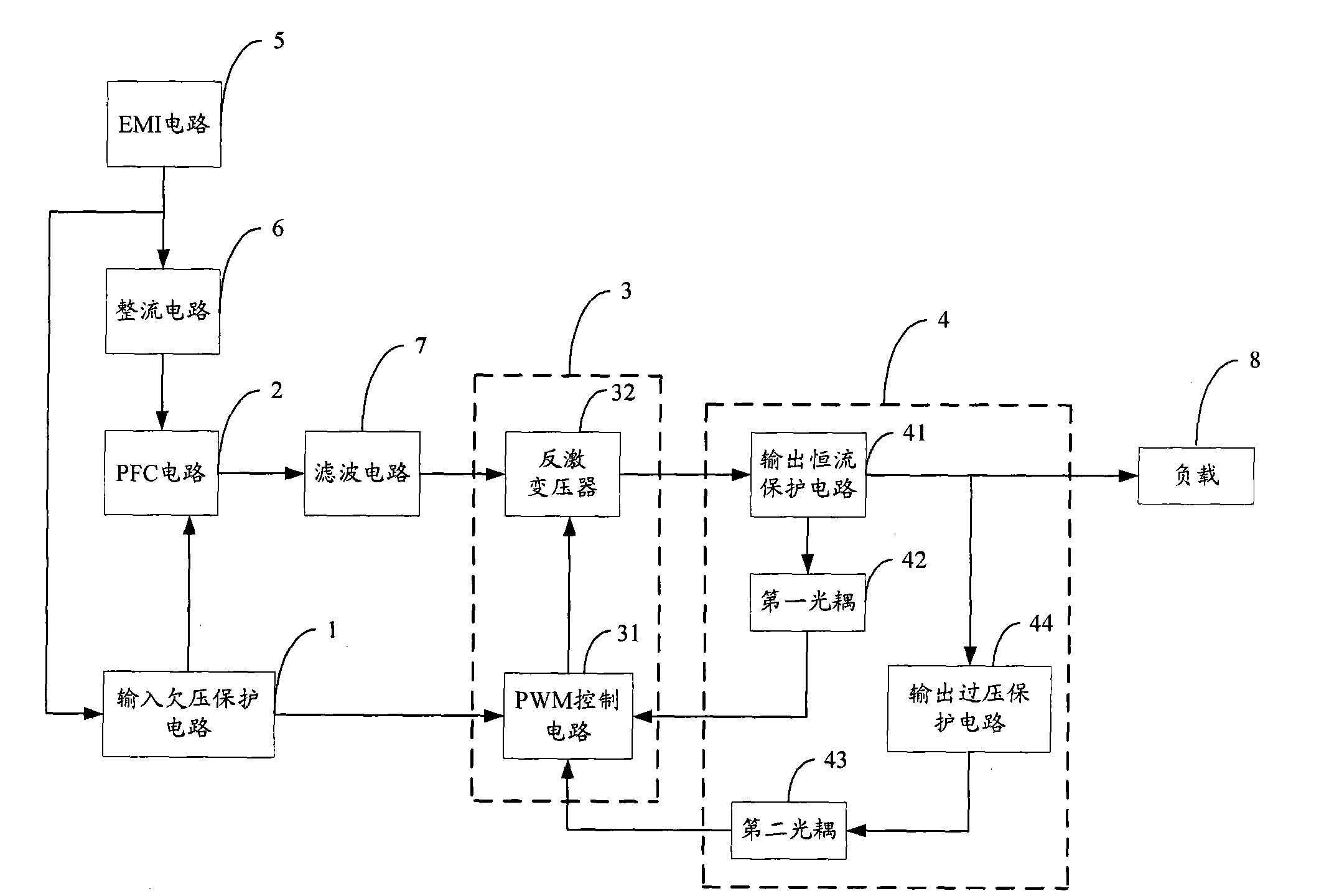

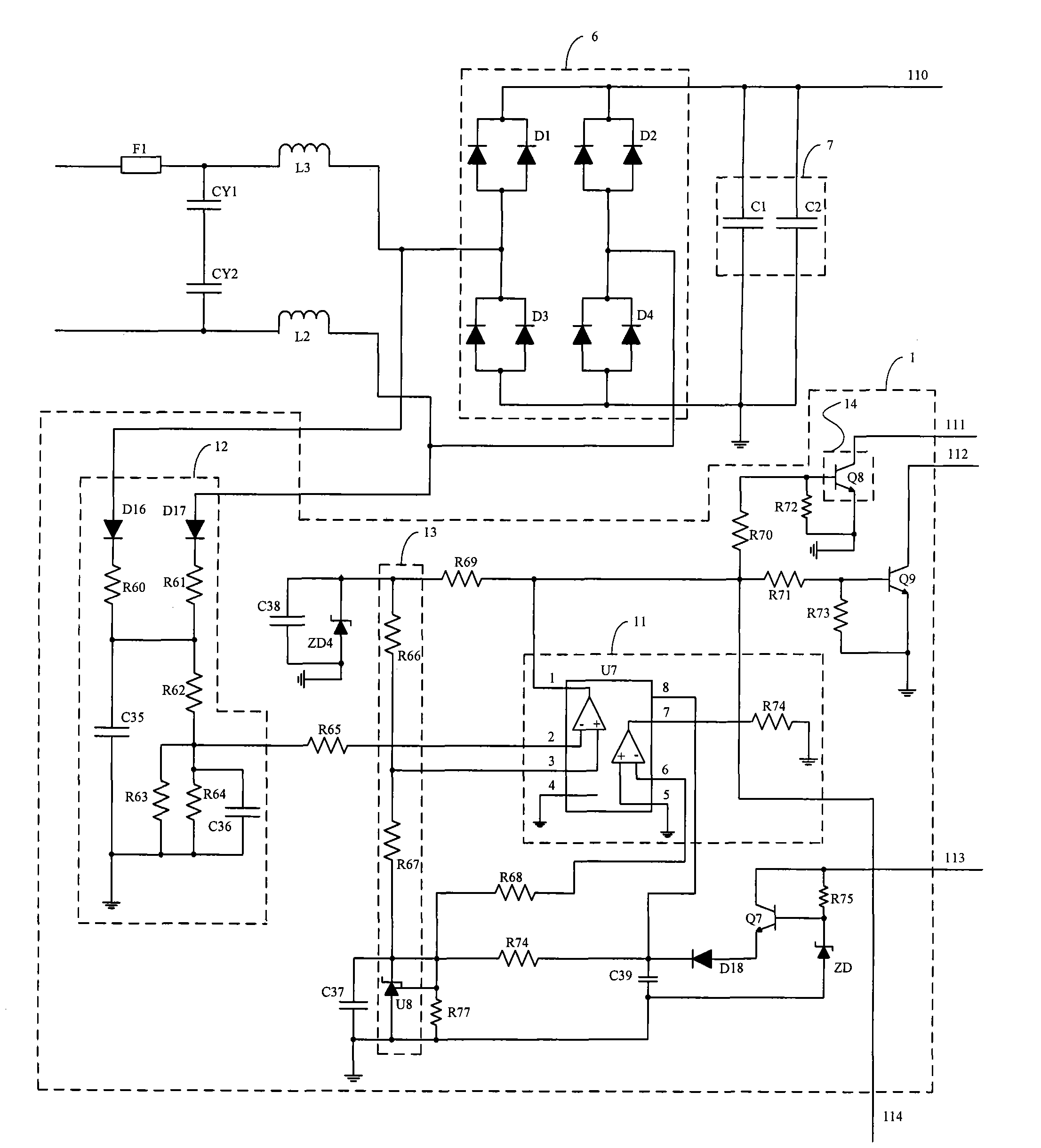

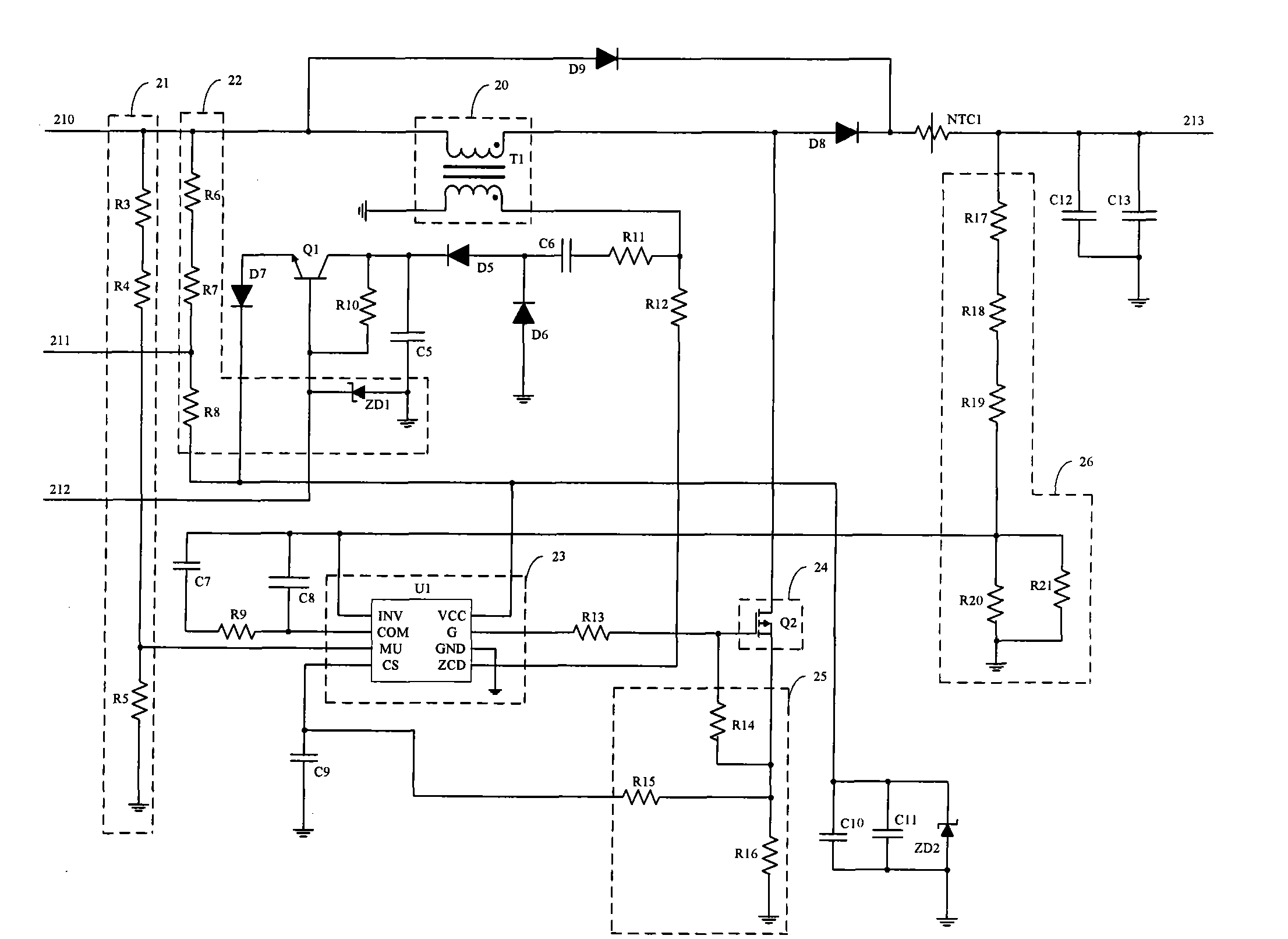

LED control circuit

InactiveCN101778507AGuaranteed constant lightProtect external loadElectric circuit arrangementsElectric light circuit arrangementPower factorEngineering

The invention provides an LED control circuit, being applicable to LED field; the LED control circuit comprises an EMI circuit, a rectifier circuit, a PFC circuit and a filter circuit connected in sequence; the input end of an input undervoltage protective circuit is connected with the input end of the rectifier circuit, the first output end is connected with the control end of the PFC circuit, and the second output end is connected with the second input end of a voltage step-down circuit; the first input end of the voltage step-down circuit is connected with the output end of the filter circuit, the output end of the voltage step-down circuit is connected with the input end of an output constant current and overvoltage protective circuit; the output end of the output constant current andovervoltage protective circuit is connected with the load, and the feedback end thereof is connected with the control end of the voltage step-down circuit. The LED control circuit provided in the invention utilizes PFC circuit to lead the input power factor to be larger than 0.99 and voltage to increase to 80V simultaneously, and then utilizes the voltage step-down circuit to lead voltage to decrease to 22V, and simultaneously has the feedback circuit output constant current to ensure LED to shine constantly.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

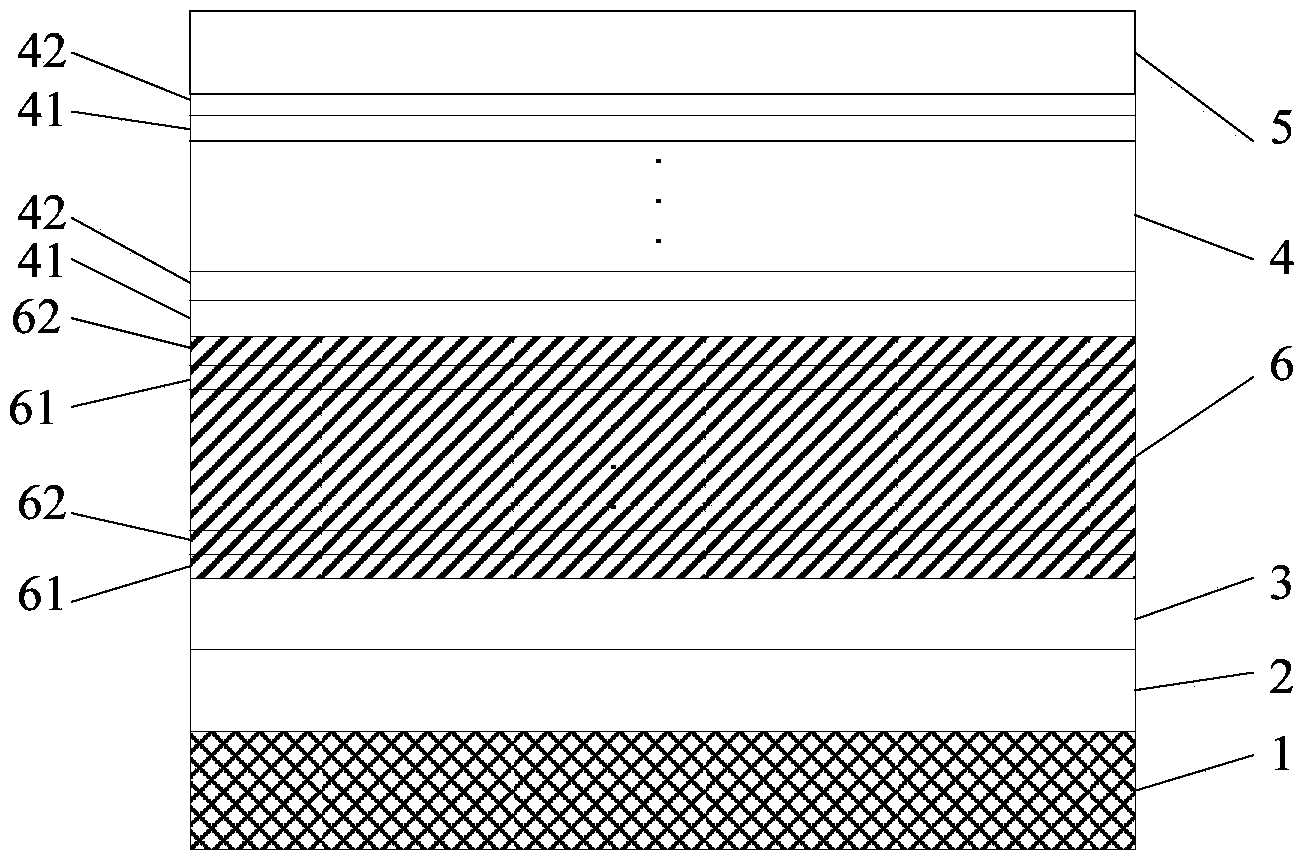

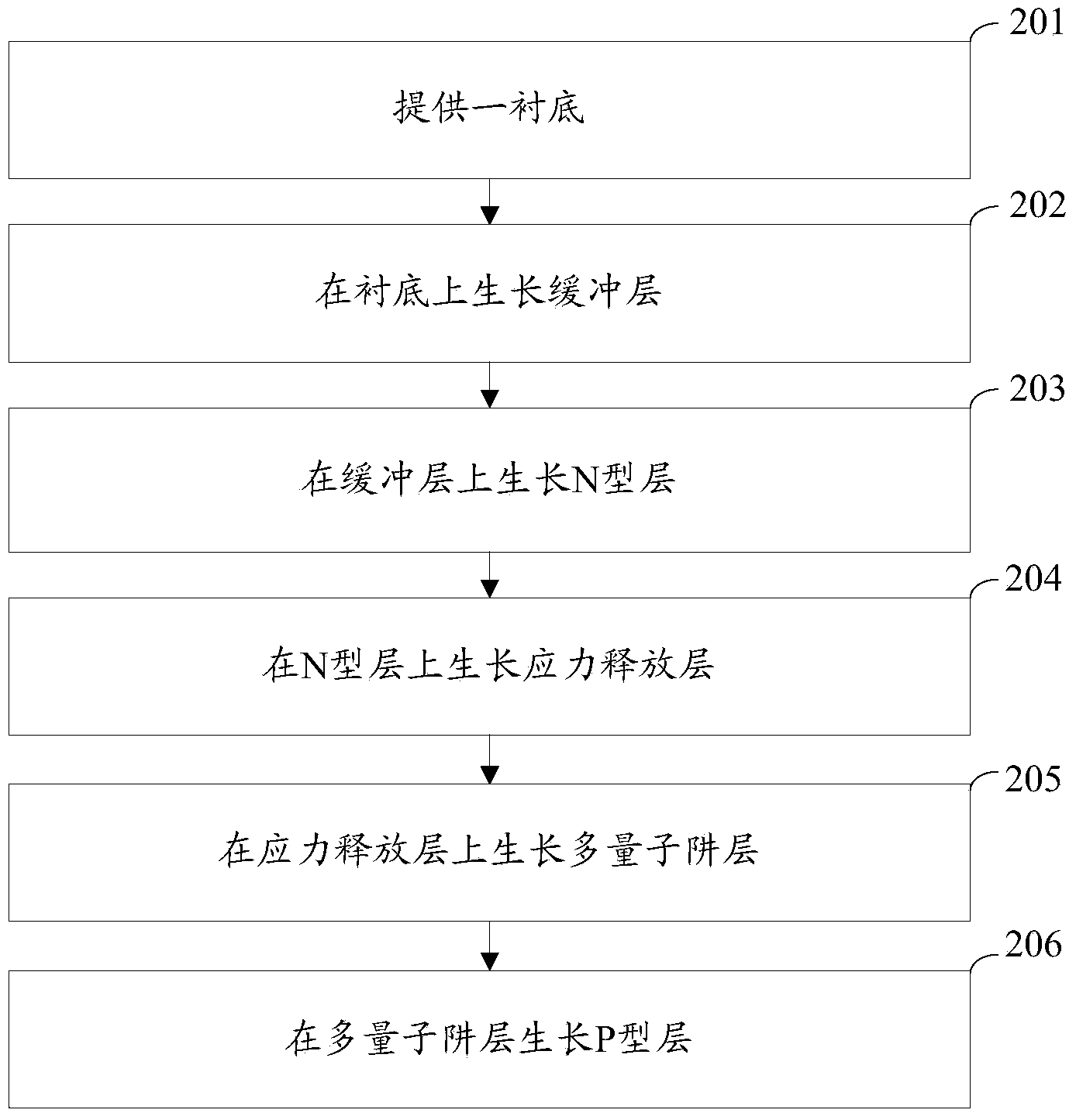

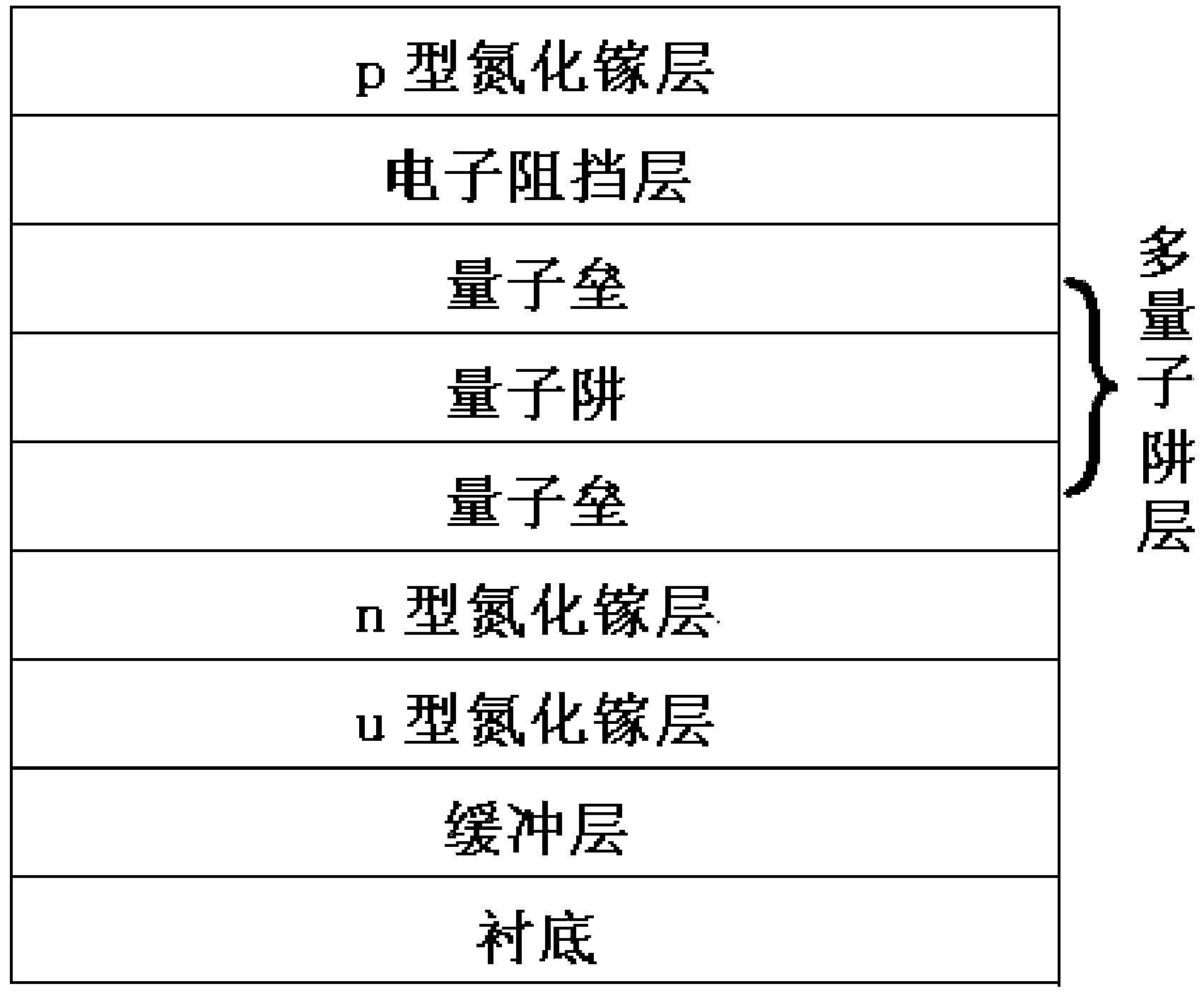

Epitaxial slice of GaN-based light emitting diode (LED) and preparation method thereof

InactiveCN104362233ALow growth temperatureImprove lattice qualitySemiconductor devicesQuantum efficiencyLight-emitting diode

The invention discloses an epitaxial slice of a GaN-based light emitting diode (LED) and a preparation method thereof, and belongs to the LED field. The preparation method of the epitaxial slice of the GaN-based LED includes a step of sequentially growing a buffer layer, an N type layer, a stress release layer, a multiple quantum well layer and a P type layer on a substrate, wherein each period of the multiple quantum well layer comprises an InyGa1-y N layer and a GaN layer, the stress release layer is of a super lattice structure, each period of the stress release layer comprises an InxGa1-x N layer and another GaN layer, y is larger than x, x is larger than 0, growth temperature of the stress release layer is gradually reduced along with periodicity change from the N type layer, and the content of In of each InxGa1-x N layer is increased layer by layer along with the periodicity change. The preparation method of the epitaxial slice of the GaN-based LED effectively delays growth of V-shaped defects by using the temperature varying and In content varying stress release layer and arranging a high temperature and low In content growth stress release layer on one side of the epitaxial slice of the GaN-based LED, close to the N type layer, and thereby effectively reduces the quantity of the V-shaped defects, improves crystalline quality of the multiple quantum well layer, and then improves inner quantum efficiency and antistatic ability of the GaN-based LED.

