White light LED and packaging method thereof

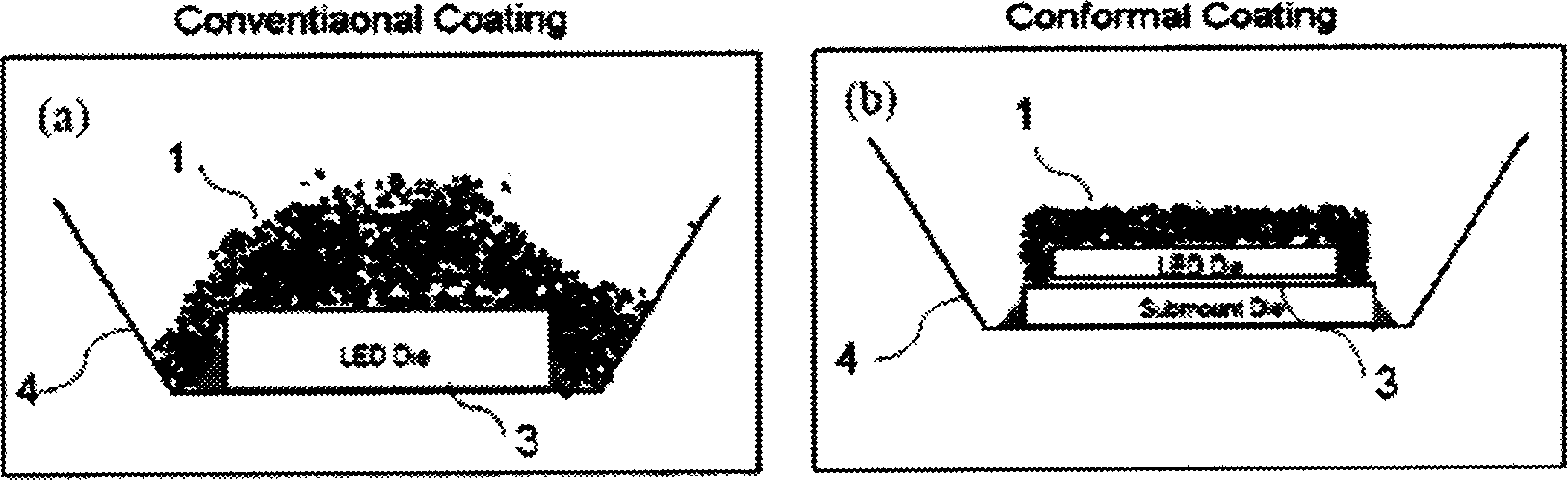

A packaging method and white light technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of ineffective conduction of phosphor layer heat, difficult control of LED light color consistency, and difficult realization of the process, so as to reduce the background The effect of reducing the loss of scattered light, improving light extraction efficiency, and improving light extraction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

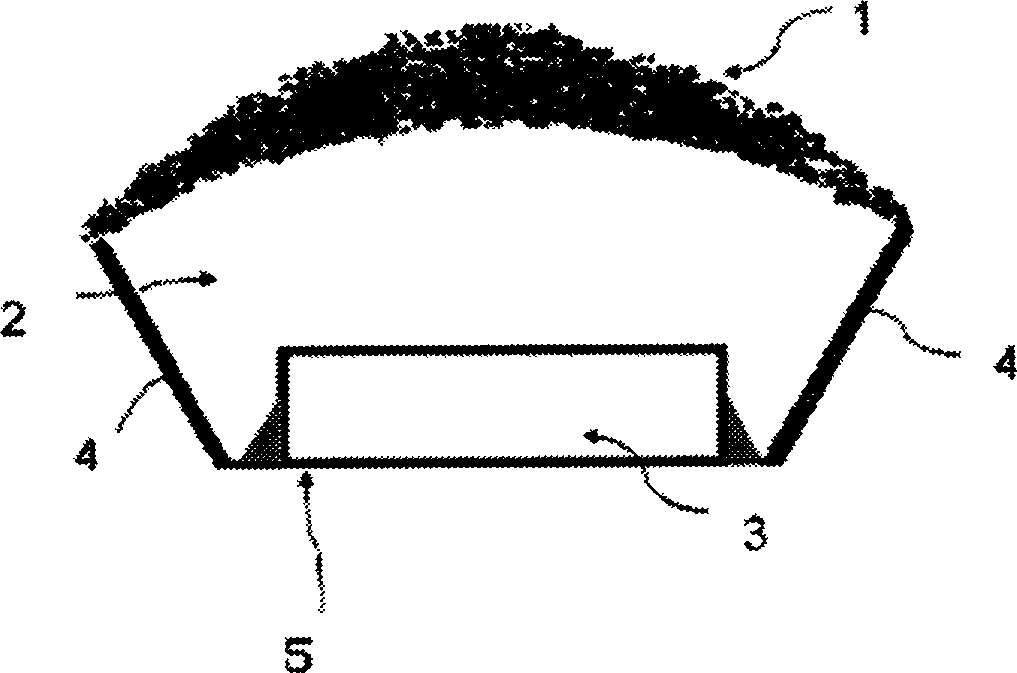

[0043] Such as figure 2 As shown, the front-mounted chip 3 is fixed on the bottom surface of the cup-and-bowl bracket 5, reflectors 4 are placed on both sides of the cup-and-bowl bracket 5, the surface of the front-mounted chip 3 is filled with silica gel 2, and the phosphor film layer 1 is covered and fixed on the silica gel 2. The edge of the phosphor film layer 1 is in contact with the cup-and-bowl bracket 5 .

