Reworking method for LED epitaxial wafer with distributed Bragg reflector (DBR)

A technology of Bragg reflectors and light-emitting diodes, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as easy breakage, manufacturer cost loss, and large warpage, so as to avoid breakage, cost loss, The effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

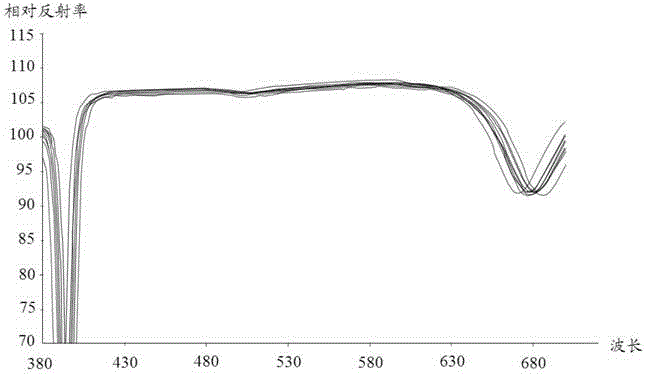

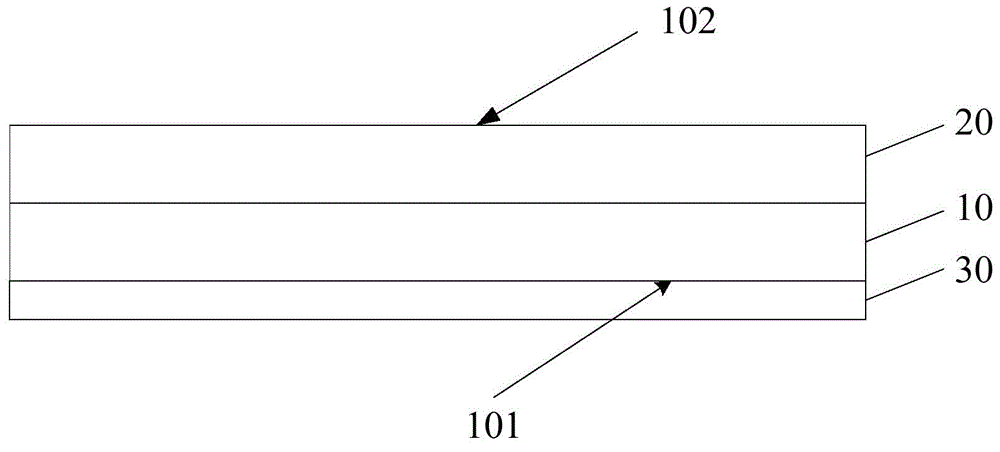

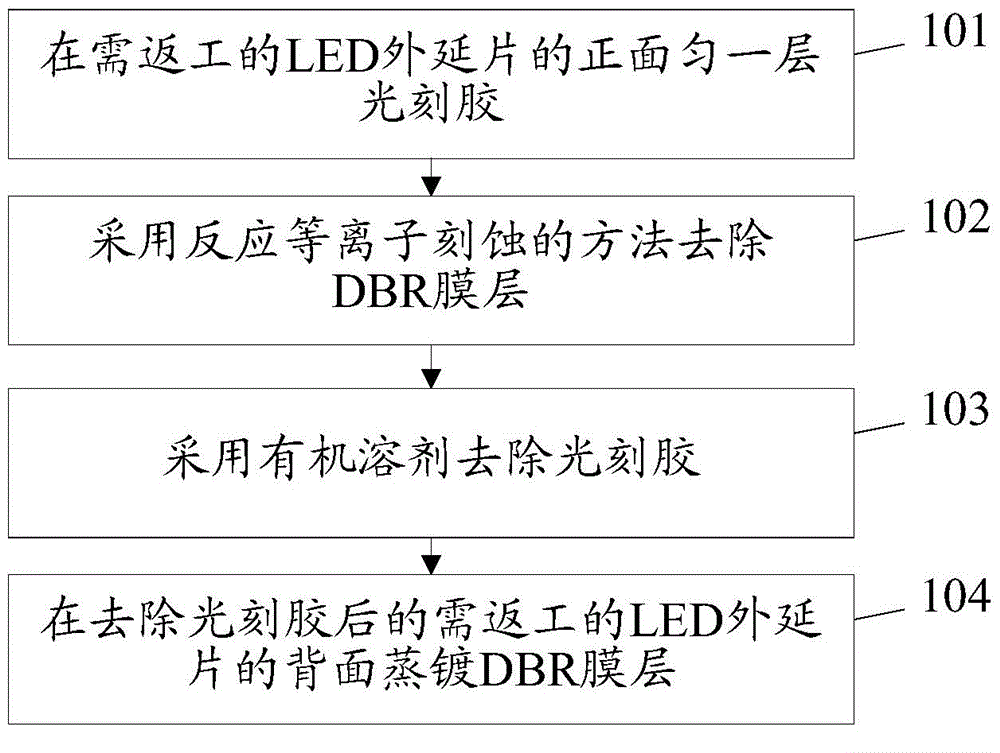

[0038] An embodiment of the present invention provides a method for reworking a light-emitting diode epitaxial wafer equipped with a distributed Bragg reflector, see figure 2 , the method includes:

[0039] Step 101: Spread a layer of photoresist on the front surface of the LED epitaxial wafer to be reworked.

[0040] Wherein, the back side of the LED epitaxial wafer to be reworked is provided with a DBR film layer, and the DBR film layer is dirty.

[0041] Step 102: Removing the DBR film layer by reactive plasma etching (Reactive Ion Etching, RIE for short).

[0042] Among them, the etching power is 400-700W, the etching pressure is 20-30mtorr, the etching temperature is 0-10°C, the etching thickness is greater than the thickness of the DBR film layer, and the etching gas is 50-80 sccm of CHF 3 and O 2 .

[0043] Step 103: removing the photoresist by using an organic solvent.

[0044] Step 104: Evaporating a DBR film layer on the backside of the LED epitaxial wafer to b...

Embodiment 2

[0048] An embodiment of the present invention provides a method for reworking a light-emitting diode epitaxial wafer equipped with a distributed Bragg reflector, see image 3 , the method flow includes:

[0049] Step 201: Spread a layer of photoresist on the front surface of the LED epitaxial wafer to be reworked.

[0050] Wherein, the back side of the LED epitaxial wafer to be reworked is provided with a DBR film layer, and the DBR film layer is dirty.

[0051] As an optional manner of this embodiment, the thickness of the photoresist may be 5um˜10um.

[0052] First, the LED epitaxial wafer to be reworked is fixed on the supporting member, and the supporting member drives the LED epitaxial wafer to rotate, and the rotational speed may be 800 rpm. Then adopt the method of manual glue spreading to spread a layer of photoresist on the front side of the rotating LED epitaxial wafer to be reworked.

[0053] Step 202: Using RIE to remove the DBR film layer.

[0054] Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com