Owner:HC SEMITEK SUZHOU

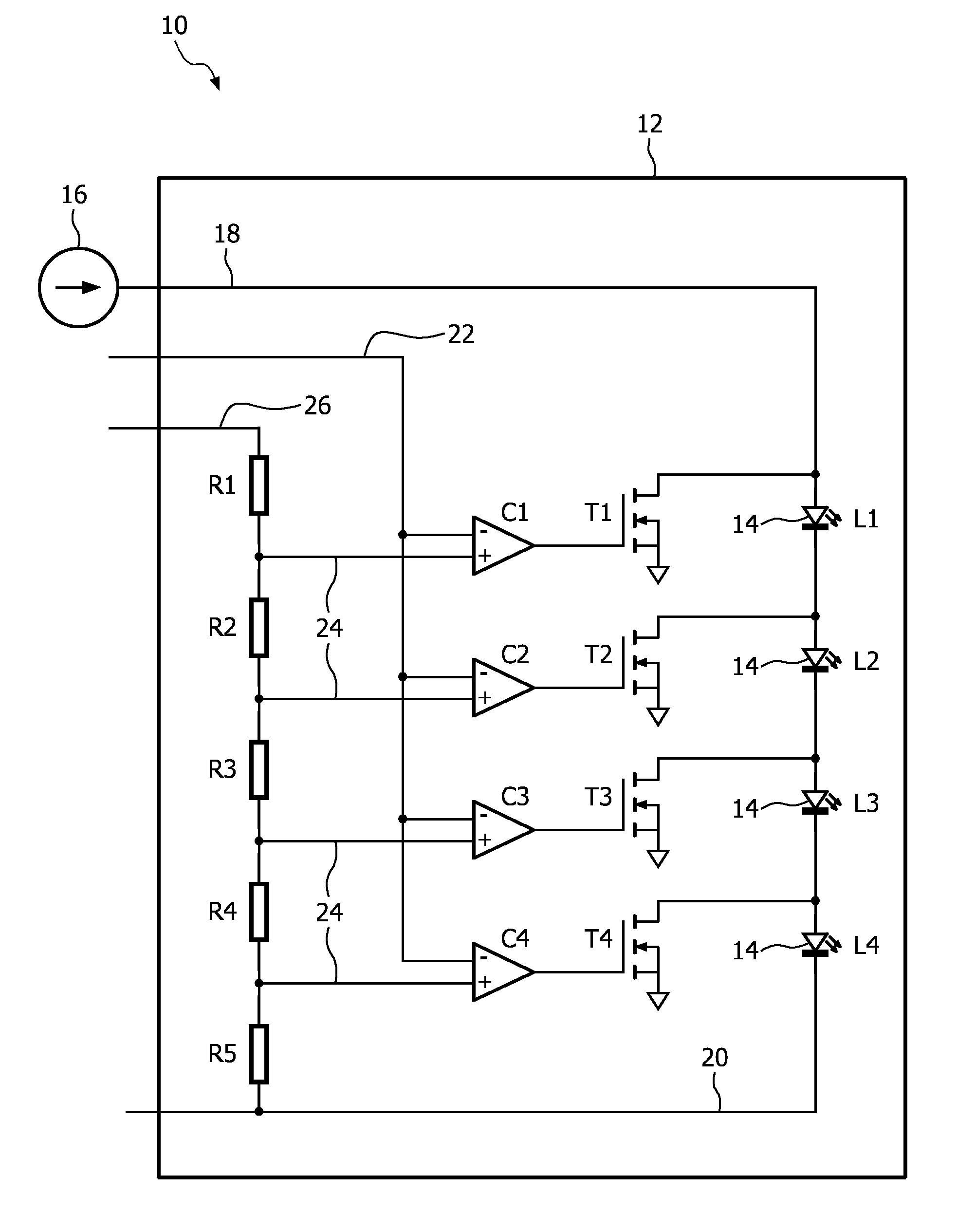

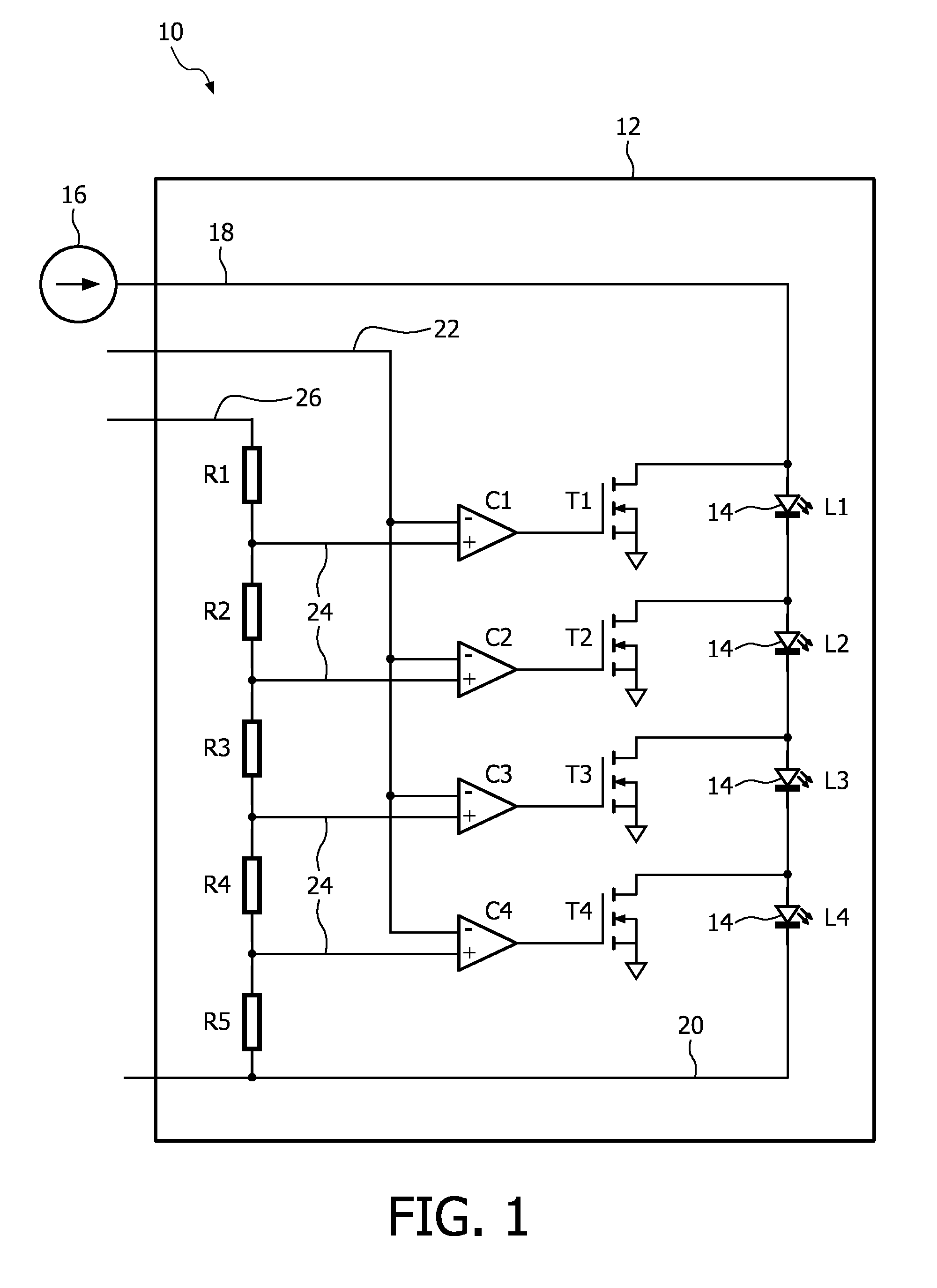

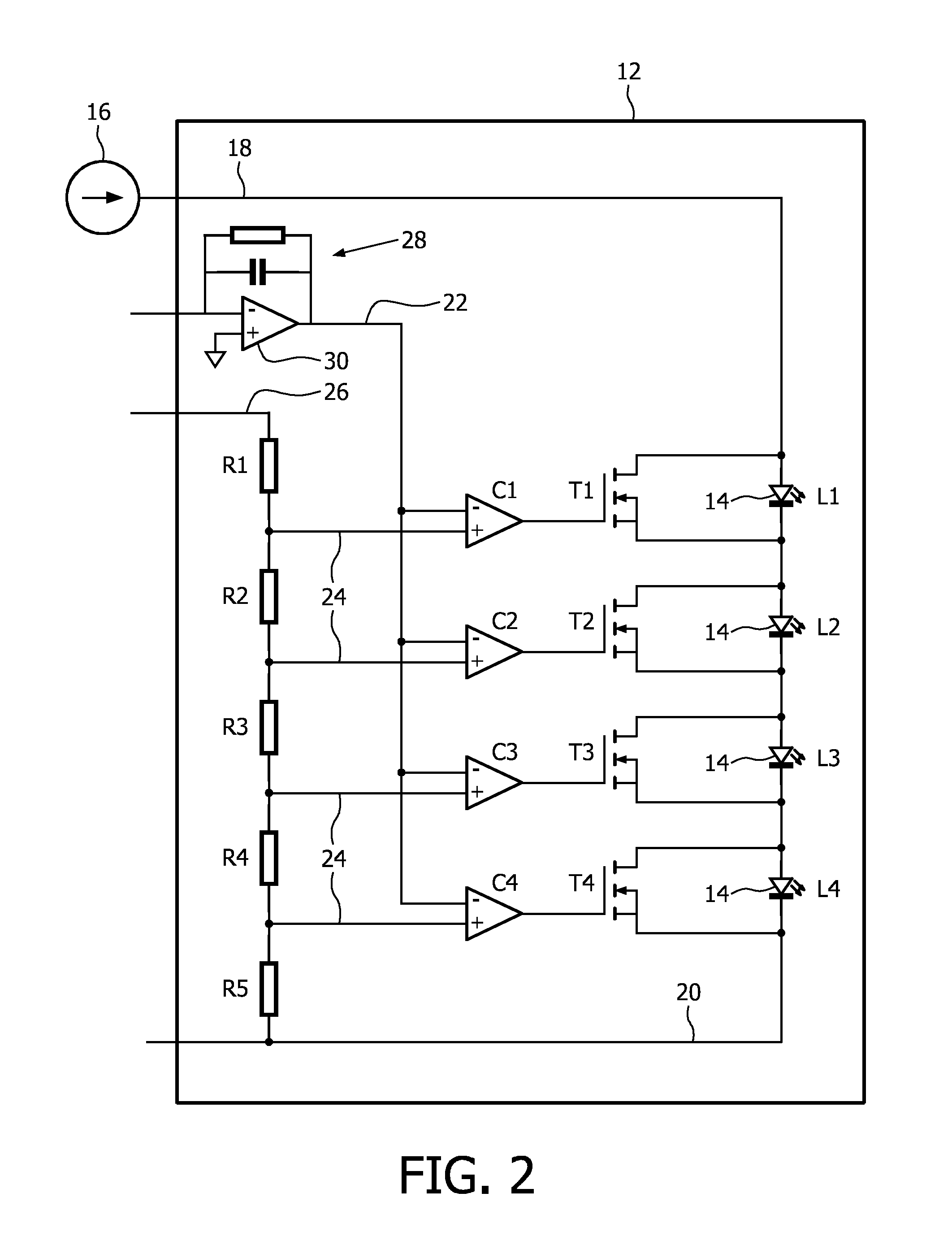

LED light

ActiveUS20110198999A1Easily signalEasy to handleVehicle headlampsElectrical apparatusEngineeringLead field

It is provided a LED light (10) for a motor vehicle, comprising several LED fields (14), wherein each LED field (14) comprises at least one LED (L1, L2, L3, L4), a housing (34) for supporting the LED fields (14) and a circuit board (12) comprising a driving electronics for operating the LED fields (14), wherein the LED fields (14) are connected in series by the driving electronics and the driving electronics is adapted to switch on and off each LED field (14) according to its position in the series in dependence of a signal, wherein the circuit board (12) is connectable to an outside of the LED light (10) located current source (16) for applying an electrical current to the LED fields (14), and wherein the circuit board (12) is integrated into the housing (34). Since complicated and / or changing switching orders of the LED fields (14) are not intended the necessary circuit board (12) for providing the corresponding driving electronics may be so small that it may be integrated into the housing (34) of the LED light (10) without significantly increasing the building space. Particularly a lot of wires between a central control unit and the different LED fields (14) are omitted as well as the central control unit itself so that the LED light (10) only requires a small building space.

Owner:LUMILEDS

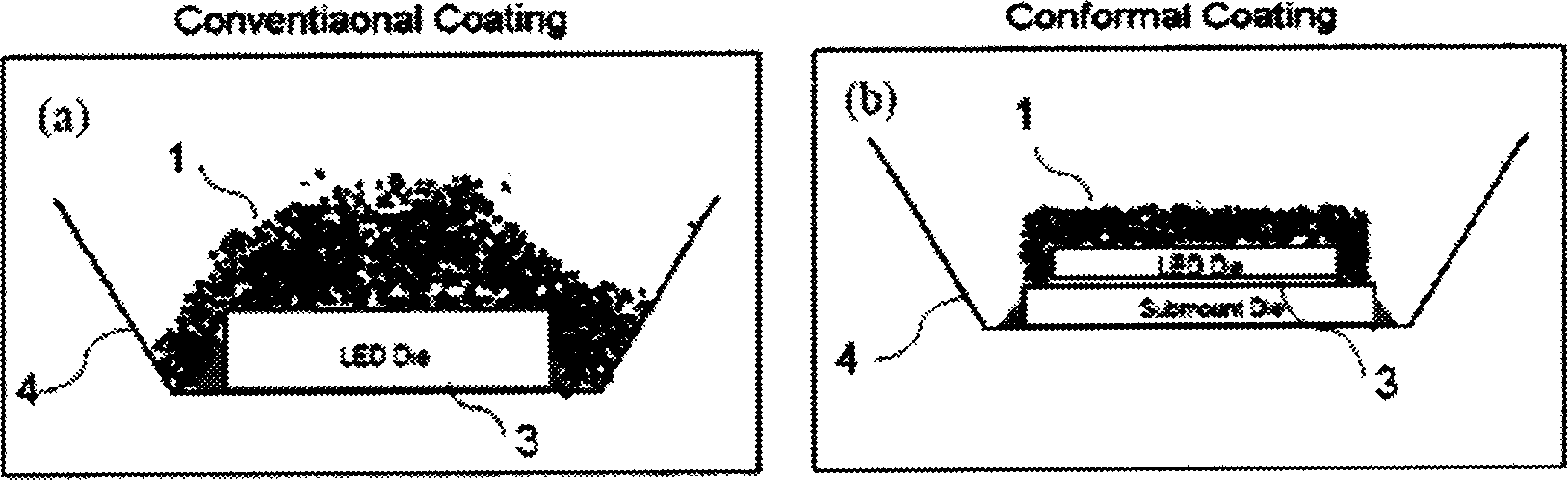

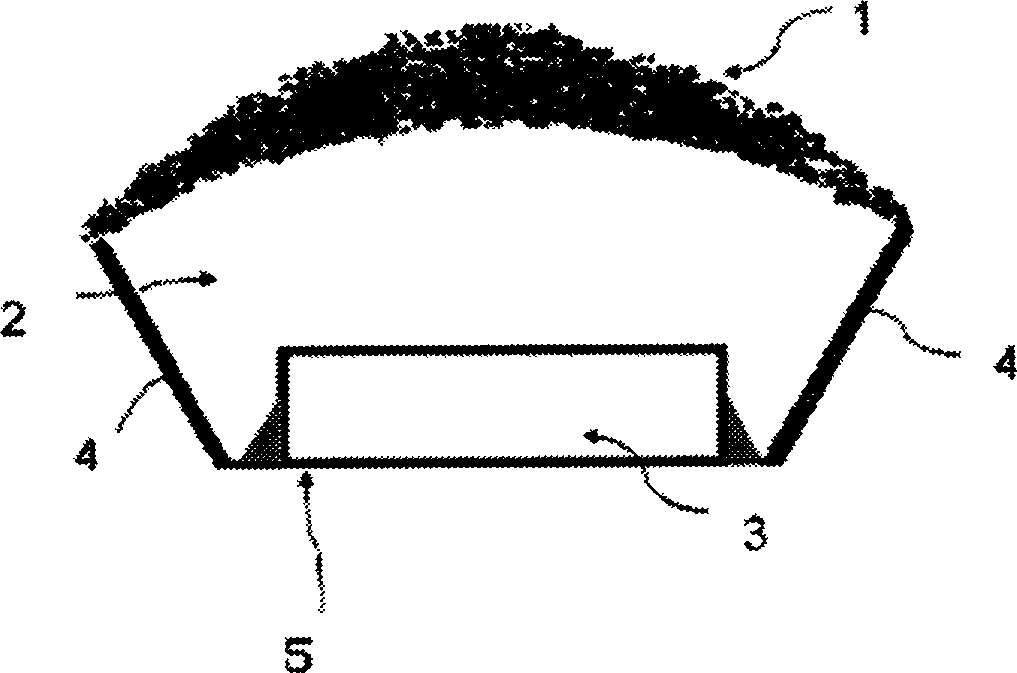

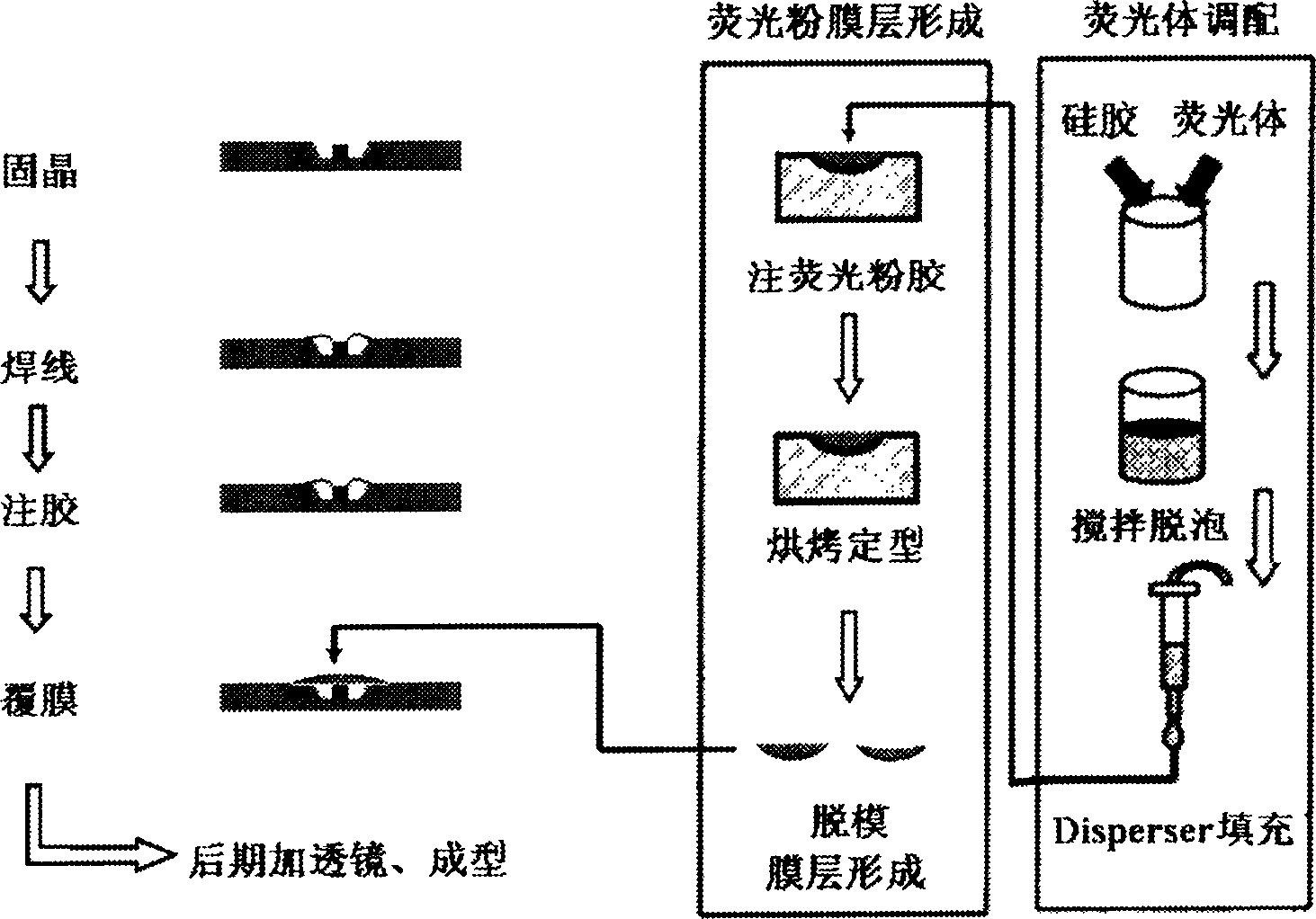

White light LED and packaging method thereof

InactiveCN1838440AImprove stabilityHigh color rendering indexSolid-state devicesSemiconductor devicesFluorescenceSilica gel

This invention relates to LED field, which discloses a white light LED and its packaging method. The white light LED includes chip, frame, silicon glue, fluorescence power film and periphery parts (such as lens). Difference between the packaging structures is that the space between the fluorescence power and chip is isolated by some materials such as silicon glue, which makes the heat of the fluorescence power and chip isolate; and the fluorescence power film brim contacts with the substrate, which makes the fluorescence power's heat conduct to the exterior to avoid the gather of fluorescence power heat. The chip is fixed on the frame, the silicon glue covers on the chip directly, the designed and prepared fluorescence power film cover on the silicon glue, and the fluorescence power film contact with the cup bowl. This method improves the light producing efficiency, and improves the stability of the light color greatly, and lowers the light decline. And the packaging method is simple, which is fit for industrial production in large scale.

Owner:SUN YAT SEN UNIV

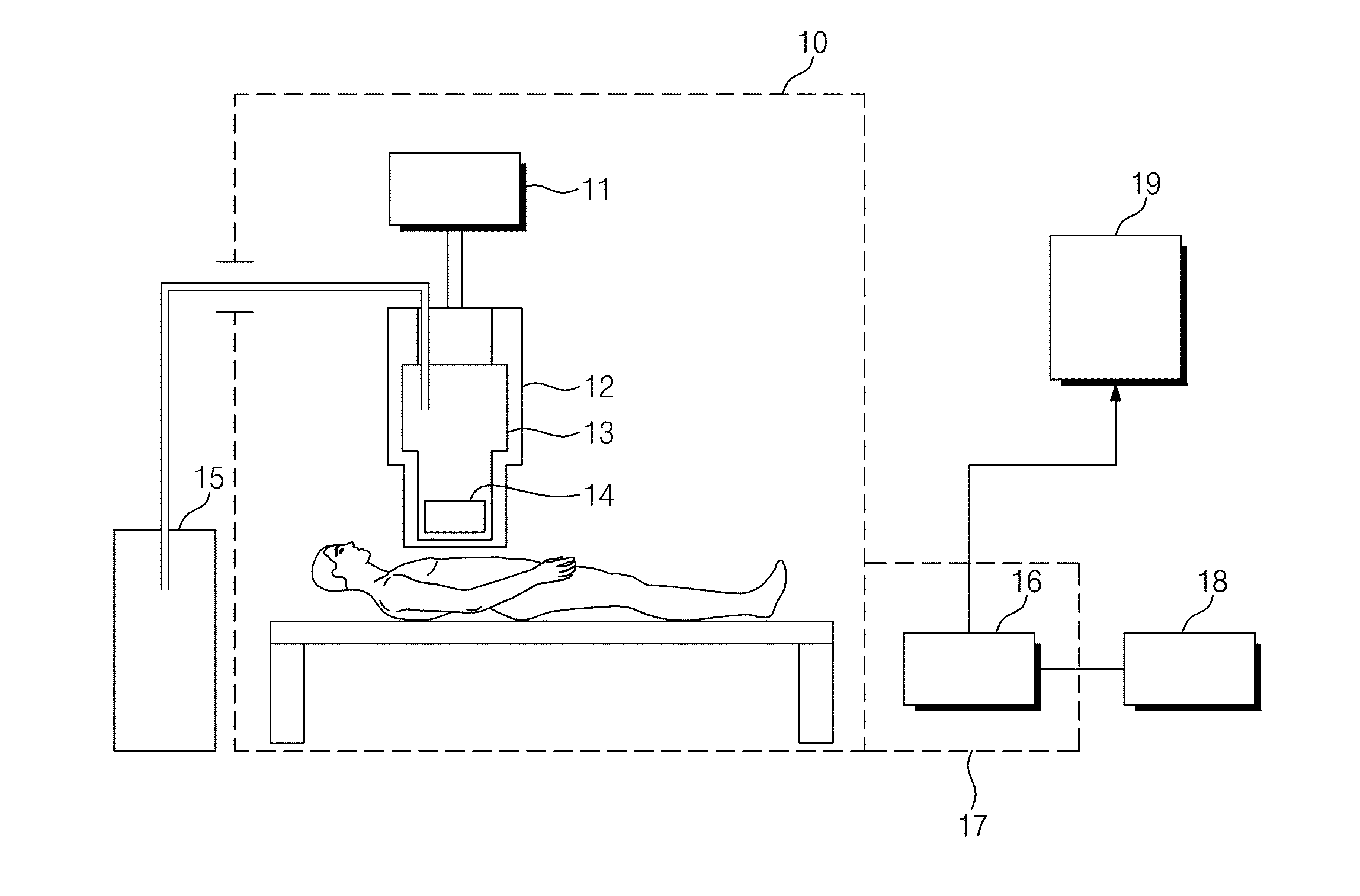

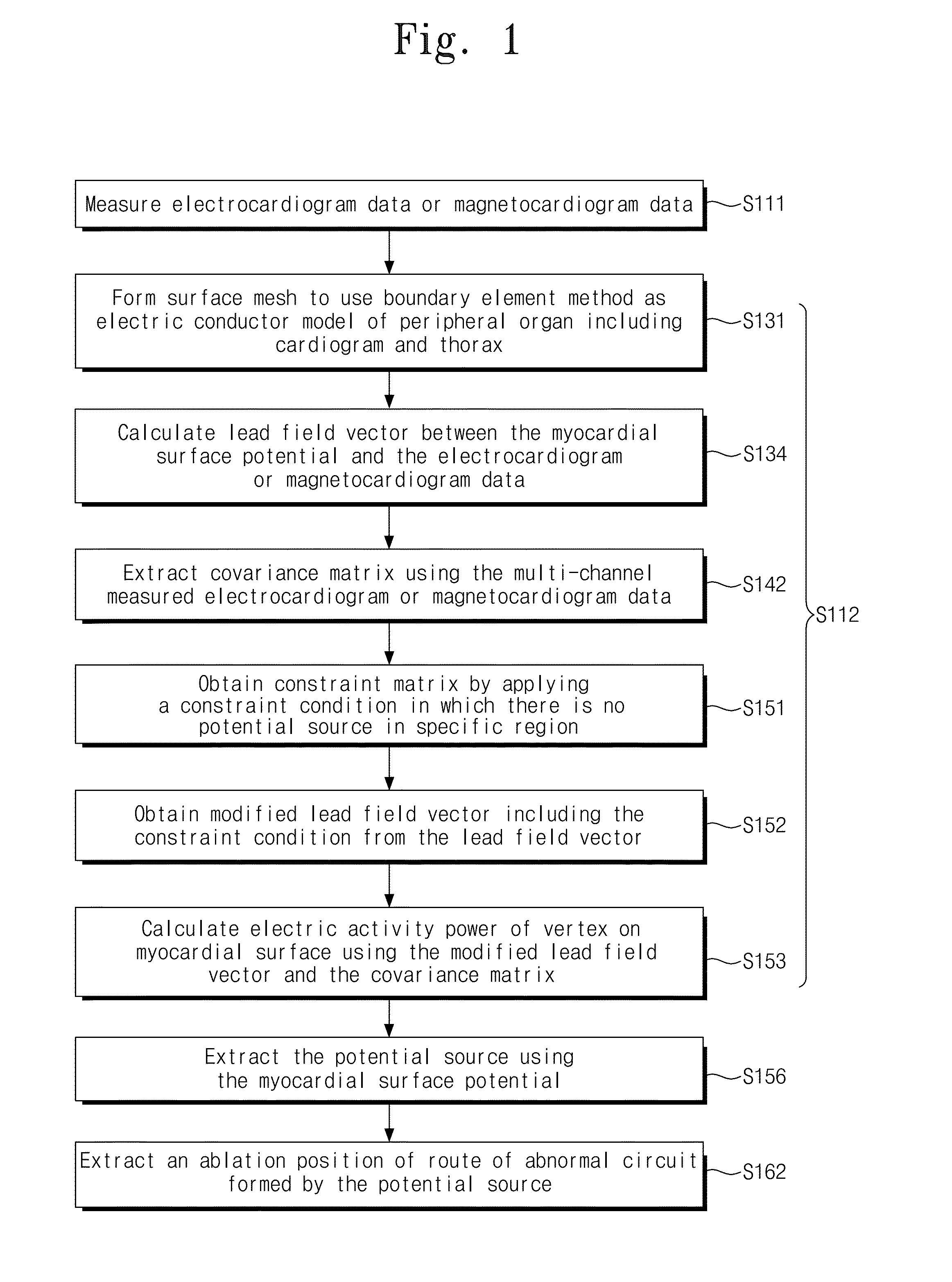

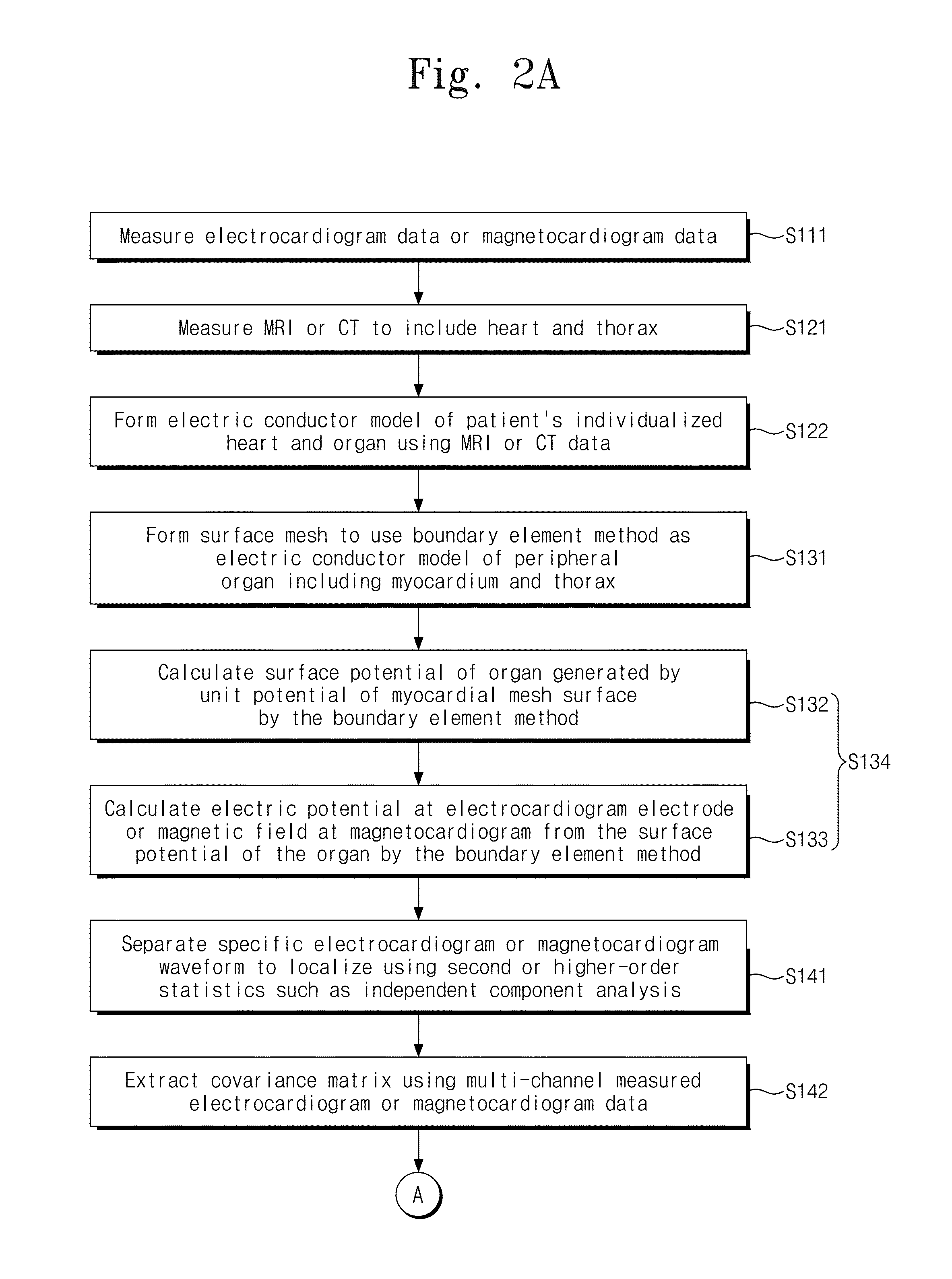

Method for non-invasive mapping of myocardial electric activity

A method for mapping of myocardial electric activity includes measuring electrocardiogram data or magnetocardiogram data and mapping the degree of electric activity of a myocardial surface using the electrocardiogram data or the magnetocardiogram data. A signal source of the electrocardiogram data or the magnetocardiogram data is a myocardial surface potential that is scalar quantity. The mapping uses a lead-field vector which represents the sensitivity between the myocardial surface potential and the electrocardiogram or magnetocardiogram data, and a modified lead-field vector which combines a constraint matrix with a constraint condition where no potential sources exist in a specific region.

