Manufacturing method of quantum dot (QD) film structure

A production method and quantum dot film technology, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of low color gamut, achieve the effect of improving packaging efficiency and reducing the limitation of environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

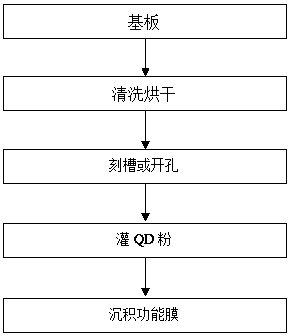

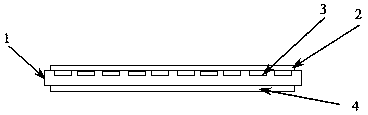

[0016] figure 1 For the production process of the quantum dot film structure, figure 2 It is a side view of the quantum dot film layer structure. Clean and dry the transparent substrate or film 1 (sapphire, glass, PET, acrylic, etc.); engrave regular grooves or holes 3 on the transparent substrate or film according to the subsequent module package arrangement requirements; QD powder (QD is in the form of powder, dispersed in ink or photosensitive adhesive); according to the different forms of slots or holes and actual needs, a waterproof and air-blocking film (polyurethane, ring, etc.) can be deposited on one or both sides of a transparent substrate or film. Oxygen resin, silicone resin, parylene and other single-layer or multi-layer composite film structure) 2 and thin film 4.

[0017] The above content is a further detailed description ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com