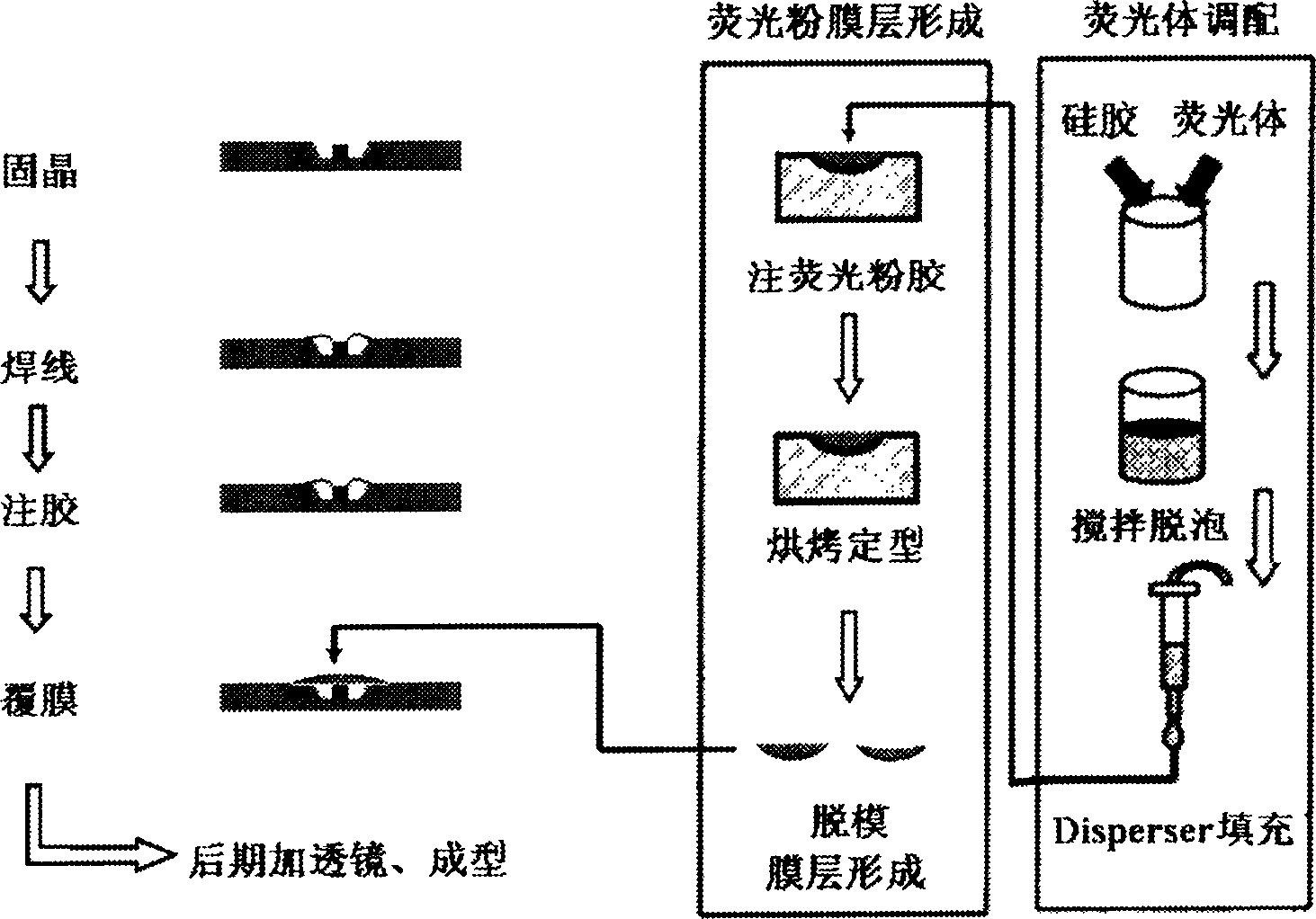

[0044] Point silver glue in the middle of the cup and bowl type support 5, and its function is to stick the chips. High power Al 2 o 3 The GaN-based blue LED front-mount chip 3 of the substrate is placed on the silver glue in the cup-and-bowl bracket 5; the peak wavelength range of the chip 3 is 460-465nm. Heat hardening and baking to harden the silver glue. Metal wires are connected to the electrodes of the chip 3 and are electrically connected to the support, so that when the current passes through the support, the LED chip can be excited to emit light. Inje...

Embodiment 2

[0050] The white light LED is packaged by the planar film coating method, and the structure diagrams of the two white light LEDs obtained are as follows: Figure 4 Shown, others are identical with embodiment 1. The obtained white light LED has better light color stability, better heat dissipation effect and light extraction efficiency than the existing white light LED.

Embodiment 3

[0052] The white light LED is packaged by the planar film coating method, and the double-layer phosphor film structure is adopted. The structure diagram of the obtained white light LED is as follows Figure 5 Shown, others are identical with embodiment 1. The obtained white light LED has better light color stability, better heat dissipation effect and light extraction efficiency than the existing white light LED. Moreover, the multi-layer fluorescent powder coating method can make the color easy to control and can improve the color rendering index.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com