Owner:KOREA RES INST OF STANDARDS & SCI

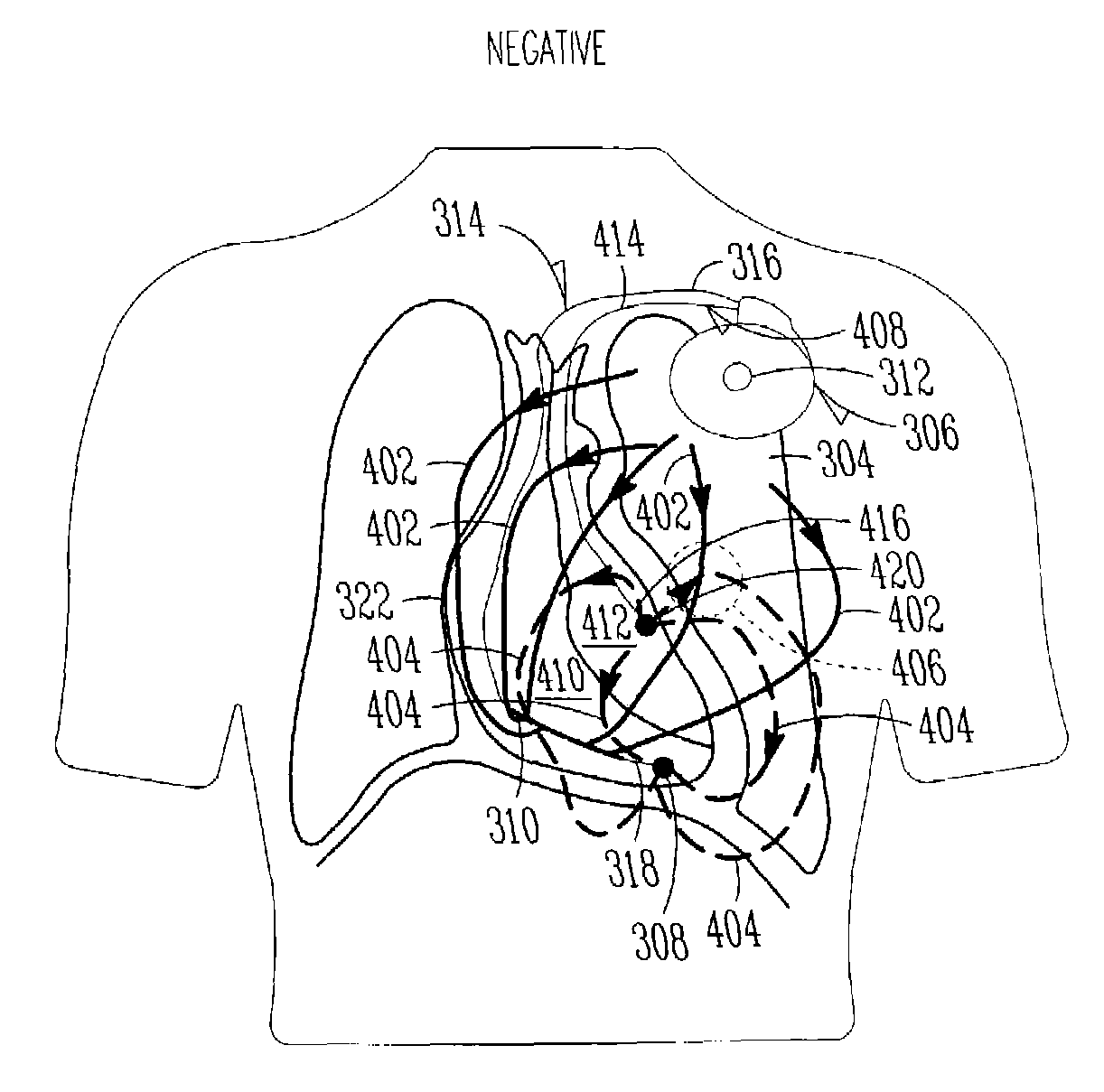

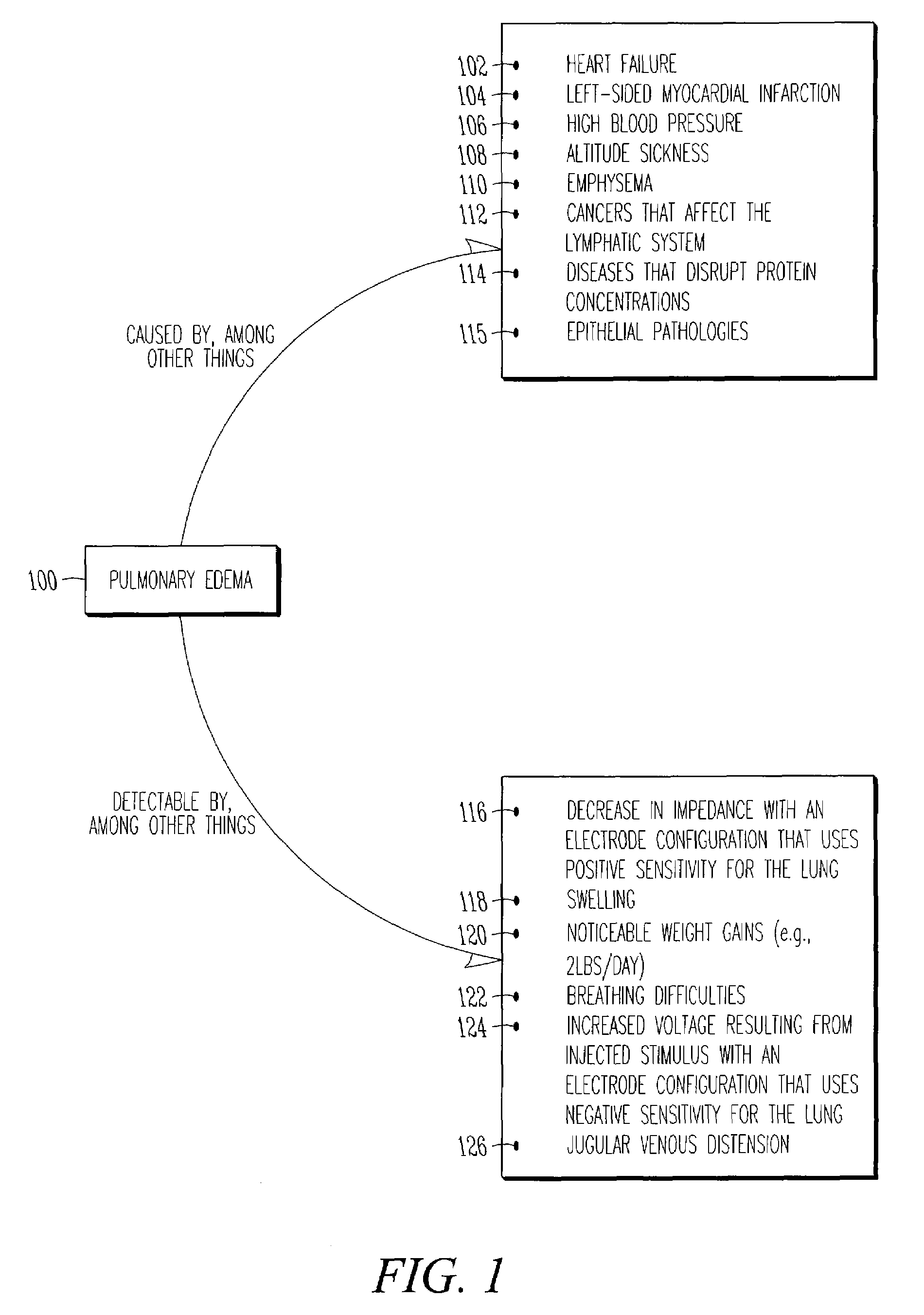

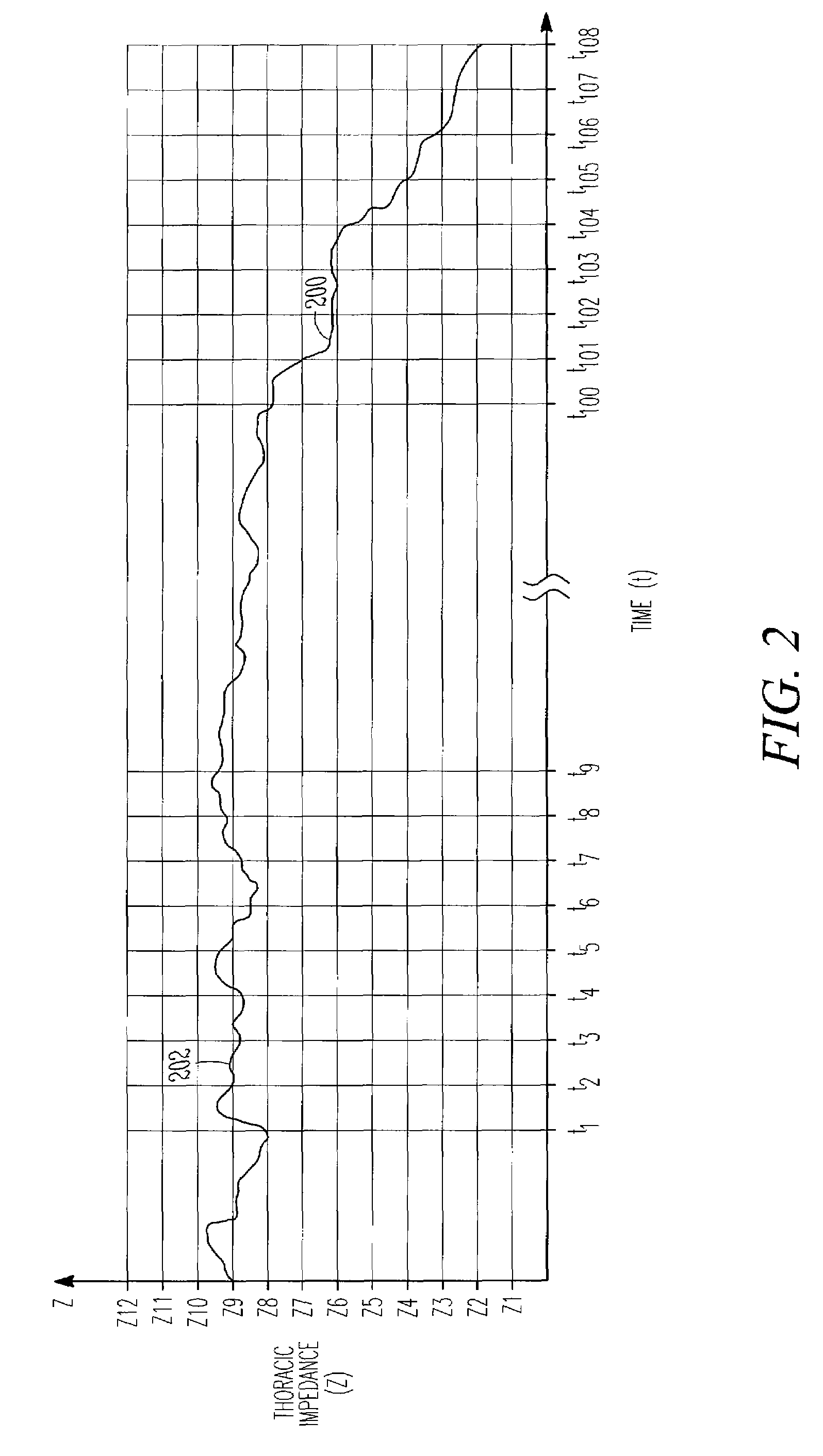

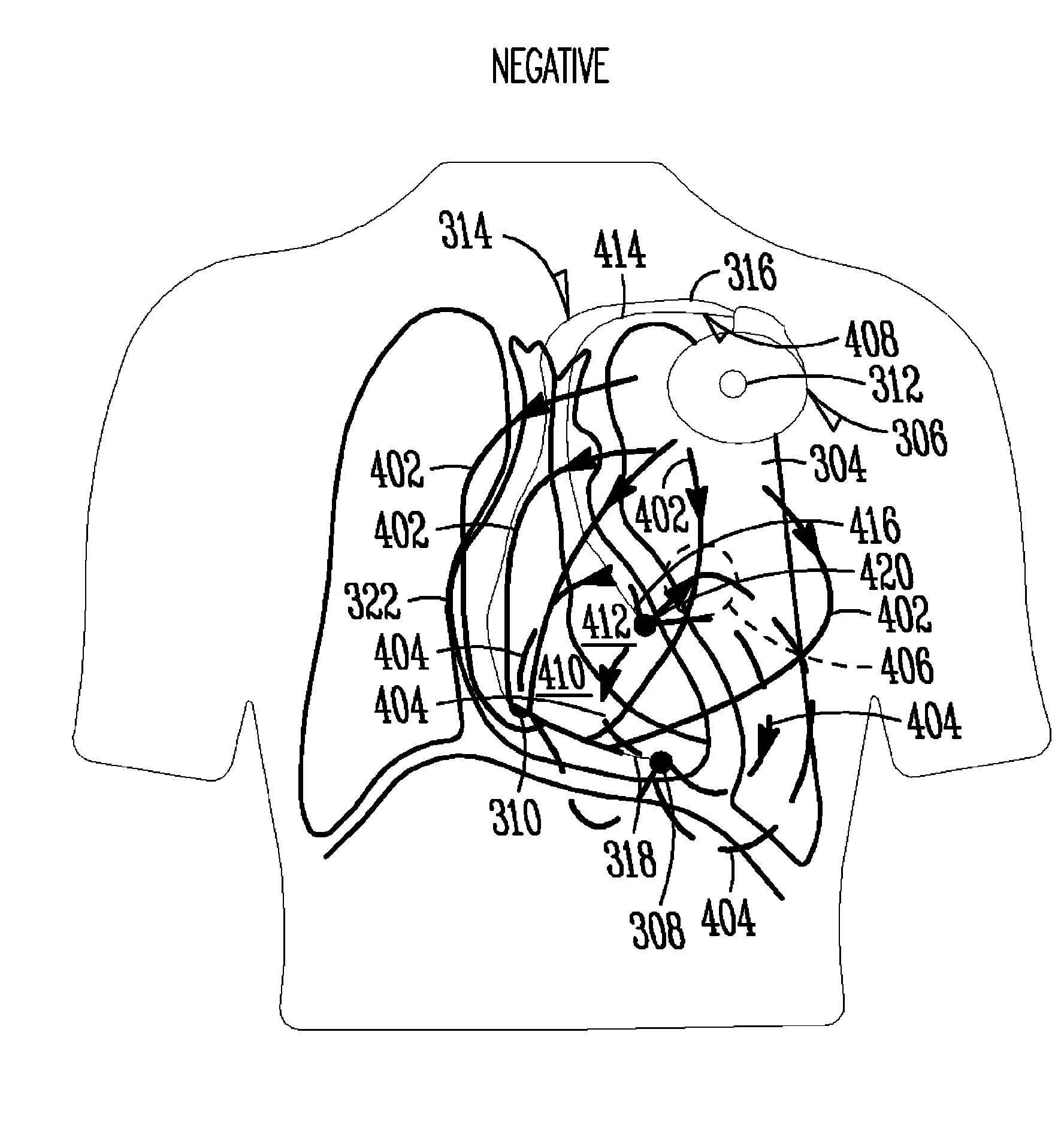

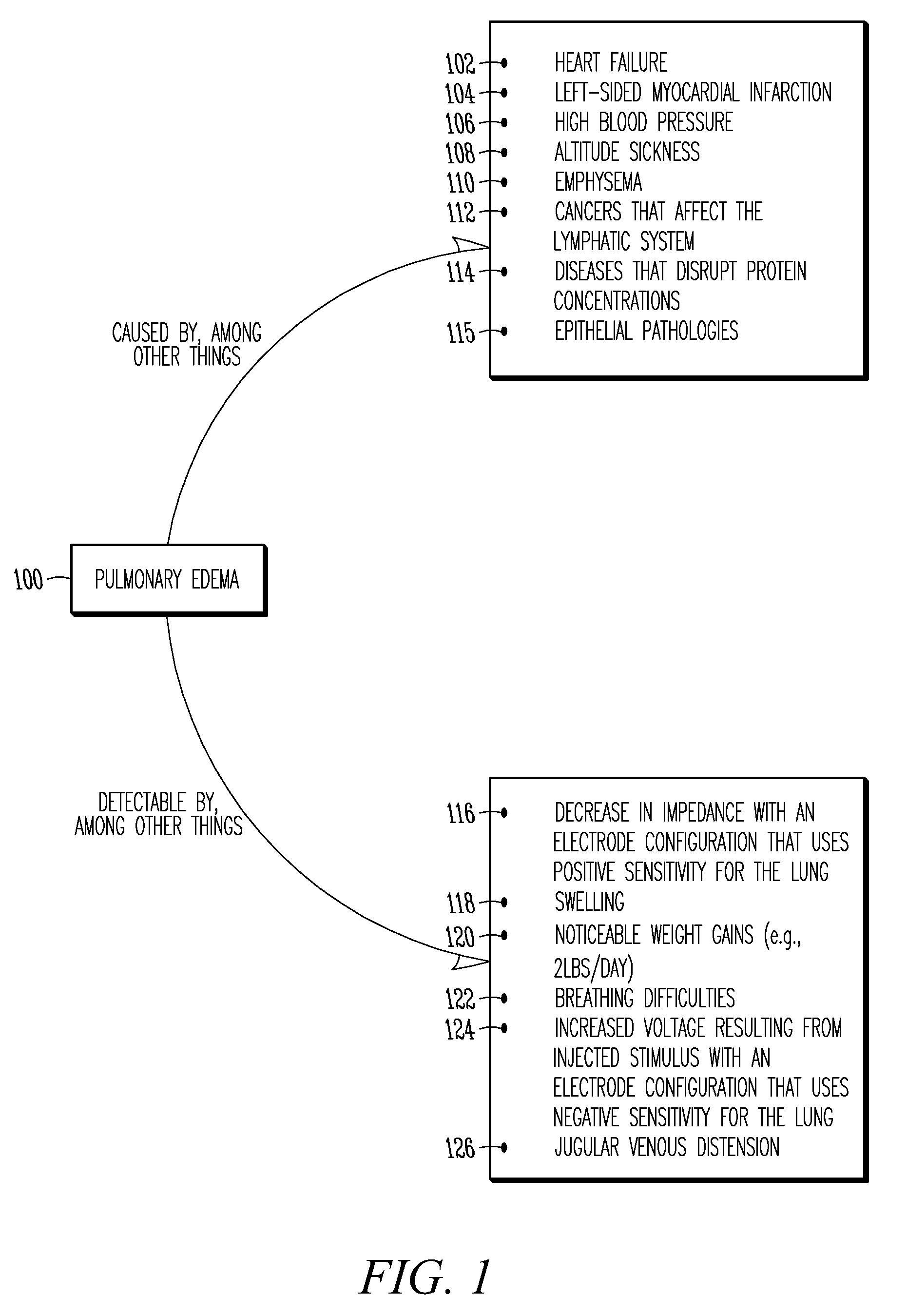

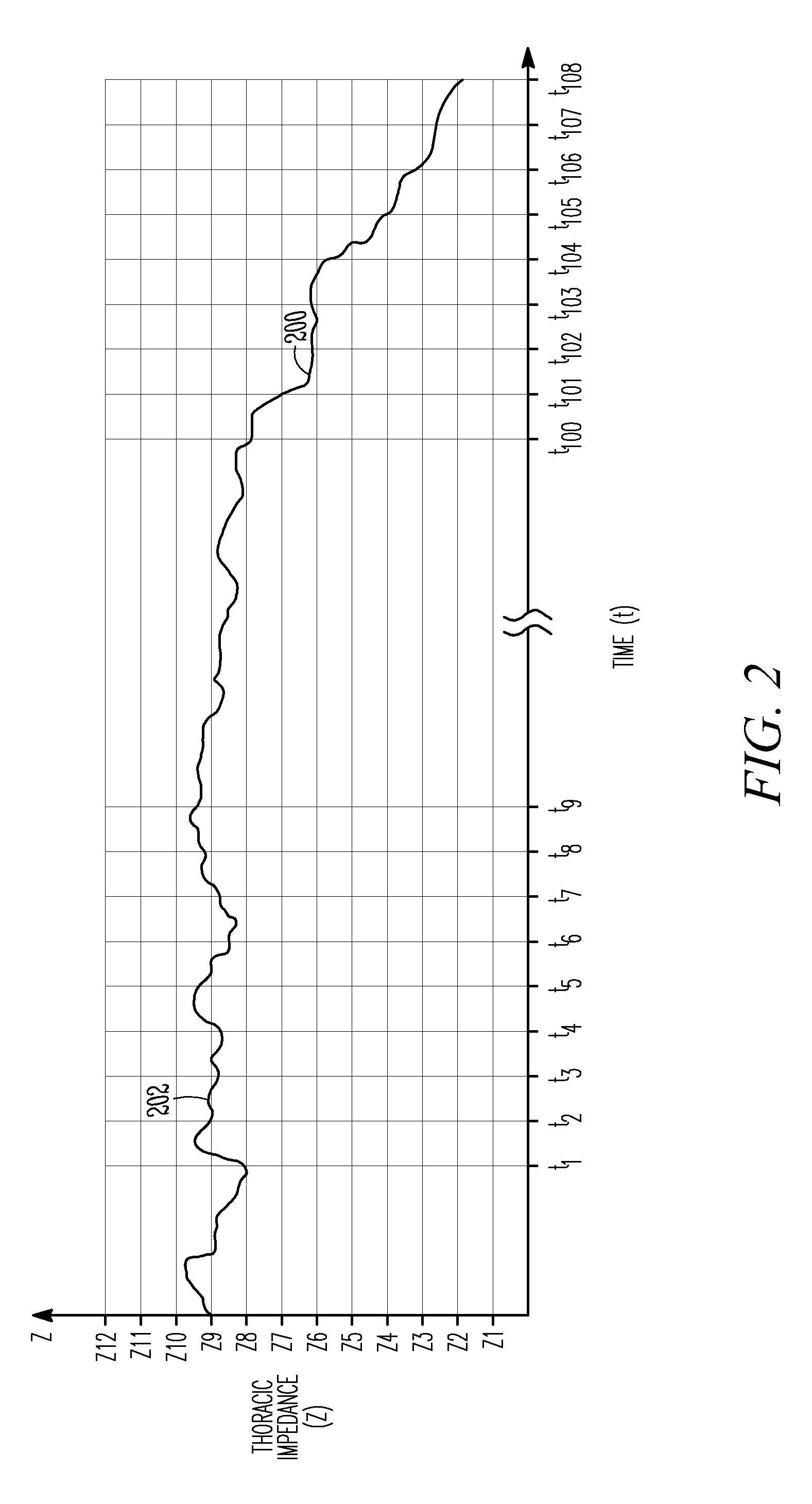

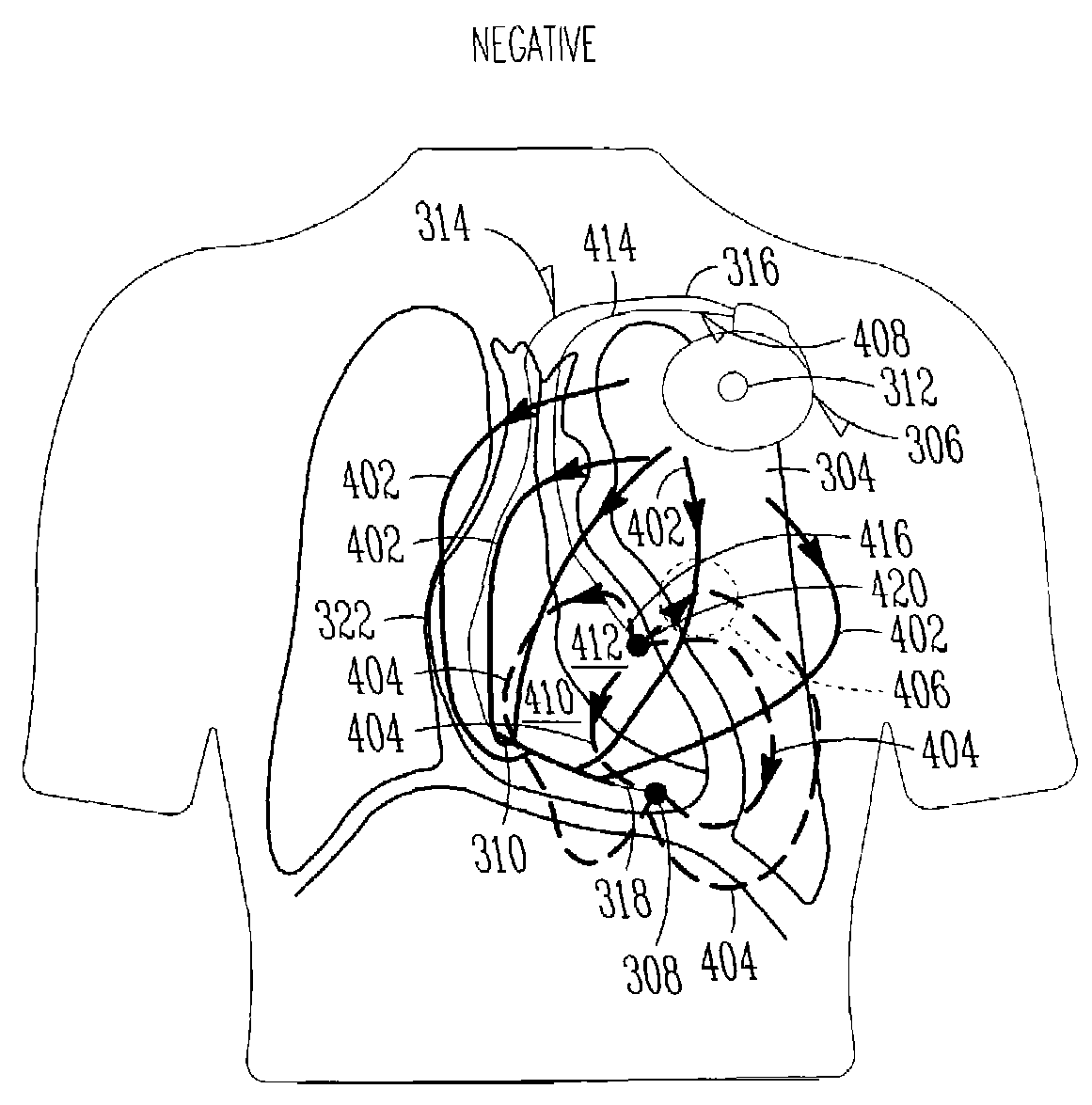

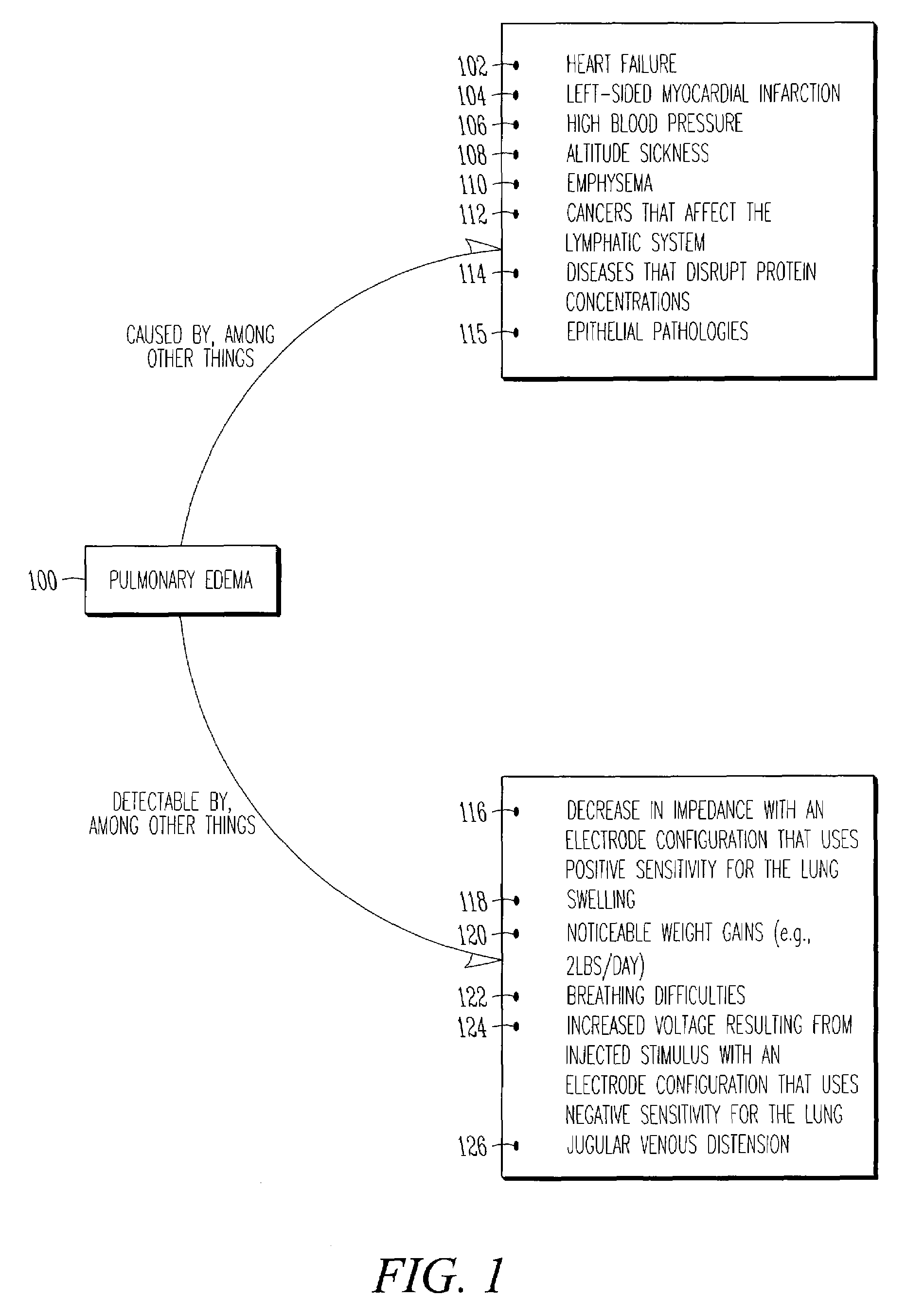

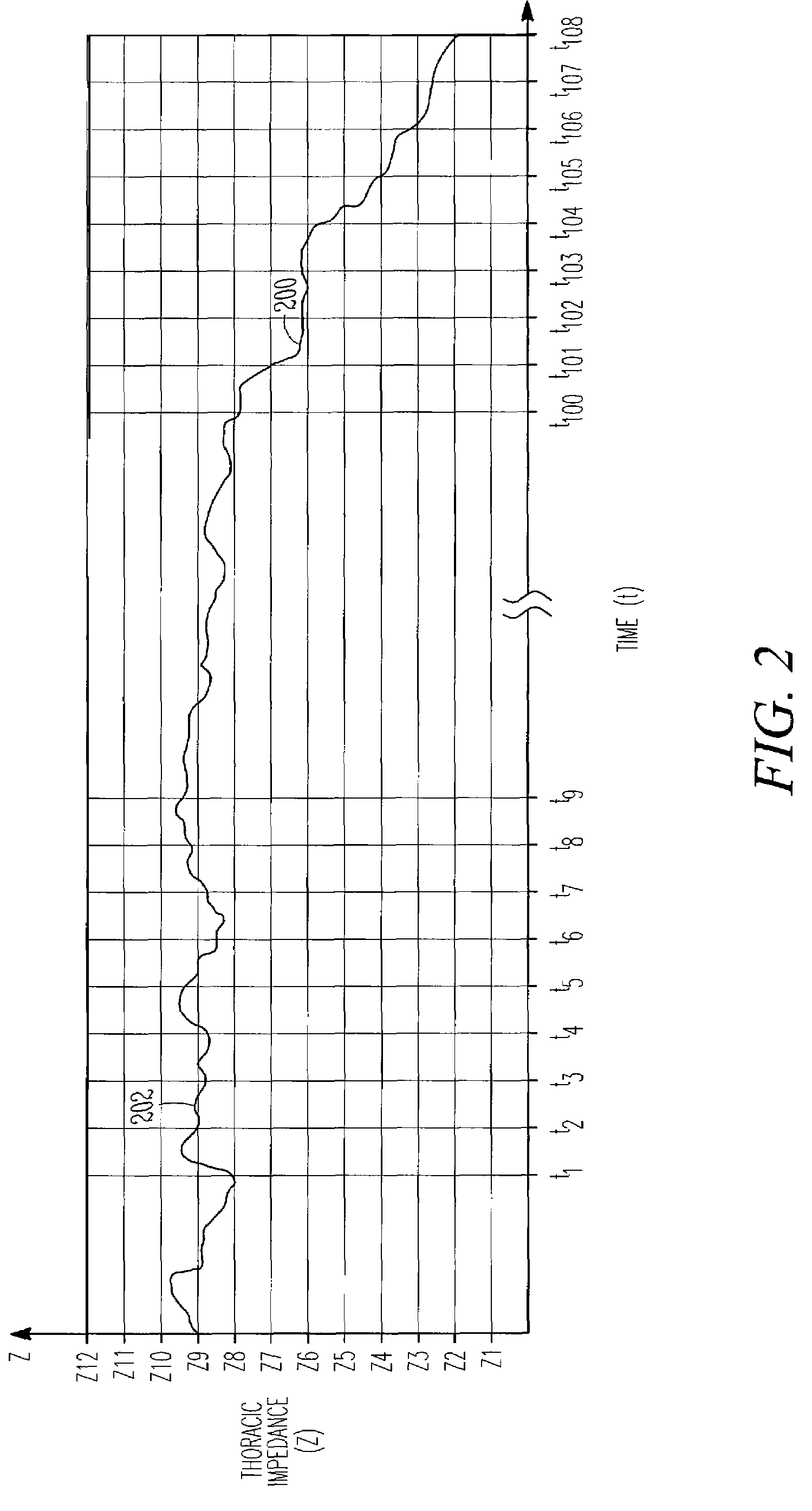

Monitoring fluid in a subject using an electrode configuration providing negative sensitivity regions

An amount of fluid in a thoracic or other region of a subject may be monitored by internally injecting an electrical energy stimulus (e.g., constant voltage source) through the region, detecting voltage resulting from the electrical energy stimulus, and calculating a fluid volume indicative signal. The injected energy stimulus creates a first lead field. The responsive voltage is detected using an electrode configuration that defines a second lead field, which is arranged in a negative sensitivity configuration with respect to the first lead field at the region being monitored.

Owner:CARDIAC PACEMAKERS INC

Monitoring fluid in a subject using an electrode configuration providing negative sensitivity regions

An amount of fluid in a thoracic or other region of a subject may be monitored by internally injecting an electrical energy stimulus (e.g., constant voltage source) through the region, detecting voltage resulting from the electrical energy stimulus, and calculating a fluid volume indicative signal. The injected energy stimulus creates a first lead field. The responsive voltage is detected using an electrode configuration that defines a second lead field, which is arranged in a negative sensitivity configuration with respect to the first lead field at the region being monitored.

