FPC substrate polyimide film special for LED and preparation method thereof

A technology of polyimide film and polyamic acid, which is applied in the field of polymer material manufacturing, can solve problems such as production and use restrictions, uncontrollable content, low thermal expansion coefficient, etc., and achieve good dimensional stability, strong economical practicability, Effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add a measured amount of N,N-dimethylacetamide solvent into an anhydrous stainless steel polymerization kettle, add 0.9mol ODA under stirring and fully dissolve, then add PMDA (1mol) equivalent to the total mole of diamine, stir rapidly for 10 minutes and then add 1,5'-naphthalene diamine (NDA) (0.1 mol) with the molar amount of the remaining diamine was reacted at 40° C. for 5 hours under normal pressure to obtain a uniform and transparent polyamic acid solution with a solid content of 20 wt%.

Embodiment 2~ Embodiment 5

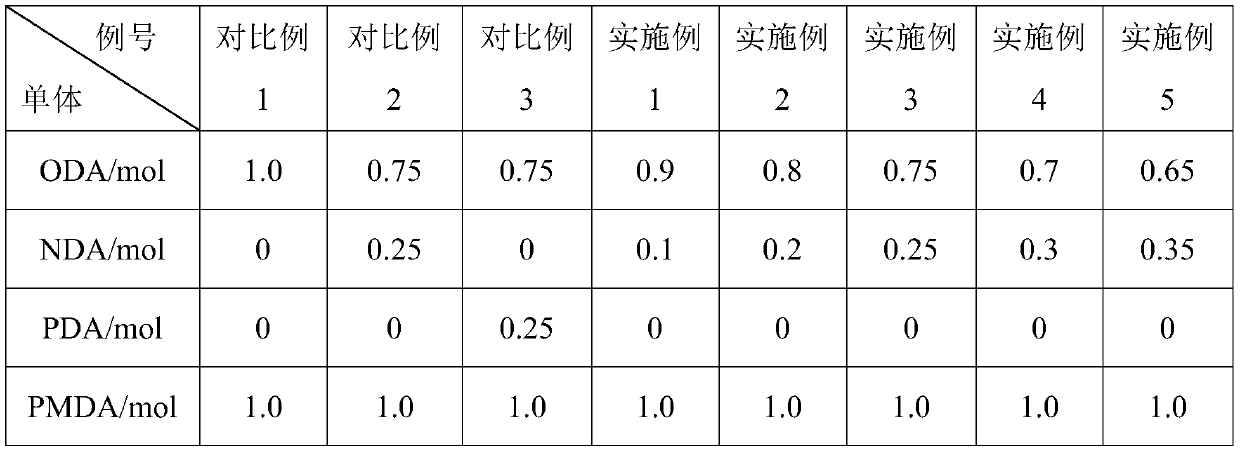

[0034] The preparation method of the polyamic acid solution is the same as step 1. The specific parameters of the amount of each substance are shown in Table 1, and the solid content of the obtained polyamic acid solution is also 20 wt%.

[0035] Wherein, the molecular weight of the polyamic acid solution prepared in Examples 1 to 5 is about 250,000±10,000 mP·s at 20°C.

Embodiment 6

[0043] Embodiment 6: the preparation of polyimide film

[0044] The polyamic acid solutions prepared in Examples 1 to 5 and Comparative Examples 1 to 3 were subjected to vacuum degassing and ultrafine filtration, and were metered by a gear pump to form films on ring-shaped stainless steel belts by extrusion and salivation. After being peeled off from the steel strip by hot air drying, a uniform PI film with a film thickness of 25±1.0 μm was obtained after the imidization was completed by programming the temperature in a hot air oven under biaxial stretching. Measured according to the test method, its performance data are shown in Table 2.

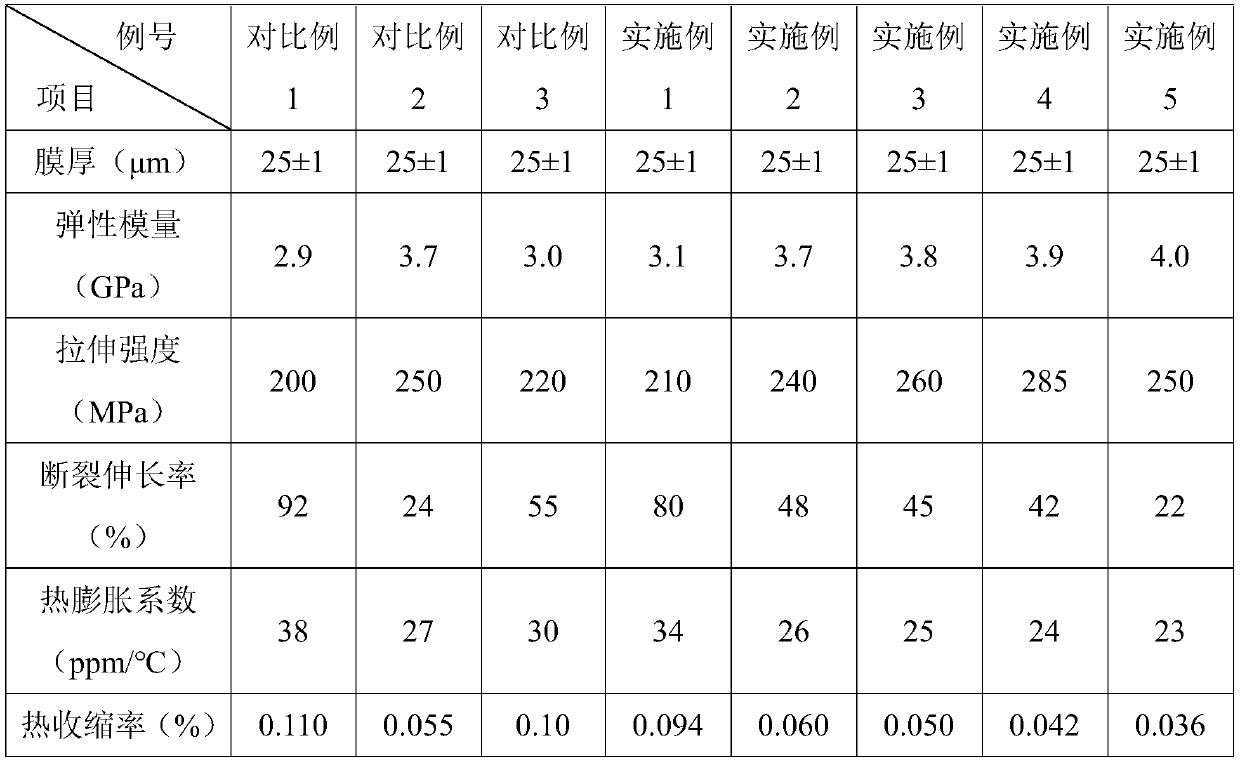

[0045] Table 2 Properties of the film

[0046]

[0047] The test results (Table 2) show that, as can be seen from Example 1, when the amount of NDA is 10%, compared with Comparative Example 1, the properties of the film are basically similar. It can be seen from Example 5 that when the amount of NDA reaches 35%, the elongation at break...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com