Owner:CARDIAC PACEMAKERS INC

Monitoring fluid in a subject using an electrode configuration providing negative sensitivity regions

Owner:CARDIAC PACEMAKERS INC

Gallium nitride based LED epitaxial slice structure and method for preparing the same

InactiveCN101183697ASolve the problem of total reflectionImprove light extraction efficiencySemiconductor devicesGallium nitrideLight-emitting diode

The invention relates to a nitride-based LED epitaxial wafer structure and a processing method, belonging to the LED field. The nitride-based LED epitaxial wafer structure has high light extraction efficiency and good crystal quality. A GaN buffer layer, a first si-doped GaN layer, a dielectric layer, a second si-doped GaN layer, an InGaN / GaN multiple quantum well, a mg-doped AlGaN layer and a mg-doped GaN layer are arranged on the substrate of the nitride-based LED epitaxial wafer structure in a bottom-up order. A sapphire substrate with (0001) face is put into the reaction chamber and heat treated under the atmosphere of H2; the temperature is lowered to grow the GaN buffer layer, on which the first si-doped GaN layer grows; then the temperature is lowered and the sample is taken out.

Owner:JIANGXI EPITOP OPTOELECTRONICS

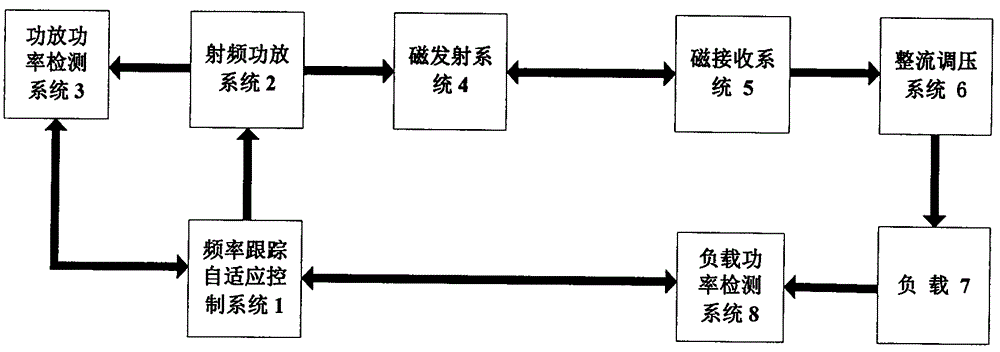

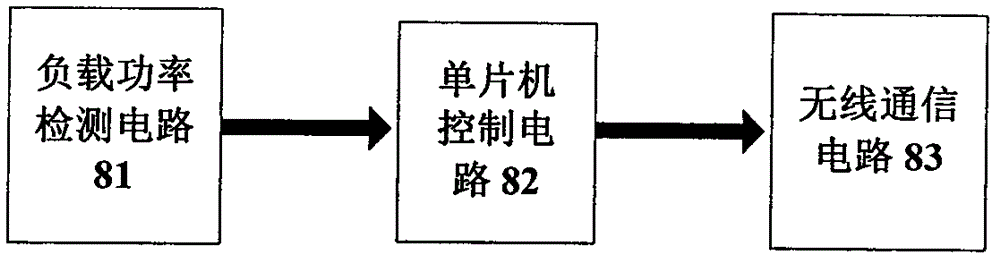

Novel magnetic coupling resonant wireless electric energy transmission device

InactiveCN103151852AImprove robustnessImprove reliabilityElectromagnetic wave systemCircuit arrangementsElectromagnetic theoryEngineering

The invention discloses a design of a novel magnetic coupling resonant wireless electric energy transmission device. The device mainly comprises parts such as a frequency tracking adaptive control system, a radio frequency power amplifier system, a power amplifier power detection system, a magnetic transmitting and receiving system and a rectifying and voltage regulating system. The system belongs to the leading field of high frequency electromagnetic theory engineering application, and solves the problem of electric energy wireless transmission robustness control. According to the device, the problem that the power and the efficiency of the conventional wireless electric energy transmission device are susceptible to interference to be obviously reduced is solved; and the device has high robustness, high reliability, intelligence and great application prospect.

Owner:TIANJIN POLYTECHNIC UNIV

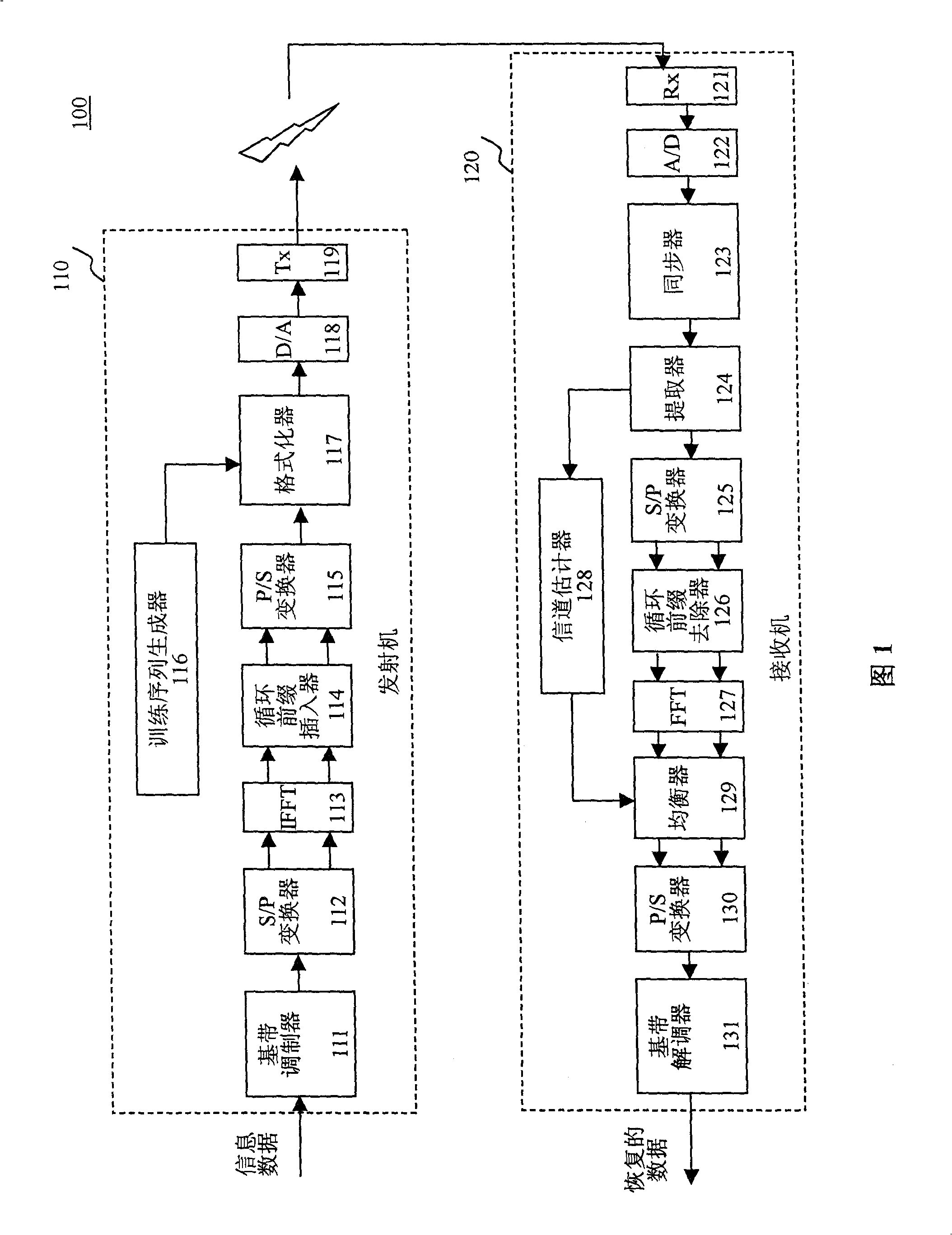

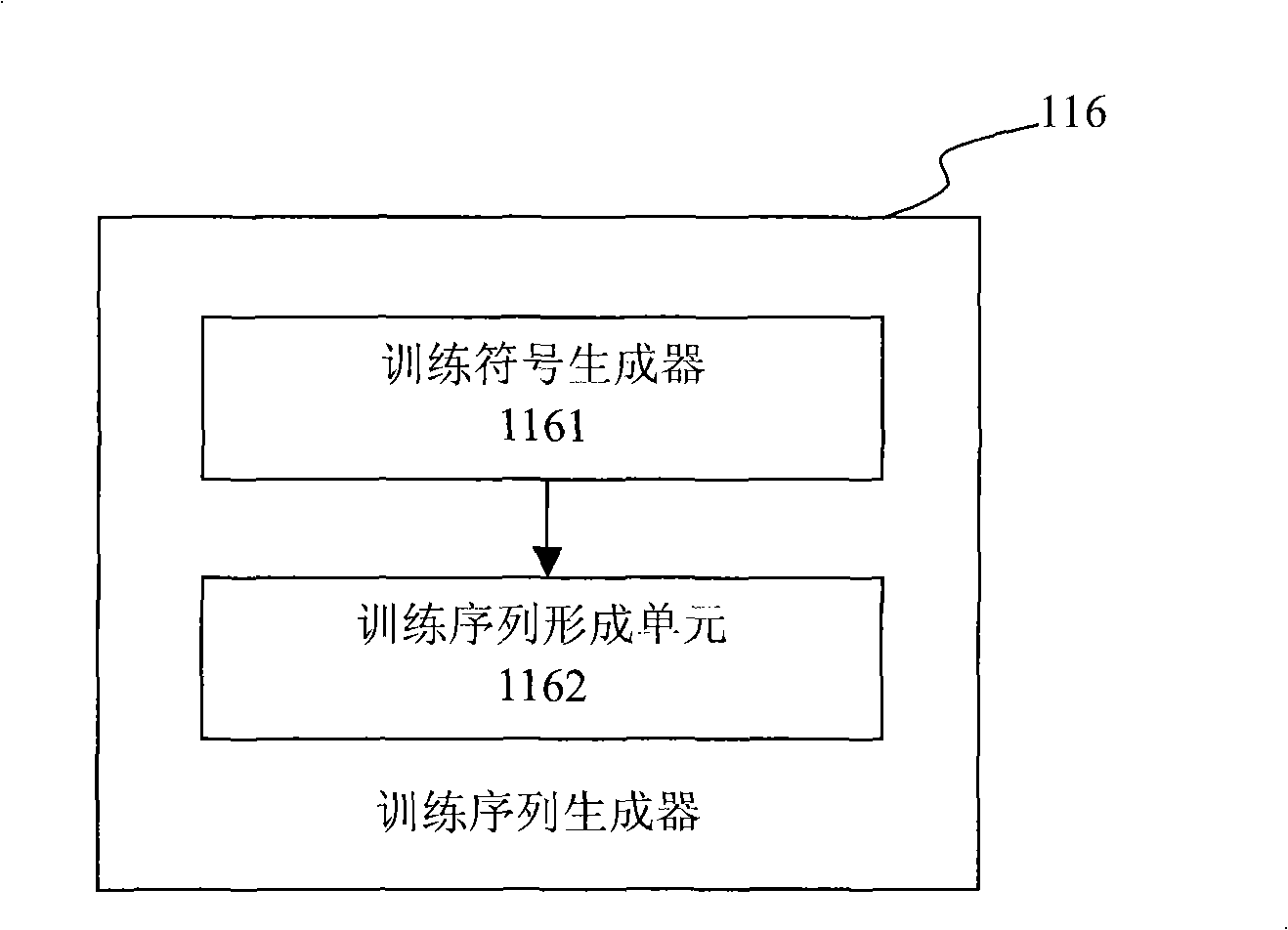

Robust channel evaluation for communication system

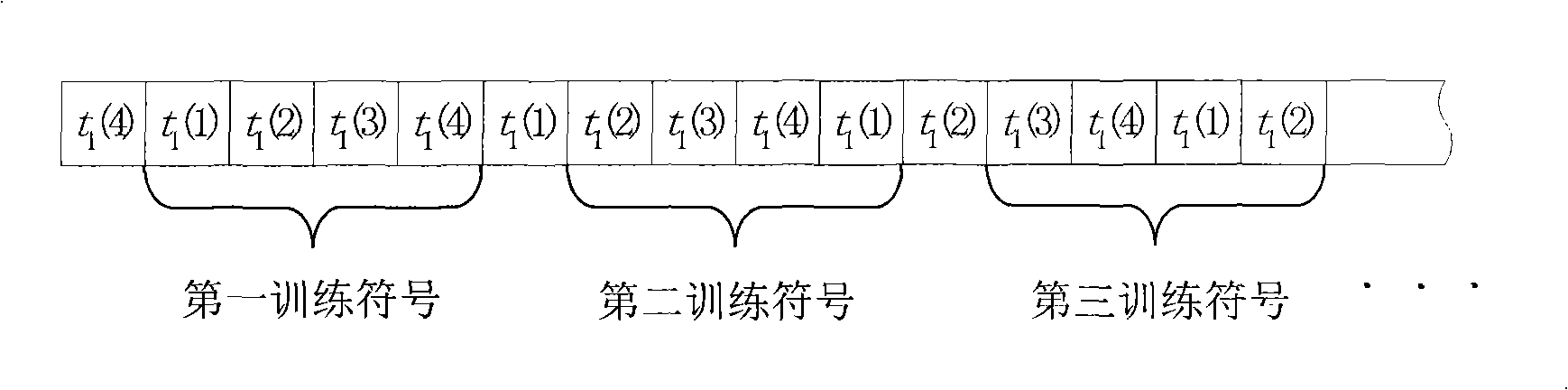

ActiveCN101325569ASpatial transmit diversityMulti-frequency code systemsTime domainCommunications system

The present invention provides an apparatus and method for realize robust channel estimation in communicating system. A training sequence is configured that training symbols therein are insensitive to synchronization errors. In an embodiment of the invention, each training symbol in the time-domain is the circulating prefix form of a front training symbol. The training sequence can be inserted into the leading field or the loading field of a frame. According to the training sequence generated by a embodiment of the invention, the circulating prefix of a training symbolic is also the circulating postfix of a front training symbolic. The sequence can be used for robust channel estimation in SISO / MIMO communicating system. When the modulating symbols are used to generate training symbols, a same group of training sequence can be used for performing demodulation performance measuring and channel estimation.

Owner:KEYSIGHT TECH

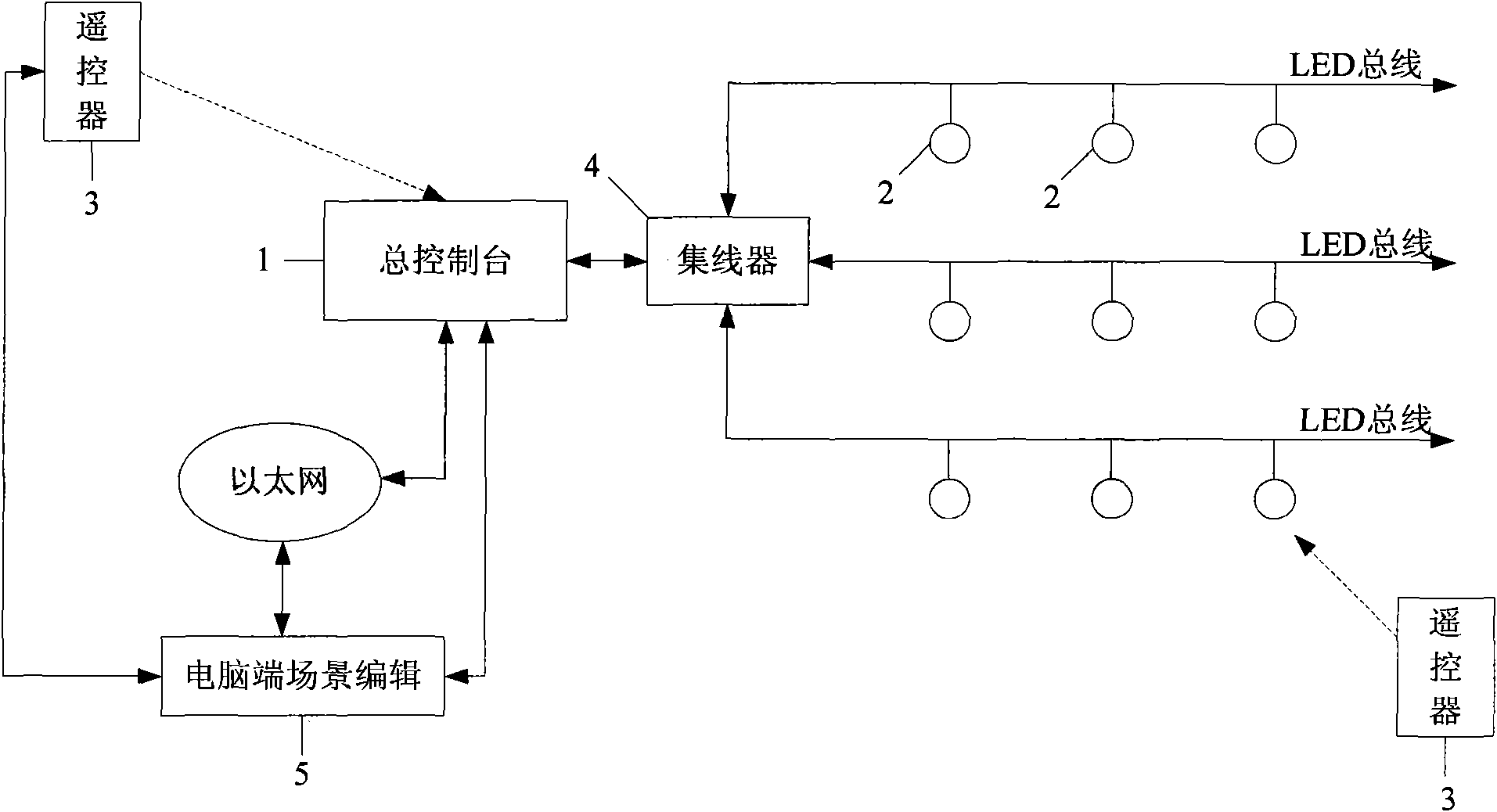

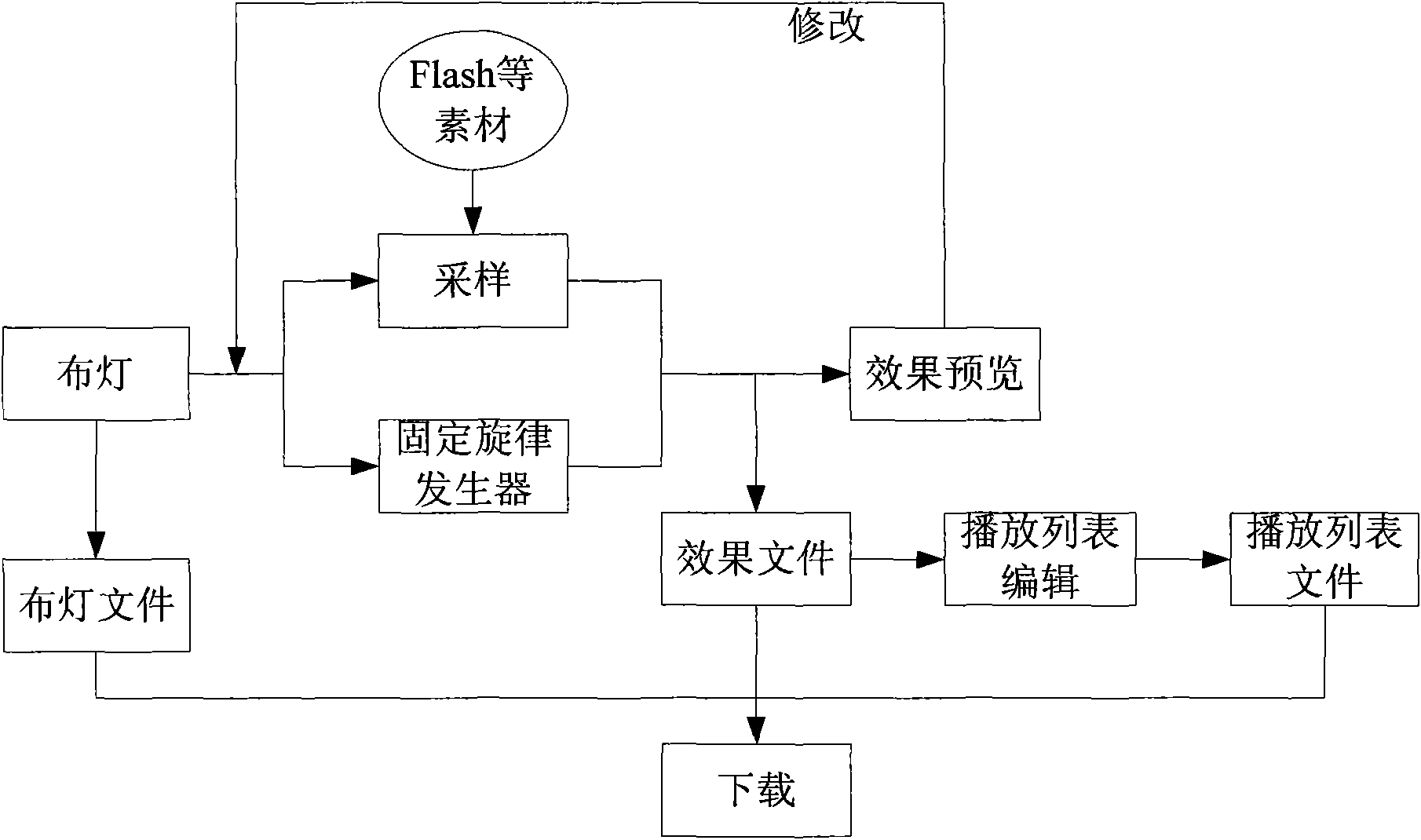

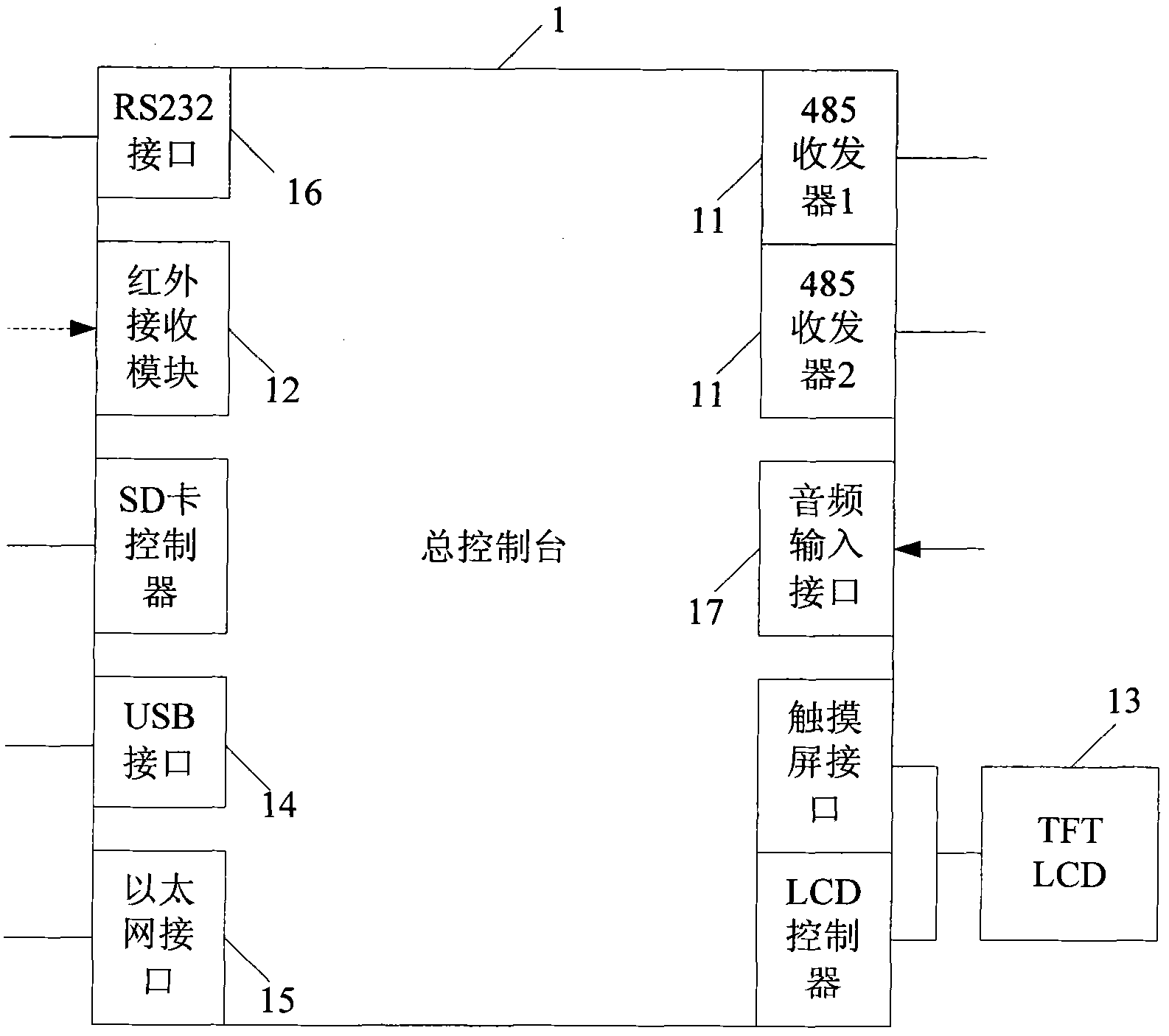

Mood LED light control system

InactiveCN102118901APowerfulRich family atmosphereElectric light circuit arrangementEnergy saving control techniquesAffective toneLED lamp

The invention discloses a mood LED light control system, comprising a main control console, a plurality of lamps and a remote controller, wherein the main control console is connected with the plurality of lamps through an LED field control bus; the remote controller is used for sending control commands to the main control console and the plurality of lamps; and the main control console is used for controlling the plurality of lamps and receiving lamp state information fed back by the plurality of lamps and the control commands received by the plurality of lamps from the remote controller. The mood LED light control system can automatically adjust the shading degree or the variation effect of indoor light according to user setting, current time, sound, and the like to enrich family affective tone and adjust the moods of users.

Owner:SHANGHAI GRANDAR LIGHT ART & TECH

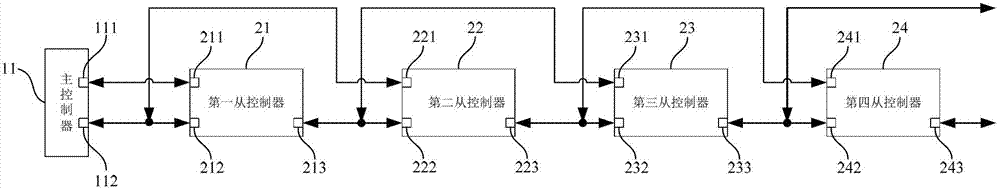

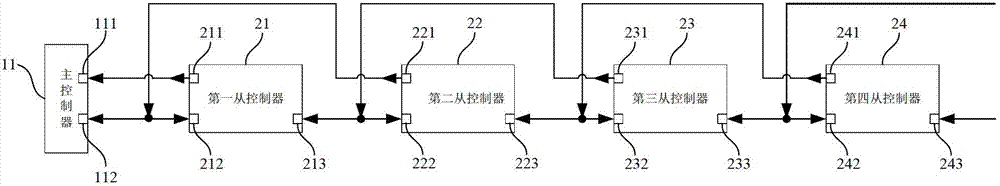

Field bus control system for intelligent light-emitting diode (LED) lamp

ActiveCN102769971AEasy to install and debugGuaranteed to workElectric light circuit arrangementEnergy saving control techniquesMaster controllerControl bus

The invention provides a field bus control system for an intelligent light-emitting diode (LED) lamp. The field bus control system at least comprises a master controller and a plurality of slave controllers, wherein the slave controllers comprise a first slave controller, a second slave controller, ..., an (N-1)th slave controller and an Nth slave controller; a signal wire of the master controller is at least directly connected to the first slave controller, the second slave controller or / and the next slave controller; and a signal wire of one of the slave controllers is at least directly connected to the next slave controller or / and the second next slave controller or / and the third next slave controller adjacent to the controller. The field bus control system aims to solve the problems of difficulty in management, limitation to a communication distance, low fault tolerant capability and the like of an LED field control bus in the prior art.

Owner:SHANGHAI GRANDAR LIGHT ART & TECH

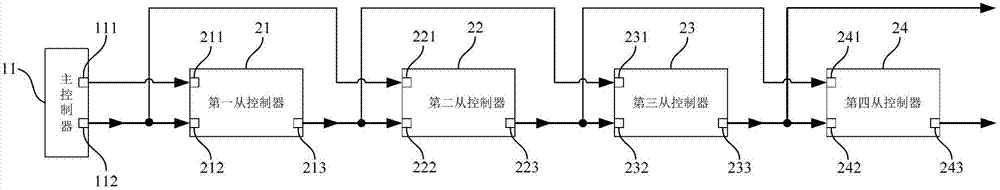

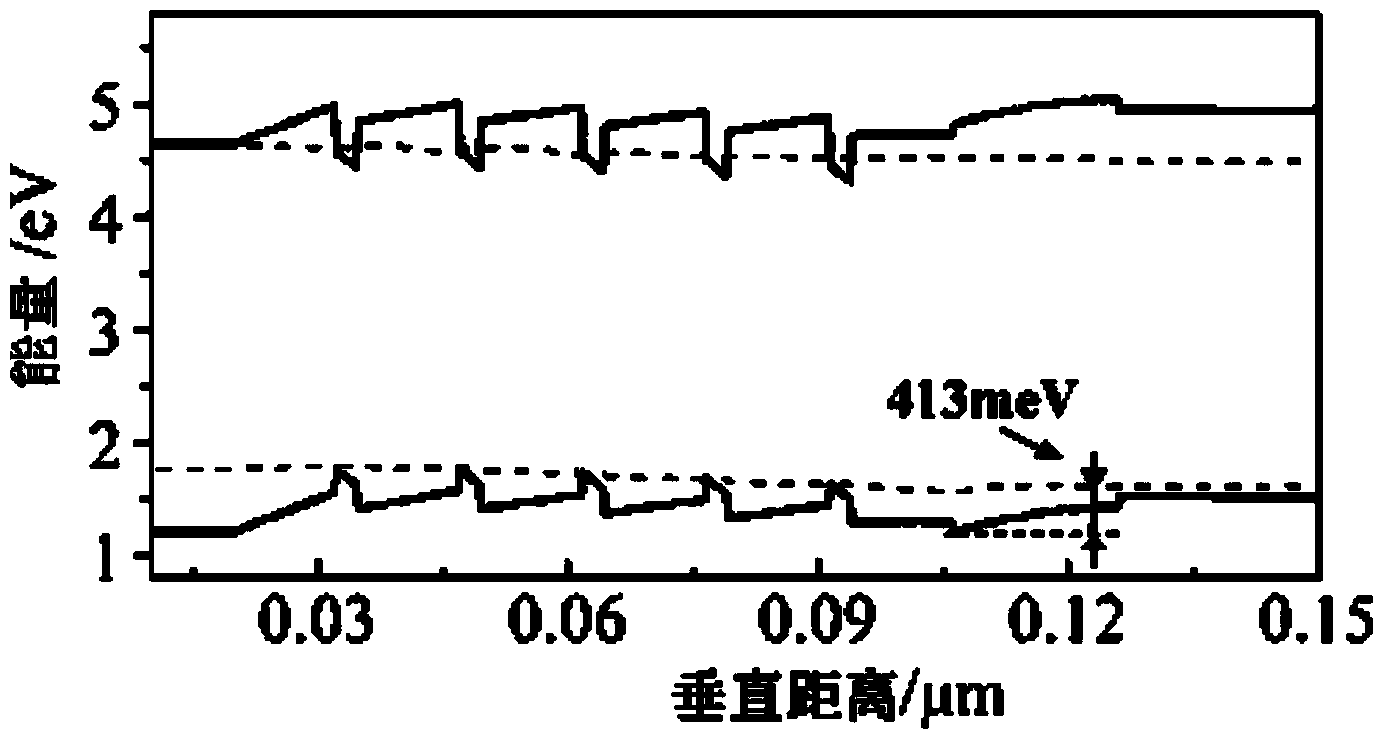

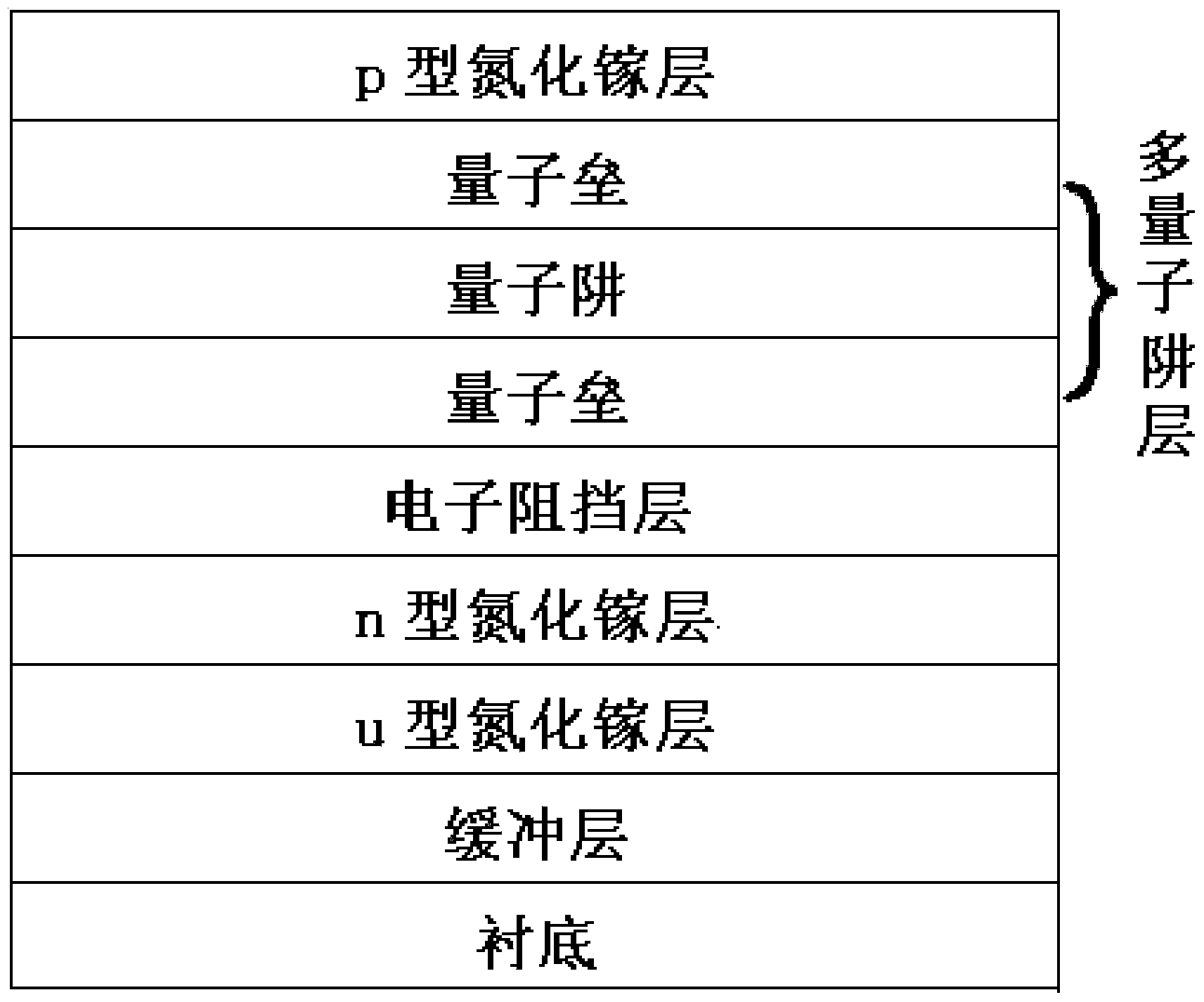

LED epitaxial structure

InactiveCN104009138ABlocking injectionReduce leakageSemiconductor devicesElectron injectionGallium nitride

The invention discloses an LED epitaxial structure. The LED epitaxial structure comprises a substrate, a buffer layer, a u type gallium nitride layer, an n type gallium nitride layer, an electron barrier layer, a multiple-quantum well layer and a p type gallium nitride layer, wherein the substrate, the buffer layer, the u type gallium nitride layer, the n type gallium nitride layer, the electron barrier layer, the multiple-quantum well layer and the p type gallium nitride layer are arranged in a stacked mode in sequence from bottom to top. According to the LED epitaxial structure, due to the fact that the electron barrier layer is arranged between the n type gallium nitride layer and the multiple-quantum well layer, electron injection is effectively stopped, electron leakage is reduced, hole injection is increased, and thus the luminous efficiency is improved; due to the fact that an n type AlGaN / GaN superlattice structure is inserted in the space between an n type GaN layer and an active area to replace the AlGaNEBL in a traditional structure, electron injection is effectively stopped, electron leakage is reduced, hole injection is increased, and thus the luminous efficiency is further improved. The LED epitaxial structure can be widely applied to the LED field.

Owner:SOUTH CHINA NORMAL UNIVERSITY

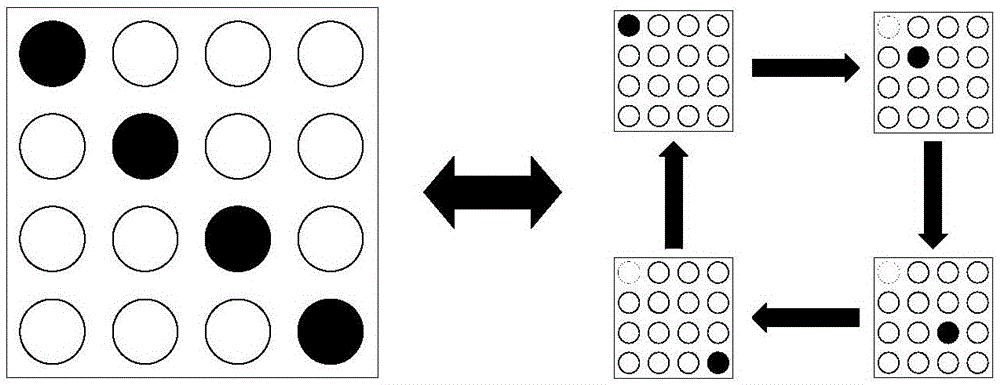

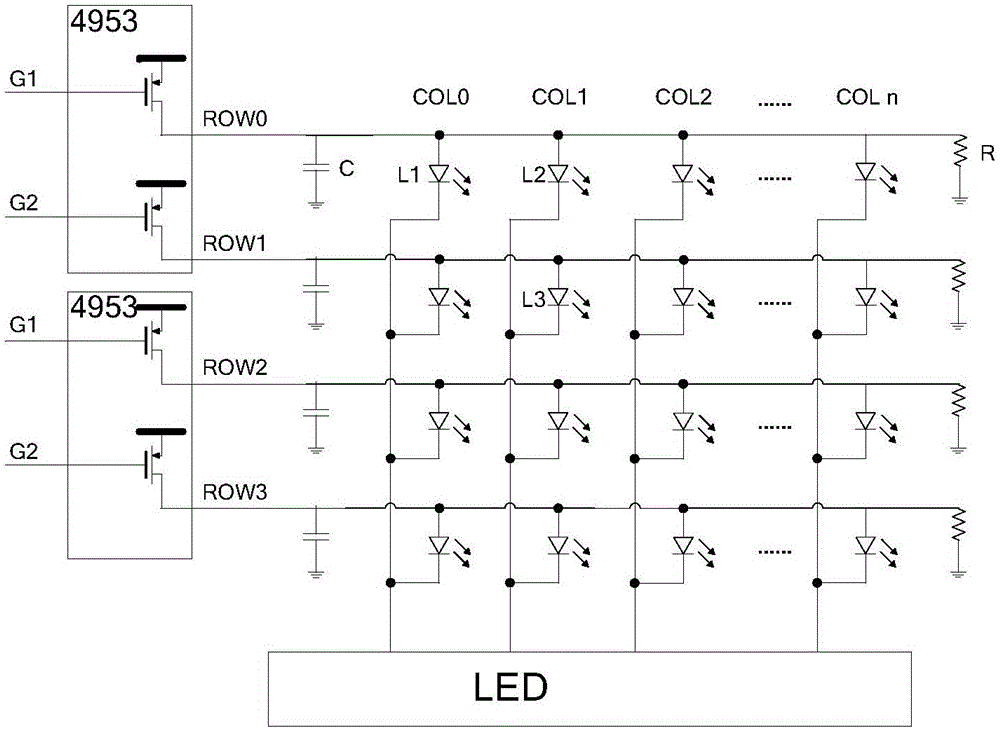

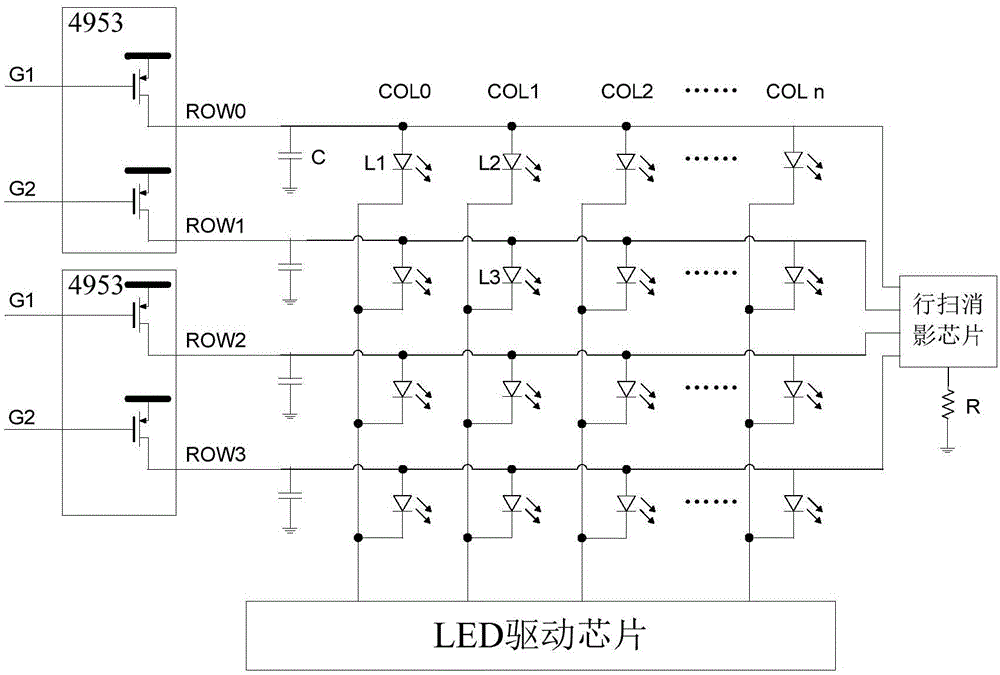

Anti-streaking row-scanning control chip and anti-streaking LED display circuit

ActiveCN105161053AImprove display claritySimplify wiring difficultyStatic indicating devicesPulse controlLED display

The invention is suitable for LED field and provides an anti-streaking row-scanning control chip and an anti-streaking LED display circuit, wherein the chip comprises a two-row-scanning enablement pin and a two-row-scanning control pin connected with an LED row line, a streaking enablement pin and an external streaking signal pin, a first switch tube and a second switch tube, and a streaking signal generation unit that is used to generate a row line streaking pulse controlling the row line discharge parasitic charge based on a row line enablement signal, a gating unit that is used for processing a row line shadow pulse and an external streaking signal, and for outputting the processed external streaking signal when the streaking mode enablement signal is the external input streaking signal state, and for outputting the processed row line streaking pulse when the streaking mode enablement signal is the internal generated streaking pulse state. The streaking function is integrated into the row-scanning control chip, or the LED row line is processed for streaking through an external streaking signal, therefore, the display screen wiring difficulty is reduced due to high integration and the application cost is reduced.

Owner:SHENZHEN SUNMOON MICROELECTRONICS

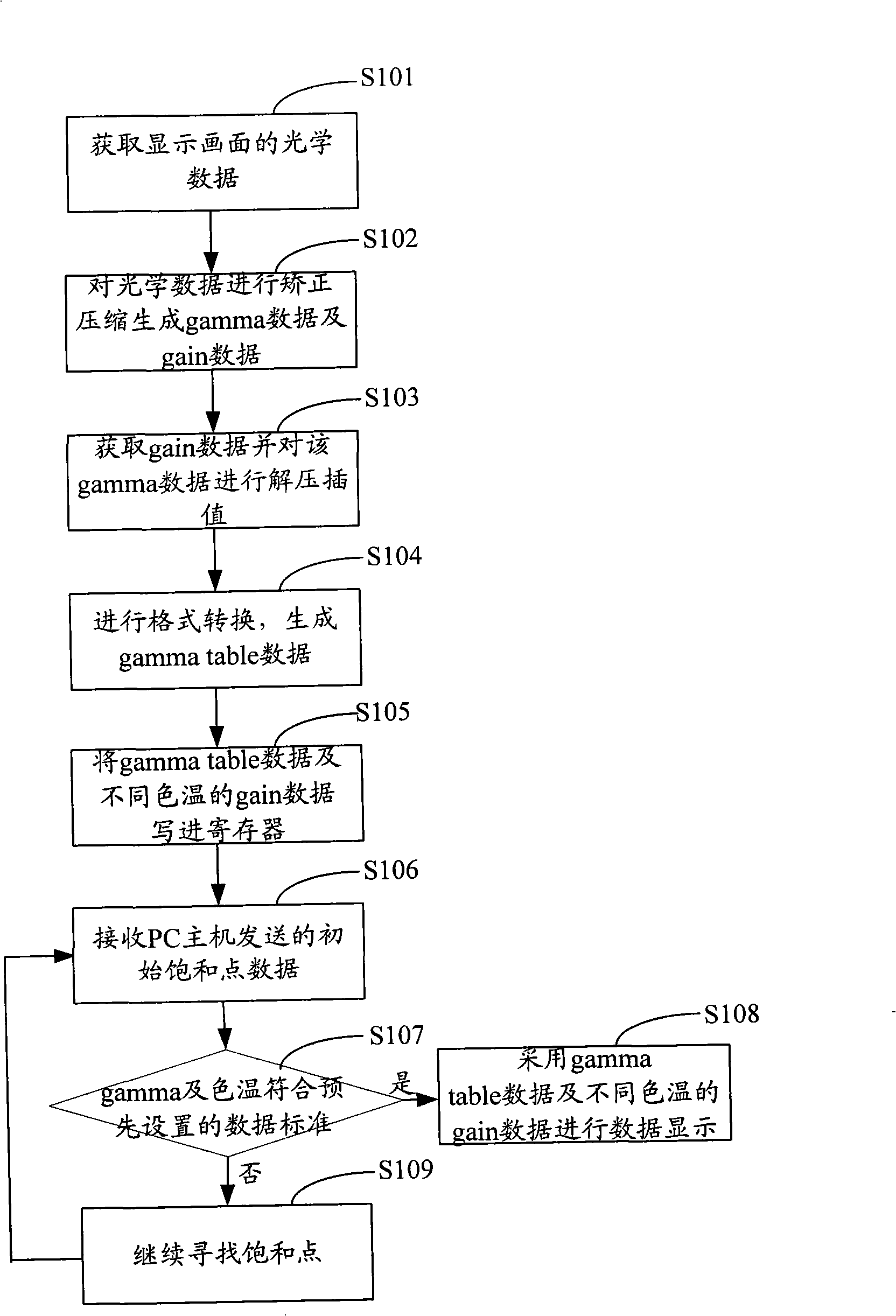

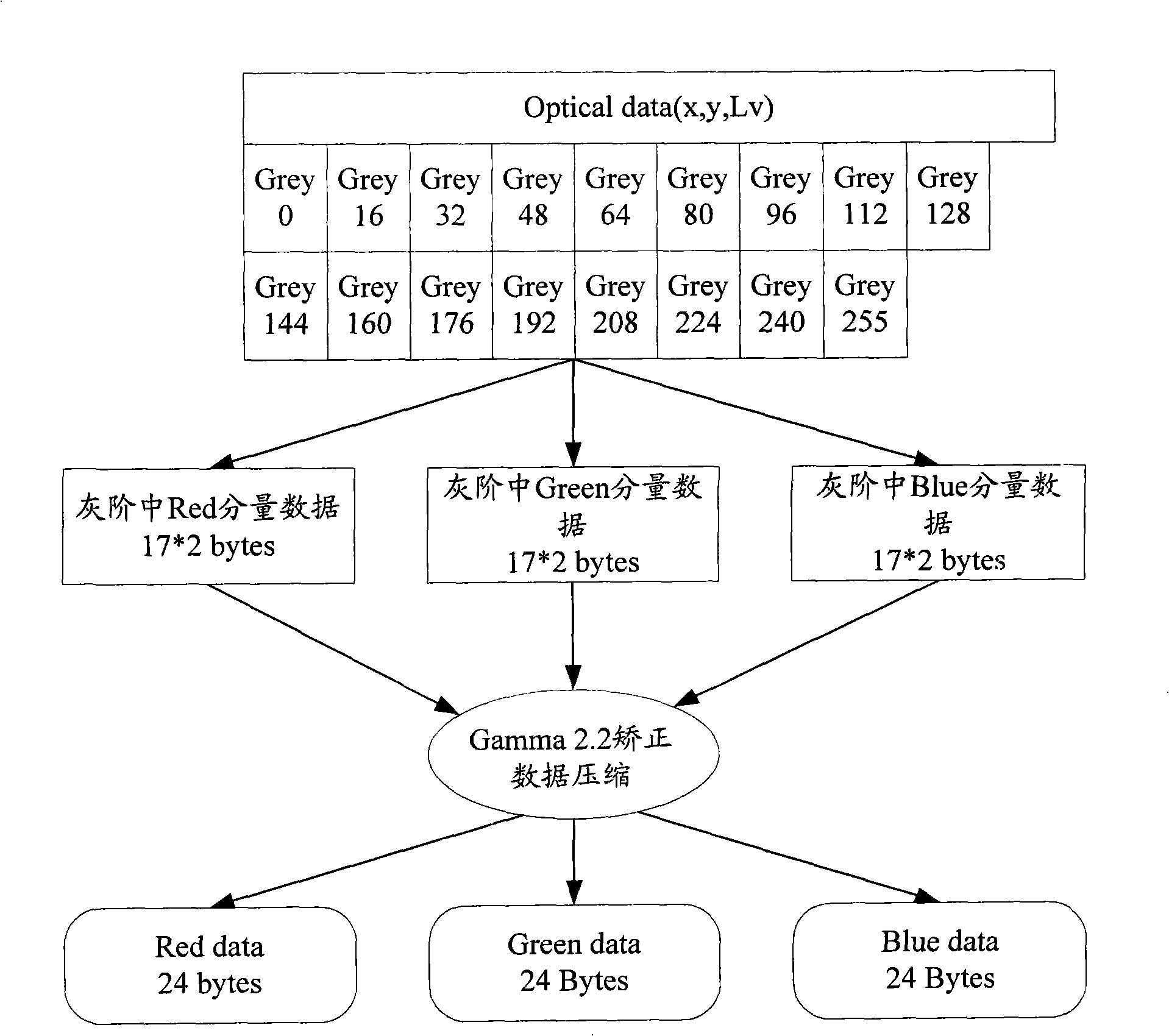

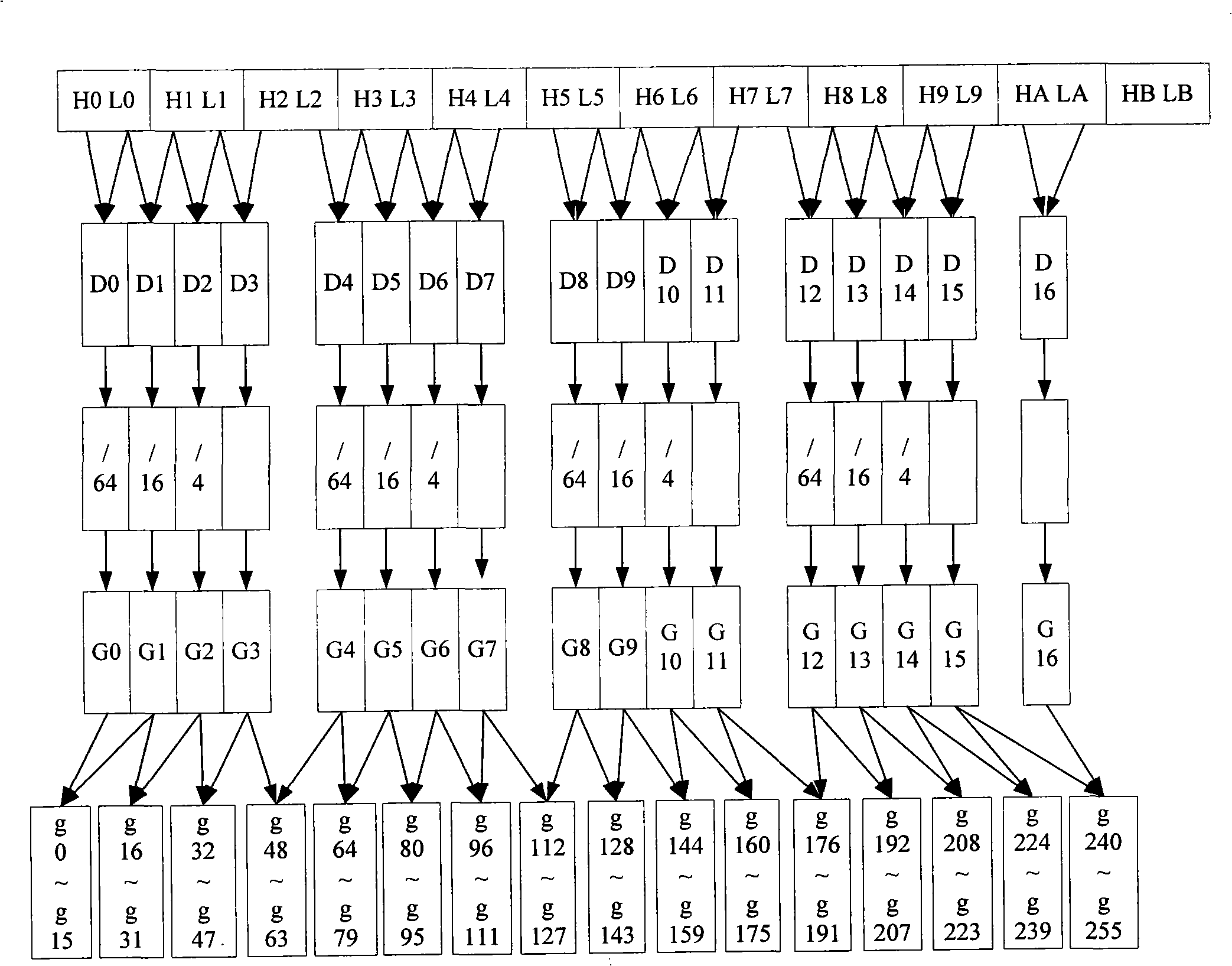

Optical data processing method and system, and LCD device

InactiveCN101345033AReduce operating pressureShorten adjustment timeStatic indicating devicesOptical data processingComputer science

The invention provides an optical data processing method, a system and an LED device, which are applicable to the LED field. The method of the invention comprises the steps as follows: a PC host computer corrects and compresses the optical data of an obtained display picture so as to generate Gamma data and the gain data of different colour temperature; the LED device obtains gain data and carries out decompression interpolation to the Gamma data; the LED device carries out format conversion to the Gamma data and generates Gamma table data. In the invention, a colour analyser sends the optical data to the PC host computer which corrects and compresses the optical data and generates the Gamma data and the gain data; the corrected and compressed data is sent to the LED device to carry out decompression verification, thus realizing the completion of correction and compression process without the LED device and reducing the running pressure of the LED device.

Owner:DAYU TECH ELECTRONICS FACTORY DONGGUAN HUANGJIANG

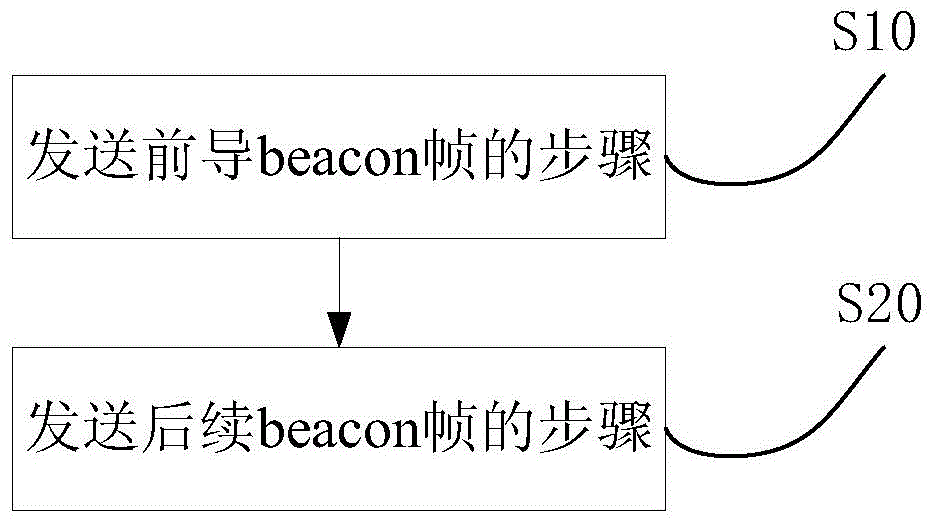

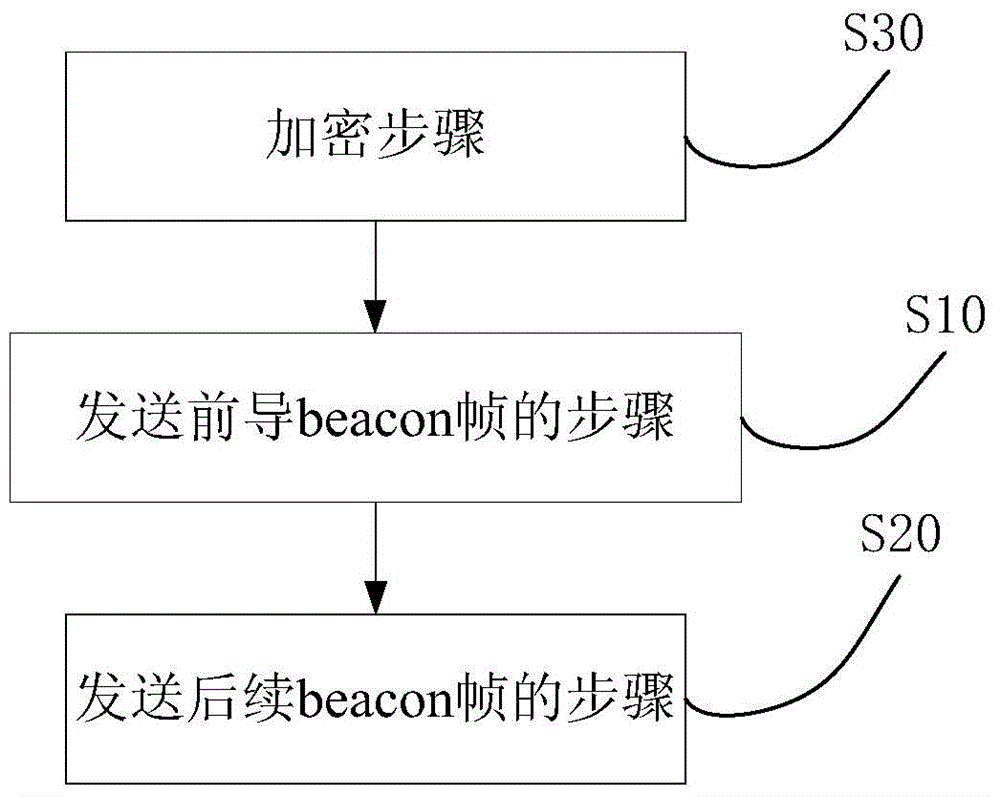

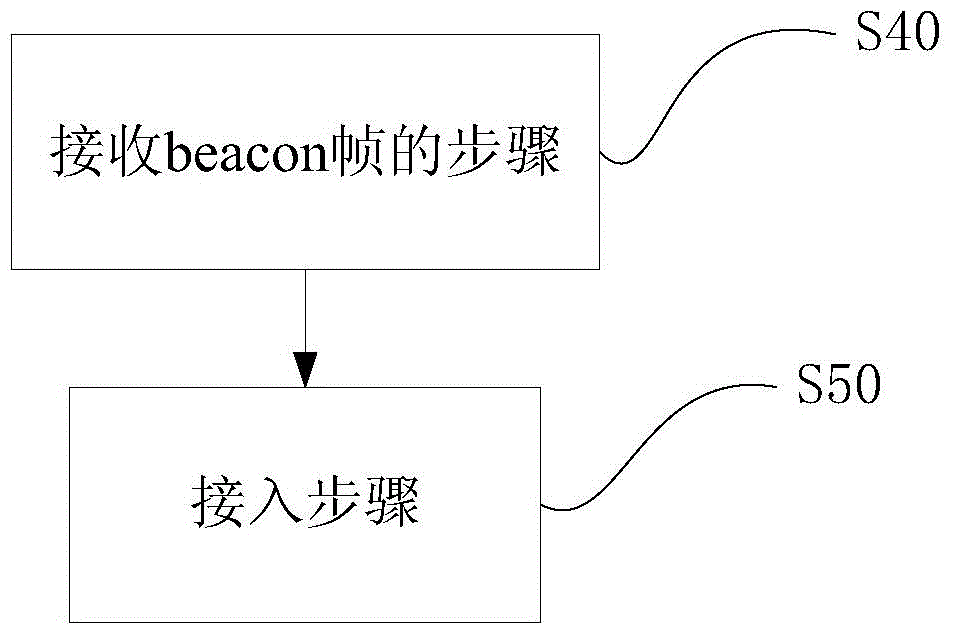

Network access method and device of WIFI equipment of intelligent household

The invention provides a network access method and device of WIFI equipment of intelligent household. The method at the sending end comprises the steps that different WIFI hot spots are switched successively to transmit leading beacon frames corresponding to the different WIFI hot spots, SSID fields of the lead beacon frames are set to form lead fields, so that a reception end determines whether a lead field combination satisfying a preset condition exists based on the received lead fields; and if the lead field combination satisfying the preset condition exists, subsequent beacon frames are sent, the source of the subsequent beacon frames is consistent with that of the lead beacon frames of the lead fields satisfying the preset condition, and the SSID fields of the subsequent beacon frames comprise WIFI routing authentication information, so that the reception end can connect the WIFI equipment to the WIFI router based on the WIFI routing authentication information. The method is rapid, convenient, safe and reliable.

Owner:QINGDAO HAIER INTELLIGENT HOME TECH CO LTD

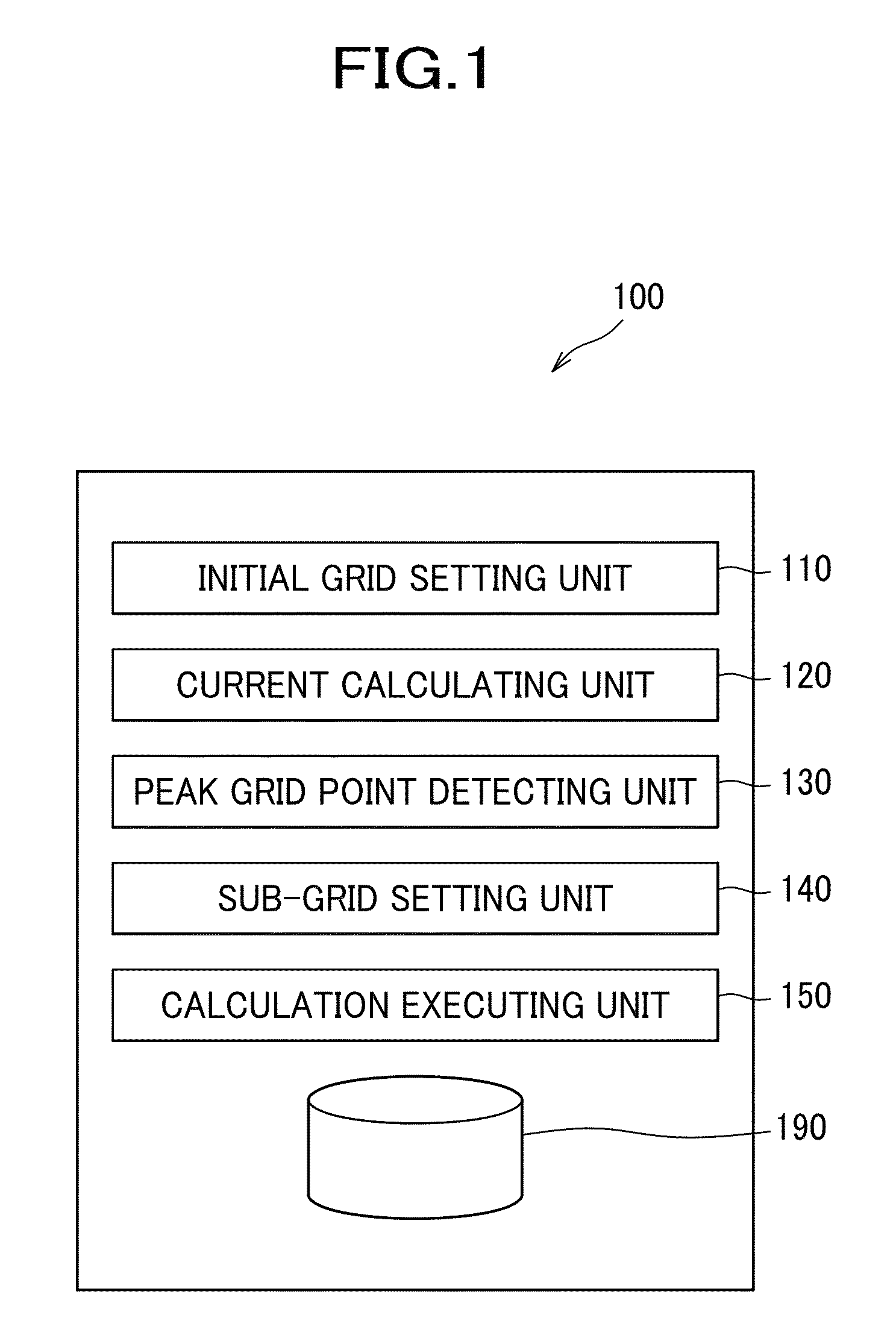

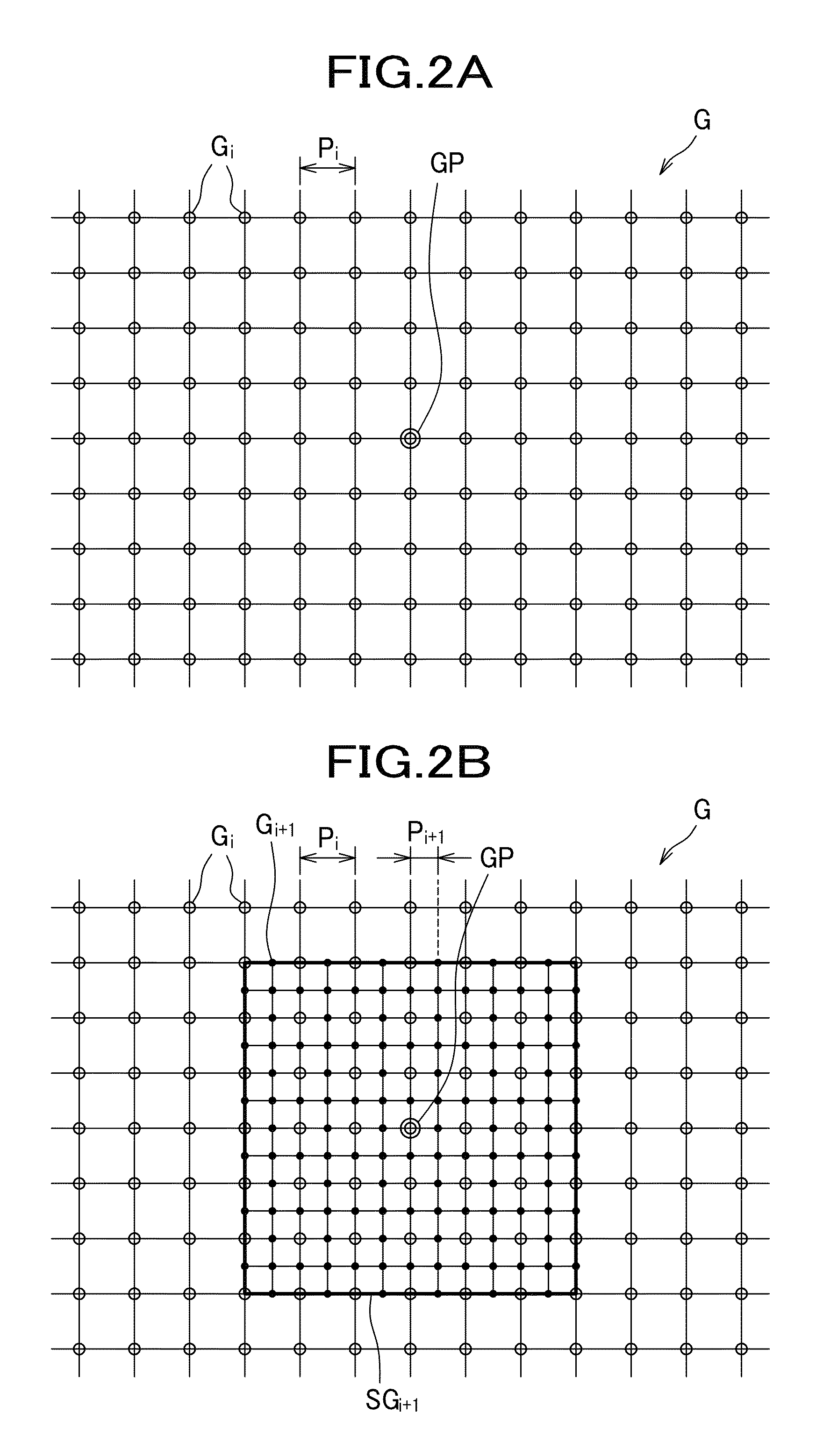

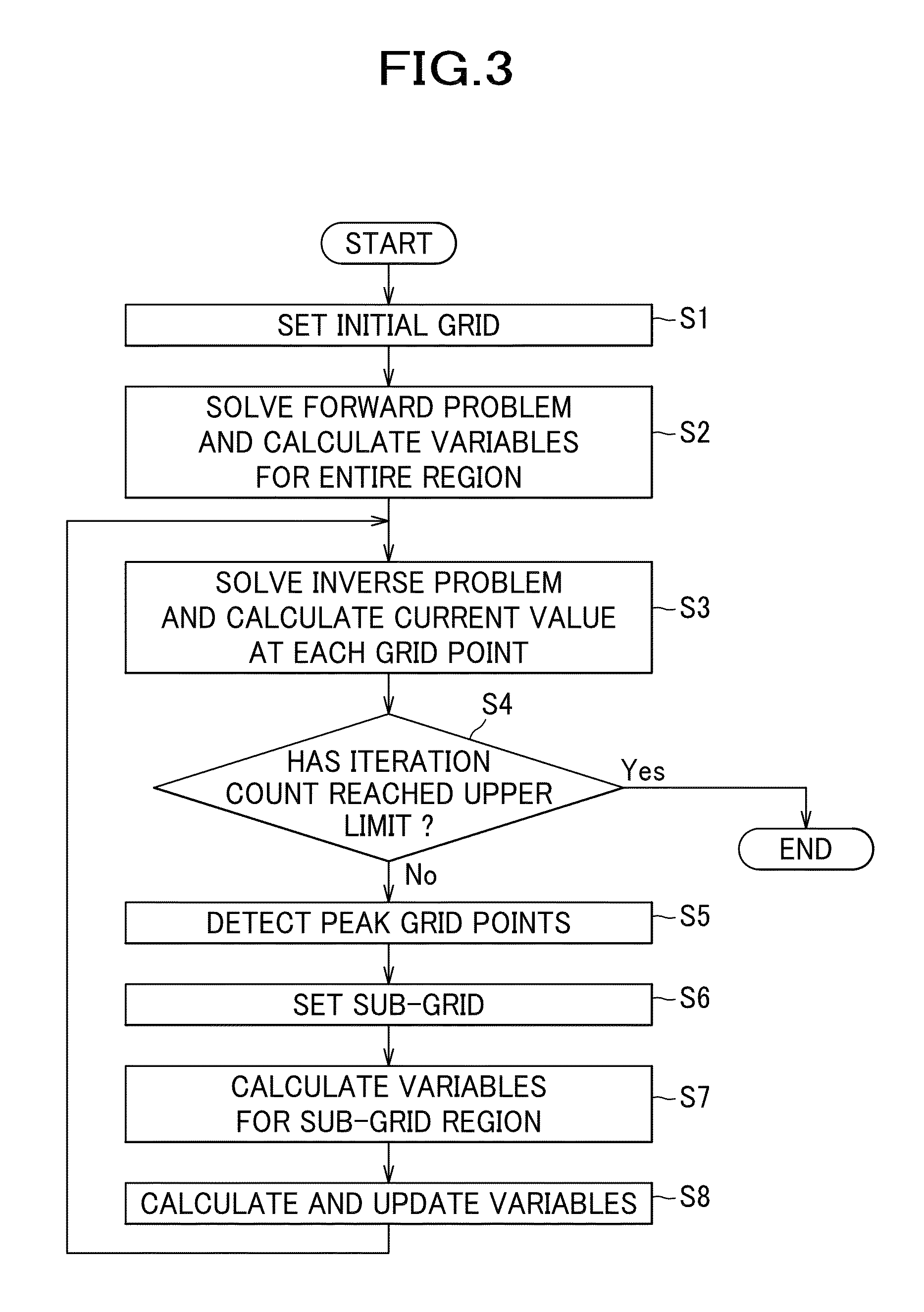

Method, apparatus and computer program for calculating current distribution inside brain

ActiveUS9367738B2Control complexityShort timeBiostatisticsBiological testingCurrent distributionSimulation

Apparatus for calculating current distribution inside brain includes: initial grid setting unit configured to set grid points constituting grid with predetermined pitch; current calculating unit configured to calculate current value at each grid point based on the electromagnetic information, by solving forward problem to obtain lead field matrix and by solving inverse problem to obtain current source vector; sub-grid setting unit configured to set grid points constituting sub-grid with smaller pitch, only for subset of the previously set grid, based on the current value at each grid point calculated in the preceding current calculating step; and calculation executing unit configured to repeat setting the sub-grid and calculating the current source vector by the sub-grid setting unit and the current calculating unit one or more times, after calculation of current source vector corresponding to the initial grid is executed by the initial grid setting unit and the current calculating unit.

Owner:HONDA MOTOR CO LTD

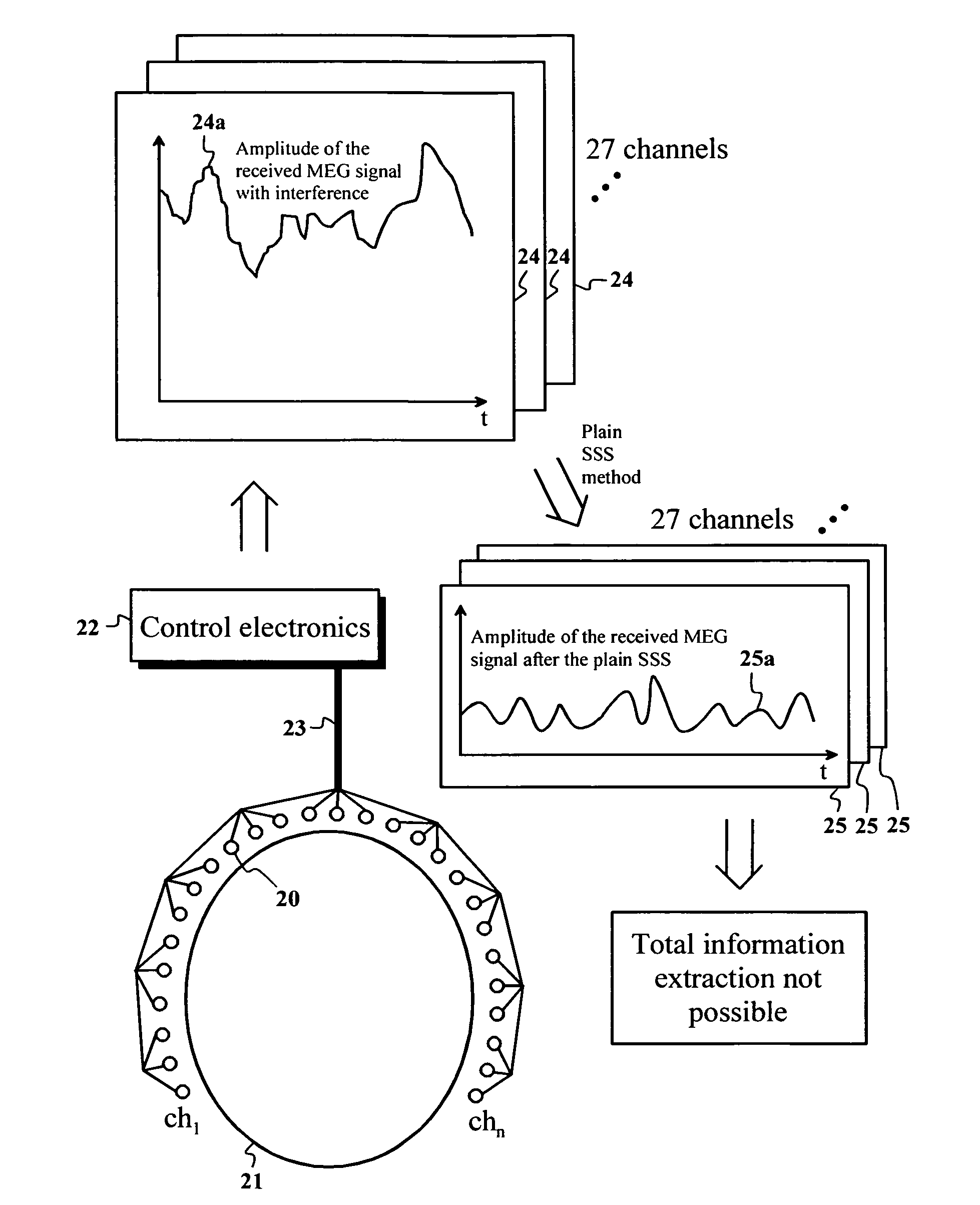

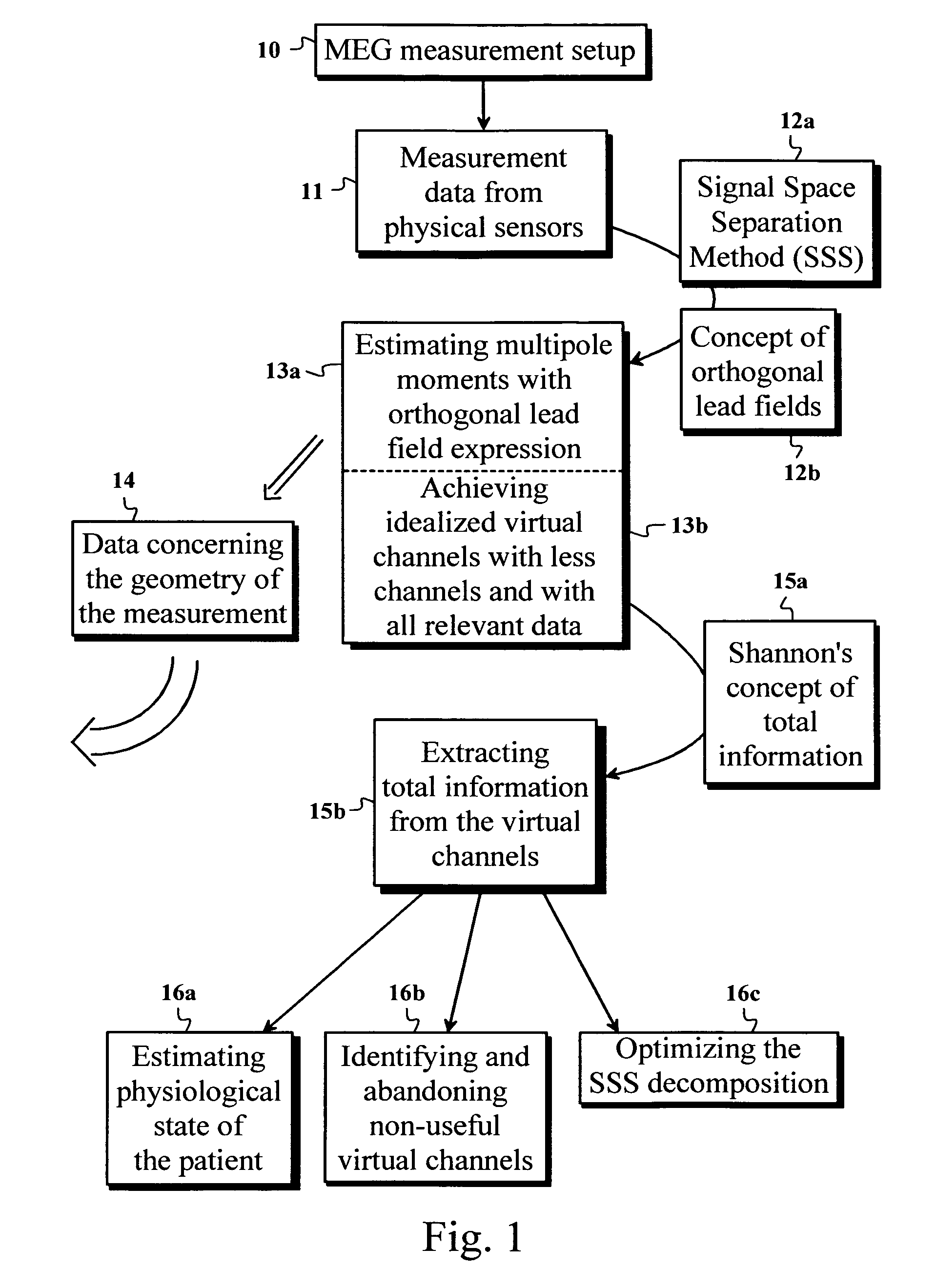

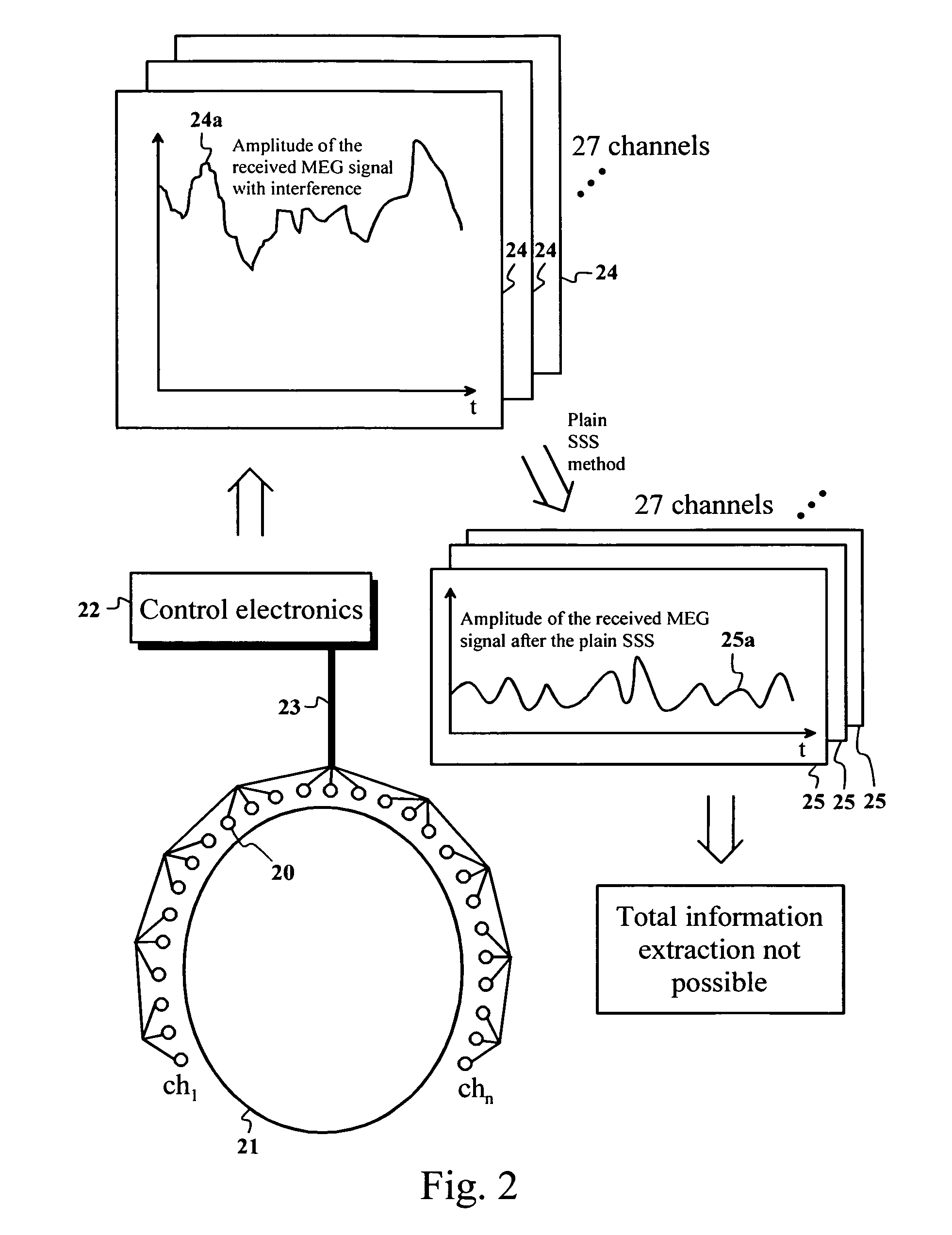

Analysis of multi-channel measurement data using orthogonal virtual channels

ActiveUS8838225B2Reduce the amount requiredSimplified postprocessingElectroencephalographyMagnetic measurementsMeasurement devicePhysiologic States

The present invention introduces a method for processing multichannel measurement data achieved especially in MEG and EEG measurements. The method uses a signal space separation (SSS) method and the orthogonality of lead fields in order to calculate linear transformation from physical measurement channels to virtual channels. The geometry related to the measurement arrangement is dissipated and the number of virtual channels is clearly lower than the number of physical sensors. The concept of total information can be applied for such transformed measurement data due to orthogonality. The method offers simplified post-processing of the biomagnetic data, such as for source modelling. The total information can also be interpreted as a robust quantity describing the physiological state of a patient.

Owner:MEGIN OY

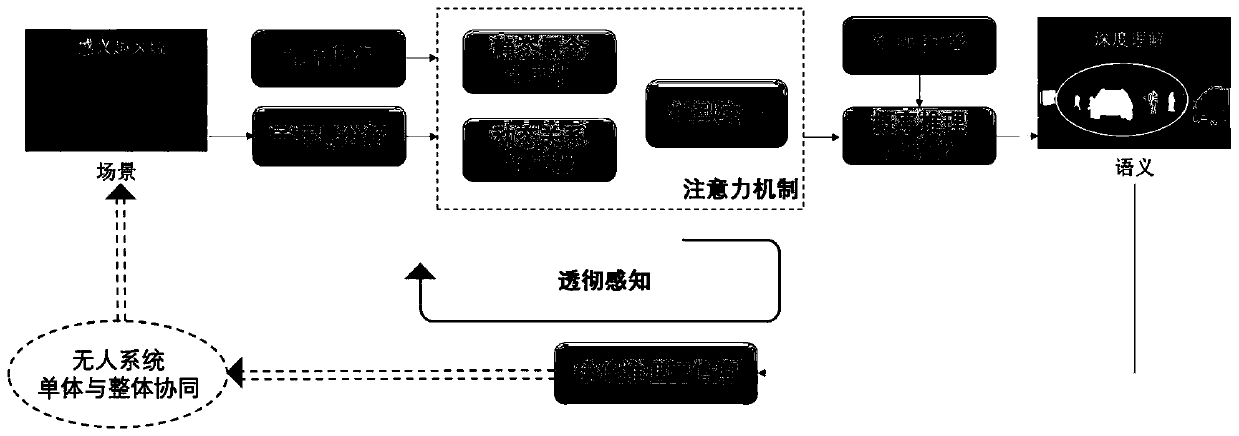

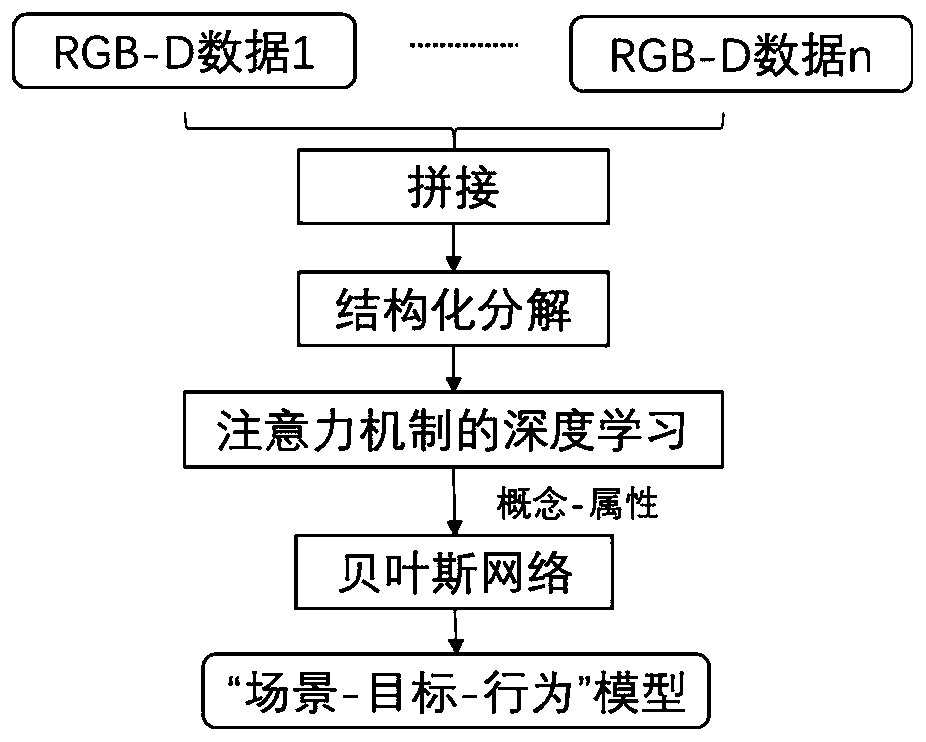

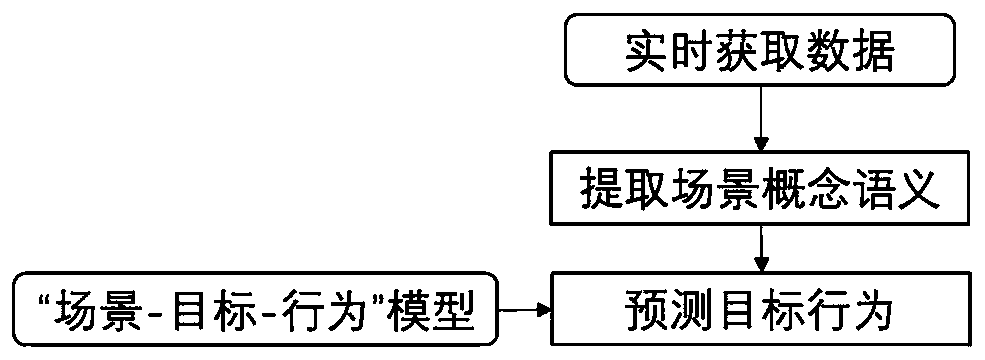

Concept learning-based thorough perception and dynamic understanding method

ActiveCN110287941ASolve dynamic perceptionSolution depthCharacter and pattern recognitionInformation miningPattern perception

According to the concept learning-based thorough perception and dynamic understanding method provided by the invention, scene analysis and information mining based on deep learning are leading fields of information science at present, are successfully applied to segmentation, classification and identification of various scenes, and obtain a large number of excellent results; on the basis of feature extraction, static reasoning based on the Bayesian network is already applied to image diagnosis or understanding, and feasibility is provided for automatically extracting scene multi-source multi-mode features and performing reasoning under a concept framework. On the basis, based on robot collaborative dynamic reasoning and perception coupling, the dynamic perception and deep understanding problems of a large-space complex scene can be effectively solved, and the accuracy is far higher than the performance of using a single deep neural network and static reasoning.

Owner:HARBIN INST OF TECH

Reworking method for LED epitaxial wafer with distributed Bragg reflector (DBR)

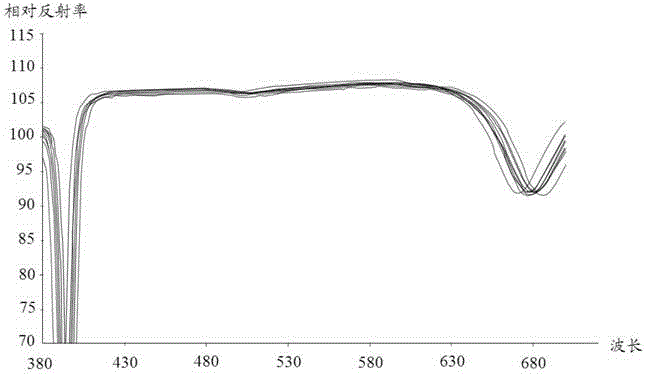

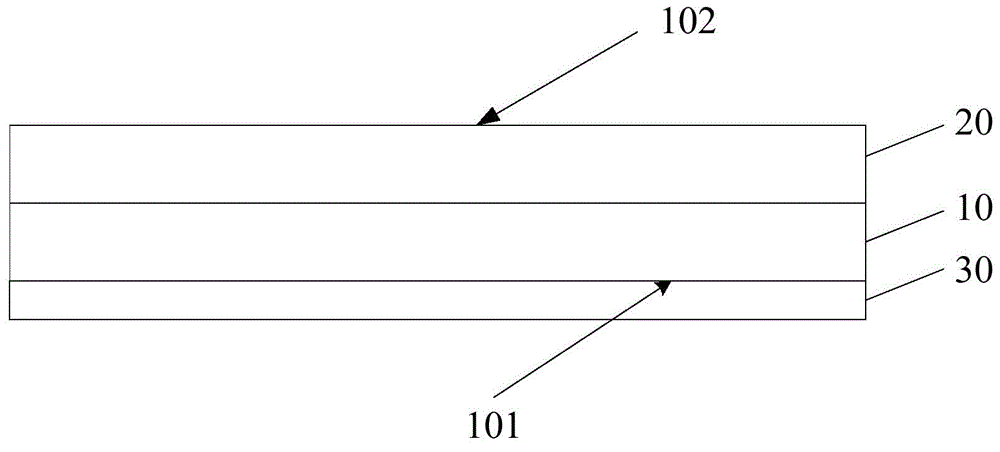

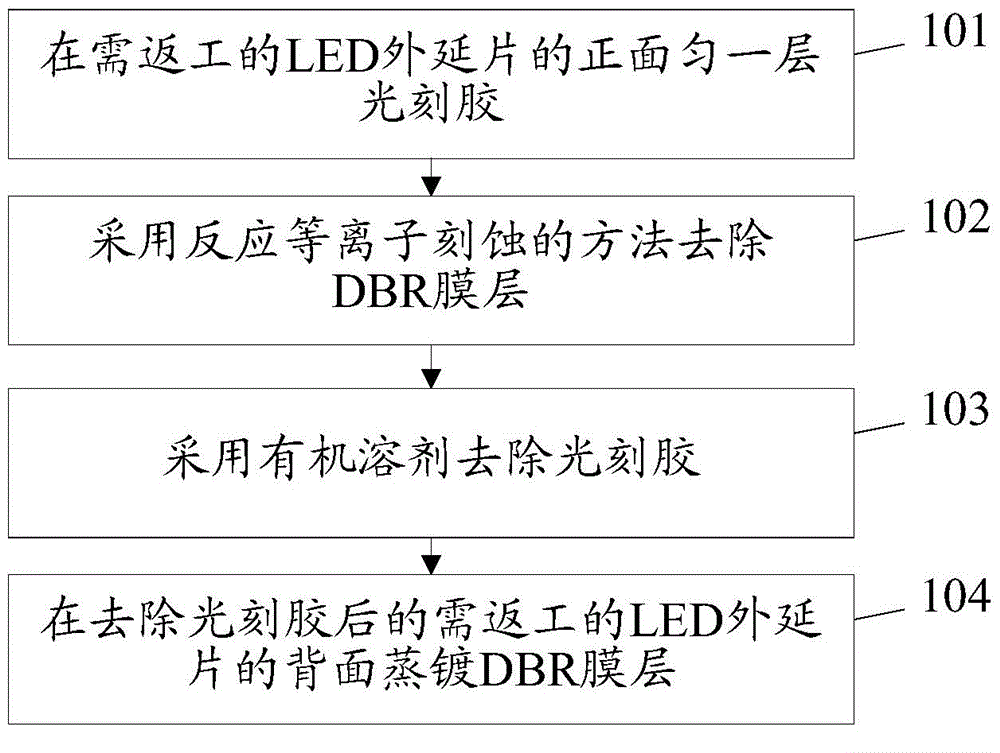

ActiveCN104022206AAvoid breakingReduce cost lossSemiconductor/solid-state device manufacturingSemiconductor devicesOrganic solventDistributed Bragg reflector

The invention discloses a reworking method for an LED epitaxial wafer with a DBR, belonging to the LED field. The method comprises that the front side of the LED epitaxial wafer which needs reworking is uniformly provided with a layer of photoresist, and the back side of the LED epitaxial layer is provided with a DBR film layer; the DBR film layer is removed in an RIE (Reactive Ion Etching) manner, the etching power ranges from 400 to 700 W, the etching pressure ranges from 20 to 30 mtorr, the etching temperature ranges from 0 to 10 DEG C, the etching thickness is greater than the thickness of the DBR film layer, and etching gas includes CHF3 and O2 of 50-80 sccm; the photoresist is removed via an organic solvent; and the back side of the LED epitaxial wafer from which the photoresist is removed is provided with a DBR film layer in a vapor plating manner. According to the reworking method, the DBR film layer at the back side of the LED epitaxial wafer which needs reworking is removed in the RIE manner, and the RIE manner includes gas etching, so that the LED epitaxial layer is avoided from fragmentation and further loss caused by grinding.

Owner:HC SEMITEK SUZHOU

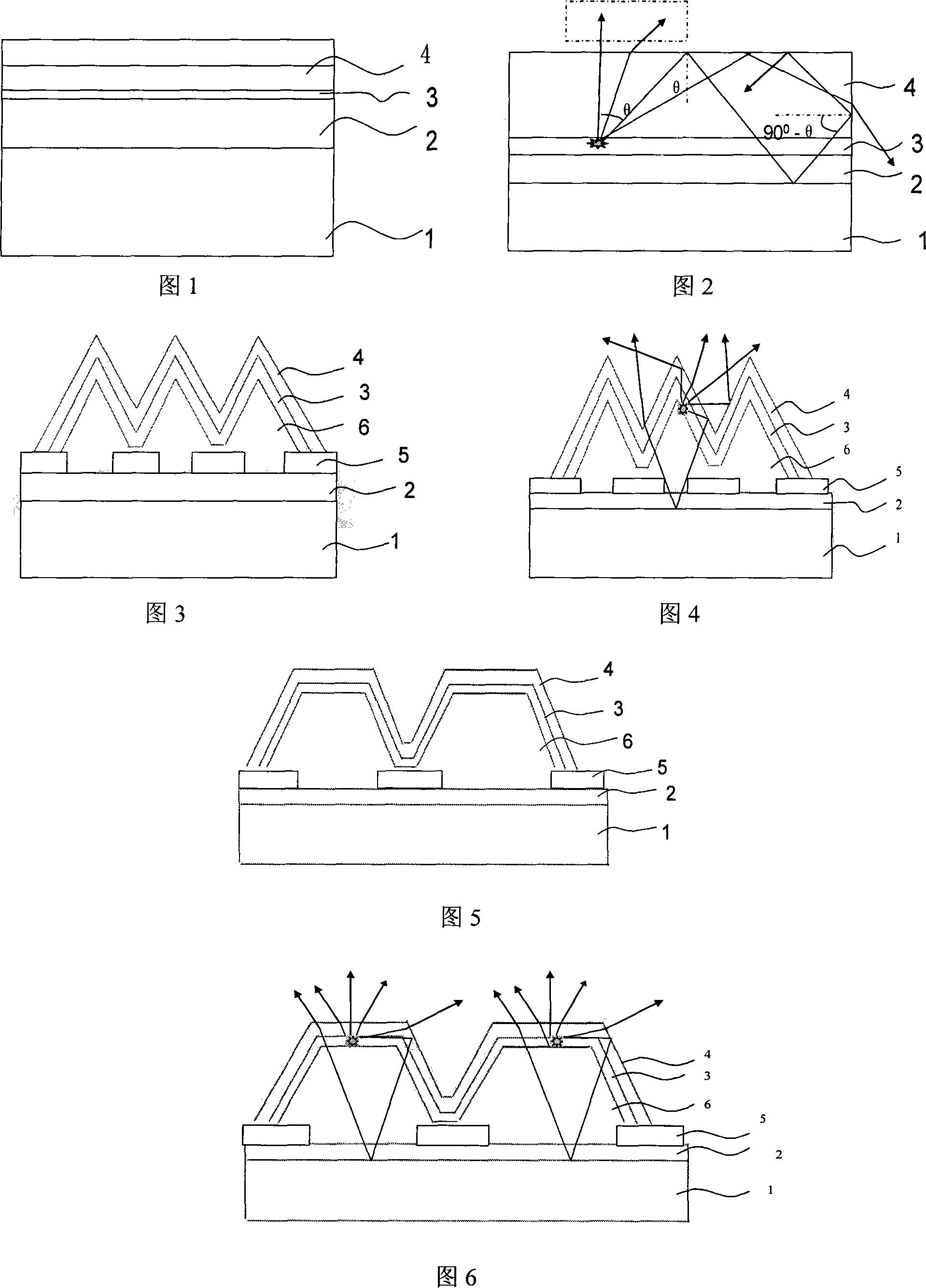

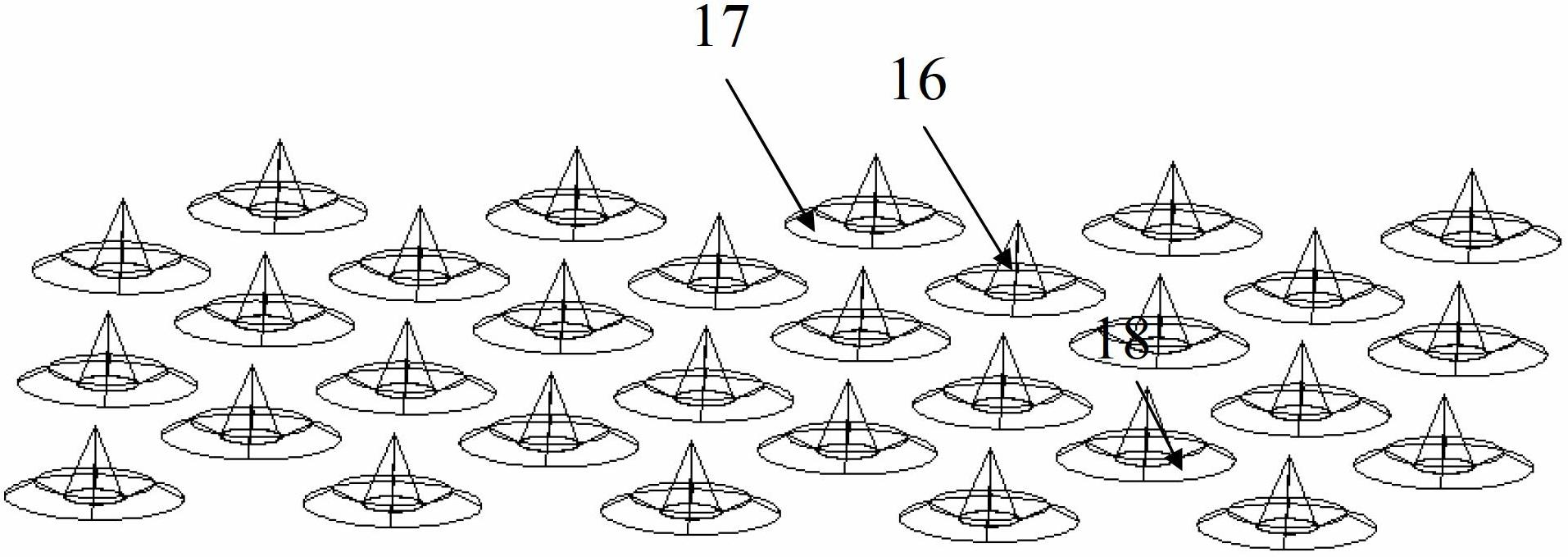

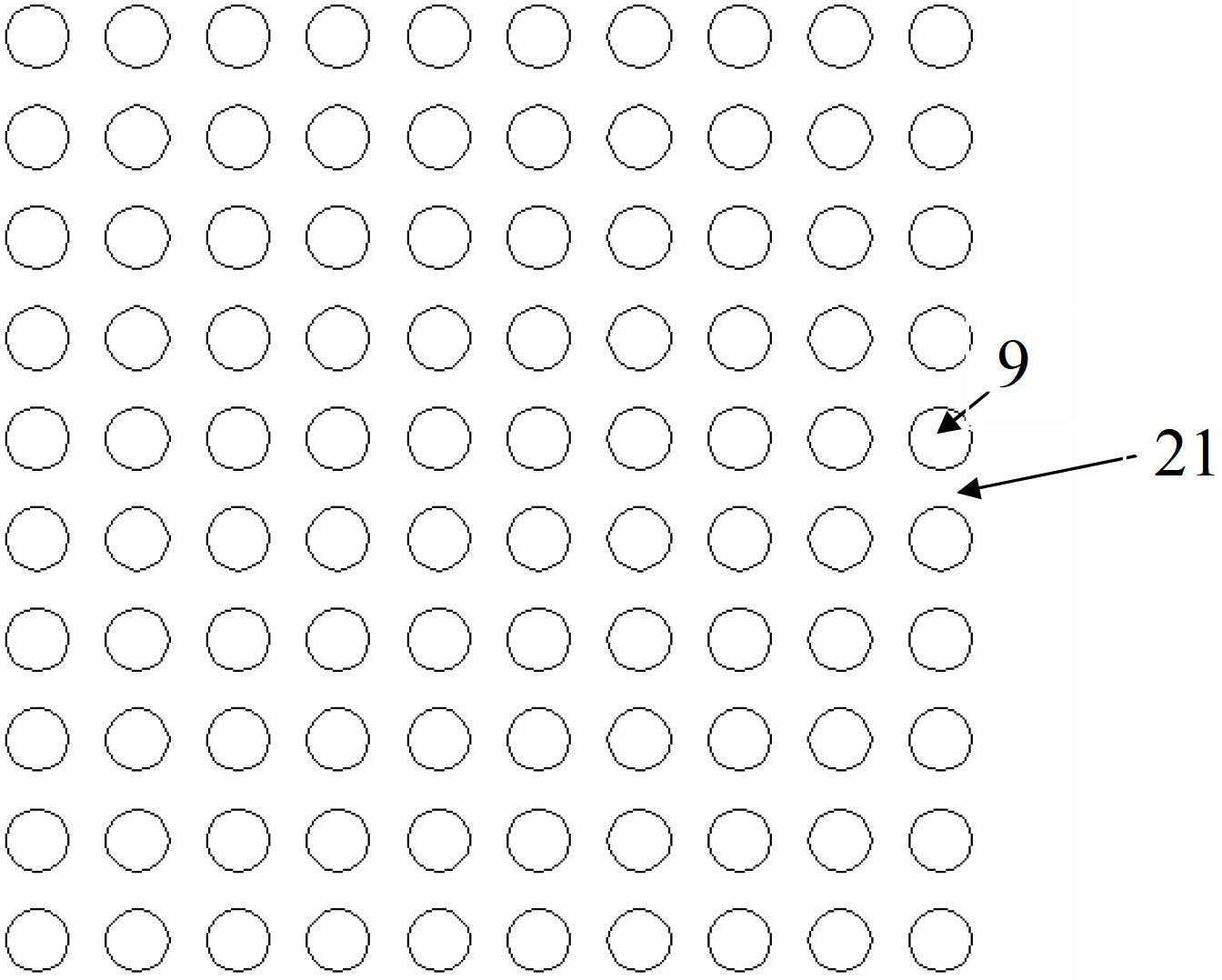

Patterned substrate, mask and patterned substrate manufacturing method

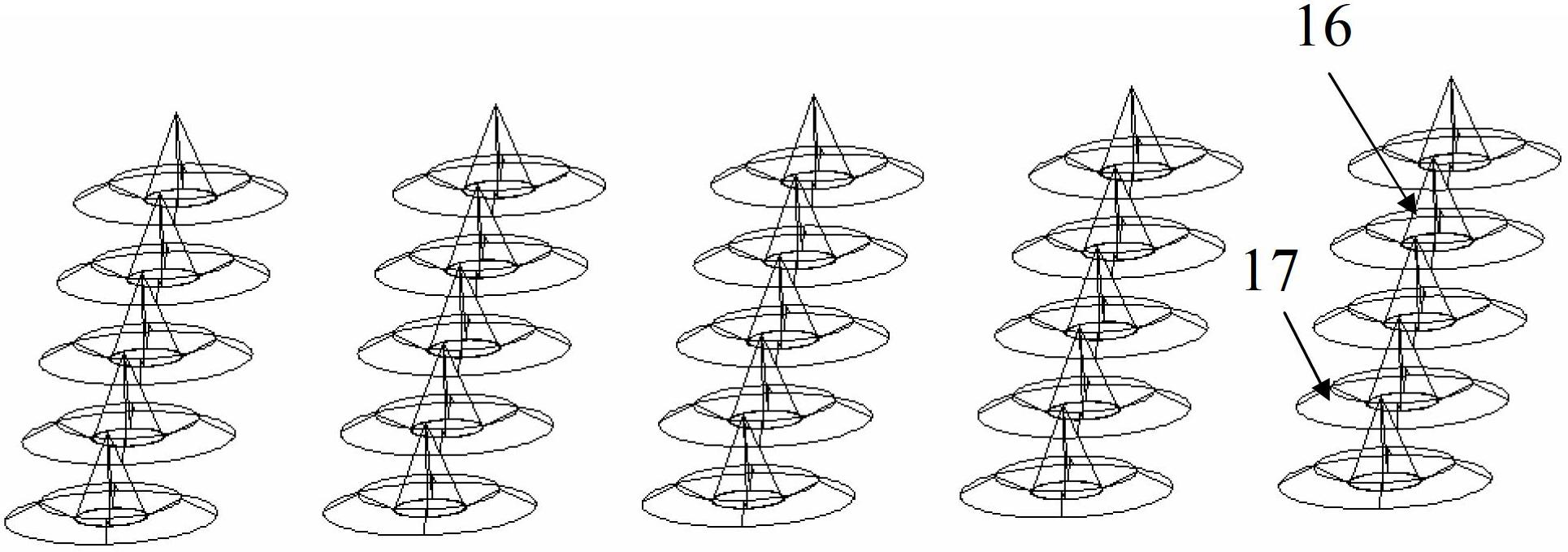

ActiveCN102694094AIncrease chance of escapeImprove luminous brightnessPhotomechanical apparatusOriginals for photomechanical treatmentSpecial designEngineering

The invention provides a patterned substrate, a mask used for manufacturing the patterned substrate and a patterned substrate manufacturing method. The patterned substrate is a patterned substrate with microstructures which consist of kinds of luminous bodies and reflecting bowls, can greatly improve the luminance of an LED (light-emitting diode) chip and can especially improve axial luminance. Masks which form the patterned substrate use pinhole diffraction and filter principles, the structure is simple, the special design is not required, the masks are easy to prepare and the cost is low. The patterned substrate manufacturing method adopts a pinhole diffraction exposure and ICP (inductively coupled plasma) etching method, the process is simple, the method is easy to realize, the progress of introducing concepts and structure of macroscopic fields into the microscopic LED field to improve the axial luminance of the LED chip is accelerated.

Owner:HANGZHOU SILAN AZURE

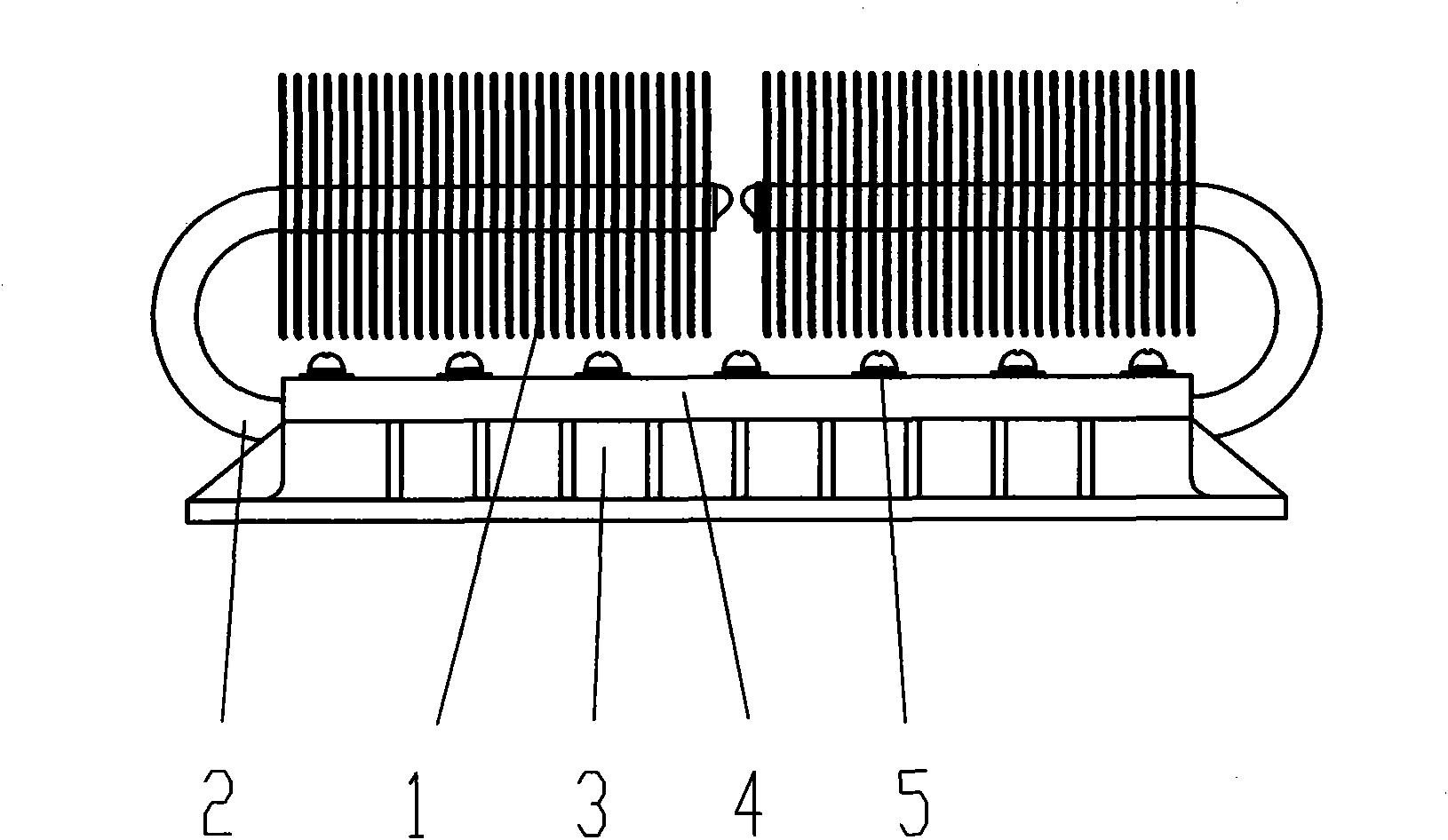

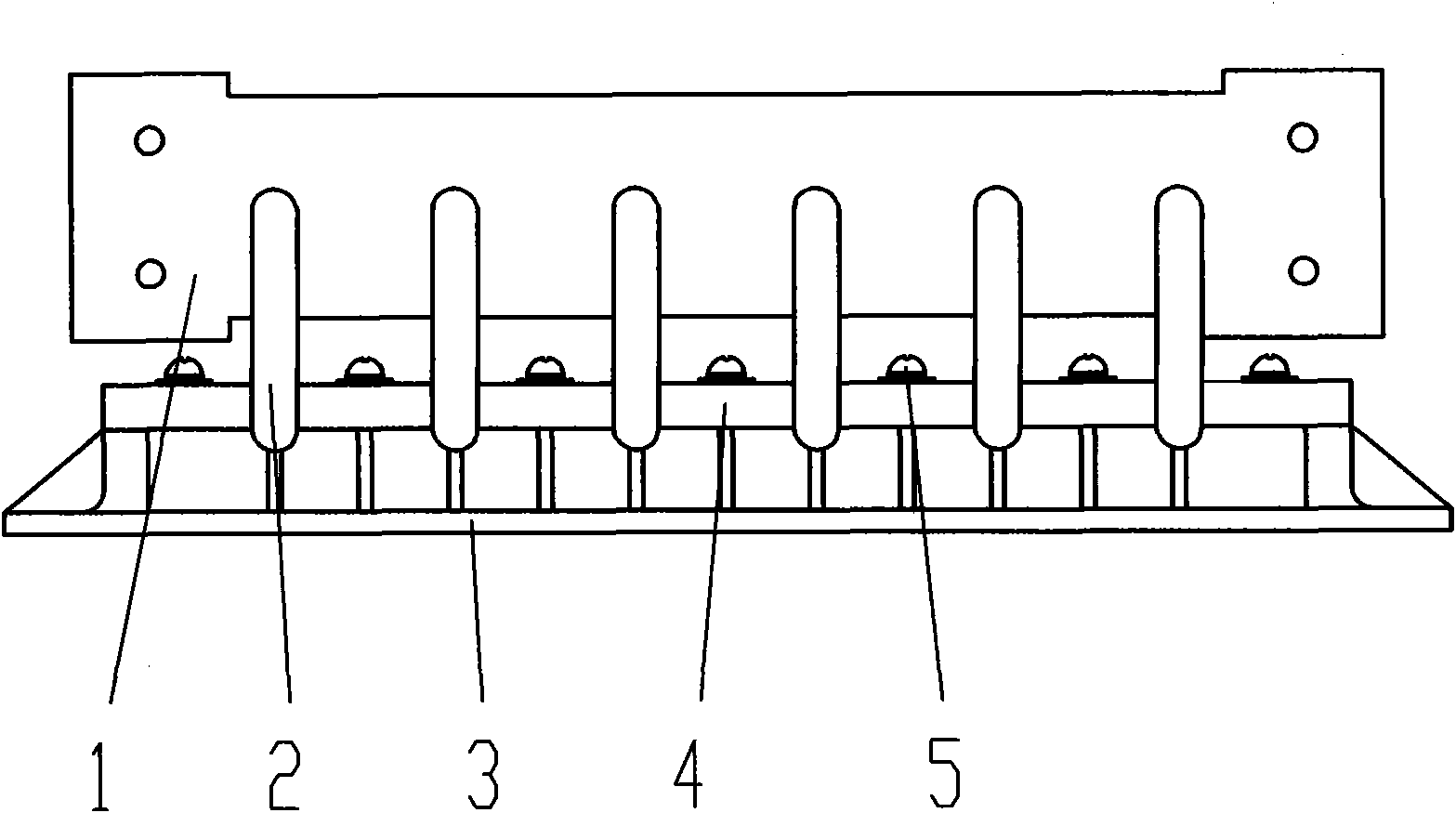

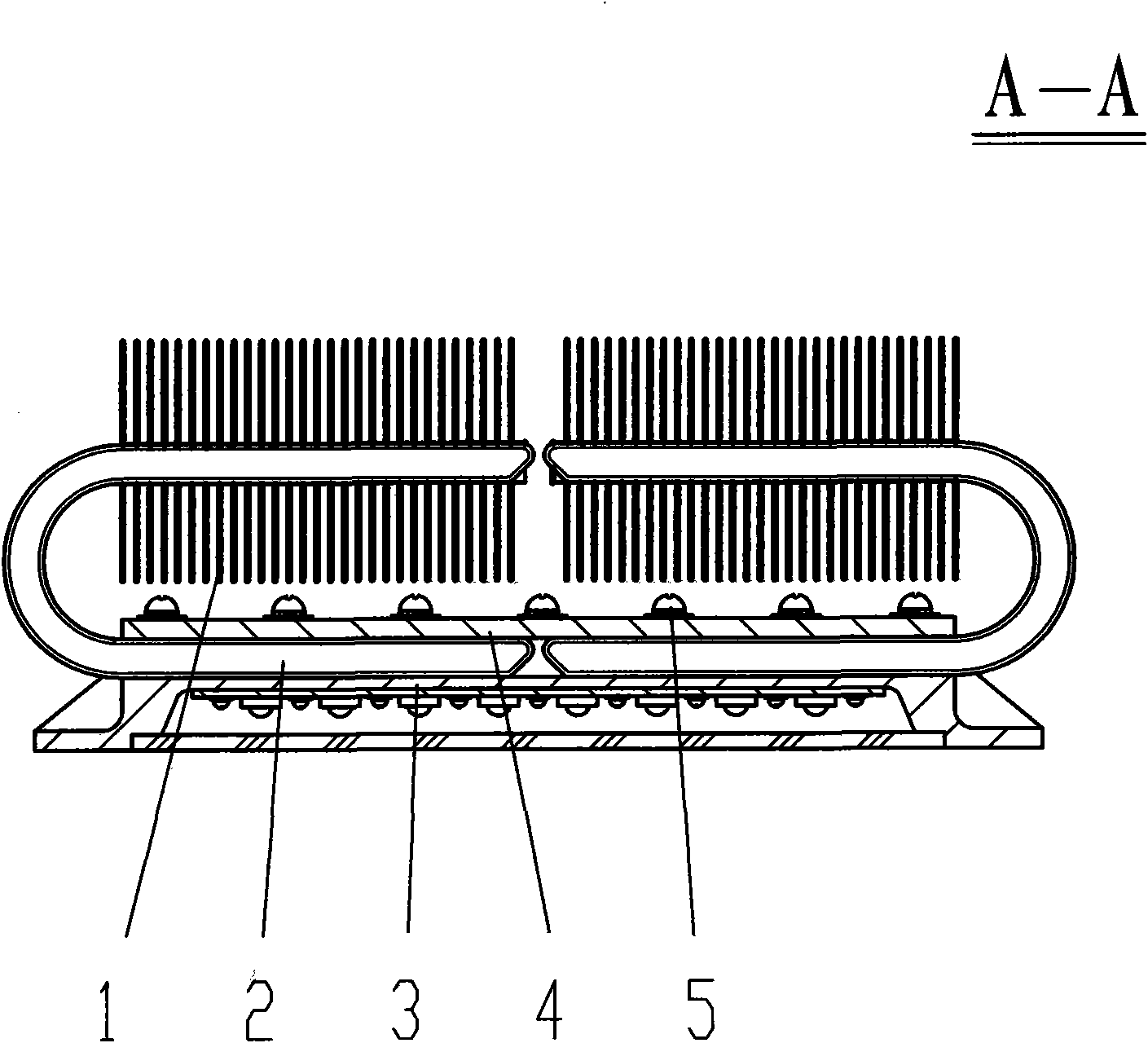

High-power LED (light emitting diode) field lamp heat dissipation device of heat pipe heat conduction type

InactiveCN102109155AIncrease cooling spaceHigh natural cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsThermal energyPunching

The invention discloses a high-power LED (light emitting diode) field lamp heat dissipation device of heat pipe heat conduction type. A plurality of pre-punching fins are penetrated into two fin plate rows by utilizing a plurality of pre-bent U-shaped heat pipes, and then the two fin plate rows are installed at the back part of a lamp seat symmetrically at two sides by utilizing a clamping plate and a screw. Thus, the heat energy generated by a high-power LED lamp is conducted to a heat pipe through a metal base plate and a lamp base, and then is conducted to fins through the heat pipe, and the heat exchange process of the fins is finished through natural convection. The high-power LED field lamp heat dissipation device has the advantages of large heat dissipation space, high natural heat dissipation efficiency, good uniform temperature, light weight and the like.

Owner:谢庆生

Transparent, low-halogen and anti-yellowing epoxy pouring sealant and preparation method thereof

InactiveCN107189734AAvoid yellowingEasy to prepareNon-macromolecular adhesive additivesMacromolecular adhesive additivesHalogenSealant

The invention discloses a transparent, low-halogen and anti-yellowing epoxy pouring sealant applied to the micro-electronics field and the LED field and a preparation method of the transparent, low-halogen and anti-yellowing epoxy pouring sealant. The pouring sealant comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 60-100 parts of low-halogen bisphenol A epoxy resin, 0.1-2 parts of an organic silicon defoamer, and 0.05-1 part of toner; the component B comprises the following raw materials in parts by weight: 60-100 parts of methylhexahydrophthalic anhydride, 0-3 parts of flexibilizer, 0.2-1 part of a light stabilizer, and 1-5 parts of a curing accelerator; the mass ratio of the component A to the component B is (1-1.2):1. The preparation method is characterized in that the component A is dispersed for 20-50min at high speed according to the formula; the component B is mixed according to the formula; then the temperature is increased to be 60-80 DEG C; the mixture is stirred for 1-3 hours. According to the transparent, low-halogen and anti-yellowing epoxy pouring sealant, a halogen-free intermediate-temperature curing accelerator is used; the mixing ratio of the materials and the production process are optimized to produce the transparent, low-halogen and anti-yellowing epoxy pouring sealant which meets the requirement of EU on the content of halogen in pouring sealing materials; meanwhile, the transparent, low-halogen and anti-yellowing epoxy pouring sealant is outstanding in anti-yellowing performance and outstanding in toughness.

Owner:DALIAN RES & DESIGN INST OF CHEM IND +1

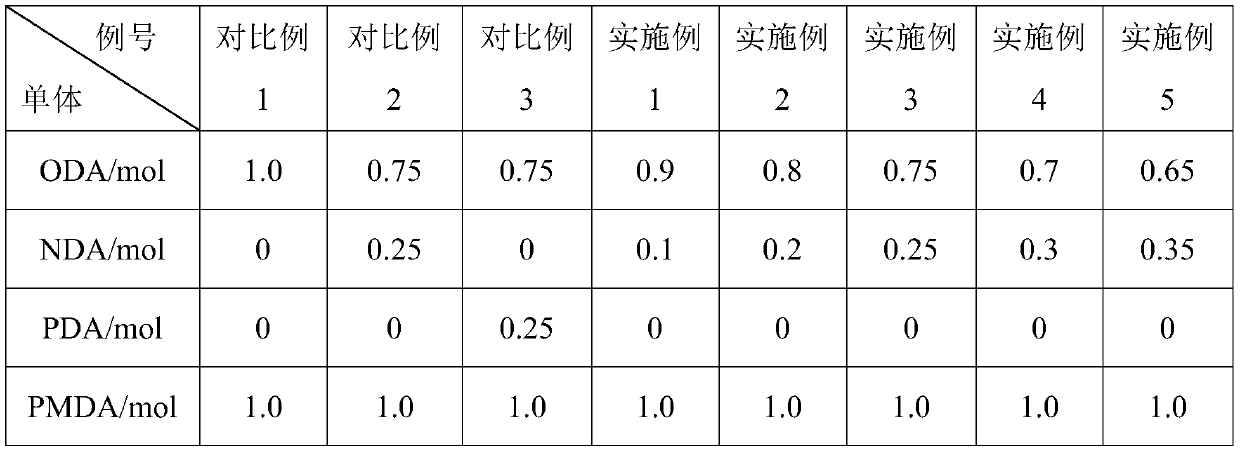

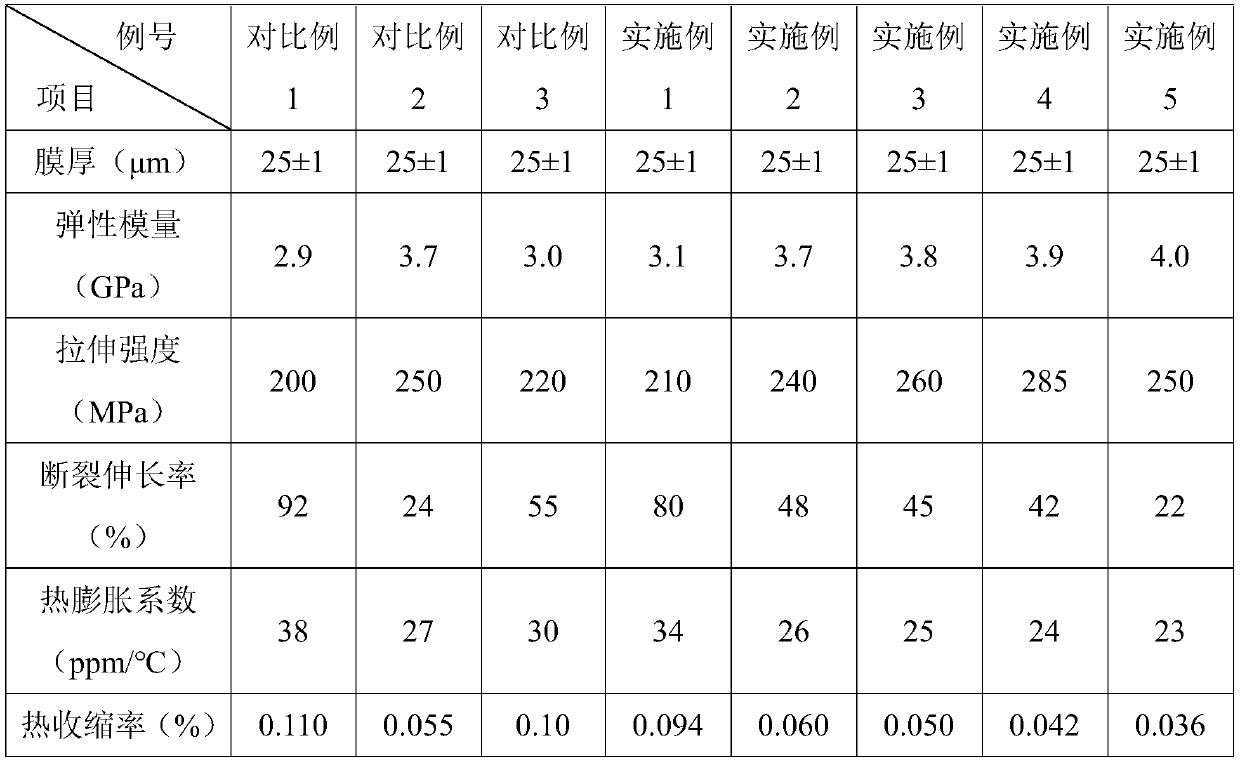

FPC substrate polyimide film special for LED and preparation method thereof

The invention belongs to the field of manufacture of high polymer materials, and discloses an FPC substrate polyimide film special for LED and a preparation method thereof. The preparation method comprises the following steps: dissolving 4,4'-diaminodiphenyl ether in a strongly polar aprotic organic solvent, and additionally dissolving pyromellitic dianhydride therein by stirring; (2) adding 1,5'-diaminonaphthalene to the solution from the step (1) for polymerization to obtain a polyamide acid solution; and (3) preparing the FPC substrate polyimide film special for LED by thermal imidization of the polyamide acid solution from the step (2). The PI film provided in the invention has the functional characteristics of high elasticity modulus, small thermal expansion coefficient and low thermal shrinkage, thus exhibiting good dimensional stability and high economic practicality, and can be extensively used as a good substrate for a flexible circuit board in the LED field.

Owner:无锡高拓新材料股份有限公司

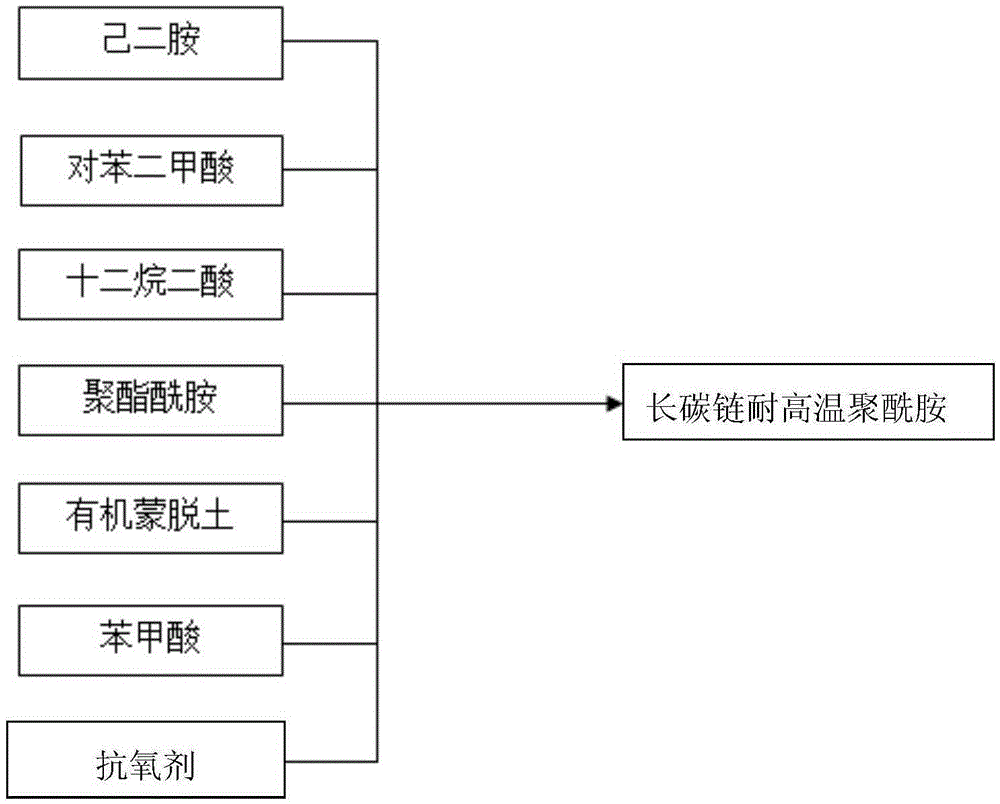

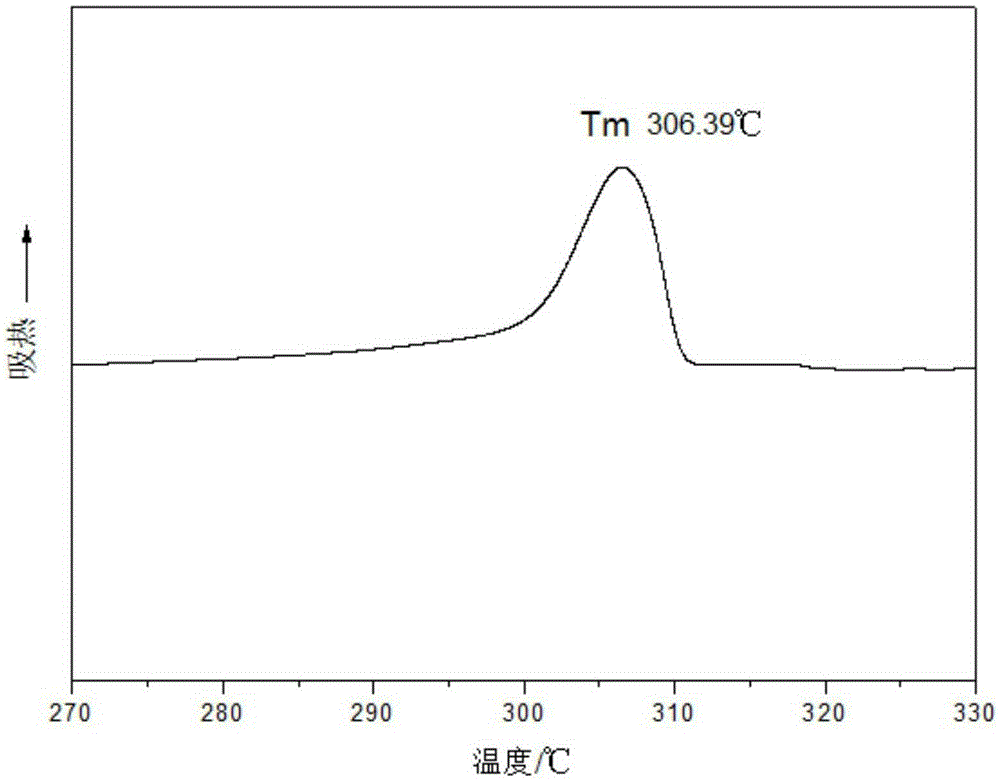

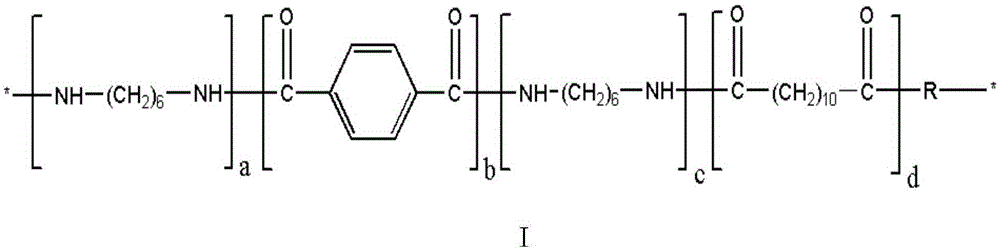

High-temperature-resistant long-carbon-chain polyamide and synthesis method thereof

The invention discloses a high-temperature-resistant long-carbon-chain polyamide and a synthesis method thereof. The structure of the high-temperature-resistant long-carbon-chain polyamide is as shown in the following formula (I) which is as shown in the specification, wherein a is 10-100, b is 10-200, c is 10-100, d is 10-100, and R refers to polyesteramide. The high-temperature-resistant long-carbon-chain polyamide disclosed by the invention has high mechanical properties and heat resistance, low water absorption and excellent processability, and can be applied to the fields such as electrical and electronic fields, LED field, automotive filed, aerospace and military fields, and the like.

Owner:ZHONGBEI UNIV

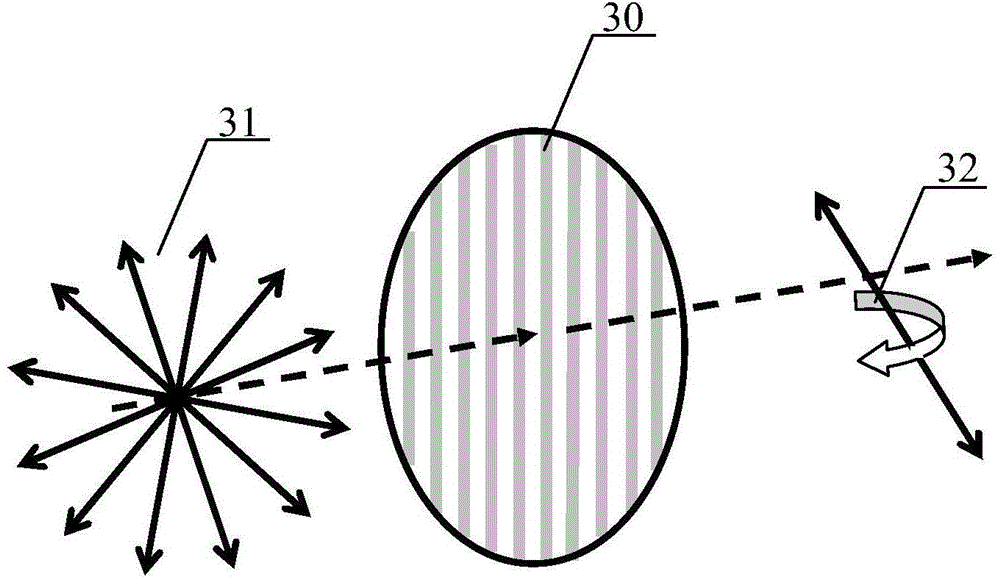

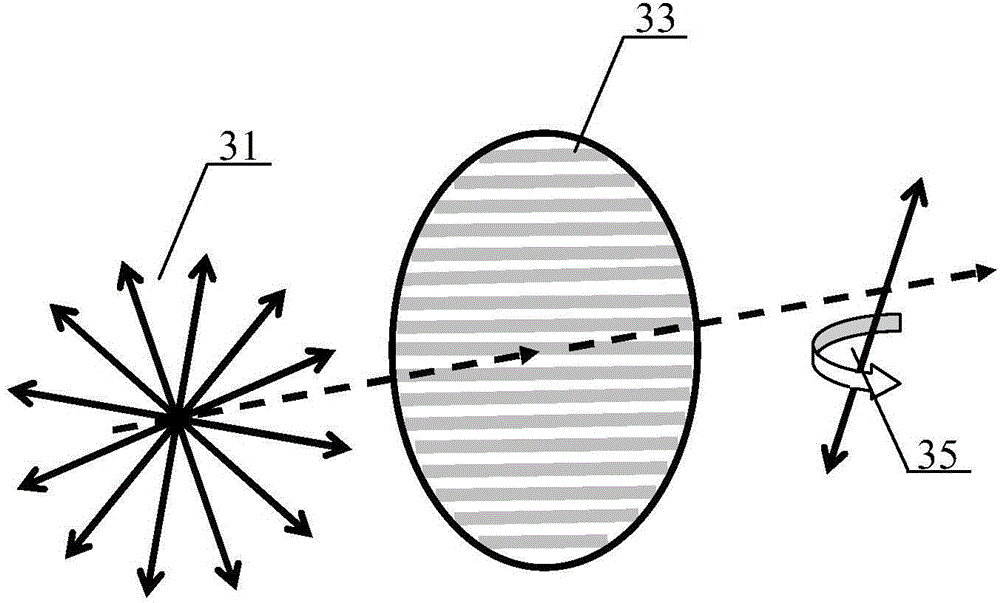

LED 3D display module and LED 3D display system

In allusion to the problems that a conventional chromatic aberration type display method exists a color cast phenomenon, a shutter type three-dimensional display method is high in cost, etc., the present invention provides a novel 3D display method in the LED field. An LED 3D display module and an LED 3D display system which are provided by the present invention enable the light to be changed from the original unpolarized light into the polarized light by utilizing the characteristic that the light possesses a vibration direction after the light passes a polariscope. If the polariscope is combined correspondingly to generate the polarized light of two different directions, and the two sets of generated polarized light is respectively mapped to a left eye and a right eye of an audience wearing a specially-produced glasses possessing the polarizing lenses, the audience can appreciate a 3D stereo image.

Owner:深圳市华天瑞彩科技开发有限公司

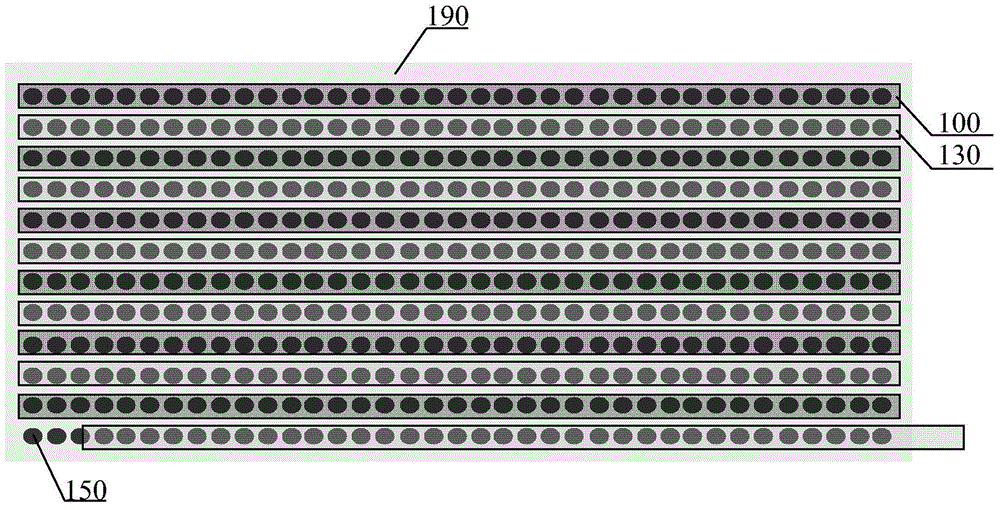

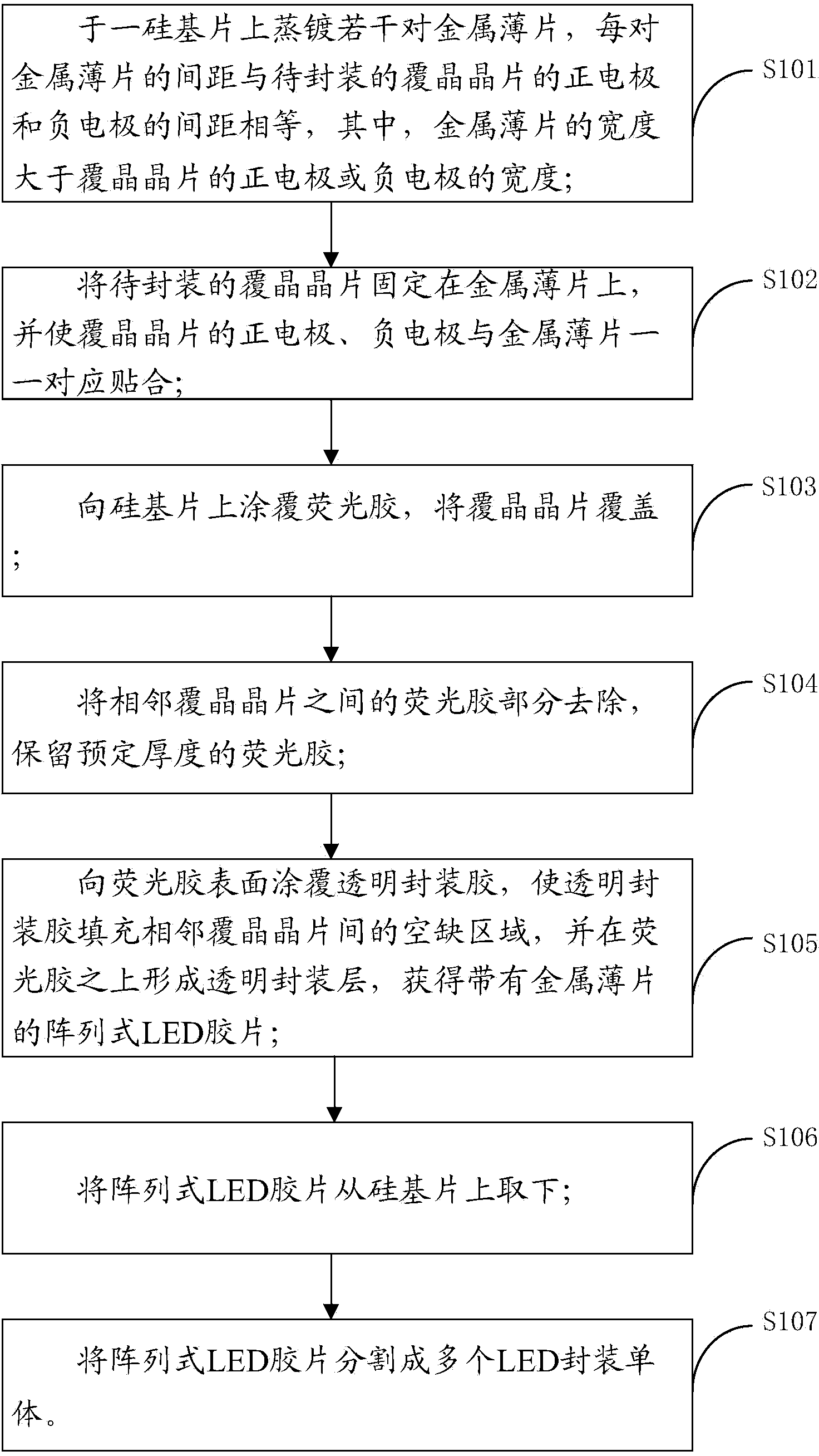

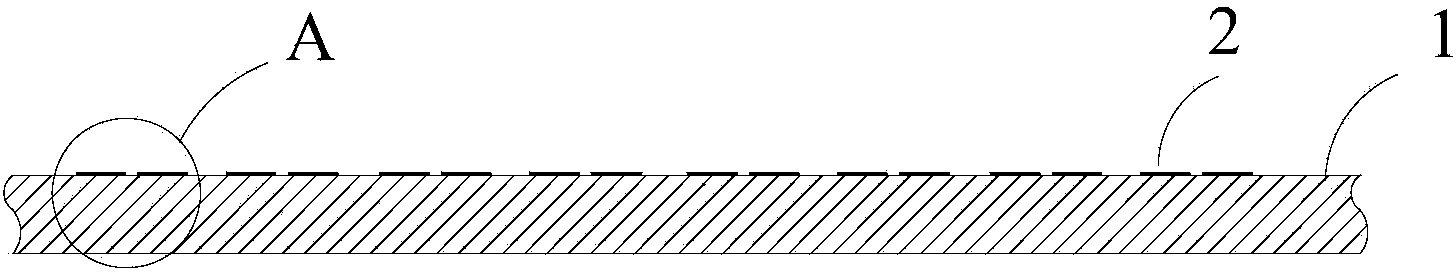

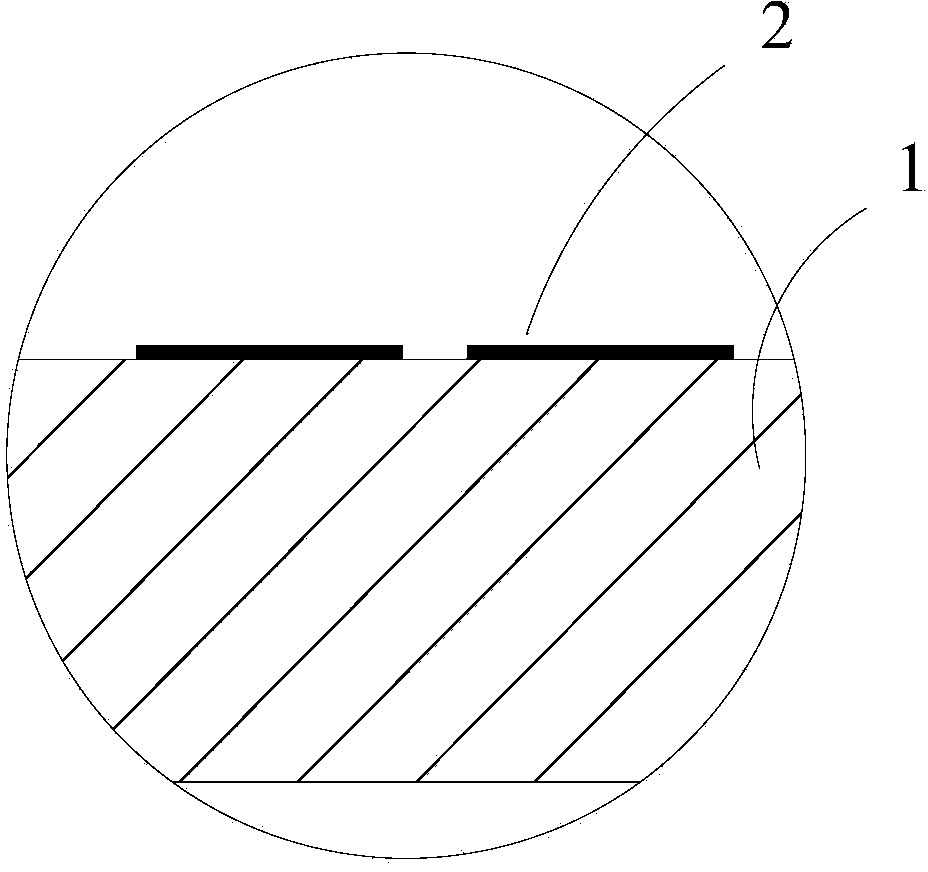

LED packaging method

InactiveCN103855279AImprove reliabilityVery stable performanceSemiconductor devicesAdhesiveEngineering

The invention provides an LED packaging method suitable for the LED field. The LED packaging method includes the following steps that a silicon chip is provided with metal sheets in a vapor deposition mode, wherein the distance between each pair of metal sheets equals the distance between the positive electrode of each flip-chip wafer and the negative electrode of the flip-chip wafer, and the width of each metal sheet is larger than that of the positive electrode and that of the negative electrode; the flip-chip wafers are fixed to the metal sheets to make the positive electrodes and the negative electrodes in one-to-one correspondence to the metal sheets; the silicon chip is coated with fluorescent adhesives; the fluorescent adhesives between adjacent flip-chip wafers are removed; transparent packaging adhesives are applied, and an array-type LED film is obtained; the array-type LED film is taken down and cut into a plurality of LED packaging single bodies. According to the LED packaging method, because the flip-chip wafers are packaged on the silicon chip and a packaging body is only composed of the flip-chip wafers, the fluorescent adhesives, the transparent packaging adhesives and the metal sheets, reliability is high, materials are saved, and cost is low. Limitations on shapes of supports do not exist, and therefore large-scale integrated packaging is facilitated; loss caused by scattering-in of photons in fluorescent powder is reduced, and therefore product brightness can be conveniently improved; because it is not needed that the bottoms of the wafers are coated with Au-Sn alloy layers, cost is reduced.

Owner:SHANGHAI REFOND OPTOELECTRONICS

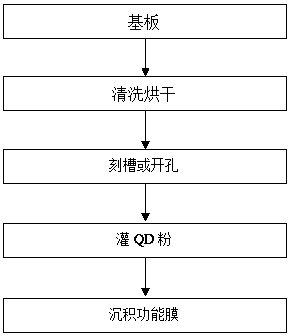

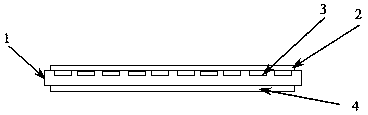

Manufacturing method of quantum dot (QD) film structure

The present invention discloses a manufacturing method of a QD film structure, and belongs to the LED field. The manufacturing method comprises the concrete steps of cleaning a substrate, drying, etching a groove or a hole, pouring the QD powder in the groove or the hole, and depositing a functional film (a waterproof air isolating thin film) to form the QD film structure. According to the presentinvention, the quantum dots are enclosed between a functional film layer and a base material thin film layer, on one hand, the contact of the quantum dots with the air and the water is avoided, the quantum dots can be used for a long time under a temperature of 120 DEG C and are not influenced by the water and the air, and the limitation of the environmental conditions is reduced. According to the packaging demands of the subsequent modules, the quantum dots are poured according to a certain arrangement form directly to manufacture a thin film structure, and the thin film structure can be cutflexibly according to the demands and even is mounted directly, thereby improving the packaging efficiency.

Owner:左洪波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com